Page 1

Marchand Electronics Inc.

PO Box 18099, Rochester NY 14618

Tel:(585) 423 0462 Fax:(585) 423 9375

info@marchandelec.com www.marchandelec.com

(c)1997....2005 Marchand Electronics Inc.

WM8 Installation Instructions

CONTENTS

Specifications

Introduction

Installation

Separate Components

Biamping

Operation

Setting Qs

Setting Fs

Setting BOOST

Setting Qb

Vented Speakers

Final Adjustments

Technical Description

Circuit

Options

Assembly (kit version)

General Wiring Practice

PC Board Assembly

Chassis Wiring

Appendix A - Schematic Diagram

Appendix B - PC Board Layout

Appendix C - Chassis Layout

Appendix D - PC Board Parts List

Appendix E - Overall Parts List

Appendix F - Troubleshooting

SPECIFICATIONS*

Frequency Response

(Boost=0, Qs=Qb) 2 Hz-100kHz

Harmonic Distortion <.01% (1 kHz)

Signal/Noise Ratio >110 dB (Ref. 10 V)

Input Impedance 80 kΩ

Output Impedance 10 Ω

Maximum Output Voltage 25 V (P-P)

Output Load Capability 100 Ω (min.)

Bass Boost Range 0-24 dB

Net Q Range .25 - 1.0

Dimensions 17"W x 8.5"D x 3.5"H

*Specifications subject to change without notice.

INTRODUCTION

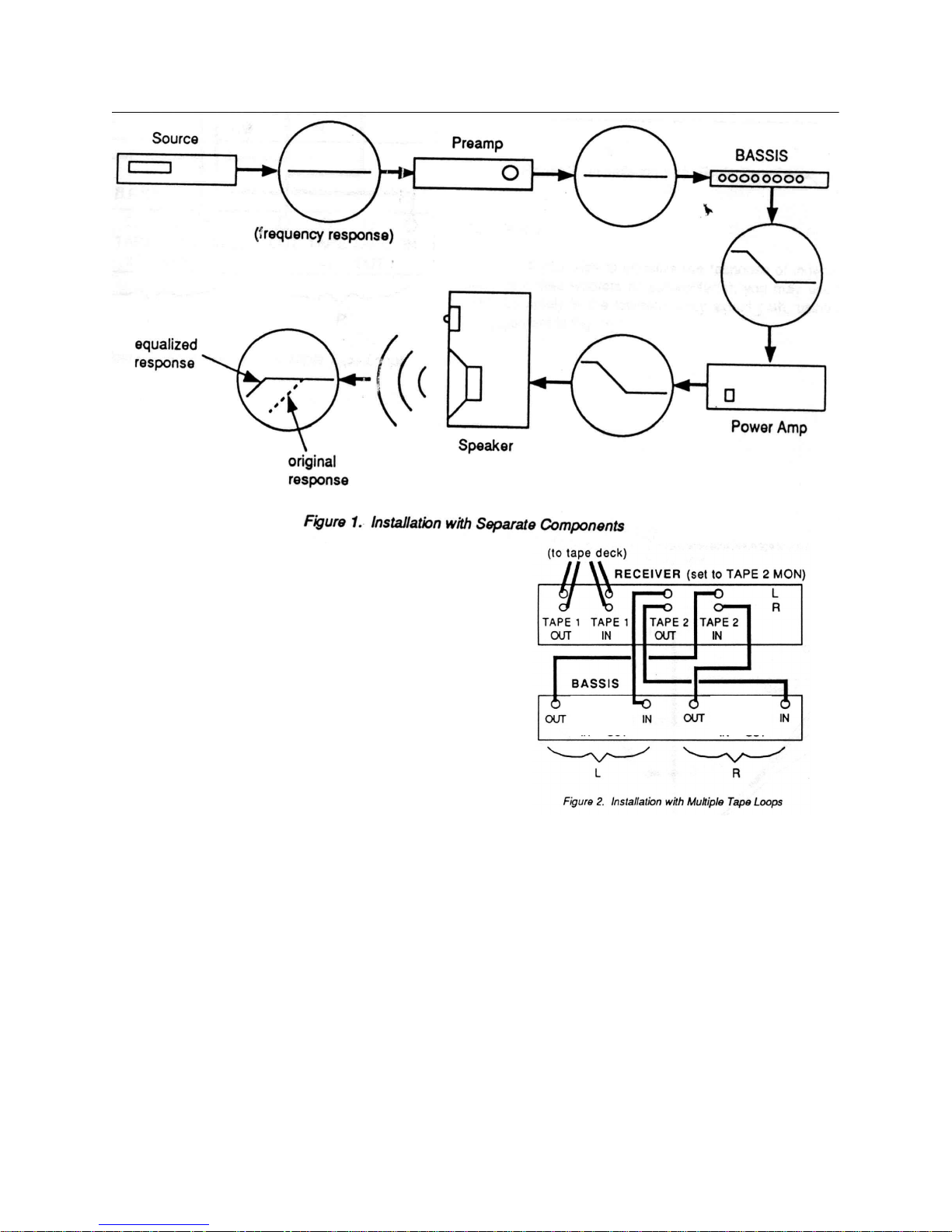

The BASSIS is a specialized electronic

equalizer which enables acoustic-suspension

(closed-box) loudspeakers to take on a wide

range of alternative bass responses improving

some vented (bass-reflex) designs.

By adjusting the front panel controls, the linelevel audio signal is equalized as the exact

inverse of a given loudspeaker's bass response,

and the new bass cutoff frequency and damping

are defined. The filtered signal is then passed to

the power amp and on to the speakers, where the

existing bass response is cancelled and replaced

by the desired bass response. Figure 1 illustrates

the frequency response at various points in the

signal path.

Marchand Electronics Inc www.marchandelec.com

1

Page 2

INSTALLATION

There are several ways of connecting the

BASSIS to you system, depending upon your

present setup. In any case, make sure all

components are turned off while making

connections, and read the rear panel labelling

carefully. Do not apply power to the unit when

installation is complete. You must make the

adjustments described in "Operation" first.

SEPARATE COMPONENTS

If you own a separate preamp/power amp

combination, you can use the arrangement shown

in Figure 1, where the OUTPUT from the preamp

is connected to the BASSIS' INPUT jacks, and

the BASSIS' OUTPUT jacks are connected to

your power amp's INPUTs. The BYPASS switch

removes the BASSIS circuitry from the signal path

by connecting the INPUT directly to the OUTPUT.

This allows easy evaluation of the equalizer's

effectiveness.

If you own an integrated amplifier or receiver

with PREAMP OUT and POWER AMP IN jacks,

the same connection as for separates can be

used.

MULTIPLE TAPE LOOPS

If your integrated amp or receiver has an

unused tape loop (or a dedicated signalprocessing loop), you may connect the BASSIS

as shown in Figure 2, below.

Be sure to press the TAPE 2 MON button on your

receiver. You can remove the BASSIS from the

signal path in two ways now: (1) turn off the

TAPE 2 MON button on your receiver, or (2) use

the BYPASS switch on the BASSIS.

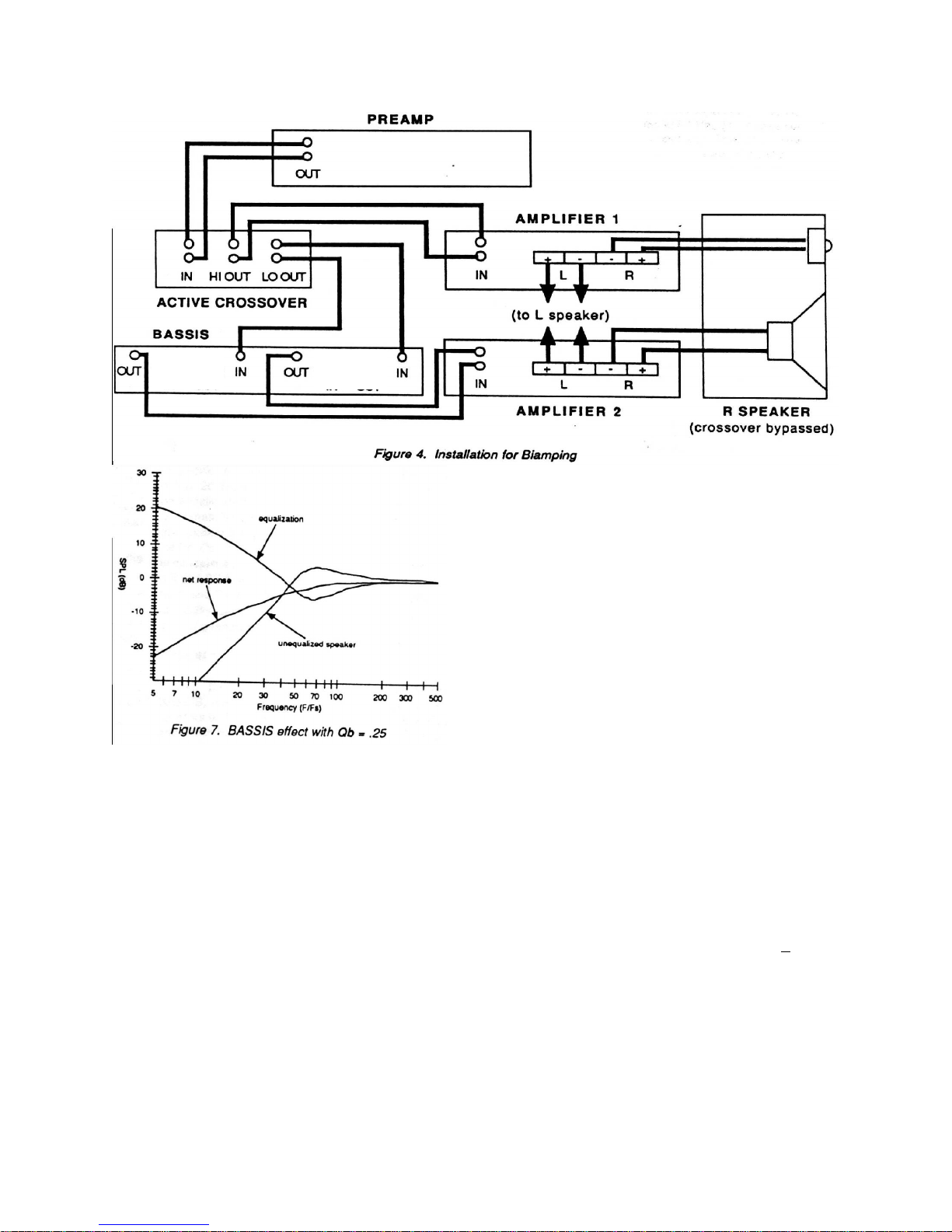

BIAMPING

If you wish to equalize the response of

independently amplified woofers or subwoofer(s),

you may use the BASSIS solely in the lowfrequency signal path, using the arrangement in

Figure 4.

Marchand Electronics Inc www.marchandelec.com

2

Page 3

OPERATION

The various controls on the BASSIS must be

adjusted to match your system's requirements

before power is applied to the unit. If the 24 dB

(factor of 16) maximum BOOST setting is applied

incorrectly, damage to your speakers and/or

amplifier may result.

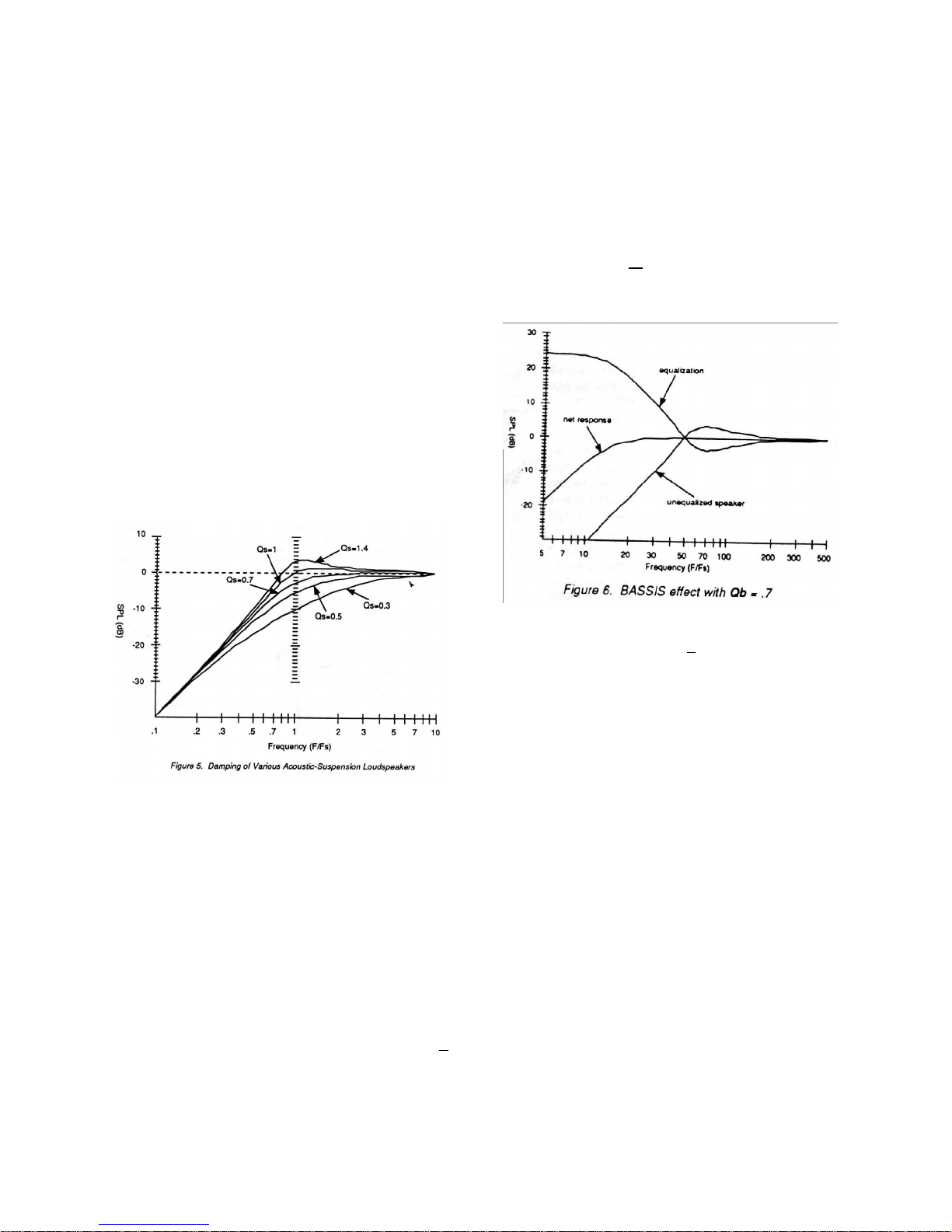

SETTING Qs

Figure 5 shows the bass response of various

acoustic-suspension loudspeakers. If the

speaker's Q is greater than 0.7, the response may

reach a peak at the "resonant frequency", then fall

off at a rate of 12 dB/octave at lower frequencies.

If your speaker has a "boomy" or "heavy" sound,

then it is likely that it Q is in the "underdamped"

range from 1.0 to 1.6. On the other hand,

speakers whose Q is .5 or .6 will be "welldamped", with a "tight" or even "lightweight"

sound (due to the prematurely-falling bass

response).

speaker's value for Qs is .5, then Figure 5 shows

that its -3 dB point is near 1.6 x Fs. Thus, if your

specs indicate a -3dB poi9nt of 75 Hz, then a

setting of Fs = 75/1.6=45Hz should be used. On

the other hand if your speaker has Qs= 1.4

(boomy-sounding), then Figure 5 indicates its -3

dB point is near .65 x Fs. Hence if its

specifications indicate a frequency response like:

"52 Hz to 22 kHz + 3dB", then you should use a

setting of Fs + 52/.65 = 80Hz. Finally, if you

assume Qs = .7 for your speakers, then Fs

equals the specified -3 dB point.

You must adjust the Left and Right channel

controls labelled Qs (Speaker Q) according to

your own speakers' characteristics. (You will

ordinarily use the same settings for Left and Right

channels.) Choose a value which approximates

the damping for your speakers, as suggested

above. If in doubt, use a setting around .7,

corresponding to the value most speaker

designers aim for. You can later fine-tune the

setting if necessary.

Setting Fs

You must now set the Left and Right channel

Fs (Speaker Corner Frequency or -- less

accurately -- Resonant Frequency) controls. If

you have frequency response specifications for

your loudspeakers of the form:"55 Hz to 18 kHz +

3dB" or ".3 dB point at 75 Hz", you can

approximate Fs by making use of Figure 5 and

your estimate for Qs. For example, if your

If you have no frequency response specs for

your loudspeakers, or if the specs are of the form

"50 Hz to 20 kHz" (without + x dB limits) then you

will have to estimate Fs. Most medium-size

"bookshelf" speakers have Fs around 65 Hz;

compact speakers (enclosure less than 14" high)

may have Fs closer to 80 Hz; large speakers

(greater than 30" high) may have Fs around 4050 Hz. For those tiny die-cast speakers like

Radio Shack's Minimus 7, try a value of 100 Hz or

higher for Fs, with Qs around .8 or .9.

While these settings are not too critical, it is

important to get in the ballpark of the correct

setting before using the BASSIS. The settings

may be fine-tuned later if necessary. As an

example of the effect of a severe mismatch,

suppose your speaker has Fs = 50 Hz, and Qs =

1, and suppose that you incorrectly set the

BASSIS according to Fs =100 Hz, Qs = .5. If you

make the remaining adjustments (Boost and Qb,

as described below) to try to extend the bass

response, the BASSIS will give a 6 dB boost

Marchand Electronics Inc www.marchandelec.com

3

Page 4

In the net response at 100 Hz and more than 12

dB too much bass at 50 Hz. (This speaker would

be nearly flat to 50 Hz. without equalization.) The

unnecessary bass boost will give a very "heavy"

sound to most recordings, and may damage the

speakers or cause distortion when listening at

high levels.

SETTING BOOST

Once the correct settings of Fs and Qs have

been made to match your loudspeakers, you may

never need to readjust these controls. However,

the remaining controls -- BOOST and Qb -- may

be adjusted to give the best results with your

choice of listening levels and source material.

BOOST indicates the amount by which low

frequency signals are amplified. If the Fs and Qs

setting are correct, only those frequencies where

your speaker is deficient will be amplified, so that

the effect is to extend bass response. (In

contrast, the BASS control on your receiver or

preamp indiscriminately boosts the entire lowfrequency portion on the signal, often leading to a

"boomy" or "heavy" quality.) A setting of BOOST

= 0 dB will not extend the bass, but will allow you

to effectively adjust your woofer's damping by

changing Qb as described below. A setting of

BOOST = 12 dB will extend bass response one

octave lower, and a setting of BOOST = 24 dB

will extend bass by two octaves.

SETTING Qb

The best setting for Qb is largely dependent

upon your taste and on the listening-room

acoustics. This control adjusts the Q (see Figure

5) of the new bass response dictated by the

BASSIS. If you want a very "tight" sound, choose

a Qb = .5 or smaller. If you want a "looser", more

"full" bass, use Qb = 1. Qb = .7 gives the

"maximally-flat" response. Figures 6 and 7 show

the results when the BASSIS is used to correct a

somewhat boomy-sounding speaker whose

response drops below 60 Hz (Qs = 1.4, Fs = 60).

In both cases BOOST = 24 dB is used, but in

Figure 6 a setting of Qb = .7 is used, while in

Figure 7 Qb = .25 is used.

It is interesting to note that settings of Qb< .5 give

a transient response with absolutely no "ringing",

so that the BASSIS allows you to achieve a "nonresonant" bass response without need for a

refridgerator-sized "transmission-line"

loudspeaker enclosure.

Marchand Electronics Inc www.marchandelec.com

4

Page 5

VENTED SPEAKERS

The BASSIS can be used to reduce the

boominess of poorly tuned vented ("ported",

"bass-reflex", or "passive radiator") speakers. In

this case, use a setting of BOOST = 0 dB (never

boost the bass below the resonant frequency of a

vented speaker!), Qs = 1.4, and adjust Qb to your

taste. Or, you can plug the vent and forego the

efficiency advantage of the vented design,

allowing you to use the entire range of

equalization options as you would for an acousticsuspension loudspeaker.

extend smoothly into the lower bass, particularly

when using high-quality source material.

On the other hand, extending the bass

response will make your system more sensitive to

"standing waves" in the listening room. You may

have to experiment with new locations for your

loudspeakers or listening seat to obtain the

smoothese overall bass response.

TECHNICAL DESCRIPTION

The equalization offered by the BASSIS can be

described in terms of the biquadratic transfer

function:

FINAL ADJUSTMENTS

You are now ready to apply power to your

system including the BASSIS. Advance your

VOLUME control slowly to make sure the unit is

working properly. If you have difficulties, see the

"Troubleshooting" section of this manual

(Appendix F). There are a few additional points to

keep in mind to obtain optimum performance.

If your source materialis LP records, you should

test your system's sensitivity to record warps.

Remove the grilles from your speakers. With the

VOLUME control set low and the BASSIS set with

BOOST = 24 dB, play the silent lead-in observing

your woofer cones. If a significant "pumping"

motion is visible at your normal VOLUME setting,

engage the 20 HZ CUT filter on the BASSIS.

Even when properly adjusted, the bass

extension offered by the BASSIS must be used

with discretion. While the BASSIS can give a 61/2" woofer the same bass response as that of a

12" woofer, it cannot increase the power handling

of small speakers. Do not engage your preamp

or receiver's LOUDNESS button or make

excellive use of the BASS tone control while

using the BASSIS. When listening at high

VOLUME levels to material with significant lowbass content, it is wise to reduce the BOOST

setting, reduce Qb, or BYPASS the unit entirely.

Fortunately, the low-bass content of most

recordings is much smaller than the content of

the remaining frequency range. In these cases

the low-frequecy boost applied by the BASSIS will

not impair the speaker or amplifier power

capabilities.

When using the BASSIS, don't expect to hear

the sort of elevated bass produced by turning up

your preamp or receiver's BASS tone control or

pressing the LOUDNESS button. Instead, the

mid-bass will be reproduced with impoved

neutrality and "openness", and the response will

2

w

+ 2 dswss + s

s

2

G(s)= --------------------------------------

2

w

+ 2 dbwbs + s

b

where ws and ds are the corner frequency

and damping ratio of the woofer and wb and d

are the new corner frequency and damping ration

chosen by the user (w =2piF and d =0.5/Q). The

numerator cancels the 2nd-order high-pass effect

of the acoustic-suspension woofer and the

denominator defines the new 2nd-order cutoff.

CIRCUIT

The circuitry for each channel of the BASSIS is

contained on an individual printed circuit board

(PC board), using high-speed op-amps and closetolerance passive components. A power supply is

contained on a third board. The schematic

diagram of a single channel is shown in Appendix

A.

The heart of the circuit is a 4-amplifier

biquadratic filter, supplemented with additional opamps to allow the independent adjustment of the

damping and cutoff frequency pararmeters. Opamps IC1, IC2 and IC3 provide the equalization,

while IIC4A is part of the 20 Hz CUT filer. Opamp IC4B provide low output impedance and high

current capability, to allow long cable runs with

minimal loading effects.

Dual potentiometer VR3 adjusts the frequency

matching the speaker's corner frequency over the

range: Fs = 30 Hz to 130 Hz. Potentioometer

VR2 adjusts the damping which exactly cancels

the speaker's response, for speakers with Qs

from .4 to 1.6. Potentiometers VR1 and VR4 set

the corner frequency and damping of the new

bass response over the range: Fb = Fs to Fs/4

and Qb = .25 to 1. Since each octave of bass

extension requires 12 dB of amplification at low

2

b

Marchand Electronics Inc www.marchandelec.com

5

Page 6

frequencies, pot VR1 is actually labelled BOOST,

with a range of 0 to 24 dB.

Switch S1 activates the 20 HZ CUT (high-pass,

infrasonic, or "subsonic") filter with an 18

dB/octave slope below 20 Hz, to avoid the

amplification of inaudible but potentially

destructive low-frequency signals. Switch S2

combines the Left and Right channels at

frequencies below the speaker's original corner

frequency (provided the settings for Fs, Qs,

BOOST, and Qb are identical for both channels)

to cancel out-of-phase RUMBLE signals. Switch

S4 provides a BYPASS function to eliminate the

equalizer from the signal pather, and Swith S3

allows the user to regain tape monitoring

capability, in the event that the BASSIS is used in

the sole tape loop of a receiver or preamp.

operation. Simply follow the steps in the

"Assembly" section of this manual, but wire the

inputs of a second + 15 V power supply to the

power cord as well, and power the Right-channel

PC board from this power supply.

OPTION 3

On the other hand, if the BASSIS is to be

used with a single-channel, independentlyamplified subwoofer, then only a single PC board

need be assembled, and a smaller enclosure may

be employed. Assembly is the same as

described in this manual, except that the switches

may be SPDT rather than DPDT.

ASSEMBLY (KIT VERSION)

OPTION 1

If you are constructing your own enclosure for

the BASSIS, you may choose to calculate the

values of fixed resistors which reflect your

particular speaker's Fs and Qs, and which provide

a fixed amount of boost. This allows you to

eliminate all but a

Single potentiometer -- which controls the

damping (Qb). Since the setting of the Qb control

influences the level of bass about the new corner

frequency (compare Figures 6 and 7), you retain

control of the net bass extension. To implement

this option, follow the assembly procedure

detailed in the next section of this manual, except:

(a) leave out the Molex connectors which attach

the BOOST and Fs pots to the PC board; (b) wire

only that part of Molex connector P2 which

attaches the Qb pot to the PC board; (c)

recalculate the values of resistors R7, R8, R16,

R4, and R26 according to your speakers'

characteristics and the desired amount of boost:

R7 = R8 = 1/(6.28 x Fs x C1)

R

R4 = R26 = R28 x 10

= R19 x Q

16

s

boost/40

.

Where BOOST is given in dB. Now you can use

a dual 10k linear pot to adjust the damping (Qb)

of the Left and Right channels simultaneously.

Or, if you want to eliminate the remaining control

as well, remove VR4 and recalculate R11 for the

desired (fixed) value of Qb:

R11 = R2 x Qb.

OPTION 2

There is space in the standard BASSIS

enclosure for an additional power supply for

constructors interested in true dual-mono

The parts for a stereo implementation include:

two BASSIS printed circuit boards and

components, one + 15 V power supply assembly

(such as Marchand Electronics' Model PS10), and

one enclosure with hardware. The Appendices of

this manual contain a detailed Overall Parts List

as well as a PC Board Parts List. You will first

assemble the circuit boards, then mount them in

the enclosure and attach the front panel controls.

GENERAL WIRING PRACTICE

The tools necessary to assemble the BASSIS

include: a 15 - 30W soldering pencil, rosin-core

solder, wire cutters, and a Phillips-head

screwdriver. Other useful tools are: a

desoldering tool or solder wick (to remove excess

solder), a project holder, long-nose pliers, and a

wire stripper. A clean, well-lit working area will

minimize frustrations.

When soldering a component to the circuit

board, first mount the component so that it fits

snugly against the silkscreened side of the board.

Next, heat the component lead and the circuit

board trace (on the foil side) simultaneously with

the soldering pencil and apply solder until it melts

and flows around the component lead. With

practice the entire process should take only 5

seconds or so. Remove the pencil and allow the

connection to cool for a few seconds before

moving. Cut off the excess lead close to the

solder joint. If a solder bridge was inadvertently

made to another trace, remove the solder

carefully with a desoldering bulb or braid. Keep

the tip of the soldering pencil clean by wiping on a

damp sponge every few minutes.

Components can be identified as follows.

Resistors use the 4-band color code in the chart

shown below. The fifth band is always brown,

indicating 1% tolerance. For example, a resistor

Marchand Electronics Inc www.marchandelec.com

6

Page 7

marked Brown-Black-Black-Gold-Brown is a 10

Ω resistor with 1% tolerance.

1st, 2nd, & 3rd Bands 4th Band

Black 0 Black x 1

Brown 1 Brown x 10

Red 2 Red x 100

Orange 3 Orange x 1000

Yellow 4 Yellow x 10,000

Green 5 Green x 100,100

Blue 6 Blue x 1,000,000

Violet 7 Silver / 100

Gray 8 Gold / 10

White 9

Figure 8. Resistor Color Code

Capacitors and diodes are individually

marked, though somewhat cryptically. C1 and C4

may be labelled "393", while C5, C7, and C15 are

marked "104K".

Before beginning assembly, it is suggested

that you compare the components to the Parts

List and sort them accordingly. (Look inside the

heat-shrink tubing if anything is missing!)

PC BOARD ASSEMBLY

Assembly of the BASSIS is simplified by a

guide which has been silkscreened on to the

printed circuit boards. Appendix B repeats this

layout diagram. To mount components onto the

boards, observe the placement shown on the

layout diagram and on the silkscreen pattern, and

match with the values shown on the PC Board

Parts List in Appendix D. The following checklist

should be completed, for both the Left and Right

channels.

[ ] [ ] 1. Bend the leads of resistors R1-R35

and solder them in place as shown on the layout

diagram. Cut off the excess leads as you go.

[ ] [ ] 2. Deleted.

[ ] [ ] 3. Mount diodes D1-D4 and solder them

in place. Be sure to observe the correct polarity

by positioning the side with the band as shown in

the diagram.

[ ] [ ] 4. Mount and solder the four (4) IC

sockets in place on the circuit board. Be sure the

side with the notch is oriented as shown. Do not

insert the op-amps into these sockets yet.

[ ] [ ] 5. Install the aluminum electrolytic

capacitors C8 and C14, being careful to orient the

+ and - leads as shown. Install the nonpolar

electrolytic capacitor C9 with either orientation.

[ ] [ ] 6. Install the remaining polypropylene,

polyester and ceramic capacitors C1-C7, C10-C13, and C15-C16. (These can be oriented either

way.)

[ ] [ ] 7. Install Q1, 2N5087.

[ ] [ ] 8. Install Q2, 2N2222.

[ ] [ ] 9. Mount the 3-pin male Molex connector

and the five (5) 5-pin male Molex connectors

according to the diagram. The edge with the

plastic protrusion corresponds to the band on the

layout diagram.

[ ] [ ] 10. Press op-amps 1C1-1C4 into the four

IC sockets, being sure to orient them so that the

notch matches the notch on the sockets, as

shown on the diagram. You may need to (gently)

bend the leads inward slightly to match the holes

in the sockets. If you resolder any of the socket

leads later, remove the corresponding op-amp

first to protect it from excessive heating.

Now inspect the foil side of the board for solder

splashes or bridges and remove them with the

desoldering tool. Check for any empty holes,

possibly indicating a missing component. (Some

unused holes may remain, to allow substitution of

capacitors with differing physical dimensions.)

Double-check the orientation of the aluminum

electrolytic capacitors, diodes, transistors,

connectors, and ICs.

L R

Marchand Electronics Inc www.marchandelec.com

CHASSIS WIRING

At this point you should have assembled the

Left and Right channel PC boards, and a + 15 V

power supply. The Overall Parts List in Appendix

E details the parts needed for assembling the

BASSIS chassis. Appendix C sketches the

interior of the unit after completion of a single

channel.

Do not apply power to the unit until all the

assembly is complete and you've read the

"Operation" section of this manual.

7

Page 8

[ ] 11. Mount the BASSIS PC boards and power

Front Panel

DPST rocker switch

Rear Panel

Fuse Holder

Rear Panel

Power entry

Rear Panel

Voltage selector

GREEN/

YELLOW

N

L

PS10 transformer

terminal block

WHITE

BLACK

WHITE

BLACK

BLACK

BLACK

BROWN

RED

RED

Wire to

case

WHITE

Sold er l ug

Re sistor

Wire to PS1 0 outp u t

gr ound

supply inside your enclosure with standoffs and

#6 screws. The PS 10-power supply should be

oriented with the transformer closer to the rear

panel.

[ ] 12. Mount potentiometers VR1-VR4 for each

channel (total of eight (8) pots on the inside of the

front panel. The dual pots (VR1 and VR3)

correspond to the BOOST and Fs labels on the

front panel. The pots should have their solder

lugs facing up.

[ ] 13. Mount the fuseholder on the rear panel but

do not insert the fuse yet.

[ ] 14. Mount the power entry connector onto the

rear panel.

[ ] 15. Mount the DPDT voltage selector switch

on the rear panel.

[ ] 16. Mount the RCA bukhead connectors on

the rear panel. Two have black insulators and

two have red insulators. Mount the red

connectors in the right channel and the black

ones in the left channel.

Power entry with voltage selector switch on rear

panel and rocker switch on front panel.

Power entry with voltage selector switch.

The PS10 power supply of the crossover should

be grounded to the cabinet through a power

resistor.

Solder one lead of the 2400 Ohm power resistor

to the solder lug.

Solder a 3” length of wire to the other end of the

power resistor.

Install the shrink tubing over the resistor and part

of the solder lug.

Attach the solder lug to the cabinet using one of

the 6-32 screws on the front panel.

Insert the free end of the wire in the center

terminal of the three position terminal block of the

PS10 output. This is the neutral DC output.

Marchand Electronics Inc www.marchandelec.com

Now the AC power wiring will be hooked up to

the power supply.

8

Page 9

Use high voltage (thick insulation) #22 hookup

teflon shoulder washer

RCA connector

teflon flat washer

gold plated solder lug

gold plated nut

rear panel

RCA connector mounting cross section

wire to make the connections between the power

entry connector, the power switch on the front

panel and the power selector switch on the rear

panel and the fuse holder. Install heat shrink

tubing over all junctions. Use wire colors as

shown.

Make sure to securely install the grounding wire

between the ground terminal on the power entry

connector and the chassis. Solder a 3” piece of

green/yellow hookup wire to one of the solder lugs

provided. Solder the free end of the wire to the

ground terminal and secure the solder lug to the

chassis with one of the 6/32 screws holding the

rear panel.

Set the voltage selector switch to the proper

voltage before proceeding.

Install a 1A fuse in the fuse holder.

We will now test the power supply. Plug the

cord in and turn on the power switch. The two

LED indicators on the power supply and the front

panel LED indicator should light up.

UNPLUG the power cord before proceeding.

[ ] 17. Cut a 4" piece of brown wire and 4" of red

wire, strip 1/4" from each end, and attach a spade

lug to one end of each wire. Slide a 1-1/2" piece

of heat-shrink tubing onto the other end of each

wire. Solder the brown wire to the cathode lead of

the front panel LED (the cathode is the lead closer

to the flattened edge of the LED). Solder the red

wire to a 10k resistor. Solder the other end of this

resistor to the remaining LED lead. Slide the

heat-shrink over the exposed leads and heat with

a match. Mount the LED in the appropriate

socket on the front panel. Leave the other ends

of these wires loose for now.

For the remaining steps, the codes shown in

Figure 9 will be used to refer to the lugs on the

potentiometers, switches and Molex connectors.

[ ] [ ] 18. For the Left and Right channel

circuit boards, cut pieces of red, brown, and

orange wire long enough to reach from male

Molex connector P4 on the circuit board to the

output terminals on the power supply (with a few

inches to spare). Strip 1/4" from each end.

Attach spade lugs to one end of each of the three

wires and twist the wires together for neatness (-unless you're color-blind, in which case you

should attach the wires one at a time to keep

track!). Attach Molex terminal pins to the other

end of each wire. Using the coding in Figure 9,

press the pin attached to the brown wire into jack

A in a 30pin female Molex connector, and press

the pins on the red and orange wires into jacks B

and C, respectively. Snap the female connector

onto P4.

[ ] [ ] 19. Screw the spade lugs attached to the

brown wires for each channel to the -15 V

terminal of the power supply, along with the spade

lug attached to the cathode of the front panel

LED. Screw the spade lugs attached to the red

wires to the Ground terminal on the power supply.

Screw the spade lugs attached to the orange

wires to the + 15 V terminal of the power supply,

along with the spade lug attached to the anode of

the front panel LED. These connections are

critical. Double check that you've linked jack A of

Marchand Electronics Inc www.marchandelec.com

9

Page 10

the Molex connector to the - 15 V terminal, jack B

to Ground, and jack C to + 15 V.

[ ] [ ] 20. Using a short piece of bared wire link

lugs C and F together on the BOOST pots, and

link lugs A and D together on the Fs pots.

[ ] [ ] 21. Cut 5 wires of different colors, long

enough to reach from male Molex connector P1

on the circuit board to the corresponding BOOST

pot. Strip 1/4" from each end and twist the wires

together for neatness. Attach Molex terminal pins

to one end of each wire, and slide a 3/4" piece of

heat-shrink tubing onto the other end. Press the

terminal pins into a 5-pin female Molex connector

as shown in Figure 9. Solder the other end of

each wire to the lugs of the BOOST pot,

observing the colors so that (see Figure 9): jack

A on the Molex connector connects to solder lug

D on the pot, jack B connects to lug E, jack C

connects to lug F, jack D connects to lug B, and

jack E connects to lug A. Slide the heat-shrink

over the solder joint and heat with a match. Snap

the female Molex connector onto male connector

P1.

[ ] [ ] 22. Using the same procedure as in Step

21 (don't forget the heatshrink tubing), connect

jack A of the female Molex connector you will use

with P3, to lug F on the Fs pot. Connect jack B to

lug E, jack C to lug D, jack D to lug B and jack E

to lug C. Snap the Molex connector onto P3 on

the circuit board.

[ ] [ ] 23. Using the same procedure as in Step

21, connect jack A of the female Molex connector

corresponding with P2, to lug A on the Qb pot.

Connect jack B to lug B on the same pot.

Connect jack C to lug C on the same pot, and use

a short piece of wire to attach lug C of the Qb pot

to lug C of the Qs pot. Now connect jack D to lug

B of the Qs pot and jack E to lug A of the Qs pot.

Snap the Molex connector onto P2 on the circuit

board.

[ ] [ ] 24. Using the same procedure, connect

jack A of the female Molex connector

corresponding to P5, to lug D (Left channel) or lug

A (Right channel) of a DPDT switch (see Figure

9). Be sure you are holding the switch so that the

keyhole tab is on the underside of the shaft.

Connect jack B to lug E (Left channel) or lug B

(Right channel). Connect jack C to lug F (Left

channel) or lug C (Right channel) of the same

switch. Skip jack D on the Molex connector. Snap

the Molex connector onto P5 on the circuit board.

When both channels are completed, mount the

DPDT switch in the 20 HZ CUT hole.

[ ] [ ] 25. Connect jack A of the Molex

connector P6 to lug F (Left channel) or lug C

(Right channel) of the remaining DPDT switch.

Connect jack D of the Molex connector to lug E (L

channel) or lug B (R channel) of the switch.

Connect jack E to lug D (L channel) or lug A (R

channel) of the switch. Mount this switch in the

BYPASS hole on the front panel.

[ ] [ ] 26. Install a jumper wire between jack B

of connector P6 and jack C of same. Snap the

Molex connector onto P6 on the circuit board.

[ ] [ ] 27. Install a jumper wire between the

tape-in and tape-out terminals of the 8-position

blue terminal block on the WM8 circuit boards.

[ ] [ ] 28. Mount all the knobs onto the pots,

and insert the fuse into the fuseholder.

Note that the knobs are mounted so that they will

turn the same angle fully clockwise as fully

counterclockwise.

You have now completed the assembly of your

BASSIS. Double check that you've completed all

the steps. At this point you may plug the unit into

a wall outlet and turn on the POWER switch to

observe whether the power light comes on.

However, do NOT attach it to your system until

you've made the adjustments discussed in

"Operation".

Marchand Electronics Inc www.marchandelec.com

10

Page 11

APPENDIX A Schematic Diagram

WM8 BASSIS

(c) 2001 Marchand Electronics Inc.

C4

IC2B

gnd

Tape In

R2

R1

R5

R9

R35

R8

R21

VR3A

FS

C1

IC1B

R6R7VR3B

IC3A

R10

R11R3R4

R27

R26

R25

C7

C15

R18

C5

C16

R24

R34

Tape Out

Input

R29

R28

GND

IC3B

R12

R13

R19

IC4B

R15

R16

VR2

Qs

R32

R17

R14

R22

Out

C3C2C1

C8

+15Volt

-15Volt

R22*

R23

R30

C10

D2*D2D1

S3

Tape

Mon

VR1A

BOOST

VR1B

VR4

Qb

C9C6 IC4A

IC1A

IC2A

S4 Bypass

S1 20Hz cut

C13

D3

Q1

Q2

RLY1

Muting

S2 Rumble

C2P65

3

211P6432

P5P55

Off-board connection

Marchand Electronics Inc www.marchandelec.com

11

Page 12

APPENDIX B PC board Layout

Marchand Electronics Inc www.marchandelec.com

12

Page 13

Marchand Electronics Inc www.marchandelec.com

13

Page 14

Marchand Electronics Inc www.marchandelec.com

Typical cabinet front panel layout

14

Page 15

Parts list for WM8-K board

----------------------------------------------------------------------- Bag #1

-----------------------------------------------------------------------R32 1 10.0 Ohm 1% Metal Film

R23, R30 2 24.9K 1% Metal Film

R10 1 33.2K 1% Metal Film

R25 1 40.2K 1% Metal Film

R14, R17 ,R6, R9 4 49.9K 1% Metal Film

R15 1 52.3K 1% Metal Film

R1,2,5,11,12,13,19,22,28,29,35 11 100 K 1% Metal Film

R3, R27 2 133 K 1% Metal Film

R7, R8, R16 , R21 4 162 K 1% Metal Film

R4, R18, R26 3 402 K 1% Metal Film

R24, R34 2 1.00M 1% Metal Film

R22* 1 10M 5% Carbon Film

C1, C4 2 0.033uF, 2% Polypropylene

C2, C3, C11, C13 4 0.1 uF, Ceramic Axial

C10 1 0.22 uF, Stacked Film

C5, C7, C15 3 0.1 uF, Polypropylene

C8, C14 2 330 uF, 25V Aluminum

C9 1 10 uF, 25V Aluminum, Non-Polar

C6, C16 2 1.0 uF, Stacked Film

D1, D2 2 1N4937 1A fast

D2* 1 1N4148 small signal

D3 1 1N5232B (5.6V zener diode)

Q1 1 2N5087

Q2 1 2N2222

IC1, IC2, IC3, IC4 4 OPA2134PA

4 IC socket, 8pin

1 Molex connector, 3pin, male

5 Molex connector, 5pin, male

1 Molex connector, 3pin, female + pins

5 Molex connector, 5pin, female + pins

1 DPDT relay, 24V coil

1 8 pos terminal block

1 Circuit board WM8, 3.2" * 4.15"

NOTE: D2* and R22* are marked D2 and R22.

D2* and R22* are are located near diode D3.

----------------------------------------------------------------------- Bag #2

----------------------------------------------------------------------- For dual single

VR1, VR3 4 2 10 K Dual Pot., Linear

VR2, VR4 4 2 10 K Pot., Linear

1 1 DPDT rocker switch

2’ 1’ 1/8" shrink tubing

6’ 3’ Hookup wire, stranded, 22AWG, Brown

6’ 3’ Hookup wire, stranded, 22AWG, Red

6’ 3’ Hookup wire, stranded, 22AWG, Orange

6’ 3’ Hookup wire, stranded, 22AWG, Yellow

6’ 3’ Hookup wire, stranded, 22AWG, Green

Marchand Electronics Inc www.marchandelec.com

15

Page 16

Parts list for WM8- KK, full kit

------------------------------------------------------------------------

Bag #3

------------------------------------------------------------------------

2 Bag-1, WM8-KK board kit

1 Bag-2, Dual model

1 PS10-K Power supply kit

1 Fuseholder, D type

1 Fuse, 1A

1 DPST Rocker Power switch

1 Voltage Selector Switch

1 Power Entry Connector

2 #6 solder lug

1 2.4K, 1W resistor

2 Gold plated RCA jacks, red

2 Gold plated RCA jacks, black

1 Line cord, 3-wire IEC

8 Knob

4 4/40 x 3/8" philips head machine screw

4 4/40 locknut

12 Standoff, 1/2", #6

12 6-32 x 1/4" philips head machine screw

16 6-32 x 1/4" philips head machine screw,black

5 6-32 x 1/2" philips head machine screw

5 6-32 x 5/8" button head cap screw

2' Hookup wire, stranded, 22AWG, Brown

2' Hookup wire, stranded, 22AWG, Red

2' Hookup wire, stranded, 22AWG, Orange

1' HV wire Yellow/Green

2' HV wire white

2' HV wire blck

1' HV wire red

1' HV wire brown

6" 1/4" heatshrink tubing

1 Hex wrench 1/16”

1 Hex wrench 5/64”

1 Cabinet base

1 Cabinet front

1 Cabinet front adapter plate

1 Cabinet rear

1 Cabinet top

4 Rubber bumper + screw

Marchand Electronics Inc www.marchandelec.com

16

Loading...

Loading...