Page 1

CIO-DAS-TEMP

Temperature Input Board

User’s Guide

Revision 4, November, 2000

© Copyright 2000

Page 2

Your new Measurement Computing product comes with a fantastic extra —

Management committed to your satisfaction!

Thank you for choosing a Measurement Computing product—and congratulations! You own the finest, and you can now enjoy

the protection of the most comprehensive warranties and unmatched phone tech support. It’s the embodiment of our mission:

To provide data acquisition hardware and software that will save time and save money.

Simple installations minimize the time between setting up your system and actually making measurements. We offer quick and

simple access to outstanding live FREE technical support to help integrate MCC products into a DAQ system.

Limited Lifetime Warranty: Most MCC products are covered by a limited lifetime warranty against defects in materials or

workmanship for the life of the product, to the original purchaser, unless otherwise noted. Any products found to be defective in

material or workmanship will be repaired, replaced with same or similar device, or refunded at MCC’s discretion. For specific

information, please refer to the terms and conditions of sale.

Harsh Environment Program: Any Measurement Computing product that is damaged due to misuse, or any reason, may be

eligible for replacement with the same or similar device for 50% of the current list price. I/O boards face some harsh

environments, some harsher than the boards are designed to withstand. Contact MCC to determine your product’s eligibility for

this program.

30 Day Money-Back Guarantee: Any Measurement Computing Corporation product may be returned within 30 days of

purchase for a full refund of the price paid for the product being returned. If you are not satisfied, or chose the wrong product by

mistake, you do not have to keep it.

These warranties are in lieu of all other warranties, expressed or implied, including any implied warranty of merchantability or

fitness for a particular application. The remedies provided herein are the buyer’s sole and exclusive remedies. Neither

Measurement Computing Corporation, nor its employees shall be liable for any direct or indirect, special, incidental or

consequential damage arising from the use of its products, even if Measurement Computing Corporation has been notified in

advance of the possibility of such damages.

Trademark and Copyright Information

Measurement Computing Corporation, InstaCal, Universal Library, and the Measurement Computing logo are either trademarks

or registered trademarks of Measurement Computing Corporation. Refer to the Copyrights & Trademarks section on

mccdaq.com/legal for more information about Measurement Computing trademarks. Other product and company names

mentioned herein are trademarks or trade names of their respective companies.

© 2012 Measurement Computing Corporation. All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form by any means, electronic, mechanical, by photocopying, recording, or otherwise

without the prior written permission of Measurement Computing Corporation.

Notice

Measurement Computing Corporation does not authorize any Measurement Computing Corporation product for use

in life support systems and/or devices without prior written consent from Measurement Computing Corporation.

Life support devices/systems are devices or systems that, a) are intended for surgical implantation into the body, or

b) support or sustain life and whose failure to perform can be reasonably expected to result in injury. Measurement

Computing Corporation products are not designed with the components required, and are not subject to the testing

required to ensure a level of reliability suitable for the treatment and diagnosis of people.

HM CIO-DAS-TEMP.doc

Page 3

Table of Contents

1 INTRODUCTION ................................................................

2 INSTALLATION .................................................................

3 INTERFACING ..................................................................

4 PROGRAMMING AND APPLICATIONS ...........................................

5 THEORY OF OPERATION .......................................................

6 REGISTER MAP .................................................................

7 SPECIFICATIONS ..............................................................

1

1

12.1 SOFTWARE ................................................................

12.2 HARDWARE ................................................................

2

33.1 CONNECTOR DIAGRAM .....................................................

33.2 CONNECTING THE AD592 SENSORS ..........................................

4

44.1 PROGRAMMING LANGUAGES ...............................................

44.2 PACKAGED APPLICATION PROGRAMS .......................................

5

55.1 OVERVIEW .................................................................

65.2 SIGNAL RESOLUTION AND CONVERSION SPEED ..............................

75.3 OPERATION OF THE COUNTERS ..............................................

75.4 LINE NOISE REJECTION .....................................................

9

96.1 CONTROL REGISTERS .......................................................

13

Page 4

This page is blank.

Page 5

1 INTRODUCTION

The CIO-DAS-TEMP is a temperature measurement board desig ned for use with the A D592

semiconductor temperature sensor. Since the AD592 is a current output dev ice, the on-board signal

conditioning is optimized for that sensor. A voltage-to-frequency converter translates the signal from the

sensor into a v alue proportional to tem perature. Functions in the Univ ersal Library convert that

proportional value into a temperature reading on which you can base a control system, or simply log for

later analysis.

The AD592 semiconductor temperature sensor is ideally suited for measurements in the ambient range. If

you are designing an HVAC system, or need to monitor the efficiency of an existing system, the

CIO-DAS-TEMP provides the best value and accuracy in the ambient range. More accurate than

thermocouples and less expensive than RTDs, the AD592 sensor is available through general distribution

or from Measurement Computing Corp. as an individual part or in a stainless steel probe.

Custom Ranges

The CIO-DAS-TEMP is a current input board with a fixed range of 0 to 500 µAmps. The front end may

be customized to allow up to 0 to 20 mA. T he CIO-DAS-TEMP provides up to a full 16 bits of

resolution and will easily reject line noise. If you have a current m easurement application and want a

precisely matched front end, please call our technical support and explain your needs to us.

2 INSTALLATION

2.1 SOFTWARE

There is a bank of switches to set before installing the board in your computer. By far the simplest way to

configure your board is to use the InstaCal

TM

InstaCal

will show you all available options, how to configure the switches to match your application

requirements, and will create a configuration file that your application software (and the Universal

Library) will refer to so the software you use w ill automatically know the exact configuration of the

board.

Please refer to the Software Installation Manual regarding the installation and operation of InstaCal

The following hard copy information is provided as a matter of completeness, and will allow you to set

the hardware configuration of the board if y ou do not have immediate access to InstaCal

computer.

TM

program provided as part of y our software pack age.

TM

and/or your

TM

.

1

Page 6

2.2 HARDWARE

2.2.1 Base I/O Address

The CIO-DAS-TEMP may be set to operate at any one of a range of base addresses. T he

CIO-DAS-TEMP uses eig ht, 8-bit addresses, so the base addresses available are in steps of eig ht. For

example, 300h, 308h, 310h and so on. Table 2-1 of occupied PC addresses below should be

supplemented by information you provide about the addresses used by any other boards or devices

installed in your computer. After all occupied addresses are known, choose an available block of eight

I/O addresses for your CIO-DAS-TEMP. Make sure it is on a 3-bit (8-address) boundary.

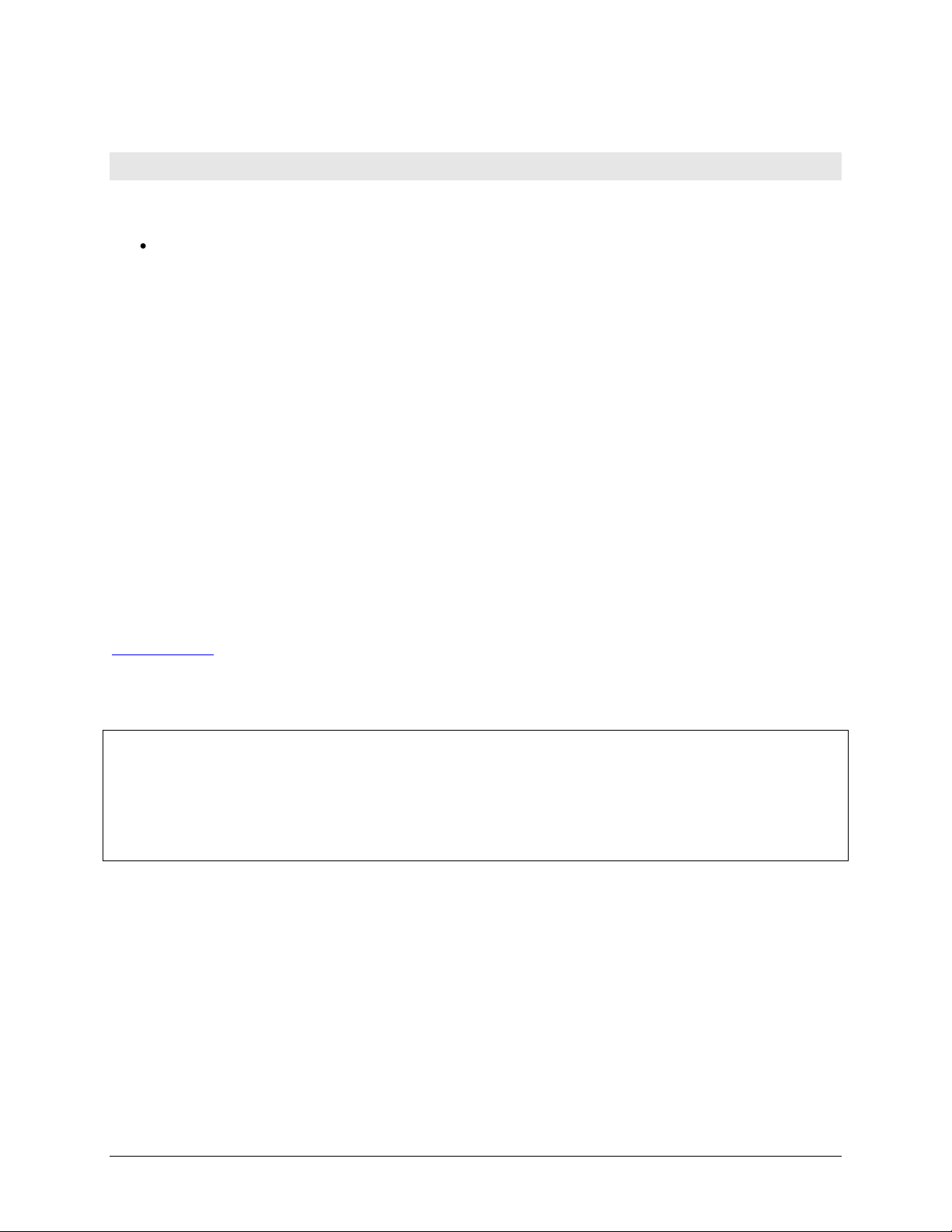

Table 2-1. PC I/O Addresses

FUNCTION HEX RANGEFUNCTIONHEX RANGE

EGA 2C0-2CF8237 DMA #1000-00F

EGA2D0-2DF8259 PIC #1020-021

GPIB (AT) 2E0-2E78253 TIMER040-043

SERIAL PORT 2E8-2EF82C55 PPI (XT)060-063

SERIAL PORT 2F8-2FF8742 CONTROLLER (AT)060-064

PROTOTYPE CARD 300-30FCMOS RAM & NMI MASK (AT)070-071

PROTOTYPE CARD310-31FDMA PAGE REGISTERS080-08F

HARD DISK (XT) 320-32F8259 PIC #2 (AT)0A0-0A1

PARALLEL PRINTER378-37FNMI MASK (XT)0A0-0AF

SDLC 380-38F8237 #2 (AT)0C0-0DF

SDLC 3A0-3AF80287 NUMERIC CO-P (AT)0F0-0FF

MDA 3B0-3BBHARD DISK (AT)1F0-1FF

PARALLEL PRINTER3BC-3BFGAME CONTROL200-20F

EGA 3C0-3CFEXPANSION UNIT (XT)210-21F

CGA 3D0-3DFBUS MOUSE238-23B

SERIAL PORT 3E8-3EFALT BUS MOUSE23C-23F

FLOPPY DISK 3F0-3F7PARALLEL PRINTER270-27F

SERIAL PORT3F8-3FFEGA2B0-2BF

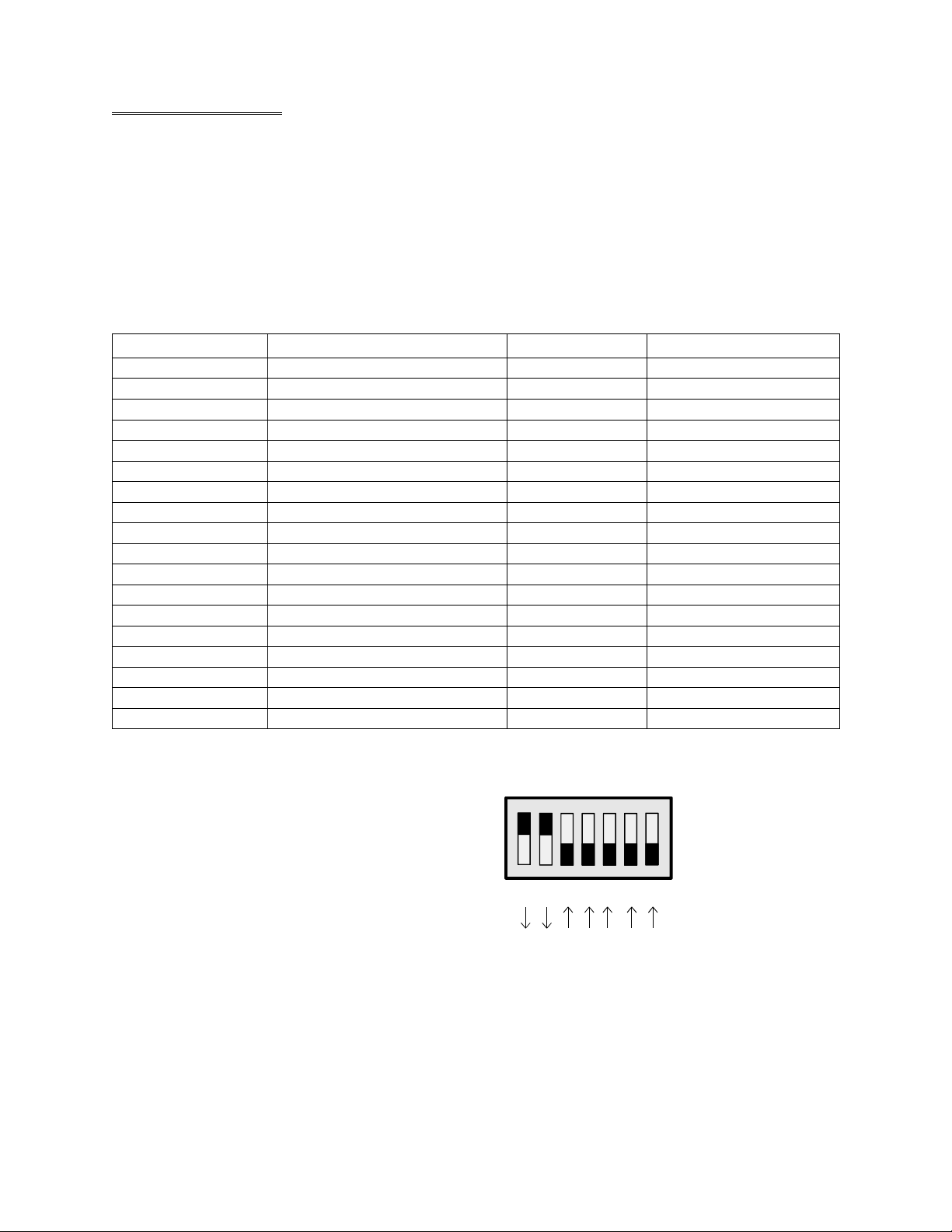

The Base Address is set by a switch on the

CIO-DAS-TEMP labeled ADDRESS. The

CIO-DAS-TEMP uses eight, 8 bit addresses.

The board is set at the factory for address 300h (

768 decimal) as shown here. It is a com mon

address for I/O boards and may already be in use

in your computer. Verify that it, or the address

you choose is available.

Address 300H Shown Below

987654

3

Figure 2-1. Base Address Switches

2

SW

A9

A8

A7

A6

A5

A4

A3

HEX

200

100

80

40

20

10

8

Page 7

3 INTERFACING

The CIO-DAS-TEMP has 32 current inputs desig ned specifically for the AD592 semiconductor-type

temperature sensor.

3.1 CONNECTOR DIAGRAM

The CIO-DAS-TEMP employs the

37-pin, D-type signal connector

common to many I/O boards. It may be

cabled to directly, or throug h a C37FF

cable and screw terminal such as the

CIO-MINI37.

Signal wires from the AD592

temperature sensors should be

connected to the input terminals labeled

TEMP0 through TEMP31.

All the power wires should be

connected in com mon to the +15V DC

power, pin 19.

Please make accurate notes and pay

careful attention to wire connections.

In a large system, finding a misplaced

wire may create hours of work.

+15VDC

TEMP 30

TEMP 28

TEMP 26

TEMP 24

TEMP 22

TEMP 20

TEMP 18

TEMP 16

TEMP 14

TEMP 12

TEMP 10

TEMP 8

TEMP 6

TEMP 4

TEMP 2

TEMP 0

NC

GND

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

37

CAL IN

36

NC

35

TEMP 31

34

TEMP 29

33

TEMP 27

32

TEMP 25

31

TEMP 23

30

TEMP 21

29

TEMP 19

28

TEMP 17

27

TEMP 15

26

TEMP 13

25

TEMP 11

24

TEMP 9

23

TEMP 7

22

TEMP 5

21

TEMP 3

20

TEMP 1

Figure 3-1. 37-Pin Connector

3.2 CONNECTING THE AD592 SENSORS

The AD592 semiconductor temperature sensor produces a current proportional to tem perature. The

sensor employs only two leads, a power lead and the return. The amount of current flowing through the

circuit is proportional to temperature and is the signal measured by the CIO-DAS-TEMP.

The AD592 chip has three leads, two of which are

used. One is the power and one is the return, the

remaining pin is not to be connected and is not

used. The power pins from one or all 32 sensors

are connected to the +15V (pin 19) of the

CIO-DAS-TEMP. The return pin is connected to

the TEMP# of the CIO-DAS-TEMP.

3

VIEW OF SENSOR FROM BOTTOM

WHERE PINS PROTRUDE

IGNAL TO

DAS-TEMP

(-) (+)

Figure 3-2. AD592 Sensor Connections

PIN 2 PIN 1PIN 3

NC

SENSOR POWER

+15V

Page 8

Semiconductor temperature sensors may be purchased from some electronics distributors or directly from

Measurement Computing Corp. An AD592 potted into a stainless steel probe may be purchased from

Measurement Computing Corp. or from other vendors of temperature sensors.

The AD592CN has excellent specifications for ambient temperature measurement (see chapter on

specifications).

In addition, because it is a current-output device, the AD592CN is relatively immune to noise pickup and

IR drops in the signal leads w hen used remotely. I t is reasonably rugged and will withstand supply

irregularities and v ariations or rev ersals up to 20V. Since the A D592s are laser- trimmed, they are

interchangeable and have a high initial accuracy that does not degrade over time

Figure 3-3 shows Measurement Computing’s

SNSR-AD592-PRB6CN (six inch, CN

specifications). T he SNSR-AD592-PRB6CN is

composed of an AD592 connected to two lead

TEMP SIGNAL

BLACK

AD592 SENSOR

PIN 2 PIN 1PIN 3

NC

(-) (+)

SENSOR POWER

RED

wires, inserted into a stainless steel probe and

potted in place.

The unit is waterproof.

There are two wires protruding from the probe.

The RED wire connects to the +15VDC power.

The BLACK wire connects to the TEMP# input

of the CIO-DAS-TEMP.

SENSOR POWER

RED

SENSOR POWER

RED

AD592 SENSOR IN STAILESS STEEL PROBE

TEMP SIGNAL

BLACK

AD592 SENSOR IN STAILESS STEEL PROBE

TEMP SIGNAL

BLACK

SENSOR AT TIP

Figure 3-3. SNSR-AD592-PRB-6-BN Sensor

4 PROGRAMMING AND APPLICATIONS

Although the CI O-DAS-TEMP is part of the larg er DAS family, there is no correspondence between

registers. S oftware written at the reg ister level for the other D AS's will not w ork with the

CIO-DAS-TEMP.

PROGRAMMING LANGUAGES

The UniversalLibrary program provides complete access to the CIO-DAS-TEMP functions from a range

of programming languages; both DOS and Windows. I f you are planning to write prog rams, or would

like to run the example programs for V isual Basic or any other language, please refer to the

UniversalLibrary manual.

PACKAGED APPLICATION PROGRAMS

Many packaged application programs now have drivers for the CIO-DAS-TEMP. I f the package you own

does not appear to hav e drivers for the CI O-DAS-TEMP please fax the package name and the rev ision

number from the install disk s. We will research the package for you and advise by return fax how to

obtain CIO-DAS-TEMP drivers.

4

Page 9

5 THEORY OF OPERATION

5.1 OVERVIEW

The CIO-DAS-TEMP is composed of a C urrent to Voltage (C/V) converter, a Voltage to F requency

(V/F) converter, a channel multiplexer, a sensor excitation power supply and control registers (see Figure

5-1).

The temperature signals,

connected to the channel

multiplexer, are converted

from a current to a voltage

then from a voltage to a

frequency. The frequency is

determined by counting

pulses from the V/F for a

given period. The frequency

is use to calculate the

temperature.

Sensor Power

Supply

AD 31

AD30

AD29

AD28

AD27

...

...

...

AD6

AD5

AD4

AD3

AD2

AD1

AD0

V to F

I to V

32 Channel Multiplexor

V to F Cl ock In

Clock & Pescaler

ISA BUS INTERFACE & CONTROL LOGIC

4MHz

2MHz

Prescaler Out

Figure 5-1. Board Block Diagram

82C54

Counter/Timer Ctrl

IN

CTR 0

V to F Output

Counter

GATE

IN

CTR 1

V to F Pe riod

Counter

GATE

IN

CTR 2

Timer

GATE

Software Trigger

OUT

OUT

OUT

The C/V converter has an output of 0 to 10 volts, which corresponds to the full scale of the current input

or 0 to 500 µA. This input range may be customized at the factory by changing one resistor and one

potentiometer. Please call if you have applications requiring up to 0 to 20 mA input.

The V/F converter has an output of 0 to 2 MHz, which corresponds to the full scale of the voltage input

of 0 to 10 volts. An AD592 sensor will produce frequency in the range of 992 kHz (−25°C) to 1.512

MHz (105°C). Other sensors such as the AD590 (−55°C to 150°C) may be used as well. The equation

for temperature is:

-6

Kelvin = ((10 Volts) * (Fout)) / ((20,000Hz) * (20,000 Ohms) * ( 1 * 10

Amps))

Kelvin = Fout / 4000

5

Page 10

5.2 SIGNAL RESOLUTION AND CONVERSION SPEED

The voltage to frequency converter provides a resolution dependent on the sampling rate. The lower the

sampling rate, the hig her the resolution. Sam pling rates may vary from 25 sam ples per second

(approximately 16-bit resolution) to 4,000 samples per second (approximately 8-bit resolution). For most

temperature measurement applications, rates up to 200 Hz are useful.

The formula for the resolution of the board is:

Full scale range / counts in counter 1

500 µA / (2 <= N <= 65,535 )

The duration of one count is 0.5 µs because the CLK input is 2 MHz

The CIO-DAS-TEMP is constructed of a current-to-voltage front-end and a v oltage-to-frequency

converter. T he V/F converter outputs a frequency that is proportional to the v oltage of its input.

Resolution increases with sample time since the V/F conversion is an average of the signal over the time

of the conversion. The longer the V/F has to settle, the more precise the measurement.

Note that the signal you are measuring should be stable ov er the period of measurement. The

CIO-DAS-TEMP is not desig ned for measurement of v ery rapid changes in temperature. For example,

the maximum sampling rate for the CIO-DAS-TEMP is 200 samples per second. If your temperatures are

changing faster than 200 significant steps per second and you need to precisely trigger and sample that

temperature, you have the wrong product and should call technical support to discuss your application.

The CIO-DAS-TEMP is capable of rejecting line noise when the conversion rate is a multiple of the line

frequency of the power to the PC power supply. Here are the recommended conversion rates and the

accompanying resolutions:

Line FrequencyResolutionRate

60 Hz 0.015 °C*30 Samples/Second

50 Hz0.0125 °C*25 Samples/Second

400 Hz0.1 °C200 Samples/Second

*Note: Exceeds the accuracy of the AD592 sensor.

6

Page 11

5.3 OPERATION OF THE COUNTERS

The 8254 counters 0 and 1 are used to make the frequency measurement of the V/F output. Counter 1 is

clocked by the 2 MHz clock source. A value loaded into counter 1 is used to count down to zero thereby

providing a precise time interval, known as the gate time. For example, if counter 1 were loaded with the

value 5,000 it would count down for 2.5 ms (5,000 / 2,000,000 = 0.0025 sec.).

While counter 1 is counting down, the output pin CTR 1 OUT goes high (a programmable feature

implemented in the Universal Library, or your software). This signal is used to gate counter 0.

Counter 0 is used to accumulate counts from the V/F converter. Recall that the V/F converter produces a

train of pulses proportional to the voltage on its input. At 0 volts the V/F produces zero Hz and at 10

volts, 2 MHz. If the V/F senses 5 volts on its input, it will output pulses at 1 MHz. If counter 1 has been

loaded with a value of 5,000, counter 0 will count pulses for 2.5 ms. 1,000,000 x 0.0025 = 2,500 pulses.

Note that the pulses counted from the V/F are exactly ½ the value loaded into counter 1; the time period

to count pulses. This is a general rule:

Voltage = 10 x (CTR 1 Load / CTR 0 Counts)

In general, a counter 1 period value of 5,000 is a g ood choice and w ill yield good results. The

relationship of degrees Kelvin to counts is:

Kelvin/Count = 500 / Full Scale Count

If the full scale count is 5,000 (as suggested) the relationship is:

500 / 5000 = 0.1K per count

5.4 LINE NOISE REJECTION

V/F converters will reject signal noise that is periodic and of a consistent am plitude because the V/F

converter averages the signal. Sinusoidal noise associated with line frequencies is an example. Since the

signal is averaged (equal areas over and under the mean cancel each other out) the measurement period

must be equal to one cycle, or a multiple of the cycle frequency if noise rejection is desired.

For example, if there is 60 Hz line noise on the signal, the measurement period would have to be:

1/60 = 0.1666

0.16666 x 2,000,000 = 33,333 counts Load this value or a multiple of it into counter 1

For 50 Hz, the calculations are similar. 1/50 x 2,000,000 = 0.02 x 2,000,000 = 40,000

5.4.1 Gate-Time, Resolution and Noise Rejection

The choice of gate time has an affect on the resolution of the measurement, line cycle noise rejection and

the rate over which multiple channels can be scanned. Increasing gate time improves both resolution and

noise rejection but it will decrease the scanning (multiple channel measurement) rate.

7

Page 12

Generally, the choice of gate time is a matter of factoring the desired resolution against the time the

actual measurement takes.

Multiple Channels:

When scanning over multiple channels, the software must explicitly select the next channel in the scan

and start a new conversion. Once the next channel is selected, enough time must be allowed for the new

channel’s current to propagate through the multiplexers and Current-to-Voltage Converter to settle at the

Voltage-to-Frequency converter input. T his is most easily done by doing an extra, or ‘dummy’

conversion, waiting for it to complete and then starting the ‘real’ conversion. Thus, if a gate time of

0.0166 seconds is chosen, the maximum scan rate will be:

Scan Rate = 1 / 2 x [gate time]

= 1 / 2 x [0.0166 seconds]

= 30 samples per second

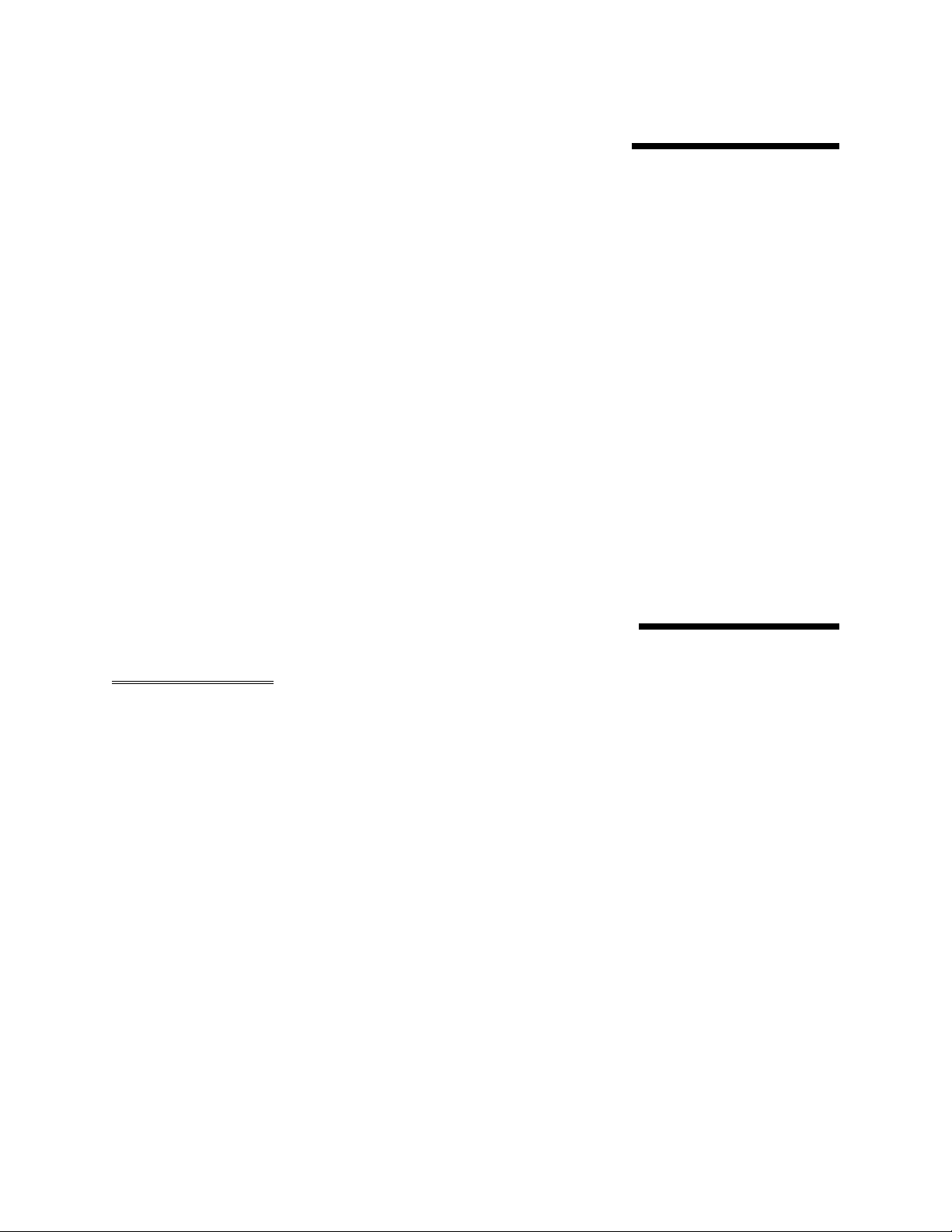

The following table can be used to select the Gate Count based on either desired maximum sampling rate

or desired resolution.

Desire Max Sample

Rate

Required

ResolutionGate TimeGate Count

Line Frequency

Rejection

60Hz0.015 °C0.01 sec33,33330 samples / sec

50Hz0.0125 °C0.02 sec40,00025 samples / sec

400Hz0.1 °C0.0025 sec5,000200 samples / sec

8

Page 13

6 REGISTER MAP

A base address register controls the beg inning, or 'Base Address' of the I /O addresses occupied by the

control registers of the CIO-DAS-TEMP. In all, eight addresses are occupied. The registers control the

programmable aspects of the CIO-DAS-TEMP performance.

6.1 CONTROL REGISTERS

After a base address has been established, the CIO-DAS-TEMP is controlled by writing to and reading

from the control registers. While it is possible to w rite your own control routines for the

CIO-DAS-TEMP, routines have been written and are available in Universal Library for DOS and

Windows programming languages. Unless you have a specific need to program at the register level, it is

recommended that you use the Universal Library or a packaged application program.

Table 5-1. Control Registers

WRITEREADI/O ADDRESS

Data Load8254 Counter 0 Data ReadBASE + 0

Data Load8254 Counter 1 Data ReadBASE + 1

Data Load8254 Counter 2 Data ReadBASE + 2

8254 Counter Control8254 StatusBASE + 3

Channel Control & StatusChannel & StatusBASE + 4

ClearInterrupt & Prescaler ControlBASE + 5

ReloadNoneBASE + 6

Counter ControlNoneBASE + 7

Register Descriptions

The register descriptions include functions of each bit in each 8-bit register as well as some design and

use descriptions

BASE + 0 Write - Counter 0 Load Register of the 82C54

01234567

Data 0Data 1Data 2Data 3Data 4Data 5Data 6Data 7

Write an initial value of 65,536 to this reg ister after programming the 82C54 control register for CTR 0

to be an event counter. It works as a down-counter, the only choice available.

BASE + 0 Read - Counter 0 Current Count Register of the 82C54

01234567

Data 0Data 1Data 2Data 3Data 4Data 5Data 6Data 7

The total of the V/F output should be read from this register after Counter 1 reaches terminal count

BASE + 1 Write - Counter 1 Load Register of the 82C54

01234567

Data 0Data 1Data 2Data 3Data 4Data 5Data 6Data 7

9

Page 14

First, program the 82C54 control register for CTR 1 to produce a single pulse for the duration of the

count period. Next, load an initial value equal to the period for which counts from the V/F converter will

be totaled See the previous explanation of initial count values for information on what value to load into

this counter. It works as a down-counter, the only choice available.

BASE + 1 Read - Counter 1 Current Count Register of the 82C54

01234567

Data 0Data 1Data 2Data 3Data 4Data 5Data 6Data 7

Will return current count.

BASE + 2 Write - Counter 2 Load Register of the 82C54

01234567

Data 0Data 1Data 2Data 3Data 4Data 5Data 6Data 7

This counter is used to sequence through multiple channels when more than one channel is read. First,

program the 82C54 control register for CTR 2 to function as a rate generator. The register at Base + 5

sets the input (prescaler) frequency for this counter.

Next, load an initial value equal to the number of clock periods between channel readings

BASE + 2 Read - Counter 2 Current Count Register of the 82C54

01234567

Data 0Data 1Data 2Data 3Data 4Data 5Data 6Data 7

Will return current count.

BASE + 3 Write - Control Register of the 82C54

01234567

BCDM0M1M2RW0RW1SC0SC1

The 82C54 counter is described in g reat detail in the Harris or Instel 82C54 data sheet. A brief

description of the control bits follows.

SC1

0 0 Select counter 0

0 1 Select counter 1

1 0 Select counter 2

1 1 Read Command

RW1

0 0 Counter latch

0 1 Read/Write least significant byte of selected counter

1 0 Read/Write most significant byte of selected counter

1 1 Read/Write least significant byte then most significant byte

SC0 Function

RW0 Function

10

Page 15

M1 M0 M0 Function

0 0 0 Program selected counter as event counter, mode 0

0 0 1 Hardware triggered one shot. Pulse is the duration of

the load value

0 1 0 Rate generator. CLK is divided by load value

0 1 1 Square wave. Period equals CLK divided by load value

1 0 0 Software triggered strobe

1 0 1 Hardware triggered strobe

When BCD = 0, the counter counts in binary, 16-bit count. When BCD = 1, the counter counts in

binary-coded-decimal.

BASE + 3 Read - Status Register of the 82C54

01234567

BCDM0M1M2RW0RW1SC0SC1

Will return current status.

BASE + 4 Write - Channel select and mux enable

01234567

CH0CH1CH2CH3CH4XXCHEN

Select channel 0 to 31 in standard binary counting. CHEN enables the mux so that the current channel

sensor is connected to the output of the mux

BASE + 4 Read - Channel, interrupt, calibration switch and EOC status

01234567

CH0CH1CH2CH3CH4CONVCALINT

CH4 through CH0 read back the current channel.

CONV is high when a conversion is in progress and low when conversion is complete, that is when the

counter value in counter 1 has reached zero.

CAL indicates the position of the CAL/NORM switch. NORM = 0, CAL = 1

INT is the status of the interrupt flip flop. It is set whenever conversion is complete (terminal count in

counter 1) whether or not interrupts are enabled. Clear INT by reading Base + 5.

BASE + 5 Write - Interrupt select and trigger mode

01234567

IR0IR1IR2TMREP0P1P2P3

P3 through P0 control a prescalar divider or a 2MHz clock by 4 to 32768 in the steps shown in Table 5-2

below. The output of the prescaler is the input to counter 2, the channel mux sequencer.

11

Page 16

Table 5-2. Prescalar Divider/2 MHz Clock Control Codes

Output FreqP0P1P2P3Output FreqP0P1P2P3

7,812.50001None0000

3,906.251001None1000

1,9530101500,0000100

976.561101250,0001100

488.280011125,0000010

244.14101162,5001010

122.07011131,2500110

61.01111115,6251110

When TMRE = 0, the Prescaler and Counter 2 are disabled. When TMRE = 1, the prescaler and Counter

2 are enabled.

IR2

0 0 0 Disable interrupts

0 0 1 Disable interrupts

0102

0113

1004

1015

1106

1117

BASE + 5 Read - Read bit settings

BASE + 6 Write - Load counter 0

A write to this address loads the v alue 65,535 into counter 0. T his must be done before trig gering a

conversion.

BASE + 7 Not used

IR1 IR0 Hardware IRQ

01234567

IR0IR1IR2TMREP0P1P2P3

12

Page 17

POWER CONSUMPTION

+5V Normal Operation 890 mA Typical 960 mA Max

ANALOG INPUT

Channels 32 Current Input, AD592 Sensor Specific

Range 0 to 500 µΑ

Input Impedance 20 KOhm (nominal)

Resolution

30 S/S 0.015 Deg C (60 Hz Line Frequency)

25 S/S 0.0125 Deg C (50 Hz Line Frequency)

200 S/S 0.1 Deg C (400 Hz Line Frequency)

Current/Temp 1.0 Degrees Kelvin / µAmp

Accuracy ± 0.02%

Linearity Error ± 0.02%

Gain Drift ±75 ppm/°C

V/F Converter AD652

Calibration 0 to 5V (pin 37) @ 10,000 KOhm Input Impedance

7 SPECIFICATIONS

COUNTERS

Counter Type 82C54 Three 16-Bit Down-counters, 10 MHz Max Input

Prescaler 2 MHz divided by 14 programmable steps

Interrupts 2 through 7 Programmable

ENVIRONMENTAL

Operating Range 0 to 60°C

Storage Range −40 to 100°C

Humidity 0 to 90% non-condensing

SENSORS

AD592 Sensor CN Suffix BN Suffix

Temp Range −25 to 105°C −25 to 105°C

Accuracy at range 0 to 70°C, ± 0.8°C 0 to 70°C, ± 1.5°C

−25 to 105 °C, ± 1.0°C −25 to 105°C, ± 2.0°C

Temperature drift ±25 ppm/°C ±25 ppm/°C

Storage Range −45 to 125C −45 to 125°C

13

Page 18

For for Notes.

14

Page 19

EC Declaration of Conformity

We, Measurement Computing Corp., declare under sole responsibility that the product:

Temperature Input BoardCIO-DAS-TEMP

DescriptionPart Number

to which this declaration relates, meets the essential requirements, is in conformity with, and CE marking

has been applied according to the relevant EC Directives listed below using the relevant section of the

following EC standards and other normative documents:

EU EMC Directive 89/336/EEC

EU 55022 C lass B

technology equipment.

EN 50082-1

IEC 801-2

IEC 801-3

equipment.

IEC 801-4

Carl Haapaoja, Director of Quality Assurance

: EC generic immunity requirements.

: Electrostatic discharge requirements for industrial process measurement and control equipment.

: Radiated electromagnetic field requirements for industrial process measurements and control

: Electrically fast transients for industrial process measurement and control equipment.

: L imits and methods of measurements of radio in terference characteristics of information

: Essential requirements relating to electromagnetic compatibility.

Page 20

Measurement Computing Corporation

10 Commerce Way

Suite 1008

Norton, Massachusetts 02766

(508) 946-5100

Fax: (508) 946-9500

E-mail: info@mccdaq.com

www.mccdaq.com

Loading...

Loading...