Page 1

CIO-EXP-RTD16

RTD EXPANSION BOARD

User’s Manual

Revision 2

© Copyright, November, 2000

Page 2

LIFETIME WARRANTY

Every hardware product manufactured by Measurement Computing Corp. is warranted against defects in materials or

workmanship for the life of the product, to the original purchaser. Any products found to be defective will be repaired or

replaced promptly

LIFETIME HARSH ENVIRONMENT WARRANTY

Any Measurement Computing Corp. product which is damaged due to misuse may be replaced for only 50% of the current pr ice.

I/O boards face some harsh environments, some harsher than the boards are designed to withstand. When that happ ens, just

return the board with an o rder for its replacement at o nly 50% of the list p rice. Measurement Comput ing Corp. does not n eed to

profit from your misfortune. By the way, we will honor this warranty for any other manufacture’s board that we have a

replacement for!

.

TM

30 DAY MONEY-BACK GUARANTEE

Any Measurement Computing Corp. product may be returned within 30 days of purchase for a full refund of the price paid for

the product being returned. If you are not satisfied, or chose the wrong product by mistake, you do not have to keep it. Please call

for a RMA number first. No credits or returns accepted without a copy of the original invoice. Some software products are

subject to a repackaging fee.

These warranties are in lieu of all other warranties, expressed or implied, including any implied warranty of merchantability or fitness for a

particular application. The remedies provided herein are the buyer’s sole and exclusive remedies. Neither Measurement Computing Corp., nor

its employees shall be liable for any direct or indirect, special, incidental or consequential damage arising from the use of its products, even if

Measurerment Computing Corp. has been notified in advance of the possibility of such damages.

MEGA-FIFO, the CIO prefix to data acquisition board model numbers, the PCM prefix to data acquisition board model numbers,

PCM-DAS08, PCM-D24C3, PCM-DAC02, PCM-COM422, PCM-COM485, PCM-DMM, PCM-DAS16D/12,

PCM-DAS16S/12, PCM-DAS16D/16, PCM-DAS16S/16, PCI-DAS6402/16, Universal Library,

Warranty

and Measurement Computing are registered trademarks of Measurement Computing Corp.

Insta

Cal,

Harsh Environment

IBM, PC, and PC/AT are trademarks of International Business Machines Corp. Windows is a trademark of Microsoft Corp. All

other trademarks are the property of their respective owners.

Information furnished by Measurement Computing Corp. is believed to be accurate and reliable. However, no responsibility is

assumed by Measurement Computing Corp. neither for its use; nor for any infringements of patents or other rights of third

parties, which may result from its use. No license is granted by implication or otherwise under any patent or copyrights of

Measurement Computing Corp.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form by any

means, electronic, mechanical, by photocopying, recording or otherwise without the prior written permission of Measurement

Computing Corp.

Notice

Measurement Computing Corp. does not authorize any Measurement Computing Corp. product for

use in life support systems and/or devices without the written approval of the President of

Measurement Computing Corp. Life support devices/systems are devices or systems which, a) are

intended for surgical implantation into the body, or b) support or sustain life and whose failure to

perform can be reasonably expected to result in injury. Measurement Computing Corp. products

are not designed with the components required, and are not subject to the testing required to

ensure a level of reliability suitable for the treatment and diagnosis of people.

HM CIO-EXP-RTD16.lwp

Page 3

Table of Contents

1 INTRODUCTION

2 SOFTWARE INSTALLATION

3 GENERAL CONFIGURATION

3.1 A/D BOARD-TYPE SELECT JUMPER

3.2 SETTING THE OUTPUT CHANNEL

3.3 CONFIGURING THE A/D BOARD

3.3.1 DAS08 Family Setup

3.3.2 DAS16 Family Setup

3.3.3 All A/D Boards

..............................................................

..................................................

..................................................

.........................................

...........................................

............................................

.....................................................

.....................................................

..........................................................

3.4 CONNECTING THE CIO-EXP-RTD16 TO THE A/D BOARD

3.4.1 Connecting to a DAS08 Series A/D Board

3.4.2 Connecting to a DAS16 Series A/D Board

3.4.3 Other A/D Boards

3.5 POWERING THE CIO-EXP-RTD16

3.5.1 Power Source Switch

........................................................

............................................

.....................................................

3.5.2 Powering with the 37 pin connector:

3.5.3 Powering with the C-PCPOWER-10 cable:

3.6 DAISY-CHAINING CIO-EXP-RTD16 BOARDS

3.7 CONNECTING A VOLTAGE SIGNAL

3.8 VERIFYING THE INSTALLATION

.........................................

............................................

4 VOLTAGE MEASUREMENT CONFIGURATION

4.1 CHANNEL SELECTION

4.2 POWER SOURCE SWITCH

......................................................

...................................................

4.3 DETERMINING THE APPROPRIATE GAIN

4.4 SETTING THE GAIN

4.4.1 First Stage Gain Switch

4.4.2 Second Stage Gain Switch

4.5 ATTENUATION

.........................................................

...................................................

................................................

.............................................................

4.6 CHANNEL CONFIGURATION SWITCH

4.7 CONNECTING VOLTAGE SIGNALS

4.7.1 Single Ended

4.7.2 Floating Differential

4.7.3 Fully Differential

............................................................

.....................................................

.......................................................

..........................................

5 RTD MEASUREMENT CONFIGURATION

5.1 CHANNEL SELECTION

5.2 POWER SOURCE SWITCH

.....................................................

..................................................

5.3 DETERMINING THE APPROPRIATE GAIN

5.4 SETTING THE GAIN

5.4.1 First Stage Gain

5.4.2 Second Stage Gain

........................................................

........................................................

......................................................

5.5 CHANNEL CONFIGURATION SWITCH

...................................

...................................

........................................

..................................

.................................

................................

....................................

.......................................

.....................................

...................................

......................................

5.6 CONNECTING THE RTD TO THE SCREW TERMINALS

.....................

......................

1

1

2

2

2

3

3

3

3

4

4

4

4

5

5

5

5

6

6

6

7

7

7

7

8

8

8

9

9

9

9

10

11

12

12

12

12

13

14

14

15

15

iii

Page 4

5.6.1 Two-wire RTD Hookup

5.6.2 Three-Wire RTD Hookup

5.6.3 Four-Wire RTD Hookup

5.7 CALIBRATION AND TEST

..................................................

................................................

.................................................

..................................................

6 CUSTOM GAIN AND EXCITATION CALCULATIONS

6.1 CUSTOM EXCITATION CURRENT - R89

.....................................

6.2 CUSTOM SECOND STAGE GAIN RESISTOR - RX100

7 SPECIFICATIONS

............................................................

.........................

.........................

16

16

17

17

17

17

18

19

iv

Page 5

1 INTRODUCTION

The CIO-EXP-RTD16 is a signal conditioning accessory designed for use with the DAS08 and DAS16

family of data acquisition boards. Circuitry to excite selected RTDs on a per channel basis converts the

RTD's output current to a voltage suitable for conversion by a DAS08 or other analog to digital

conversion board.

This manual is loosely organized into sections that explain the CIO-EXP-RTD16:

Installation: Installation and initial setup.

Voltage Reading: Explains how to set up for and make voltage only readings.

RTD: Describes how two, three, and four-wire type RTDs are connected.

Please carefully read the Installation section and follow the initial installation and test steps. Verify the

installation with a voltage measurement prior to connecting RTDs and attempting to measure

temperature.

2 SOFTWARE INSTALLATION

There is no software shipped with the CIO-EXP-RTD16. The CIO-EXP-RTD16 is an accessory board

intended to be used with an A/D board such as a CIO-DAS08 or -DAS16. A program called InstaCal is

shipped with every DAS board. InstaCal has installation information in it about the CIO-EXP-RTD16.

Refer to the Software Installation Manual for complete information.

To update the InstaCal configuration file to include CIO-EXP-RTD16 information, start InstaCal, select

the board number of the DAS board that has the CIO-EXP-RTD16 connected to it, and select the channel

number the CIO-EXP-RTD16 is connected to. The options for the CIO-EXP-RTD16 will be available to

set and change. After this is done, you can use the InstaCal calibrate and test options.

You must use InstaCal to update and configure the configuration file CB.CFG to include the

CIO-EXP-RTD16 settings before you can use the CIO-EXP-RTD16 with InstaCal, Universal Library and

some applications packages. Initially, accept the default settings so that you can verify the installation.

You may have to go back and make changes with InstaCal once you have selected a sensor and read the

section on installing that sensor.

1

Page 6

3 GENERAL CONFIGURATION

3.1 A/D BOARD-TYPE SELECT JUMPER

The CIO-EXP-RTD16 may be used with either DAS08 or DAS16 family boards because the signal

assignments of the 37 pin connector match those of the DAS08, and may be adapted to those of the

DAS16 with a C-EXP2DAS16-10 cable. Jumper JB10 on the CIO-EXP-RTD16 board located near the

37-pin connectors is used to select the either the DAS08 or DAS16 A/D board family.

Select the A/D board type (DAS08 or DAS16) using the JB 10 jumper

(Figure 3-1).

The jumper is shown here with the CIO-EXP-RTD16 configured for

DAS08

DAS16

use with a CIO-DAS08 family board.

Figure 3-1. DAS08/16 Select Jumper

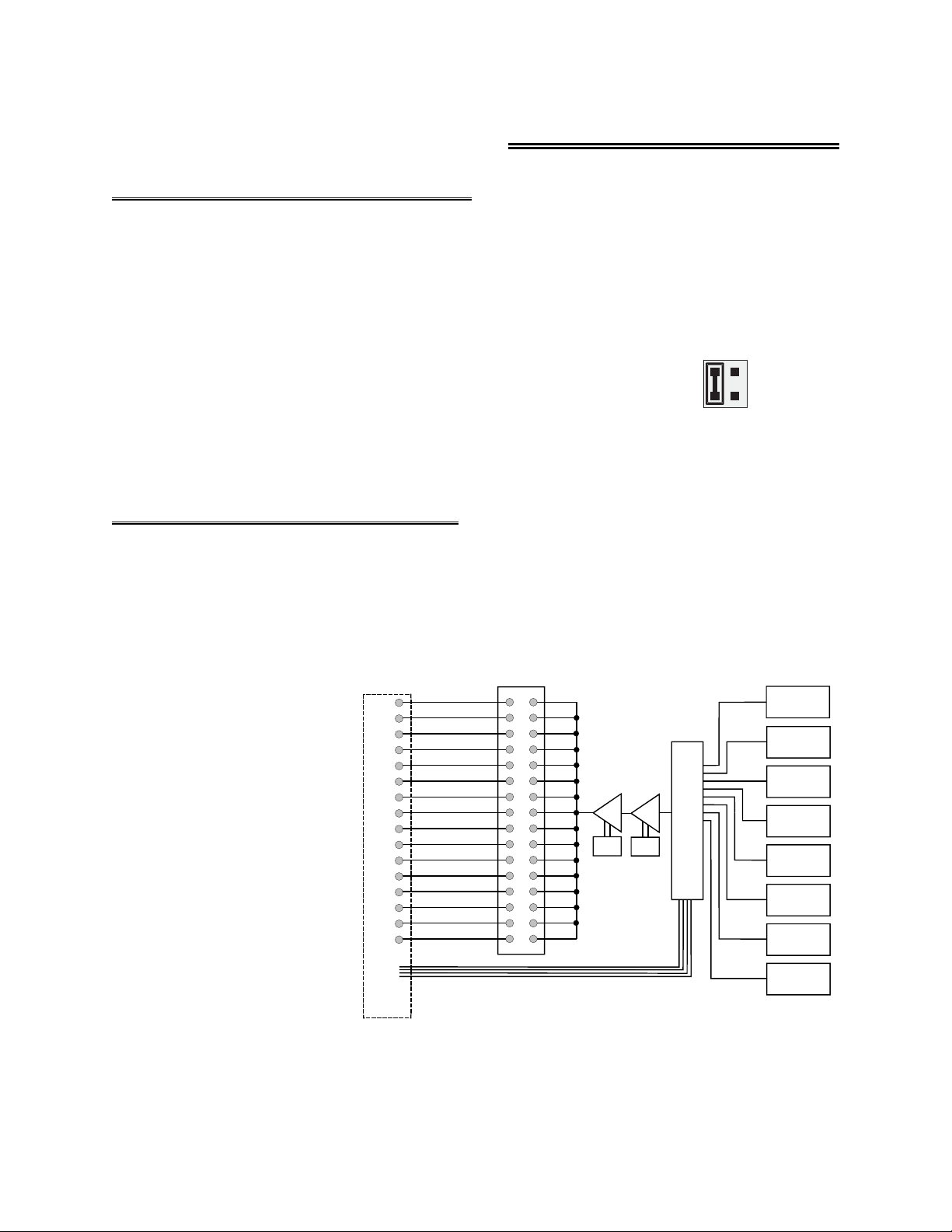

3.2 SETTING THE OUTPUT CHANNEL

Jumper positions labeled “CH SEL” located near the 37-pin connectors are used to select one

CIO-EXP-RTD16 output channel to which the output from the addressed RTD will be connected. This

setting determines which A/D channel is used to acquire data from the CIO-EXP-RTD16 when it is

connected to an A/D board.

There are 16 jumpers for the

output. Each jumper corresponds

to one of the 16 output pins on

the 37-pin connector.

When the CIO-EXP-RTD16 is

connected to a DAS08 series

board, any one of the first 8

channels (labeled 0-7) may be

used.

When the CIO-EXP-RTD16 is

connected to a DAS16 series

board, any one of 16 jumper

positions may be used.

In each case, the jumper

corresponds to an input channel

number on the A/D board. See

Figure 3-2 and 3-3.

37 D

CONNECTOR

37

36

35

34

33

32

31

30

18

17

16

15

14

13

12

11

7-10

OUTPUT CHANNEL SELECT

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

AMP

AMP

GAIN

GAIN

1 OR 7

1,2, 4, 8

MUX CONTROL

INPUT 0

INPUT 1

INPUT 2

INPUT N

INPUT N + 1

8 CHANNEL MULTIPLEXOR

16-CHANNEL MULTIPLEXER

INPUT 13

INPUT 14

INPUT 15

Figure 3-2. Channel-Selection Block Diagram

2

Page 7

NOTE: If the jumper setting does not agree with the selection made in InstaCal setup, InstaCal and the

Universal Library will not be able to make readings from the CIO-EXP-RTD16.

One individual channel must be selected for each bank of 16 EXP channels. For example, if you are

using several CIO-EXP-RTD16 boards, the jumper setting for each board must be unique. If you select

channel 0 for the first board, do not use this channel for any of the other boards.

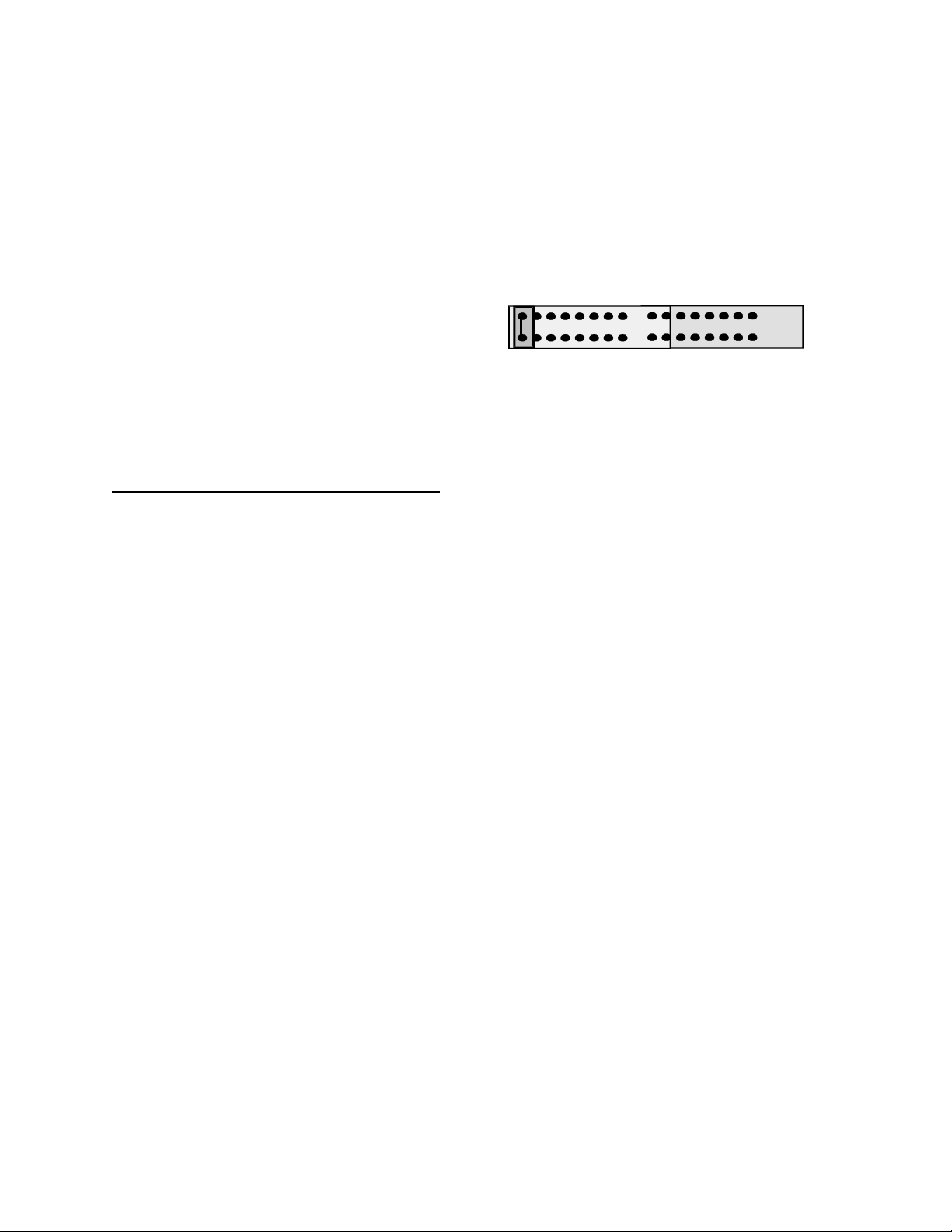

Figure 3-3 is a diagram of the jumper

positions.

1234567

0

8 9 10 11 12 1415

13

Place the jumper on the pin which

corresponds to the A/D board's input

channel.

CH SEL

CHANNEL 0 SELECTED

FOR BOARD OUTPUT

Figure 3-3. Channel Selection Jumper Locations

3.3 CONFIGURING THE A/D BOARD

3.3.1 DAS08 Family Setup

The input mode of the A/D board must be single-ended to be compatible with the CIO-EXP outputs.

Some of the boards in the DAS08 series have differential inputs that can be converted to single-ended

inputs. See the information shipped with your A/D board for conversion to single-ended inputs.

3.3.2 DAS16 Family Setup

The input mode of the A/D board must be single-ended to be compatible with the CIO-EXP outputs.

Most of the DAS16 series is switch selectable for either 8 differential or 16 single ended inputs. When

used with the CIO-EXP, set the switch to 16 channel, single-ended mode.

3.3.3 All A/D Boards

If the range of your A/D board is switch selectable and you are using RTDs, set the range of the A/D

board to 5V Unipolar, if available, or 10V Unipolar if not. Some software packages base the calculation

of temperature on these ranges only. (The optional Universal Library does allow other ranges, but 5V

Unipolar is preferred.)

If your A/D board has a UNI / BIP switch (for setting the range to either unipolar or bipolar), the

preferred setting is UNI (unipolar).

If the range on your A/D board is fully programmable, the software you use for temperature measurement

will determine the correct range to use

If you are not using RTDs, set the range of the A/D board to accommodate the maximum output expected

from the CIO-EXP-RTD16 board.

3

Page 8

3.4 CONNECTING THE CIO-EXP-RTD16 TO THE A/D BOARD

L

3.4.1 Connecting to a DAS08 Series A/D Board

A CIO-DAS08 series board may be connected directly through a C37FF series cable from the P1

connector on the CIO-EXP-RTD16 to the A/D analog connector. The JB10 jumper should be left in the

DAS08 position as set at the factory.

3.4.2 Connecting to a DAS16 Series A/D Board

The CIO-EXP can be used with DAS16 series boards, expanding the DAS16's 16 inputs to 256 inputs.

The connection requires a special 37-conductor cable (CEXP2DAS16-10) since pin relationship of

CIO-EXP and DAS16 signals is not 1:1.

Install the CEXP2DAS16-10 cable connector labeled “MUX” into the P1 connector of the

CIO-EXP-RTD16 board and the other end into the DAS16 series board’s analog connector.

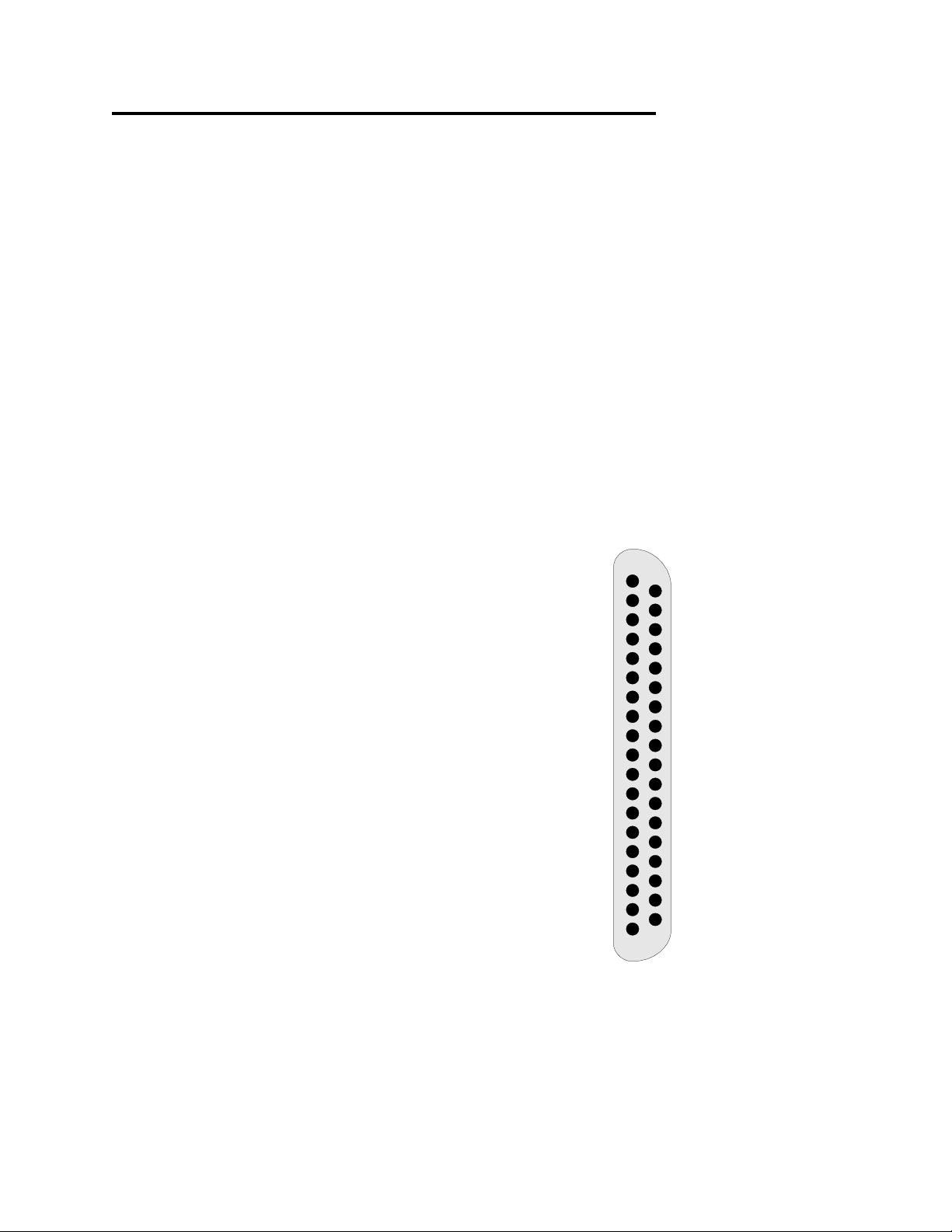

3.4.3 Other A/D Boards

If you need to connect to a board other than

those described above, call technical support.

We may have the cable you need.

Alternatively, you could use this connector

diagram to construct a cable.

The signal from the CIO-EXP-RTD16 is a

multiplexed voltage from each RTD input to a

single jumper-selected channel and an analog

ground (LLGND). There should be no voltage

between analog ground and power ground.

The MUX address lines control the setting of

the channel multiplexer. When all are low, the

mux is set to channel 0. The lines are binary

coded with MUXADDR1 being the LSB and

MUXADDR4 being the MSB.

The output digital address lines from an A/D

card are typically named Dig. Out 0 to Dig.

Out 3 respectively.

NC / LLGND

LGND / OUTPUT 8

OUTPUT 9

OUTPUT 10

OUTPUT 11

OUTPUT 12

OUTPUT 13

OUTPUT 14

OUTPUT 15

MUX ADDR 4

MUX ADDR 3

MUX ADDR 2

MUX ADDR 1

NC

NC

NC

NC

NC

NC

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

OUTPUT 0

OUTPUT 1

OUTPUT 2

OUTPUT 3

OUTPUT 4

OUTPUT 5

OUTPUT 6

OUTPUT 7

+5 VOLTS FROM PC

POWER GROUND

NC

NC

NC

NC

NC

NC

NC

NC

Figure 3-4. 37-Pin Connector Pin-out

4

Page 9

3.5 POWERING THE CIO-EXP-RTD16

The CIO-EXP-RTD16 can be powered through the 37-pin cable or the Molex connector. The power that

can be carried through the 37-pin connector is limited so we recommend this only when a single

CIO-EXP-RTD16 is used.

The power required to run a CIO-EXP-RTD16 channel is dependent on the sensor connected to it.

Voltage measurements do not draw additional power from the CIO-EXP-RTD16, but RTDs do for the

excitation current.

3.5.1 Power Source Switch

One of the switches on the four-position DIP

switch labeled “2” controls the source of the +5V

power to the CIO-EXP-RTD16.

When positioned down, (+5 COMP), the +5V

power is drawn from the personal computer

through the signal cable. In the +5REM position

(up) power is drawn through the MOLEX

connector.

The right-hand switch selects the source of the

excitation current. The choices are 1 mA source

or a custom current selected by installing a

resistor at R89.

X1

4 3 2 1

GND

X7

CUSTOM IEXC

+5 REM

N

O

+5 COMP

IEXC=1MA

Figure 3-5. Power Source Switch

3.5.2 Powering with the 37 pin connector:

You may power the CIO-EXP-RTD16 via the 37-pin cable. Only one CIO-EXP-RTD16 can be powered

via the 37-pin cable. If you are powering multiple boards, use the C-PCPOWER-10 cable.

3.5.3 Powering with the C-PCPOWER-10 cable:

The CIO-EXP-RTD16 may be powered from the PC's power supply by connecting it to that power supply

through a C-PCPOWER-10 cable. This cable has the same Molex connector that is used inside the PC

and so may be connected directly to the PC's power supply through one of the spare connectors. The

cable is keyed, so it should not be forced. When inserted properly it will slide easily and snap in place.

5

Page 10

3.6 DAISY-CHAINING CIO-EXP-RTD16 BOARDS

Connect one CIO-EXP-RTD16 to another using a C37FF-# ribbon cable. Connect from P2 on the

‘upstream’ board to P1 on the ‘downstream’ board. Make sure each of the boards in the chain have a

unique channel selected (CH SEL jumper is set to a different number on each board).

3.7 CONNECTING A VOLTAGE SIGNAL

Make your initial test of the CIO-EXP-RTD16 with a simple voltage signal of between 0 and 5V. If you

have a variable signal source, all the better.

Each input circuit has four screw terminals

associated with it. These terminals are shown in

Add Jumper

CH0

Figure 3-6 to the right.

To connect a voltage signal to the input circuit you

need only use three screw terminals, these are:

−

−

SENSE

IEXC

+IEXC

+SENSE

+SENSE Connect the + voltage to this

-SENSE Place a wire between this and -IEXC

-IEXC Connect the Ground to this

Signal-Low

(Gnd.)

Single-Ended Voltage Input

Voltage

Source

Signal-High

Figure 3-6. Connection Terminal Block for

Voltage Test (Channel 0 Shown)

There is not room on the board for the full name next to each terminal so the eight screw terminals

associated with each input circuit are labeled on the CIO-EXP-RTD16 as follows:

+IEXC High side of RTD excitation current

+SENSE High side of input signal from voltage or RTD current

-IEXC Low side of excitation current or chassis ground for volts

-SENSE Low side of input signal from voltage or RTD

The use of the terminals is dependent on the type of sensor you have connected to the input circuit, and

the nomenclature on the terminals has been chosen to make the most sense for RTD sensors.

3.8 VERIFYING THE INSTALLATION

To verify the installation, test or calibrate the CIO-EXP-RTD16, use the InstaCal program installed on

your computer. This software came with your A/D board if you bought the board from the same

manufacturer as the CIO-EXP-RTD16. If your A/D board is not from the same manufacturer but is

compatible, please call technical support and request a copy of InstaCal.

Use InstaCal's TEST option to verify that a signal present at one of the CIO-EXP-RTD's inputs can be

read. You will not need to set any jumpers other than those previously mentioned, and should not set any

switches or install any passive components until you have verified the installation.

6

Page 11

4 VOLTAGE MEASUREMENT CONFIGURATION

The CIO-EXP-RTD16 is an amplification, signal conditioning and multiplexing accessory for DAS

boards. The inputs are suitable for connecting a voltage to the DAS board so it may be measured. The

CIO-EXP-RTD16 is a “one of sixteen” multiplexer which means that for every channel in your DAS

board, you can multiplex sixteen different signals into it. You can expand the number of inputs of your

DAS board by sixteen for every CIO-EXP-RTD16 board, up to the number of inputs on the DAS board.

For example, a DAS08 has eight inputs. Eight times sixteen is one hundred and twenty eight. Using

CIO-EXP-RTD16 boards you can bring 128 inputs into the PC with one DAS08 in one slot.

It is unlikely that you purchased a CIO-EXP-RTD16 to measure voltages. The CIO-EXP-RTD16 has

quite a bit of special circuitry designed for RTD sensors. For only voltage measurements, a CIO-EXP16

or CIO-EXP32 would be less expensive and do the same job.

However, you may have one or two voltages to measure in addition to RTD sensors and would like to

connect those signals to the CIO-EXP-RTD16. This chapter explains how to make those connections.

4.1 CHANNEL SELECTION

The General Configuration section describes the channel selection, setting the jumper and verifying the

installation and operation of the CIO-EXP-RTD16 with your data acquisition board. Configure your

boards as described in that section before continuing with this section.

4.2 POWER SOURCE SWITCH

The General Configuration section describes the power selection options, setting the power select switch

and verifying the installation and operation of the CIO-EXP-RTD16 with your data acquisition board.

Configure your boards as described in that section before continuing with this section.

4.3 DETERMINING THE APPROPRIATE GAIN

To accurately measure a voltage, the full scale of the signal should be matched to the full range of the

input circuit. Most DAS boards have an input range of ±5V, which is the native range of the analog to

digital converter at the heart of the board. Some DAS boards include amplification on the input circuit to

allow the signal to be amplified to make better use of the resolution of the A/D.

For example, a sine wave which varies between 0 and 1 volt would only be using 1/10th of the ±5V A/D

converter's resolution. By switching the input signal of the DAS board to unipolar (no negative voltage)

and amplifying the sign wave signal by 5, the entire range of the A/D converter is used and a higher

resolution measurement may be made.

In order to match your signals with the input range of the A/D board, you should do a similar calculation

and set switches on the CIO-EXP-RTD16 for the correct gain.

Gain, or amplification, allows you to boost your signal to take full advantage of the resolution of the A/D

converter. While amplifying the signal, any noise is amplified as well. If your signal ranges greater than

±5V, please go to section on attenuation.

The first stage has gain options of 1, 2, 4 or 8 and the second stage gain options are 1, 7 or CUSTOM.

7

Page 12

To choose a switch-selectable amplification, calculate as follows:

If your signal is bipolar, divide 10 by the full range of the signal. For example, if your signal ranges

between ±1/2 volt, the full range is 1 volt. Divide 10 by 1 for a result of 10. That is the maximum gain

you can use.

If your signal is unipolar and ranges less than 0 to 5V, divide 5 by the full range of the signal. For

example, if the signal ranges from 0 to 1/2 volt, the full range is 1/2 volt. Divide 5 by 0.5 for a result of

10. That is the maximum gain you can use.

4.4 SETTING THE GAIN

4.4.1 First Stage Gain Switch

A set of three Gain Select switches on the

S1 switch block selects the first stage gain

(Figure 4-1). The fourth switch on this

block (marked CUSTOM) is used to select

a custom second stage gain.

When all three switches are up, the first

stage gain is 1. Moving a switch down

selects that gain. The other two switches

should be up. (Gains choices for the first

stage are NOT additive.)

Thus, gains of 1, 2, 4 or 8 can be selected

by these switches. A gain of X2 is shown in

Figure 4-1.

4.4.2 Second Stage Gain Switch

Switch #3 on the S2 DIP switch block (Figure

4-2) is labeled X1 and X7. Setting this switch

down (ON) will amplify the output of the first

stage amplifier by 7. The factory default position

(up) has a gain of 1 (unity).

GAIN

SELECT

O

N

CUSTOM

X2

X4

X8

Figure 4-1. First Stage Gain Select Switches (S1)

CUSTOM IEXC

+5 REM

X1

When set to X7, the first stage gain is multiplied

by 7 yielding overall gains of 7, 14, 28 or 56.

A custom second stage gain of greater than 7 and

less than 64 may be added by installing a

precision resistor at RX100 and setting the switch

marked CUSTOM on.

Figure 4-2. Second Stage Gain Switch (#3 of S2)

N

O

4 3 2 1

GND

+5 COMP

X7

IEXC=1MA

8

Page 13

When using the custom second stage gain, set the switch marked CUSTOM on the S1 bank to the ON

position (down) and set the X7 switch on the S2 bank to the ON position (X7). Install a precision

resistor of the appropriate value in the RX100 location. Calculate the value using the formula found in

the Custom Gain and Excitation Calculations chapter.

4.5 ATTENUATION

If your signal range is greater than ±5V, you

will have to divide it until the result is less than

or equal to ±5V for bipolar, or 0-5V for

unipolar signals.

A voltage divider is constructed from a pair of

precision resistors selected according to the

equation:

Attenuation = (R1 + R2) / R2

PC GROUND

You will need to construct the voltage divider

remote from the CIO-EXP-RTD16.

4.6 CHANNEL CONFIGURATION SWITCH

A channel configuration switch is associated with

each channel. The switch is used to configure the

input circuit for 2, 3 or 4-wire hookup to RTDs.

NOTE: When doing voltage measurements, set

the switches to the 4-wire position (switches

labeled “4” in white on the board in the ON

position - switches labeled “3” OFF).

RES IN

INPUT

Ra

Volts In

Rb

RES OUT

RES

IN

RES

OUT

OUT

Volts Divided

PC GROUND

Figure 4-3. Voltage Divider Schematic

3

3

4

1

Set for 2 or 4-Wire Connection

3

4

INPUT CONFIG

O

N

4

Set for 3-Wire Connection

3

4

O

0

N

Figure 4-4. Channel Configuration Switches

4.7 CONNECTING VOLTAGE SIGNALS

Voltage signals may be single ended or differential, and the full scale may have to be matched to the

range of the CIO-EXP-RTD16 and DAS board combination via amplification or division. To connect a

voltage and make an accurate measurement, each of these factors must be considered.

4.7.1 Single Ended

A single-ended input has two wires; a signal high and a Ground (−IEXC). The Low Level Ground signal

must be the same ground the PC is on. Single-ended mode is selected by installing a jumper between the

signal input low and ground (−SENSE to −IEXC) (Figure 4-5).

9

Page 14

Each input circuit has four screw terminals associated with it.

These terminals are shown in Figure 4-5 to the right.

Add Jumper

CH0

To connect a voltage signal to the input circuit you only use

three screw terminals; these are:

+SENSE Signal high, or CH HI on a DAS board

-SENSE Signal low, or CH LO on a DAS board

-IEXC Low Level Ground (LLGND)

Figure 4-5. Single-Ended Voltage Input

4.7.2 Floating Differential

A floating differential input has two wires from the

signal source and a 10K ground reference resistor

installed at the CIO-EXP-RTD16 input. The two

signals from the signal source are Signal High and

Signal Low. The reference resistor is connected

between the CIO-EXP-RTD16 -SENSE and -IEXC

pins (Figure 4-6).

A floating differential hookup is handy when the signal

source is floating with respect to ground, such as a

battery-powered device. The floating differential input

will reject up to 10V of EMI energy on the signal

wires.

−

−

SENSE

IEXC

+IEXC

+SENSE

−

SENSE

Voltage

Source

−

IEXC

Voltage

Source

+SENSE

Signal-High

+IEXC

Add 10K

Resistor

Signal-Low

(Gnd.)

Single-Ended Voltage Input

Signal-Low

Floating-Differential Voltage Input

Signal-High

Figure 4-6. Floating-Differential Voltage Input

CAUTION

:

Verify that the signal source is really floating. Check it with a voltmeter before risking the

CIO-EXP-RTD16 and PC!

10

Page 15

4.7.3 Fully Differential

X

A differential signal has three wires from

the signal source. The signals are Signal

High, Signal Low and Signal Ground

(-IEXC) (which is LLGND).

A differential connection allows you to

connect the CIO-EXP-RTD16 to a signal

source with a ground that is different from

the PC ground, but less than 10V

difference, and still make a true

measurement of the signal.

−

SENSE

−

IEXC

+SENSE

+IEXC

Ground cable s hield at –IE

terminal o nly.

EXAMPLE: A laboratory instrument with

its own wall plug.

NOTE: There are sometimes voltage

differences in wall GND between outlets.

Measure it to verify that it doesn’t exceed

10V.

Signal-Low

Voltage

Source

Signal-High

Differential Volta ge I nput

Figure 4-7. Differential Voltage Input

11

Page 16

5 RTD MEASUREMENT CONFIGURATION

An RTD is a temperature sensor that consist of a resistive element, usually a length of wire encased in a

sheath. Various wire materials are used with platinum being the most common. There are three types of

hookups: two-wire, three-wire, and four-wire. An excellent source of information on RTDs and how to

select one for your application may be found in the OMEGA Engineering catalog.

5.1 CHANNEL SELECTION

The General Configuration section describes the channel selection, setting the jumper and verifying the

installation and operation of the CIO-EXP-RTD16 with your data acquisition board. Configure your

boards as described in that section before continuing with this section.

5.2 POWER SOURCE SWITCH

The General Configuration section describes the power selection options, setting the power select switch

and verifying the installation and operation of the CIO-EXP-RTD16 with your data acquisition board.

Configure your boards as described in that section before continuing with this section.

5.3 DETERMINING THE APPROPRIATE GAIN

To select the best gain for RTD type, base resistance and temperature range, consider that RTD

resistance changes with temperature, but the magnitude of the change also changes with temperature.

RTD type determines the ‘slope’ of the ohms vs. temperature curve. The most popular type has an

‘alpha’ of .00385, known as the European standard. Its value is .00385 ohms per ohm per °C.

The Universal Library and InstaCal support six different RTD types. Please call if you do not see the

RTD you are interested in listed here.

Material

Platinum 0.00392 American standard

Platinum 0.00391

Platinum 0.00385 European standard (Most popular, OMEGA’s standard also)

Copper 0.00427

Nickel/Iron 0.00581

Nickel/Iron 0.00527

To determine which gain to use, you must know the maximum temperature the RTD will be used to

measure, and thus the maximum change in resistance that the RTD will undergo. Here is a table for

platinum:

‘alpha’

12

Page 17

For 100 ohm RTD, alpha = .00385:

Temp (°C

) Resistance (ohms)

-200 18.49

-100 60.25

0 100.00

100 138.50

200 175.84

300 212.02

400 247.04

At a temperature of 400°C, the maximum resistance is 247.04 ohms

The equation for the voltage out of the CIO-EXP-RTD16 (the voltage your DAS board will convert into a

number) is:

= I

V

OUT

EXC

* R

* GAIN

RTD

Normally, the CIO-EXP-RTD16 supplies 1 mA of excitation current. The choices for standard gains are

1, 2, 4, 7, 8, 14, 28, or 56.

Thus, if you want to measure temperature in the range of -200 to 400°C with the RTD listed above, the

maximum voltage output would be:

V = 0.001 * 247.04 = 0.24704

With a gain of 14, the DAS board will read 3.459 volts. If the gain is 28, the output is 6.917 volts. The

DAS board would have to be set to the 0 to 10 volt range.

If you are limiting your range of interest to -200 to 100°C, a common range, the calculations are:

V = 0.001 * 138.50 = 0.1385. Gain of 28 = 3.878V. Gain of 56 = 7.756V. In this case, a gain of 28 and

a range of 0 to 5 volts would be best (0.517 to 3.878 volts would be the temperature range − 200 to 100).

A 12-bit A/D converter would be using 67% of its range of 4096 counts, or a total of 2752 counts, or

divisions of 300°C. The converter would be able to resolve to 0.109°C. That is more than enough

converter resolution even though you are not using the full range of the DAS board in this example.

If your DAS board has 16 bits of resolution, the DAS board would resolve to 0.006°C. This is far in

excess of the accuracy of the RTD.

The stages of gain you choose are not only dependent on the RTD you choose, but on the range of

temperature you are measuring. Use the equation above to fine tune the CIO-EXP-RTD16 circuit to your

advantage, then be sure to update the InstaCal program so the Universal Library linearization routines

will operate properly.

5.4 SETTING THE GAIN

Set the first and second stage gains according to the base resistance of the RTD, the RTD type and the

temperature range you intend to measure. The base resistance is the resistance of the RTD at zero

degrees Centigrade. The following table is a “quick reference” guide of recommended gains.

13

Page 18

Base Resistance Stage 1 Gain Stage 2 Gain Total Gain

100 Ohms 8 7 56

1000 Ohms 4 7 28

5.4.1 First Stage Gain

A set of three Gain Select switches on the S1

switch block selects the first stage gain (Figure

4-4). The fourth switch on this block (marked

CUSTOM) is used to select a custom second

stage gain.

When all three switches are up, the first stage

gain is 1. Moving a switch down (ON) selects

that gain. The other two switches should be up.

(Gains choices for the first stage are NOT

additive.)

Thus, gains of 1, 2, 4 or 8 can be selected by

these switches. A gain of X2 is shown in Figure

5-1.

5.4.2 Second Stage Gain

Switch #3 on the S2 DIP switch block (Figure

5-2) is labeled X1 and X7. Setting this switch

down (ON) will amplify the output of the first

stage amplifier by 7. The factory default

position (up) has a gain of 1 (unity).

GAIN

SELECT

O

N

CUSTOM

X2

X4

X8

Figure 5-1. First Stage Gain Select Switches

CUSTOM IEXC

+5 REM

X1

When set to X7, the first stage gain is

multiplied by 7 yielding overall gains of 7, 14,

28 or 56.

4 3 2 1

GND

X7

N

O

+5 COMP

IEXC=1MA

A second stage gain of 7 is recommended for

RTD applications.

Figure 5-2. Second Stage Gain Switch Location

A custom second stage gain of greater than 7 and less than 64 may be added by installing a precision

resistor at RX100 and setting the switch marked CUSTOM on.

When using the custom second stage gain, set the switch marked CUSTOM on the S1 bank to the ON

position (down) and set the X7 switch on the S2 bank to X1. Install a precision resistor of the

appropriate value in the RX100 location. Calculate the value using the formula found in the Custom

Gain and Excitation Calculations chapter.

14

Page 19

5.5 CHANNEL CONFIGURATION SWITCH

RTD connections may use 2, 3, or 4 wires coming from the probe. The three-wire connection is the

most common. The purpose of the three-wire connection is that the circuit will null-out resistance

variations in the connecting wires. A four-switch DIP switch block labeled INPUT CONFIG must be set

to match the number of wires connecting to each RTD. There is one switch block per RTD.

Type INPUT CONFIG Switch Settings

RTD

2 Wire 4 & 4 ON; 3 & 3 OFF

3 Wire 3 & 3 ON; 4 & 4 OFF

4 Wire 4 & 4 ON; 3 & 3 OFF

Channel Configuration Switch

Associated with each RTD is an

INPUT CONFIGuration switch. The

switch is used to configure the input

circuit for 2, 3, or 4 wire connections

(Figure 5-3).

Two and four-wire connections share

the same switch position. Set both

‘4’ switches ON and set both ‘3’

switches OFF.

3

4

1

INPUT CONFIG

O

N

3

4

3

4

3

4

O

N

0

For three-wire connection, set both

‘3’ switches ON and set both ‘4’

Set for 2 or 4-Wire Connection

Set for 3-Wire Connection

switches OFF.

Figure 5-3. Input Configuration Switches

5.6 CONNECTING THE RTD TO THE SCREW TERMINALS

The connections made to the screw terminal depend on the type of RTD you are using. The inputs of the

CIO-EXP-RTD16 are designed to provide the excitation and signal conditioning required to use RTDs.

An RTD may have 2, 3, or 4 wires that connect to the CIO-EXP-RTD16. Figures 5-4, 5-5, and 5-6 show

the three types of RTD connections and how to connect them to the input channels.

15

Page 20

5.6.1 Two-wire RTD Hookup

gaug

A two wire RTD has two leads, one to each side

of the temperature sensitive resistor. The

excitation current is connected directly to the

leads at the CIO-EXP-RTD16 screw terminals. A

two wire connection is less accurate than the 4

wire type, and so is not the first choice for the

best measurements. The reason for the inaccuracy

is that there is a varying resistance associated with

the excitation current flowing in the sense leads

and this resistance is added to the measurement.

The amount of inaccuracy is determined by the

wire

e and length.

5.6.2 Three-Wire RTD Hookup

A three-wire RTD connection allows the use of

special circuit to compensate for resistance

variations in the lead wires with temperature

changes (Figure 5-5 at right).

NOTE: The +Sense terminal is not used in this

non-standard hookup.

CIO-EXP-RTD BOARD

2-WIRE

RTD

Add Jumper Wires

Between Terminals

+IEXC (EXCITATION CURRENT (+))

+ SENSE

- SENSE

-IEXC (EXCITATION CURRENT

-

(−))

Figure 5-4. Two-Wire RTD Connections

3-WIRE

RTD

CIO-EXP-RTD BOARD

+IEXC (EXCITATION CURRENT (+))

+ SENSE

- SENSE

-IEXC (EXCITATION CURRENT

-

(−))

NOTE: The CIO-EXP-RTD uses a non-stan dard 3-wire hook-up.

Figure 5-5. Three-Wire RTD Connections

16

Page 21

5.6.3 Four-Wire RTD Hookup

W

A four wire RTD has four leads. One to each side

of the temperature sensitive resistor and an

excitation current source and return. This

connection eliminates the inaccuracy associated

with the two-wire RTD hookup. Because no

current flows on the sense lines there is no voltage

drop in the sense lines, thus the error associated

with two-wire RTDs is eliminated. .

IRE

RTD

EXCITATION CURRENT (+)

SENSE HIGH (+)

SENSE LOW (-)

EXCITATION CURRENT (-)

Figure 5-6. Four-Wire RTD Hookup

5.7 CALIBRATION AND TEST

After your CIO-EXP-RTD16 is configured and your RTDs are connected, return to InstaCal and

complete the setup information. Then, use calibration to verify the calibration of your RTDs, and finally,

use TEST to make several temperature measurements.

6 CUSTOM GAIN AND EXCITATION CALCULATIONS

There are resistor positions on the CIO-EXP-RTD16 which are unpopulated. These two resistors are

labeled R89 and RX100. R89 is the custom excitation current resistor and RX100 is the custom second

stage gain resistor. The formulas and constraints to needed to calculate a resistor value are given below.

The value of the resistor must be exact to yield the result you desire. There are two ways to insure the

value is exact. The first is to measure the resistor with an Ohmmeter to check its value, rejecting

resistors that do not meet the desired value. The second way is to purchase precision resistors with a 1%

tolerance. Even then, it’s advisable to check the value with an Ohmmeter before soldering the resistor

into the board.

Please solder carefully!

Remember, you are making a modification to the CIO-EXP-RTD16 and if it is not made well the quality

of the signal may be affected. Use only solder with a water soluble flux and be sure to remove all the

flux after you have finished soldering. Flux residue can add capacitance to a circuit which will affect the

signal.

6.1 CUSTOM EXCITATION CURRENT - R89

The formula for IEXC on the CIO-EXP-RTD16 is:

IEXC = (10V − Vref) / 5K Where Iexc is Minimum = 0.1 mA and Maximum = 1 mA

Vref is nominally 5V, so Iexc is nominally 1 mA

The procedure for selecting a value for R89 to get a custom excitation current is:

17

Page 22

Calculate a new Vref using the desired Iexc:

Vref = 10V - 5K * Iexc

Then calculate R89 value:

R89 = 10K [ ( 2 − 10V / Vref ) / ( 10V / Vref − 1 ) ]

Install the custom excitation current resistor in R89.

Set switch S2 position 1 to OFF

6.2 CUSTOM SECOND STAGE GAIN RESISTOR - RX100

The formula for calculating the value of RX100 is:

RX100 = 149K / ( Gain - 6.96 ) Where Gain cannot be less than 7 nor greater than 64.

Install the custom gain resistor at position RX100 (next to S1 on board).

Set S1, switch 4 to ON. That is the switch labeled CUSTOM.

Set the S2, second stage gain to X7, ON.

Because this is a second stage gain, you can still use the first stage gains of 2, 4, and 8 or turn them all off

for a first stage gain of 1. That will make the second stage gain the only gain more than one.

18

Page 23

7 SPECIFICATIONS

Power consumption

+5V 380mA typical, 533mA max

Analog input section

Multiplexer type HI507

Number of channels 16 differential

Input ranges ±10V

Gain options

First stage X1, X2, X4 or X8

Second stage X1, X7 or User defined between X7 and X64

Multiplexor switching time 5 µS typical to 0.01% of 5V step

Channel to channel settling time 50 µS max to 0.01% of 5V step

Gain Error ±0.02% of full scale typical, 0.25% of full scale max

Gain Non-Linearity

Gain = X1, X2 or X4 ±0.002% of full scale typical, 0.015% of full scale max

Gain = X8 ±0.002% of full scale typical, 0.025% of full scale max

Offset Error Each channel adjustable to zero

Gain drift ±10 ppm/°C typical

Offset drift

Gain = X1 ±60µV/°C typical

Gain = X2 ±40µV/°C typical

Gain = X4 ±25µV/°C typical

Gain = X8 ±20µV/°C typical

Common Mode Range ±10V

CMRR @ 60Hz

Gain = X1 94 dB

Gain = X2, X4 or X8 100 dB

Absolute maximum input voltage ±50V

Miscellaneous 79 Hz low pass filter each channel

Analog Output

Amplifier type OP07

Number of channels 1

Output Range ±10V

19

Page 24

Current Excitation

Excitation Switch selectable for 1 mA on board or custom value

determined by resistor selection

Voltage compliance 2V

Accuracy Trimmable

Digital Section

Digital Type

Din 0 - 2 HI508 multiplexor

Din 3 1 CMOS load

Number of channels 4 inputs

Input High 2.0 volts min, +5.5 volts absolute max

Din 0 - 2 2.4V min

Din 3 1.7V min

Input Low 2.0 volts min, +5.5 volts absolute max

Din 0 - 2 0.8V max

Din 3 1.0V max

Environmental

Operating temperature range 0 to 60°C

Storage temperature range −40 to 100°C

Humidity 0 to 90% non-condensing

20

Page 25

EC Declaration of Conformity

We, Measurement Computing Corp.., declare under sole responsibility that the product:

CIO-EXP-RTD16 RTD Expansion Board

Part Number Description

to which this declaration relates, meets the essential requirements, is in conformity with, and CE marking

has been applied according to the relevant EC Directives listed below using the relevant section of the

following EC standards and other informative documents:

EU EMC Directive 89/336/EEC: Essential requirements relating to electromagnetic compatibility.

EU 55022 Class B: Limits and methods of measurements of radio interference characteristics of

information technology equipment.

EN 50082-1: EC generic immunity requirements.

IEC 801-2: Electrostatic discharge requirements for industrial process measurement and control

equipment.

IEC 801-3: Radiated electromagnetic field requirements for industrial process measurements and control

equipment.

IEC 801-4: Electrically fast transients for industrial process measurement and control equipment.

Carl Haapaoja, Director of Quality Assurance

Page 26

Measurement Computing Corporation,

16 Commerce Blvd.,

Middleboro, MA 02346

Tel: (508) 946-5100

Fax: (508) 946-9500

E-mail: info@MeasurementComputing.com

www.MeasurementComputing.com

Loading...

Loading...