Page 1

CIO-DAS08-PGH

g

g

CIO-DAS08-PGM

CIO-DAS08-PGL

Analo

Input & Di

ital I/O

.

Revision 9

October, 2000

Page 2

Your new Measurement Computing product comes with a fantastic extra —

Management committed to your satisfaction!

Thank you for choosing a Measurement Computing product—and congratulations! You own the finest, and you can now enjoy

the protection of the most comprehensive warranties and unmatched phone tech support. It’s the embodiment of our mission:

To provide data acquisition hardware and software that will save time and save money.

Simple installations minimize the time between setting up your system and actually making measurements. We offer quick and

simple access to outstanding live FREE technical support to help integrate MCC products into a DAQ system.

Limited Lifetime Warranty: Most MCC products are covered by a limited lifetime warranty against defects in materials or

workmanship for the life of the product, to the original purchaser, unless otherwise noted. Any products found to be defective in

material or workmanship will be repaired, replaced with same or similar device, or refunded at MCC’s discretion. For specific

information, please refer to the terms and conditions of sale.

Harsh Environment Program: Any Measurement Computing product that is damaged due to misuse, or any reason, may be

eligible for replacement with the same or similar device for 50% of the current list price. I/O boards face some harsh

environments, some harsher than the boards are designed to withstand. Contact MCC to determine your product’s eligibility for

this program.

30 Day Money-Back Guarantee: Any Measurement Computing Corporation product may be returned within 30 days of

purchase for a full refund of the price paid for the product being returned. If you are not satisfied, or chose the wrong product by

mistake, you do not have to keep it.

These warranties are in lieu of all other warranties, expressed or implied, including any implied warranty of merchantability or

fitness for a particular application. The remedies provided herein are the buyer’s sole and exclusive remedies. Neither

Measurement Computing Corporation, nor its employees shall be liable for any direct or indirect, special, incidental or

consequential damage arising from the use of its products, even if Measurement Computing Corporation has been notified in

advance of the possibility of such damages.

Trademark and Copyright Information

Measurement Computing Corporation, InstaCal, Universal Library, and the Measurement Computing logo are either trademarks

or registered trademarks of Measurement Computing Corporation. Refer to the Copyrights & Trademarks section on

mccdaq.com/legal for more information about Measurement Computing trademarks. Other product and company names

mentioned herein are trademarks or trade names of their respective companies.

© 20 Measurement Computing Corporation. All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form by any means, electronic, mechanical, by photocopying, recording, or otherwise

without the prior written permission of Measurement Computing Corporation.

Notice

Measurement Computing Corporation does not authorize any Measurement Computing Corporation product for use

in life support systems and/or devices without prior written consent from Measurement Computing Corporation.

Life support devices/systems are devices or systems that, a) are intended for surgical implantation into the body, or

b) support or sustain life and whose failure to perform can be reasonably expected to result in injury. Measurement

Computing Corporation products are not designed with the components required, and are not subject to the testing

required to ensure a level of reliability suitable for the treatment and diagnosis of people.

HM CIO-DAS08PGx.lwp

©

Copyright 2000 Measurement Computing Corp.

Page 3

TABLE OF CONTENTS

1: INTRODUCTION

.................................................................................

1.1 SOFTWARE INSTALLATION

1.2 HARDWARE INSTALLATION

2: SIGNAL CONNECTION

2.1 CONNECTOR DIAGRAM

2.2 DIFFERENTIAL INPUTS

..........................................................................

.........................................................................

..........................................................................

2.3 DIGITAL OUTPUTS & INPUTS

3: ANALOG CONNECTIONS

3.1 ANALOG INPUTS

.................................................................................

3.2 WIRING CONFIGURATIONS

..........................................................................

......................................................................

4: REGISTER ARCHITECTURE

4.1 CONTROL & DATA REGISTERS

4.2 A/D DATA REGISTER

............................................................................

4.3 STATUS AND CONTROL REGISTER

4.4 PROGRAMMABLE GAIN REGISTER

4.5 COUNTER LOAD & READ REGISTERS

4.6 COUNTER CONTROL REGISTER

4.7 COUNTER/TIMER

4.8 DIGITAL INPUT

4.9 DIGITAL OUTPUT

...............................................................................

.................................................................................

...............................................................................

4.10 TRIGGER & INTERRUPT LOGIC

5: SPECIFICATIONS

...............................................................................

...................................................................

.....................................................................

...................................................................

...................................................................

.................................................................

.............................................................

.............................................................

..........................................................

................................................................

..............................................................

1

1

2

4

4

4

4

5

5

9

13

13

14

14

15

17

17

18

19

19

20

21

Page 4

This page is blank

Page 5

1: INTRODUCTION

There are three versions of the CIO-DAS08-PGx board, CIO-DAS08-PGL, CIO-DAS08-PGH and CIO-DAS08-PGM. (The

CIO-DAS08-PGM duplicates MetraByte DAS-8PGA ranges and codes). These versions will be referred to as CIO-DAS08-PGx

throughout this manual except where the differences between the versions require specifying a particular version.

If you have one of these boards and are not sure which one, you can identify the -PGH or -PGL versions by noting the part number

of the amplifier. The amplifier, U6, is located approximately in the center of the board. The part number of the amplifier on the

-PGH version is PGA202. The part number of the amplifier on the -PGL version is PGA203. Call the factory for aid in

identifying the -PGM version.

The CIO-DAS08-PGx boards are an extension of the popular CIO-DAS08 architecture. The boards are identical at the register

level, performance, and connector, with the following exceptions:

1. Gains are programmable as follows:

a. CIO-DAS08-PGM gains are 0.5, 1, 10, 100, and 500.

b. CIO-DAS08-PGH gains are 0.5, 1, 5, 10, 50, 100, 500, and 1000.

c. CIO-DAS08-PGL gains are 0.5, 1, 2, 4, and 8.

2. Analog inputs are differential. (However, provision has been made to add resistors to convert the inputs to

pseudo-single-ended mode.) To maintain compatibility with signal conditioning boards such as the CIO-EXP16, an

optional SIP resistor provides ground reference to the CH# Low inputs.

3. A stable crystal (“XTAL”) oscillator provides the A/D pacer clock pulse. To give compatibility with programs written for

the AD08, a jumper selects either the stable XTAL or the PC Bus clock.

4. A DC/DC converter supplies stable ±15VDC power to the analog circuitry. The board can be ordered without the

DC/DC converter. This reduces the cost but limits the ranges of analog inputs. It is available only on orders of ten or

more units.

5. There is only one connector on the board.

1.1 SOFTWARE INSTALLATION

Before you open your computer and install the board, install and run InstaCal, the installation, calibration and test utility included

with your board. InstaCal will guide you through switch and jumper settings for your board. Detailed information regarding these

settings can be found below. Refer to the Software Installation manual for InstaCal installation instructions.

1

Page 6

1.2 HARDWARE INSTALLATION

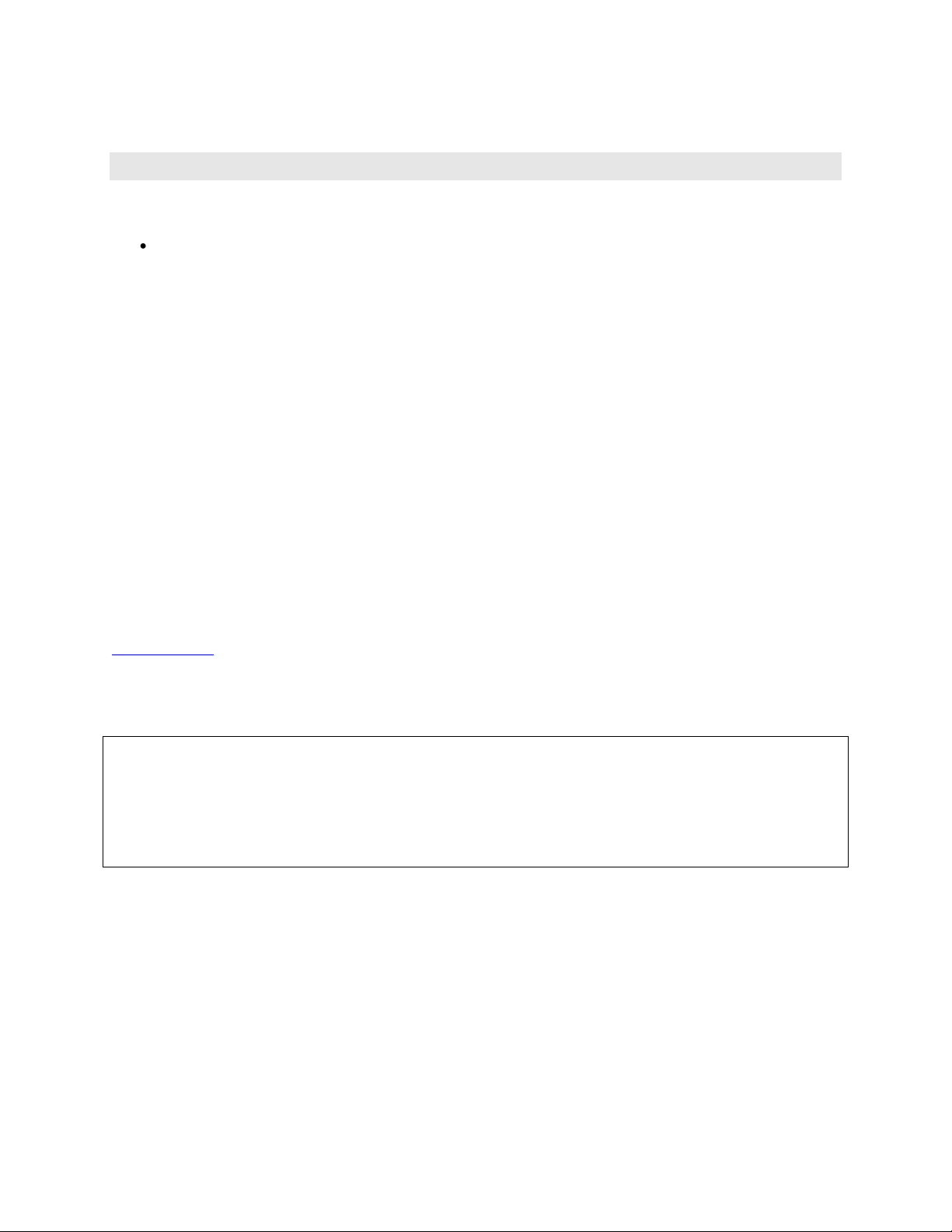

1.2.1 Base Address

The base address of the CIO-DAS08-PGx is set by switching a bank of DIP

switches on the board (Figure 1-1). This bank of switches is labeled

ADDRESS and numbered 9 to 3.

Ignore the word ON and the numbers printed on the switch

The switch works by adding up the weights of individual switches to make a

base address. A 'weight' is active when the switch is down. Shown here,

switches 9 and 8 are down, all others are up. Weights 200H and 100H are

active, equaling 300H base address. The board is shipped with this default

address selected. If this address is already in use on your computer, select a

different address. Figure 1-1. Base address Select Switches

Table 1-1 lists the address ranges for the PC computer.

Table 1-1. Base Addresses

FUNCTIONHEX RANGEFUNCTIONHEX RANGE

EGA2C0-2CF8237 DMA #1000-00F

EGA2D0-2DF8259 PIC #1020-021

GPIB (AT)2E0-2E78253 TIMER040-043

SERIAL PORT2E8-2EF8255 PPI (XT)060-063

SERIAL PORT2F8-2FF8742 CONTROLLER (AT)060-064

PROTOTYPE CARD300-30FCMOS RAM & NMI MASK (AT)070-071

PROTOTYPE CARD310-31FDMA PAGE REGISTERS080-08F

HARD DISK (XT)320-32F8259 PIC #2 (AT)0A0-0A1

PARALLEL PRINTER378-37FNMI MASK (XT)0A0-0AF

SDLC380-38F8237 #2 (AT)0C0-0DF

SDLC3A0-3AF80287 NUMERIC CO-P (AT)0F0-0FF

MDA3B0-3BBHARD DISK (AT)1F0-1FF

PARALLEL PRINTER3BC-3BFGAME CONTROL200-20F

EGA3C0-3CFEXPANSION UNIT (XT)210-21F

CGA3D0-3DFBUS MOUSE238-23B

SERIAL PORT3E8-3EFALT BUS MOUSE23C-23F

FLOPPY DISK3F0-3F7PARALLEL PRINTER270-27F

SERIAL PORT3F8-3FFEGA2B0-2BF

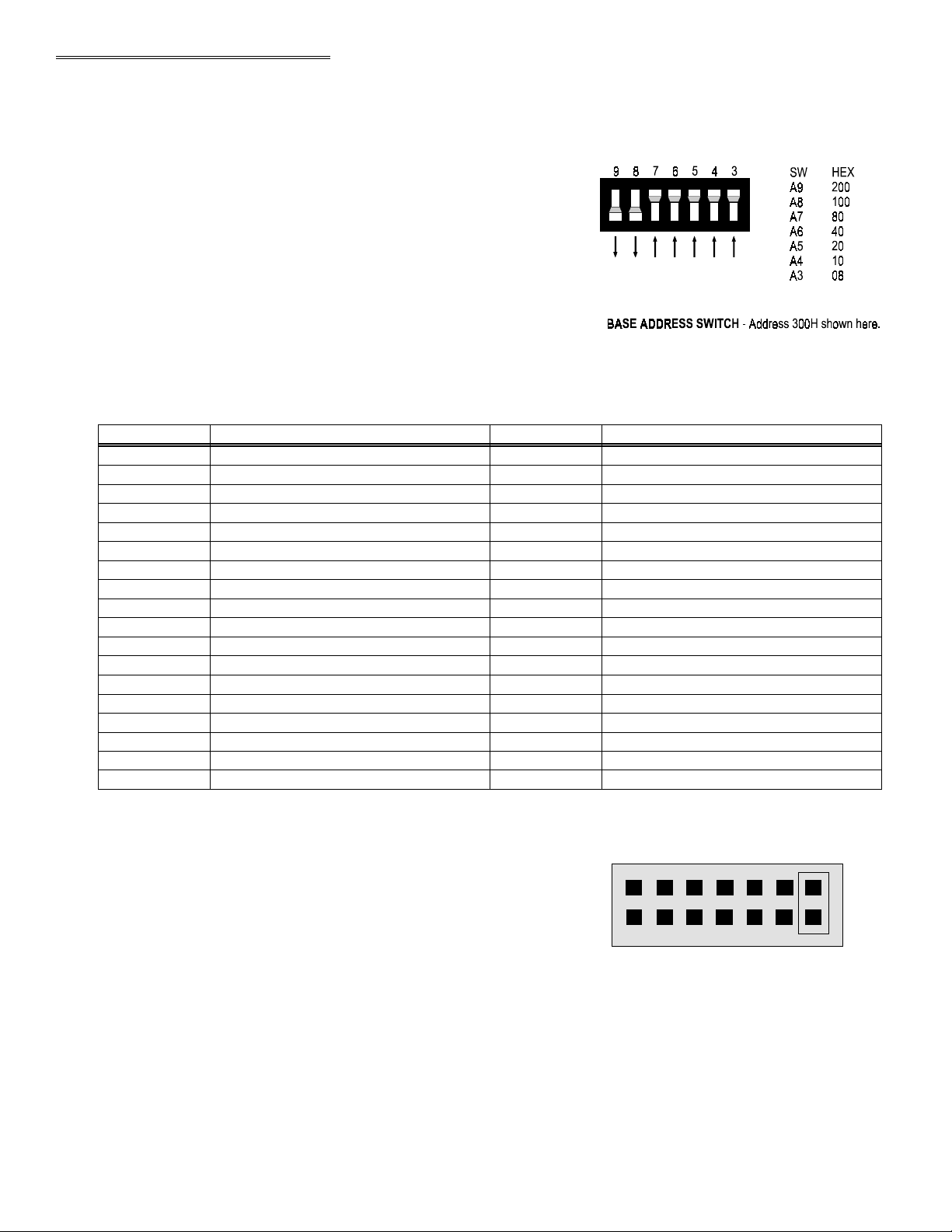

1.2.2 Interrupt Level Select

The interrupt jumper need only be set if the software you are using

requires it. If you do set the interrupt jumper, please check your PC's

current configuration for interrupt conflicts, and do not use IR2 in PC/AT

class machines (or higher).

There is a jumper block on the CIO-DAS08-PGx located just above the

PC bus interface (gold pins). The factory default setting is that no

interrupt level is set. The jumper is in the 'X' position (Figure 1-2).

If you need to pace conversions through hardware (either the on - board

pacer or an external clock), move this jumper to one of the other positions

(see table 1-2). Figure 1-2. Interrupt Select Jumper Block

2

INTERRUPT JUMPER BLOCK - Jumper in

X position = No IRQ.

234567X

Page 7

The following table shows some typical interrupt assignments on a PC. The CIO-DAS08-PGx use interrupt levels 2 through 7.

The levels most often available are 5 and 7.

Table 1-2. IRQ Assignments

DESCRIPTIONNAMEDESCRIPTIONNAME

REAL TIME CLOCK (AT)IRQ8PARITYNMI

RE-DIRECTED TO IRQ2IRQ9TIMERIRQ0 (AT)

UNASSIGNEDIRQ10KEYBOARDIRQ1

IRQ2

UNASSIGNEDIRQ11RESERVED (XT)

INT 8-15 (AT)

UNASSIGNEDIRQ12COM OR SDLCIRQ3

80287 NUMERIC CO-PIRQ13COM OR SDLCIRQ4

HARD DISKIRQ14HARD DISK (XT) or LPT (AT)IRQ5

UNASSIGNEDIRQ15FLOPPY DISKIRQ6

LPTIRQ7

NOTE: IRQ8-15 are AT only.

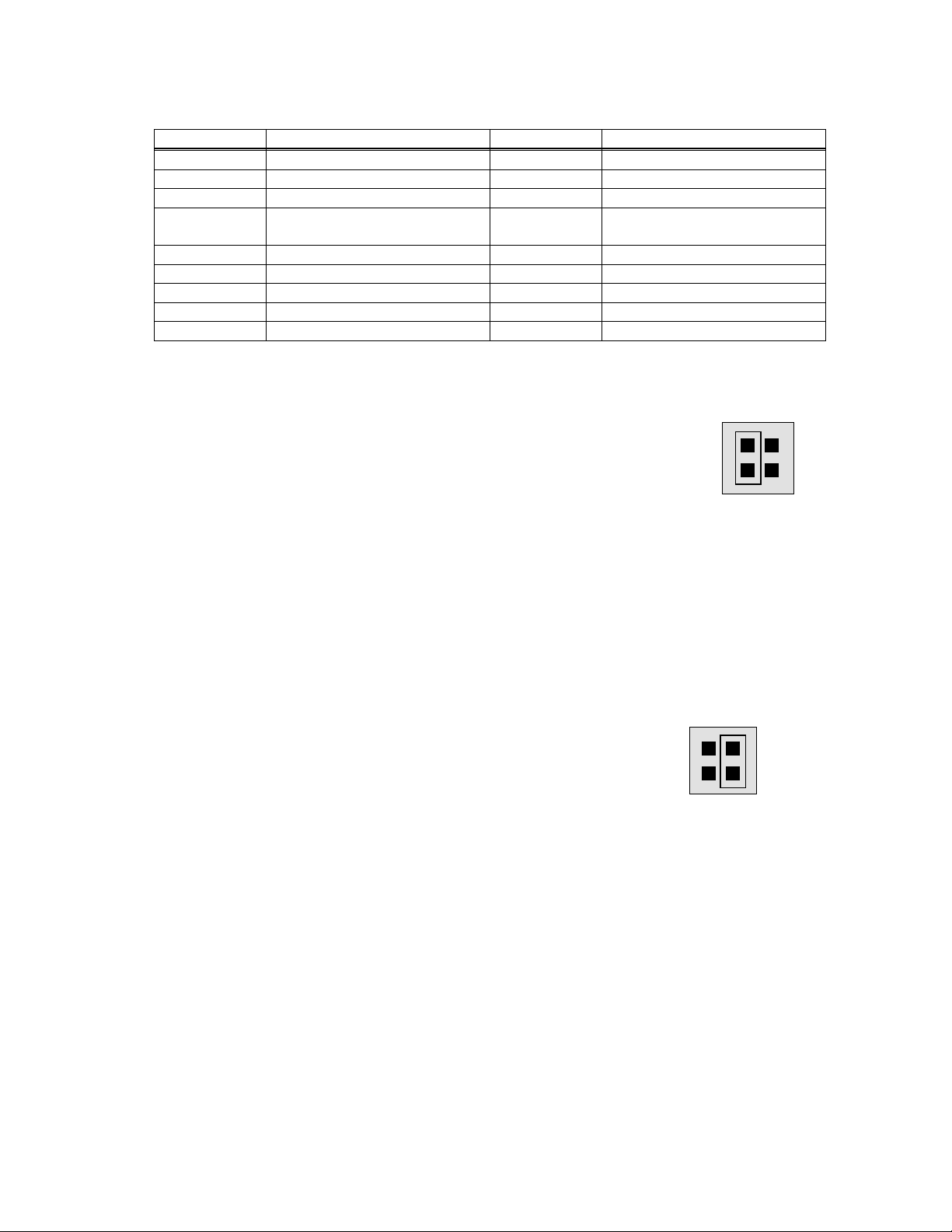

1.2.3 XTAL/PC Bus Clock Jumper

The A/D pacer clock sources for the MetraByte DAS-8PGA differs from the DAS-8.

The source for the DAS-8PGA is fixed at 1 MHz while the source for the DAS-8 gets

its clock pulse from the PC Bus Clock.

1 MHz

CLK

BUS

The CIO-DAS08-PGx pacer clock is selected by jumper to satisfy software written

for either board (Figure 1-3). The default choice for this jumper is the 1 MHz

position. You can alternately select the PC Bus Clock as the source for the A/D pacer

clock.

CLOCK SOURCE JUMPER - For a

standard DAS-8PGA 1 MHz A/D

Pacer Clock, place the jumper on the

two leftmost pins. For a DAS-8 type

A/D Pacer from PC Bus Clk, place the

jumper on the two rightmost pins.

Figure 1-3. Pacer Clock Select Jumper

1.2.4 Wait State

A wait state can be enabled on the CIO-DAS08-PGx by selecting WAIT STATE ON

at the jumper provided on the board. Enabling the wait state causes the personal

O

O

F

N

F

computer's bus transfer rate to slow down for board reads and writes ..

The wait state jumper is provided in case your computer ever has an I/O bus transfer

rate which is too fast for the CIO-DAS08-PGA. If your board were to fail sporadically

in random ways, try selecting the wait state ON.

WAIT STATE JUMPER BLOCK - A

wait state is not selected on this

jumper block. For a wait state,

place the jumper on the two

leftmost pins.

Figure 1-4. Wait State Jumper Block

1.2.5 Installing The CIO-DAS08-PGx In The Computer

1. Turn the power off.

2. Remove the cover of your computer. Please be careful not to dislodge any of the cables installed on the boards in your

computer as you slide the cover off.

3. Locate an empty expansion slot in your computer.

WAIT

STATE

4. Push the board firmly down into the expansion bus connector. If it is not seated fully it may fail to work and could short circuit

the PC bus power onto a PC bus signal. This could damage the motherboard in your PC as well as the board.

3

Page 8

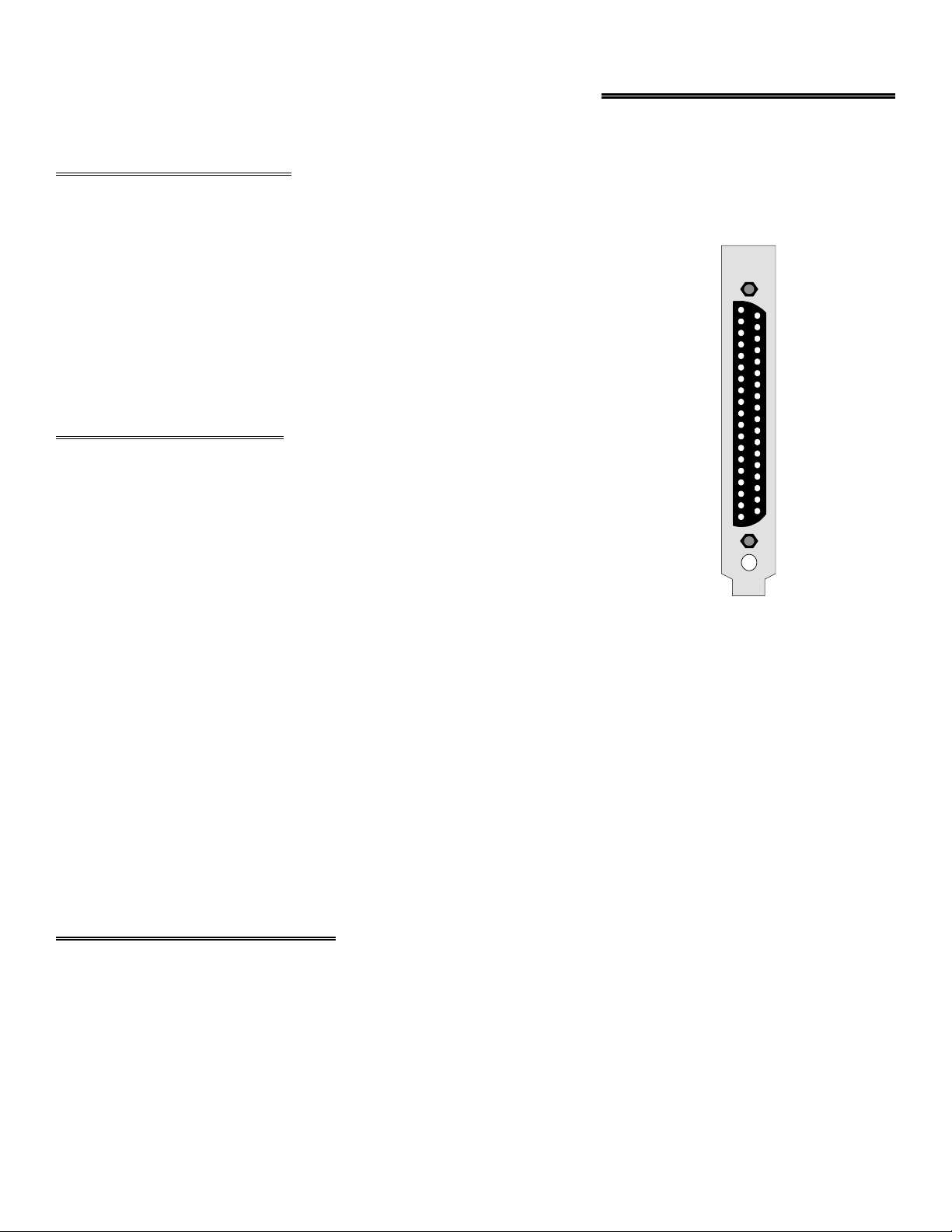

2.1 CONNECTOR DIAGRAM

The analog connector is a 37-pin, D-type connector accessible from the rear of

the PC through the expansion backplate (Figure 2-1).

2: SIGNAL CONNECTION

The connector accepts female 37 D-type connectors, such as those on the

C73FF-2, 2 foot cable with connectors.

If frequent changes to signal connections or signal conditioning is required,

please refer to the information on the CIO-TERMINAL and CIO-MINI37

screw terminal boards, CIO-EXP32, 32 channels analog MUX/AMP. Isolation

amplifiers can be mounted using the ISO-RACK08 and 5B isolation modules.

2.2 DIFFERENTIAL INPUTS

Differential inputs are 3-wire analog hookups consisting of a signal high, signal

low and chassis ground. The benefits of differential inputs are the ability to

CH0 LO 19

CH1 LO 18

CH2 LO 17

CH3 LO 16

CH4 LO 15

CH5 LO 14

CH6 LO 13

CH7 LO 12

LLGND 11

DIGITAL OUT 4 10

DIGITAL OUT 3 9

DIGITAL OUT 2 8

DIGITAL OUT 1 7

COUNTER 2 OUT 6

COUNTER 1 OUT 5

COUNTER 1 IN 4

COUNTER 0 OUT 3

COUNTER 0 IN 2

+15 FROM DC/DC 1

37 CH0 HIGH

36 CH1 HIGH

35 CH2 HIGH

34 CH3 HIGH

33 CH4 HIGH

32 CH5 HIGH

31 CH6 HIGH

30 CH7 HIGH

29 +5 VOLTS

28 DIG GND

27 DIGITAL IN 3

26 DIGITAL IN 2

25 DIGITAL IN 1

24 INTERRUPT INPUT

23 GATE 2

22 GATE 1

21 GATE 0

20 -15V FROM DC/DC

reject noise which affects both signal high and low, and the ability to

compensate for ground loops or potentials between signal low and chassis

ground.

Figure 2-1. Analog Connector

Although differential inputs are often preferable to single ended inputs, there are occasions when the floating nature of a

differential input can confound attempts to make a reading. In those cases, the inputs can be converted to modified differential.

Examine the diagram of the CIO-DAS08-PGx board. Near the 37-pin connector is located a position for an optional Single Inline

Package (SIP) of resistors. Installing the SIP converts the analog inputs from fully differential to modified differential with a

resistive reference to ground. A SIP resistor network is included with the board for this purpose.

NOTE:

When using the CIO-DAS08-PGx with the CIO-EXP16 or CIO-EXP32, the optional SIP resistor must be

installed. The CIO-EXP16 and CIO-EXP32 (and MetraByte EXP16) were designed to interface to a single-ended input.

Failure to install the SIP resistor when the board is used with these expansion boards will result in floating, unstable

readings.

Special instructions and solder are packaged with the SIP resistor. Follow the installation instructions carefully

and use the solder provided. Use of any other solder, or failure to follow instructions can result in a degradation

of the analog input's accuracy and may require out-of-warranty repair

.

2.3 DIGITAL OUTPUTS & INPUTS

All the digital outputs inputs on the CIO-DAS08-PGx are TTL level. TTL is an electronics industry term, short for Transistor

Transistor Logic, with describes a standard for digital signals which are either at 0V or 5V.

4

Page 9

3: ANALOG CONNECTIONS

3.1 ANALOG INPUTS

Prior to jumping into actual connection schemes, you should have at least a basic understanding of Single-Ended/Differential

inputs and system grounding/isolation. If you are already comfortable with these concepts you may wish to skip to the next section

(on wiring configurations).

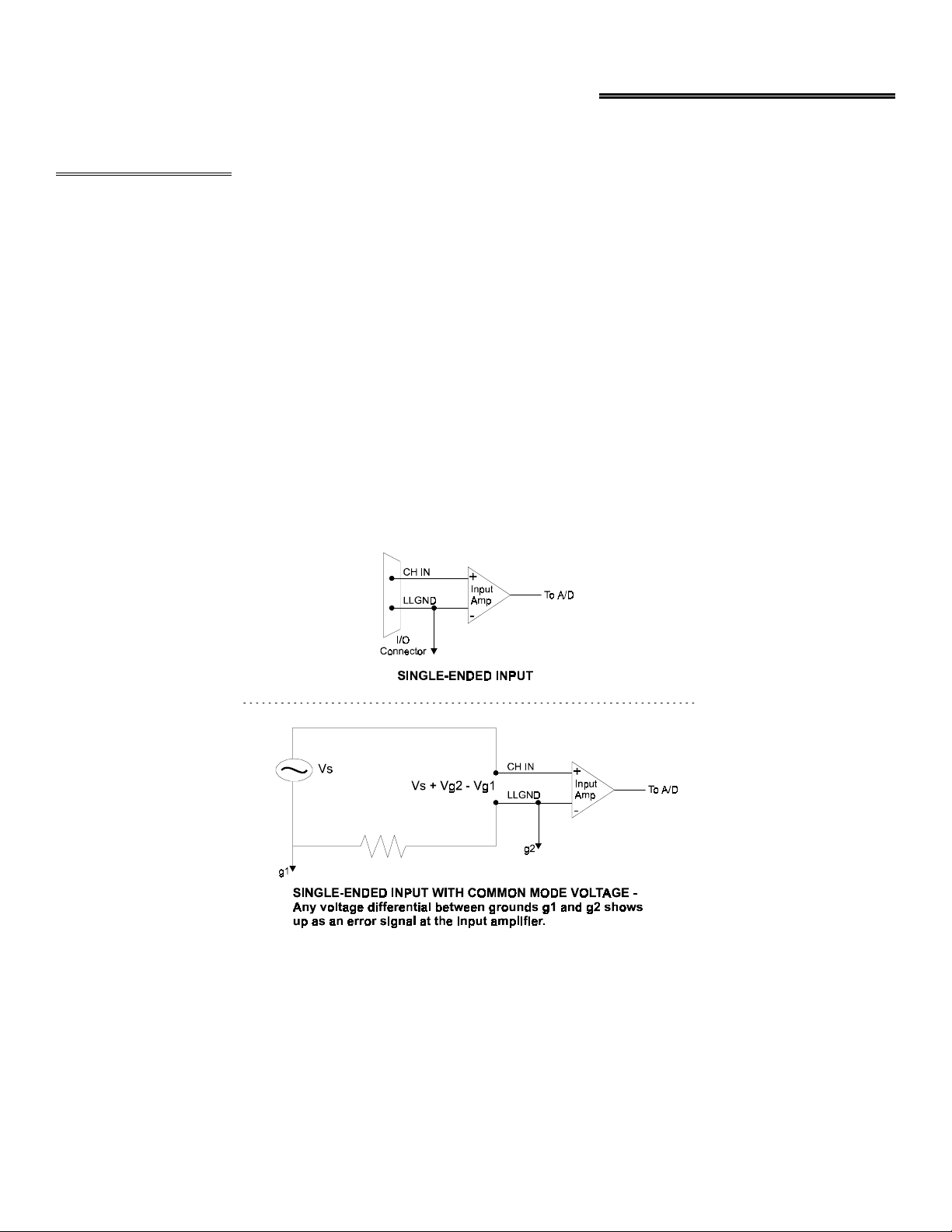

3.1.1 Single-Ended and Differential Inputs

The CIO-DAS08-PGx provides either 8 differential or 16 single-ended input channels. The concepts of single-ended and

differential inputs are discussed in the following section

Single-Ended Inputs

A single-ended input measures the voltage between the input signal and ground. In this case, in single-ended mode the

CIO-DAS08-PGx measures the voltage between the input channel and LLGND. The single-ended input configuration requires

only one physical connection (wire) per channel and allows the board to monitor more channels than the differential configuration

using the same connector and onboard multiplexer (Figure 3-1). However, since the CIO-DAS08-PGx is measuring the input

voltage relative to its own low level ground, single-ended inputs are more susceptible to both EMI (electro magnetic interference)

and any ground noise at the signal source. The following diagrams show the single-ended input configuration. Note: For

simplicity, the input multiplexer is not shown.

.

Figure 3-1. Single-Ended Input Configuration (Simplified)

5

Page 10

3.1.2 Differential Inputs

Differential inputs measure the voltage between two distinct input signals. Within a certain range (referred to as the common mode

range), the measurement is almost independent of signal source to CIO-DAS08-PGA ground variations. A differential input is also

much more immune to EMI than a single-ended one. Most EMI noise induced in one lead is also induced in the other, the input

only measures the difference between the two leads, and the EMI common to both is ignored. This effect is a major reason there is

twisted pair wire as the twisting assures that both wires are subject to virtually identical external influence. Figure 3-2 below

shows a typical differential input configuration.

Figure 3-2. Differential Input Configuration

6

Page 11

Before moving on to the discussion of grounding and isolation, it is important to explain the concepts of common mode, and

common mode range (CM Range). Common mode voltage is depicted in Figure 3-2 as Vcm. Though differential inputs measure

the voltage between two signals, without (almost) respect to the either signal’s voltages relative to ground, there is a limit to how

far away from ground either signal can go. Though the CIO-DAS08-PGx has differential inputs, it will not measure the difference

between 100V and 101V as 1 Volt (in fact the 100V would destroy the board!). This limitation or common mode range is depicted

graphically in Figure 3-3. The CIO-DAS08-PGx common mode range is +/- 10 Volts. Even in differential mode, no input signal

can be measured if it is more than 10V from the board’s low level ground (LLGND).

+13V

+12V

+11V

+10V

+9V

+8V

+7V

+6V

+5V

+4V

+3V

+2V

+1V

-1V

-2V

-3V

-4V

-5V

-6V

-7V

-8V

-9V

-10V

-11V

-12V

-13V

3.1.3 System Grounds and Isolation

Gray area represents common mode range

Both V+ and V- must always re ma in w ithin

the common m ode range re la tiv e to L L Gn d

With Vcm= +5VDC,

+Vs must be less than +5V, or the comm on m ode range w ill be e x c eeded (>+10V)

Vcm

Vcm (Common M ode Voltage) = +5 Volts

Figure 3-3. Common Mode Range Limits

There are three scenarios possible when connecting your signal source to your board.

1. The board and the signal source may have the same (or common) ground. This signal source can be connected directly to the

board.

2. The board and the signal source may have an offset voltage between their grounds (AC and/or DC). This offset it commonly

referred to a common mode voltage. Depending on the magnitude of this voltage, it may or may not be possible to connect

the board directly to your signal source. We will discuss this topic further in a later section.

3. The board and the signal source may already have isolated grounds. This signal source may be connected directly to the

board.

3.1.4 Which system do you have?

Try the following experiment. Using a battery powered voltmeter

1

, measure the voltage (difference) between the ground signal at

your signal source and at your PC. Place one voltmeter probe on the PC ground and the other on the signal source ground.

Measure both the AC and DC Voltages.

If both AC and DC readings are 0.00 volts, you may have a system with common grounds. However, since voltmeters will average

out high frequency signals, there is no guarantee. Please refer to the section below titled Common Grounds.

1

If you do not have access to a voltmeter, skip the experiment and take a look at the following three sections. You may be able to identify your system type from the

descriptions provided.

7

Page 12

If you measure reasonably stable AC and DC voltages, your system has an offset voltage between the grounds category. This

offset is referred to as a Common Mode Voltage. Please be careful to read the following warning and then proceed to the section

describing Common Mode systems.

WARNING

If either the AC or DC voltage is greater than 10 volts, do not connect the CIO-DAS08-PGA to this signal

source. You are beyond the boards usable common mode range and will need to either adjust your grounding

system or add special Isolation signal conditioning to take useful measurements. A ground offset voltage of

more than 30 volts will likely damage the board and possibly your computer. Note that an offset voltage much

greater than 30 volts will not only damage your electronics, but it can also be hazardous to your health.

If you cannot obtain a reasonably stable DC voltage measurement between the grounds, or the voltage drifts around considerably,

the two grounds are most likely isolated. The easiest way to check for isolation is to change your voltmeter to it’s ohm scale and

measure the resistance between the two grounds. It is recommended that you turn both systems off prior to taking this resistance

measurement. If the measured resistance is more than 100 Kohm, it’s a fairly safe bet that your system has electrically isolated

grounds.

3.1.5 Systems with Common Grounds

In the simplest (but perhaps least likely) case, your signal source will have the same ground as the CIO-DAS08-PGx. This would

typically occur when providing power or excitation to your signal source directly from the board. There may be other common

ground configurations, but it is important to note that any voltage between the board ground and your signal source ground is a

potential error voltage if you set up your system based on a common ground assumption.

As a safe rule of thumb, if your signal source or sensor is not connected directly to an LLGND pin on your board, it’s best to

assume that you do not have a common ground even if your voltmeter measured 0.0 Volts. Configure your system as if there is

ground offset voltage between the source and the board. This is especially true if you are using the board at high gains, since

ground potentials in the sub millivolt range will be large enough to cause A/D errors, yet will not likely be measured by your

handheld voltmeter.

3.1.6 Systems with Common Mode (ground offset) Voltages

The most frequently encountered grounding scenario involves grounds that are somehow connected, but have AC and/or DC offset

voltages between the board and signal source grounds. This offset voltage my be AC, DC or both and may be caused by a wide

array of phenomena including EMI pickup, resistive voltage drops in ground wiring and connections, etc. Ground offset voltage is

a more appropriate term to describe this type of system, but since our goal is to keep things simple, and help you make appropriate

connections, we’ll stick with our somewhat loose usage of the phrase Common Mode.

3.1.7 Small Common Mode Voltages

If the voltage between the signal source ground and board ground is small, the combination of the ground voltage and input signal

will not exceed the CIO-DAS800’s +/-10V common mode range, (i.e. the voltage between grounds, added to the maximum input

voltage, stays within +/-10V), This input is compatible with the CIO-DAS08-PGx and the system can be connected without

additional signal conditioning. Fortunately, most systems will fall in this category and have a small voltage differential between

grounds.

3.1.8 Large Common Mode Voltages

If the ground differential is large enough, the +/- 10V common mode range will be exceeded (i.e. the voltage between the board

and signal source grounds, added to the maximum input voltage you’re trying to measure exceeds +/-10V). In this case the board

cannot be directly connected to the signal source. You will need to change your system grounding configuration or add isolation

signal conditioning. (Please look at our ISO-RACK and ISO-5B-series products to add electrical isolation, or give our technical

support group a call to discuss other options).

WARNING

Relying on the earth prong of a 120VAC for signal ground connections is not advised.. Different ground plugs

may have large and potentially even dangerous voltage differentials. Remember that the ground pins on

120VAC outlets on different sides of the room may only be connected in the basement. This leaves the

possibility that the “ground” pins may have a significant voltage differential (especially if the two 120 VAC

outlets happen to be on different phases!)

8

Page 13

3.1.9 Board and Signal Source Have Isolated Grounds

g

g

Some signal sources will already be electrically isolated from the board. Figure 3-4 shows a typical isolated ground system. These

signal sources are often battery powered, or are fairly expensive pieces of equipment (since isolation can be expensive), isolated

ground systems provide excellent performance, but require some extra effort during connections to assure optimum performance

is obtained. Please refer to the following sections for further details.

3.2 WIRING CONFIGURATIONS

Combining all the grounding and input type possibilities pro vides us with the following potential connection configurations. The

combinations along with our recommendations on usage are shown in Table 3-1 below.

Table 3-1. Analog Input Configuration Recommendations

GROUND

CATEGORY

INPUT

CONFIGURATION

OUR VIEW

RecommendedSingle-Ended InputsCommon Ground

AcceptableDifferential InputsCommon Ground

Common Mode

Voltage < +/-10V

Common Mode

Voltage < +/-10V

Common Mode

Voltage > +/- 10V

Common Mode

Voltage > +/-10V

Single-Ended Inputs

Differential Inputs

Not RecommendedSingle-Ended Inputs

RecommendedDifferential Inputs

Unacceptable without

adding Isolation

Unacceptable without

adding Isolation

AcceptableSingle-ended InputsAlready Isolated Grounds

Already Isolated

Grounds

RecommendedDifferential Inputs

The following sections depicts recommended input wiring schemes for each of the seven possible input configuration/grounding

combinations.

3.2.1 Common Ground / Single-Ended Inputs

Single-ended is the recommended co nfiguration for common ground co nnections. However, if some of your inputs are common

ground and some are not, we recommend you use the differential mode. There is no performance penalty (other than loss of

channels) for using a d ifferential input to measure a common ground signal source. H owever the reverse is not true . Figure 3-4

below shows a recommended connection diagram for a common ground / single-ended input system.

Signal

S our c e w ith

C om m o n G nd

Optional wire

since signal source

and A/D board share

common ground

Signal source and A/D board

sharin

common ground connected

to s in

le- en d e d in p u t.

I/O

Connector

CH IN

LL GND

+

Inp u t

Amp

-

A/D Board

To A / D

Figure 3-4. Common Ground / Single-Ended Inputs

9

Page 14

3.2.2 Common Ground / Differential Inputs

g

g

g

The use of differential inputs to monitor a signal source with a common ground is a acceptable configuration though it requires

more wiring and offers fewer channels than selecting a single-ended configuration. Figure 3-5 below shows the recommended

connections in this configuration.

Signal

So ur ce w ith

Co mm o n Gnd

Optional wire

since signal source

and A/D board sha re

common ground

Required conn ection

of LL GND to CH Low

I/O

Connector

CH High

CH Low

LL GND

+

Input

Amp

-

A/D Board

To A /D

Signal source and A/D board

sharin

com m on ground connected

to differential input.

Figure 3-5. Common Ground / Differential Inputs

3.2.3 Common Mode Voltage < +/-10V/Single-Ended Inputs

This is not a recommended configuration. In fact, the phrase common mode has no meaning in a single-ended system and this case

would be better d escribed as a system with offset grounds. Ho wever, you can try this configuration. No system damage should

occur and depending on the overall accuracy you require, you may receive acceptable results.

3.2.4 Common Mode Voltage < +/-10V/Differential Inputs

Systems with varying ground potentials should always be monitored in the differential mode. Care is required to assure that the

sum of the input signal and the ground differential (referred to as the common mode voltage) does not exceed the common mode

range of the A/D board (+/-10V on the CIO-DAS08-PGx). The diagram below show recommended connections in this

configuration.

Signal Source

w ith Com mon

Mo d e V o lta g e

The voltage differential

between these grounds,

added to the maximum

input signal must stay

within +/-10 V

GND

I/O

Connector

CH Hi

CH Low

LL GND

h

+

Inp ut

Amp

-

A/D Board

To A / D

Signal source and A/D board

with common m ode volta

e

connected to a differential input.

Figure 3-6. Common Mode Voltage < +/-10V/Differential Inputs

10

Page 15

3.2.5 Common Mode Voltage > +/-10V

g

g

g

g

g

g

g

g

g

g

g

g

g

g

The CIO-DAS08-PGx will not directly monitor signals with common mode voltages greater than +/-10V. You will either need to

alter the system ground configuration to reduce the overall common mode voltage, or add isolated signal conditioning between the

source and your board. See Figures 3-7 and 3-8.

Iso la tio n

Barrier

arge common

L

mode voltage

between signal

source & A/D board

When the voltage difference

between si

A/D board

enou

common mode ran

exceeded, isolated si

conditionin

GND

nal source and

round is large

h so the A/D board’s

must be added.

e is

CH IN

I/O

Conn ector

LL GND

+

-

Input

Amp

To A /D

A/D Board

nal

System with a Large Common Mode Voltage,

Connected to a Sin

le-Ended Input

Figure 3-7. Common Mode Voltage - >+/- 10V Single-Ended Input

Isolation

Barrier

arge comm on

L

mode voltage

between signa l

source & A /D b o a rd

When the voltage difference

between si

A/D board

enou

comm on m ode ran

exceeded, isolated si

conditionin

GND

nal source and

round is large

h so the A/D board’s

must be added.

CH Hi

h

+

Inpu t

Amp

-

A/D Board

I/O

Connector

CH Low

LL GND

10 K

e is

nal

10K is a recommended value. You may short LL GND to CH Low

instead, but this will reduce your system’s noise immunity.

To A / D

System with a Large Comm on Mode Voltage,

Connected to a Differential Input

Figure 3-8. Common Mode Voltage - >+/- 10V Differential Input

11

Page 16

3.2.6 Isolated Grounds / Single-Ended Inputs

g

Single-ended inputs can be used to monitor isolated inputs, though the use of the differential mode will increase you system’s

noise immunity. Figure 3-9 below shows the recommended connections is this configuration.

Isolated

signal

s o urc e

CH IN

LL GND

I/O

Connector

+

Inpu t

Amp

To A /D

-

A/D Board

Isolated Signal Source

Connected to a Single-Ended Input

Figure 3-9 . Isolated Grounds - Single-Ended Inputs

3.2.7 Isolated Grounds / Differential Inputs

Optimum performance with isolated signal sources is assured with the use of the differential input setting. Figure 3-10 shows the

recommend connections is this configuration..

Signal Source

an d A/D Bo a rd

A lread y I s o la ted .

GND

10 K

CH High

CH Low

LL GND

+

-

Input

Amp

To A /D

These

rounds are

electrically isolated.

I/O

Connector

10K is a recomm ended value. You may short LL GN D to CH Low

instead, b ut this will reduce your system’s noise imm unity.

A/D Board

Already isolated signal source

and A/D board connected to

a differential input.

Figure 3-10. Isolated Grounds - Differential Inputs

12

Page 17

4: REGISTER ARCHITECTURE

4.1 CONTROL & DATA REGISTERS

The CIO-DAS08-PGx is controlled and monitored by writing to and reading from eight consecutive 8-bit I/O addresses. The first

address, or BASE ADDRESS, is determined by setting a bank of switches on the board.

Register manipulation is best left to experienced programmerss as most of the possible functions are implemented in easy to use

Universal Library™.

The register descriptions follow the format:

Where the numbers along the top row are the bit positions within the 8-bit byte and the numbers and symbols in the bottom row is

the function associated with each bit.

To write to or read from a register in decimal or HEX, the bit weights listed in table 4-1 apply.

01234567

A/D8A/D7A/D6A/D5A/D4A/D3A/D2A/D1

Table 4-1. Register Bit Weights

HEX VALUEDECIMAL VALUEBIT POSITION

110

221

442

883

10164

20325

40646

801287

To write control words or data to a register, the individual bits must be set to 0 or 1 then combined to form a byte.

The method of programming required to read/write bits from bytes is beyond the scope of this manual.

In summary form, the registers and their function are listed in Table 4-2. Each register has eight bits which may constitute a byte

of data or eight individual bit read/write functions.

Table 4-2. Board Register Functions

WRITE FUNCTIONREAD FUNCTIONADDRESS

Start 8 Bit A/D ConversionA/D Bits 9-12 (LSB)BASE

Start 12 Bit A/D ConversionA/D Bits 1(MSB)-8BASE +1

BASE +2

EOC, IP1-IP3, IRQ, MUX

Address

OP1-OP4, INTE & MUX

Address

Programmable Gain ControlChannel MUX and Gain StatusBASE +3

Load Counter 0Read Counter 0BASE +4

Load Counter 1Read Counter 1BASE +5

Load Counter 2Read Counter 2BASE +6

Counter ControlNot UsedBASE +7

13

Page 18

4.2 A/D DATA REGISTER

BASE ADDRESS (Read / Write)

READ

On read, it contains the least significant four digits of the analog input data.

These four bits of analog input data must be combined with the eight bits of analog input data in BASE + 1, forming a complete

12 bit number. The data is in the format 0 = minus full scale. 4095 = +FS.

WRITE

Writing any data to the register causes an immediate 8-bit A/D conversion.

BASE + 1 (Read / Write)

READ

On read, the most significant A/D byte is read.

01234567

0000A/D12 LSBA/D11A/D10A/D9

01234567

A/D8A/D7A/D6A/D5A/D4A/D3A/D2A/D1 MSB

The A/D Bits code corresponds to the voltage on the input according to the table below.

UNIPOLARBIPOLARHEXDECIMAL

+Full Scale+Full ScaleFFF4095

½ Full Scale0 Volts8002048

00

WRITE

Writing to this register starts a 12-bit A/D conversion.

A note of caution: Place several NO-OP instructions between consecutive 12-bit A/D conversions to avoid over-running the A/D

converter.

−

Full Scale

0 Volts

4.3 STATUS AND CONTROL REGISTER

BASE + 2 (Read / Write) Read Functions

READ = STATUS

EOC = 1 the A/D is busy converting and data should not be read.

01234567

MUX0MUX1MUX2IRQIP1IP2IP3EOC

EOC = 0 the A/D is not busy and data can be read.

IP3 to IP1 are the digital input lines on the 37 pin analog connector.

IRQ is the status of an edge triggered latch connected to Interrupt Input (pin 24) of the analog connector. It is high (1) when a

positive edge has been detected. It can be reset to 0 by writing to the INTE mask at BASE + 2 write.

14

Page 19

MUX 2 to MUX 0 is the current multiplexer channel. The current channel is a binary coded number between 0 and 7 .

WRITE = CONTROL

BASE + 2 (Read / Write) Write Functions

OP4 to OP1 are the digital output lines on the 37 pin analog connector.

INTE = 1 enables interrupts (positive edge triggered) onto the PC bus IRQ selected via the IRQ jumper on the CIO-DAS08-PGA.

INTE = 0 disables the passing of the interrupt detected at pin 24 to the PC bus.

IRQ is set to 1 every time an interrupt occurs. If you want to process successive interrupts then set INTE = 1 as the last step in

your interrupt service routine.

MUX2 to MUX0. Set the current channel address by writing a binary coded number between 0 and 7 to these three bits.

NOTE

Every write to this register sets the current A/D channel MUX setting to the number in bits 2-0.

4.4 PROGRAMMABLE GAIN REGISTER

01234567

MUX0MUX1MUX2INTEOP1OP2OP3OP4

The register's layout when written to is :

BASE + 3 (Read / Write) Write Functions

The register's layout when read from is :

BASE + 3 (Read / Write) Read Functions

The gain/range of a board is controlled by writing a control code to the register. The codes are as follows:

CONTROL CODESBI-POLAR

CIO-DAS08-PGH

10.00.5

5.01

1.05

0.510

0.150

0.05100

0.01500

0.0051000

BIT 0BIT 1BIT 2BIT 3BIT 4BIT 5BIT 6BIT 7

R0R1R2R3XXXX

BIT 0 BIT 1BIT 2BIT 3BIT 4BIT 5BIT 6BIT 7

R0R1R2R3MA0MA1MA2X

R0R1R2R3HEXDECRANGE VGAIN

000188+

000000+

0101A10+

010022+

0011C12+

001044+

0111E14+

011066+

CIO-DAS08-PGH

CONTROL CODESUNI-POLAR

R0R1R2R3HEXDECRANGE VGAIN

1000110 to 10.01

1100330 to 1.010

1010550 to 0.1100

1110770 to 0.011,000

15

Page 20

There are fewer ranges available for the CIO-DAS08-PGL. Gains of 2, 4 & 8 are often called binary gains. These ranges are not

available on the MetraByte DAS-8PGA.

CONTROL CODESBI-POLAR

CIO-DAS08-PGL

R0R1R2R3HEXDECRANGE VGAIN

10.00.5

5.01

2.52

1.254

0.6258

CONTROL CODESUNI-POLAR

CIO-DAS08-PGL

CONTROL CODESBI-POLAR

CIO-DAS08-PGM

10.00.5

5.01

0.52

0.054

000188+

000000+

010022+

004044+

011066+

R0R1R2R3HEXDECRANGE VGAIN

1000110 to10.01

1100330 to 5.02

1010550 to 2.54

1100770 to 1.258

R0R1R2R3HEXDECRANGE VGAIN

000188+

000000+

0101A10+

0011C12+

0111E14+0.018

CONTROL CODESUNI-POLAR

CIO-DAS08-PGM

R0R1R2R3HEXDECRANGE VGAIN

1001990 to10.01

1101B110 to 1.02

1010D130 to 0.14

1111F150 to 0.018

To set the input range of the CIO-DAS08-PGx board, select the desired range from the table and write the code in decimal or

hexadecimal to base address + 3. Here is an example in BASIC:

100 OUT &H303, 8 'Set gain = 0.5 (±10V range)

The range of the analog inputs is now set to ±10V or 2.44mV per bit (10/4096).

MA2 to MA0 = Indicates the analog input channel that is currently selected (by writing to base +2).

16

Page 21

4.5 COUNTER LOAD & READ REGISTERS

COUNTER 0

BASE ADDRESS + 4 (Read / Write)

COUNTER 1

BASE ADDRESS + 5 (Read / Write)

COUNTER 2

BASE ADDRESS + 6 (Read / Write)

The data in the counter read register, and the action taken on the data in a counter load register, is wholly dependent upon the

control code written to the control register.

The counters are 16-bit counters, each with an 8-bit window, the read / load register. Data is shifted into and out of the 16-bit

counters through these 8-bit windows according to the control byte.

You will need an 8254 data sheet if you want to program the 8254 directly at the register level.

01234567

D0D1D2D3D4D5D6D7

01234567

D0D1D2D3D4D5D6D7

01234567

D0D1D2D3D4D5D6D7

4.6 COUNTER CONTROL REGISTER

BASE ADDRESS + 7 (Write Only)

WRITE

SC1 to SC0 are the counter select bits. They are binary coded between 0 and 2.

RL1 to RL0 are the read and load control bits:

Latch Counter00

Read/load high byte10

Read/load low byte01

Read/load low the high byte (word transfer)11

M2 to M0 are the counter control operation type bits:

Change on terminal count000

Programmable one-shot100

Rate generator010

Square wave generator110

Software triggered strobe001

Hardware triggered strobe101

01234567

BCDM0M1M2RL0RL1SC0SC1

OPERATIONRL0RL1

OPERATION TYPEM0M1M2

BCD = 0 then counter data is 16-bit binary. (65,535 max)

17

Page 22

BCD = 1 then counter data is 4-decade Binary Coded Decimal. (9,999 max)

4.7 COUNTER/TIMER

The 82C54 counter/timer chip (Figure 4-1) may be used for event counting, frequency and pulse measurement and as a pacer

clock for the A/D converter. All the inputs, outputs and gates of the counter are accessible through the 37 pin analog connector

with the exception of the counter 2 input.

The counter is easy to understand. The GATE line determines whether or not TTL level pulses present at the CLK input will

decrement the counter. The OUT line then transitions (pulses or shifts) depending on the codes in the control register and the

count value in the count register.

The counter gates, inputs and outputs are all simple TTL.

The primary purpose of the counter timer chip is to pace the A/D samples. The input of counter 2 is jumper selectable for a

crystal controlled source or the PC bus clock source.

The PCLK signal is divided by 2 prior to the input at counter 2, therefore, if the PCLK signal on your PC/AT were 8 MHz, the

signal at the input of counter 2 would be 4MHz. The 10 MHz crystal source is divided by 10.

Assuming a 4 MHz signal at counter 2, the rates out of counter 2 (pin 6) can vary between 2 MHz (4 MHz / 2) to 61 Hz (4 MHz /

65,535). For rates slower than 61 Hz, wire the output of counter 2 to the input of counter 1. Next, wire the output of counter 1 to

the interrupt input (pin 24). The slowest rate is then once every 17 minutes.

When using the crystal source, the minimum rate would be about 15 Hz using only one counter.

10K

+5

RN1

10

10 MHz

CRYSTAL

1 MHz

2

21

2

22

4

23

CLK BUS

U8

3

GATE 0

CLK 0

GATE 1

CLK 1

GATE 2

CLK 2

COUNTER 0

COUNTER 1

COUNTER 2

U14

3

5

6

37 PIN

CON

PC BUS PCLK - B20

Figure 4-1. Counter /Timer Block Diagram

18

Page 23

4.8 DIGITAL INPUT

The digital inputs are simple TTL level lines. They feed into an 8-bit register which has other on-board signals fed into it. The

resultant 8-bit status byte can be read at BASE address + 2.

The digital inputs IP1, IP2 & IP3 can be used as status lines to trigger or hold off A/D conversions. Be aware of possible conflicts

when pacing conversions from the on - board pacer and simultaneously using IP1 through IP3 as general purpose digital inputs.

4.9 DIGITAL OUTPUT

The digital output lines, OP1, OP2, OP3 & OP4 are TTL level lines which are controlled with part of an 8-bit register located at

BASE address + 2.

The lines are used to control the multiplexer address on an external CIO-EXP32 differential amplifier/ multiplexer if one is

installed. For that reason, we recommend not using them as general purpose digital outputs.

19

Page 24

4.10 TRIGGER & INTERRUPT LOGIC

The trigger logic on the CIO-DAS08-PGx is quite simple. Pin 24 of the 37 pin connector is an input to a flip-flop which can be

read at BASE address + 2 on the IRQ bit. The board can be triggered by polling this bit until a trigger pulse (rising edge) has

occurred. It must be reset by a write to BASE + 2 before it will respond to additional rising edges.

By writing a 1 to the INTE control bit at BASE + 2, the rising edge detected by the flip-flop will be translated into an interrupt

pulse which can be used to interrupt the CPU's 8259 interrupt controller on the PC motherboard.

The interrupt level jumper on the board may need to be installed. Move it from the 'X' (default) position to the IRQ number you

want the interrupt pulse on.

The 82C54 counter/timer chip is primarily a pacer for A/D samples. It is an integral part of the trigger logic. To employ the 82C54

as an A/D pacer, wire the output of the counter (pin 6) that you will program to provide pacing pulses directly into the Interrupt

Input (pin 24).

20

Page 25

5: SPECIFICATIONS

Power consumption

+5V: 900 mA typical, 1125 mA max

Analog input section

A/D converter type AD574

Resolution 12 bits

Number of channels 8 differential (configurable as quasi-differential via installation of SIP resistor)

Input Ranges

CIO-DAS08/PGH ±10V, ±5V, ±1V, ±0.5V , ±0.1V, ±0.05V, ±0.01V, ±0.005V, 0 to 10V, 0 to 1V, 0 to

0.1V, 0 to 0.01V software selectable

CIO-DAS08/PGL ±10V, ±5V, ±2.5V, ±1.25V, ±0.625V, 0 to 10V, 0 to 5V, 0 to 2.5V, 0 to 1.25V

software selectable

CIO-DAS08/PGM ±10V, ±5V, ±0.5V, ±0.05V, ±0.01V, 0 to 10V, 0 to 1V, 0 to 0.1V, 0 to 0.01V

software selectable

Polarity Unipolar/Bipolar, software selectable

A/D pacing Internal counter or external source (Interrupt Input, jumper selectable, rising edge) or

software polled

A/D Trigger sources External hardware/software (Digital In 1)

Data transfer Interrupt or software polled

DMA None

A/D conversion time 25 µs

Throughput 20 kHz, PC dependent

Accuracy ±0.01% of reading ±1 LSB

±0.05% of full scale

Differential Linearity error ±1 LSB

Integral Linearity error ±0.5 LSB

No missing codes guaranteed 12 bits

Gain drift (A/D specs) ±25 ppm/°C

Zero drift (A/D specs) ±10µV/°C

Common Mode Range ±10V

CMRR 72 dB

Input leakage current (@25 Deg C) 100 nA

Input impedance 10 Meg Ohms min

Absolute maximum input voltage ±35

Digital Input / Output

Digital Type (main connector)

Output: 74LS273

Input: 74LS244

Configuration 4 fixed output bits, 3 fixed input bits

Number of channels 4 out, 3 in

Output High 2.7 volts min @ −0.4mA

Output Low 0.4 volts max @ 8 mA

Input High 2.0 volts min, 7 volts absolute max

Input Low 0.8 volts max, −0.5 volts absolute min

Interrupts 2 - 7, jumper selectable

Interrupt enable Programmable

Interrupt sources External (Interrupt In), rising edge

21

Page 26

Counter section

Counter type 82C54

Configuration 3 down-counters, 16 bits each

Counter 0 - independent, user configurable

Source: user connector (Counter 0 In)

Gate: user connector (Gate 0)

Output: user connector (Counter 0 Out)

Counter 1 - independent, user configurable

Source: user connector (Counter 1 In)

Gate: user connector (Gate 1)

Output: user connector (Counter 1 Out)

Counter 2 - independent, user configurable

Source: 1 MHz (from 10MHz Xtal via divide-by-ten) or PC SysClk (via divide by 2 circuit)

selectable by jumper

Gate: user connector (Gate 2)

Output: user connector (Counter 2 Out)

Clock input frequency 10 Mhz max

High pulse width (clock input) 30 ns min

Low pulse width (clock input) 50 ns min

Gate width high 50 ns min

Gate width low 50 ns min

Input low voltage 0.8V max

Input high voltage 2.0V min

Output low voltage 0.4V max

Output high voltage 3.0V min

Environmental

Operating temperature range 0 to 50°C

Storage temperature range −20 to 70°C

Humidity 0 to 95% non-condensing

22

Page 27

EC Declaration of Conformity

We, Measurement Computing Corp., declare under sole responsibility that the product:

CIO-DAS08-PGx

DescriptionPart Number

to which this declaration relates, meets the essential requirements, is in conformity with, and CE marking has been applied according to

the relevant EC Directives listed below using the relevant section of the following EC standards and other normative documents:

EU EMC Directive 89/336/EEC: Essential requirements relating to electromagnetic compatibility.

EU 55022 Class B: Limits and methods of measurements of radio interference characteristics of information technology equipment.

EN 50082-1: EC generic immunity requirements.

IEC 801-2: Electrostatic discharge requirements for industrial process measurement and control equipment.

IEC 801-3: Radiated electromagnetic field requirements for industrial process measurements and control equipment.

IEC 801-4: Electrically fast transients for industrial process measurement and control equipment.

Carl Haapaoja, Director of Quality Assurance

Page 28

Measurement Computing Corporation

10 Commerce Way

Suite 1008

Norton, Massachusetts 02766

(508) 946-5100

Fax: (508) 946-9500

E-mail: info@mccdaq.com

www.mccdaq.com

Loading...

Loading...