Page 1

CIO-EXP-GP

g

User’s Manual

Revision 2

January, 2001

© Copyri

ht 2001, Measurement Computing Corporation

Page 2

LIFETIME WARRANTY

Every hardware product manufactured by Measurement Computing Corp. is warranted against defects in materials or

workmanship for the life of the product, to the original purchaser. Any products found to be defective will be

repaired or replaced promptly.

LIFETIME HARSH ENVIRONMENT WARRANTY

TM

Any Measurement Computing Corp. product which is damaged due to misuse may be replaced for only 50% of the

current price. I/O boards face some harsh environments, some harsher than the boards are designed to withstand.

When that happens, just return the board with an order for its replacement at only 50% of the list price. Measurement

Computing Corp. does not need to pro fit from your misfortune. By the way, we will honor this warranty for any other

manufacture’s board that we have a replacement for!

30 DAY MONEY-BACK GUARANTEE

Any Measurement Computing Corp. product may be returned within 30 days of purchase for a full refund of the

price paid for the product being returned. If you are not satisfied, or chose the wrong product by mistake, you do not

have to keep it. Please call for a RMA number first. No credits or returns accepted without a copy of the original

invoice. Some software products are subject to a repackaging fee.

These warranties are in lieu of all other warranties, expressed or implied, including any implied warranty of

merchantability or fitness for a particular application. The remedies provided herein are the buyer’s sole and

exclusive remedies. Neither Measurement Computing Corp., nor its employees shall be liable for any direct or

indirect, special, incidental or consequential damage arising from the use of its products, even if Measurement

Computing Corp. has been notified in advance of the possibility of such damages.

MEGA-FIFO, the CIO prefix to data acquisition board model numbers, the PCM prefix to data acquisition bo ard

model numbers, PCM-DAS08, PCM-D24C3, PCM-DAC02, PCM-COM422, PCM-COM485, PCM-DMM,

PCM-DAS16D/12, PCM-DAS16S/12, PCM-DAS16D/16, PCM-DAS16S/16, PCI-DAS6402/16, Universal Library,

InstaCal, Harsh Environment Warranty and Measurement Computing Corp. are registered trademarks of

Measurement Computing Corp.

IBM, PC, and PC/AT are trademarks of International Business Machines Corp. Windows is a trademark of

Microsoft Corp. All other trademarks are the property of their respective owners.

Information furnished by Measurement Computing Corp. is believed to be accurate and reliable. However, no

responsibility is assumed by Measurement Computing Corp. neither for its use; nor for any infringements of patents

or other rights of third parties, which may result from its use. No license is granted by implication or otherwise under

any patent or copyrights of Measurement Computing Corp.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form by any means, electronic, mechanical, by photocopying, recording or otherwise without the prior written

permission of Measurement Computing Corp.

Notice

Measurement Computing Corp. does not authorize any Measurement Computing Corp. product for

use in life support systems and/or devices without the written approval of the President of

Measurement Computing Corp. Life support devices/systems are devices or systems which, a) are

intended for surgical implantation into the body, or b) support or sustain life and whose failure to

perform can be reasonably expected to result in injury. Measurement Computing Corp. products

are not designed with the components required, and are not subject to the testing required to

ensure a level of reliability suitable for the treatment and diagnosis of people.

HM CIO-EXP-GP.lwp

Page 3

Table of Contents

1 INTRODUCTION

2 SOFTWARE INSTALLATION

3 GENERAL CONFIGURATION

3.1 A/D Board Type Select Jumper

3.2 Setting The Output Channel

3.3 Configuring the A/D Board

3.3.1 DAS08 Family Setup

3.3.2 DAS16 Family Setup

3.3.3 All A/D Boards

..............................................................

..................................................

..................................................

..............................................

.................................................

..................................................

...................................................

...................................................

........................................................

3.4 CONNECTING THE CIO-EXP-GP TO THE A/D BOARD

3.4.1 Connecting to a DAS08 Series A/D Board

3.4.2 Connecting to a DAS16 Series A/D Board

3.4.3 Other A/D Boards

3.5 Powering The CIO-EXP-GP

3.5.1 Power Source Switch

......................................................

.................................................

...................................................

3.5.2 Powering with the 37-Pin Connector

3.5.3 Powering with the Molex Connector

3.5.4 Powering Through the Power Screw Terminals:

3.6 Daisy-Chaining CIO-EXP-GP Boards

3.7 Connecting a Test Voltage

3.8 Verifying the Installation

..................................................

....................................................

........................................

4 CONFIGURATION FOR VOLTAGE MEASUREMENT

4.1 Channel Selection

4.2 Powering the CIO-EXP-GP

4.3 Determining The Appropriate Gain

4.4 Setting the Gain

4.4.1 Setting Board Gain

4.4.2 Setting Channel Gain

4.5 Attenuation

...............................................................

4.6 Setting the Input Configuration

4.7 Connecting Voltage Signals

4.7.1 Single-Ended Inputs

4.7.2 Floating Differential

4.7.3 Fully Differential

4.8 Verifying the Installation

..........................................................

.................................................

..........................................

............................................................

.....................................................

..................................................

.............................................

................................................

...................................................

...................................................

......................................................

...................................................

.................................

.................................

......................................

......................................

.............................

...........................

5 CONFIGURATION FOR THERMOCOUPLE MEASUREMENT

5.1 Selecting The Output Channel

5.2 Selecting The CJC Output Channel

5.3 Input Configuration

.......................................................

5.3.1 Setting the Input Configuration

5.3.2 Enabling Open Thermocouple Detection (OTD)

5.3.3 Adding a Ground Reference

5.4 Determining the Appropriate Gain

..............................................

.........................................

..........................................

...........................

.............................................

..........................................

....................

.................

1

1

2

2

2

3

3

3

3

4

4

4

4

5

5

5

5

5

6

6

7

8

8

8

8

9

9

10

10

11

11

12

12

12

13

14

14

14

15

15

15

17

17

Page 4

5.5 Setting the Gain

5.5.1 Setting the Board Gain

5.5.2 Setting the Channel Gain

5.6 Verifying the Installation

6 CONFIGURATION FOR RTD MEASUREMENTS

6.1 Channel Selection

6.2 VEXC Jumper Select

6.3 CJC Jumper Selection

6.4 Powering the CIO-EXP-GP

6.5 Determining the Appropriate Gain

6.6 Setting the Gain

6.6.1 Setting the Board Gain

6.6.2 Setting the Channel Gain

6.7 Input Configuration

6.7.1 Setting the Input Configuration

6.8 Connecting RTDs To Screw Terminals

6.8.1 Two-Wire RTD Hookup

6.8.2 Three-Wire RTD Hookup

6.8.3 Four-Wire RTD Hookup

6.9 Verifying the Installation

...........................................................

.................................................

...............................................

...................................................

...............................

.........................................................

......................................................

.....................................................

................................................

..........................................

...........................................................

.................................................

...............................................

.......................................................

..........................................

......................................

................................................

...............................................

................................................

...................................................

7 CONFIGURATION FOR RESISTANCE MEASUREMENTS

7.1 Channel Select

7.2 VEXC Jumper Select

7.3 CJC Jumper Select

7.4 Powering the CIO-EXP-GP

7.4.1 Selecting the Power Source for the Board

............................................................

......................................................

........................................................

................................................

.................................

7.4.2 Selecting the Power Source for the Excitation Voltage

7.4.3 Selecting the Excitation Voltage

7.5 Determining the Appropriate Gain

7.6 Setting the Gain

7.6.1 Setting the Board Gain

7.6.2 Setting the Channel Gain

...........................................................

.................................................

...............................................

7.7 Setting the Input Configuration

7.8 Configuring the Bridge

....................................................

7.8.1 Bridge Completion Resistors

7.8.2 Nulling Potentiometers & Arm Resistor

7.8.3 Strain Gauge Bridge Configuration Examples

7.9 Verifying the Installation

8 SPECIFICATIONS

9 APPENDIX

....................................................................

9.1 About Strain Gauges

9.1.1 What Are Strain Gauges?

............................................................

...................................................

......................................................

...............................................

9.1.2 Specification of Strain Gauges

9.2 Reference Material for Application of Strain Gauges

.........................................

..........................................

.............................................

............................................

..................................

.............................

...........................................

.........................

.....................

......................

18

18

18

19

20

20

20

20

20

20

22

22

23

23

23

24

24

24

24

25

26

26

26

26

26

26

26

28

28

28

29

29

30

30

31

32

32

35

36

38

38

38

38

38

Page 5

1 INTRODUCTION

The CIO-EXP-GP is an eight-channel, signal conditioning accessory designed for use with the DAS08

and DAS16 family of data acquisition boards. It can condition signals from bridge sensors, RTDs or

thermocouples on a per-channel basis. It converts the sensor's output to a voltage suitable for conversion

by a DAS08/DAS16 or other analog to digital conversion board.

This manual is organized into sections that explain the CIO-EXP-GP on a sensor by sensor basis. The

CIO-EXP-GP is complex, and the information on bridge sensors may confuse those interested in RTDs

only, and vice-versa. Here are the sections of this manual:

Software Installation All users should review this section regardless of the

application.

General Configuration: All users should review this section regardless of the

application.

Configuration for Voltage Measurement: Users interested in voltage measurement applications

should review this section.

Configuration for Thermocouples Users interested in temperature measurement

applications using thermocouples should review this

section.

Configuration for RTD Measurement Users interested in temperature measurement

applications using RTDs should review this section.

Configuration for Resistance Measurement: Users interested in resistance or strain gauge

measurement applications should review this section.

Please carefully read the installation and general configuration sections, and each of the sections

pertaining to the sensors you intend to use. There are optional resistors, jumpers, switches, and other

connections to be made on the CIO-EXP-GP. Failure to set up the channels correctly for the sensor in

use will result in inaccurate or invalid measurements.

2 SOFTWARE INSTALLATION

Software is not included with the CIO-EXP-GP, but each of the data acquisition boards with which it is

intended to be used includes software called InstaCal™ that may be used to aid installation, verify

operation and perform calibration of the CIO-EXP-GP. The disk or CD labeled InstaCal contains this

software package. If you ordered the Universal Library™, you should load InstaCal from that CD or

disk set.

The board has a variety of switches and jumpers to set before installing the board in your computer.

InstaCal will show you all available options, how to configure the various switches and jumpers to match

your application requirements, and will create a configuration file that your application software (and the

Universal Library) will refer to so the software you use will automatically have access to the exact

configuration of the board.

Please refer to the Software Installation Manual regarding the installation and operation of InstaCal. Use

InstaCal along with the following hard copy information to set the hardware configuration of the board.

1

Page 6

3 GENERAL CONFIGURATION

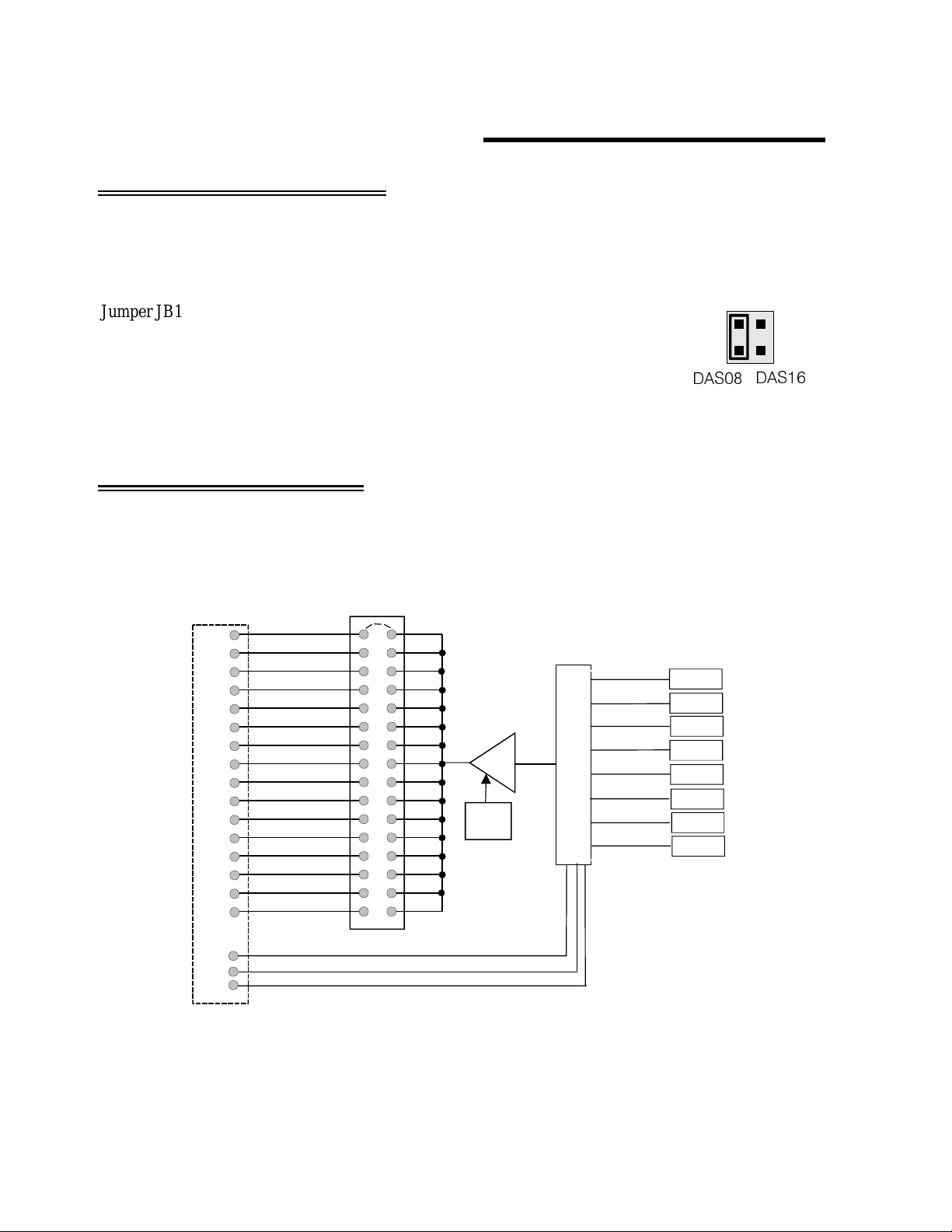

3.1 A/D Board Type Select Jumper

The CIO-EXP-GP can be used with either DAS08 or DAS16 family boards because the signal

assignments of the 37-pin connectors match those of the DAS08 and may be adapted to those of the

DAS16 with a C-EXP2DAS16-10 cable. Select the A/D board type via the JB10 jumper.

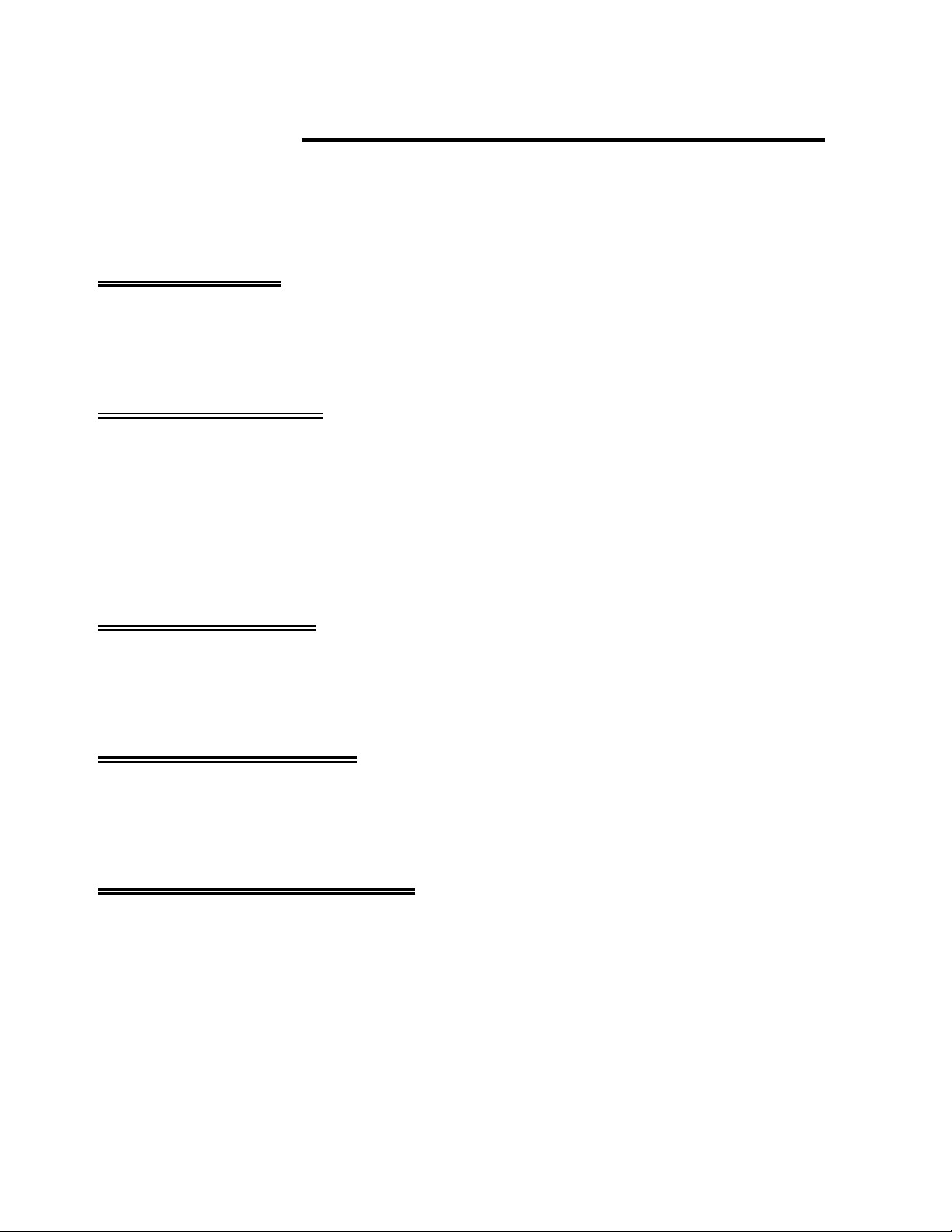

Jumper JB10 on the ,CIO-EXP-GP located near the 37-pin connector, selects the

A/D board family as DAS08 or DAS16.

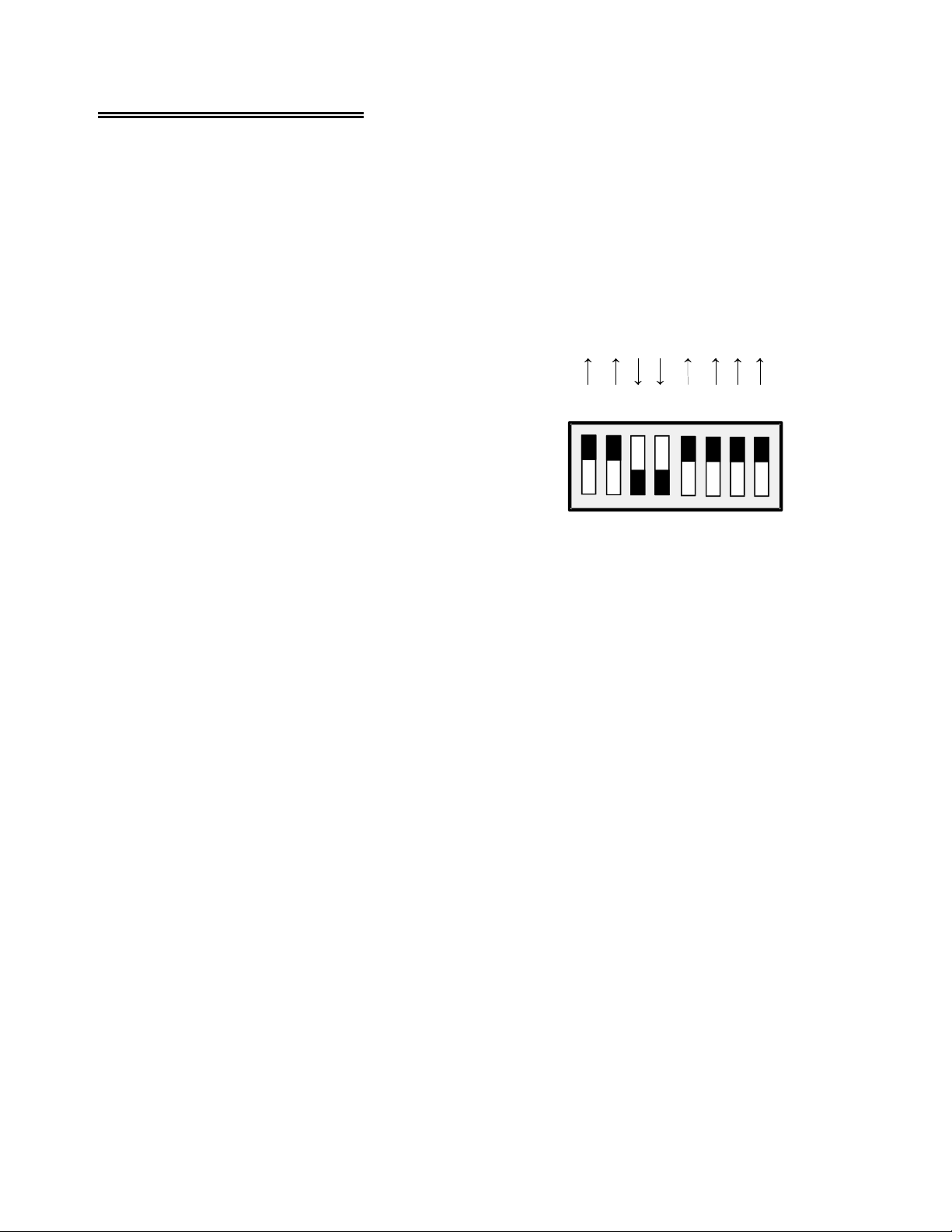

Figure 3-1 shows the jumper set to use the CIO-EXP-GP with a CIO-DAS08

family board.

'$6

DAS Family Select

3.2 Setting The Output Channel

Jumpers labeled “CH SEL” located near the 37-pin connector select the A/D board channel that the

output from the active sensor will be connected to.

'$6

Figure 3-1

37-Pin

CONNECTORS

37

36

35

34

33

32

31

30

18

17

16

15

14

13

12

11

9

8

7

P1 & P2

MUX ADDR 3

MUX ADDR 2

MUX ADDR 1

OUTPUT CHA NNEL

SELECT JUMPER

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

AMP

GAIN

1 OR 2.5

INPUT 0

INPUT 1

INPUT 2

INPUT 3

INPUT 4

INPUT 5

8-CHANNEL MULT I P LE XER

INPUT 6

INPUT 7

Figure 3-2. Output Channel Select Jumper

2

Page 7

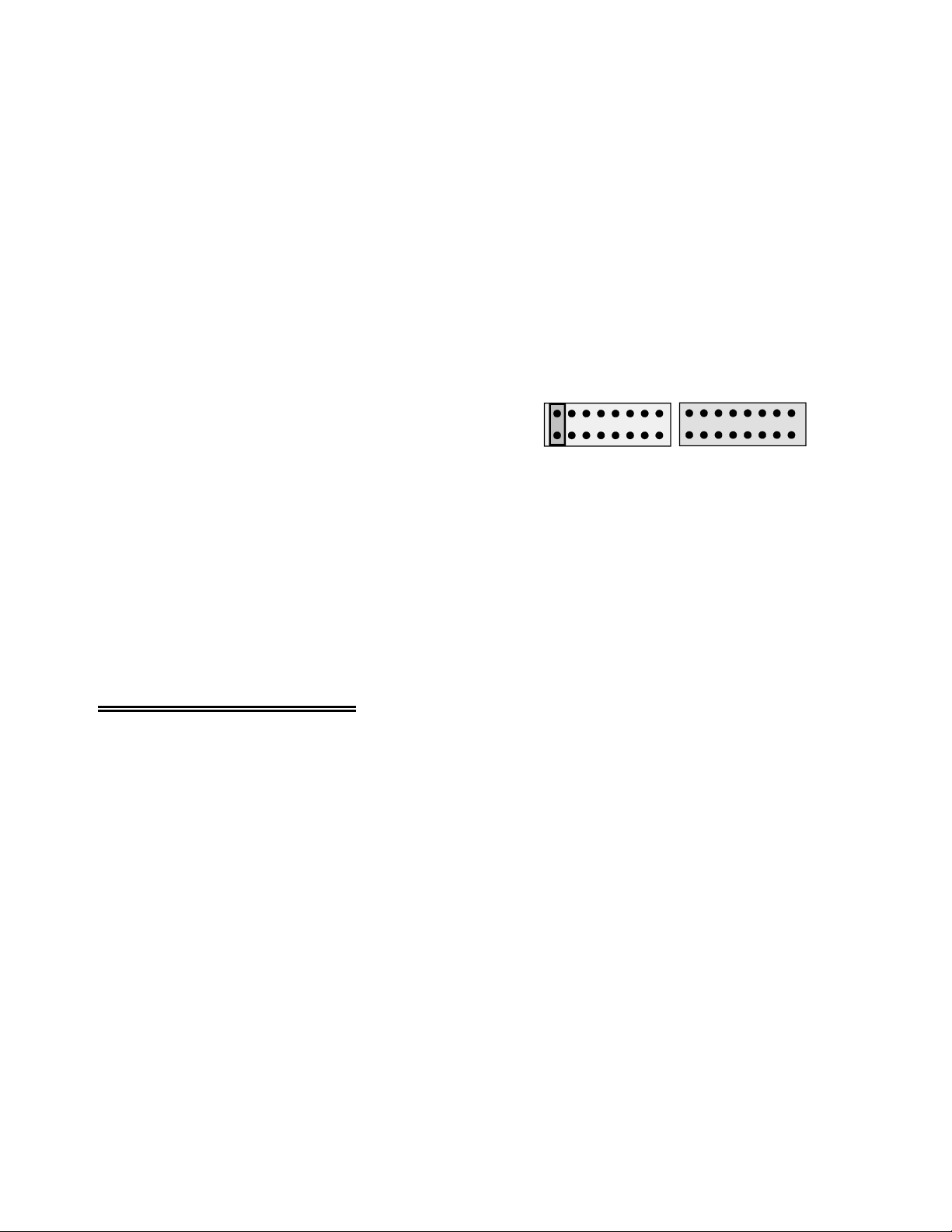

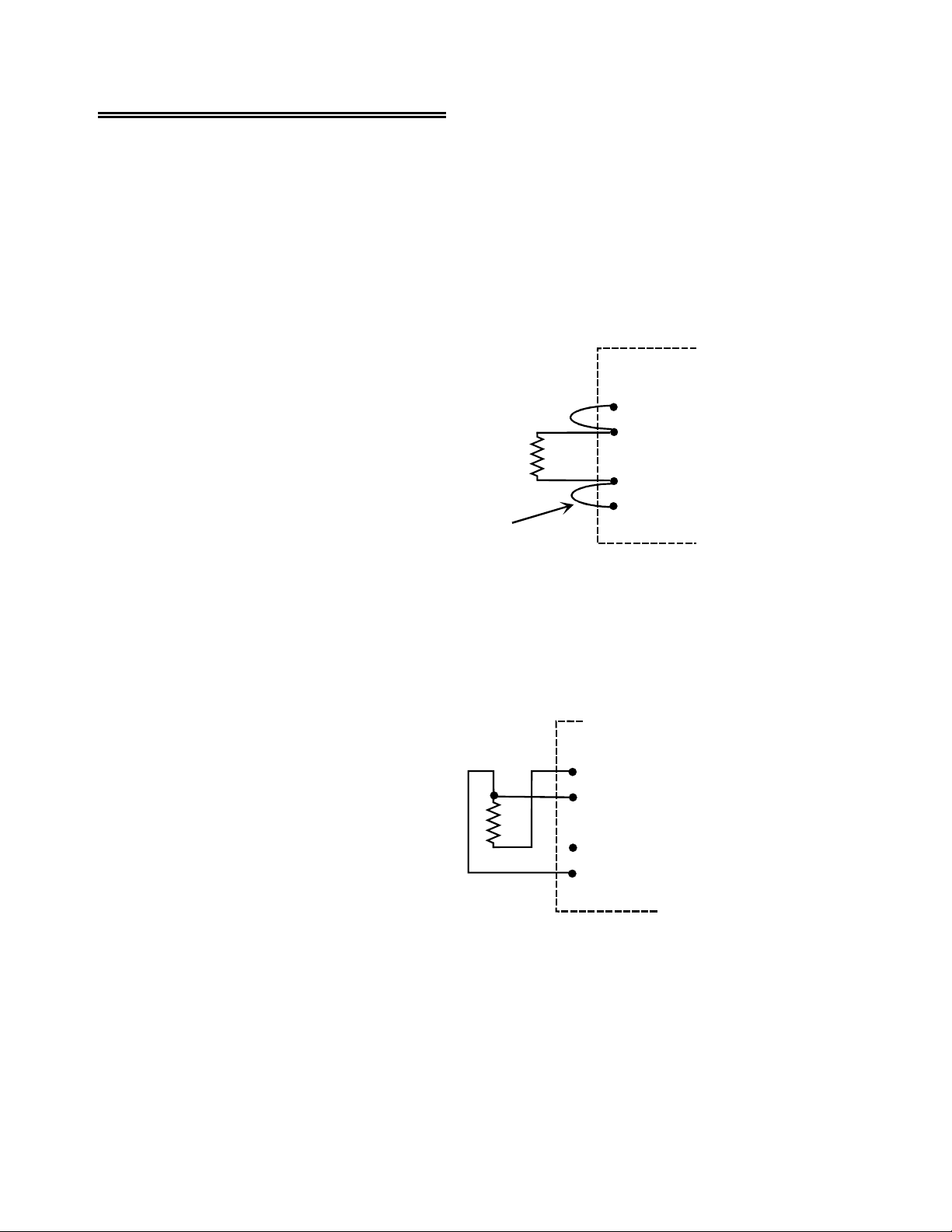

There are three groups of 16-position jumpers. One jumper group determines the signal output channel,

one jumper group determines the excitation voltage output channel and one determines the Cold Junction

Compensation (CJC) output channel. Signal output is always used, CJC output is used only with

thermocouples and excitation output may be used with bridge sensors.

There are 16 jumper locations for each function. Each corresponds to one of the 16 pins on the 37 pin

connector. When the CIO-EXP-GP is connected to a DAS08, only the first 8 channels (labeled 0-7) can

be used. When the CIO-EXP-GP is connected to a DAS16, all 16 jumper positions can be used. In each

case, the jumper corresponds to a channel number on the A/D board.

If the jumper setting does not agree with the selection made in InstaCal setup, InstaCal and the Universal

Library will not be able to make readings from the CIO-EXP-GP. Figure 3-3 is a diagram of the Channel

Select jumper. There are two other groups of output jumpers similar to this group.

The top group (shown here) is marked CH SEL

1234567

0

8 9 10 1112 14 15

13

(Channel Select), the center jumper group is

VEXC SEL (excitation voltage select) and the

bottom group is marked CJC SEL (Cold Junction

Compensation Select).

CH SEL

CHANNEL 0 SELECTED

FOR SENSOR OUTPUT

Figure 3-3. Output Channel Select Jumper

Place the jumper on the pin which corresponds to the A/D board's input channel. Each jumper set must

select a unique A/D channel. For example, if you are using the excitation or CJC outputs in addition to

the signal output, each should be set to a different channel number.

One individual channel must be selected for each bank of 8 EXP channels. For example, if you are using

several CIO-EXP-GP boards, the jumper setting for each board must be unique. If you select channel 0

for the first board, do not use this channel for any of the other boards.

3.3 Configuring the A/D Board

3.3.1 DAS08 Family Setup

The input mode of the A/D board must be single-ended to be compatible with the CIO-EXP outputs.

Some of the boards in the DAS08 series have differential inputs that can be converted to single-ended

inputs. See the information shipped with your A/D board for conversion to single-ended inputs.

3.3.2 DAS16 Family Setup

The input mode of the A/D board must be single-ended to be compatible with the CIO-EXP outputs.

Most of the DAS16 series is switch selectable for either 8 differential or 16 single ended inputs. When

used with the CIO-EXP, set the switch to 16 channel, single-ended mode.

3.3.3 All A/D Boards

If you are using an A/D board with switch - selectable ranges, consider the application and determine the

best fit for range vs. expected voltage. For example, when measuring resistance such that the output of

the EXP board is expected to be in the range of 3 to 4.5 Volts, a unipolar 5V range would be the best

choice.

3

Page 8

If the range on your A/D board is fully programmable, the software you use for measurement will

determine the range.

3.4 CONNECTING THE CIO-EXP-GP TO THE A/D BOARD

3.4.1 Connecting to a DAS08 Series A/D Board

A CIO-DAS08 series board may be connected directly through a C37FF series cable from the P1

connector on the CIO-EXP-GP to the A/D analog connector. The JB10 jumper should be left in the

DAS08 position as set at the factory.

3.4.2 Connecting to a DAS16 Series A/D Board

Connection to a DAS16 series board requires a special 37-conductor cable (CEXP2DAS16-10) since pin

relationship of CIO-EXP and DAS16 signals is not 1:1.

Install the CEXP2DAS16-10 cable connector labeled “MUX” into the P1 connector of the CIO-EXP-GP

board and the other end into the DAS16 series board’s analog connector.

3.4.3 Other A/D Boards

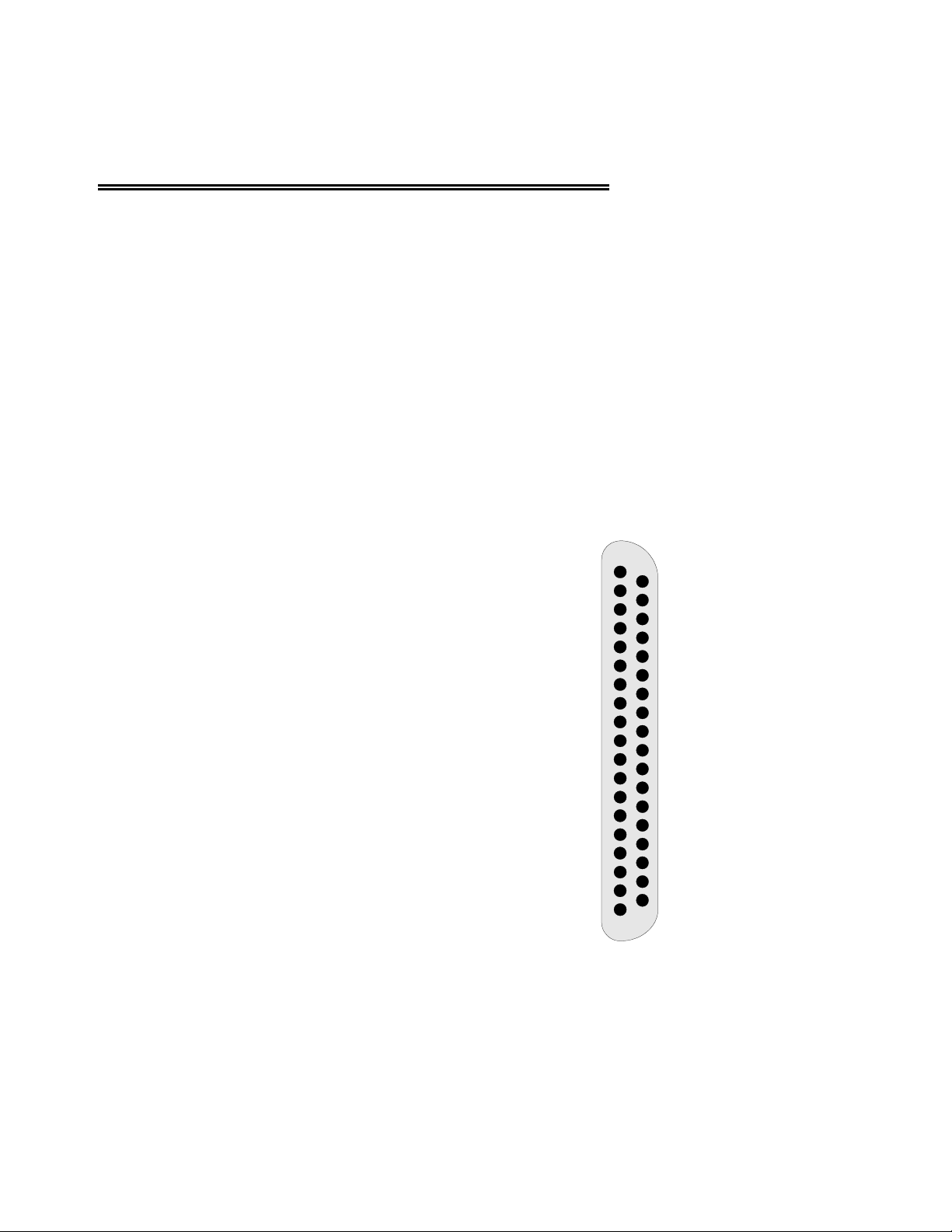

For other boards, use the connector diagram in

Figure 3-4 to construct a cable, or call us and

discuss the possibility of a custom

manufactured cable.

The signals from the CIO-EXP-GP are

voltages from each channel and an analog

ground. There should be no voltage between

the analog ground and the power ground.

The MUX address lines control the setting of

the channel multiplexer. When all are low, the

mux is set to channel 0. The lines are binary

coded. MUXADDR1 is the LSB and

MUXADDR3 is the MSB.

A jumper (CH SEL) selects which output

channel is read by the DAS08 or DAS16

board.

DAS16 LLGND

OUTPUT 8 / LLGND

OUTPUT 9

OUTPUT 10

OUTPUT 11

OUTPUT 12

OUTPUT 13

OUTPUT 14

OUTPUT 15

SHUNT CALIBRATION

MUX ADDR 3

MUX ADDR 2

MUX ADDR 1

NC

NC

NC

NC

NC

NC

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

OUTPUT 0

OUTPUT 1

OUTPUT 2

OUTPUT 3

OUTPUT 4

OUTPUT 5

OUTPUT 6

OUTPUT 7

+5 VOLTS FROM PC

POWER GROUND

NC

NC

NC

NC

NC

NC

NC

NC

Figure 3-4. 37-Pin Connectors

4

Page 9

3.5 Powering The CIO-EXP-GP

The CIO-EXP-GP can be powered through the 37-pin cable, the power screw terminal or the Molex

connector. The power that can be carried through the 37-pin connector is limited so we recommend

using this source only when a single CIO-EXP-GP is used.

The power required to run a CIO-EXP-GP is dependent on the board configuration. Remember that

additional power will be drawn when the CIO-EXP-GP is configured for resistance measurement (bridge

configuration) due to the current required for each bridge.

3.5.1 Power Source Switch

One of the switches on the eight-position DIP switch (S17) near

the output channel jumpers controls the source of the +5 volts

power to the board. Shown in Figure 3-5 it is the 3rd switch

from the left.

When positioned down, (ON, +5 COMP), the +5V power is

drawn from the personal computer through the signal cable.

When positioned up (OFF, REM) , +5V power is taken from

the optional external 5V power connector (the Molex connector

labeled P19) or the +5V screw terminal connection.

REM

X1

S17

0.5V

1V

2V

10V

4V

+5 COMP

X2.5

GND

Figure 3-5. Power Source Switch

3.5.2 Powering with the 37-Pin Connector

You can power the CIO-EXP-GP via the 37-pin cable. No more than one CIO-EXP-GP should be

powered using the 37-pin cable.

This option is not available when using some A/D boards. If the A/D board you are using supplies +5V

at pin 29 (or at pin 1 when using the C-EXP2DAS16 signal cable), you can power the CIO-EXP-GP

through the 37 pin connector by setting the power select switch on S17 to “+5 COMP”.

3.5.3 Powering with the Molex Connector

The CIO-EXP-GP can be powered off the PC's power supply by connecting the optional external 5V

power connector (the Molex connector labeled P19) to the PC’s power supply through a C-MOLEX-10

cable. This cable has the same Molex connector that is used inside the PC and so can be connected

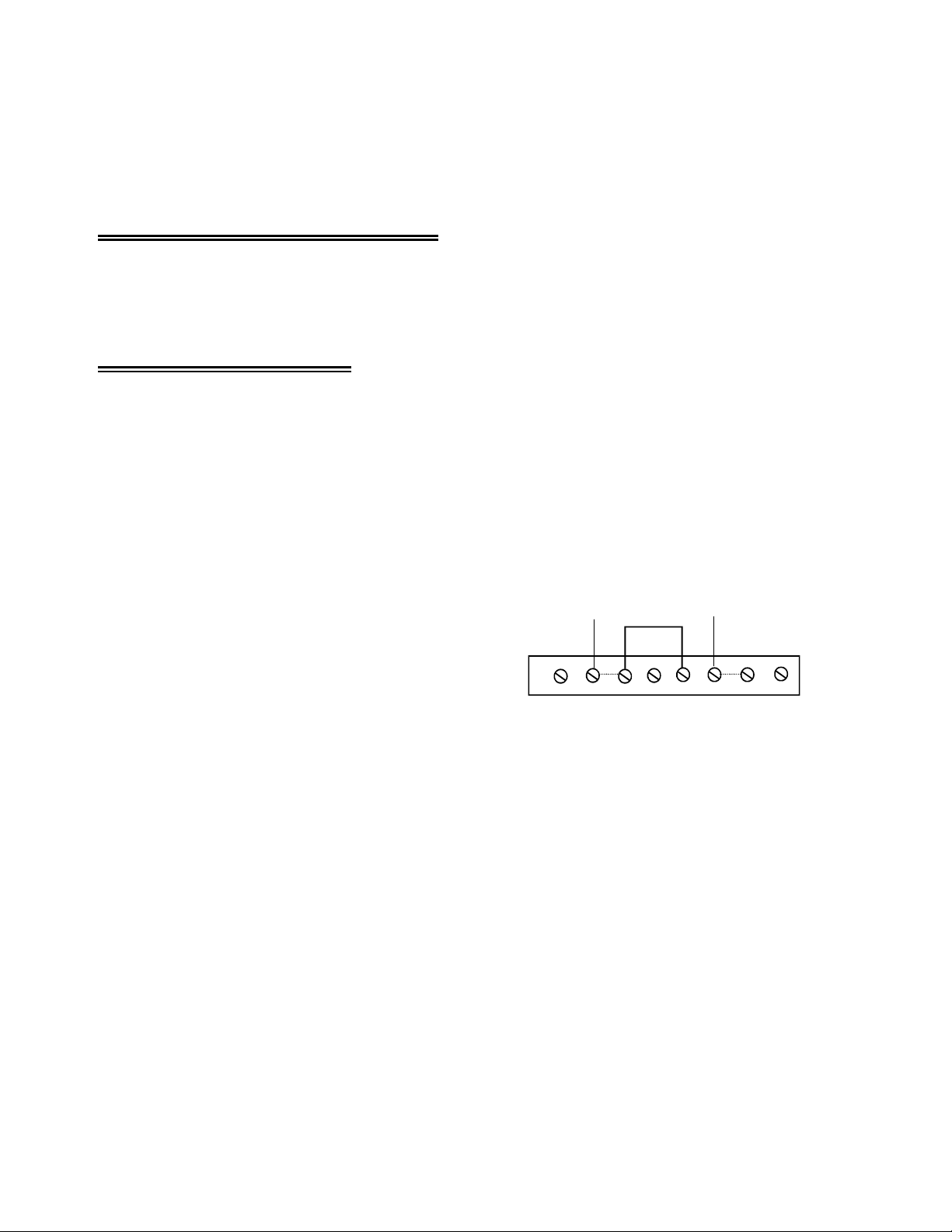

directly to the PC's power supply through one of the spare connectors. The cable is keyed, so it should

not be forced. When inserted properly it will slide easily and snap in place.

3.5.4 Powering Through the Power Screw Terminals:

A set of screw terminals labeled “+5V REM” and “REM GND” are located below the 37-pin connectors

P1 and P2. You can power the CIO-EXP-GP from a +5V (±5%) power supply capable of at least 400

mA. For this option, set the power select switch on S17 to “REM”.

CAUTION:

Connect the ground of the power supply to the ground of the personal computer with a

heavy gauge wire. If you do not strap the two grounds together, a voltage between these grounds will

5

Page 10

affect measurements. If the potential exceeds the protection range of the input circuits, the board may be

SENSE

(

)

C

S

NS

damaged.

At this time, ignore the other screw terminals located next to the power and ground terminals. They are

needed only with certain sensors and will be explained in those sections.

3.6 Daisy-Chaining CIO-EXP-GP Boards

Connect one CIO-EXP-GP to another using a C37FF-# ribbon cable. Connect from P2 on the ‘upstream’

board to P1 on the ‘downstream’ board. Make sure each of the boards in the chain have a unique channel

selected (CH SEL jumper is set to a different number on each board).

3.7 Connecting a Test Voltage

Make your initial test of the CIO-EXP-GP with a voltage

signal of between -5 and 5V. If you use an AC signal

source, keep the frequency below 70Hz to avoid

attenuation by the CIO-EXP-GP’s low pass filter.

Each input circuit has eight screw terminals associated

with it. These terminals are shown in the diagram to the

right.

To connect a voltage signal to the input circuit you use

three screw terminals as follows:

+SENSE Connect to + voltage

−

SENSE Jumper to −P

−

P Connect to Ground

There is not enough room on the board for the full name

next to each terminal so the eight screw terminals

associated with each input circuit are labeled on the

CIO-EXP-GP as follows:

+P Excitation voltage

−

SENSE Low side of input

−

SENSE Hardwired to the other −SENSE, same function

−

IEXC Excitation current return

−

P Excitation voltage return, common with −IEXC

+SENSE High side of input

+SENSE Hardwired to other +SENSE, same function

+IEXC Excitation current

SHORTING WIRE

−

+P EXCITATION. VOLTS

+P

VOLTS IN OR COMMON

−

−

E

E

−

EXCITATION CURRENT

INSTALLED

−

IEX

+ VOLTS IN

+ VOLTS IN

−

P

+ SENSE

+ SENSE

CH0

Figure 3-6. Input Screw Terminals

+EXCITATION CURRENT

(+)IEXC

The use of the terminals is dependent on the type of sensor you have connected to the input circuit, and

the nomenclature on the terminals has been chosen to make the most sense for bridge and RTD sensors.

For voltage and thermocouple sensors the names on the terminals are not typical. Please refer to the

section on the measurement you are making in order to learn how to use the terminals.

6

Page 11

3.8 Verifying the Installation

For verification of the installation, leave any switches or jumpers not mentioned above in their default

positions. Each of the gain switches (CH0 through CH7 and S17-7) should be off (toward the upper edge

of the board) for a gain of X1 (unity gain). The channel configuration switches (labeled “IN CONFIG”

should be left in the default position (the switches labeled “4” in the ON position and those labeled “3”

in the OFF position - the label is printed on the board, not the switch).

To verify the installation, use the InstaCal program installed on your computer. This software came with

your A/D board if you bought the board from the same manufacturer as the CIO-EXP-GP. If your A/D

board is not from the same manufacturer but is compatible, please call technical support and request a

copy of InstaCal.

Use InstaCal's TEST option to verify that a signal present at one of the CIO-EXP-GP inputs can be read.

You will not need to set any jumpers other than those previously mentioned, and should not set any

switches or install any passive components until you have verified the installation.

When using an AC signal source, keep the frequency below 70Hz to avoid attenuation by the low pass

filter.

7

Page 12

4 CONFIGURATION FOR VOLTAGE MEASUREMENT

The CIO-EXP-GP is an amplification, signal conditioning and multiplexing accessory for DAS boards.

The inputs are suitable for connecting a low frequency voltage to the DAS board so it can be measured.

The CIO-EXP-GP is a one-of-eight multiplexer which means that for every channel in your DAS board,

you can multiplex eight different signals to it. You can expand the number of inputs of your DAS board

by eight for every CIO-EXP-GP board, up to the number of inputs on the DAS board. For example, a

DAS08 has 8 inputs. Eight times eight is sixty four. Using CIO-EXP-GP boards you can bring 64 inputs

into the PC with one DAS08 in one slot.

It is unlikely that you purchase a CIO-EXP-GP to measure voltages. The CIO-EXP-GP has a 70Hz low

pass filter and quite a bit of elaborate circuitry designed for bridges, TCs, and RTD sensors. For

applications requiring only voltage measurements, a CIO-EXP16 or CIO-EXP32 would be less expensive

and do the same job.

Possibly you have one or two voltages to measure in addition to bridge or RTD sensors and would like to

connect those signals to the CIO-EXP-GP.

4.1 Channel Selection

The General Configuration section describes the channel selection, setting the jumper and verifying the

installation and operation of the CIO-EXP-GP with your data acquisition board. Configure your boards

as described in that section before continuing with this section.

4.2 Powering the CIO-EXP-GP

The General Configuration section describes the power selection options, setting the power select switch

and verifying the installation and operation of the CIO-EXP-GP with your data acquisition board.

Configure your boards as described in that section before continuing with this section.

4.3 Determining The Appropriate Gain

To accurately measure a voltage, the full scale of the signal should be matched to the full range of the

input circuit. (Most DAS boards have an input range of ±5V, which is the native range of the analog to

digital converter at the heart of the board. Some DAS boards include amplification on the input circuit to

allow the signal to be amplified to make better use of the resolution of the A/D.) For example, an input

signal which varies between 0 and 1 volt would only be using 1/10th of a ±5V A/D converter's

resolution. By switching the input signal of the DAS board to unipolar (no negative voltage) and

amplifying the input signal by 5, the entire range of the A/D converter is used and a higher resolution

measurement may be made. By adding this gain and selecting this range, the resolution on a 12-bit A/D

improves from 2.4 millivolts per bit to 0.24 millivolts per bit. If you needed to measure a change of 1

millivolt, you would need an amplification of 10.

In order to match your signals with the input range of the A/D board, you should do a similar calculation

and set switches on the CIO-EXP-GP for the required gain. Remember to make sure that the settings in

InstaCal match the switches on the DAS and CIO-EXP-GP boards.

If you are measuring signals greater than the maximum full scale range of the A/D, see the section on

attenuation.

8

Page 13

To choose a switch-selectable amplification, here are the calculations you need to perform:

Divide the full range selected for the A/D board by the full range of the signal to be measured to

determine the maximum gain of the CIO-EXP board. For best resolution, use the highest gain possible

up to the calculated maximum gain.

For example, if the A/D board is to be used at a range of ±5V, the full range of the board is 10. If your

signal ranges between -0.5 volts and 0.5 volts, the full range of the signal is 1 volt. Divide 10 by 1 for a

result of 10. That is the maximum gain you can use.

If your signal is unipolar and ranges less than 0 to 5V, you would likely choose the 5V unipolar range for

the A/D board (if available). Given an input signal ranging from 0 to 0.5 volts, the full range of the

signal is 1/2 volt. Divide 5 (the full range of the A/D) by 0.5 (the full range of the signal for a result of

10. That is the maximum gain you can use.

4.4 Setting the Gain

Gain (amplification) allows you to boost your signal to take full advantage of the resolution of the A/D

converter. However, when amplifying a signal, any noise is amplified as well.

Amplification for ALL channels (board output gain) is switch selectable (S17) for X1 or X2.5.

Input amplification for EACH CHANNEL is switch selectable (GAIN switches CH0 through CH7) for

X1, X10, X100 or X1000. A user-specified gain may be set by supplying a precision resistor at position

RX### and setting the “U” option on the CH ## GAIN switch to ON.

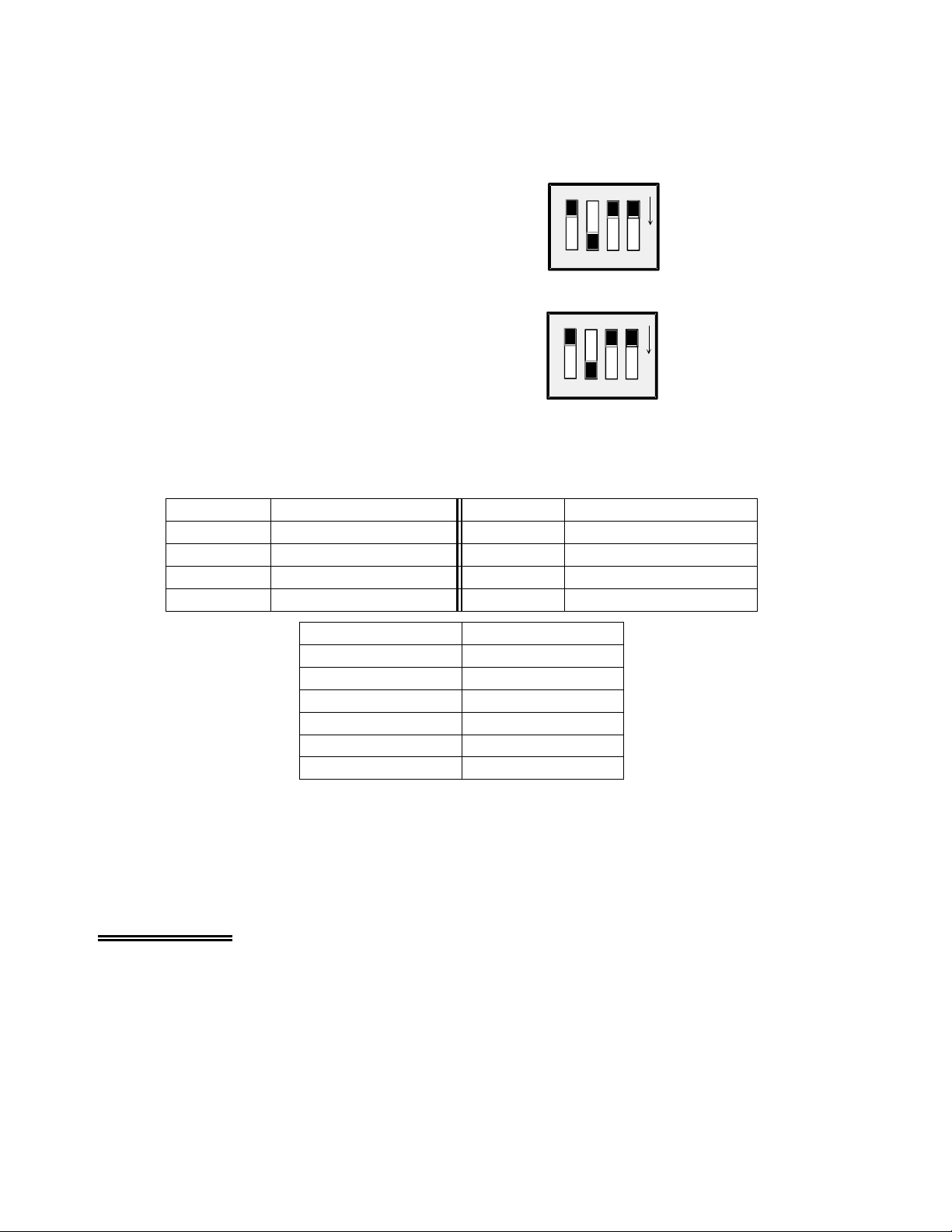

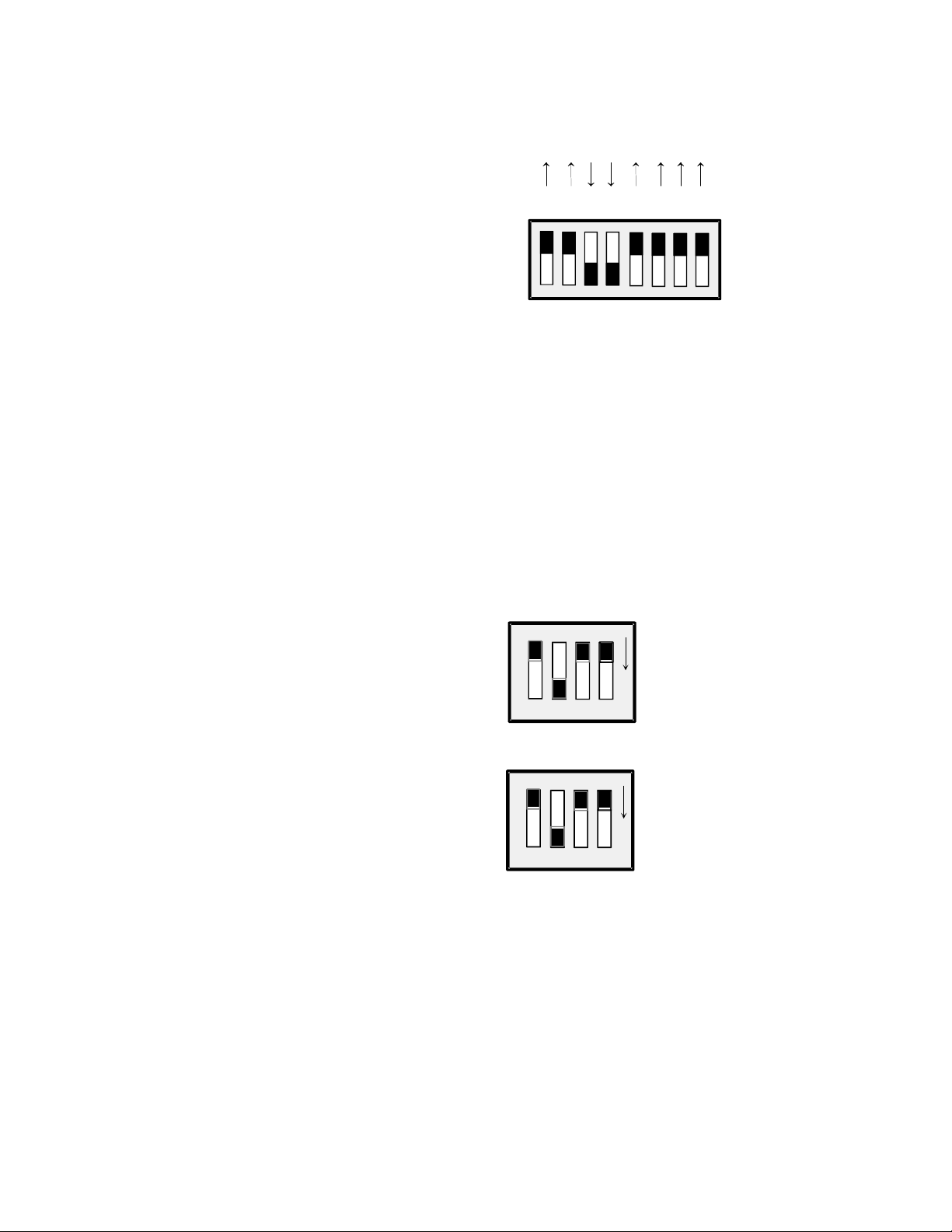

4.4.1 Setting Board Gain

There is a switch on DIP switch block S17

labeled X1 and X2.5. Sliding this switch down

amplifies the output of the multiplexers by 2.5.

The factory default position (up) has a gain of 1

(unity). Refer to Figure 4-1.

The X2.5 gain switch is useful in some voltage

and bridge measurements. If you desire a

voltage gain of 2.5, 25, 250 or 2500, set this

switch down.

Figure 4-1. Board Output Gain Switch Location

For voltage measurements, a gain of 2500 is very high and will reduce your signal to noise ratio.

The effect of this switch is multiplicative with respect to the individual channel gains. For example, if

you have set an input channel gain to X100 and the board output gain to X2.5, the signal is amplified by

250 before it reaches the A/D board.

GND

X1

X2.5

REM

S17

0.5V

1V

2V

4V

+5 COMP

10V

9

Page 14

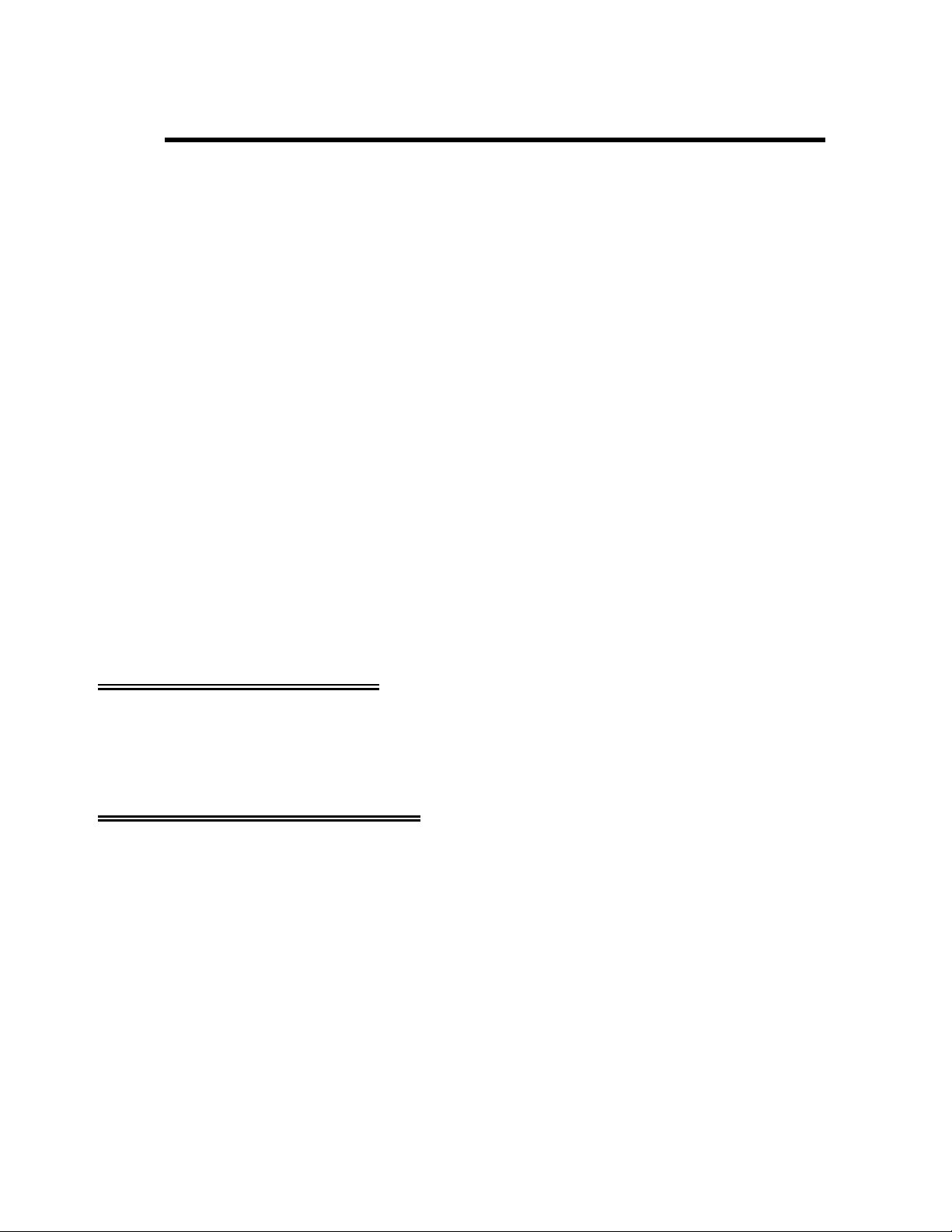

4.4.2 Setting Channel Gain

Select a gain (higher than unity) by moving the switch for

that gain down. All other switches should be left in the

UP position.

.

A custom gain may be selected on the CIO-EXP-GP by

installing a precision resistor and setting the switch

marked “U” (User) in the down position. See Table 4-1

following for board positions and some sample gain

values.

Figure 4-2. Input Channel Gain Select Switches

Table 4-1. Resistor Positions for User-Selected Gains

CH4

U

X10

CH0

Resistor PositionChannelResistor PositionChannel

X100

N

O

X1000

GAIN FOR CHANNELS 0 and 4

SET FOR A GAIN OF 10.

SLIDER DOWN SELECTS GAIN

ALL OTHERS TO BE OFF (UP)

N

O

RX1044RX1000

RX1055RX1011

RX1066RX1022

RX1077RX1033

Resistor ValueGain

776 Ohms50

364 Ohms100

161 Ohms200

40 Ohms500

17 Ohms700

10 Ohms800

The equation for selecting the USER gain resistor is:

= [40000 / (Gain − 1)] − 40

R

USER

Amplifying a signal on one channel will not affect the reading on another channel.

4.5 Attenuation

If your signal is in a range greater than the full scale range of the A/D, you must either set the A/D for a

higher full scale range (if available) or divide (attenuate) the signal until the result is less than or equal to

the A/D’s full scale range. This section describes signal attenuation.

10

Page 15

INPUT

A voltage divider is constructed from a pair of

precision resistors selected according to the

Ra

equation:

Volts In

OUT

Attenuation = (Ra + Rb) / Rb

See Figure 4-3 at right for the schematic of a

Rb

Volts Divided

voltage divider.

PC GROUND

PC GROUND

Figure 4-3. Voltage Divider

For example, if your signal is 0 to 10V, it must be attenuated to 5V max. for an attenuation of 2:1 or

simply 2.

Using 10k resistors: 2 = (10K + 10K) /10K.

For any attenuation, pick a suitable resistor for Rb. Then use this formula to calculate Ra:

Ra = (A−1) x Rb

You will need to construct the voltage divider remote from the CIO-EXP-GP board.

4.6 Setting the Input Configuration

Channel Configuration Switch - Voltages

A channel configuration switch is associated with each

channel (Figure 4-5). The switches are used to configure the

input circuits for voltage inputs, thermocouple inputs, 2, 3, or

4-wire RTDs and bridges.

For voltage measurements on a particular channel, set the

switches labeled “4” to the ON (

channel

.

down)

Set the switches labeled “3” in the OFF (

position for that

position

up)

.

4

IN CONFIG

4

N

O

3

4

3

3

4

3

N

O

CH0

CHANNEL CONFIGURATION SWITCHES SET

VOLTAGE, THERMOCOUPLES, OR 2/4-WIRE RTDs

BOTH 4s ARE ON (DOWN), BOTH 3s ARE OFF (UP)

Figure 4-5. Channel Configuration Switches

4.7 Connecting Voltage Signals

Voltage signals can be single ended or differential, and the full scale may have to be matched to the range

of the CIO-EXP-GP and DAS board combination via amplification or attenuation. To connect a voltage

and make an accurate measurement, each of these issues must be addressed (see section 4.3).

CH4

11

Page 16

SENSE

(

)

C

S

NS

Each input circuit has eight screw terminals associated

with it. These terminals are shown in Figure 4-4 to the

right.

SHORTING WIRE

−

VOLTS IN OR COMMON

+P EXCITATION. VOLTS

−EXCITATION CURRENT

+EXCITATION CURRENT

To connect a voltage signal to the input circuit you

+ VOLTS IN

need only use three screw terminals. These are:

INSTALLED

+ VOLTS IN

+SENSE Signal high, or CH HI on a DAS board

−

SENSE Signal low, or CH LO on a DAS board.

Must be jumpered to −P for single-ended

−

P Low Level Ground (LLGND)

−

+P

−

E

E

−

−

P

IEX

+ SENSE

+ SENSE

(+)IEXC

H

Figure 4-4. Input Screw Terminals

4.7.1 Single-Ended Inputs

A single-ended input has two wires connected to the CIO-EXP-GP; a signal high and a Low Level

Ground (LLGND). The LLGND signal

selected by installing a jumper between the signal low (−SENSE) and ground (−P). The -SENSE

terminal is then connected to the signal ground and the +SENSE terminal is connected to the signal.

must be the same ground the PC is on.

Single-ended mode is

4.7.2 Floating Differential

A floating differential input has two wires from the signal source and a 10K ground reference resistor

installed at the CIO-EXP-GP input. The two signals from the signal source are Signal High and Signal

Low. The reference resistor is connected between the CIO-EXP-GP “−SENSE” and “-P” pins and the

Signal Low is connected to the -SENSE terminal. The +SENSE terminal is connected to the Signal High.

A floating differential hookup is handy when the signal source is floating with respect to ground, such as

a battery. The floating differential input will reject up to 10V of EMI energy on the signal wires.

CAUTION: Is the signal source really floating? Check it with a voltmeter before risking the

CIO-EXP-GP and PC.

4.7.3 Fully Differential

A differential signal has three wires from the signal source. The signals are Signal High, Signal Low and

Signal Ground (LLGND). Signal High is connected to the +SENSE terminal and Signal Low is

connected to the -SENSE terminal. The ground reference must be connected to the -P terminal.

A differential connection allows you to connect the CIO-EXP-GP to a signal source with a ground that is

different than the PC ground, but less than 10V difference, and still make a true measurement of the

signal. For example, a laboratory instrument with its own wall plug. Sometimes there is a voltage

between wall outlet grounds.

12

Page 17

4.8 Verifying the Installation

To verify the installation, use the InstaCal program installed on your computer. This software came with

your A/D board if you bought the board from the same manufacturer as the CIO-EXP-GP. If your A/D

board is not from the same manufacturer but is compatible, please call technical support and request a

copy of InstaCal.

Use InstaCal's TEST option to verify that a signal present at one of the CIO-EXP-GP inputs can be read.

When using an AC signal source, keep the frequency below 70Hz to avoid attenuation by the low pass

filter.

13

Page 18

5 CONFIGURATION FOR THERMOCOUPLE MEASUREMENT

Thermocouples are temperature sensors constructed of wires of two dissimilar metals fused together at a

point. This junction of two metals produces a voltage that varies relative to temperature. Thermocouple

voltages require several manipulations in order to be useful. These are:

1. A very low voltage is produced and so must be amplified by a factor of between 100 and 1,000.

2. The voltage produced by the thermocouple is not linear with respect to temperature, so it must be

linearized. Linearization in this case is calculated by software after the voltage is acquired.

3. A voltage-producing junction is also created at the screw terminal where the thermocouple is

connected to the CIO-EXP-GP. The temperature at this “cold junction” must be measured and the

voltage calculated and subtracted from the total measured from the thermocouple. This is also calculated

by software. The circuit that measures this temperature is the Cold Junction Compensation (CJC) circuit.

4. Thermocouples are subject to EMI and RFI noise due to the very low level of the voltage and the large

amplification factor. These affects can be reduced through averaging and filtering. There is a 70Hz low

pass filter on the CIO-EXP-GP. Averaging may be done in software.

Thermocouples are not as accurate as RTDs or other precision temperature sensors, but they are much

less expensive. Sometimes, an attempt is made to make a measurement beyond the accuracy of the

thermocouple such as measuring 1/10th of a degree over the full scale. Read the accuracy and

repeatability specification of the thermocouple, and consider the effects of linearization on the reading

before choosing thermocouples.

The CIO-EXP-GP is not the optimum choice for thermocouple-only applications. The CIO-EXP32 and

EXP16 are less expensive and just as accurate for thermocouple measurements. The CIO-EXP-GP has

extra circuitry devoted to bridge and RTD sensors.

5.1 Selecting The Output Channel

The General Configuration section describes the channel selection, setting the jumper and verifying the

installation and operation of the CIO-EXP-GP with your data acquisition board. Configure your boards

as described in that section before continuing with this section.

5.2 Selecting The CJC Output Channel

There is a set of jumpers near the 37-pin connectors labeled “CJC SEL”, which stands for cold junction

compensation select. These jumpers connect the on-board measurement of the cold junction temperature

to one of the A/D board channels for use in temperature calculations.

The CJC temperature reference is universally used by software to compensate for the voltage induced at

the cold junction (the screw terminal). The software package you are using will determine which channel

you need to set this jumper on. The default is channel 7 (the channel used by default by the Universal

Library). If you are not using the Universal Library, check your software documentation before selecting

a channel. Failure to supply the CJC reference by installing the jumper on the correct channel will result

in inaccurate temperature calculations by the software.

14

Page 19

The jumper for the CJC channel select (Figure 5-1)

CH4

C

0

1234567

89

10 11 12 14 15

13

looks just like the jumper for output channel

selection.

Set this jumper according to the instructions for the

software package you are using.

CJC SEL

CHANNE L 4 SELECTED

FOR COLD JUNCTION SENSOR OUTPUT

Figure 5-1. CJC Channel Select Jumper Pad

The CJC uses one analog input channel of the A/D board. The channel selected must be unique (the CJC

SEL jumper must not be set to the same number as that for CH SEL jumper or VEXC SEL jumper on this

board or any other EXP board that may be daisy-chained to this board).

5.3 Input Configuration

For thermocouple measurement, the channel input configuration switches must be set for two wire

measurement. Also, a ground reference should be established and open thermocouple detection should

be enabled. These options are selected by setting some switches and closing some solder pads on the

underside of the CIO-EXP-GP.

5.3.1 Setting the Input Configuration

A channel configuration switch is associated with each

channel. The switch is used to configure the input circuit

for two or four wire measurements. When measuring

thermocouples, two wire measurement should be used.

Set the two switches labeled “4” on each IN CONFIG

Channel Configuration switch to the ON (

down)

position for

each channel used for thermocouple measurement. (See

Figure 5-2 on the right.)

4

IN CONFIG

4

N

O

3

4

3

3

4

3

Set the two switches labeled “3” on each IN CONFIG switch

for thermocouple channels to the OFF (up) position.

N

O

CH0

HANNEL CONFIGURATION SWITCH SET FOR THERMOCOUPLES

BOTH 4s ARE ON (DOWN), BOTH 3s ARE OFF (UP)

Figure 5-2. Channel Configuration Switches

5.3.2 Enabling Open Thermocouple Detection (OTD)

Open thermocouple detection (OTD) is enabled for a channel by installing a resistor and closing the 'TC'

pad with a solder bridge (see Figures 5-3 and 5-4). There are locations marked “TC” for each channel for

this purpose.

OTD provides the high side of the thermocouple signal with a reference to −50mVDC at very low

current. If a thermocouple opens, it ceases to produce a voltage. If that happens, the OTD voltage drives

the signal on that channel to full minus. Most software is set up to alarm for an open thermocouple when

a temperature falls to full scale minus value. The CIO-EXP-GP will accurately measure thermocouples

without the 'TC' pad closed but you must close it and install a 100K resistor to have OTD.

15

Page 20

Table 5-1. 100K ohm Resistors to be Installed for OTD:

RX41Channel 6RX 29Channel 4RX 17Channel 2RX 5Channel 0

RX47Channel 7RX 35Channel 5RX 23Channel 3RX11Channel 1

Please solder the pads with the solder provided. It has a water soluble flux which should be washed off.

If you use another type of solder or do not wash off the flux it may affect your readings.

EXCITATION VOLAGE (+)

EXCITATION. VOLTS (+)

- THERMOCOUPLE LEAD

EXCITATION CURRENT (-)

+ THERMOCOUPLE LEAD

EXCITATION CURRENT (+)

SENSE LOW (-)

SENSE LOW (-)

EXCITATION VOLTS (-)

SENSE HIGH (+)

SENSE HIGH (+)

80Hz Low

Pass Filter

10K

GAIN SW

AMP

100K

TO CHANNEL

MULTIPLEXOR

-TC PULL

50 mV

GND REF

Figure 5-3. OTD and Ground Reference Jumper Pads - Schematic

NOTE: If you want to change the use of the input circuit to an RTD or bridge sensor, remove the solder

that closes the TC pad (and the G pad also).

Figure 5-4. OTD and Ground Reference Jumper Pads - Locations (Typ.)

16

Page 21

5.3.3 Adding a Ground Reference

p

The CIO-EXP-GP inputs are fully differential which helps reject noise on thermocouple wires. If

thermocouples connected to the CIO-EXP-GP inputs are to work properly, the 'G' pad must be closed on

any channel used for thermocouple measurement (see Figures 5-3 and 5-4). The 'G' pad provides a

reference from ground to the analog low input via a 10K resistor. Only enough current passes through

the resistor to provide a reference to ground. The analog high and low inputs are still able to float within

the common mode range.

NOTE: If you want to change the use of the input circuit to an RTD or bridge sensor, remove the solder

that closes the G pad (and the TC pad also).

5.4 Determining the Appropriate Gain

The voltage from a thermocouple must be amplified in order to take advantage of the A/D board's full

resolution. Without amplification, you would not get much resolution from thermocouples, as you can

see in the tables below. Typical gain settings for use with thermocouples are between X10 and X250.

Tables 5-3 and 5-4 below may be used to help determine the appropriate gain to use for the temperature

range and thermocouple type in use.

Table 5-3. Resolution vs Thermocouple Gain Settings for a ±5V, 12 bit A/D

Type

µV/°C

40T

62E

−200

−200

Max °CMin °COutput

°C/bit

@X10

°C/bit

@X100

°C/bit

@X250

°C/bit

@X1000

0.040.190.484.78750051J

0.060.240.616.11,250-20040K

0.060.240.616.1350

0.030.160.393900

0.351.43.4934.91,45007S

0.351.43.4934.91,45007R

A J-type thermocouple outputs 51mV per degree centigrade at 20°C. At a gain of 100, a 12 bit A/D on

the ±5V range resolves to 0.00002442 volts per bit (24.42µV/bit). With an output of 51mV/°C, that

represents about 0.5°C/bit. Look under the gain of 100 for a J-type and you will find 0.48°C/bit.

The table below shows the thermocouple output voltage at maximum temperature amplified by four

possible gain values. Where the output voltage exceeds 5V, the reading is clipped.

Table 5-4. Voltage Output @ Maximum Temperature

Type

@Max

Tem

0.511,25050.6mVK

0.6990068.8E

17

Vout at Max TempMax °COutput

X1000X250X100X10

4.20.4275042.3mVJ

4.51.80.1835017.8mVT

3.81.50.151,45015mVS

4.21.70.171,45016.7R

4210.6

5112.75.1

18

6917.26.9

15

17

Page 22

Voltages which exceed the ±5V range are in bold italics in the table above. Table 5-5 shows the

temperature at which the reading is clipped (the maximum readable temperature for thermocouple types

at a given gain).

Table 5-5. Maximum Readable Temperatures with A/D on ±5V Range

Max readable temp vs GainMax °CType

X1000X250X100X10

95°C366°C750 °C750°C750J

121°C484°C1,232°C1,250°C1,250K

115°C350°C350°C350°C350T

80°C287°C660°C900°C900E

576°C1,450°C1,450°C1,450°C1,450S

548°C1,450°C1,450°C1,450°C1,450R

From these tables, you can determine that if you want to use a J-type thermocouple to make a reading of

700 degrees, the gain should be set at 100. This yields a resolution of 0.48 degrees C per bit.

5.5 Setting the Gain

Once you have determined the gain required for your application, set the gain of the CIO-EXP-GP using

the following guide.

Amplification for ALL channels (board output gain) is switch selectable (S17) for X1 or X2.5.

Input amplification for EACH CHANNEL is switch selectable (CH0 through CH7) for X1, X10, X100 or

X1000. A user-specified gain may be set by supplying a precision resistor at position RX### and setting

the “U” option on switch CH ## to ON.

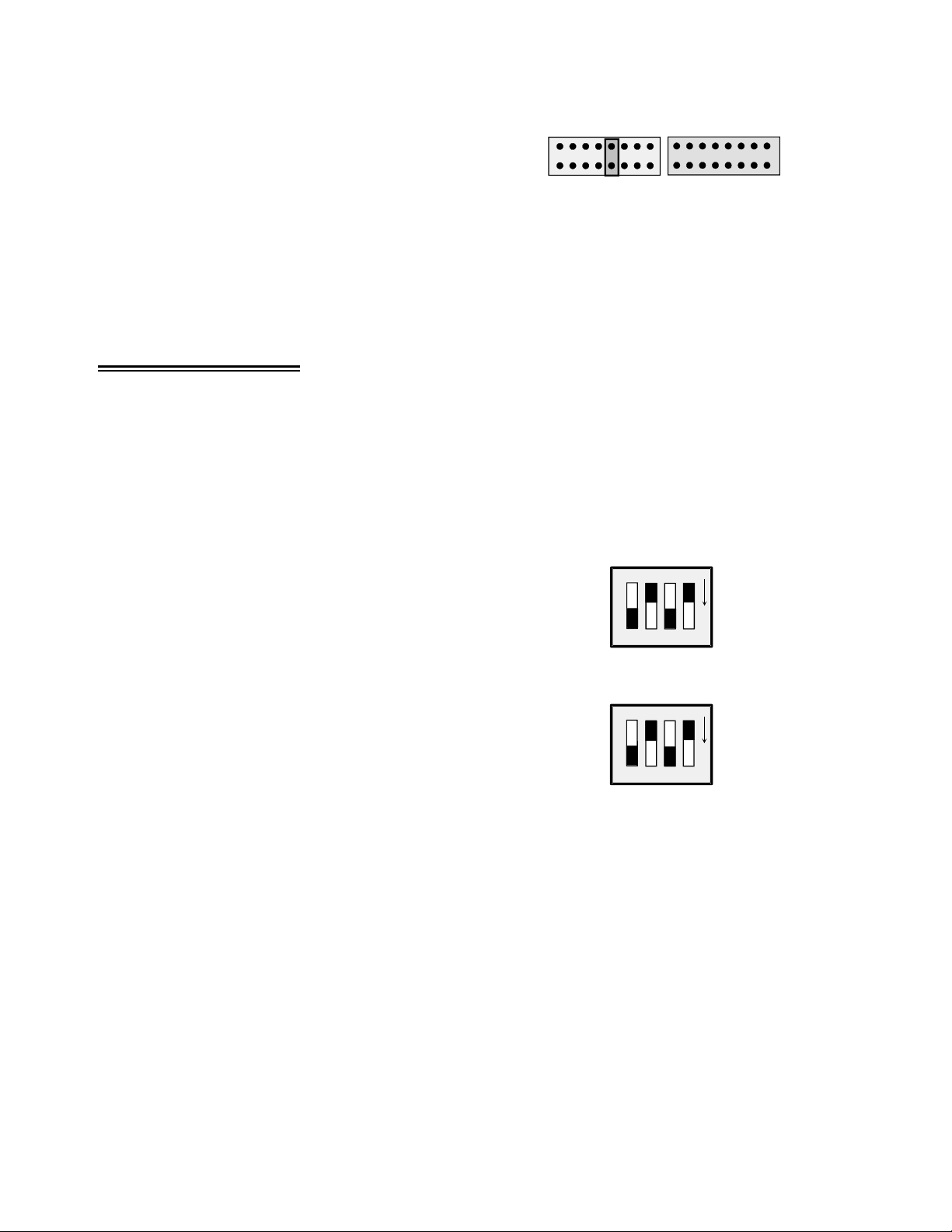

5.5.1 Setting the Board Gain

Output Gain Switch

There is a switch on DIP switch block S17 (Figure 5-5) labeled

X1 and X2.5. Sliding this switch down amplifies the output of

the multiplexers by 2.5. The factory default position (up) has a

gain of 1 (unity).

The X2.5 gain switch is useful in some thermocouple

measurements. If you desire a voltage gain of 2.5, 25 or 250, set

this switch down. Recommended gains for thermocouples are

between X10 and X200.

Figure 5-5. Output Gain Switch Location

The effect of this switch is multiplicative with respect to the individual channel gains. For example, if

you have set an input channel gain to X100 and the board output gain to X2.5, the signal is amplified by

250 before it reaches the A/D board.

REM

X1

S17

0.5V

1V

2V

4V

+5 COMP

10V

X2.5

GND

5.5.2 Setting the Channel Gain

18

Page 23

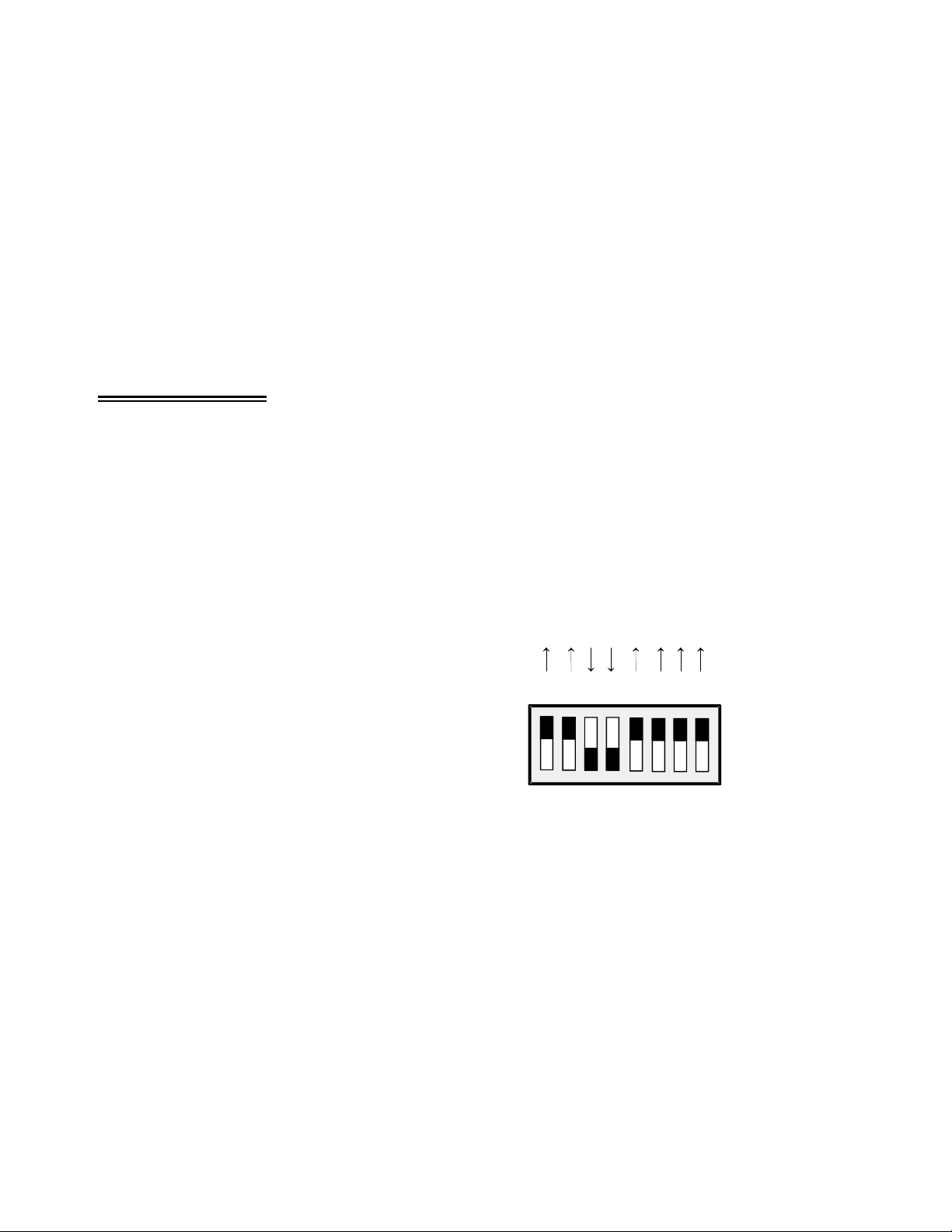

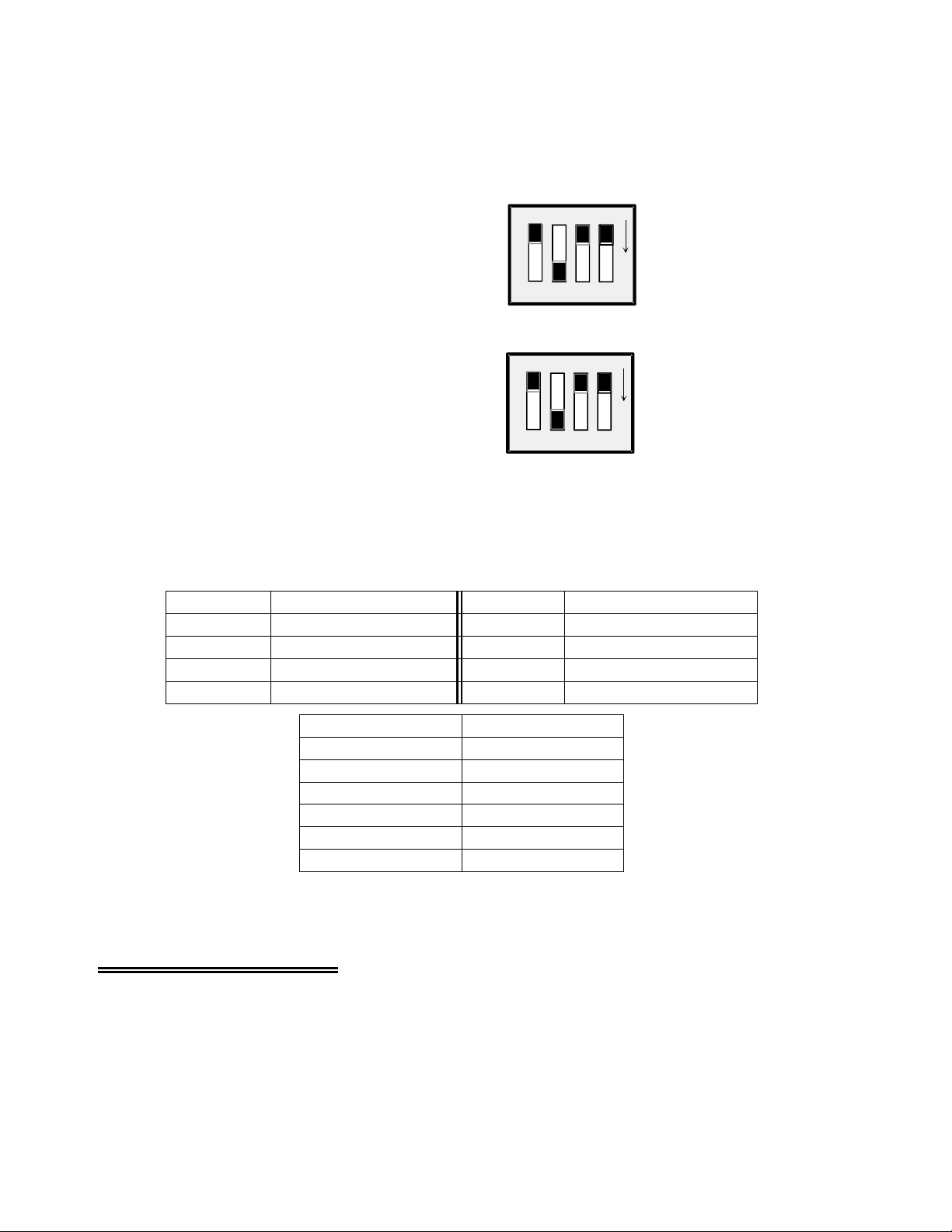

There is a gain switch for each channel (Figure 5-6). Set the input channel gain to match the expected

voltage output of the bridge you are measuring to the input range of the A/D board as described above.

Channel Gain Switches

There is a set of DIP gain switches for each input

circuit labeled GAIN (Figure 5-6). There are four,

two-position switches for each channel. The gain

switches are labeled U, X10, X100, and X1000.

Select a gain (higher than unity) by moving the

switch for that gain down. All other switches should

be left in the UP position.

A custom gain may be selected on the CIO-EXP-GP

by installing a precision resistor and setting the

switch marked “U” (User) in the down position. See

Table 5-2 below for positions and some sample gain

values.

CH4

U

X10

N

O

X1000

X100

GAIN FOR CHANNELS 0 and 4

SET FOR A GAIN OF 10.

SLIDER DOWN SELECTS GAIN

ALL OTHERS TO BE OFF (UP)

N

O

CH0

Figure 5-6. Channel Gain Switches

Table 5-2. User Gain Resistors - Identities

Resistor PositionChannelResistor PositionChannel

RX1044RX1000

RX1055RX1011

RX1066RX1022

RX1077RX1033

Resistor ValueGain

776 Ohms50

364 Ohms100

161 Ohms200

40 Ohms500

17 Ohms700

10 Ohms800

The equation for selecting the gain resistor is:

= (40000 / (Gain − 1) ) − 40

R

USER

5.6 Verifying the Installation

Your channel is now configured to make thermocouple measurements. To verify the installation, use the

InstaCal program installed on your computer. This software came with your A/D board if you bought the

board from the same manufacturer as the CIO-EXP-GP. Use the CALIBRATE option to calibrate the

CJC and verify the operation of the channel. Use the TEST option to make a measurement in

engineering units.

19

Page 24

6 CONFIGURATION FOR RTD MEASUREMENTS

An RTD is a temperature sensor that consist of a resistive element, usually a length of wire encased in a

sheath. Various wire materials are used with platinum being the most common. There are three types of

hookups: two-wire, three-wire, and four-wire. An excellent source of information on RTDs and how to

select one for your application may be found in the OMEGA Engineering catalog.

6.1 Channel Selection

The General Configuration section describes the channel selection, setting the jumper and verifying the

installation and operation of the CIO-EXP-GP with your data acquisition board. Configure your boards

as described in that section before continuing with this section.

6.2 VEXC JUMPER Select

There is a set of jumpers near the 37-pin connectors labeled “VEXC SEL”, which stands for channel

excitation voltage select. These jumpers connect the on-board excitation voltage to one of the A/D board

channels so that it may be measured. Measurement Computing Corp. does not use a measurement of the

excitation voltage in any of its software. You do not need to set this jumper if you are using the

CIO-EXP-GP with Measurement Computing Corp. software, or with packages such as Labtech Notebook

which use the Universal Library. Use this jumper only with software from other manufacturers that

specifically require it.

6.3 CJC Jumper Selection

There is a set of jumpers near the 37 pin connector labeled “CJC SEL”, which stands for cold junction

compensation select. Remove this jumper. There is no cold junction compensation used with bridge

sensors.

6.4 Powering the CIO-EXP-GP

The General Configuration section describes the power selection options for powering the CIO-EXP-GP

itself. Configure your boards as described in Powering the CIO-EXP-GP in the General Configuration

section before continuing with this section.

6.5 Determining the Appropriate Gain

To accurately measure a voltage, the full scale of the signal should be matched to the full range of the

input circuit. (Most DAS boards have an input range of ±5V, which is the native range of the analog to

digital converter at the heart of the board. Some DAS boards include amplification on the input circuit to

allow the signal to be amplified to make better use of the resolution of the A/D.) For example, an input

signal which varies between 0 and 1 volt would only be using 1/10th of a ±5V A/D converter's

resolution. By switching the input signal of the DAS board to unipolar (no negative voltage) and

amplifying the sign wave signal by 5, the entire range of the A/D converter is used and a higher

resolution measurement may be made. By adding this gain and selecting this range, the resolution on a

20

Page 25

12-bit A/D improves from 2.4 millivolts per bit to 0.24 millivolts per bit. If you needed to measure a

change of 1 millivolt, you would need an amplification of 10.

In order to match your signals with the input range of the A/D board, you should do a similar calculation

and set switches on the CIO-EXP-GP for the required gain. Remember to make sure that the settings in

InstaCal match the switches on the DAS and CIO-EXP-GP boards.

When using RTD’s, the expected output from the sensor should be calculated and the gain of the

CIO-EXP-GP set accordingly.

To select the best gain for RTD type, base resistance and temperature range, consider that RTD

resistance changes with temperature, but the magnitude of the change also changes with temperature.

RTD type determines the ‘slope’ of the ohms vs. temperature curve. The most popular type has an

‘alpha’ of .00385, known as the European standard. Its value is .00385 ohms per ohm per °C.

The Universal Library and InstaCal support six different RTD types. Please call if you do not see the

RTD you are interested in listed here.

Material

‘alpha’

Platinum 0.00392 American standard

Platinum 0.00391

Platinum 0.00385 European standard (Most popular, OMEGA’s standard also)

Copper 0.00427

Nickel/Iron 0.00581

Nickel/Iron 0.00527

To determine which gain to use, you must know the maximum temperature the RTD will be used to

measure, and thus the maximum resistance value of the RTD. Here is a table for platinum:

For 100 ohm RTD, alpha = .00385:

Temp (°C

) Resistance (ohms)

-200 18.49

-100 60.25

0 100.00

100 138.50

200 175.84

300 212.02

400 247.04

At a temperature of 400°C, the maximum resistance is 247.04 ohms

The equation for the voltage out of the CIO-EXP-GP (the voltage your DAS board will convert into a

number) is:

= I

V

OUT

EXC

* R

* GAIN

RTD

Normally, the CIO-EXP-GP supplies 1 mA of excitation current. The choices for standard gains are 1,

10, 25 and 100. (Higher gains are possible but are not generally practical for RTD applications.)

Thus, if you want to measure temperature in the range of -200 to 400°C with the RTD listed above, the

maximum voltage output would be:

V = 0.001 * 247.04 = 0.24704

21

Page 26

If gain is set to X10, the DAS board will see 2.474 volts. This is ideal for a DAS board with a 2.5V

unipolar range.

If the gain were set to X25, the output would be 6.185 volts. The DAS board would have to be set in the

0 to 10 volt range.

If you are limiting your range of interest to -200 to 100°C, a common range, the calculations are:

V = 0.001 * 138.50 = 0.1385. Gain of 10 = 1.385V. Gain of 25 = 3.4625V. In this case, a gain of X25

and a DAS range of 0 to 10 volts would be best. A 12-bit A/D converter would be using 69% of its range

of 4096 counts, or a total of 2836 counts. The converter would be able to resolve to 0.035 degrees C.

That is more than enough converter resolution even though you are not using the full range of the DAS

board in this example.

If your DAS board has 16 bits of resolution, the DAS board would resolve to 0.0022 degrees. This is far

in excess of the accuracy of the RTD.

The stages of gain you choose are not only dependent on the RTD you choose, but on the range of

temperature you are measuring. Use the equation above to fine tune the CIO-EXP-GP circuit to your

advantage, then be sure to update the InstaCal program so the Universal Library linearization routines

will operate properly.

6.6 Setting the Gain

Once you have determined the gain required for your application, set the gain of the CIO-EXP-GP using

the following guide.

Amplification for ALL channels (board output gain) is switch selectable (S17) for X1 or X2.5.

Input amplification for EACH CHANNEL is switch selectable (CH0 through CH7) for X1, X10, X100 or

X1000. A user-specified gain may be set by supplying a precision resistor at position RX### and setting

the “U” option on switch CH ## to ON.

6.6.1 Setting the Board Gain

There is a switch on DIP switch block S17

(Figure 6-1) labeled X1 and X2.5. Sliding this

switch down amplifies the output of the

multiplexers by 2.5. The factory default

position (up) has a gain of 1 (unity).

The X2.5 gain switch is useful in some voltage

and bridge measurements. If you desire a

voltage gain of 2.5, 25, 250 or 2500, set this

switch down.

The effect of this switch is multiplicative with respect to the individual channel gains. For example, if

you have set an input channel gain to X10 and the board output gain to X2.5, the signal is amplified by

25 before it reaches the A/D board.

REM

X1

1V

2V

4V

+5 COMP

10V

X2.5

GND

Figure 6-1. Board Gain

S17

0.5V

22

Page 27

6.6.2 Setting the Channel Gain

Channel Gain Switches

There is a set of gain switches for each input circuit

(Figure 6-2). There are two, 4-switch DIP blocks for

each channel. One is labeled “GAIN” and the other “IN

CONFIG”. The gain switches are labeled U (user), 10,

100, and 1000.

Set the gain of your choice by placing a slide switch into

the ON (down) position.

The “U” switch and associated user resistor is of no

value to RTD measurement since the minimum specified

value produces a gain of X100, for which there is a

switch. A gain of X100 is the maximum you would use

with an RTD.

CH4

N

O

U

X10

X1000

X100

GAIN FOR CHANNELS 0 and 4

SET FOR A GAIN OF 10.

SLIDER DOWN SELECTS GAIN

ALL OTHERS TO BE OFF (UP)

N

O

CH0

Figure 6-2. Channel Gain Switches

6.7 Input Configuration

RTDs may have 2, 3 or 4 wires coming from the probe. A switch labeled “IN CONFIG” must be set to

match the number of wires on your RTD. There is one switch per channel.

RTD Type

IN CONFIG Setting

2 Wire 4 & 4 ON, 3 & 3 OFF

3 Wire 3 & 3 ON, 4 & 4 OFF

4 Wire 4 & 4 ON, 3 & 3 OFF

6.7.1 Setting the Input Configuration

A channel configuration switch is associated with

each channel. The switch is used to configure the

input circuit for 2, 3, or 4-wire RTDs (Figure 6-2).

Two- and four-wire RTDs share the same switch

position. Set both “4” switches ON (down) and

both “3” switches OFF (up).

For three-wire RTDs, set both “3” switches ON

(down) and both “4” switches OFF (up).

IN CONFIG

3

4

3

4

N

O

CH0

SET FOR 2- AND 4-WIRE RTDs SET FOR 3-WIRE RTDs

IN CONFIG

3

4

3

4

N

O

CH0

Figure 6-2. Channel Configuration Switches - RTDs

23

Page 28

6.8 Connecting RTDs To Screw Terminals

The connections made to the screw terminal depend on the type of RTD you are using. The inputs of the

CIO-EXP-GP are designed to provide the excitation and signal conditioning required for RTDs. An RTD

can have two, three, or four wires which you must connect to the CIO-EXP-GP. This section shows the

three types of RTD connections and describes how to connect them to the input channels.

6.8.1 Two-Wire RTD Hookup

A two wire RTD has two leads, one to each side of the temperature sensitive resistor. The excitation

current is connected directly to the leads at the CIO-EXP-GP screw terminals.

A two wire RTD is less accurate than the 4 wire

type, and so is not the first choice for the best

measurements. The reason for the inaccuracy is

that there is a slight resistance associated with the

excitation current flowing in the sense leads and

this resistance is added to the RTD’s resistance.

The inaccuracy is determined by the wire gauge

and length. However, as a general rule, the

difference in accuracy between the 2- and 4-wire

RTDs is often less than 0.1% of full scale.

2 WIRE

RTD

Shorting Wires

Between Terminals

CIO-EXP-GP BOARD

EXCITATION CURRENT (+)

SENSE HIGH (+)

SENSE LOW (-)

EXCITATION CURRENT (-)

Figure 6-3. Two-wire RTD Hookup

6.8.2 Three-Wire RTD Hookup

A three wire RTD has three leads, one for each side of the temperature sensitive resistor and one for the

excitation current.

The current return and sense signals of one side

are shared. In the case of the EXP-GP the shared

signals are unconventional. The CIO-EXP-GP is

a true clone of the original EXP-GP, and shares

the unconventional circuit configuration, which

3 WIRE

RTD

Note: EXP-GP uses non-standard

3 wire RTD hookup

EXCITATION CURRENT (+)

SENSE HIGH (+)

is corrected on the CIO-EXP-RTD. The

unconventional configuration does not affect the

quality of the measurement but, if you are

familiar with RTDs and use a standard

SENSE LOW (-)

EXCITATION CURRENT (-)

connection, please be mindful of this difference.

Figure 6-4. Three-Wire RTD Hookup

6.8.3 Four-Wire RTD Hookup

A four wire RTD has four leads. One to each side of the temperature sensitive resistor and an excitation

current source and its return.

24

Page 29

These connections eliminate the fixed inaccuracy

associated with the 2-wire RTD. Since virtually no

current flows on the sense lines, there is no voltage

drop in the sense lines. Thus, the error associated with

2-wire RTDs is eliminated. We recommend the 4-wire

RTD, but you must judge if the added cost is worth the

additional accuracy.

4 WIRE

RTD

EXCITATION CURRENT (+)

SENSE HIGH (+)

SENSE LOW (-)

EXCITATION CURRENT (-)

Figure 6-5. Four-Wire RTD Hookup

6.9 Verifying the Installation

To verify the installation, use the InstaCal program installed on your computer. This software came with

your A/D board if you bought the board from the same manufacturer as the CIO-EXP-GP. If your A/D

board is not from the same manufacturer but is compatible, please call technical support and request a

copy of InstaCal.

Use InstaCal's TEST option to verify that a signal present at one of the CIO-EXP-GP inputs can be read.

25

Page 30

7 CONFIGURATION FOR RESISTANCE MEASUREMENTS

Resistance measurements are made using the CIO-EXP-GP by constructing a resistor “bridge” containing

known resistor values that are to be compared to the resistor value to be measured. This is known as a

Wheatstone Bridge. The typical application is a strain gauge.

Strain gauge sensors are variable-resistance devices. When installed in one leg of the resistor bridge (as

the “unknown” resistor, their value can be measured. The Wheatstone Bridge circuit is extremely

sensitive to changes in resistance in one leg relative to the others. There are various types of bridge

sensors, but the descriptions and examples here are for strain gauges.

7.1 Channel Select

The General Configuration section describes the channel selection, setting the jumper and verifying the

installation and operation of the CIO-EXP-GP with your data acquisition board. Configure your boards

as described in that section before continuing with this section.

7.2 VEXC Jumper Select

There is a set of jumpers near the 37 pin connector labeled “VEXC SEL”, which stands for channel

excitation voltage select. This jumper will connect the on board excitation voltage to one of the A/D

board channels so that it can be measured. Measurement Computing Corp. does not use a measurement

of the excitation voltage in any of its software. You do not need to set this jumper if you are using the

board with Measurement Computing Corp. software, or with packages such as Labtech Notebook which

use the Universal Library. Use this jumper only with software from other manufacturers that specifically

require it.

7.3 CJC Jumper Select

There is a set of jumpers near the 37 pin connector labeled “CJC SEL”, which stands for cold junction

compensation select. Remove this jumper. There is no cold junction compensation used with bridge

sensors.

7.4 Powering the CIO-EXP-GP

There are two power issues to address. The first is the source of the 5 volt power to the board. The

second is the source of the bridge excitation voltage power.

7.4.1 Selecting the Power Source for the Board

The General Configuration section describes the power selection options for powering the CIO-EXP-GP

itself. Configure your boards as described in Powering the CIO-EXP-GP in the General Configuration

section before continuing with this section.

7.4.2 Selecting the Power Source for the Excitation Voltage

Bridge sensors consume a lot of power. In some cases the bridge sensors consume so much power that if

fully populated with eight sensors the on board excitation circuit would not have adequate power to

26

Page 31

supply all eight sensors. This is an extreme case but is indicative of the attention you must pay to power

requirements when using bridge sensors.

Also, when selecting the power source for the excitation voltage, consider the voltage you will use for

excitation. The options available are 0.5, 1, 2, 4 and 10V. In general, higher excitation voltages are

better because a higher voltage increases the difference between the balance points of the bridge circuit,

which increases the accuracy of your measurement. The excitation voltage must be less than the source.

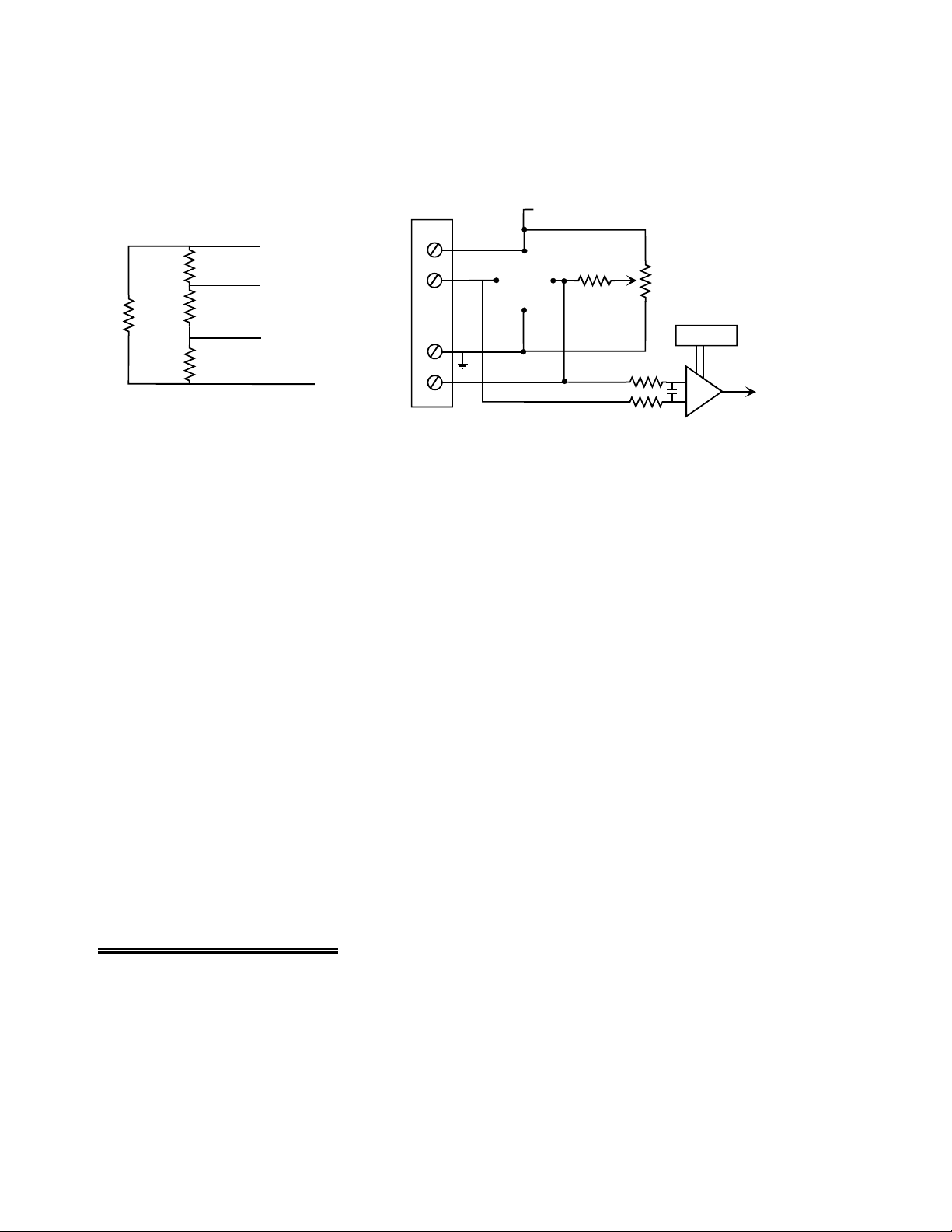

Jumper JB11 (Figure 7-1), located near the bottom edge of the board,

JB11

selects the source of the bridge excitation voltage. The three choices are

+P EXT

+12V

+5V (the same 5V source chosen for board power above), +12V (from the

+5V

PC through the 37 pin connector) or +PEXT (an external power supply

connected at the ±P EXT screw terminal).

Figure 7-1

Output Gain & Power Select

If you choose a separate power supply, it must be a floating, isolated supply (one with three terminals).

Do not tie the GND and −V terminal together. It must not exceed +15V.

The +5V and +12V jumpers are only valid with CIO-DAS08 family boards. The +12V jumper is not

valid with the CIO-DAS08-AO and -PGx. For more information on excitation voltages, refer to the

section on bridge sensors.

+5V Excitation Voltage Source

If your choice for the excitation voltage source is +5V, you may choose a 0.5V, 1V, 2V or 4V excitation

voltage for your bridge sensors. The +5V option is always available, since +5V is required to power the

CIO-EXP-GP.

+12V Excitation Voltage Source

If your choice for the excitation voltage source is +12V PC power, you have the choice of 0.5, 1, 2, 4, or

10 volt excitation for your bridge sensors. The option to power from the PC 12 volt supply exists only

with DAS08 family boards, except that +12V is not valid with the CIO-DAS08-AO or PGA.

+PEXT Excitation Voltage Source

An external power supply can be used. If you choose a separate power supply, it must be a floating, or

isolated supply (one with three terminals). Do not tie the GND and -V ter minal togethe r). Output voltage

must not exceed +15V. If your power supply is not floating, it is likely that you will create a ground loop

(current flow in the ground lines). A ground loop will induce an error in your reading. Connect the

power supply to the CIO-EXP-GP at the terminals labeled −PEXT and +PEXT on the screw terminal

block located adjacent to the 37-pin connector, P2.

27

Page 32

7.4.3 Selecting the Excitation Voltage

DIP switch S17 has five switches to select bridge

excitation voltage. Only set one ON. All others must

be OFF.

X1

REM

Figure 7-2 shows the switch and the excitation power

source jumper set for the factory defaults. Excitation

is set for 10V ON. Power source must be set to +12V

S17

(as shown in Figure 7-1) or +PEXT.

Do not select an excitation voltage at the switch that

+5 COMP

X2.5

GND

4V

10V

0.5V

1V

2V

exceeds the excitation power supply voltage.

Figure 7-2. Excitation Voltage Select Switches

7.5 Determining the Appropriate Gain

To accurately measure a voltage, the full scale of the signal should be matched to the full range of the

input circuit. (Most DAS boards have an input range of ±5V, which is the native range of the analog to

digital converter at the heart of the board. Some DAS boards include amplification on the input circuit to

allow the signal to be amplified to make better use of the resolution of the A/D.) For example, an input

signal which varies between 0 and 1 volt would only be using 1/10th of a ±5V A/D converter's

resolution. By switching the input signal of the DAS board to unipolar (no negative voltage) and

amplifying the sign wave signal by 5, the entire range of the A/D converter is used and a higher

resolution measurement may be made. By adding this gain and selecting this range, the resolution on a

12-bit A/D improves from 2.4 millivolts per bit to 0.24 millivolts per bit. If you needed to measure a

change of 1 millivolt, you would need an amplification of 10.

In order to match your signals with the input range of the A/D board, you should do a similar calculation

and set switches on the CIO-EXP-GP for the required gain. Remember to make sure that the settings in

InstaCal match the switches on the DAS and CIO-EXP-GP boards.

When using strain gauges, the expected output from the sensor should be calculated and the gain of the

CIO-EXP-GP set accordingly. There are some examples at the end of this chapter detailing these

calculations. You may also find it helpful to refer to the Appendix for additional strain gauge

information.

7.6 Setting the Gain

Once you have determined the gain required for your application, set the gain of the CIO-EXP-GP using

the following guide.

Amplification for ALL channels (board output gain) is switch selectable (S17) for X1 or X2.5.