Page 1

DAC488

User's Manual

12-Bit Digital-to-Analog Converter Systems; Models DAC488/2 and DAC488/4

the smart approach to instrumentation ™

IOtech, Inc.

25971 Cannon Road

Cleveland, OH 44146-1833

Phone: (440) 439-4091

Fax: (440) 439-4093

E-mail: sales@iotech.com

Internet: www.iotech.com

i

DAC488

12-Bit Digital-to-Analog Converter Systems

Models DAC488/2 and DAC488/4

Released Per EO#1927R11

© 1998 by IOtech, Inc. June 1998 Printed in the United Stat es of America.

User's Manual

107-0901

p/n

Rev.

1.0

Page 2

Warranty

Your IOtech warranty is as stated on the product warranty card. You may contact IOtech by phone, fax

machine, or e-mail in regard to warranty-related issues.

Phone: (440) 439-4091, fax: (440) 439-4093, e-mail: sales@iotech.com

Limitation of Liability

IOtech, Inc. cannot be held liable for any damages resulting from the use or misuse of this product.

Copyright, Trademark, and Licensing Notice

All IOtech documentation, software, and hardware are copyright with all rights reserved. No part of this

product may be copied, reproduced or transmitted by any mechanical, photographic, electronic, or other

method without IOtech’s prior written consent. IOtech product names are trademarked; other product

names, as applicable, are trademarks of their respective holders. All supplied IOtech software (including

miscellaneous support files, drivers, and sample programs) may only be used on one installation. You may

make archival backup copies.

FCC Statement

IOtech devices emit radio frequency energy in levels compliant with Federal Communications Commission

rules (Part 15) for Class A devices. If necessary, refer to the FCC booklet How To Identify and Resolve

Radio-TV Interference Problems (stock # 004-000-00345-4) which is available from the U.S. Government

Printing Office, Washington, D.C. 20402.

CE Notice

Many IOtech products carry the CE marker indicating they comply with the safety and emissions

standards of the European Community. As applicable, we ship these products with a Declaration of

Conformity stating which specifications and operating conditions apply.

Warnings and Cautions

Refer all service to qualified personnel. This caution symbol warns of possible personal injury or

equipment damage under noted conditions. Follow all safety standards of professional practice and the

recommendations in this manual. Using this equipment in ways other than described in this manual can

present serious safety hazards or cause equipment damage.

This warning symbol is used in this manual or on the equipment to warn of possible injury or death

from electrical shock under noted conditions.

This ESD caution symbol urges proper handling of equipment or components sensitive to damage from

electrostatic discharge. Proper handling guidelines include the use of grounded anti-static mats and

wrist straps, ESD-protective bags and cartons, and related procedures.

Calibration Notice

As applicable, IOtech calibrates its hardware products to published specifications. Periodic hardware

calibration is not covered under the warranty and must be performed by qualified personnel as specified in

this manual. Improper calibration procedures may void the warranty.

Quality Notice

IOtech has maintained ISO 9001 certification since 1996. Prior to shipment, we thoroughly test our

products and review our documentation to assure the highest quality in all aspects. In a spirit of

continuous improvement, IOtech welcomes your suggest i ons.

Page 3

Introduction to this Manual

This manual covers the setup and operation of the DAC488/4 and the DAC488/2 digital-to-analog converter

systems. This manual is organized as follows:

• Chapter 1 - DAC488 Overview gives an overview of the basic features of a DAC488 system. DAC488

accessories and specifications are also provided.

• Chapter 2 - DAC488 Setup explains in detail the various hardware features of the DAC488 unit.

• Chapter 3 - DAC488 Power & Assembly provides detailed instructions on line-voltage selection and

fuse replacement, rack-mount and bench-top installation, as well as power-up activation.

• Chapter 4 - DAC488 Operation explains the DAC488 theory of operation. Descriptions of the

DAC488 command groups, triggering, internal buffer, control modes, as well as IEEE 488 bus support,

are provided.

• Chapter 5 - IEEE 488 Background describes the history and the basic concepts of IEEE 488

operation, including the various IEEE 488 bus commands and bus lines.

• Chapter 6 - DAC488 Calibration explains the manual and automatic procedures for calibrating the

DAC488 unit.

• Chapter 7 - DAC488 Commands discusses the entire command set covering the DAC488/4 and

DAC488/2 units. The command syntax, groups, and reference are provided. The description format of

the individual commands includes the command type, syntax, description, and an example program

excerpt.

• Chapter 8 - Troubleshooting provides a reference for possible solutions to technical problems. Before

calling for technical assistance, refer to this chapter.

•

The Appendix provides background information concerning the IEEE 488 bus, the serial bus, and

ASCII controls.

• The Index provides a comprehensive alphabetical listing of the main terms and topics in this manual.

Also, the Abbreviations on the last pages of this manual, provides an overall list of abbreviations,

including acronyms and ASCII control codes, as an additional reference for this manual and for other

related literature.

CAUTION

CAUTION

CAUTIONCAUTION

Using this equipment in ways other than described in this manual can cause personal

injury or equipment damage. Before setting up and using your equipment, you should

read all documentation that covers your system. Pay special attention to cautions and

warnings formatted like this one.

DAC488 User’s Manual i

Page 4

Table of Contents

1 - DAC488 Overview

Introduction…… 1

Accessories…… 2

Specifications…… 2

Digital I/O…… 2

Analog Output…… 3

IEEE 488…… 3

General…… 4

2 - DAC488 Setup

The Package…… 5

Hardware Setup…… 6

Front & Rear Panel Layouts…… 6

Default Settings…… 7

IEEE 488 Bus Address Selection…… 7

Mode Selection…… 7

Analog Output Ports…… 7

Digital I/O Port…… 8

Transistor-Transistor Logic (TTL) Lev el s…… 9

High Voltage/High Current Digital Outputs…… 9

External Trigger/SRQ Input…… 11

To Configure the Digital Output Lines…… 11

3 - DAC488 Power & Assembly

Introduction…… 13

Internal Components…… 13

Factory Service…… 13

Power Line & Fuse Configuration…… 14

Line Voltage Selection…… 14

To Select the Line Voltage…… 15

Fuse Replacement…… 16

To Replace the Fuse…… 16

Rack-Mount & Bench-Top Assembly…… 17

Rack Mount…… 17

Bench Top…… 17

Power-Up & Performance Tests…… 18

Power-Up Activation…… 18

Programming Examples……19

KYBDCTRL.BAS Program…… 19

To Run the Keyboard Controller Program…… 19

DAC488 Command Responses…… 20

Performance Verification…… 20

To Verify the Port Volt age - 10-V ol t Range…… 21

To Verify the Port Voltage - 5-Volt Range…… 21

To Verify the Port Voltage - 1-Volt Range…… 22

Data Transfer Speeds…… 22

4 - DAC488 Operation

Introduction…… 23

Command Groups…… 23

System & Port Commands…… 23

Command Support…… 24

Port Triggering…… 24

Trigger Processing & Trigger Overrun…… 25

Internal Buffer…… 26

Buffer Data…… 26

Buffer Save-and-Restore Program…… 27

Control Modes…… 28

Direct Control Mode…… 28

Indirect Control Mode……28

Stepped Control Mode…… 28

Waveform Control Mode…… 29

Multiple Port Synchronization…… 30

Synchronized Waveforms Program…… 30

Digital I/O Port…… 32

User-Defined System Defaults…… 33

IEEE 488 Bus Support…… 33

Bus Lines…… 33

Bus Commands…… 34

Bus Addresses…… 34

Bus Terminators…… 34

5 - IEEE 488 Background

History…… 35

General Bus Structure…… 35

Bus Lines & Bus Commands…… 36

Bus Management Lines…… 36

Handshake Lines…… 37

Data Transfer Lines…… 37

Bus Command Groups…… 38

More On Service Requests…… 39

6 - DAC488 Calibration

Introduction…… 41

Calibration Procedures…… 41

Manual Calibration Procedure…… 42

Part I: Connections & Preparations…… 42

Part II: Acquiring the Gain Calibration

Constants…… 42

Part III: Acqui ri ng t he Offset Calibration

Constant…… 43

BASIC Calibration Program…… 43

Automatic Calibration Procedure…… 47

Part I: Connections & Preparations…… 47

Part II: Automatic Calibration Process…… 48

Part III: Automatic Cal i bration Report…… 49

ii DAC488 User’s Manual

Page 5

7 - DAC488 Commands

A - Appendix

Introduction…… 51

Command Syntax…… 51

Command Groups…… 53

System Commands…… 53

Port Commands…… 53

Command Support……53

Command Summary…… 54

Command Reference…… 57

@ - Trigger On Command…… 58

A - Autorange…… 59

B - Buffer Data…… 60

C - Control Mode…… 61

D - Digital Output…… 63

E? - Query Error Status…… 64

F - Buffer Definition…… 66

G - GET Trigger Mask…… 67

H - Offset Calibration…… 68

I - Interval…… 69

J - Gain Calibration…… 70

K - End-Or-Identify Control…… 71

L - Buffer Location…… 72

M - Service Request Mask…… 73

N - Number of Cycles…… 74

O - Output Format…… 75

P - Port Select…… 76

Q - External Trigger Mask…… 77

R - Range Select…… 78

S - System Defaults…… 79

T - Command Trigger Mask…… 80

U - User Status…… 81

V - Value Output…… 84

W - Test…… 85

X - Execute…… 86

Y - Bus Terminator…… 87

? - Query…… 88

Serial Poll Status Byte…… 89

IEEE 488 Bus & Serial Bus Lines…… 93

IEEE 488 Bus Commands…… 94

ASCII Codes…… 95

ASCII Code Summary…… 95

Decimal Values 00 to 63 - ACG, UCG & LAG……

95

Decimal Values 64 to 127 - TAG & SCG…… 96

ASCII Code Details…… 97

Decimal Values 00 to 31 - ACG & UCG

Characteristics…… 97

Decimal Values 00 to 31 - ACG & UCG

Descriptions…… 98

Decimal Values 32 to 63 - LAG…… 99

Decimal Values 64 to 95 - TAG…… 100

Decimal Values 96 to 127 - SCG…… 101

Index…… 103

Abbreviations…… 106

8 - Troubleshooting

Radio Interference Problems…… 91

Electrostatic Discharge (ESD) Damage…… 91

Other Issues…… 91

Power-Up Activation…… 91

Trigger Processing & Trigger Overrun…… 92

Query Error Status…… 92

DAC488 User’s Manual iii

Page 6

−

Notes

iv DAC488 User’s Manual

Page 7

DAC488 Overview 1

Introduction…… 1

Accessories…… 2

Specifications…… 2

Digital I/O…… 2

Analog Output…… 3

IEEE 488…… 3

General…… 4

Introduction

The DAC488 is a multiple output Digital-to-Analog Converter (DAC) interface for the IEEE 488 bus. Each

port uses a 12-bit plus-sign D/A converter and is isolated from IEEE common and the other ports by up to

500 volts. Each port can be programmed for full-scale output of ±1 volt, ±5 volts and ±10 volts. Voltage

values may be specified in volts or bits in increments of 1 part in 4096 plus-sign. The resolution of the

ranges is 250 µVolts, 1.25 mVolts and 2.5 mVolts respectively.

Four operational modes are available to allow each port to be controlled directly from the IEEE bus or in an

automatic manner. An internal 8,191 sample buffer is included which can be loaded with waveform

voltages. These voltages may then be output in sequence either on a periodic interval or in a triggered

fashion. The DAC488 sample buffer is automatically saved in Non-Volatile RAM (NV-RAM) as it is

loaded, allowing a once only configuration of the device for many applications. All configuration settings

may also be saved in Non-Volatile RAM for use as the permanent defaults.

Each of the ports can be triggered from three different sources: An external trigger, a trigger command, or a

Group Execute Trigger (

trigger sources may be selected for each port.

GET) bus command. Since each port can be triggered independently, different

The interface also provides 8 TTL level digital inputs and 8 digital outputs. The digital outputs may be

internally configured as either TTL level or 100 mA outputs to allow interfacing with solenoids, relays or

other devices. An external trigger/SRQ input is also provided which can trigger the interface or generate an

SRQ on either a falling or rising edge of a TTL compatible signal. All digital signals as well as +5 Volts

and ground are accessible via a 20-pin card edge connector (Standard version) or a DB25 pin connector

(CE version) located on the rear panel.

Calibration may be done automatically by connecting the interface to a Keithley Model 199 DMM. No

mechanical adjustments are required. After calibration, a complete calibration report will be printed if the

interface is connected to an IEEE printer.

Throughout this manual, the term “DAC488” refers to either a DAC488/4 or a DAC488/2.

DAC488 User’s Manual DAC488 Overview 1

Page 8

Accessories

Additional accessories that can be ordered for the DAC488 include:

• CA-1: Power Cable

• CA-7-1: 1.5 foot IEEE 488 Cable

• CA-7-3: 6 foot shielded IEEE 488 Cable

• CA-7-4: 6 foot reverse entry IEEE 488 Cable

• CA-8-20: 6 foot, 20 conductor ribbon cable with a card edge connector on one end, the other end

• CA-35-2: 2 foot, DB25 male-to-female pin Connector

• CA-35-6: 6 foot, DB25 male-to-female pin Connector

• CN-40-12: DAC488 Analog Output Connector

• CN-6-20: 20-pin card edge Connector.

• CN-20: Right Angle IEEE 488 adapter, male and female

• CN-22: IEEE 488 multi-tap bus strip, four female connectors in parallel

• CN-23: IEEE 488 panel mount feed-through connector, male and female

Specifications

unterminated.

Please read this manual carefully! If equipment is used in any manner not specified in

this manual, the protection provided by the equipment may be impaired.

CAUTION

CAUTION

CAUTIONCAUTION

Digital I/O

WARNING

WARNING

WARNINGWARNING

Do not use the DAC488 unit outdoors! This unit is intended for indoor use only!

Unexpected outdoor conditions could result in equipment failure, bodily injury or

death!

Terminal Installation Category: Standard: Not Applicable. CE: Category 1.

Transistor-Transist or Logic (TTL) Leve ls: Digital outputs will drive 2 TTL loads or sink 100mA

(selectable using internal configuration jumper).

Digital Inputs and Digital Outputs: 8 inputs, TTL level compatible; 8 outputs, internally selectable TTL

level compatible or open collector with 100 mA @ 50 V drive capability.

Service Request/External Trigger Input: 1 line, TTL level compatible.

Connectors: Standard: One 20-pin card edge connector. CE: One DB25 (25-pin) connector.

2 DAC488 Overview DAC488 User’s Manual

Page 9

Analog Output

Terminal Installation Category: Standard: Not Applicable. CE: Category 1.

DC Output Voltage and Resolution

DC Output Current and Output Resistance: 10 mA maximum; and <500 mΩ (typical)

Accuracy (25 ±±±± 5°°°°C; Iout = 1 mA):

Warm Up Time to Rated Accuracy: 1 hour

Temperature Coefficient (0°°°° to 20°°°° C, and 30°°°°to 50°°°° C): ±(0.002% of setting + 100 µV) / °C

Channel to Channel Isolation: Standard: 500 V max, 100,000 V-Hz.

Channel to Digital Low Isolation: Standard: 500 V max, 100,000 V-Hz.

Connectors: One 12-pin quick disconnect analog.

WARNING

WARNING

WARNINGWARNING

There may be up to 200 V isolation potential between analog common and earth (CE

version) or up to 500 V isolation potential (Standard version). Avoid contact with

analog output terminals and the cables connected to them. Do not apply power until

after the AC line and analog output connections have been properly made. The AC

line must remain connected to the unit whenever the analog output terminals are

connected to a device exceeding 60 VDC or 30 Vrms common mode voltage. Contact

with voltage potentia ls could cause bodily injury or death!

CAUTION

CAUTION

CAUTIONCAUTION

Solid wire is recommended for the analog output terminal connections. If stranded

wire is used, then strip the wire 6 mm, and twist or tin the stripped end. After

tightening the connector, check that no loose wire strands are present.

1V Range: ± 1.02375 V, 250 µV/bit

5V Range: ± 5.11875 V, 1.25 mV/bit

10V Range: ± 10.2375 V, 2.5 mV/bit.

1V Range: ±(0.05% of setting + 1 mV)

5V Range: ±(0.05% of setting + 3 mV)

10V Range: ±(0.05% of setting + 10 mV)

CE: 200 volts max, 100,000 V-Hz

CE: (Channel Common to Earth) 200 V max, 100,000 V-Hz

IEEE 488

CAUTION

CAUTION

CAUTIONCAUTION

The IEEE 488 terminal must only be used to control a non-isolated IEEE 488 system.

The common mode voltage (cable shell to earth) must be zero.

Terminal Installation Category: Standard: Not Applicable. CE: Category 1.

Implementation: SH1, AH1, T4, TE0, L4, LE0, SR1, RL0, PP0, DC1, DT1,E1.

Terminators: Programmable CR, LF, LF CR and CR LF with EOI.

Programmable: IEEE Bus Terminators, EOI Control, SRQ Mask, Port Voltage, Gain, Offset, Digital I/O

lines, Output Format, Internal Buffer, Mode.

Connector: Standard IEEE 488 connector with metric studs.

DAC488 User’s Manual DAC488 Overview 3

Page 10

General

WARNING

WARNING

WARNINGWARNING

Service: This product contains no operator serviceable parts. Fuse replacement and

the changing of selected line voltage must be performed by qualified service personnel.

Never open the DAC488 case while it is connected to the AC line, or when analog

output terminals are connected to a device exceeding 60 VDC or 30 Vrms common

mode voltage!

Terminal Installation Category: Standard: Not Applicable. CE: Category 2 for Line Voltage Input

terminal. All other terminals are Category 1.

Dimensions: 425 mm wide x 45 mm high x 309 mm deep (16.75" x 1.75" x 12")

Weight: 3.32 kg. (7.31 lbs)

Environment: Standard: Indoor use, 0° to 50°C; 0 to 95% RH (non-condensing).

CE: Indoor use at altitudes below 2000 meters, 0° to 40°C; 0 to 80% RH up to 31°C decreasing

linearly 4% RH/°C to 40°C.

Controls: Power Switch (external), line voltage selection switch (internal), mode and IEEE address DIP

switch (external), calibration enable switch (external), digital output port configuration jumper

(internal)

Indicators: LEDs for TALK, LISTEN, SRQ, ERROR, TEST and POWER

Power: Internally selectable 105-125 V or 210-250 V; 50-60 Hz, 35 VA Max

Fuse: 3/8A, Slo Blo, 3AG (for 105-125 V power line) or 3/4A, Slo Blo, 3AG (for 210-250 V power line)

CAUTION

CAUTION

CAUTIONCAUTION

Line Voltage: The protective conductor terminal on the AC line connector must be

connected to an external protective earthing system. Failure to make such a

connection will impair protection from shock. If common mode voltages connected to

the analog input terminals exceed 60 VDC or 30 Vrms, the AC line connector must

remain connected even when the unit is powered “off.” If it becomes necessary to

disconnect the AC line connector, you must first disconnect all power to the analog

input terminals.

CAUTION

CAUTION

CAUTIONCAUTION

Fuse Failure: Fuse failure indicates a possible problem within the device circuitry. If a

fuse blows, contact a qualified service representative. Replacement fuses are to be

installed by qualified service personnel with the unit disconnected from the power

source and with all other terminals disconnected. If the line voltage selector is

changed, then the fuse designated for that line voltage must be used.

4 DAC488 Overview DAC488 User’s Manual

Page 11

DAC488 Setup 2

The Package…… 5

Hardware Setup…… 6

Front & Rear Panel Layouts…… 6

Default Settings…… 7

IEEE 488 Bus Address Selection…… 7

Mode Selection…… 7

Analog Output Ports…… 7

Digital I/O Port…… 8

Transistor-Transistor Logic (TTL) Lev el s…… 9

High Voltage/High Current Digital Outputs…… 9

External Trigger/SRQ Input…… 11

To Configure the Digital Output Lines…… 11

The Package

All DAC488 components are carefully inspected prior to shipment. When you receive your digital-toanalog converter system, carefully unpack all items from the shipping carton and check for any damage

which may have occurred during shipment. Promptly report the damage to the shipping agent and your

sales representative. Retain all shipping materials in case you must return the unit to the factory.

Every DAC488 package includes the following items listed by part number:

• DAC488/2 or DAC488/4: Digital-to-Analog Converter with Digital I/O and IEEE 488

• WINDOWS PANELS: Programmed Disks in IBM format, including Installation Card and Licensing

Agreement (PR-10)

• 107-0901: DAC488 User’s Manual

• PR-2: Warranty Card

• DAC488-003: Accessories Kit for DAC488, which includes the following:

• CA-1: Power Cable

• CA-35-2 or CA-35-6: DB25 Male-to-Female Connector, 2 or 6 feet respectively (CE version)

• CN-6-20: 20-pin Card Ed ge Connector (S tandard version)

• CN-40-12: 12-pin Analog Output Connector

• FE-1: Rubber Feet (4)

• EN-6: Rack Ears (2)

• HA-41-6: Rack Screws (4)

• PR-9: Rack Mounting Instruct i ons

• FU-1-.375: 3/8A Replacement Fuse

• FU-1-.75: 3/4A Replacement Fuse

DAC488 User’s Manual DAC488 Setup 5

Page 12

Hardware Setup

Front & Rear Panel Layouts

Six LED indicators on the DAC488 front panel, display the unit status. The following list describes the

functions of these indicators:

• TALK: ON when DAC488 is in the Talker state; OFF when in the Idle or Listener state.

• LISTEN: ON when DAC488 is in the Listener state; OFF when in the Idle or Talker state.

• SRQ: ON when DAC488 generated a service request; OFF when no SRQ is pending.

• ERROR: ON when an error has occurred; OFF when no error condition exists.

• TEST: ON when used in conjunction with the Test (

been established with the DAC488. The TEST LED will flash when the DAC488 is calibrating in the

auto-calibration mode. The TEST LED will then remain lit when finished calibrating in the autocalibration mode.

• POWER: ON when power is being applied while the power switch is in the ON position; OFF when

power is not present.

W) command to veri fy tha t communication has

6 DAC488 Setup DAC488 User’s Manual

Page 13

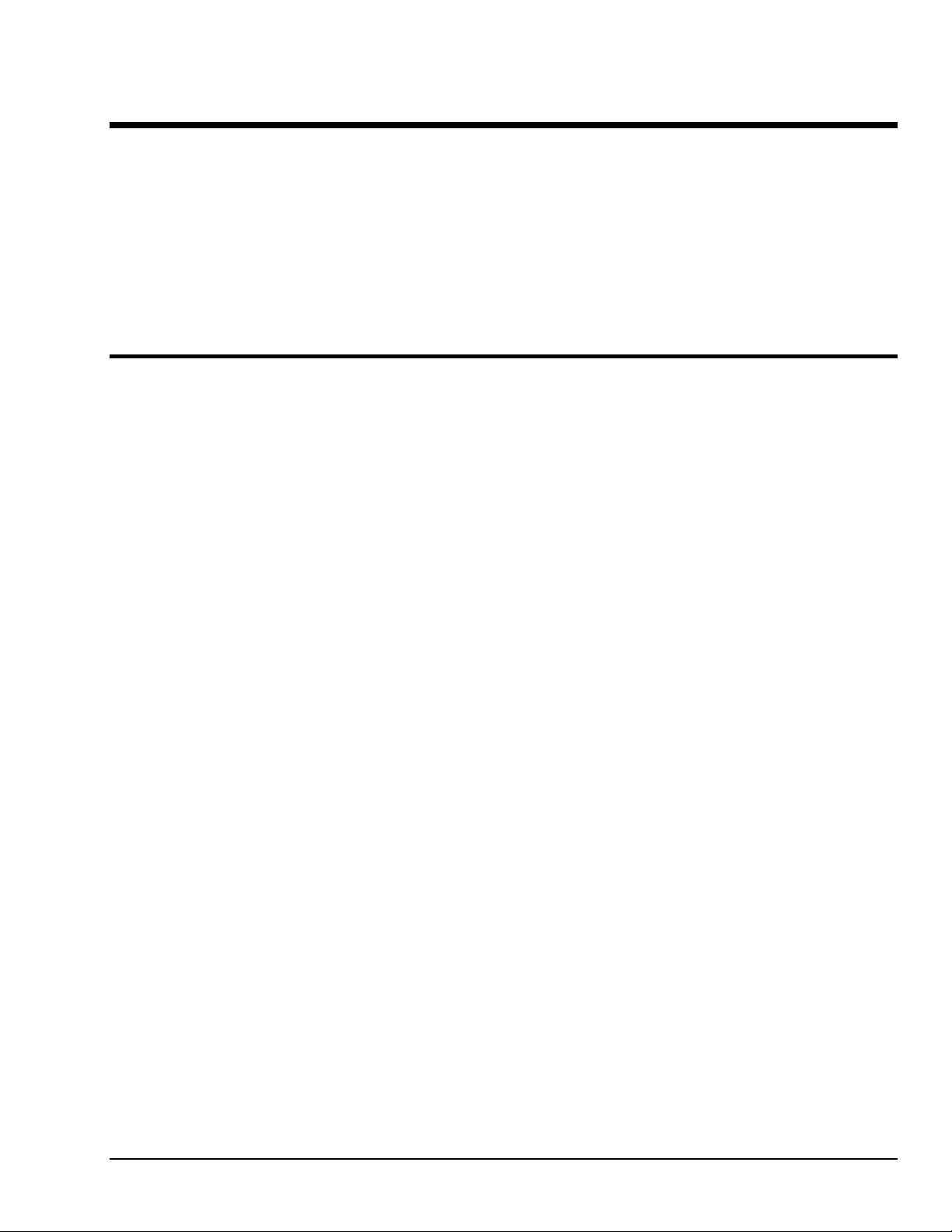

Default Settings

The DAC488 unit may be operated from either 110 VAC or 220 VAC.

The operating voltage is set by an internal switch. The factory set

operating voltage appears on the label placed over the power jack on the

rear panel . To change the operating vol t age, see section Line Voltage

Selection in Chapter 3.

The DAC488 unit has one 8-microswitch DIP switch (SW1) accessible

from the rear panel. This DIP switch determines the IEEE 488 bus

address and its operating mode. The switch is read only when the unit is

powered on and should be set prior to applying power. The figure

illustrates the factory default for the DIP microswitch settings. To

modify the default settings, disconnect the power cord from the AC line

and change the micros witch se ttings using a small screwdriver. The

enclosure does not need to be opened to change the DIP microswitch

settings.

IEEE 488 Bus Address Selection

The IEEE 488 bus address is set by positioning the

rear-panel DIP microswitches 1 through 5. T he

address can be set from 0 through 30 and is read

only at power on. The address is selected by

simple binary weighting with microswitch 1 being

the Least Significant Bit (LSB) and microswitch 5

the Most Significant Bit (MSB). The factory

default setting is address 9, as shown in the

diagram. If address 31 is selected, it defaults to

address 30 because the IEEE 488 standard has

reserved address 31.

Mode Selection

The DAC488 can be operated in one of two modes:

Normal operating mode or automatic calibration

mode, which are selected by the rear-panel DIP

microswitch 8. The factory default setting for

microswitch 8 is normal operating mode, as shown

in the diagram.

Analog Output Ports

The DAC488 can be considered as multiple

isolated IEEE 488 to Analog Converters. The unit

occupies one IEEE 488 bus address. Each port has

a low (L), high (H) , and ground (case ground) l ine.

The case ground line may be connected to the

shield of shielded cable if this type of cable is used

to carry the analog signals. The pinouts for all

analog ports are labeled on the rear panel of the

unit. Each analog output is capable of sourcing

and sinking a maximum current of 1 0 mA.

DAC488 User’s Manual DAC488 Setup 7

Page 14

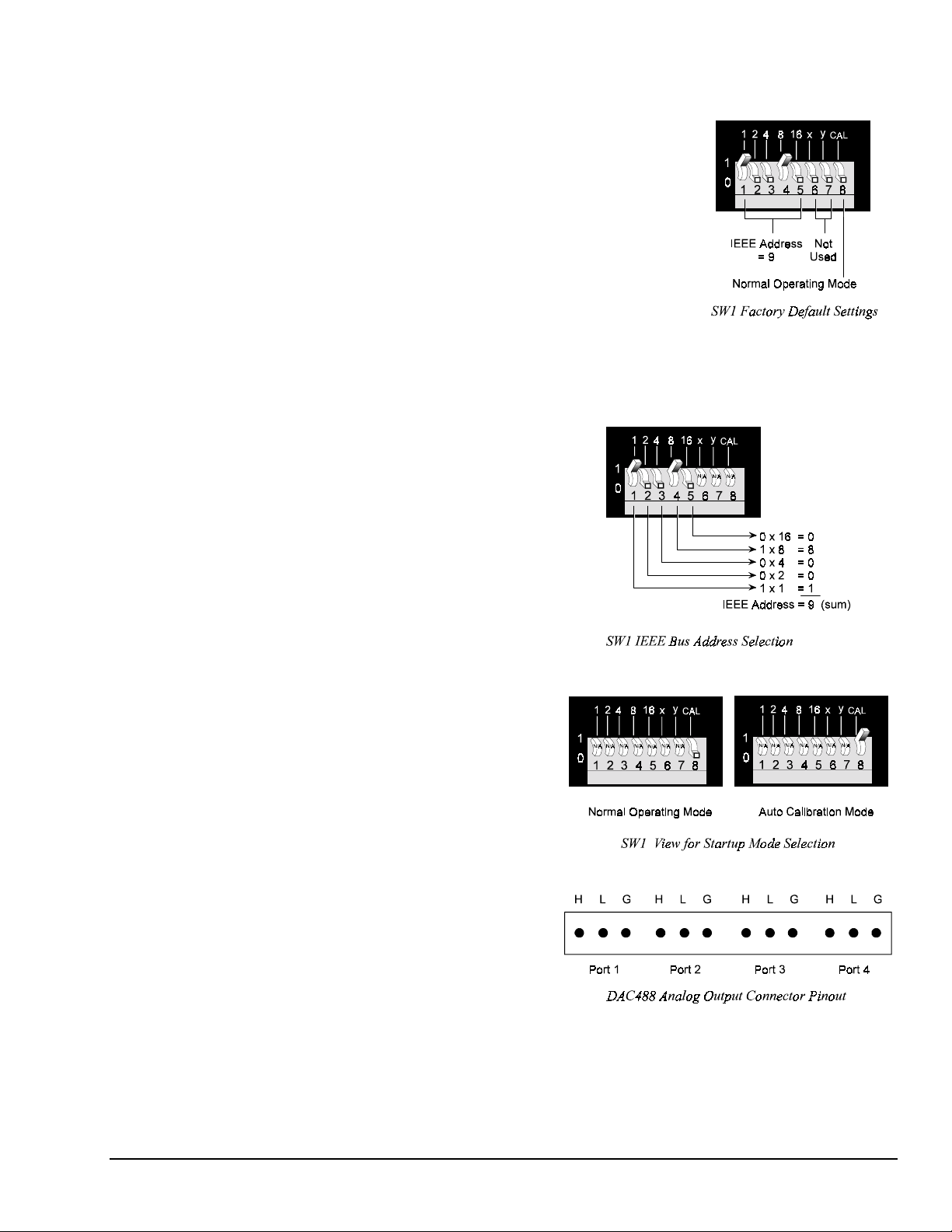

Digital I/O Port

The DAC488 has eight digital input

lines and eight digital output lines. At

power on, the configuration of digital

output lines is determined by the

options saved as the startup

configuration. In order to set the digital

output lines to a particular state upon

power on, the System Defaults (

command must be used after all the

lines have been configured. For

example, if it is desired to have digital

output line 1 set high and the other lines

set low at power on, the lines would be

set to this configuration using the

Digital Output (

configuration would be saved using the

System Defaults (

S

)

D) command. Then this

S

) co mmand.

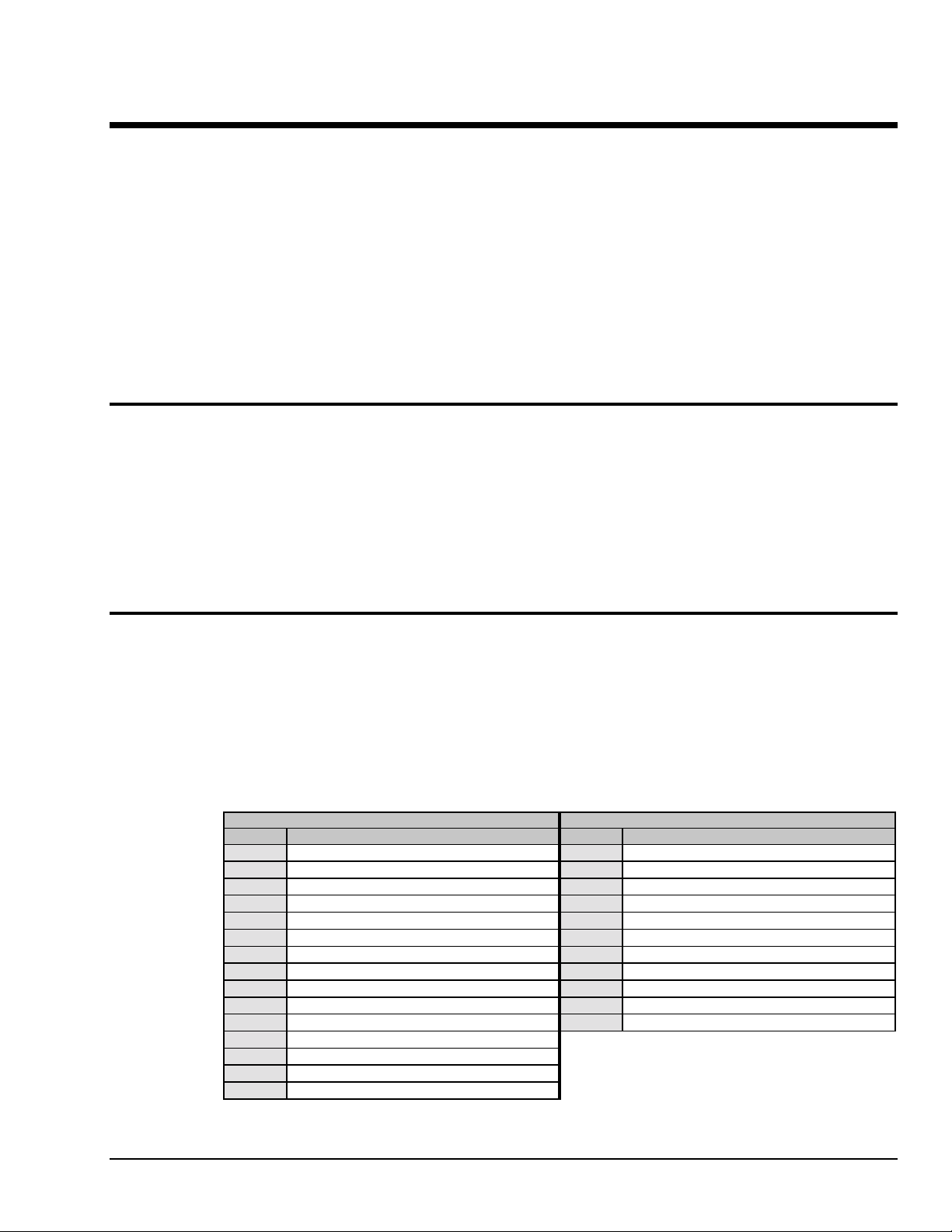

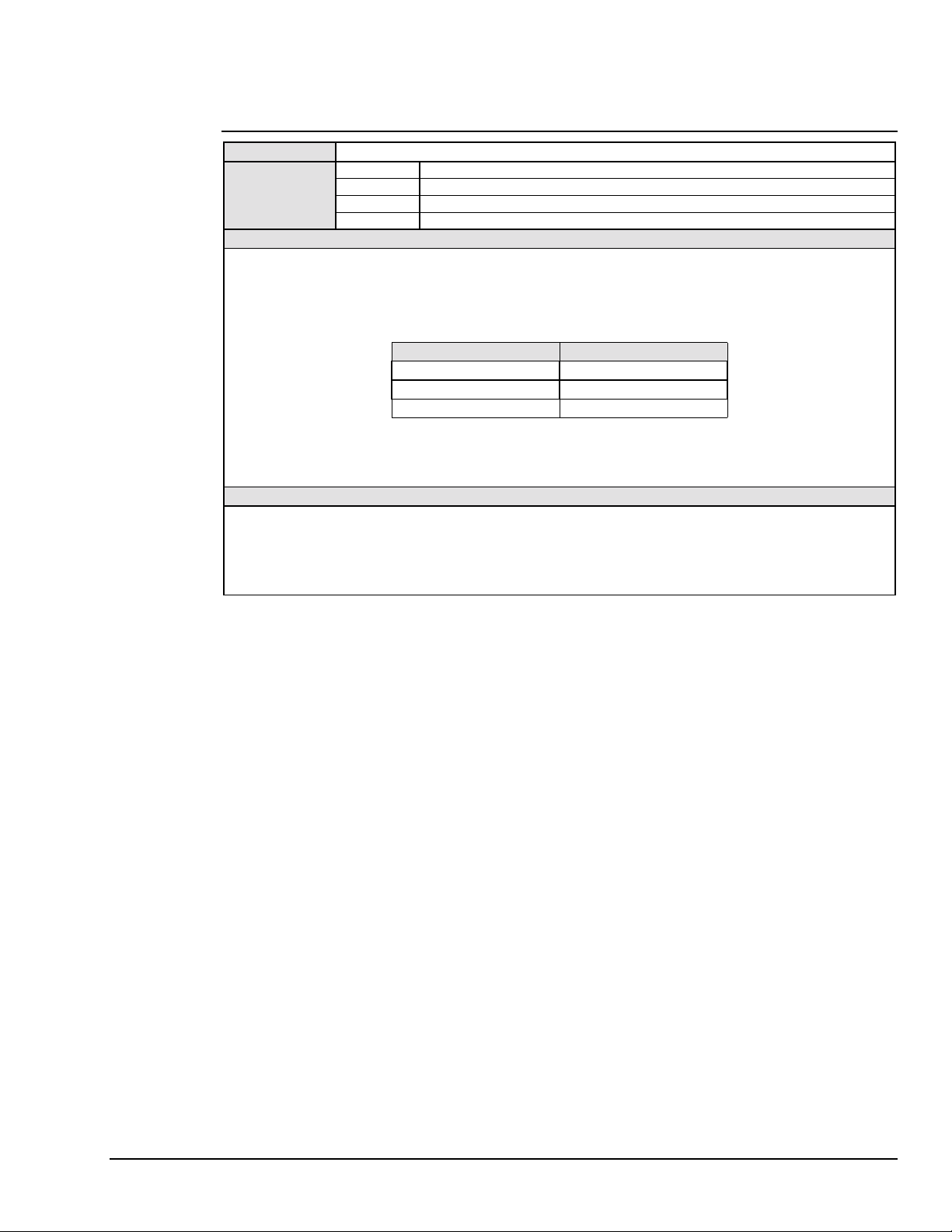

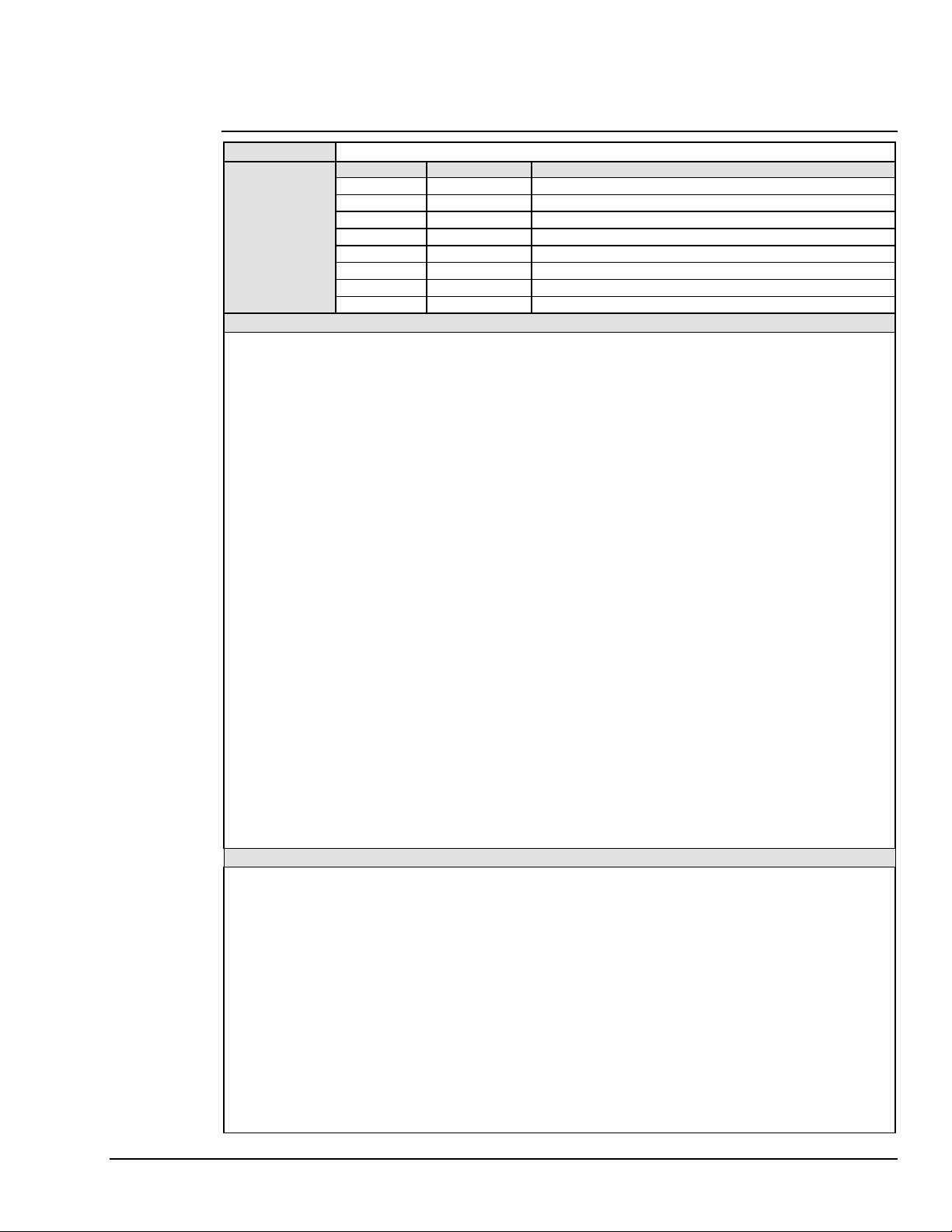

Digital I/O Port Pinouts

Connector Pin Connector Pin

Standard

(20-pin)

1 23 Digital Input Bit 1 (LSB ) 17 15 Flyback

2 10 Digital Input Bit 2 18 2 Ext. Trigger/SRQ Input

3 22 Digital Input Bit 3 19 14

4 9 Digital Input Bit 4 1 Digital Ground

5 21 Digital Input Bit 5 11 Digital Ground

6 8 Digital Input Bit 6 12 Digital Ground

7 20 Digital Input Bit 7 13 Digital Ground

8 7 Digital Input Bit 8 (MSB) 24 Digital Ground

9 19 Digital Output Bit 1 (LSB )

10 6 Digital Output Bit 2

11 18 Digital Output Bit 3

12 5 Digital Output Bit 4

13 17 Digital Output Bit 5

14 4 Digital Output Bit 6

15 16 Digital Output Bit 7

16 3 Digital Output Bit 8 (MSB)

CE Version

(DB25)

Connector Pin

Description

Standard

(20-pin)

20

CE Version

(DB25)

+5 V (≤ 50 mA load)

25 Digital Ground

Connector Pin

Description

8 DAC488 Setup DAC488 User’s Manual

Page 15

Transistor-Transistor Logic (TTL) Levels

The digital output lines will drive 2 TTL loads. All digital input lines are less than 1.5 TTL loads. All

inputs are protected against damage due to high static voltages. Normal precautions should be taken to

limit the input voltages to the range of -0.3 to +7.0 volts. All I/O lines are referenced to Digital Ground

(Standard Version Pin 2 0, CE Version Pin 1).

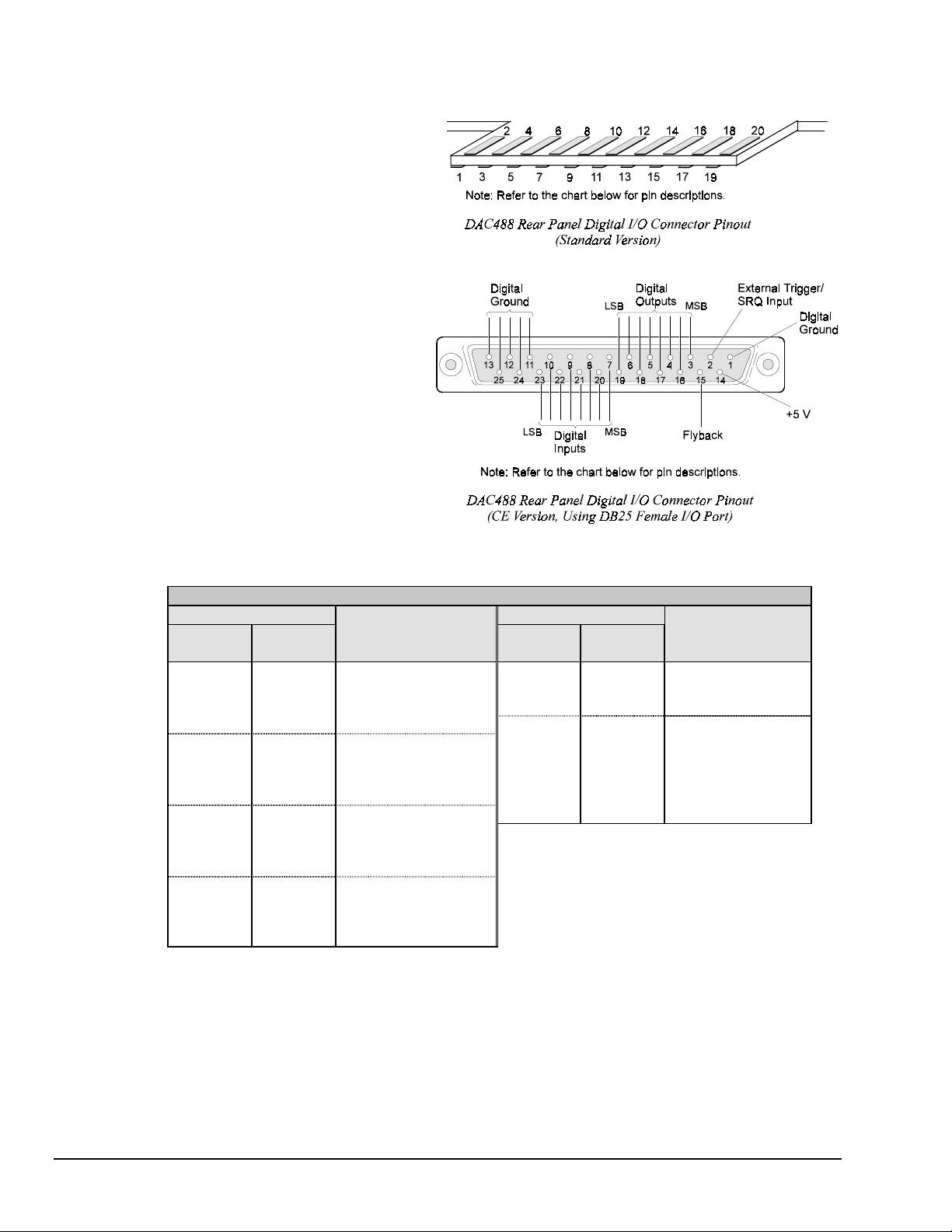

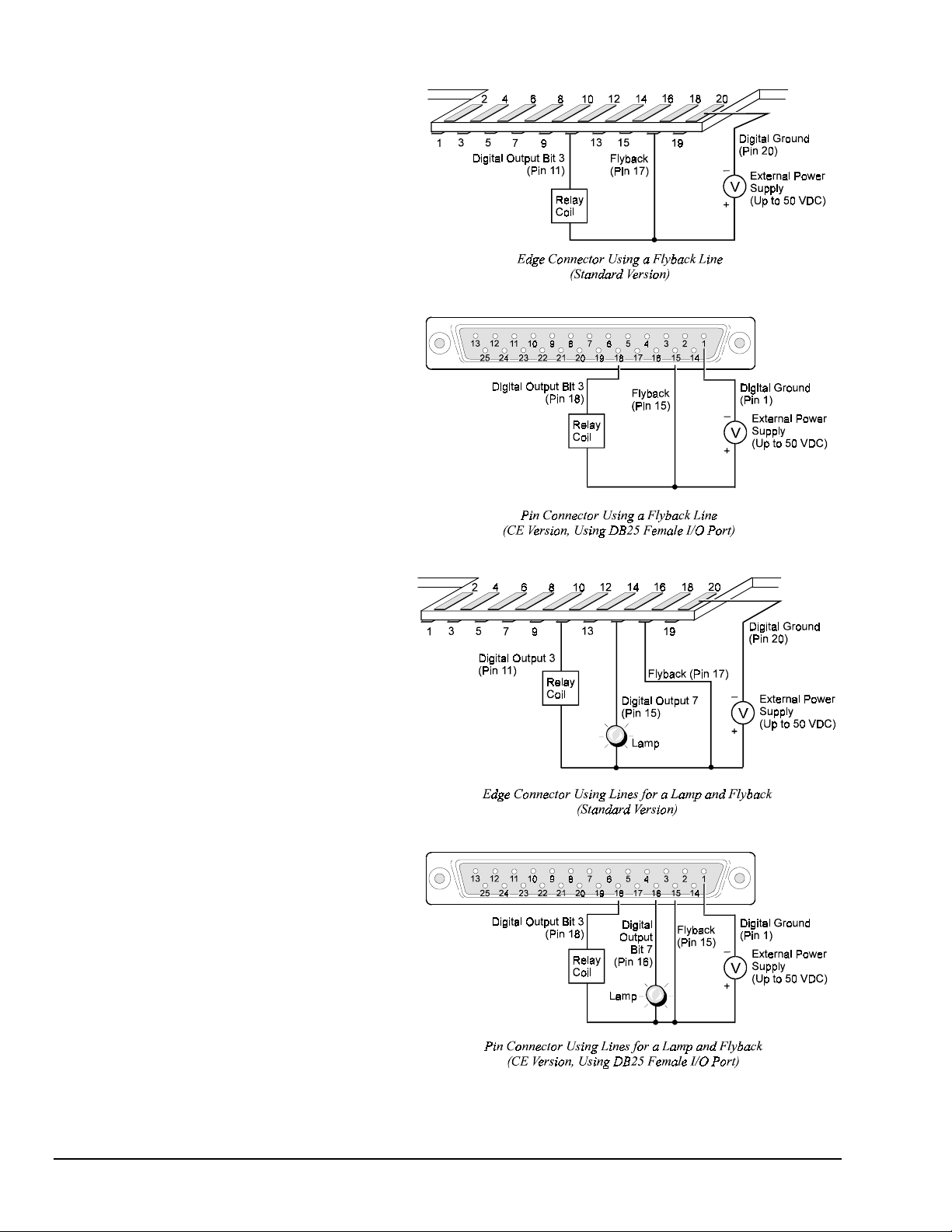

High Voltage/High Current Digital Outputs

In addition to interfacing with TTL

logic levels, the digital output lines

can be configured as high

voltage/high current outputs. These

outputs can sink up to 100 mA at 50

VDC through the use of open

collector drivers with integral diodes

for inductive load transient

suppression. This allows for

interfacing the digital outputs with

relays, lamps and solenoids.

As shown in the following

schematics, the gates driving the

digital outputs (when configured for

high voltage/high current operation)

contain internal diodes to suppress

inductive transients. The cathodes

of these diodes are tied together and

connected to the Flyback pin on the

digital I/O port. By connecting the

Flyback pin to the positive end of

the supply driving the relays, the

internal diodes will be connected in

parallel with the relay coils and thus

prevent inductive spikes from

damaging the internal circuitry of

the DAC488.

DAC488 User’s Manual DAC488 Setup 9

Page 16

When used with relays or solenoids,

the Flyback pin on the edge card

connector should be connected to

the positive supply lead of the power

supply used with the external

devices being driven, as shown in

the following figures . To configure

the digital output lines for this

purpose, it is necessary to open the

enclosure and reposition the

configuration jumper. For

instructions on how this is done, see

section To Configure the Digital

Output Lines in the following text.

Once the digital output lines have

been configured for high level

operation, they can be used to drive

devices such as relays, solenoids and

displays. For example, a typical

application may require a lamp and

a relay to be driven by the Standard

version DAC488. For this example,

the relay is connected to digital

output pin 11 and the lamp is

connected to digital output pin 15,

as shown in the following diagram.

Using this same example for the CE

version DAC488, the relay is

connected to digital output pin 18

and the lamp is connected to digital

output pin 16, also shown in the next

diagram.

Since a relay is used for this

application, the Flyback terminal is

connected to the positive terminal of

the external power supply. Note

also that the Ground lead of the

power supply should be connected

to pin 20 (Digital Ground) on the

Standard card edge connector, or to

pin 1 (Digital Ground) on the CE

pin connector.

10 DAC488 Setup DAC488 User’s Manual

Page 17

External Trigger/SRQ Input

The External Trigger/SRQ input (Standard pin 18; CE pin 2) can be used to trigger the DAC488 once it has

been properly armed. The DAC488 can be programmed to trigger on a positive-going or negative-going

edge by using the External Trigger Mask (

pulse. A trigger pulse may also be used to generate an SRQ by using the Service Request Mask (

command. The maximum rate at which the DAC488 can be triggered is 1 trigger pulse every 1 millisecond.

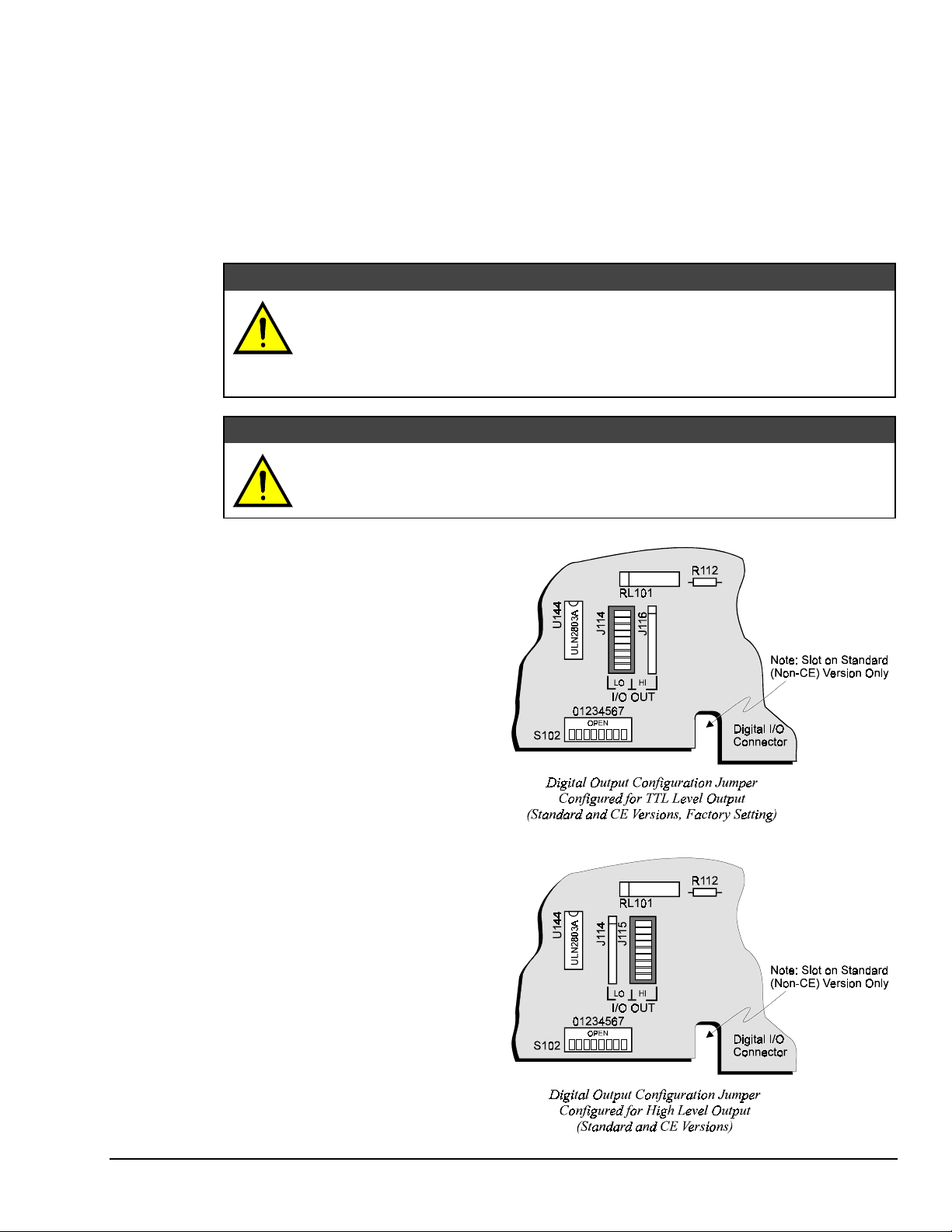

To Configure the Digital Output Lines

Service: This product contains no operator serviceable parts. Fuse replacement and

the changing of selected line voltage must be performed by qualified service personnel.

Never open the DAC488 case while it is connected to the AC line, or when analog

output terminals are connected to a device exceeding 60 VDC or 30 Vrms common

mode voltage!

Do not connect external high level devices to the digital output lines unless they have

first been configured for this purpose. Otherwise the interface may be damaged.

1. First, disconnect any cables from the

analog output terminals. Next,

disconnect the power cord from the

AC line and from the interface. Then

disconnect any other cables prior to

disassembly.

Q) command. Any TTL leve l signal may be used as a trigger

WARNING

WARNING

WARNINGWARNING

CAUTION

CAUTION

CAUTIONCAUTION

M)

2. Place the interface on a flat surface.

Remove the six screws on top of the

case and remove the top cover.

3. Located in front of the rear-panel DIP

switch (SW1) are three sockets and a

configuration jumper. This jumper is

factory set to configure the digital

output lines for low level TTL logic

levels, as shown in the figure.

4. To configure the digital output lines

as high voltage/high c urrent outputs,

first remove the configuration jumper.

5. Next, reinsert it so that the center

socket is now connected to the right

socket, as shown in the second figure.

6. Once the jumper has been

repositioned for your particular

application, make note of the new

setting for later reference.

7. Carefully reassemble the unit.

DAC488 User’s Manual DAC488 Setup 11

Page 18

−

Notes

12 DAC488 Setup DAC488 User’s Manual

Page 19

DAC488 Power & Assembly 3

Introduction…… 13

Internal Components…… 13

Factory Service…… 13

Power Line & Fuse Configuration…… 14

Line Voltage Selection…… 14

To Select the Line Voltage…… 15

Fuse Replacement…… 16

To Replace the Fuse…… 16

Rack-Mount & Bench-Top Assembly…… 17

Rack Mount…… 17

Bench Top…… 17

Power-Up & Performance Tests…… 18

Power-Up Activation…… 18

Programming Examples……19

KYBDCTRL.BAS Program…… 19

To Run the Keyboard Controller Program…… 19

DAC488 Command Responses…… 20

Performance Verification…… 20

To Verify the Port Voltage - 10-Volt Range…… 21

To Verify the Port Voltage - 5-Volt Range…… 21

To Verify the Port Voltage - 1-Volt Range…… 22

Data Transfer Speeds…… 22

Introduction

Internal Components

The heart of the DAC488 is a 6809 microprocessor [U101] supported by 16K bytes of firmware EPROM

[U102] and 32K bytes of battery-backed-up RAM [U103]. Interface to the IEEE 488 bus is accomplished

by a 9914 interface chip [U105]. A 65C22 [U109] generates real-time interrupts for the firmware operating

system and also drives the front panel LED indicators.

Isolation of the analog ports is accomplished using separate bipolar power supplies for each port. OptoIsolators are used to isolate the digital and analog circuitry. High voltage/high current output capability is

available on the digital o ut put port thr ough a 74HCTLS240 and a ULN2803A peripheral driver [U144].

Calibration of the analog ports through p rogram control is accomplished by the use of two 8-bit D/A

converters on each analog circuit. One converter is used to adjust the gain and the other converter to adjust

the offset.

Factory Service

Chapter 8 provides a troubleshooting reference for possible solutions to technical problems. Before calling

for technical assistance, refer to this chapter.

However, if problems in using the DAC488 still persist, you should contact the factory. Many problems

can be resolved by discussing the problems with the appropriate applications department. If the problem

cannot be solved by this method, you will be instructed as to the proper return procedure.

DAC488 User’s Manual DAC488 Power & Assembly 13

Page 20

Power Line & Fuse Configuration

The power configuration of the DAC488 unit consists of selecting the line voltage and replacing the fuses.

Each DAC488 unit has a factory default to operate at 105-125 volts AC. However, each unit may be

operated at either 105-125 or 210-250 VAC.

Do not use the DAC488 unit outdoors! The unit is intended for indoor use only!

Outdoor conditions could result in equipment failure, bodily injury or death!

Never disassemble the DAC488 case while it is connected to the AC power line, or

when analog output terminals are connected to a device exceeding 60 VDC or 30 Vrms

common mode voltage! Internal voltage potentials exist which could cause bodily

injury or death!

To change the operating voltage of the DAC488 unit, it is necessary to open the enclosure. However,

before modifying the voltage, disconnect any input or output connections from the rear panel of the affected

unit and then disconnect the power cord from the power line terminal.

Line voltage must be set for 105-125 or 210-250 VAC to match the power being supplied to the DAC488

unit. If the line voltage is changed, the fuse must also be changed. Refer to the following text for the line

voltage switch and fuse locations.

WARNING

WARNING

WARNINGWARNING

WARNING

WARNING

WARNINGWARNING

Line Voltage Selection

As already mentioned, the DAC488 may be operated with 105-125 or 210-250 VAC, 50-60 Hz power, as

set by its internal line-voltage switch (labelled S104). Each unit is shipped from the factory with this

operating voltage setting marked on its rear panel. If this is not the appropriate power setting to be supplied

to the unit, then the line voltage and power fuse must be changed to avoid damage to the unit. The linevoltage selection procedure is outlined in the following steps.

CAUTION

CAUTION

CAUTIONCAUTION

Service: This product contains no operator serviceable parts, or operator replaceable

parts within the case. Fuse replacement and the changing of selected line voltage must

be performed by qualified service personnel. Never open the DAC488 case while it is

connected to the AC line, or when analog output terminals are connected to a device

exceeding 60 VDC or 30 Vrms common mode voltage. Contact with voltage potentials

could cause bodily injury or death!

14 DAC488 Power & Assembly DAC488 User’s Manual

Page 21

Note: If disassembly or disconnections are necessary, first turn off the power, then disconnect the analog

output cables, next disconnect the AC power line, and then any other cables, prior to disassembly.

To Select the Line Voltage

1. Turn off the power, then disconnect the analog output cables. Next, disconnect the AC power line

cord, and then all other test cables from the unit.

2. Place the unit on a flat surface. Remove the six screws on top of the case and remove the top cover.

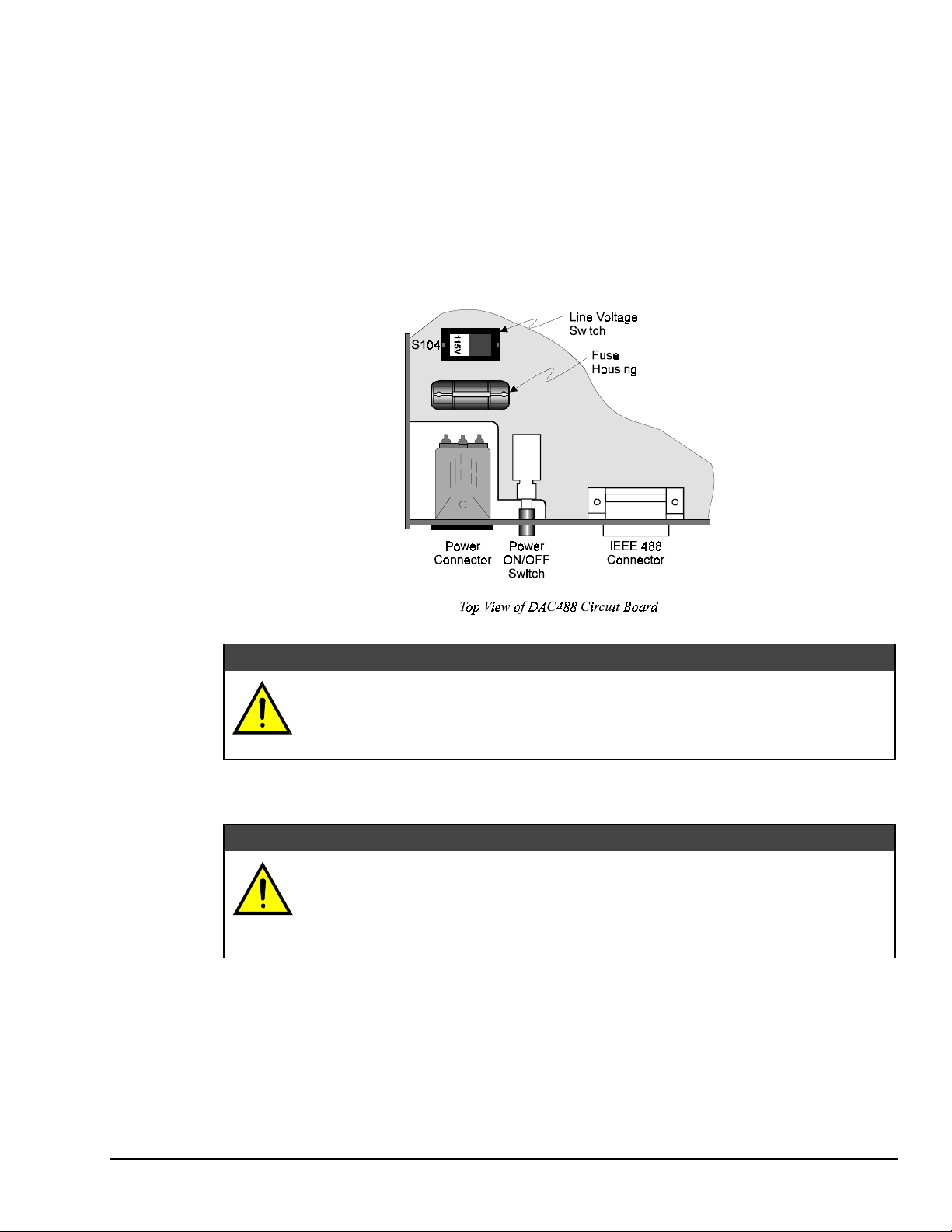

3. Located next to the main power supply transformer is the line voltage selection switch (labelled S104).

Using a small screwdriver, insert the tip of the screwdriver into the slot of the switch and slide the

switch to the left or right until it "clicks" into place with the desired line voltage selection visible.

CAUTION

CAUTION

CAUTIONCAUTION

It is possible to place the line voltage switch (S104) in a partial position which could

cause equipment damage or malfunction. When changing the position of the line

voltage selection switch (S104), make sure the switch is completely positioned to the

115 V or 220 V selection. The switch will “click” into place when properly positioned.

4. Install a power line fuse appropriate for the line voltage. See section Fuse Replacement – Step 3,

following this section.

CAUTION

CAUTION

CAUTIONCAUTION

Fuse Failure: Fuse failure indicates a possible problem within the device circuitry. If a

fuse blows, contact a qualified service representative. Replacement fuses are to be

installed by qualified service personnel with the unit disconnected from the power

source and with all other terminals disconnected. If the line voltage selector is

changed, then the fuse designated for that line voltage must be used.

5. Make note of the new voltage setting for later reference.

6. Carefully reassemble the unit.

Note: For re-assembly, first reconnect the AC power line, next reconnect the analog output terminals, and

then any other cables, prior to reapplying power to the entire system.

DAC488 User’s Manual DAC488 Power & Assembly 15

Page 22

Fuse Replacement

The DAC488 unit contains an internal AC line fuse. The fuse is located next to the internal line-voltage

switch (S104). You may replace the fuse by using the procedures found in the following text.

Note: If disassembly or disconnections are necessary, first turn off the power, then disconnect the analog

To Replace the Fuse

1. Turn off the power, then disconnect the analog output cables. Next, disconnect the AC power line

cord, and then all other cables from the unit.

2. Place the unit on a flat surface. Remove the six screws on top of the case and remove the top cover.

3. Located next to the line-voltage selection switch (labelled S104) is the power fuse. Gently pull upward

on the plastic fuse housing. The entire housing with the fuse inside should be removed.

4. Open the fuse housing by pushing up on the tab on the bottom of the housing. Remove the fuse, and

replace it with the proper type using the following list as a guide:

CAUTION

CAUTION

CAUTIONCAUTION

Service: This product contains no operator serviceable parts, or operator replaceable

parts within the case. Fuse replacement and the changing of selected line voltage must

be performed by qualified service personnel. Never open the DAC488 case while it is

connected to the AC line, or when analog output terminals are connected to a device

exceeding 60 VDC or 30 Vrms common mode voltage. Contact with voltage potentials

could cause bodily injury or death!

output cables, next disconnect the AC power line, and then any other cables, prior to disassembly.

• For line voltage 105-125 V, use fuse type 3/4 A, Slo Blo, 3AG

• For line voltage 210-250 V, use fuse type 3/8 A, Slo Blo, 3AG

CAUTION

CAUTION

CAUTIONCAUTION

Fuse Failure: Fuse failure indicates a possible problem within the device circuitry. If a

fuse blows, contact a qualified service representative. Replacement fuses are to be

installed by qualified service personnel with the unit disconnected from the power

source and with all other terminals disconnected. If the line voltage selector is

changed, then the fuse designated for that line voltage must be used.

5. Close the housing. Insert the fuse into the fuse holder.

6. Make note of the new fuse rating for lat er reference. If you have also changed the operating linevoltage selection, return to the previous section Line Voltage Selection – Step 5.

7. Carefully reassemble the unit.

Note: For re-assembly, first reconnect the AC power line, next reconnect the analog output terminals, and

then any other cables, prior to reapplying power to the entire system.

16 DAC488 Power & Assembly DAC488 User’s Manual

Page 23

Rack-Mount & Bench-Top Assembly

The DAC488 includes accessories for rack-mount or bench-top assembly.

Rack Mount

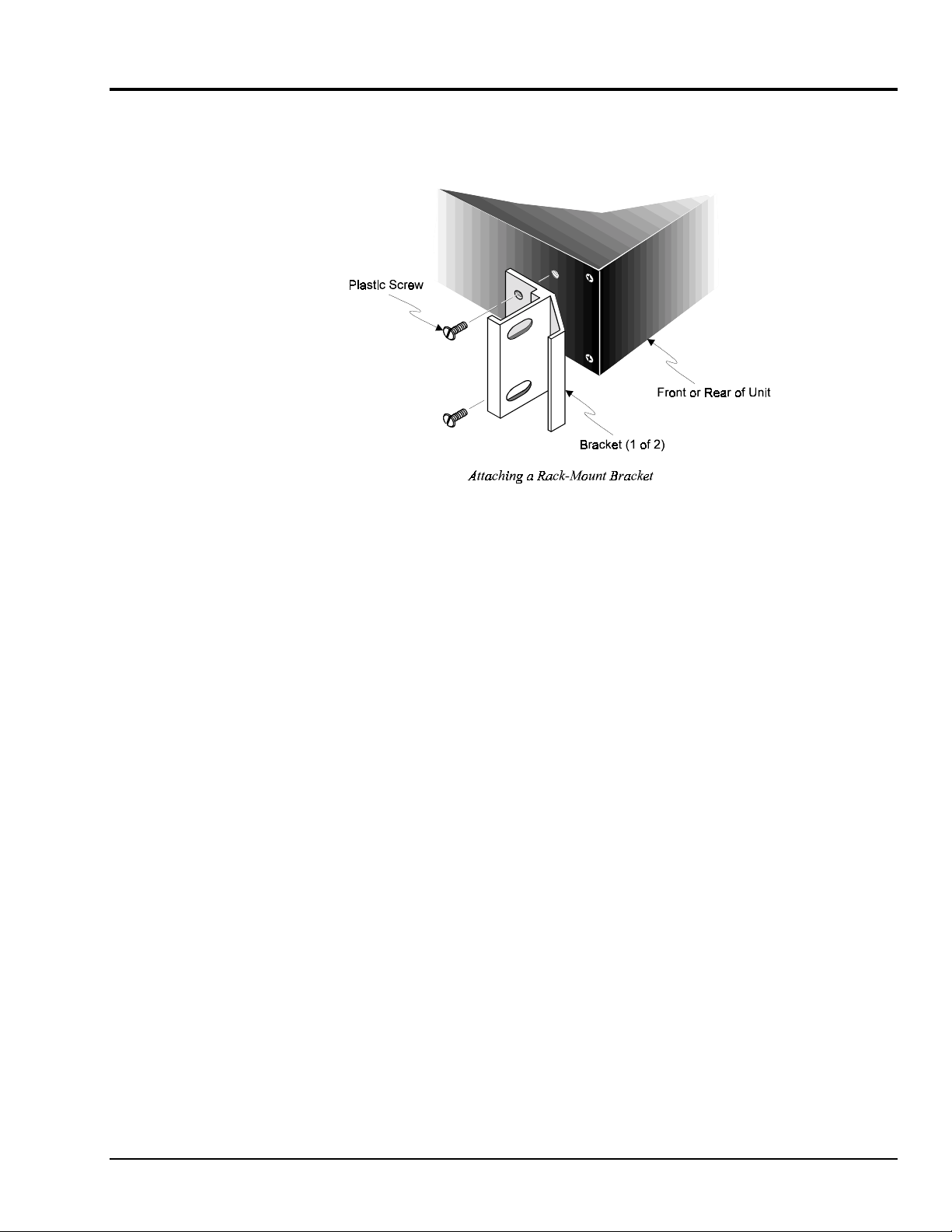

If rack-mount assembly is required, remove the two plastic screws from the pre-drilled holes on each side of

the unit. Since the unit can be mounted with the front or rear panel facing the front of the rack fixture,

remove only those screws from the set of holes that will be toward the front of the rack. Attach the two rack

ears using the enclosed screws.

Bench Top

If bench-top assembly is required, install the self-adhesive rubber feet on the bottom of the unit

approximately one inch from each corner.

DAC488 User’s Manual DAC488 Power & Assembly 17

Page 24

Power-Up & Performance Tests

Power-Up Activation

Line Voltage: The protective conductor terminal on the AC line connector must be

connected to an external protective earthing system. Failure to make such a

connection will impair protection from shock.

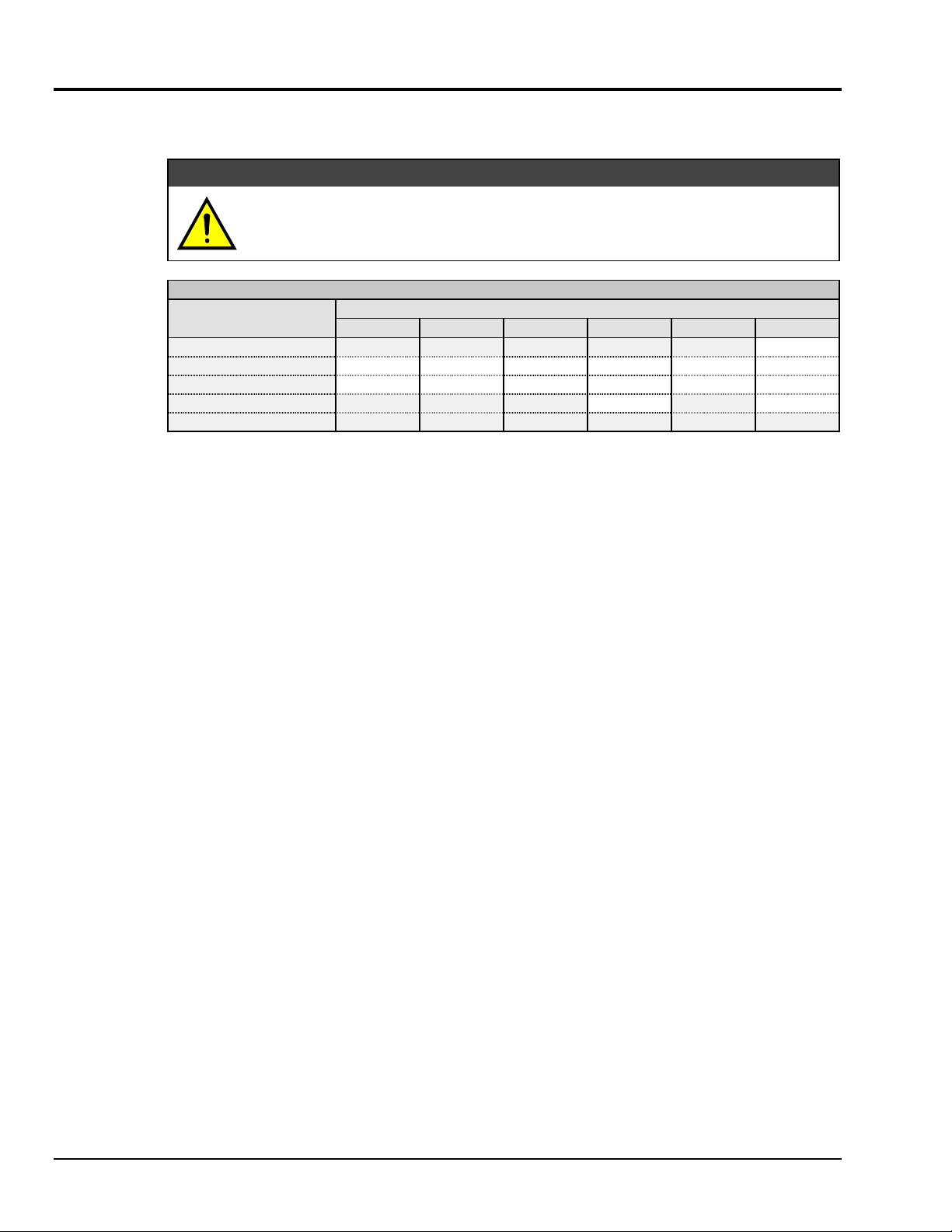

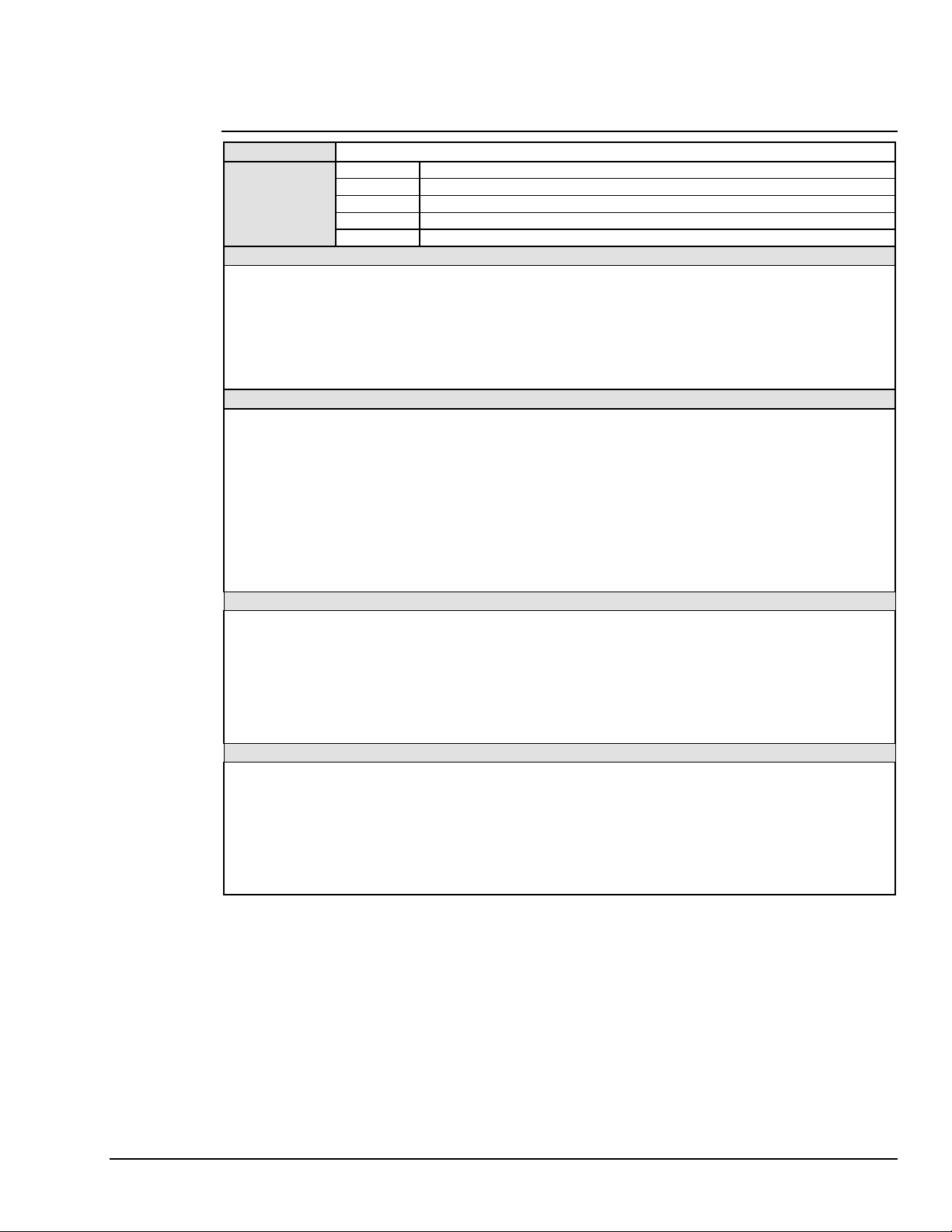

Condition

Normal (No Errors)

ROM Error

RAM Error

NV-RAM Checksum Error

No Power

With the power c ord plugged i n and connected to the DAC488, turn on the unit by depressing the rear-panel

power switch. All of the front-panel LED indicators should light up for approximately one second while the

DAC488 performs an internal ROM and RAM self-check. At the end of this self-check all of the LED

indicators should turn off except for POWER.

Otherwise, the DAC488 may be in an error condition according to the one of the four following LED

patterns:

TALK LISTEN SRQ ERROR TEST POWER

(Off) (Off) (Off) (Off) (Off) ON

ON ON ON ON ON ON

FLASHINGFLASHINGFLASHINGFLASHINGFLASHING ON

(Off) (Off) (Off) ON (Off) ON

(Off) (Off) (Off) (Off) (Off) (Off)

CAUTION

CAUTION

CAUTIONCAUTION

LED Patterns for Error Conditions

LED Indicators

• If all of the LED indicators remain on: T hen a ROM error has occurred.

• If the POWER LED indicator remains on while the rest of the LED indicators flash continuously:

Then a RAM error has occurred. Try cycling the power to the DAC488 to determine that the error is

repeatable.

• If the POWER and ERROR LED indicator remain on while the rest of the LED indicators are off:

Then a checksum error on Non-Volatile RAM occurred, and the saved configurations may be lost. The

checksum error condition may be cleared by doing a save of a configuration using the System Defaults

(

S) command. The error condition may also be cleared by using the Query Error Status (E?)

command.

• If all of the LED indicators are off: Then there may not be any power being supplied to the DAC488.

In this event, check to make sure that the AC power cable is securely connected at both ends.

Otherwise, there may be a problem with the fuse. For more information, see section Power Line &

Fuse Configuration earlier in this chapter.

18 DAC488 Power & Assembly DAC488 User’s Manual

Page 25

Programming Examples

The DAC488 programming examples use the Personal488 PC/IEEE 488 controller interface and the BASIC

Keyboard Controller (KBC) program. This KBC program

listed below.

KYBDCTRL.BAS Program

10 ' Personal488 Keyboard Controller Program

20 '

30 ' For use with the IOtech Personal488

40 ' IEEE 488 interface

50 '

100 OPEN "\DEV\IEEEOUT" FOR OUTPUT AS #1

110 IOCTL#1,"BREAK"

120 PRINT#1,"RESET"

130 OPEN "\DEV\IEEEIN" FOR INPUT AS #2

140 '

150 ON ERROR GOTO 300

160 PRINT#1,"ERROR OFF"

170 '

180 LINE INPUT "CMD> ",CMD$

190 PRINT#1,CMD$

200 '

210 IF IOCTL$(2)<>"1" THEN 180

220 PRINT INPUT$(1,2);

230 GOTO 210

290 '

300 ' Error Handler

310 '

320 IOCTL#1,"BREAK"

330 PRINT#1,"STATUS"

340 INPUT#2,ST$

350 PRINT CHR$(7);"Error #";MID$(ST$,15,2);": ";MID$(ST$,27)

360 RESUME NEXT

KYBDCTRL.BAS is included on the disk and is

The Keyboard Controller (KBC) program allows direct communication with the DAC488 (or any IEEE 488

device on the bus) via the keyboard, and displays any responses on the screen. This program is a

convenient method of exercising the DAC488 and becoming familiar with the commands and their actions.

To Run the Keyboard Controller Program

1. First, set the rear-panel DIP switch for bus address 9.

2. Connect an IEEE 488 cable from the IEEE 488 connector on the DAC488 to the IEEE 488 connector

on the Personal488 PC/IEEE 488 controller interface card.

3. Turn on the DAC488 by depressing the rear-panel power switch.

4. From the MS-DOS prompt on your computer screen, run the Keyboard Controller Program

KYBDCTRL.BAS and verify that the CMD> prompt appears on the screen.

DAC488 User’s Manual DAC488 Power & Assembly 19

Page 26

DAC488 Command Responses

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

CMD>

CMD>OUTPUT 09;W1X

CMD>OUTPUT 09;W0X

CMD>ENTER 09

A1 C0 P1 R0 V+00.00000

CMD>OUTPUT 09;P1 C0 A0 R3 V5.678

CMD>ENTER 09

A0 C0 P1 R3 V+05.67750

CMD>OUTPUT 09;P1 C0 A0 R3 V4.321

CMD>ENTER 09

A0 C0 P2 R2 V+04.32000

The above is a listing of the commands given to the DAC488 and the response received. Some commands

and command responses are separated by extra vertical and horizo ntal spaces for clarity although these

spaces will not actually appear when using the program. These eight command responses are explained as

follows:

• Line 1: Initial command prompt from the Keyboard Controller program.

• Line 2: Instruct the DAC488 to turn on its TEST LED indicator. The TEST LED indicator should light

up.

• Line 3: Instruct the DAC488 to turn off its TEST LED indicator. The TEST LED indicator should turn

off.

• Line 4: Retrieve the DAC488 default status: Autorange on, Direct control mode, Port 1 selected,

Ground range , and 0.0 volts.

• Line 5: Program the DAC488 Port 1 for 5.678 volts. A digital multimeter (DMM) connected to Port 1

should read 5.677 volts (± 10 mV) after this command string is executed.

• Line 6: Retrieve the DAC488 status: The programmed 5.678 volts was rounded to 5.67750 volts.

• Line 7: Program the DAC488 Port 2 for 4.321 volts. A digital multimeter (DMM) connected to Port 2

should read 4.320 volts (± 10 mV) after this command string is executed.

• Line 8: Retrieve the DAC488 status: The programmed 4.321 volts was rounded to 4.32000 volts.

Performance Verification

To verify that each DAC488 port is functioning within the specifications, the following procedure may be

used. If the port voltage is measured using a Keithley 199 DMM/Scanner, the reading should fall between

the low and high limits listed in the tables. The procedure is given for Port 1 although each port may be

tested by the Port Select (

DMM/Scanner using the calibration cable described in Chapter 6.

P

) command. It is assumed that the DAC488 is connected to the Keithley 199

20 DAC488 Power & Assembly DAC488 User’s Manual

Page 27

To Verify the Port Voltage – 10-Volt Range

1. Send the following command string to the DAC488:

•

C0

= Direct Control Mode • R3 = 10-Volt Range

•

P1 = Port 1 • V10 = Output +10 Volts

•

A0 = Autorange Off • X = Execute

2. Send the following command string to the 199 DMM:

•

F0 = DC Volts • N1 = Scanner Channel 1

•

R3

= 30-Volt Range • S1 = 5 ½ Digit Resolution

Z0 = Zero Disabled • X = Execute

•

3. For each test, the specific Value Output (

V) command, its commanded output voltage, and its

corresponding Low Limit and High Limit, are as follows:

V10 = Output +10 V +9.985 ≤ Reading ≤ +10.015 Volts

•

•

V5 = Output +5 V +4.990 ≤ Reading ≤ +5.010 Volts

•

V1 = Output +1 V +0.994 ≤ Reading ≤ +1.006 Volts

•

V0 = Output 0 V -0.005 ≤ Reading ≤ +0.005 Volts

•

V-1 = Output -1 V -1.006 ≤ Reading ≤ -0.994 Volts

•

V-5 = Output -5 V -5.010 ≤ Reading ≤ -4.990 Volts

•

V-10 = Output -10 V -10.015 ≤ Reading ≤ -9.985 Volts

To Verify the Port Voltage – 5-Volt Range

1. Send the following command string to the DAC488:

C0 P1 A0 R3 V10 X where:

F0 R3 Z0 N1 S1 X where:

C0 P1 A0 R2 V5 X where:

•

C0 = Direct Control Mode • R2 = 5-Volt Range

•

P1 = Port 1 • V5 = Output +5 Volts

•

A0 = Autorange Off • X = Execute

2. Send the following command string to the 199 DMM:

•

F0 = DC Volts • N1 = Scanner Channel 1

•

R3

= 30-Volt Range • S1 = 5 ½ Digit Resolution

Z0 = Zero Disabled • X = Execute

•

V

3. For each test, the specific Value Output (

) command, its commanded output voltage, and its

corresponding Low Limit and High Limit, are as follows:

•

V5 = Output +5 V +4.9920 ≤ Reading ≤ +5.0080 Volts

•

V2.5 = Output +2.5 V +2.4945 ≤ Reading ≤ +2.5055 Volts

•

V1

= Output +1 V +0.9960 ≤ Reading ≤ +1.0040 Volts

V0 = Output 0 V -0.0030 ≤ Reading ≤ +0.0030 Volts

•

•

V-1 = Output -1 V -0.9960 ≤ Reading ≤ -1.0040 Volts

•

V-2.5 = Output –2.5 V -2.4945 ≤ Reading ≤ -2.5055 Volts

•

V-5 = Output -5 V -4.9920 ≤ Reading ≤ -5.0080 Volts

F0 R3 Z0 N1 S1 X

where:

DAC488 User’s Manual DAC488 Power & Assembly 21

Page 28

To Verify the Port Voltage – 1-Volt Range

1. Send the following command string to the DAC488:

•

C0

= Direct Control Mode • R1 = 1-Volt Range

•

P1 = Port 1 • V1 = Output +1 Volt

•

A0 = Autorange Off • X = Execute

2. Send the following command string to the 199 DMM:

•

F0 = DC Volts • N1 = Scanner Channel 1

•

R2

= 3-Volt Range • S1 = 5 ½ Digit Resolution

Z0 = Zero Disabled • X = Execute

•

3. For each test, the specific Value Output (

V) command, its commanded output voltage, and its

C0 P1 A0 R1 V1 X where:

F0 R2 Z0 N1 S1 X where:

corresponding Low Limit and High Limit, are as follows:

V1 = Output +1 V +0.9980 ≤ Reading ≤ +1.0020 Volts

•

•

V0.5 = Output +0.5 V +0.4985 ≤ Reading ≤ +0.5015 Volts

•

V0.1 = Output +0.1 V +0.0989 ≤ Reading ≤ +0.1011 Volts

•

V0 = Output 0 V -0.0010 ≤ Reading ≤ +0.0010 Volts

•

V-0.1 = Output –0.1 V -0.1011 ≤ Reading ≤ -0.0989 Volts

•

V-0.5 = Output –0.5 V -0.5015 ≤ Reading ≤ -0.4985 Volts

•

V-1 = Output -1 V -1.0020 ≤ Reading ≤ -0.9980 Volts

Data Transfer Speeds

The DAC488 has been measured to perform at the approximate speeds listed below. All explanations

discuss only one port, although the information given is val id for any port. These values are relative to the

controller used. The speeds you encounter may vary.

• Output of Data to the Analog Ports: When sending data to the analog outputs on a port of the

DAC488, the outputs may be changed about once every 4 milliseconds when specifying voltages in

bits, or once every 25 milliseconds when specifying voltages in volts.

• Output of Data to the Digital Output Port: Data may be sent to the digital output port at an

approximate rate of once every 2.5 milliseconds.

• Input of Data from the Digital Inp ut Port: The digital input port may be read at an approximate rate

of once every 75 milliseconds.

22 DAC488 Power & Assembly DAC488 User’s Manual

Page 29

DAC488 Operation 4

Introduction…… 23

Command Groups…… 23

Port Triggering…… 24

Internal Buffer…… 26

Control Modes…… 28

Introduction

The DAC488 provides multiple independently programmable 12-bit plus-sign Digital-to-Analog Converters

(DACs). Three voltage ranges, ±1, ±5, and ±10, are available on a per port basis as well as an autorange

feature which automatically selects the range giving the best resolution for the specified voltage. The DAC

ports may be programmed in terms volts or bits. The resolution per bit on each range is: 250 µV/bit (±1 V

range), 1.25 mV/bit (±5 V range), and 2.5 mV/bit (±10 V range). Volts are programmed with decimal

floating poi nt numbers in the range of ±10.2375 or ±1.2375E+1. Voltages may also be programmed in

decimal bits (range = ±4095) or 16-bit hexadecimal two's complement numbers (range = F001 to 0FFF).

System & Port Commands…… 23

Command Support…… 24

Trigger Processing & Trigger Overrun…… 25

Buffer Data…… 26

Buffer Save-and-Restore Program…… 27

Direct Control Mode…… 28

Indirect Control Mode……28

Stepped Control Mode…… 28

Waveform Control Mode…… 29

Multiple Port Synchronization…… 30

Synchronized Waveforms Program…… 30

Digital I/O Port…… 32

User-Defined System Defaults…… 33

IEEE 488 Bus Support…… 33

Bus Lines…… 33

Bus Commands…… 34

Bus Addresses…… 34

Bus Terminators…… 34

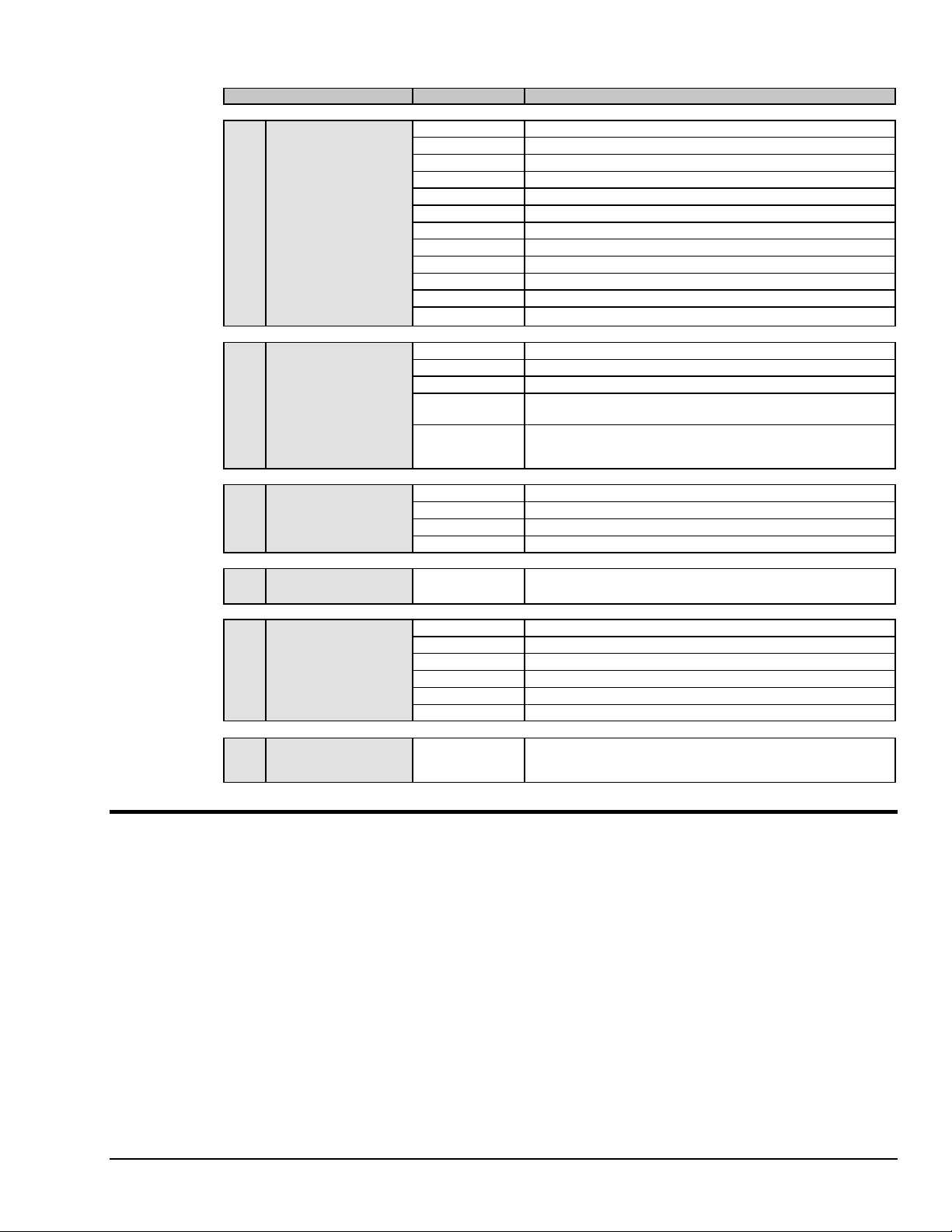

Command Groups

Operation of the DAC488 is accomplished using a set of commands that configure the entire interface as

well as each DAC port. The DAC488 commands can be divided into two main groups: System commands

and port commands.

System & Port Commands

System commands affect the operation of the entire interface and are not specific to a given port.

Meanwhile, port commands only affect the operation of the selected port. The port is selected using the

Port Select (

Syntax Name Syntax Name

@

D

E?

G

K

M

O

P

Q

S

T

U

W

X

Y

Pn

) command. The 15 system commands and the 11 port commands are listed below:

Command Trigger

Digital Output

Query Error Status

GET Trigger Mask

End-Or-Identify Control

Service Request Mask

Output Format

Port Select

External Trigger Mask

System Defaults

Command Trigger Mask

User Status

Test

Execute

Bus Terminator

System Commands Port Commands

A

B

C

F

H

I

J

L

N

R

V

Autorange

Buffer Data

Control Mode

Buffer Definition

Offset Calibration

Interval

Gain Calibration

Buffer Location

Number of Cycles

Range Select

Value Output

DAC488 User’s Manual DAC488 Operation 23

Page 30

Command Support

Support for the above commands, includes the Query (?) command extension, and the use of the Serial Poll

Status Byte. Refer to Chapter 7 for more details.

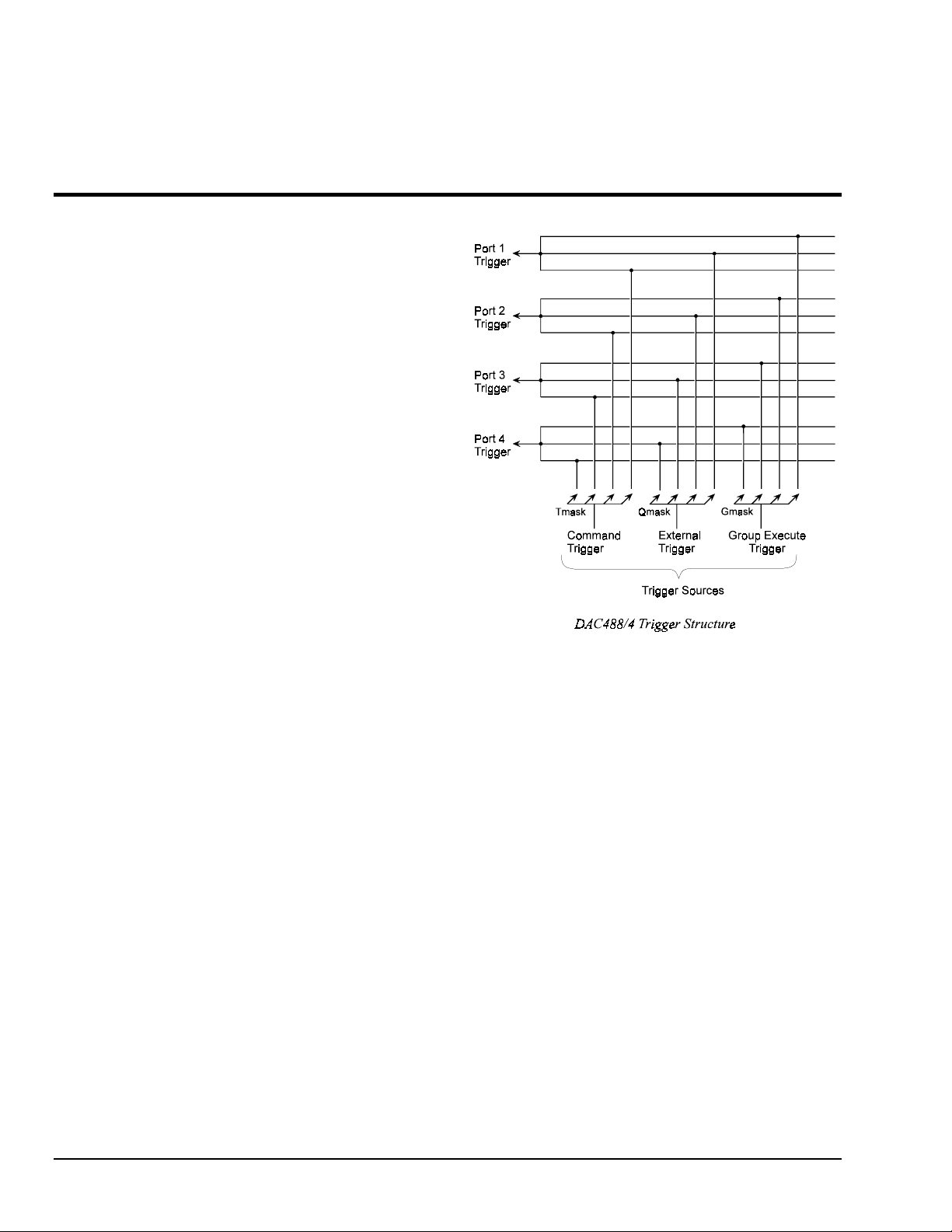

Port Triggering

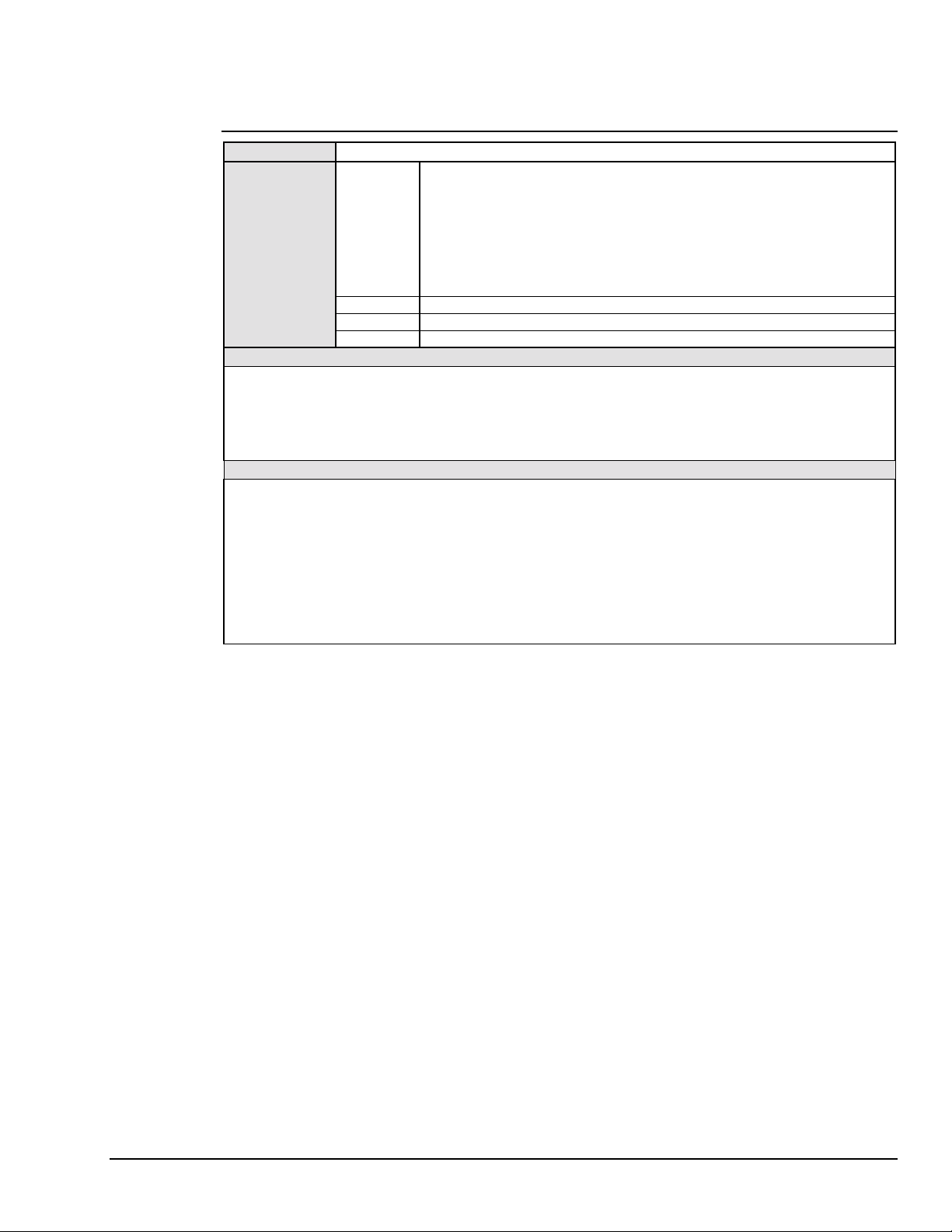

Triggering is t he process of changing a DAC

output at the occurrence of a trigger event.

The three trigger events which can trigger a

DAC port are: a Trigger On (

IEEE Group Execute Trigger (

external trigger pulse applied to the external

trigger/SRQ input. Any DAC port may be

configured to trigger on one or more of the s e

trigger sources. These trigger sources and

their relationship to a DAC port are shown in

the following diagram.

As shown in the diagram, the trigger sources

are routed to the ports by using the trigger

mask c ommands. The trigge r mask

commands are illustrated as switches. The

trigger mask commands are used to enable a

trigger source to trigger the selected DAC

port. All trigger signals are then combined to

allow a port to be triggered upon the

occurrence of any of the three trigger events.

@) command, an

GET) or an

Triggering is provided as a means of

synchronizing multiple DAC ports. Voltages

may be output at two or more ports

simultaneously by programming each port for

the desired voltages and trigger event(s).

When the trigger event occurs, the

programmed voltages will appear at the ports

simultaneously.

24 DAC488 Operation DAC488 User’s Manual

Page 31

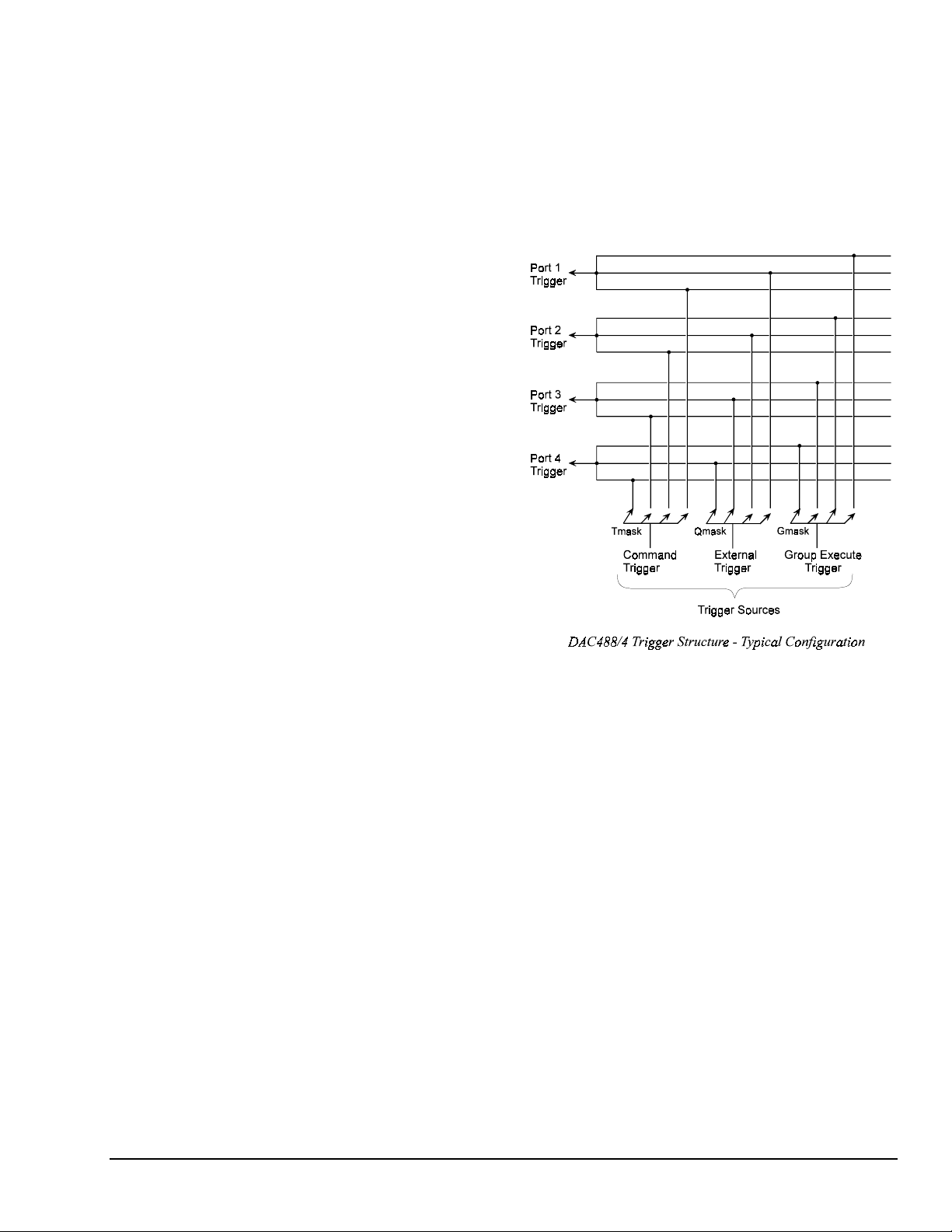

For example, a typical configuration may require Port 1 to have all trigger sources disabled, Port 2

configured to trigger on an IEEE Group Execute Trigger, Port 3 to trigger on an external trigger, and Port 4

to trigger on any of the three trigger sources.

The commands to configure the ports for this configuration are shown below:

PRINT#1,"OUTPUT09;G0 Q0 T0 X"

PRINT#1,"OUTPUT09;G2 X"

PRINT#1,"OUTPUT09;Q4 X"

PRINT#1,"OUTPUT09;G8 Q8 T8 X"

• Line 1:

G0 disables all ports from

triggering on an IEEE Group Execute

Trigger,

triggering on an external trigger,

Q0 disables all ports from

T0

disables all ports from triggering on a

command trigger (

@), and X executes the

commands.

• Line 2:

G2 enables port 2 for triggering

on an IEEE Group Execute Trigger and

X executes the command.

• Line 3:

on an external trigger and

Q4 enables port 3 for triggering

X executes the

command.

• Line 4:

on an IEEE Group Execute Trigger,

G8 enables port 4 for triggering

Q8

enables port 4 for triggering on an

external trigger,

triggering on an a command trigger (

X executes the commands.

and

T8 enables port 4 for

@),

After these commands are executed, the

trigger sources will be routed to the ports as

illustrated in the figure.

Trigger Processing & Trigger Overrun

Operation of the DAC488 is controlled by an internal 1 millisecond timer. Each DAC port is updated at a

maximum rate of once every millisecond. When a trigger event occurs, the DAC will output the

programmed voltage within 1 millisecond of receiving the trigger. If a second trigger event occurs before

the DAC has finished processing the first trigger, the second trigger will be held pending and a trigger

overrun error will occur. The error condition may be cleared by issuing the Error Query command (E?) and

then reading the response from the DAC488. After the first trigger is processed, the pending trigger will

then be processed. Any additional triggers which may occur while a trigger is held pending will be ignored.

DAC488 User’s Manual DAC488 Operation 25

Page 32

Internal Buffer

Buffer Data

The DAC488 contains an internal buffer consisting of 8,192 locations numbered 0 to 8,191. The buffer is

shared by all ports. Each port may be given a different section of the buffer or ports may use the same

buffer locations without conflict.

This buffer may be loaded with voltage values to be output when the Stepped or Waveform modes are used.

All data in the internal buffer is saved in Non-Volatile RAM. Therefore buffer data which was previously

loaded will be available at power on. Examples showing the use of the internal buffer are given in the

upcoming descriptions of Stepped and Waveform Control modes.

The following diagram shows the factory

default allocation of the internal buffer to

each of the DAC ports on the DAC488/4. On

the DAC488/2, only the Port 1 and Port 2

sections of the internal buffer are allocated.

Buffers are defined using the Buffer

Definition (

this command specify the starting location

start) and the number of locations (size)

(

in the defined buffer. Once the buffer is

defined it may be loaded with voltage values

using the Buffer Data (

Before using the Buffer Data command, the

Buffer Location (L) command should be used

to set the location pointer to the desired

value. The location pointer points to the area

where data will be stored when the Buffer

Data command is used. After each use of the

Buffer Data command, the location pointer is

incremented.

F

) command. The parameters of

B) co mmand.

26 DAC488 Operation DAC488 User’s Manual

Page 33

Buffer Save-and-Restore Program

This BASIC program DACBUFR.BAS may be used to save the contents of the DAC488 internal buffer to

disk. It can also be used to load the saved values from disk into the internal buffer.

10 'BASIC program to save and restore the DAC488 buffer contents

20 '

30 'Initialize the IOtech IEEE488 Driver

40 OPEN "\dev\ieeeout" FOR OUTPUT AS #1

50 IOCTL #1, "BREAK"

60 PRINT #1, "RESET"

70 OPEN "\dev\ieeein" FOR INPUT AS #2

75 ON TIMER(5) GOSUB 2000

80 CLS

90 PRINT "DAC488/4 Waveform Buffer Save and Restore Program"

100 PRINT : PRINT " 1 - Save the Waveform Buffer "

110 PRINT " 2 - Restore the Waveform Buffer "

120 PRINT " 3 - Exit the program"

130 PRINT : INPUT "Select the desired function "; FUN

140 IF FUN < 1 OR FUN > 3 THEN PRINT "Invalid selection!": GOTO 100

150 IF FUN = 3 THEN END

160 IF FUN = 1 THEN GOSUB 500 ELSE GOSUB 1000

170 GOTO 80

500 ' Save DAC488/4 waveform buffer

510 '

515 WCNT = 0: TIMER ON

520 OPEN "buffer.sav" FOR OUTPUT AS #3

530 PRINT #1, "output 09;p1c0l0x"

540 PRINT "Saving the DAC488/4 waveform buffer"

550 FOR LOP = 1 TO 2048

560 PRINT #1, "output 09;b?b?b?b?"

570 PRINT #1, "enter 09"

580 LINE INPUT #2, SS$

590 PRINT #3, SS$

600 NEXT LOP

610 CLOSE #3

620 TIMER OFF

630 RETURN

1000 ' Restore DAC488/4 waveform buffer

1010 '

1020 OPEN "buffer.sav" FOR INPUT AS #3

1030 PRINT #1, "output 09;p1c0l0x"

1040 PRINT "Restoring the DAC488/4 waveform buffer"

1045 WCNT = 0: TIMER ON

1050 FOR LOP = 1 TO 2048

1060 LINE INPUT #3, SS$

1070 RS$ = MID$(SS$, 1, 12) + "x" + MID$(SS$, 13, 12) + "x" + MID$(SS$, 25, 12) + "x" +

MID$(SS$, 37, 12) + "x"

1080 PRINT #1, "output 09;"; RS$

1090 NEXT LOP

1100 CLOSE #3

1110 TIMER OFF

1120 RETURN

2000 PRINT "Working - "; : WCNT = WCNT + 1

2010 IF WCNT > 6 THEN PRINT : WCNT = 0

2020 RETURN

DAC488 User’s Manual DAC488 Operation 27

Page 34

Control Modes

Four modes of DAC port operation are available: Direct, Indirect, Stepped, and Waveform. Each port is

independent and may be operated in a different mode. The modes of operation are described below.

Direct Control Mode

Each of the DAC ports may be directly controlled from the IEEE 488 bus. In the Direct Control mode, a

DAC voltage is output upon receipt of the Execute (

selecting the DAC port, the range or autorange, specifying the DAC output voltage, and issuing the Execute

command.

One use of the Direct mode is to output voltages at one or more DAC ports directly under program control

from an IEEE controller. To output 4 volts on port 1 the following command string could be used:

PRINT#1,"OUTPUT09;C0 P1 A0 R2 V4 X"

In this example, C0 selects Direct Control mode, P1 selects port 1, A0 disables Autor anging, R2 selects the

±5 Volt range and

output 4 volts at port 1.

Indirect Control Mode

Indirect control implies that the DAC output will change only when a trigger event occurs. Indirect control

is accomplished by selecting the DAC port, the range or autorange, specifying the DAC output voltage and

the desired trigger source. When the trigger event occurs, the programmed voltage will be output.

One use of the Indirect mode is to output voltages at one or more DAC ports upon the occurrence of a

trigger event. The command string shown below causes the DAC488 to output 7.5 volts at Port 2 upon

receipt of an external trigger signal.

PRINT#1,"OUTPUT09;C1 P1 Q1 A0 R2 V4 X"

X) command. Direct control is accomplished by

V4 is the voltage to be output (4 volts). This command string causes the DAC488 to

In this example, C1 selects the Indirect control mode, P1 selects port 1, Q1 enables port 1 to trigger on the

positive edge of an external trigger sense pulse,

V4 is the voltage to be output (4 volts).

Stepped Control Mode

The Stepped control mode may be used to control

the DAC in a stepped manner. In this mode, a

sequence of DAC voltages are loaded into the

DAC488 internal buffer. After the voltages are

loaded into the buffer, the DAC output can then

be stepped through each of the values b y using

any of the three trigger sources. When the last

voltage in the buffer is output, the DAC488 will

automatically return to the first location defined

by the Buffer Definition (

allowing the sequence to be repeated.

One application of Stepped mode may be to use

the DAC488 to output a series of test voltages

which may control another device. The example

shows how the DAC488 would be configured to

output the next vo ltage in a sequence of voltages

each time an external trigger is received.

In this example, the voltage at port 1 is stepped to the next value in the buffer each time an external trigger

is received. Each T on the graph represents a trigger event. The voltage sequence is 1 volt, 3 volts, 4 volts.

F) command thereby

A0

disables autoranging, R2 selects the ±5 Volt range and

28 DAC488 Operation DAC488 User’s Manual

Page 35

The commands required to load the internal buffer for this example are:

PRINT#1,"OUTPUT09;C2 P1 F0,3 L0 Q1 X"

PRINT#1,"OUTPUT09;B1,1X B2,3X B2,4X"

PRINT#1,"OUTPUT09;L0 X"

• Line 1:

C2 selects Stepped Control mode, P1 selects port 1, F0,3 defines a buffer with the fir s t

location as location 0 and the number of values in the sequence to 3,

to 0 (first location) and

• Line 2:

B1,1X selects the ±1 volt range, 1 volt for firs t point, B2,3X selects the ±5 volt range, 3 volts

for second point and

• Line 3:

L0

the location pointer will start at location 3, not location 0.

The output of the sequence is controlled by the rate at which external triggers occur. In the graph

previously shown, each T represents an external trigger event.

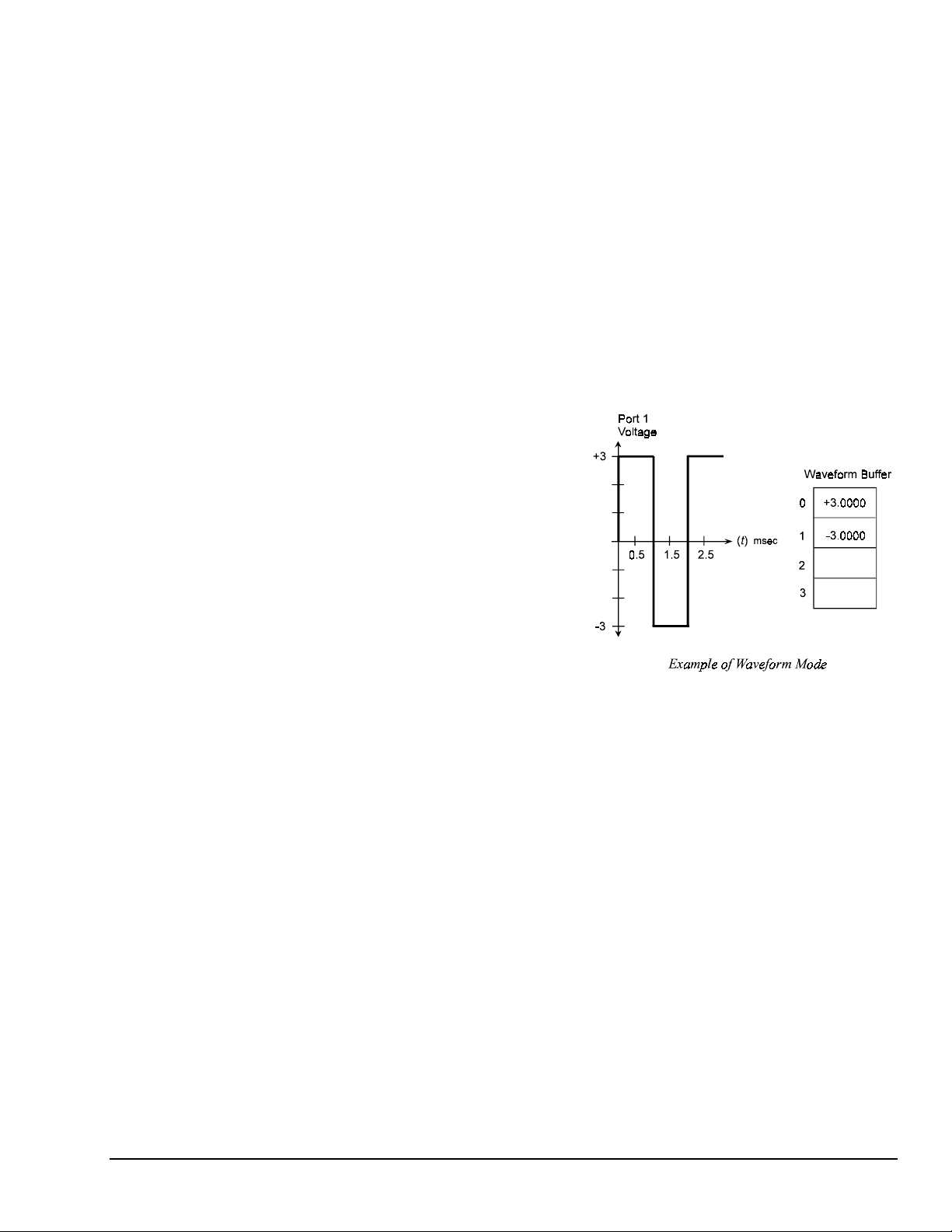

Waveform Control Mode

The Waveform control mode may be used to control the

DAC in an automatic manner. A buffer is defined using

the Buffer Definition (

are loaded into the buffer using the Buffer Location (

command and the Buffer Data (

DAC488 is triggered, these preloaded voltage values

are then output at a regular interval. The time interval

between the output of each value is set by using the

Interval (

waveform is set by using the Number of Cycles (

command.

I) command. The number of cycles of the

L0 sets the location pointer back

Q1 enables port 1 to trigger on an external trigger.

B2,4X selects the ±5 volt range, 4 volts for third point.

sets the location pointer back to location 0 before the port is triggered. If this is not done,

F) command and volt age values

L)

B) command. Once the

N)

One application of waveform mode may be to use the

DAC488 as a precise function generator. The

waveform example shows how the DAC488 would be

configured to output a 6 volt peak to peak 500 Hz

square wave centered at zero.

More complex waveforms may be generated by loading the b uffer with values computed using a high-level

language program. Sample programs are i ncluded with the DAC488 which will load the buffer with voltage

values to genera t e a Sine, Triangle, Ramp and other waveforms.

The commands required to load the internal buffer for this example are:

PRINT#1,"OUTPUT09;C3 P1 F0,2 G1 L0 I1 X"

PRINT#1,"OUTPUT09;B2,3X B2,-3X N0 X"

PRINT#1,"OUTPUT09;L0 X"

PRINT#1,"OUTPUT09;TRIGGER"

• Line 1:

location as location 0 and the number of points in the sequence to 2,

the location pointer to 0 (the first location) and

C3

selects Waveform control mode,

P1

selects port 1,

I1 sets the time interval between points to 1

F0,2

defines a buffer with the first

G1 selects trigger on GET, L0 sets

millisecond.

• Line 2:

volts for second point,

• Line 3:

B2,3X

selects the ±5 volt range, 3 volts for fir s t point and

N0 sets the number of cycles to continuous.

L0 sets the buffer location pointer back to location 0 before the port is triggered. If this is not

B2,-3X

selects the ±5 volt range, -3

done, the location pointer will start at location 2, not location 0.

• Line 4: When the IEEE Group Execute Trigger is executed, the DAC488 will output the waveform at

port 1 co ntinuously.

DAC488 User’s Manual DAC488 Operation 29

Page 36

Multiple Port Synchroni z a ti on

Multiple DAC port output changes may be synchronized in any of the triggered modes of operation

(Indirect, Stepped and Waveform). This is done by using the trigger mask commands to enable the ports to

trigger on the same trigger event(s).

Synchronization in Waveform mode is automatically accomplished by programming multiple ports with the

same time interval using the Interval (

command. The BASIC program

synchronized wavefor ms may be gene rated. Thi s program is included below.

Synchronized Waveforms Program

The following BASIC program DAC4WAVE.BAS is used with the DAC488 to generate a waveform at a user

selectable frequency and 20 volts peak-to-peak centered at 0 volts:

10 REM Basic program to load the DAC488/4 buffer w multiple waveforms

20 REM Initialize the IOtech IEEE488 Driver

30 CLS : KEY OFF

40 OPEN "\dev\ieeeout" FOR OUTPUT AS #1

50 IOCTL #1, "BREAK"

60 PRINT #1, "RESET"

70 OPEN "\dev\ieeein" FOR INPUT AS #2

80 PRINT "DAC488 Waveform Demonstration Program"

90 PRINT

100 PRINT"Set address of DAC488 to 09 and connect to controller"

110 PRINT

120 PRINT"Hit any key to start"

130 IF INKEY$="" THEN GOTO 130

140 PRINT:PRINT #1, "CLEAR 09"

150 PRINT #1, "output 09;P3XE?" 'Determine if DAC488/4 or DAC488/2

160 PRINT #1, "ENTER 09"

170 INPUT#2,A$

180 IF A$ = "E0" THEN DAC2$ = "N" ELSE DAC2$ = "Y"

190 IF DAC2$ = "Y" THEN MODEL$ = "2" ELSE MODEL$ = "4"

200 PRINT "Initializing the DAC488/";MODEL$;" this will take a while"

210 REM First a 256 point sinewave

220 PRINT #1, "output 09;c3l0x"

230 POINTS = 256: REM number of points in the sine wave

240 PI = 3.1415926535#

250 INC = (2! * PI) / POINTS

260 FOR LOOP = 1 TO POINTS

270 PVAL = 4095*SIN(LOOP * INC)

280 PRINT #1, "output 09;b3,#";CINT(PVAL);"x":NEXT

290 REM Now a triangle wave

300 INC = 4096 / 64

310 FOR LOOP = 0 TO 4095 STEP INC

320 PRINT #1,"output 09;b3,#";LOOP;"x":NEXT

330 FOR LOOP = 4095 TO -4095 STEP -INC

340 PRINT #1,"output 09;b3,#";LOOP;"x":NEXT

350 FOR LOOP = -4095 TO 0 STEP INC

360 PRINT #1,"output 09;b3,#";LOOP;"x":NEXT

370 REM Now a square wave

380 PRINT #1,"output 09;b3,#4095xb3,#-4095x"

390 REM Main Loop

400 CLS

I

) command and the same buffer size using the Buffer Definition (F)

DAC4WAVE.BAS included on the program disk shows how multiple,

30 DAC488 Operation DAC488 User’s Manual

Page 37

410 IF MODEL$ = "2" THEN GOTO 420 ELSE GOTO 440

420 INPUT" Select a port 1,2 ";PORT

430 GOTO 450

440 INPUT" Select a port 1-4 ";PORT

450 IF PORT < 1 OR PORT > 4 GOTO 410

460 IF PORT > 2 AND DAC2$ ="Y" THEN GOTO 410

470 PRINT

480 INPUT"Select an interval in milliseconds (1-255) ";INTRVL

490 IF (INTRVL <= 0) OR (INTRVL > 255) GOTO 480

500 PRINT" Select a waveform (1-6) ";WAVE

510 PRINT" 1 - Sinewave "

520 PRINT" 2 - Rectified Sine Wave"

530 PRINT" 3 - Triangle "

540 PRINT" 4 - Ramp "

550 PRINT" 5 - Inverted Ramp "

560 PRINT" 6 - Square Wave "

570 INPUT WAVE

580 IF WAVE < 1 OR WAVE > 6 GOTO 500

590 IF WAVE = 1 GOTO 660

600 IF WAVE = 2 GOTO 700

610 IF WAVE = 3 GOTO 740

620 IF WAVE = 4 GOTO 780

630 IF WAVE = 5 GOTO 820

640 IF WAVE = 6 GOTO 860

650 PRINT: PRINT: GOTO 410

660 REM sinewave output routine

670 PRINT #1,"output 09;p";PORT"c3f0,256l0i";INTRVL;"n0t0x"

680 PRINT #1,"output 09;t"; (2^(PORT-1));"x@"

690 GOTO 650

700 REM rectified sinewave output routine

710 PRINT #1,"output 09;p";PORT"c3f0,128l0i";INTRVL;"n0t0x"

720 PRINT #1,"output 09;t"; (2^(PORT-1));"x@"

730 GOTO 650

740 REM triangle wave output routine

750 PRINT #1,"output 09;p";PORT"c3f256,256l256i";INTRVL;"n0t0x"

760 PRINT #1,"output 09;t"; (2^(PORT-1));"x@"

770 GOTO 650

780 REM ramp wave output routine

790 PRINT #1,"output 09;p";PORT"c3f256,64l256i";INTRVL;"n0t0x"

800 PRINT #1,"output 09;t"; (2^(PORT-1));"x@"

810 GOTO 650

820 REM inverted ramp wave output routine

830 PRINT #1,"output 09;p";PORT"c3f384,64l384i";INTRVL;"n0t0x"

840 PRINT #1,"output 09;t"; (2^(PORT-1));"x@"

850 GOTO 650

860 REM square wave output routine

870 PRINT #1,"output 09;p";PORT"c3f512,2l512i";INTRVL;"n0t0x"

880 PRINT #1,"output 09;t"; (2^(PORT-1));"x@"

890 GOTO 650

DAC488 User’s Manual DAC488 Operation 31

Page 38

Digital I/O Port

The digital I/O port on the DAC488 may be used to read eight TTL level inputs and control eight TTL level

outputs. The digital outp ut port may also be configured for high voltage/high current operation. Once the

output port is configured for high level operation, the output can control relays and other high leve l devices.

One use of the high level outputs may be to energize a relay under program control. The following

Standard and CE diagrams each show how a digital output line can control a relay which in turn, connects