Page 1

ADAC/5500 Series User’s Manual

12-Bit and 16-Bit PCI Data Acquisition Series Boards

the smart approach to instrumentation ™

IOtech, Inc.

25971 Cannon Road

Cleveland, OH 44146-1833

Phone: (440) 439-4091

Fax: (440) 439-4093

E-mail (sales): sales@iotech.com

E-mail (post-sales): productsupport@iotech.com

Internet:

www.iotech.com

ADAC/5500 Series

Data Acquisition Boards

© 2002, 2003, 2004 by IOtech, Inc. 928795 Printed in the United States of America

1107-0905 Rev 2.0

p/n

Page 2

Warranty Information

Your IOtech warranty is as stated on the product warranty card. You may contact IOtech by phone, fax machine, or

e-mail in regard to warranty-related issues. Phone: (440) 439-4091, fax: (440) 439-4093, e-mail: sales@iotech.com

Limitation of Liability

IOtech, Inc. cannot be held liable for any damages resulting from the use or misuse of this product.

Copyright, Trademark, and Licensing Notice

All IOtech documentation, software, and hardware are copyright with all rights reserved. No part of this product may be

copied, reproduced or transmitted by any mechanical, photographic, electronic, or other method without IOtech’s prior written

consent.

other product names, as applicable, are trademarks of their respective holders. All supplied IOtech software (including

miscellaneous support files, drivers, and sample programs) may only be used on one installation. You may make archival

backup copies.

DIRECT CONNECTTM is a Registered Trademark of IOtech, Inc. IOtech product names are trademarked;

CE Notice

Many IOtech products carry the CE marker indicating they comply with the safety and emissions standards of the European

Community. As applicable, we ship these products with a Declaration of Conformity stating which specifications and

operating conditions apply.

Warnings, Cautions, Notes, and Tips

Refer all service to qualified personnel. This caution symbol warns of possible personal injury or equipment damage under

noted conditions. Follow all safety standards of professional practice and the recommendations in this manual. Using this

equipment in ways other than described in this manual can present serious safety hazards or cause equipment damage.

This warning symbol is used in this manual or on the equipment to warn of possible injury or death from electrical shock

under noted conditions.

This ESD caution symbol urges proper handling of equipment or components sensitive to damage from electrostatic

discharge. Proper handling guidelines include the use of grounded anti-static mats and wrist straps, ESD-protective bags and

cartons, and related procedures.

This symbol indicates the message is important, but is not of a Warning or Caution category. These notes can be of great

benefit to the user, and should be read.

In this manual, the book symbol always precedes the words “Reference Note.” This type of note identifies the location of

additional information that may prove helpful. References may be made to other chapters or other documentation.

Tips provide advice that may save time during a procedure, or help to clarify an issue. Tips may include additional reference.

Specifications and Calibration

Specifications are subject to change without notice. Significant changes will be addressed in an addendum or revision to

the manual. As applicable, IOtech calibrates its hardware to published specifications. Periodic hardware calibration is

not covered under the warranty and must be performed by qualified personnel as specified in this manual. Improper

calibration procedures may void the warranty.

Quality Notice

IOtech has maintained ISO 9001 certification since 1996. Prior to shipment, we thoroughly test our products and review

our documentation to assure the highest quality in all aspects. In a spirit of continuous improvement, IOtech welcomes

your suggestions.

1.1

ii

Page 3

Warranty, Warnings, Cautions, and Notes ……………………………………………………....…. iii

1. INTRODUCTION

1.1 CHOICE OF MODELS.......................................................................................................1

1.2 PRODUCT DESCRIPTION ...............................................................................................1

1.2.1 Analog Inputs..............................................................................................................4

1.2.2 Analog Outputs...........................................................................................................4

1.2.3 Digital I/O....................................................................................................................4

1.2.4 Counters 0 and 1 ........................................................................................................4

1.2.5 Timers 0 and 1............................................................................................................4

1.2.6 PCI Interface...............................................................................................................4

1.3 SOFTWARE COMPATIBILITY ..........................................................................................5

1.4 CE COMPLIANCE .............................................................................................................5

1.5 FUSE AND CONNECTOR PLACEMENT..........................................................................6

2. GETTING STARTED

STEP 1 – INSTALL SOFTWARE..................................................................................................7

STEP 2 – INSTALL BOARDS IN AVAILABLE PCI BUS-SLOTS.................................................8

STEP 3 – CONFIGURE BOARDS................................................................................................9

3. HARDWARE CONFIGURATION

3.1 DMA AND INTERRUPT UTILIZATION............................................................................10

3.2 DMA ENGINE ..................................................................................................................11

3.3 ANALOG INPUT CONFIGURATION...............................................................................11

3.4 ADC RANGE....................................................................................................................11

3.5 DAC RANGE....................................................................................................................13

4. EXTERNAL CONNECTIONS

4.1 CONNECTING USER WIRING .......................................................................................14

4.1.1 Signal Types.............................................................................................................14

4.1.2 Choosing A/D Input Configuration............................................................................15

4.1.2.1 Single-Ended.....................................................................................................15

4.1.2.2 Pseudo-Differential (PD)....................................................................................16

4.1.2.3 Fully-Differential (DIFF) .....................................................................................16

4.2 ADAC/5500 SERIES, ON-BOARD CONNECTORS........................................................18

4.2.1 Signal Definitions......................................................................................................18

4.2.1.1 Analog Input Channels......................................................................................19

4.2.1.2 Analog Outputs..................................................................................................19

4.2.1.3 Digital I/O Lines .................................................................................................19

4.2.1.4 Terminal Panel Control......................................................................................19

4.2.1.5 Counters And Timers.........................................................................................20

4.2.1.6 Ground Lines.....................................................................................................21

4.2.1.7 Power Lines.......................................................................................................21

4.2.2 J1 Pin Assignments, ADAC/5500MF Only................................................................22

4.2.3 J1 Pin Assignments, ADAC/5501MF, ADAC/5502MF, ADAC/5503HR, &

ADAC/5504HR..........................................................................................................23

4.2.4 P3 and P5 Pin Assignments.....................................................................................24

4.2.5 Signal Definitions for P3, P5, and G17’s DB37 Connector.......................................25

4.3 SCREW-TERMINAL BOARDS........................................................................................26

4.3.1 ADAC-TB-8 Screw-Terminal Board..........................................................................26

4.3.2 ADAC-TB-16 Screw-Terminal Board........................................................................27

4.3.3 ADAC-DC-37 Screw-Terminal Board .......................................................................28

ADAC Series PCI Boards 938697 -iii- ADAC/5500 Series User Manual

Page 4

5. ADAC/5500 Series PCI CARD OPERATION

5.1 DEVICE DRIVERS...........................................................................................................29

5.1.1 LABVIEW™ ...............................................................................................................29

5.1.2 TESTPOINT™ ...........................................................................................................29

5.1.3 WINDOWS DRIVERS (ADLIB WDM).......................................................................29

5.2 THEORY OF OPERATION..............................................................................................30

5.2.1 Process Definitions ..................................................................................................30

5.2.2 Clocking the ADC......................................................................................................32

5.2.3 Starting (Triggering) an ADC Acquisition..................................................................33

5.2.4 Stopping an ADC Acquisition (Clock).......................................................................34

5.2.5 ADC Clock and FIFO Errors.....................................................................................35

5.2.6 ADC Data Transfer Modes .......................................................................................35

5.2.7 Clocking the DAC......................................................................................................36

5.2.8 Starting (Triggering) a DAC Acquisition....................................................................36

5.2.9 Stopping a DAC Acquisition (CLOCK)......................................................................37

5.2.10 DAC Data Transfer Mode .........................................................................................37

5.2.11 Digital Acquisition......................................................................................................38

6. SPECIFICATIONS

6.1 ADAC/5500MF.................................................................................................................40

6.2 ADAC/5501MF AND ADAC/5502MF...............................................................................43

6.3 ADAC/5503HR AND ADAC/5504HR...............................................................................47

6.4 TERMINATION BOARDS................................................................................................52

6.4.1 ADAC-TB-8...............................................................................................................52

6.4.2 ADAC-TB-16.............................................................................................................53

6.4.3 ADAC-DC-37 ............................................................................................................54

ADAC Series PCI Boards 938697 -iv- ADAC/5500 Series User Manual

Page 5

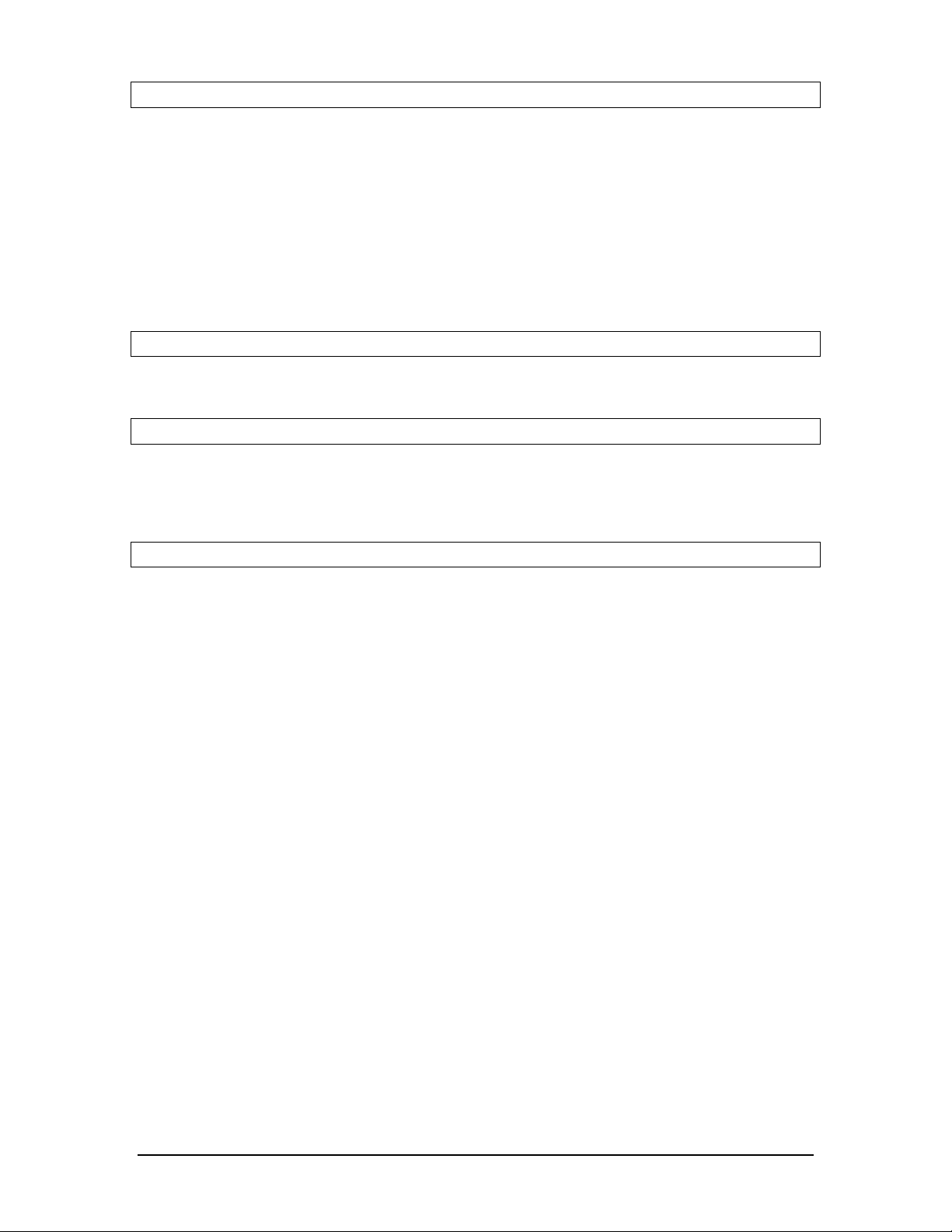

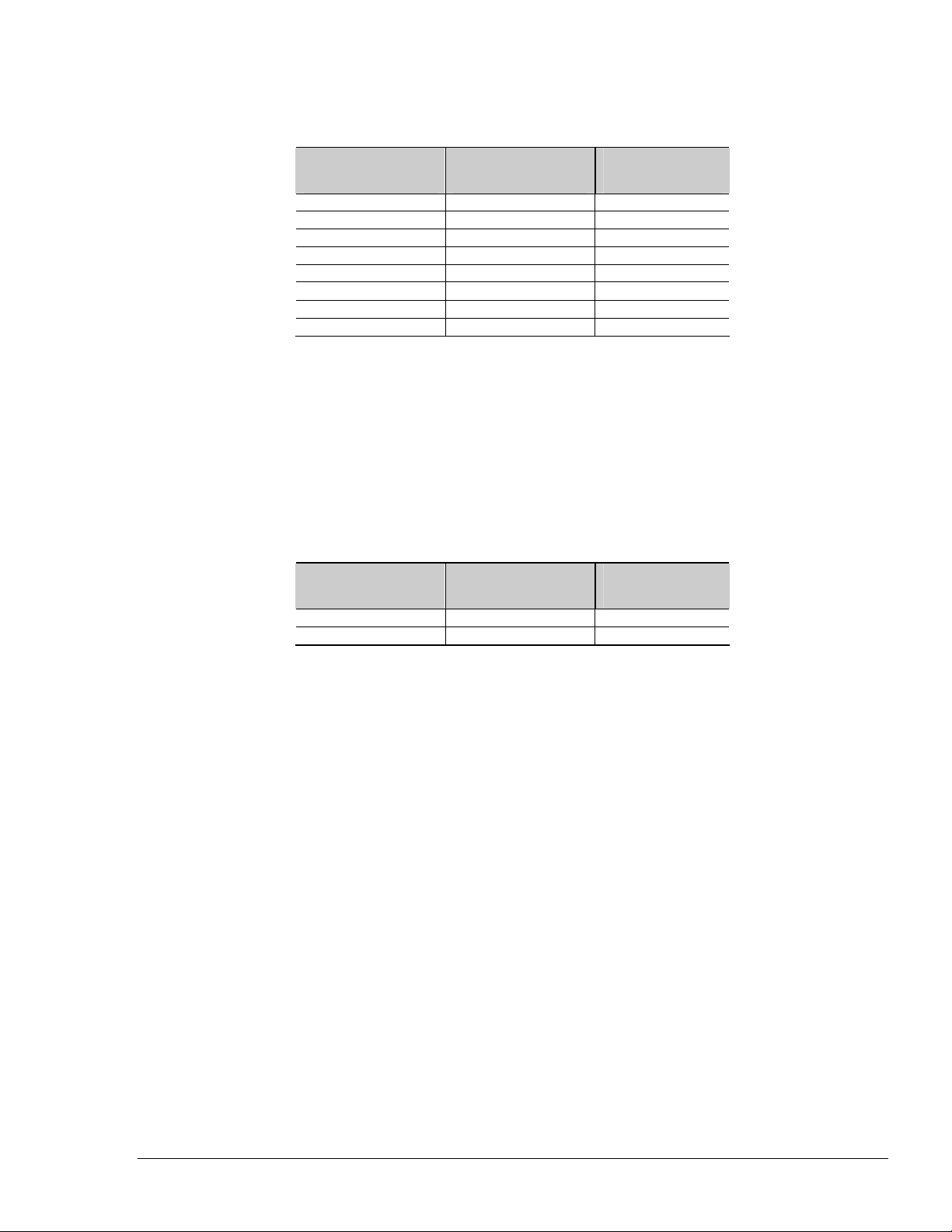

ADAC/5500 Series Boards

Feature

Analog Inputs

Ranges-

Unipolar

Bipolar

Resolution

A/D Sample

Rate

Gains

(Programmable)

D/A Outputs

(16-Bit)

Digital I/O

Counters

(16-Bit)

Timers

Associated

Terminal

Boards

Associated

Cables

(see figure)

/5500MF /5501MF

8 SingleEnded

0 to 10V 0 to10V

± 10V ± 10V

12-bit 12-bit 12-bit 16-bit 16-bit

100 kHz 100 kHz 100 kHz 200 kHz 200 kHz

N/A 1, 2, 4, 8 1, 10, 100, 1000 1, 2, 4, 8 1, 10, 100

0 2 Clocked DACs

16

(Two 8-bit

registers)

2 2 2 2 2

2 2 2 2 2

ADAC-TB-8 ADAC-TB-16

CA-G55ADAC

/5501MF-V

16 Single-Ended, or

16 Pseudo-Diff., or

8 Differential

0 to 5V

0 to 2.5V

0 to 1.25V

± 5V

± 2.5V

± 1.25V

(/5501MF-V only)

16 – from main I/O

(Two 8-bit registers)

16 – from aux. P3*

16 – from aux. P5*

ADAC-DC-37 (qty. 2)

CA-G55-ADAC

CA-G17-ADAC

CA-G37-x-ADAC

/5502MF

/5502MF-V

16 Single-Ended, or

16 Pseudo-Diff., or

8 Differential

0 to10V

0 to 1V

0 to 95mV

0 to 9.5mV

± 10V

± 1V

± 95mV

± 9.5mV

2 Clocked DACs

(/5502MF-V only)

16 – from main I/O

(Two 8-bit registers)

16 – from aux. P3*

16 – from aux. P5*

ADAC-TB-16

ADAC-DC-37 (qty. 2)

CA-G55-ADAC

CA-G17-ADAC

CA-G37-x-ADAC

/5503HR

/5503HR-V

16 Single-Ended, or

16 Pseudo-Diff., or

8 Differential

0 to10V

0 to 5V

0 to 2.5V

0 to 1.25V

± 10V

± 5V

± 2.5V

± 1.25V

2 Clocked DACs

(/5503HR-V only)

16 – from main I/O

(Two 8-bit registers)

16 – from aux. P3*

16 – from aux. P5*

ADAC-TB-16

ADAC-DC-37 (qty. 2)

CA-G55-ADAC

CA-G17-ADAC

CA-G37-x-ADAC

/5504HR

/5504HR-V

16 Single-Ended, or

16 Pseudo-Diff., or

8 Differential

0 to10V

0 to 1V

0 to 99.84 mV

± 10V

± 1V

± 99.86mV

2 Clocked DACs

(/5504HR-V only)

16 – from main I/O

(Two 8-bit registers)

16 – from aux. P3*

16 – from aux. P5*

ADAC-TB-16

ADAC-DC-37 (qty. 2)

CA-G55-ADAC

CA-G17-ADAC

CA-G37-x-ADAC

*

The CA-G17-ADAC cables connect to

40-pin headers P3 (DIO2) and P5 (DIO3)

located on the ADAC Series board.

ADAC/5500 Series, Possible Connections to Terminal Boards

ADAC Series PCI Boards 938697 -v- ADAC/5500 Series User Manual

Page 6

1. INTRODUCTION

1.1 CHOICE OF MODELS

ADAC/5500 PCI Series cards are part of an extensive line of data acquisition boards for use in PCs. ADAC series

boards are low cost and are optimized for use with Windows. We offer “sensor specific” DIRECT CONNECT™

boards, isolated digital I/O boards, boards for DSP applications, and much more. Visit our web site to learn about our

complete line of products.

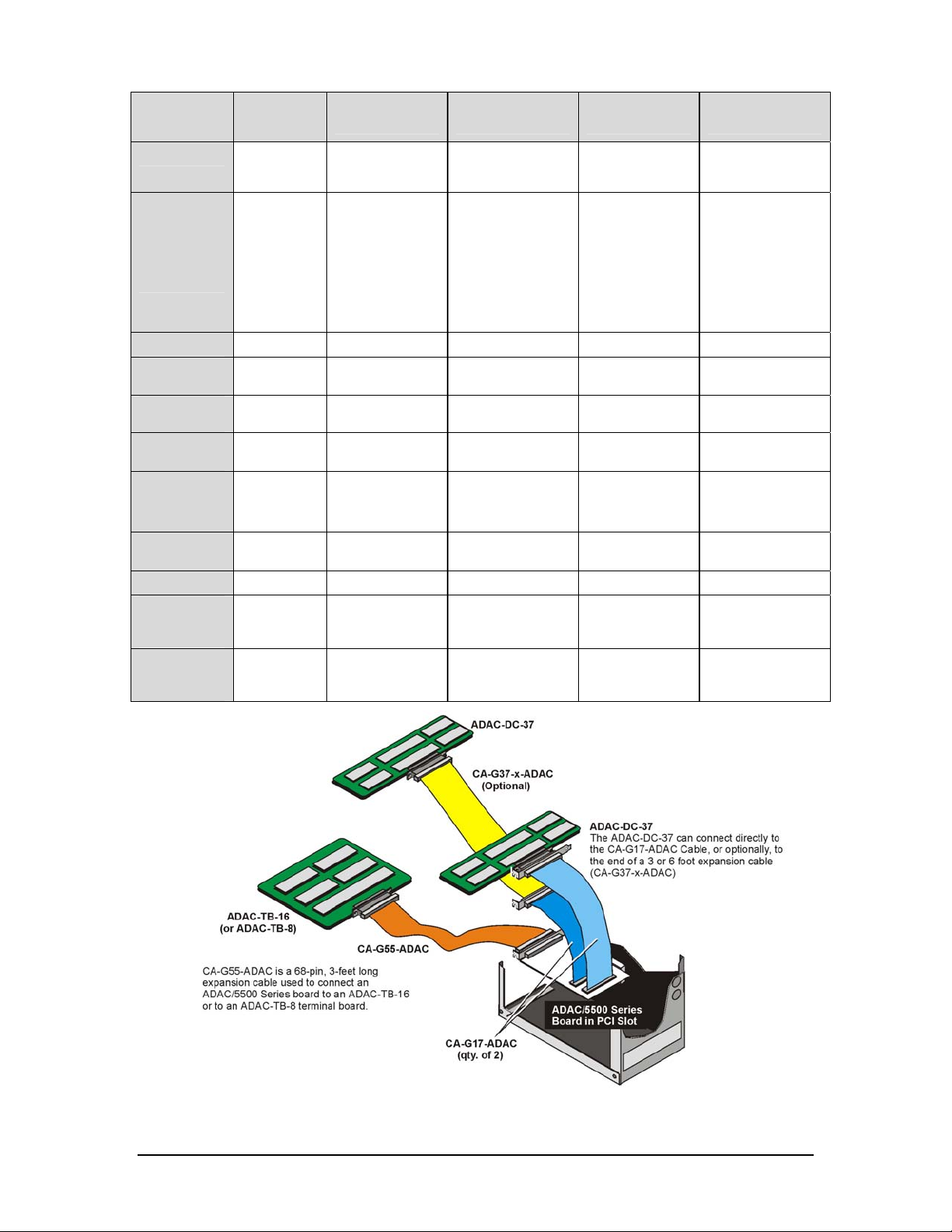

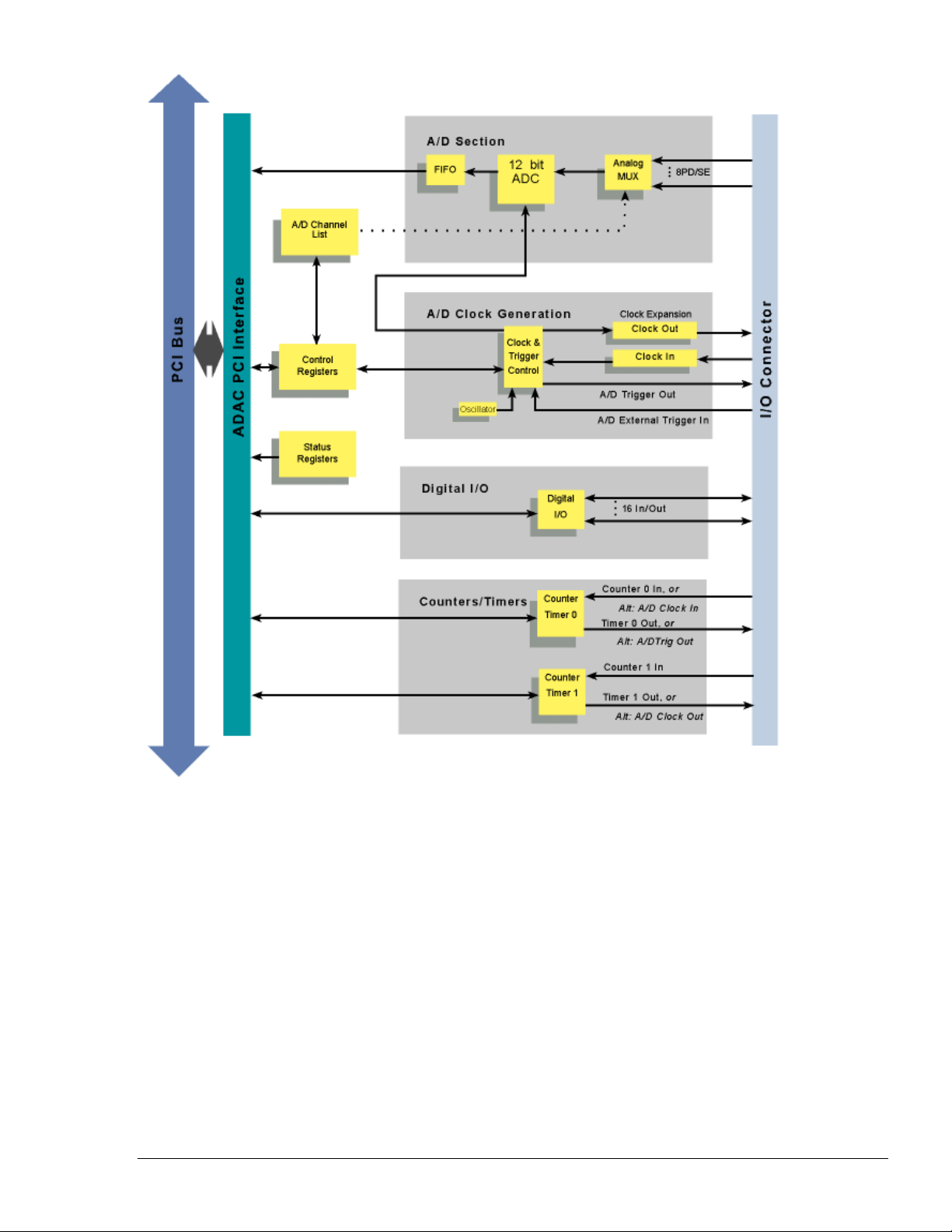

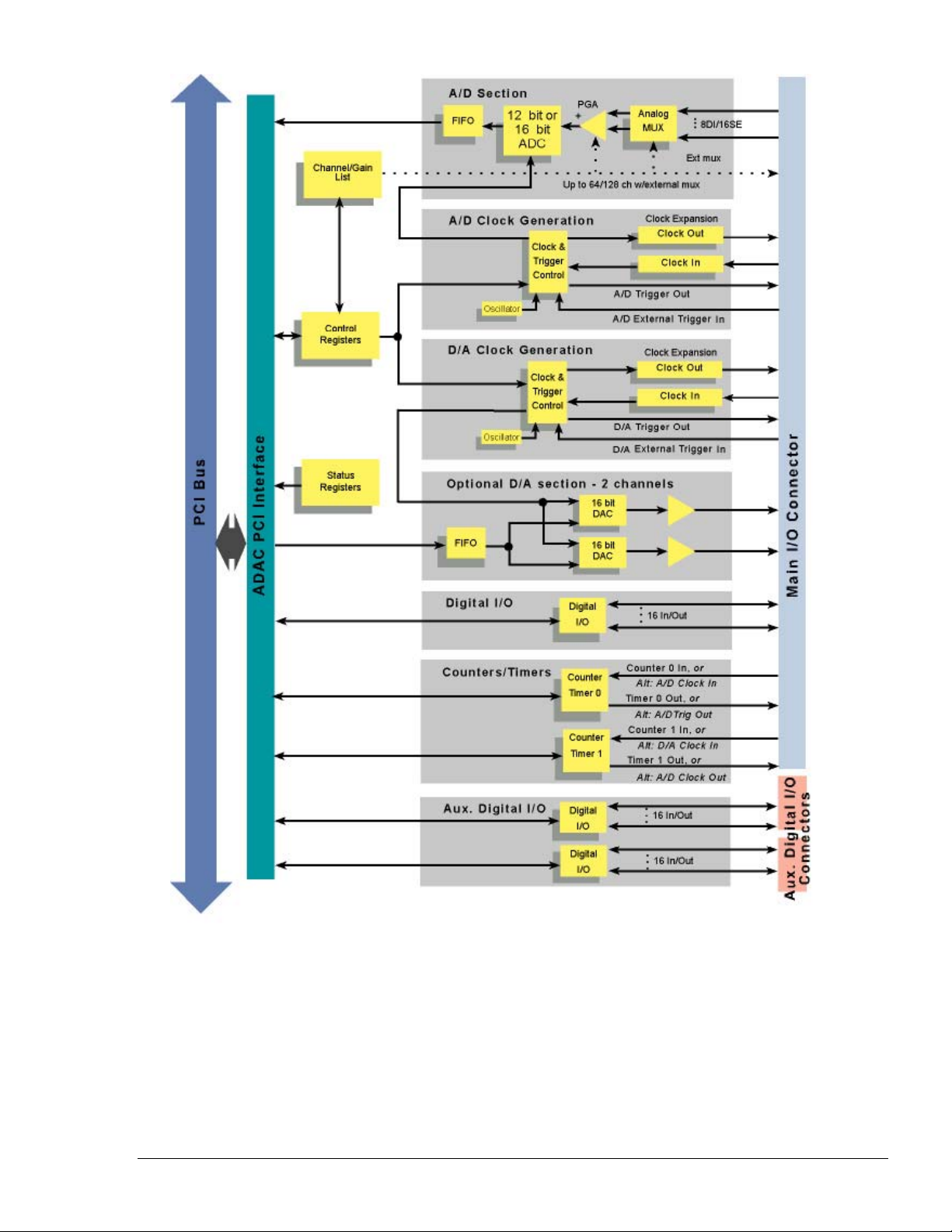

1.2 PRODUCT DESCRIPTION ADAC/5500 SERIES

The ADAC/5500 Series includes several models of data acquisition boards. These are discussed briefly below, and in

the preceding table. Pages 2 and 3 consist of block diagrams to provide a better understanding of board function.

The ADAC/5500MF has 8 single-ended analog inputs multiplexed to a 12-bit A/D converter with maximum

throughput of 100 kHz, two counter input channels, two timer output channels and 16 lines of digital I/O.

The ADAC/5501MF has 16 single-ended/pseudo-differential or 8 differential analog inputs multiplexed to a 12-bit

A/D converter with maximum throughput of 100 kHz, programmable gains of 1, 2, 4 or 8, two optional clocked 16-bit

D/A voltage outputs, two counter input channels, two timer output channels and 48 lines of digital I/O.

The ADAC/5502MF is the same as the ADAC/5501MF, but with programmable gains of 1, 10, 100 or 1000.

The ADAC/5503HR has 16 single-ended/pseudo-differential or 8 differential analog inputs multiplexed to a 16-bit

A/D converter with maximum throughput of 200 kHz, programmable gains of 1, 2, 4 or 8, two optional clocked 16-bit

D/A voltage outputs, two counter input channels, two timer output channels and 48 lines of digital I/O.

The ADAC/5504HR is the same as the ADAC/5503HR, but with programmable gains of 1, 10, 100.

V-versions of the boards include two clocked DACs, with exception of ADAC/5500MF, which has no “V”- version

counterpart.

All boards feature on-board digital calibration for both A/D and D/A, and a DMA engine for optimum performance in

a Windows environment. Board connections are terminated in a 68-pin “high density” SCSC III connector at the rear of

the PC.

ADAC Series PCI Boards 196 - 1 - ADAC/5500 Series User Manual 908

Page 7

Figure 1.1

Block Diagram for ADAC/5500MF

ADAC Series PCI Boards 196 - 2 - ADAC/5500 Series User Manual

908

Page 8

Figure 1.2

Block Diagram for ADAC/5501MF, ADAC/5502MF, ADAC/5503HR and ADAC/5504HR

ADAC Series PCI Boards 196 - 3 - ADAC/5500 Series User Manual

908

Page 9

1.2.1 Analog Inputs

The ADAC/5500MF has 8 single-ended analog inputs multiplexed to a 12-bit A/D converter. The input multiplexer is

supported by 176 elements of channel list RAM, which allows the board to access channels in any order. The 12-bit

A/D has a maximum throughput of 100 kHz and a programmable input range of ±10 V or 0-10 V. An A/D Pacer Clock

is provided to allow sampling rates from 0.0009 Hz to 100 kHz. An on-board Counter/Timer circuit provides two

counters and two timers dedicated to user connections.

The ADAC/5501MF, ADAC/5502MF, ADAC/5503HR and ADAC/5504HR models support 16 single-ended / pseudodifferential analog inputs, or 8 differential analog inputs (expandable to 64) multiplexed to a 12 or 16-bit A/D

converter. The input multiplexer is supported by a 176 element channel gain RAM which allows the board to select

gain on a per channel basis and to access channels in any order. The 12-bit A/D has maximum throughput of 100 kHz

and the 16-bit A/D has a maximum throughput of 200 kHz. An A/D Pacer clock is provided to allow sampling rates

from 0.0009Hz to 200 kHz.

1.2.1.1 4-20mA Current Loop Inputs – n/a

1.2.2 Analog Outputs

The ADAC/5501MF, ADAC/5502MF, ADAC/5503HR and ADAC/5504HR models may be equipped with two

optional clocked DACs (D/A). Both DAC channels are DC accurate with 16-bit resolution and

200 kHz throughput. The output ranges of the DACs are programmable to ±10 V or 0 to +10 V. A Pacer clock is

provided to allow sampling rates from 0.0009Hz to 200 kHz.

1.2.3 Digital I/O

All boards have 16 lines of TTL level digital I/O programmable in 8-bit ports as either inputs or outputs. All 16 lines

are brought out via the main 68-pin SCSI III connector, user accessible at the back of the PC.

Two additional 40 pin headers on the ADAC/550 1MF, ADAC/5502MF, ADAC/5503HR and ADA C/5504HR models

(internal to the PC) provide access to an additional thirty two 5 V CMOS/LSTTL compatible digital lines,

programmable in 16-bit ports as either inputs or outputs. Both sets of digital I/O lines may be brought to the back of the

computer with optional adapter connectors that are compatible with the ADAC line of isolated digital I/O panels.

1.2.4 Counters 0 and 1

Counter 0 and 1 can provide either cumulative or incremental counting capabilities. The counters are capable of

counting 5 V LSTTL rising edges to a maxim um count of 131071 decimal.

1.2.5 Timers 0 and 1

Timer0 and Timer1 provide a 50% duty cycle square wave 5 V LSTTL output with an output frequency range of

7.7 Hz to 500 kHz. The Timer’s output frequency is based on a 1 MHz oscillation with a divisor of 1 to 65536 decimal.

1.2.6 PCI Interface

The ADAC/5500 Series boards communicate to the PCI bus through an ADAC PCI interface controller. The boards are

fully Plug&Play compatible with no switches, potentiometers, or jumpers. The boards feature digitally calibrated A/D

and D/A’s, and Plug&Play compatibility to provide automatic integration into the PC’s configuration when first

installed. The interface also provides access to all on-board registers for software configuration of all on-board

functions. For maximum performance, the ADAC/5500 boards feature a 32-bit bus-mastering DMA engine on the

ADC and DAC hardware to provide high-speed transfers between the board and system memory.

ADAC Series PCI Boards 196 - 4 - ADAC/5500 Series User Manual 908

Page 10

1.3 SOFTWARE COMPATIBILITY

The ADAC/5500 Series boards are shipped with ADAC ADLIB WDM (a full-featur e Windows/NT/2000/XP

driver library based on Microsoft’s Windows Driver Model). This library provides functions to set all of the software

programmable modes of operation, and includes examples to acquire and output data.

In addition, drivers are available for PC data acquisition packages such as LabVIEW™, and TestPoint. See Section

5.1 DEVICE DRIVERS for details.

1.4 CE COMPLIANCE

The ADAC/5500 Series meets the essential health and safety requirements, and is in conformity with the EC Directives

as listed in the relevant sections of the following EC standards and other normative documents:

EN 55022 Class B: Limits and methods of measurements of radio interference characteristics of

information technology equipment.

EN 50082-1: EC generic immunity requirements.

IEC 801-2: Electrostatic discharge requirements for industrial process measurement and

control equipment.

IEC 801-3: Radiated electromagnetic field requirements for industrial process measurement

and control equipment.

IEC 801-4: Electrically fast transients for industrial process measurement and control

equipment.

ADAC Series PCI Boards 196 - 5 - ADAC/5500 Series User Manual 908

Page 11

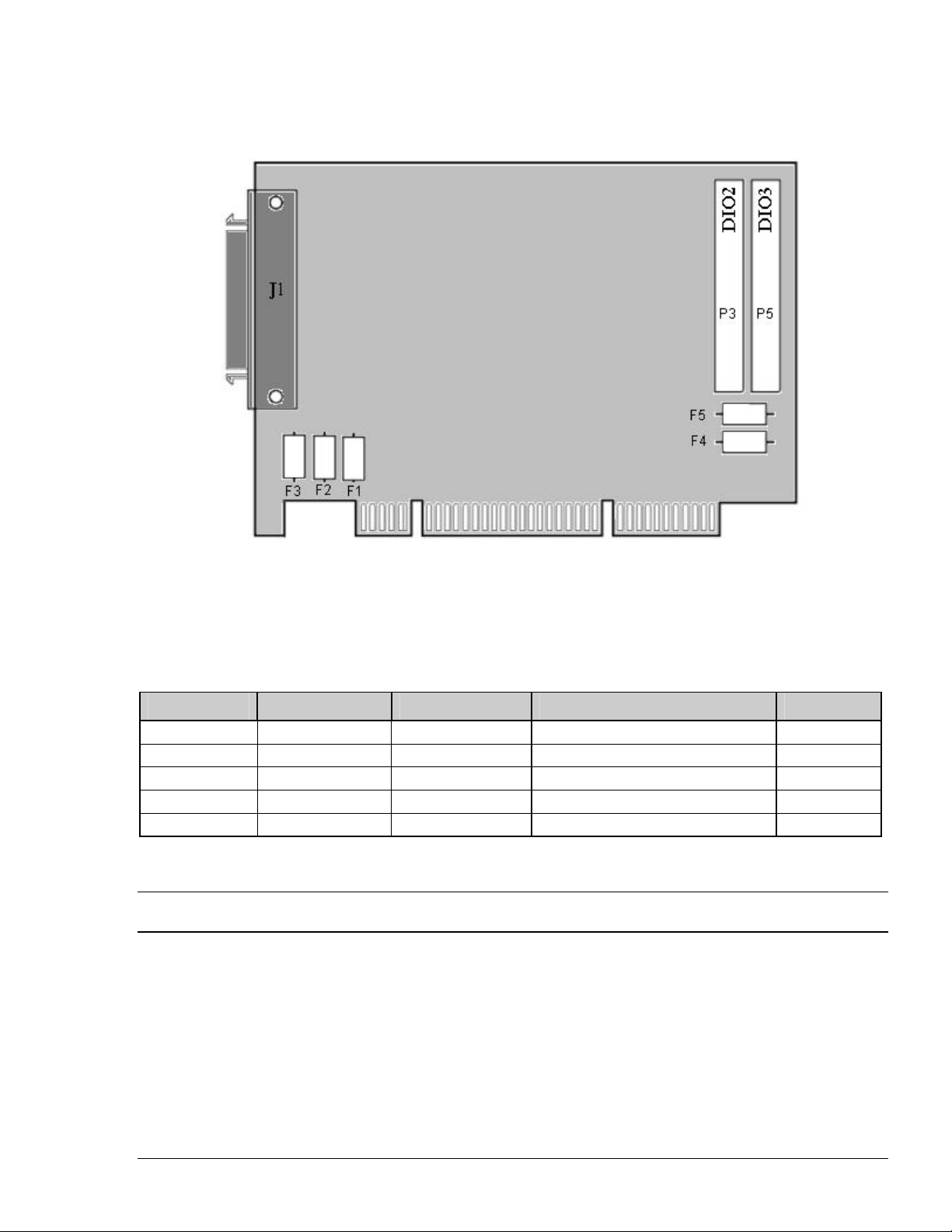

1.5 FUSE AND CONNECTOR PLACEMENT

NOT TO SCALE

Figure 1.3

Fuse and Connector Placement for ADAC/5500 Series Boards.

Fuse # Power Line Fuse Value Manufacturer’s p/n IOtech p/n

F1 -15 V to J1 1.0A, 63 V LITTLEFUSE # 0433001.NR FU-7-1

F2 +15 V to J1 1.0A, 63 V LITTLEFUSE # 0433001.NR FU-7-1

F3 +5 V to J1 1.0A, 63 V LITTLEFUSE # 0433001.NR FU-7-1

F4 +5 V to P3 3.0A, 63 V BUSSMAN # TR/3216-FF-3A FU-7-3

F5 +5 V to P5 3.0A, 63 V BUSSMAN # TR/3216-FF-3A FU-7-3

Note that the ADAC/5500MF does NOT contain the J2 & J3 Aux. Digital I/O connectors

ADAC Series PCI Boards 196 - 6 - ADAC/5500 Series User Manual

908

Page 12

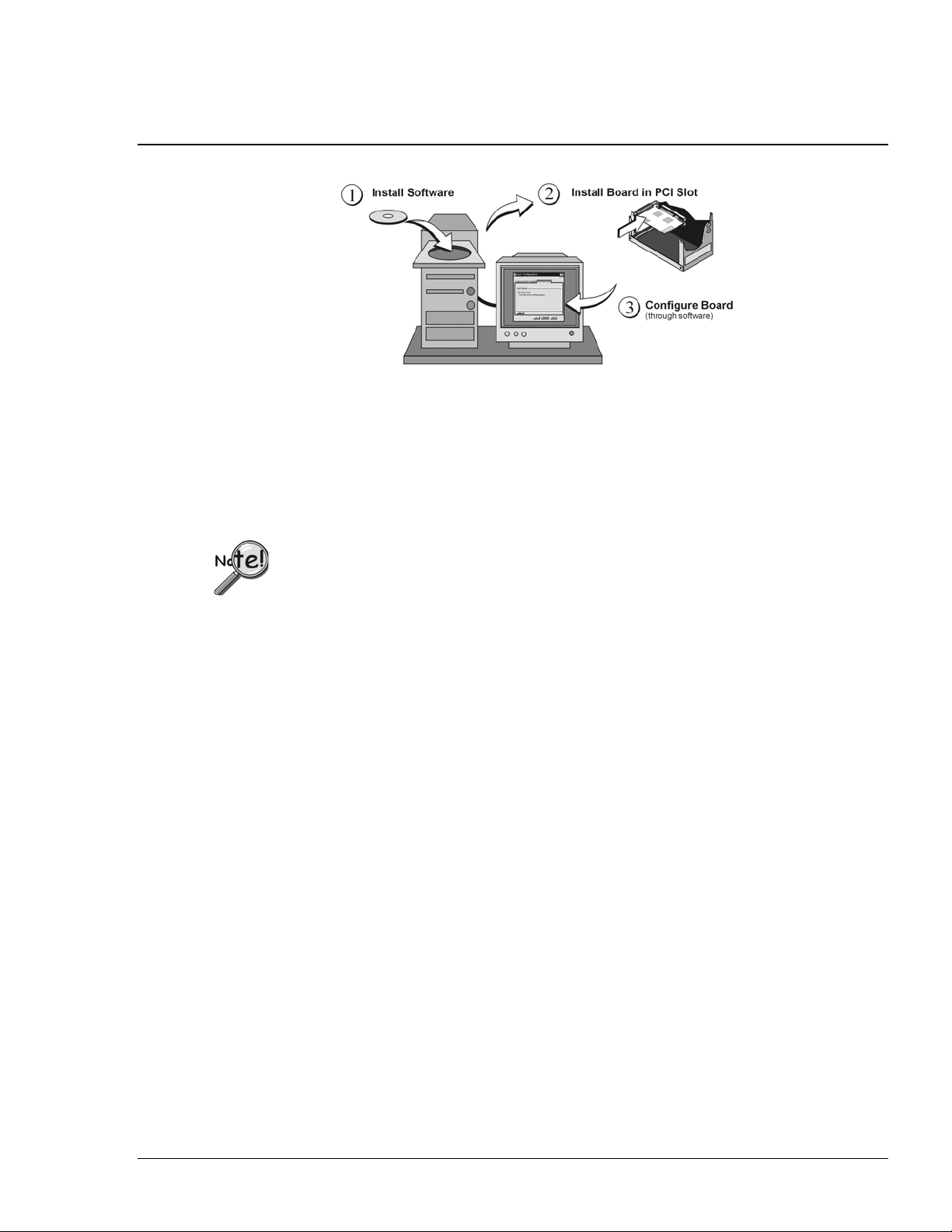

2. GETTING STARTED

This section contains information from the ADAC/5500 Series Inst al lat i o n Guide, p/n 1107-0940. If you have already

installed your software and ADAC board, you shou ld move on to chapter 3, Hardware Configuration.

STEP 1 – INSTALL SOFTWARE

IMPORTANT: Software must be installed before installing hardware.

1. Remove previous version ADAC drivers, if present. You can do this through Microsoft’s

Add/Remove Programs feature.

2. Place the Data Acquisition CD into the CD-ROM drive. Wait for PC to auto-run the CD. This

may take a few moments, depending on your PC. If the CD does not auto-run, use the

Desktop’s Start/Run/Browse feature.

3. After the intro-screen appears, follow the screen prompts.

Upon completing the software installation, continue with step 2, Install Boards in Availab le PCI Bus-

Slots.

ADAC Series PCI Boards 896897 - 7 - ADAC/5500 Series User Manual

Page 13

STEP 2 – INSTALL BOARDS IN AVAILABLE PCI BUS-SLOTS

IMPORTANT: Software must be installed before installing hardware.

Turn OFF power to, and UNPLUG the host PC and externally connected equipment prior

to removing the PC’s cover and installing an ADAC/5500 Series Board. Failure to do so

could result in electric shock, or damage to equipment.

CAUTION

WARNING

Take ESD precautions (packaging, proper handling, grounded wrist strap, etc.)

Use care to avoid touching board surfaces and onboard components. Only handle boards by

their edges (or ORBs, if applicable). Ensure boards do not come into contact with foreign

elements such as oils, water, and industrial particulate.

IMPORTANT: Bus Mastering DMA must be Enabled.

For an ADAC/5500 Series board to operate properly, Bus Mastering DMA must be

enabled on the PCI slot [for which the board is to be installed]. Prior to installation,

verify that your computer is capable of performing Bus Mastering DMA for the

applicable PCI slot. Note that some computers have BIOS settings that enable [or disable]

Bus Mastering DMA. If your computer has this BIOS option, ensure that Bus Mastering

DMA is Enabled on the appropriate PCI slot.

Refer to your PC Owner's Manual for additional informati on reg arding your PC and

enabling Bus Mastering DMA for PCI slots.

1. Turn OFF power to, and UNPLUG the host PC and externally connected equipment.

2. Remove the PC’s cover. Refer to your PC Owner’s Manual as needed.

3. Choose an available PCI bus-slot.

4. Carefully remove ADAC/5500 Series Board from its anti-static protective bag. If you have not already

done so, write down the serial number and type of ADAC board in the space provided on page 3 of this

document.

5. On the PC’s rear panel, loosen and remove the screw for the blank adapte r plate that corresponds with the

chosen PCI bus. See left-hand figure, below.

Removing a Blank Adapter Plate

Installing an ADAC/5500 Series Board

6. Remove the blank adapter plate. Refer to your PC Owner’s Manual if needed.

ADAC Series PCI Boards - 8 - ADAC/5500 Series User Manual

Page 14

7. Align the groove in the ADAC/5500 Series board’s PCI edge-connector with the ridge of the desired PCI

slot. See preceding right-hand figure.

8. Push the board firmly into the PCI slot. The board should “snap” into position.

9. Secure the board by inserting the rear-panel adapter-plate screw.

10. Using the previous steps, install additional boards into available PCI bus-slots, if applicable to your

application.

11. Replace the computer’s cover.

12. Plug in all cords and cables that were removed in step 1.

13. Apply power to, and start up the PC.

Note: At this point some PCs may prompt you to insert an installation disk. While this is rare, if you do

receive such a prompt simply place the install CD-ROM into the disk drive and follow additional

screen prompts.

STEP 3 – CONFIGURE BOARDS

Always turn the computer power OFF and unplug it before connecting or disconnecting a

screw terminal panel or a cable to the PCI card. Failure to do so could result in electric

shock, or equipment damage.

WARNING

Before you can use your ADAC/5500 Series Board, you will need to con figure it according to information

contained in chapters 3 and 4 of this document. However, prior to doing so you may find it helpful to review

the following points:

All configuration, including data-acquisition settings such as analog input, data collection rates,

•

input voltage range, and operating modes are made through ADAC configuration software. The

ADAC configuration software (ADAC Config) file can be accessed from the Windows desktop

Start Menu by navigating as follows:

Start ⇒ Programs ⇒ ADAC ⇒ ADACConfig ⇒ ADAC Config

Desktop Path to ADAC Config

ADAC ADLIB WDM software drivers provide an application level software interface to

•

Windows 98/ME/NT/2000/XP. Software packages such as LabVIEW™ communicate through

our ADLIB driver software. These packages configure and collect, or output, acquisition data in a

GUI based interface.

• The ADAC/5501MF, ADAC/5502MF, ADAC/5503HR and ADAC/5504HR analog inputs are

impedance buffered and drive a differential gain amplifier that can be referenced in a number of

ways, allowing the following programmable input configurations: Single-Ended, Pseudo-

Differential, and Fully-Differential.

ADAC Series PCI Boards 795 - 9 - ADAC/5500 Series User Manual

928

Page 15

•

The ADAC/5500MF analog inputs are impedance buffered. They can only be referenced in SingleEnded input configuration. A 176 element channel-conf iguration RAM is provided to allo w each ADC

channel to be programmed with a different Range. Note that input range selection also applies to

expansion channels located on the ADAC line of accessory screw terminal boards. The termination

boards are detailed in section 4.3.

•

The analog inputs on the ADAC/5500, ADAC/5501MF, ADAC/5502MF, ADAC/5503HR and

ADAC/5504HR may be configured for either ±10 V bipolar or 0-10 V unipolar operation. The input

range is programmable on a channel-by-channel basis in a 176-element channel configuration RAM. Note

that the range selection also applies to expansion channels.

•

The programmable gain circuitry on the ADAC/5501MF, ADAC/5502MF, ADAC/5503HR and

ADAC/5504HR must be taken into account in defining the usable error free input range. The boards

provide a wide range of programmable ranges and resolutions.

•

The ADAC/5500 Series Boards each bring out ±15 V and +5 V to the main I/O connector (J1). In

addition, the ADAC/5501MF, ADAC/5502MF, ADAC/5503HR and ADAC/5504HR bring +5 V to the

auxiliary digital I/O connectors (P3 and P5), located on the backside of those boards. These power lines

are individually fused to protect the ADAC/5500 Series Board. Note that connecting or disconnecting

cables or screw terminal panels (as well as any user connections to these power lines) may blow a fuse, or

cause damage to the board.

•

Incorrect connection of user wiring is one of the most common problems experienced by users of data

acquisition boards. To ensure proper results, you must first determine what type of signal source you are

measuring (Ground Referenced Source or Floating Source), and then choose the appropriate input

configuration on your data acquisition card (Differential, Pseudo-Differential, or S ingle-Ended). Chapter

4 of this manual includes detailed information.

3. HARDWARE CONFIGURATION

The ADAC/5500 Series contains no hardware jumpers; all board configuration elements are software selectable. Dataacquisition settings such as analog input, data collection rates, input voltag e range, and op erating modes are configured

through application software. ADAC ADLIB WDM software drivers provide an application level software interface to

Windows 98/ME/NT/2000/XP. Software packages such as LabVIEW™ communicate through our ADLIB driver

software. These packages configure and collect, or output, acquisition data in a GUI based interface.

3.1 DMA AND INTERRUPT UTILIZATION

The PCI specification uses a shared interrupt scheme to increase the availability of interrupts in an attempt to alleviate

limitations imposed by ISA interrupt constraints. This shared interrupt scheme, known as interrupt chaining, comes at a

price. When a PCI card that uses interrupts is installed into a PC, the system software adds the device to a list of

interrupt service routines for all PCI devices that share a common interrupt signal. When a PCI device generates an

interrupt, the system software detects the interrupt and executes the first Interrupt Service Routin e (ISR) in the list. The

first routine in the list may not be your data acquisition device. If not, th e first device determines if its device asserted

the interrupt, if so the software services the interrupt and returns. The processor immediately interrupts again because

the second device is still generating an interrupt request. The processor again jumps to the first device in the list, the

device determines it has not requested an interrupt and jumps to the entry point of the second ISR to be serviced. If the

first device in the list were to generate interrupts at a high frequency, the second device might over-run or under-run,

generating an error condition while awaiting service. Well-behaved PCI devices generate interrupts infrequently.

ADAC driver software only determines if the ADAC board has requested an interrupt, if so it defers the ISR to a

callback procedure and quickly returns control to the interrupted process. Now that the facts are on the table, interrupt

latency on the PCI bus can be extremely inefficient for high-speed data acquisition. To overcome this inefficiency we

incorporate an on-board DMA engine analogous to the older ISA type of DMA controller. The on-board DMA engine

ADAC Series PCI Boards 795 - 10 - ADAC/5500 Series User Manual 928

Page 16

supports scatter/gather, also known as buffer chaining, with a pair of chain address registers that point to system

memory to be used in the buffered transfer. The DMA controller is loaded with the previously allocated physical

addresses of these buffers and only generates interrupt requests when the current transfer buffer has been completed,

thus reducing the burden of CPU interrupt intervention.

3.2 DMA ENGINE

Both analog input and analog output channels have on-board DMA engine support for high-speed data transfers. The

two analog output channels have individual DMA engines and clocking methods available. DAC1’s clocking source

may be set to the DAC0 clocking source to allow simultaneously DAC transfers. All PCI bus transfers are 32-bit

operations. Analog input and analog output transfers are each independently software selectable to allow either 16-bit

or 32-bit data transfers. An immediate improvement of twice the memory bandwidth can be achieved by transferring

two analog input data points or two analog output data points into memory as a single 32-bit PCI transfer.

3.3 ANALOG INPUT CONFIGURATION

For selecting the best configuration for your application see Section 4.1 Connecting User Wiring.

The ADAC/5501MF, ADAC/5502MF, ADAC/5503HR and ADAC/5504HR an alog inputs ar e impedan ce buffered and

drive a differential gain amplifier that can be referenced in a number of ways allowing th e following programmable

input configurations: Single-Ended, Pseudo-Differential and Fully-Differential.

The ADAC/5500MF analog inputs are impedance buffered, and can only be referenced in Single-Ended input

configuration.

For selecting the best configuration for your application see Section 4.1 Connecting Us er Wiring.

A 176 element channel configuration RAM is provided to allow each ADC channel to be programmed with a

different input range.

3.4 ADC RANGE

The analog inputs on the ADAC/5500, ADAC/5501MF, ADAC/5502MF, ADAC/5503HR and ADAC/5504HR may be

configured for either ±10 V bipolar or 0-10 V unipolar operation. The input range is programmable on a channel by

channel basis in a 176-element channel configuration RAM. Note that the range selection also applies to expansion

channels.

The programmable gain circuitry on the ADAC/5501MF, ADAC/5502MF, ADAC/5503HR and ADAC/5504HR must

also be taken into account in defining the usable error free input range. The boards provide a wide range of

programmable ranges and resolutions. The following tables indicate the maximum resolution under different

conditions. Note that resolution is not accuracy. Resolution defines the minimum definable voltage increment. Absolute

DC accuracy and relative accuracy defines exactly how close the reading will be to the actual voltage input. Refer to

Section 6, SPECIFICATIONS for accuracy specifications.

Fixed Gain

x1 ± 10.00 V 5.00 mV/bit

x1 0 to 10.00 V 2.50 mV/bit

Full Scale Range

Bipolar

Unipolar

Microvolt

Resolution

ADAC Series PCI Boards 795 - 11 - ADAC/5500 Series User Manual 928

Page 17

Programmable

Gain

x1 ± 10.00 V 5.00 mV/bit

x2 ± 5.00 V 2.50 mV/bit

x4 ± 2.50 V 1.25 mV/bit

x8 ± 1.25 V 0.625 mV/bit

x1 0 to 10.00 V 2.50 mV/bit

x2 0 to 5.00 V 1.25 mV/bit

x4 0 to 2.50 V 0.625 mV/bit

x8 0 to 1.25 V 0.3125 mV/bit

Full Scale Range

Bipolar

Unipolar

Microvolt

Resolution

Table 3.2 ADAC/5501MF Input Range/Resolution

Programmable

Gain

x1 ± 10.00 V 5.00 mV/bit

x10 ± 1 V

x100 ±95 mV

X1000 ±9.5 mV

x1 0 to 10.00 V 2.50 mV/bit

x10 0 to 1.00 V

x100 0 to 97.5 mV

X1000 0 to 9.75 mV

Full Scale Range

Bipolar

Unipolar

Microvolt

Resolution

500 µV/bit

50.0 µV/bit

5.00 µV/bit

250 µV/bit

25.0 µV/bit

2.50 µV/bit

Table 3.3 ADAC/5502MF Input Range/Resolution

Programmable

Gain

x1 ± 10.00 V

x2 ± 5.00 V

x4 ± 2.50 V

x8 ± 1.25 V

x1 0 to 10.00 V

x2 0 to 5.00 V

x4 0 to 2.50 V

x8 0 to 1.25 V

Full Scale Range

Bipolar

Unipolar

Microvolt

Resolution

310.140 µV/bit

155.070 µV/bit

77.535 µV/bit

38.768 µV/bit

155.070 µV/bit

77.535 µV/bit

38.768 µV/bit

19.384 µV/bit

Table 3.4 ADAC/5503HR Input Range/Resolution

ADAC Series PCI Boards 795 - 12 - ADAC/5500 Series User Manual 928

Page 18

Programmable

Gain

x1 ± 10.00 V

x10 ± 1 V

x100 ± 99.68 mV

x1 0 to 10.00 V

x10 0 to .1 V

x100 0 to 99.84 mV

Full Scale Range

Bipolar

Unipolar

Microvolt

Resolution

310.140 µV/bit

31.0140 µV/bit

3.10140 µV/bit

155.070 µV/bit

15.5070 µV/bit

1.55070 µV/bit

Table 3.5 ADAC/5504HR Input Range/Resolution

3.5 DAC RANGE

The output range of both DACs are independently programmable to either ±10 V or 0 to 10 V.

The following table indicates the maximum resolution for each available range. Note that resolution is not accuracy.

Resolution defines the minimum definable voltage increment. Absolute DC accuracy and relative accuracy define

exactly how close the actual voltage output will be to the expected output. Refer to Section 6, SPECIFICATIONS, for

accuracy specifications.

Range

Configuration

BIPOLAR ± 10.00 V

UNIPOLAR 0 to 10.00 V

Full Scale Range

Microvolt

Resolution

305.600 µV/bit

152.800 µV/bit

Table 3.6 ADAC/5500 Series Analog Output Range/Resolution

ADAC Series PCI Boards 795 - 13 - ADAC/5500 Series User Manual 928

Page 19

4. EXTERNAL CONNECTIONS

WARNING

Always turn the computer power OFF and unplug it before connecting or disconnecting a screw

terminal panel or a cable to the PCI card. Failure to do so could result in electric shock, or

equipment damage.

The ADAC/5500 cards bring out ±15 V and +5 V to the main I/O connector J1, and +5 V to the auxiliary digital I/O

connectors P3 and P5. These power lines are individually fused to protect the ADAC/5500 card. Connecting or

disconnecting cables or screw terminal panels (as well as any user connections to these power lines) may blow a fuse,

or worse, cause damage to the board. If you are getting incorrect data readings on your ADAC/5500 card, check all

fuses to make sure they have not blown. Replacement fuses can be obtained from the factory, or from most electronics

stores (such as Radio Shack in the USA). Fuse values on the ADAC/5500 card are as follows:

Fuse # Power Line Fuse Value Manufacturer’s p/n IOtech p/n

F1 -15 V to J1 1.0A, 63 V LITTLEFUSE # 0433001.NR FU-7-1

F2 +15 V to J1 1.0A, 63 V LITTLEFUSE # 0433001.NR FU-7-1

F3 +5 V to J1 1.0A, 63 V LITTLEFUSE # 0433001.NR FU-7-1

F4 +5 V to P3 3.0A, 63 V BUSSMAN # TR/3216-FF-3A FU-7-3

F5 +5 V to P5 3.0A, 63 V BUSSMAN # TR/3216-FF-3A FU-7-3

4.1 CONNECTING USER WIRING

Incorrect connection of user wiring is one of the most common problems experienced by users of data acquisition

boards. To ensure proper results, you must first determine what type of signal source you are measuring (Ground

Referenced Source or Floating Source), and then choose the appropriate input configuration on your data acquisition

card (Differential, Pseudo-Differential, or Single-Ended).

4.1.1 Signal Types

Floating Sources

A Floating Source is a signal that has no connection to the building's power ground. Examples of Floating Sources are

batteries, battery powered devices, and signals from optically isolated devices. When connecting Floating Sources to a

data acquisition card, the ground reference of the signal must be tied to the analog ground (AGND) in order to establish

a common reference point.

Ground Referenced Sources

A Ground Referenced Source is one that is connected to the same common ground as the host PC, and therefore has the

same ground as the data acquisition cards. An example is equipment that plugs into the same building power source as

the host PC.

Due to differences in a building's power system, the Ground Referenced Source and the data

acquisition board's ground may be at different voltage levels. This difference is referred to as a

Common Mode Voltage. Common Mode Voltage can be eliminated by using either PseudoDifferential (PD) or Fully-Differential (DI) input configurations on the data acquisition board.

ADAC Series PCI Boards 795 - 14 - ADAC/5500 Series User Manual

928

Page 20

Signal Level

In addition to the grounding of source signals, the maximum voltage level of the signal should be taken into account

when choosing the optimum input configuration on the data acquisition board. When working with signals with a

maximum level below 1 V (Low Level), care must be taken to minimize possible affects caused by noise in the

environment. The addition of noise will have less effect on signals in the 1-10 V range (High Level), and therefore

High Level signals can use more types of input configurations.

4.1.2 Choosing A/D Input Configuration

Once you have determined what type of input signal source you have, and th e voltage level, you then need to select the

proper/optimum input configuration on your data acquisition card:

4.1.2.1 Single-Ended

Applications with a Floating Source are typically wired to a data acquisition board configured for SingleEnded (SE) configuration. Since only one wire from each input signal is connected to a multiplexed input of

the A/D, the Single-Ended configuration provides a larger number of inputs per board than Differential (see

below) configuration. Grounded Signal Sources can be wired in Single-Ended configur ation only when signal

leads are less than 12 feet AND when all signals share a common ground (the signals must be local to one

another).

With the Single-Ended configuration, the input signals are tied to the Channel Hi side of an an alog input, and

all signal low sides are tied to the SGND ground on the data acquisition card.

Single-Ended configuration sh ould only be used when:

• There is no Common Mode Voltage

• Ground isolation is not required

• Signal leads are less than 12 feet.

Note that of all the three possible input configurations, Single-Ended offers the least amount of noise rejection.

Because of this, Low Level signals should only be wired in Single-Ended configuration when you are certain

that there is little or no noise being introduced to the signal from the system, or the environment. We DO NOT

recommend using Single-Ended configuration with Low Level signals.

Figure 4.1 shows proper wiring for Single-Ended configuration.

Figure 4.1

Single-Ended Configuration

ADAC Series PCI Boards 795 - 15 - ADAC/5500 Series User Manual

928

Page 21

4.1.2.2 Pseudo-Differential (PD)

For multiple signal sources that share a common ground (signals must be local to one another), the PseudoDifferential mode may be the most desirable. The Pseudo-Differential configuration is similar to SingleEnded, but the analog low side of each signal is isolated from analog ground (AGND) by a 10 MΩ resistor and

a capacitor. All input returns are tied together to PDIN. Pseudo-Differential configuration allows the system to

reject any common-mode voltage difference that may exist.

Pseudo Differential configuration should be used when:

• Common Mode Voltage exists

• Common Mode Noise does not exist

• Each Source has a local ground

• Input signals are greater than 1 V (High Level)

• Signal leads are longer than 12 feet

Figure 4.2 shows proper wiring for Pseudo-Differential configuration.

4.1.2.3 Fully-Differential (DIFF)

In installations where each Ground Referenced Source signal has a local ground (signal located remote from

one another), the Fully-Differential configuration must be used. Since the Fully-Differential configuration

only responds to the difference in a signal between its high and low vo ltages, an y Co mmon Mod e Voltag e will

be cancelled out. In addition, Fully-Differential configuration provides the best performance of the three

configurations in an electrically noisy environment.

The Fully-Differential configuration should be used when any of the following exists:

• Each source has a local ground

• Signal sources are remote from one another

• Common Mode Voltage exists

• Common Mode Noise exists

• Signal sources are low-level (less than 1 V)

• Signal source leads are longer that 12 feet

Figure 4.2

Pseudo-Differential Configuration

ADAC Series PCI Boards 795 - 16 - ADAC/5500 Series User Manual

928

Page 22

Fully-Differential for Grounded Signal Sources

See Figure 4.3 for an example of connecting Grounded Signal Sources in Fully Differential configuration.

Figure 4.3

Fully-Differential Configuration for Grounded Sources

Fully-Differential for Floating Signal Sources

Floating Signal Sources are typically wired to a data acquisition board in Single-Ended configuration,

however, when the Floating Source signal leads pass through an electrically noisy environment, FullyDifferential configuration will give the best performance. When wiring Floating Signal sources in FullyDifferential configuration, a resistor must be connected from the low side of the sources to analog ground

(AGND). These resistors create a return path to AGND for the bias currents of the instrumentation amplifier.

If a return path is not provided, the bias current will build up on stray capacitance, resulting in drift and

possible saturation of the amplifier.

If the input signal is DC coupled a 10 K ohm to 100 K ohm resistor must be connected from the input signal's

return to the data acquisition board's AGND.

For AC coupled input signals a 10 K ohm to 100 K ohm resistor must be connected from both input signal

high and input signal low to AGND.

ADAC Series PCI Boards 795 - 17 - ADAC/5500 Series User Manual

928

Page 23

Figure 4.4 shows how to properly wire a Floatin g Source Signal in Fully-Differential configuration. In the

case where there is a combination of Ground Referenced Sources and Floating Sources, the Fully-Differential

mode should be used.

Figure 4.4

Fully-Differential Configuration for Floating Sources

4.2 MAIN I/O CONNECTOR (J1)

The main board connector is a 68 pin “SCSI III” style connector. This connector carries all the Analog I/O connections

as well as the 16 Digital I/O connections.

The ADAC/5500 input channels may be connected directly to any High Level voltage source. If long leads are run

from transducers to the system, it is very important that the leads be shielded to protect against pickup of power

frequency and other noise.

The factory has a line of screw terminal panels which can be used to ease field wiring to the PCI cards. Any of these

panels may be connected to the PCI card with an SCSC-III type cable (which can be ordered from the factory as a G55

cable).

The ADAC line of screw terminal panels includes:

ADAC-TB-8 - For use with the ADAC/5500MF boards only, this panel provides access to the 8 on-board analog input

channels, as well as the DIO ports 0 and 1 and various clocking and triggering signals.

ADAC-TB-16 - For use with the ADAC/5501MF, ADAC/5501MF-V, ADAC/5502MF, ADAC/5503HR,

ADAC/5503HR-V, and ADAC/5504HR boards only, this panel provides access to the 16 on-board analog input

channels, as well as the DIO ports 0 and 1, various clocking and triggering signals, and two optional DACs.

4.2.1 Signal Definitions

The following is a description of each of the signals available at the J1-pin connector at the front edge of the board.

ADAC Series PCI Boards 795 - 18 - ADAC/5500 Series User Manual

928

Page 24

4.2.1.1 Analog Input Channels

These channel signals are over-voltage protected to 20 V above or below the ±15 V power supply. The

channel inputs can withstand input voltages of up to ±20 volts when the power to the system is off.

ADAC-TB-8

CH 0..CH 7 - These signals are the positive half of the associated single-ended input channels.

ADAC-TB-16

CH 0..CH 14 EVEN - These signals are either the positive half of th e associated differential input

channel pairs 0 through 7, or single-ended/pseudo-differential input channels 0 through 14 even.

CH 1..CH 15 ODD - These signals are either the negative half of the associated differential input

channel pairs 0 through 7, or single-ended/pseudo-differential input channels 1 through 15 odd.

4.2.1.2 Analog Outputs

DAC 1, DAC 0 - These signals are the voltage output signals from the optional DACs.

RTN 1, RTN 0 - These signals are the return lines for the voltage outputs. These inputs are

essentially tied to AGND (Analog Ground) on the board.

4.2.1.3 Digital I/O Lines

DIO 0..DIO 15 - These signals are the 16 TTL level digital controls lines configurable as 8 bit input

or output lines. These lines are not clocked.

4.2.1.4 Terminal Panel Control

These signals are used to control the various optional terminal panels. The function of some signals may vary

slightly depending on the panel used.

MUX 0..MUX 7 - These signals are used to control the external multiplexers on active panels. These

lines directly reflect the current state of the Channel RAM bits of the same name.

ADCLKIN - This is the ADC External Pacer clock input. This input recognizes TTL level signals

and is edge sensitive. The active edge is selectable as either rising or falling.

The ADCLKIN signal line is shared with the on-board COUNTER 0 Clock Input

signal (CNTR0) pin #39 on the 68-pin J1 connector. Therefore only one input signal

may be connected to the ADCLKIN / CNTR0 terminal at any given time. Attempting to use COUNTER 0 when the ADC Pacer Clock Source is set for an External

Clock Input would not be possible, unless COUNTER 0 was being used to count the

ADC’s External Clock Input signal.

ADCLKOUT - This signal is the ADC’s External Clock Output. Each time the ADC is clocked from

any of the available clocking sources the ADCLKOUT signal pulses high for a period of 1

microsecond. This output can be used to synchronize multiple A/D converters on different PCI cards

allowing simultaneous A/D conversions by connecting the ADCLKOUT to the ADCLKIN input of

each PCI card.

ADAC Series PCI Boards 795 - 19 - ADAC/5500 Series User Manual

928

Page 25

The ADCLKOUT signal line is shared with the on-board TIMER 1 Clock Output

signal (TMR1) pin #5 on the 68-pin J1 connector. Therefore only one output signal

may be generated to the ADCLKOUT / TMR1 terminal at any given time. The

TIMER 1 is automatically disabled in hardware when the ADCLKOUT is enabled.

ADTGIN - This is the External ADC Trigger/Gate input. This input recognizes TTL level signals

and is used to start or stop the ADC acquisition process. The input is selectable as either rising/falling

edge or active high/low level sensitivity.

ADTGOUT - This signal is the internal ADC’s Trigger output. Each time the ADC is triggered from

any of the available triggering sources the ADTGOUT signal pulses high for a period of 1

microsecond. This output can be used to synchronize multiple A/D converters on different

ADAC/5500 cards allowing simultaneous A/D triggering by connecting the ADTGOUT to the

ADTGIN input of each PCI card.

The ADTGOUT signal line is shared with the on-board TIMER 0 Clock Output

signal (TMR0) pin #4 on the 68-pin J1 connector. Therefore only one output signal

may be generated to the ADTGOUT / TMR0 terminal at any given time. The

TIMER 0 is automatically disabled in hardware when the ADTGOUT is enabled.

DACLKIN - This is the External DAC0 Pacer clock input. This input recognizes TTL level signals

and is edge sensitive. The active edge is selectable as either rising or falling.

The DACLKIN signal line is shared with the on-board COUNTER 1 Clock Input

signal (CNTR1) pin #40 on the 68-pin J1 connector. Therefore only one input signal

may be connected to the DACLKIN / CNTR1 terminal at any given time. Attempting to use COUNTER 1 when the DAC Pacer Clock Source is set for an External

Clock Input would not be possible unless COUNTER 1 was being used to count the

DAC’s External Clock Input signal.

DATGIN - This is the External DAC0 Trigger/Gate input. This input recognizes TTL level signals

and is used to start or stop the DAC acquisition process. The input is selectable as either rising/falling

active edge or active high/low level sensitivity.

4.2.1.5 Counters And Timers

CNTR0 - This is the general purpose Counter 0 clock input. This input recognizes TTL level signals

and is rising edge sensitive. The input clock rate cannot exceed 500 kHz. The clock source must

provide a minimum pulse width of 100 ns.

The COUNTER 0’s External Clock Input line (CNTR0) is shared with the ADC’s

External Clock Input signal (ADCLKIN) pin #39 on the 68-pin J1 connector.

Therefore only one input signal may be connected to the ADCLKIN / CNTR0

terminal at any given time. Attempting to use COUNTER 0 when the ADC Pacer

Clock Source is set for an External Clock Input would not be possible, unless

COUNTER 0 was being used to count the ADC’s External Clock Input signal.

ADAC Series PCI Boards 795 - 20 - ADAC/5500 Series User Manual

928

Page 26

CNTR1 - This is the general purpose Counter 1 clock input. This input recognizes TTL level signals

and is rising edge sensitive. The input clock rate cannot exceed 500 kHz. The clock source must

provide a minimum pulse width of 100 ns.

The COUNTER 1’s External Clock Input line (CNTR1) is shared with the DAC’s

External Clock Input signal (DACLKIN) pin #40 on the 68-pin J1 connector.

Therefore only one input signal may be connected to the DACLKIN / CNTR1

terminal at any given time. Attempting to use COUNTER 1 when the ADC Pacer

Clock Source is set for an External Clock Input would not be possible, unless

COUNTER 1 was being used to count the DAC’s External Clock Input signal.

TIMER0 - This LSTTL output signal provides a 50% duty cycle square wave derived from an

independent TMR0 internal software pacer clock. The pacer clock period can be set from 1 us to

65535 us, producing an output clock rate from 500 KHz down to approximately 7.6295 Hz.

The TIMER 0’s External Clock Output line (TMR0) is shared with the ADC’s

External Trigger Output signal (ADTGOUT) pin #4 on the 68-pin J1 connector.

Therefore only one output signal may be generated to the ADTGOUT / TMR0

terminal at any given time. TIMER 0 is automatically disabled in hardware when

the ADC’s External Trigger Output is enabled.

TIMER1 - This LSTTL output signal provides a 2nd clock source, with characteristics identical to

TIMER0, using a separate, independent, TMR1 internal software pacer clock.

4.2.1.6 Ground Lines

SGND - This signal is the reference ground used for A/D conversion s. If you are measuring from a

fully floating source in differential mode, it would be beneficial to tie one of the channel inputs to this

point. This signal should not be used for sinking large amounts of current. This signal also acts as the

common reference line when the board is configured for single-ended inputs.

PDIN - This signal is the common return line used when the board is configured for pseudo

differential input mode.

AGND - This signal is the power return for the ±15 V power supply lines. It is distinguished from the

DGND line because it generally helps separate the poten tially high frequency digital ground noise

from the analog circuits that are powered by ±15 V.

DGND - This signal is the +5 V power return line. It is generally noisier than AGND and is a good

logic low reference point.

4.2.1.7 Power Lines

+15 V, -15 V - This power is only intended to power the optional terminal panels with active

circuitry on them. These voltages are supplied by one of the on-board DC/DC converters.

Approximately ±30 mA are available on these lines. Both lines are fused

@ 125 mA.

The TIMER 1’s External Clock Output line (TMR1) is shared with the ADC’s

External Clock Output signal (ADCLKOUT) pin #5 on the 68-pin J1 connector.

Therefore only one output signal may be generated to the ADCLKOUT / TMR1

terminal at any given time. TIMER 1 is automatically disabled in hardware when

the ADC’s External Clock Output is enabled.

+5 V - This signal is sourced directly from the PCI Bus. Take great care when using this power.

These lines are fused @ 3 Amps.

ADAC Series PCI Boards 795 - 21 - ADAC/5500 Series User Manual

928

Page 27

(

)

4.2.2 J1 Pin Assignments For ADAC/5500MF Only

Standard 68-Pin SCSCI Type III, Socket (Female) Connector with Orb

Pin

Signal

Description /

Pin

Signal

Description / Comments

Comments

1 DGND Digital Ground 35 +5 V (fused) Power

2 +15 V (fused) Power 36 +5 V

3 -15 V (fused) Power 37 +5 V (fused) Power

4 ADTGOUT / TMR0 Internal ADC Trigger Output

/ Timer 0 Clock Output

5 ADCLKOUT / TMR1 Internal ADC Trigger Output

/ Timer 1 Clock Output

6 N/C Not Connected 40 CNTR1 Counter 1 Clock Input

7 DIO_15 TTL Level Digital I/O Ch. 15 41 DIO_14 TTL Level Digital I/O Ch. 14

8 DIO_13 TTL Level Digital I/O Ch. 13 42 DIO_12 TTL Level Digital I/O Ch. 12

9 DIO_11 TTL Level Digital I/O Ch. 11 43 DIO_10 TTL Level Digital I/O Ch. 10

10 DIO_9 TTL Level Digital I/O Ch. 9 44 DIO_8 TTL Level Digital I/O Ch. 8

11 DIO_7 TTL Level Digital I/O Ch. 7 45 DIO_6 TTL Level Digital I/O Ch. 6

12 DIO_5 TTL Level Digital I/O Ch. 5 46 DIO_4 TTL Level Digital I/O Ch. 4

13 DIO_3 TTL Level Digital I/O Ch. 3 47 DIO_2 TTL Level Digital I/O Ch. 2

14 DIO_1 TTL Level Digital I/O Ch. 1 48 DIO_0 TTL Level Digital I/O Ch. 0

15 DGND Digital Ground 49 N/C Not Connected

16 N/C Not Connected 50 N/C Not Connected

17 N/C Not Connected 51 N/C Not Connected

18 N/C Not Connected 52 N/C Not Connected

19 N/C Not Connected 53 N/C Not Connected

20 N/C Not Connected 54 N/C Not Connected

21 AGND Analog Ground 55 AGND Analog Ground

22 N/C Not Connected 56 N/C Not Connected

23 SGND Signal Ground 57 N/C Not Connected

24 N/C Not Connected 58 N/C Not Connected

25 AIN_7 Analog Input, Ch. 7 59 AIN_3 Analog Input, Ch. 3

26 N/C Not Connected 60 N/C Not Connected

27 AIN_6 Analog Input, Ch. 6 61 AIN_2 Analog Input, Ch. 2

28 N/C Not Connected 62 N/C Not Connected

29 AIN_5 Analog Input, Ch. 5 63 AIN_1 Analog Input, Ch. 1

30 N/C Not Connected 64 N/C Not Connected

31 AIN_4 Analog Input, Ch. 4 65 AIN_0 Analog Input, Ch. 0

32 N/C Not Connected 66 N/C Not Connected

33 N/C Not Connected 67 N/C Not Connected

34 AGND Analog Ground 68 DGND Digital Ground

38 ADTGIN External Gate (level controlled),

39 ADCLKIN / CNTR0 External ADC Clock In, or

fused

Power

or External Trigger (edge active)

Counter 0. Rising or Falling

Edge Sensitive.

ADAC Series PCI Boards 795 - 22 - ADAC/5500 Series User Manual

928

Page 28

(

)

4.2.3 J1 Pin Assignments for ADAC/5501MF, ADAC/5502MF, ADAC/5503HR, & ADAC/5504HR

Standard 68-Pin SCSCI Type III, Socket (Female) Connector with Orb

Pin

1 DGND Digital Ground 35 +5 V (fused) Power

2 +15 V (fused) Power 36 +5 V

3 -15 V (fused) Power 37 +5 V (fused) Power

4 ADTGOUT / TMR0 Internal ADC Trigger Output /

5 ADCLKOUT /

6 DATRIGIN DAC0 External Gate (Level

7 DIO_15 TTL Level Digital I/O Ch. 15 41 DIO_14 TTL Level Digital I/O Ch. 14

8 DIO_13 TTL Level Digital I/O Ch. 13 42 DIO_12 TTL Level Digital I/O Ch. 12

9 DIO_11 TTL Level Digital I/O Ch. 11 43 DIO_10 TTL Level Digital I/O Ch. 10

10 DIO_9 TTL Level Digital I/O Ch. 9 44 DIO_8 TTL Level Digital I/O Ch. 8

11 DIO_7 TTL Level Digital I/O Ch. 7 45 DIO_6 TTL Level Digital I/O Ch. 6

12 DIO_5 TTL Level Digital I/O Ch. 5 46 DIO_4 TTL Level Digital I/O Ch. 4

13 DIO_3 TTL Level Digital I/O Ch. 3 47 DIO_2 TTL Level Digital I/O Ch. 2

14 DIO_1 TTL Level Digital I/O Ch. 1 48 DIO_0 TTL Level Digital I/O Ch. 0

15 DGND Digital Ground 49 CJ2 Reserved

16 CJ1 Reserved 50 CJ0 Reserved

17 MUX7 Reserved 51 MUX6 Reserved

18 MUX5 Reserved 52 MUX4 Reserved

19 MUX3 Reserved 53 MUX2 Reserved

20 MUX1 Reserved 54 MUX0 Reserved

21 AGND Analog Ground 55 AGND Analog Ground

22 ADEX_LO Reserved, AD Expansion LO 56 ADEX_HI Reserved, AD Expansion HI

23 SGND Signal Ground 57 PDIN Pseudo-Differential Input return

24 AIN_15 Analog Input, Ch. 15 58 AIN_7 Analog Input, Ch. 7

25 AIN_14 Analog Input, Ch. 14 59 AIN_6 Analog Input, Ch. 6

26 AIN_13 Analog Input, Ch. 13 60 AIN_5 Analog Input, Ch. 5

27 AIN_12 Analog Input, Ch. 12 61 AIN_4 Analog Input, Ch. 4

28 AIN_11 Analog Input, Ch. 11 62 AIN_3 Analog Input, Ch. 3

29 AIN_10 Analog Input, Ch. 10 63 AIN_2 Analog Input, Ch. 2

30 AIN_9 Analog Input, Ch. 9 64 AIN_1 Analog Input, Ch. 1

31 AIN_8 Analog Input, Ch. 8 65 AIN_0 Analog Input, Ch. 0

32 RTN1 Voltage output return, line 1. 66 DAC1 (Note 2) Digital-to-Analog Converter 1

33 RTN0 Voltage output return, line 0. 67 DAC0 (Note 1) Digital-to-Analog Converter 0

34 AGND Analog Ground 68 DGND Digital Ground

Signal

TMR1

Description / Comments

Timer 0 Clock Output

Internal ADC Trigger Output /

Timer 1 Clock Output

Controlled), or External

Trigger (Edge Active).

Pin

38 ADTGIN External Gate (level controlled), or

39 ADCLKIN / CNTR0 External ADC Clock In, or Counter

40 DACLKIN / CNTR1 External ADC Clock In, or Counter

Signal

fused

Description / Comments

Power

External Trigger (edge active)

0. Rising or Falling Edge

Sensitive.

0. Rising or Falling Edge

Sensitive.

Note 1: The clock source of the primary DAC0 channel may be software command, DAC0 Pacer clock,

or an external event (DACLKIN).

Note 2: The clock source of the secondary DAC1 channel may be software command, DAC1 Pacer clock, or Channel 0

clock source.

ADAC Series PCI Boards 795 - 23 - ADAC/5500 Series User Manual

928

Page 29

4.2.4 P3 and P5 Pin Assignments

The ADAC/5501MF, ADAC/5502MF, ADAC/5503HR and ADAC/5504HR include two auxiliary 40-pin headers.

These are located on the back of the boards, and provide access to the two 16-bit DIO ports (DIO2 and DIO3). Two

CA-G17-ADAC cables can be used to bring the DIO2 and DIO3 headers to separate37-pin D-type connectors [one

GA-17 cable per DIO header]. GA17’s orb (following figure) mounts at the back of the host PC.

The DB37-end of a CA-G17-ADAC Cable, which includes an Orb for PC Mounting

SIGNAL NAME P3 PIN or

P5 PIN

DGND 1 1 DGND 21 11

+ 5 V (fused) 2 20 D9 22 30

DGND 3 2 DGND 23 12

D0 4 21 D10 24 31

DGND 5 3 DGND 25 13

D1 6 22 D11 26 32

DGND 7 4 DGND 27 14

D2 8 23 D12 28 33

DGND 9 5 DGND 29 15

D3 10 24 D13 30 34

DGND 11 6 DGND 31 16

D4 12 25 D14 32 35

DGND 13 7 DGND 33 17

D5 14 26 D15 34 36

DGND 15 8 DGND 35 18

D6 16 27 STROBE2 / 3 36 37

DGND 17 9 DGND 37 19

D7 18 28 DGND 38 n/c

DGND 19 10 DGND 39 n/c

D8 20 29 DGND 40 n/c

G17 PIN

(37-pin D)

SIGNAL NAME P3 PIN or

P5 PIN

G17 PIN

(37-pin D)

P3 & P5 Auxiliary Digital I/O Connectors

Standard 40-Pin Male Headers

A CA-G17-ADAC Cable, Installed

Signal definitions for the P3 and P5 Auxiliary 40-Pin DIO headers and the DB37 connector follow.

ADAC Series PCI Boards 795 - 24 - ADAC/5500 Series User Manual

928

Page 30

4.2.5 Signal Definitions for P3, P5, and GB17’s DB37 Connector

The following descriptions apply to each of the signals that are available at the 40-pin auxiliary DIO headers,

designated as P3 and P5. The headers are located on the back of boards: ADAC/5501MF, ADAC/5502MF,

ADAC/5503HR, and ADAC/5504HR. In addition, the signals apply to the correspond ing pins on GA17’s

DB37 connector as indicated in the table on the preceding page.

GA17’s orb (following figure) mounts at the back of the host PC.

The DB37-end of a CA-G17-ADAC Cable, which includes an Orb for PC Mounting

D0... D15 These signals are the sixteen 5 V CMOS/LSTTL level digital input/output lines of DIO2 on

connector P3, and the D103 connector on P5.

On G17’s DB37 connector, D0 through D15 correspond to pins 21 through 36, with DB0

assigned to pin 21, DB1 assigned to pin 22, DB2 assigned to pin 23, etc.

DGND This signal is the +5 V power return line. It may also be used as a reference ground for TTL

signals. On G17’s DB37 connector, the DGND lines connect to pins 1 through 19,

inclusive.

+5 V This signal is +5 V power voltage signal that is sourced directly from the PC bus. The +5 V

lines are fused at 3 amps. See WARNING. On G17’s DB37 connector, the +5 V power

signal corresponds to pin 20.

WARNING

Possible electric shock. Take great care when using the +5 V power as the

voltage signal is sourced directly from the PC Bus. The +5 V lines are

fused at 3 Amps.

STROBE The Strobe2 signal is provided on the DIO2 37-pin interface and the Strobe3 signal is

provided on the DIO3 interface. When either port is configured as an input port, the

associated Strobe signal is disabled and placed in a High Impedance state (Z off). When

DIO port is configured as an output port, the associated strobe signal will be pulsed low for

1 microsecond following each data output event that occurs.

On system power-up the DIO Strobe signals are disabled and placed in a High Impedance

state (Z off). 3.3 V CMOS signal.

In regard to the G17 DB37 connector, pin-3 7 is use d fo r th e strobe si g nal.

ADAC Series PCI Boards 795 - 25 - ADAC/5500 Series User Manual

928

Page 31

4.3 SCREW-TERMINAL BOARDS

4.3.1 ADAC-TB-8 Screw-Terminal Board Connections

The ADAC-TB-8 provides screw-terminal access to all of a ADAC/5500MF board’s analog and

digital I/O signals. The terminal board connects to the ADAC/5500MF via a 3-foot long 68-pin

conductor expansion cable, p/n CA-G55-ADAC. The terminal board accepts wire up to 14 AWG.

ADAC-TB-8

WARNING

Always turn the computer power OFF and unplug it before connecting or

disconnecting a screw terminal panel or a cable to the PCI card. Failure to do

so could result in electric shock, or equipment damage.

ADAC Series PCI Boards 795 - 26 - ADAC/5500 Series User Manual

928

Page 32

4.3.2 ADAC-TB-16 Screw-Terminal Board

One ADAC-TB-16 provides screw-terminal access to all analog and digital I/O signals from any one of the

following boards: ADAC/5501MF, ADAC/5501MF-V, ADAC/5503HR, and ADAC/5503HR-V. The

terminal board connects to the board via a 3-foot long 68-pin conductor expansion cable, p/n CA-G55-ADAC.

The terminal board accepts wire up to 14 AWG.

ADAC-TB-16

WARNING

Always turn the computer power OFF and unplug it before connecting or

disconnecting a screw terminal panel or a cable to the PCI card. Failure to do

so could result in electric shock, or equipment damage.

ADAC Series PCI Boards 795 - 27 - ADAC/5500 Series User Manual

928

Page 33

4.3.3 ADAC-DC-37 Screw-Terminal Board for Auxiliary Digital I/O

The ADAC-DC-37 provides access to 16 of the 32 available auxiliary digital I/O channels from

ADAC/5501MF, ADAC/5501MF-V, ADAC/5503HR, and ADAC/5503HR-V boards. Two ADACDC-37 terminal boards are required to access all 32 digital I/O channels.

As depicted on page 4, each DC-37 terminal board can connect to an ADAC/5500 Series Board via a

CA-G17-ADAC cable, or to an optional CA-G37-x-ADAC extension cable, which interfaces

between a CA-G17 cable’s orb and the ADAC-DC-37 board.

ADAC-DC-37

WARNING

Always turn the computer power OFF and unplug it before connecting or

disconnecting a screw terminal panel or a cable to the PCI card. Failure to do

so could result in electric shock, or equipment damage.

ADAC Series PCI Boards 795 - 28 - ADAC/5500 Series User Manual

928

Page 34

5. ADAC/5500 SERIES PCI CARD OPERATION

5.1 DEVICE DRIVERS

The simplest method of operating the card is by using a program package such as LabVIEW™. This package can be

incorporated to do a wide range of display, data logging and control functions. For those who prefer to write their own

programs, the ADAC/5500 cards include the ADAC ADLIB WDM Series of driver packages. These packages provide

easy to use software function calls that can be used to perform most available board functions

5.1.1 LabVIEW™

The ADAC/5500 cards are fully supported by the ADAC-LVi data acquisition VIs for LabVIEW™. Please refer to the

ADAC-LVi manual (p/n 1107-0901) for details on using ADAC cards with LabVI EW™. The ADAC-LVi software and

user manuals are included on the ADAC CD that ships with the ADAC/5500 boards. Follow the instructions on the CD

for proper installation.

5.1.2 TestPoint™

The ADAC/5500 cards are fully supported by the TestPoint software. Please refer to the TP Help manual for details on

using ADAC cards with TestPoint. The TestPoint driver software and user help manual are included on the ADAC CD

that ships with the ADAC/5500 boards. Follow the instructions on the CD for proper installation. Note that the ADAC

driver software is also included with new releases of the TestPoint software. The TP ADAC-32 User’s Manual is p/n

1107-0903.

5.1.3 Windows Drivers (ADLIB WDM)

ADLIB WDM is a set of sophisticated, high level, dynamically linked library (DLL) data acquisition subroutines for

programmers involved in the developing of process and/or data acquisition applications. ADLIB WDM is both a

Microsoft C interface library (C, Visual C++) and a Visual Basic interface library for Windows 98/ME/NT/2000/XP.

The functions supplied with ADLIB WDM provide an easy to use interface to the line of PC data acquisition products,

shielding the programmer from the complexity of low level DAQ board programming and complicated DMA and

interrupt handling mechanisms of the PC and the Windows environment. Based on Microsoft’s Windows Driver

Model, ADLIB WDM supports DMA, Interrupt and Software Po lled data transfer methods for acquiring da ta. ADLIB

WWDM has full support for analog high level (10 V) and analog low level (mV) inputs.

The ADLIB WDM software and user manuals are inclu ded on the ADAC CD that ships with the ADAC/5500 boards.

Follow the instructions on the CD for proper installation.

ADAC Series PCI Boards 795 - 29 - ADAC/5500 Series User Manual 928

Page 35

5.2 THEORY OF OPERATION

5.2.1 Process Definitions

In order to best understand how to operate the various board functions, it is important to first understand the language

that will be used to describe the board processes. The following is a list of pertinen t terms and definitions used in this

document.

ADC

Analog to Digital Converter, also referred to as A/D. This is the circuitry that samples the voltage present at one of the

inputs and translates that reading to a number that is representative of the input voltage. The number supplied by the

ADC is referred to as the ADC DATA or RAW DATA and its units are bits or binary digits.

DAC

Digital to Analog Converter, also referred to as D/A. This is the circuitry that translates a binary data word to a specific

voltage level. The optional DACs on the ADAC/5500 Series boards are specified for DC accuracy. The DACs on these

boards can be clocked and triggered; the outputs are updated as soon as they receive new data.

ADC Channel

This term is used to refer to any of the 256 addressable connections to the multiplexed ADC. The ADAC/5 500MF has

8 on-board ADC channels available and supports the ADAC-TB-8 panel. The ADAC/5501MF, ADAC/5502MF,

ADAC/5503HR and ADAC/5504HR have 16 on-board channels available and support the ADAC-TB-16 and ADACTB-8 panels for a maximum number of 256 input channels.

ADC Data- also Raw Data

This is the unscaled number returned by the ADC. For two’s complement data coding (which is standard for bipolar

inputs), this number will be either in the range of -2000...+1999 (for 12-bit A/D boards) or -32242…+32241 (for 16-bit

boards). For straight binary data coding (which is standard for unipolar inputs), this number will be in th e range of

0..+3999 on 12-bit A/D boards and 0...+644 83 on 16-bit boards. This number is typically multiplied by some scale

factor to convert the number to more useful engineering units. For example: the bipolar ±10 V input uses a scale factor

of .005 V/bit. An ADC reading of +1000 when multiplied by .005 V results in +5 .000 V. Similarly, the 16 bit scale

factor for the ±10 V scale is .000130140 V/bit.

DAC Data- also Raw Data

This is the unscaled number sent to each DAC channel. For two’s complement data coding (which is standard for

bipolar inputs), this number will be either in the range of -32722...+32722. For straight binary data coding (which is

standard for unipolar inputs), this number will be in the range of 0..+65445. This number is typically multiplied by

some scale factor to convert the number to more useful engineering units. For example: 0-10 V input uses a scale factor

of .000152800V/bit. A DAC DATA value of 32723 when multiplied by .0001528 0 results in 5.000044 V at the DAC

output line.

ADC Conversion

This is the process of sampling a single input or transducer’s voltage and generating a representative data value.

DAC Conversion

This is the process of outputting a single voltage generated from representative data value.

ADAC Series PCI Boards 795 - 30 - ADAC/5500 Series User Manual 928

Page 36

ADC Acquisition

This term is used to refer to a series of A/D conversions. This series may consist of sampling a single channel several

times or sampling several channels sequentially one or more times. An acquisition has a clearly defined Starting point

and Ending point. Thus an acquisition may be STARTED and STOPPED.

DAC Acquisition

This term is used to refer to a series of D/A conversions. This series may consist of outputting a sing le DAC channel

several times or outputting both channels simultaneously one or more times. An acquisition has a clearly defined

Starting point and Ending point. Thus an acquisition may be STARTED and STOPPED.

ADC and DAC Clock

This is the signal or impetus that initiates an A/D or D/A conversion. To CLOCK the ADC or DAC is to start an A/D

conversion. The term clock is used for this process because typically a clock signal consists of a series of pulses that are

periodic or evenly timed. If the conversions are evenly spaced it is then possible to digitally reconstruct the input