Page 1

2017-2018 Model Shown

User Manual and Guide

XT12-HR

©Copyright Market Direct Campers & Caravans 2018

Read owner’s manual before using the equipment. Third party component manuals should be read in conjunction

with this manual. Maintenance guidelines must be met or exceeded, failing to meet these guidelines may result in

serious injury or death and property damage.

Page 2

1300 4X4 4X4

1

Page 3

1300 4X4 4X4

Table of Contents

INTRODUCTION ......................................................... 3

Store Locations ........................................................ 5

Contact Details ......................................................... 5

ABOUT YOUR HYBRID OFFROAD CARAVAN ......... 6

Specifications ........................................................... 6

Bearings and Seals ................................................... 6

Fridge Fitting Chart .................................................. 7

Hitch ......................................................................... 7

How to Hitch your coupling ................................ 8

Uncoupling ......................................................... 11

Setting up your Caravan ............................................ 13

Loading Your Caravan ............................................ 13

Choosing a Spot to Set Up ..................................... 13

Levelling Your Caravan .......................................... 14

Important Safety Notice ..................................... 20

Brake Adjustment ............................................... 21

Brake Cleaning and Inspection ........................... 21

Magnets .............................................................. 21

Shoes and Linings ............................................... 22

Corrosion Prevention ............................................. 22

Wheels and Tyres ...................................................... 22

Highway .............................................................. 22

Off Road ............................................................. 22

Electrical Systems ...................................................... 23

Chargers & Inverters .............................................. 23

Battery Care ........................................................... 23

12 Volt Wiring Diagram .......................................... 24

Control Panel .......................................................... 25

Gas & Water Systems ............................................. 25

Site Power .............................................................. 14

Kitchen ................................................................... 15

Preparing for Bad Weather .................................... 15

Packing Down Your Caravan .................................. 16

Storage & Care .......................................................... 16

Long Term Storage ................................................. 16

Interior ................................................................... 16

Exterior .................................................................. 16

Batteries ................................................................. 16

Securing Your Caravan ........................................... 17

Torque Settings ...................................................... 17

Wheel Nuts ........................................................ 17

Hitch ................................................................... 18

Trailing Arm Pivot Bolts ..................................... 18

Brakes and Handbrake - Electric ............................ 18

Features ............................................................. 18

Operation ........................................................... 18

Trailer Plug Wiring ............................................. 18

Breakaway Switch .............................................. 19

Hand Brake ........................................................ 19

Adjuster ............................................................. 20

Correct Use of Your El

ectric Brakes ................... 20

Hot Water System .................................................. 25

Water Pumps .......................................................... 25

Connecting the Gas ................................................ 26

Protecting from Mould ........................................... 26

Pre-Trip Checklist ....................................................... 27

Useful Accessories ..................................................... 27

Levelling Blocks ...................................................... 27

Wheel Chocks ......................................................... 28

Covers ..................................................................... 28

Stone Protection .................................................... 28

Trouble Shooting ........................................................ 29

Water ...................................................................... 29

Gas .......................................................................... 29

Electrical ................................................................. 30

Brakes ..................................................................... 31

Handy Tips ................................................................. 32

Driving Off Road ..................................................... 32

Trip Planning........................................................... 33

Warranty Statement ................................................... 34

Maintenance ............................................................... 35

Maintenance Schedule ........................................... 36

Supplier Contact Details ............................................. 44

2

Page 4

1300 4X4 4X4

INTRODUCTION

WARNING– Before using this product you should read this manual and those

manuals supplied by component manufacturers applicable to this product.

This manual is supplied as a reference to required maintenance of the product. Failure to

use and maintain the product in accordance with what is outlined in this manual may affect

your warranty.

Incorrect and/or insufficient maintenance may cause product failure resulting in property loss, damage

or injury or death. Maintenance intervals are critical for normal use, extreme use may require shorter or

additional maintenance intervals.

Manual content does not imply. express or other any warranty, the owner should read the limited

warranty terms included in this booklet.

Before using this product, you should be certain your tow vehicle is suitably rated and equipped to tow the

product safely and legally. The trailer and vehicle pairing must we within the safe “Maximum Towing

Capacity”, “Ball Weight Capacity” and “Gross Combination Mass” as stated by the vehicle manufacturer.

This caravan is fitted with electric brakes and a “Breakaway System”. Requirements for breakaway

systems can vary from state to state. It is mandatory to supply a maintenance charge to the breakaway

battery source while driving. You MUST ensure this capability is fitted to your vehicle. The maintenance

charge is supplied to the caravan via the Anderson plug on the drawbar.

3

Page 5

1300 4X4 4X4

4

Page 6

1300 4X4 4X4

QUEENSLAND

Brisbane

Cairns

Townsville

Caboolture

NEW SOUTH WALES

Sydney

Newcastle

VICTORIA

Melbourne

North Geelong

WESTERN AUSTRALIA

Wangara

Kenwick

SOUTH AUSTRALIA

Adelaide

NATIONAL TOLL FREE

WARRANTY HOTLINE

SPARE PARTS

1300 4X4 4X4

1300 MDC CARE

1300 MDC PARTS

Store Locations

3/711 Beaudesert Rd

Rocklea QLD 4107

178-180 Hume Hwy

Lansvale NSW 2166

126 Canterbury Rd

Kilsyth South VIC 3137

63 Innovation Circuit

Wangara WA 6065

1246 South Rd

Clovelly Park SA 5042

395 Sheridan St

Cairns North QLD 4870

Unit 1, 2364 Pacific Hwy

Heatherbrae NSW 2324

129 Douro Street

Nth Geelong VIC 3215

1752 Albany Way

Kenwick WA 6107

437 Bayswater Rd

Garbutt QLD 4814

4 Boeing Place

Caboolture QLD 4510

Contact Details

1300 494 494

1300 632 2273

1300 632 72787

5

Page 7

1300 4X4 4X4

Specifications apply to:

2017-18 Model Only

Berth

2

Trailer Length

5500mm (hitch to tailgate)

GTM

Chassis Construction

Aluminium Composite Panel, Fully Welded Frame +

Chassis

Fully Independent Trailing Arm Suspension with 4 Shock

Absorbers

2 x 16” Rims + 1 spare, Goodride Mud Terrain 265/75

R16

Hitch

Brakes

Stone Guard

Gas Cylinders

Jerry Can Holder

Cooktop

Kitchen Construct

Water Tank

Water Delivery

Hot Water System

Hot/Cold Internal Ensuite with External Van Side

Mounted Shower Tent

Battery

Awning

AC Charger (240v)

DC Charger (12v)

Inverter

Bearings are a consumable item should be removed, inspected and repacked with grease every 5,000km and

ABOUT YOUR HYBRID OFFROAD CARAVAN

Specifications

3000kg

150mm x 50mm x 4mm (galvanised)

Body Construction

Suspension

Wheels & Tyres

3500kg Vehicle Components

12”Electric Off Road with Hand Brake

Shower (Ensuite)

Included With Stone Tamer Mudflaps

2 x 9kg Gas Cylinder Holders incl 2 Gas Cylinders

2 x 20L Jerry Can Holders

SMEV 3 Burner Hob Deluxe Cooker

External 304 Grade Stainless Steel

2 x 80L Fresh Water

12v Electric Pump x 1

Truma “Boiler” 14 Litre Gas

2 x 100AH Deep Cycle AGM Batteries

Electric

Projecta IDC3500-12v 35A 7 Stage

Projecta IDC25-9-32v 25A 3 stage

Projecta IM1000-12v 1000w Continuous/2000w Peak

Bearings and Seals

replaced every 10,000km as best practice. See maintenance schedule for guidance.

Bearing Number: Inner Bearing 25520 Outer Bearing 25520 Seal: 55 x 85 x 12

6

Page 8

1300 4X4 4X4

MT35FP

ED65

35L

30L

35 Glacier G61

40L

35L RF40

RF47

Fridge Fitting Chart

Engel Evakool Bushman Ironman LARB

Hitch

Current 2018 onward model XT12HR is fitted with a Vehicle Components ADR approved DO35 hitch. Previous models

may be fitted with a McHitch coupling. For information on McHitch couplings and spare parts contact the manufacturer

www.mchitch.com.au

Phone: (02) 63 512 533

Fax: (02) 63 512 633

Mobile: 0402 863 867

Email: joe@mchitch.com.au

7

Page 9

1300 4X4 4X4

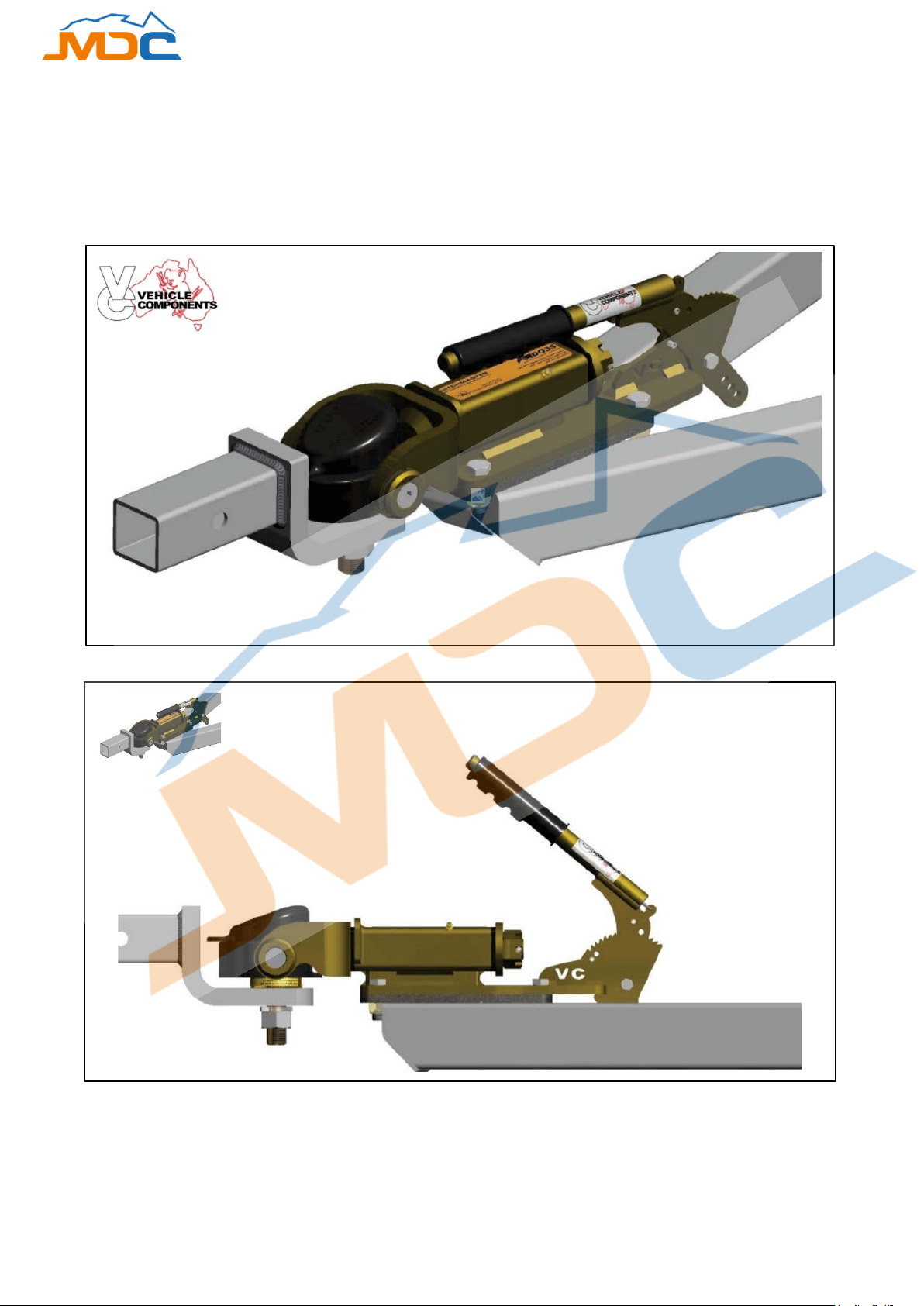

How to Hitch your coupling

Here is a short guide on how to safely use your coupling to couple and uncouple the

trailer from the towing vehicle.

Make sure the handbrake is applied prior to coupling and uncoupling.

8

Page 10

1300 4X4 4X4

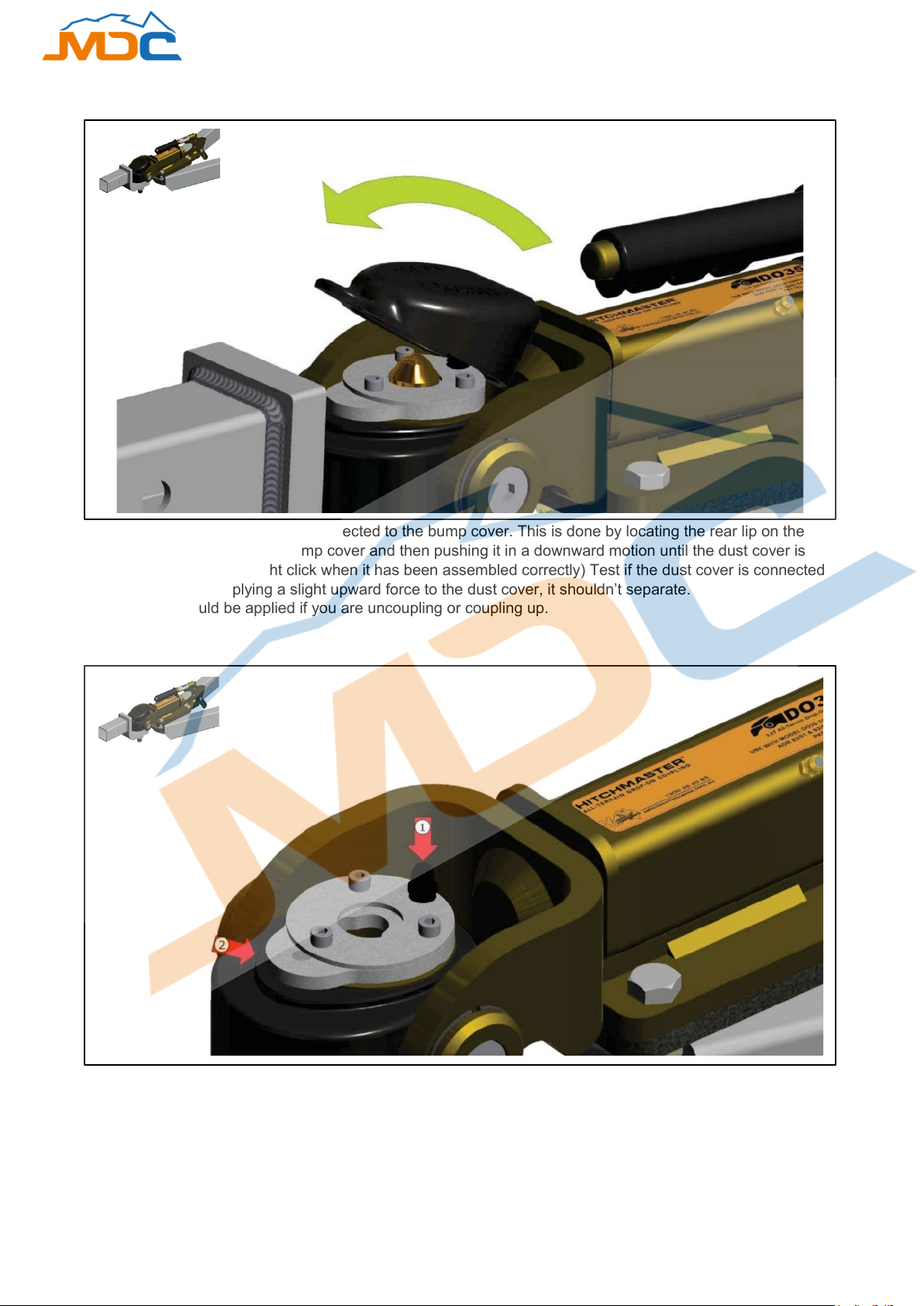

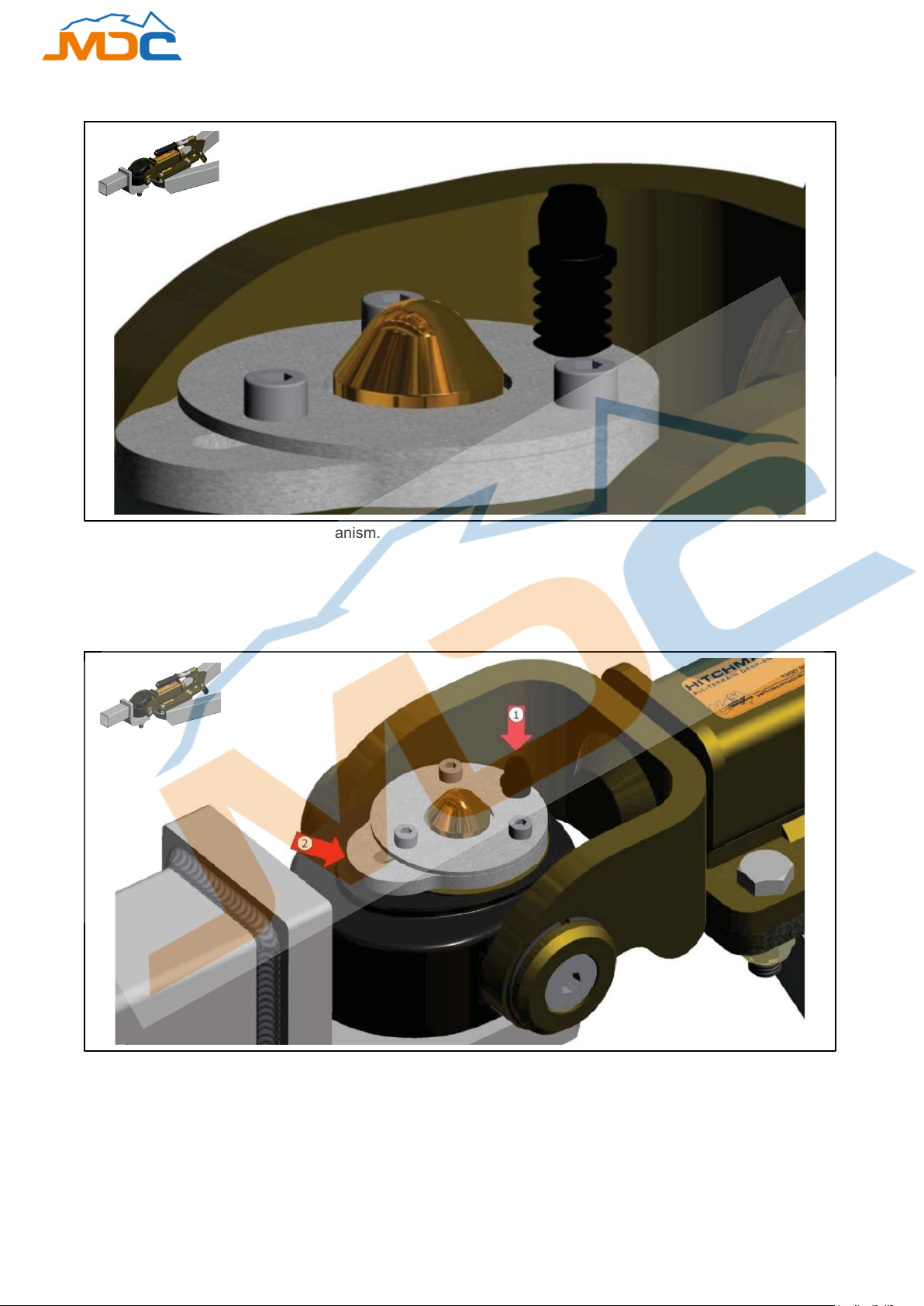

Make sure the dust cap is securely connected to the bump cover. This is done by locating the rear lip on the

dust cap onto the groove of the bump cover and then pushing it in a downward motion until the dust cover is

secure (there should be a slight click when it has been assembled correctly) Test if the dust cover is connected

to the bump cover by applying a slight upward force to the dust cover, it shouldn’t separate.

This procedure should be applied if you are uncoupling or coupling up.

STEP 1

Push down the button (1) and push the locking mechanism back (2). When the locking mechanism (2) is all

the way back, release the button (1) locking the plate in place

9

Page 11

1300 4X4 4X4

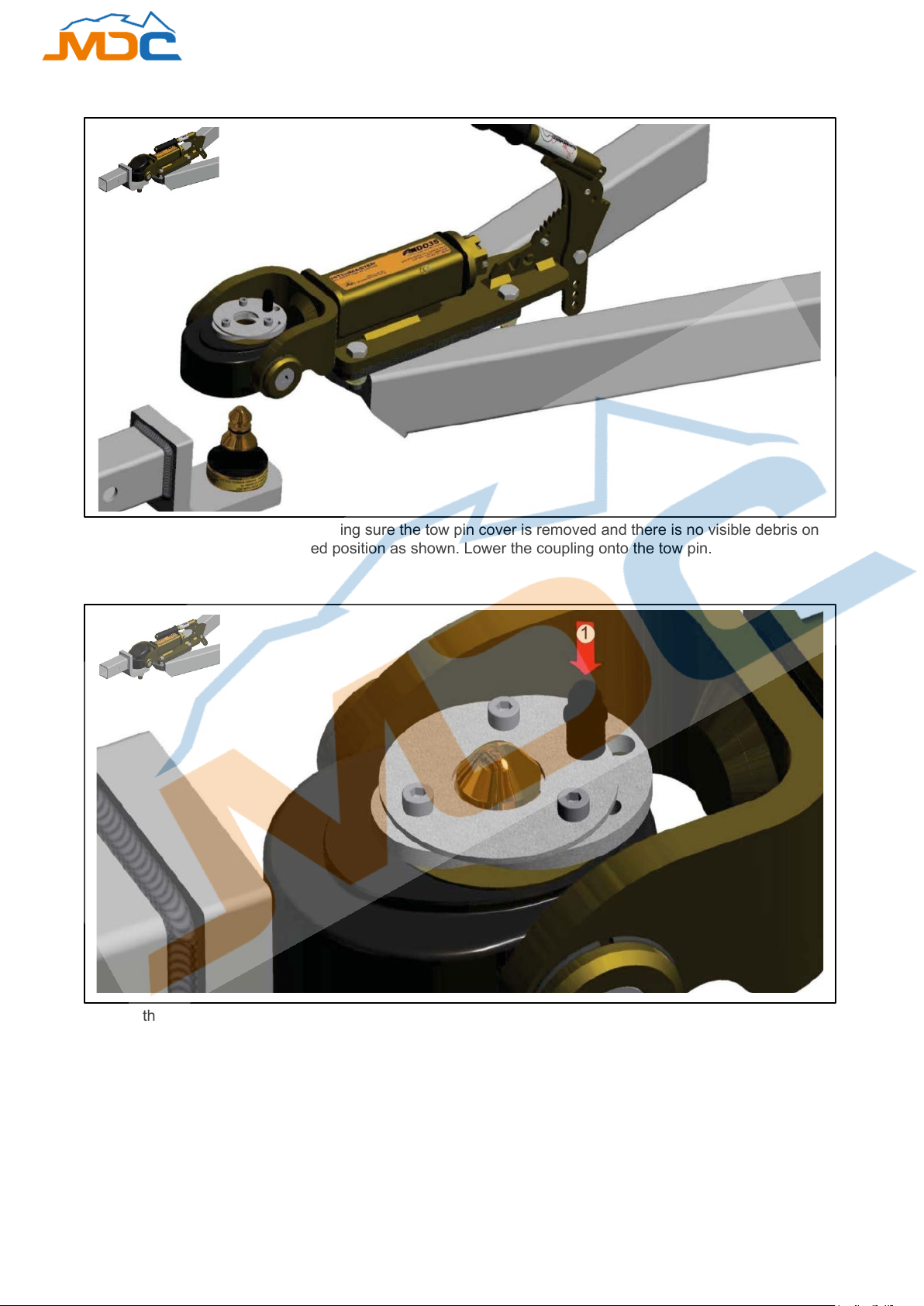

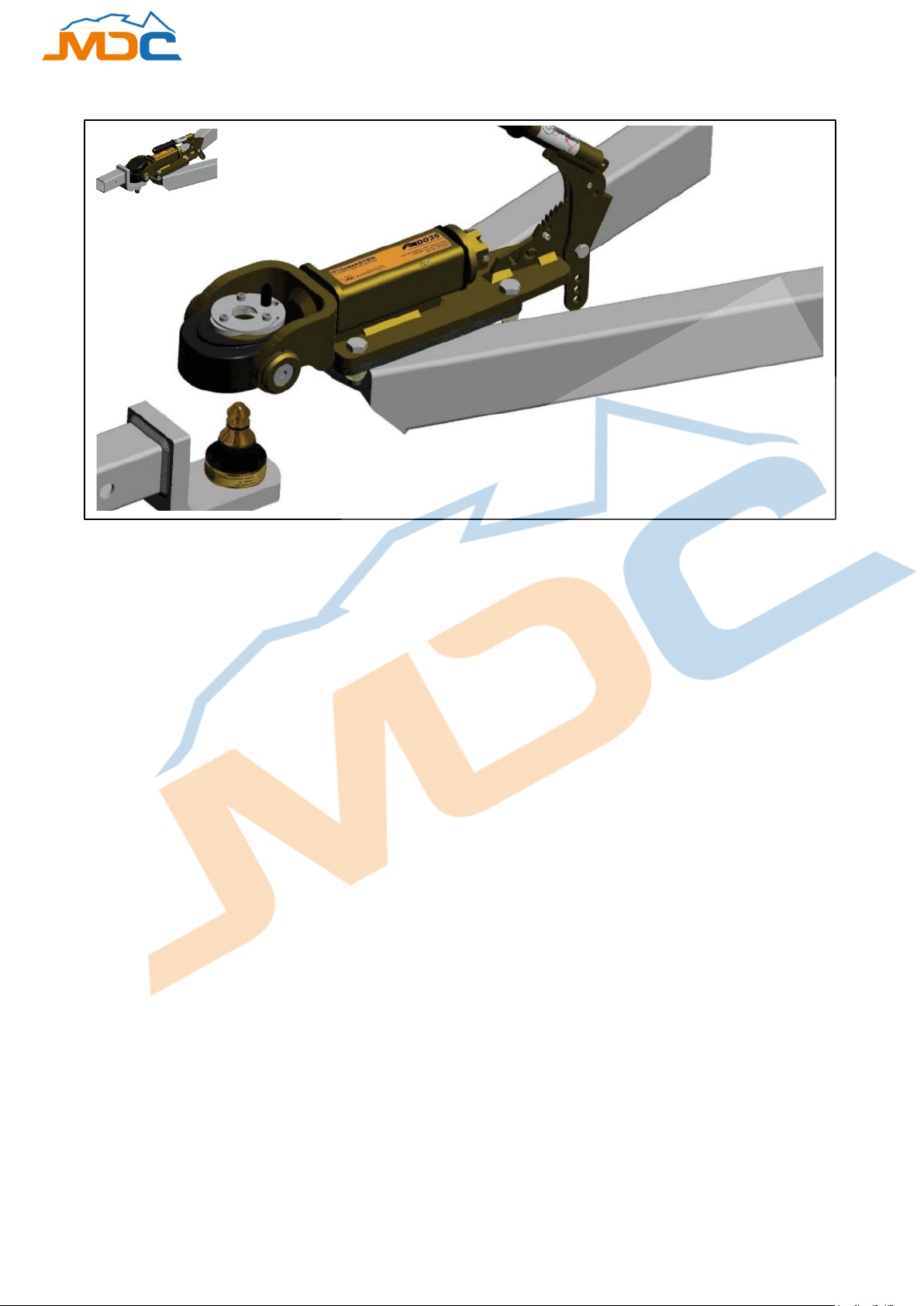

STEP 2

Offer up the tow pin to the coupling making sure the tow pin cover is removed and there is no visible debris on

it. Locking plate should be in unlocked position as shown. Lower the coupling onto the tow pin.

STEP 3

Make sure the tow pin is seated inside the universal and the tow pin top is sticking out of the locking

mechanism (see below). Press the button (1) to release the locking mechanism there will be an audible

locking noise at which point the mechanism will return to the initial position as shown in step 1. Verify the pin is

correctly through the mechanism and assemble the cap. If the cap will not fit check the locking mechanism is

in the correct locked orientation.

10

Page 12

1300 4X4 4X4

Detail view of pin through locking mechanism.

Uncoupling

STEP 1

Push down the button 1 and push the locking mechanism back 2. When the locking mechanism is all the way

back release the button while holding the mechanism to ensure it does not spring back to the locked position.

11

Page 13

1300 4X4 4X4

STEP 2

Lift the coupling up off the tow pin.

12

Page 14

1300 4X4 4X4

Seng up your Caravan

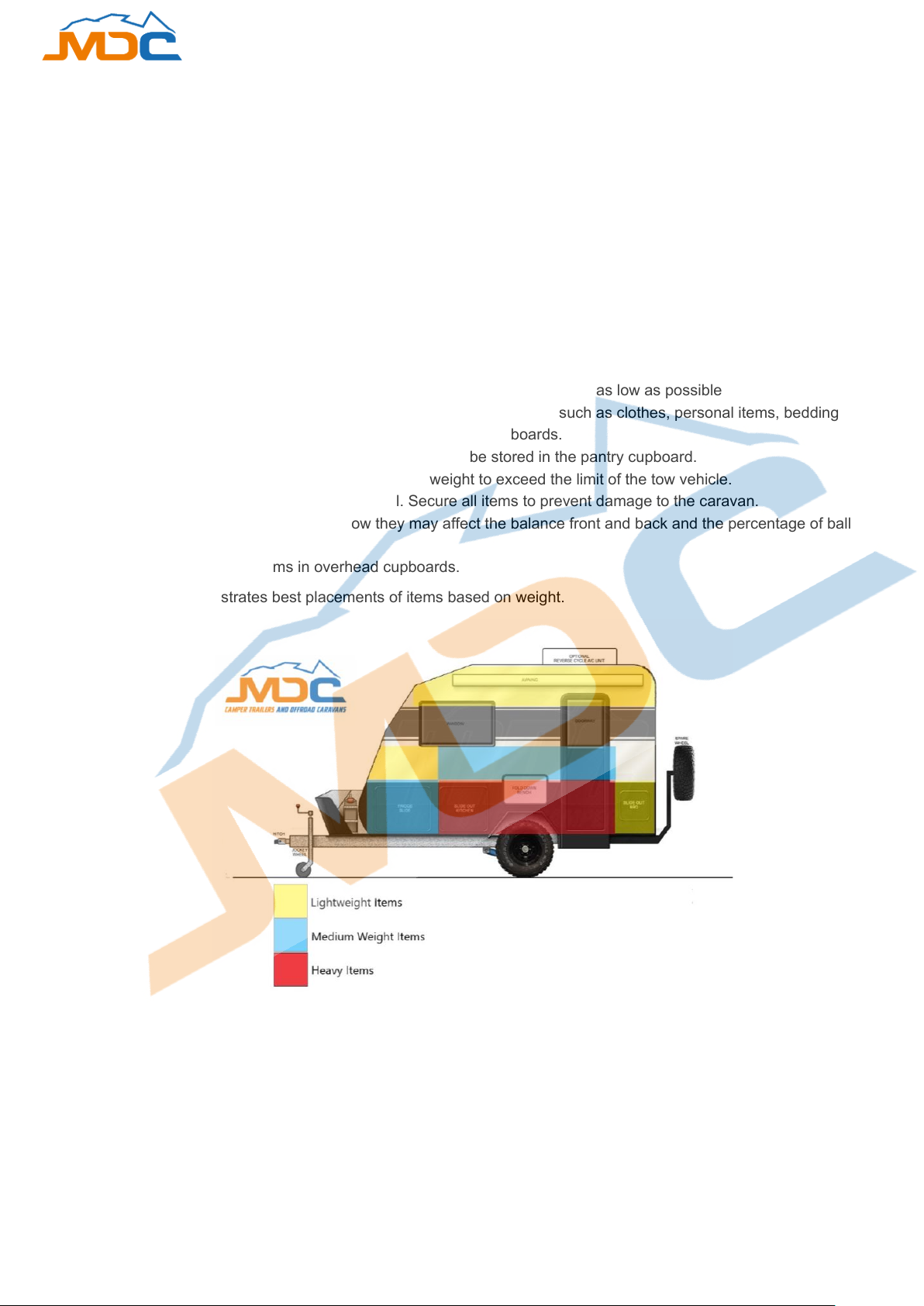

Loading Your Caravan

It is important to load your caravan correctly to distribute weight evenly and achieve a suitable ball weight load and

prevent loading in a manner that can cause a caravan to sway and/or roll excessively left and right. The optimum ball

weight on a caravan is between 9 and 11% of the total caravan weight.

WARNING: BALL LOADING (DOWNWARD LOAD ON TOW HITCH) MUST NOT EXCEED 350KG OR THE

MAXIMUM ALLOWABLE LOAD BY THE VEHICLE MANUFACTURER OR TOW BAR RATING, WHICH EVER IS

THE LOWEST. Exceeding these limits may result in an accident causing serious injury or death and/or

property damage.

• Always load evenly to both sides of the caravan

• Load heavy weight over or as close to over the axle as possible and as low as possible

• Overhead cupboards should only be used for lightweight items such as clothes, personal items, bedding etc.

• Heavy cooking equipment should be stored in lower cupboards.

• Tinned food, bottled goods for cooking etc should be stored in the pantry cupboard.

• Never load in a manner that causes the ball weight to exceed the limit of the tow vehicle.

• Ensure no items can move during travel. Secure all items to prevent damage to the caravan.

• Consider water tank levels and how they may affect the balance front and back and the percentage of ball

weight.

• Never store heavy items in overhead cupboards.

The diagram below illustrates best placements of items based on weight.

Choosing a Spot to Set Up

When choosing a spot to set up your caravan, start with a flat area with no overhanging trees. Birds and bats

occupying trees can defecate leaving droppings on your caravan that can damage paint and leaves and sap can also

stain the coating. Ensure you are not camping in an area prone to flooding or with bad drainage in the event of rain.

Even the slightest hollow in the ground can put you in a mini lake. In hot weather if possible, set your caravan up so

the sun’s arc goes from front to back or back to front with the annex/awning in the general direction the sun is arcing

across. Doing this will keep the bulk of the caravan in shade and the inside cooler as it will be shaded by the awning.

13

Page 15

1300 4X4 4X4

Levelling Your Caravan

The stabiliser legs on your caravan are not designed for supporting the full weight of the trailer, they are there to

stabilise it once it is level. Using your stabilisers as a lifting mechanism will void your warranty as will extending them

with a “rattle gun” or “impact wrench”. Levelling front to back can be done by raising and lowering the jockey wheel

prior to adjusting the ramps as illustrated below. Once levelled the legs can be lowered to keep the trailer stable. On

soft ground you may want to use timber sole boards under the stabiliser feet. Getting the trailer level from left to right

should be done with drive on stepped

Site Power

The Projecta charger in your caravan is connected via the 15A exterior socket. To use site power, you will require a

15A power lead connected to a 15A outlet (figure 1). In the event a 15A outlet is unavailable you will need a

conversion box that will step up from 10A to 15A with a safety switch. Never leave power leads coiled when in use, lay

the lead out back and forward in a manner that won’t be a trip hazard or risk damage to the lead.

14

Page 16

1300 4X4 4X4

Kitchen

Before sliding out kitchen, raise the pad bolt and turn to lock in the up position (Fig: 2)

Push down blue latch on the slide mechanism and pull kitchen out. (Fig: 2a)

When kitchen is extended fit the support leg into its receiver (Fig: 3)

Extend support leg and secure locking screw (Fig: 3a)

Fig: 3 Fig: 3a

Preparing for Bad Weather

During inclement weather the following should be done:

• Close all roof vents and hatches to prevent water entering.

• Protect the awning from high winds by retracting or securing with guy ropes and pegs.

• Ensure your caravan is not parked in ground that will become boggy and prevent exiting the camp area

• Close all external doors and hatches to prevent water ingress and wind damage

15

Page 17

1300 4X4 4X4

Packing Down Your Caravan

When packing down your caravan ensure the following:

• All gas and electric appliances are turned off

• Gas is turned off at the gas bottle

• All loose items are secured and unable to move and damage themselves or the caravan

• All cabinet doors are secured and locked along with all drawers closed

• Site power lead is removed and stowed

• Doorstep is raised and secured

• All roof hatches lowered and secure

• All windows closed and locked

• Main door is closed and locked

• All dust covers in place and secure

Storage & Care

Long Term Storage

To maximise the life of your caravan you should consider additional protection from the elements. UV light and

moisture can have an adverse effect on materials when left unprotected outside. This section outlines some of the

things you can do as an owner to protect your investment.

Interior

Moisture in the smallest amounts can cause mould. High humidity and cooling temperatures can create condensation,

additionally condensation can form under mattresses due to temperature differences between warm bodies on top and

the bed base being cold from outside temperatures. As a precaution you can do the following:

• Check under mattress for moisture before packing up. If moisture is found allow to thoroughly dry before

closing your camper.

• Store 1 or 2 moisture absorbing packs/dehumidifier packs in the caravan to draw away any residual water

vapour.

• If packing up with damp or humid conditions, open and dry out the caravan at the first opportunity when

returning home. Dry all canvas thoroughly and follow point 2.

Exterior

Ensure all seals on the caravan have proper compression at 30-50%, are free of dirt and have nothing protruding past

the seals. UV light and the elements can over time cause seals and fittings to perish and become brittle. The use of a

caravan cover or tarpaulin will extend the life of components and keep your investment looking better for longer.

Batteries

When storing your caravan, ensure all power is turned off to ensure batteries aren’t drained. Batteries should be

maintenance charged at least monthly when stored. Allowing batteries to drain below 12.05 volts may permanently

damage them.

16

Page 18

1300 4X4 4X4

Securing Your Caravan

When parked and unhitched you should always use suitable wheel chocks to ensure the trailer can’t move in the event

of a handbrake failure. For security a wheel clamp or and hitch lock are highly recommended.

Torque Settings

Wheel Nuts

Wheel nuts should be tightened to correct torque using a torque wrench. Never trust a “rattle gun” as these may over

or under tighten. A quality torque wrench will ensure nuts are tightened correctly. It’s important to remember to check

your wheel nuts at 50km, 500km and 1000km and periodically thereafter. The correct torque setting of 125Nm for

12mm studs, 140nm for 14mm studs and alloy wheels and 200nm for 14mm studs with steel rims. Refer to the plate

on your drawbar.

17

Page 19

1300 4X4 4X4

Hitch

The high tensile bolts securing your hitch should be tightened to 76Nm. These should be checked at 5000km intervals

or 2500km in harsh off-road conditions.

Trailing Arm Pivot Bolts

The pivot bolts are a high tensile steel. The service interval for these bolts is 5000km under normal use and 2500km

for harsh off-road conditions. During travel they should be inspected daily to ensure they have not rotated or become

damaged. Correct torque is 190Nm

Brakes and Handbrake - Electric

Features

Your trailer is fitted with electric brakes that require a brake controller that can be operated from the driver’s seat.

1. Manual adjusted to provide the correct braking capability for varying road, off-road and load conditions.

2. They can be modulated to provide variable braking force, thus easing the brake load on the towing vehicle.

3. There is very little lag time between the moment the tow vehicle’s brakes are actuated and the moment the

trailer brakes are actuated.

4. They can provide some braking independent of the tow vehicle in the event of an emergency.

Operation

When electrical current is fed into the system by the controller, it activates the electromagnets in the brakes. These

electromagnets are energized and are attracted to the rotating surface of the drums which moves the actuating levers

in the direction that the drums are turning thus applying pressure from the brake linings to the drum surface

Trailer Plug Wiring

The following diagrams outline the correct wiring for 7 pin plug

18

Page 20

1300 4X4 4X4

Breakaway Switch

By law, all trailers with an ATM of 2000kg or greater must have a “Breakaway System” to halt the trailer in the event it

becomes detached from the tow vehicle whilst traveling. Your caravan is fitted with this system with the switch

mounted on the drawbar with a steel wire lanyard to connect to your tow vehicle. In the event that the caravan

becomes detached, the lanyard will pull the pin from the breakaway switch and the onboard batteries will activate the

brake system. The lanyard must be attached to a solid part of the vehicle. It is a mandatory requirement that power be

supplied by the tow vehicle to the breakaway power source while towing. This is done via the 50amp Anderson Plug

on the drawbar. Consult a qualified auto electrician to ensure this is fitted to your tow vehicle.

In NSW there is an additional requirement that the breakaway power source be monitored from the driver position with

a minimum of a “visual alarm” for low battery voltage. Consult a qualified auto electrician to ensure this is fitted to your

vehicle.

Breakaway Switch Anderson Plug

CAUTION:

• DO NOT CONNECT THE BREAKAWAY LANYARD TO THE SAME POINT AS THE SAFETY CHAIN

SHACKLES.

• DO NOT USE THE BREAKAWAY AS AN ALTERNATIVE TO THE HANDBRAKE AND DO NOT REMOVE

THE PIN AS AN ALTERNATIVE SECURITY MEASURE. REMOVING THE PIN WILL RAPIDLY DISCHARGE

THE BATTERIES.

• IT IS A MANDATORY REQUIREMENT THAT THE BREAKAWAY BATTERY SOURCE BE CHARGED

DURING TOWING.

• NSW REQUIRES A BATTERY MONITOR VIEWABLE FROM THE DRIVERS POSITION WITH A MINIMUM

OF A VISUAL ALARM FOR LOW BATTERY VOLTAGE

Hand Brake

Parking brakes are mechanically operated by cable means. The cable attachment occurs outside of the brake backing

plate. Cable force applied to the parking lever creates a torque through the pivot pin and cam assembly. Torque

transferred to the parking cam results in a spreading force between the primary and secondary shoes. The shoes in

turn, move towards the drum until contact is made. Friction generated between the drum and lining contact surface

results in parking brake capability.

Use the cable adjuster to give sufficient tension to be able to set the handbrake lever on the last two notches of the

coupling or handbrake is 1/3 raised when unladen. This needs to be checked again when the trailer or caravan is

loaded. If the cable is too tight, the brakes will be applied as the axle moves backward under spring deflection.

19

Page 21

1300 4X4 4X4

Adjuster

To adjust the handbrake cable tension release locknuts A, B and C in the diagram Handbrake Adjuster 1 below. To

tighten the handbrake cable turn the adjuster wheel D in a clockwise direction. Once adjusted retighten lock nuts and

test. Always ensure that wheels turn freely when handbrake is off. Overtightened cables can cause brakes to drag and

damage the brake linings.

Correct Use of Your Electric Brakes

Your trailer brakes are designed to work in synchronisation with your tow vehicle brakes. Never use your tow vehicle

or trailer brakes alone to stop the combined load. Your trailer and tow vehicle will seldom have the correct amperage

flow to the brake magnets to give you comfortable, safe braking unless you make proper brake system adjustments.

Changing trailer load and driving conditions, as well as uneven alternator and battery output, can mean unstable

current flow to your brake magnets. It is therefore imperative that you maintain and adjust your brakes as set forth in

the controller manual, use a properly modulated brake controller and perform the synchronisation/adjustment

procedure recommended by the brake controller supplier.

Important Safety Notice

Proven and in some cases approved service methods and correct repair procedures are

essential for the safe, reliable operation of the brakes, suspension and axles as well as the

personal safety of the individual doing the work. This manual intends to provide general

directions for performing service and repair work with tested, effective techniques. By

following these guidelines, it will help assure

reliability. The numerous variations in procedures, techniques, tools and parts for servicing

axles, as well as in the skill of the individual doing the work will determine outcomes. This

manual cannot possibly anticipate all such variations nor provide advice or cautions as to each. Accordingly, anyone

who departs from the instructions provided in this manual must first establish that they neither compromise their

personal safety nor the vehicle integrity by their choice of methods, tool’s or parts.

*If at all in doubt please refer all repairs and maintenance to a suitably qualified or experienced mechanical repairer.

*Market Direct Campers accepts no liability for personal injury, loss or damage resulting from incorrect applications,

methods and failure to perform maintenance safely and correctly.

20

Page 22

1300 4X4 4X4

Brake Adjustment

Brakes should be adjusted (1) after the first 300 km’s of operation when the brake shoes and drums have “seated,” (2)

at 5000 km’s intervals, (3) or as use and performance requires. The brakes should be adjusted in the following

manner:

Never crawl under your trailer unless it is resting on properly placed jack stands. Do not

place supports on any part of the suspension system and use the designated jack point or

under the spring base plate to jack trailer.

Brake Cleaning and Inspection

Your trailer brakes must be inspected and serviced at 5000km or more often as required by use and performance.

Magnets and shoes must be changed when they become worn or scored to avoid inefficient vehicle braking.

Brake Lubrication

This should only be done by qualified persons.

Caution

Do not get grease or oil on the brake linings, drums or magnets.

Magnets

Your electric brakes are equipped with high quality electromagnets that are designed to provide the proper input force

and friction characteristics. Your magnets should be inspected and replaced if worn unevenly or abnormally.

Even if wear is normal as indicated by your straightedge, the magnets should be replaced if any part of the magnet coil

has become visible through the friction material facing of the magnet. It is also recommended that the drum armature

surface be refaced when replacing magnets.

Magnets should also be replaced in pairs - both sides of the axle. Always use genuine MDC OEM parts.

21

Page 23

1300 4X4 4X4

Shoes and Linings

A simple visual inspection of your brake linings will tell if they are useable.

Replacement is necessary if the lining is worn (to within 1.5mm or less), contaminated with grease or oil or abnormally

scored or gouged. It is important to replace both shoes on each brake and both brakes of the same axle. This is

necessary to retain the “balance” of your brakes. Be sure to replace your shoes only with genuine MDC parts available

from our outlets.

Corrosion Prevention

It’s important to take steps to prevent corrosion of parts on your trailer to extend the service life. Many fittings are high

tensile and therefor zinc plated. Fittings such as this can benefit from additional protection. Some helpful products to

prevent corrosion are “Lanotec”, “WD40”, “Inox” and similar products. These can be spray applied and do a very good

job of protecting metal surfaces, particularly in corrosive and aggressive environments near the ocean and inland

waterways.

Often, we take our campers and caravans to salt water environments. Driving through salt water is never

recommended as the residual chloride ions accelerate corrosion greatly. If you are camping near or driving through

these kinds of environments, we highly recommend that your trailer be thoroughly cleaned after use. Flushing the

chassis and washing and rinsing your trailer is important.

Wheels and Tyres

Highway

Your caravan is fitted with 16” wheels and 265/75 R16 Goodride Tyres. The tyres are a “Light Truck” typre with a mud

terrain tread and a maximum load rating on single axle of 1550kg at 80psi.

Recommended highway pressure at tare weight of the caravan is 50-56psi

Recommended highway pressure at ATM of 3000kg is 74-77psi

Off Road

Off road driving requires lower tyre pressures and lower speeds. When driving on rough and corrugated road, a

reduction of speed and controlled deflation of tyres is required to protect the caravan and its suspension from damage.

In extreme circumstances tyre pressures may be reduced significantly. When lowering from highway pressure, a rule

of thumb is to reduce your speed by the same percentage as the lowering of tyre pressure.

Because off road conditions can vary greatly, you must lower your pressures and reduce speed until vibration and

shock through the suspension is at a moderate level to suit the conditions you are experiencing, and the loaded weight

of your caravan.

WARNING: When returning to the highway or when increasing speed, you must reinflate the tyres to correct highway

pressures. Failure to reinflate can cause severe handling problems resulting in injury or death.

22

Page 24

1300 4X4 4X4

Electrical Systems

Chargers & Inverters

For detailed information on the appliances installed in your camper please refer to the manuals included in your

camper handover.

Caution

Electrical devices can be dangerous. Under no circumstances should repairs and

modifications be attempted by unqualified or untrained persons. MDC accepts no liability for

any personal injury, damages or loss as a result of unqualified or untrained persons repairing

or altering the electrical systems on this product. If in doubt call your local MDC outlet or

phone: 1300 831407

Battery Care

Your camper is fitted with 100Ah AGM Batteries. Storage type batteries require periodical maintenance to perform at

their peak and extend their service life. The following is an outline on how to gain the best performance and lifecycle

from the battery fitted in your camper:

• Always use a quality charger that caters to the voltage requirements of an AGM battery. Absorption charging

is from 14.6v to 14.8v, float charging is from 13.2v to 13.8v.

• Never leave your battery stored at low volts. Before storing your camper ensure that battery/s is fully charged

and all power is disconnected/switched off.

• When possible leave the battery connected to a smart charger that will cycle and maintain the battery during

storage. If this isn’t possible check and charge at regular intervals to prevent excessive discharge.

• Never use unregulated solar power direct to your batteries.

• When in use try to keep your battery at or as close to maximum capacity as possible.

• Allowing your battery voltage to drop below 12.5v can permanently damage its performance and reduce its

service life.

23

Page 25

1300 4X4 4X4

12 Volt Wiring Diagram

24

Page 26

1300 4X4 4X4

Control Panel

1. 12v outlets

2. Toilet & Fridge

3. Water pump and tank level gauge

4. Hot water

5. Spare

6. Amp Usage

7. Battery Voltage

*Volt Meter will indicate battery voltage when idle or charge voltage when charging

* Amp meter will show current being used not charge current

Gas & Water Systems

Hot Water System

WARNING: The flue outlet on your gas hot water system must be uncovered prior to use. Open the protective dust

cabinet and remove the white cover before use.

Do not operate whilst towing.

Do not operate in enclosed spaces

Your caravan is fitted with a Truma boiler hot water system. Please read the manual provided with this system at the

time of purchase. For further information go to

ultrarapid-hws.html

To watch the video tutorial on turning on the hot water system, scan the code with your smartphone.

https://www.truma.com/au/en/products/truma-hot-water-system/truma-

Water Pumps

The pump when switched on is activated by the release of pressure at the tap and will pump water continuously until

the tap is turned off and pressure restored. Should the pumps activate while the taps is turned off this could indicate a

leak and require investigation and rectification.

25

Page 27

1300 4X4 4X4

Connecting the Gas

WARNING: Your caravan is fitted with a gas detector. Check operation of the gas detector each time you use

your caravan.

Your caravan is fitted with plumbed gas with the regulator and gas bottle placement at the front of the trailer. Always

ensure gas bottles are serviceable and within the 10-year service life. This information is stamped on the bottle base.

Once you connect your gas bottle you can connect the kitchen gas hose to the bayonet connection provided. (Fig:5)

Once the bayonet is secure, ensure all controls on the stove are in the “Off” position and then turn on the gas bottle

valve. If your kitchen stove is fitted with electric ignition, plug the connector into the 12v socket beside the kitchen and

turn on the required burner whilst pressing the ignition button. When the burner ignites hold the button down for 5

seconds then release. NOTE: It will take up to a minute or so for the gas to purge the line and flow through the

burners.

Your gas monitor will be located at floor level.

Protecting from Mould

Mould is very difficult to clean once a porous surface

is affected. There are several ways you can prevent

the occurrence of mould on your caravan.

Never leave your camper packed away wet. If you

must leave a campsite with wet canvas or a damn

interior, be sure to open and dry out your tent

thoroughly at the very first opportunity when you get

home. Mould can develop in just a couple of days so

don’t take the risk.

When packing up dry, it is important to check under the mattress that there is no build-up of condensation overnight.

Body heat on a mattress can create enough temperature difference with the exterior for moisture to form under it. If left

unchecked this can cause mould when your caravan is stored.

26

Page 28

1300 4X4 4X4

Pre Hook Up

Water Tanks full & locking cap secure

All latches and door locks secure

Bearings checked and serviced at last service

All cables and plugs are in serviceable condition

Hitch creased and checked

Tyres in serviceable condition and correct pressure

Wheel nuts tight and torqued to correct tension

Bearing caps secure

All external fittings secure

Stabiliser legs working & secure in travel position

Gas bottles and jerry cans secured

Stabiliser leg handle in trailer

Chains and shackles in serviceable condition

Check gas detector operation

Hooked Up To Vehicle

Hitch secured to receiver all pins and locks engaged

Trailer lights plugged in

Anderson plug connected

All cables clear of possible damage

Safety chains and shackles connected to car

Chains are crossed and at correct length

All lights working

Trailer brakes engaging when brakes applied

Trailer is sitting at correct level

Jockey wheel is raised and locked

Do a walk around and check visually

Pre-Trip Checklist

Working from a checklist will help avoid forgetting important tasks particularly nin regard to safety. Individual camper

set ups may differ depending on tow vehicle and any modifications made by the owner. The table below is for

guidance only.

Useful Accessories

Levelling Blocks

These are excellent for levelling your trailer on set up. Stabiliser legs are not meant for correcting the trailer angle, they

are there to keep it stable when people are in it. Using levelling blocks will extend the service life of the stabiliser legs

and make set up much safer and faster. See below images.

27

Page 29

1300 4X4 4X4

Wheel Chocks

Wheel chocks are an important safety device when leaving your trailer parked on even the slightest incline. On level

ground it is recommended to chock both sides of the wheel. On a hill you should chock the wheels on the downhill side

ensuring the chocks

Covers

Hard floor campers and caravans will benefit greatly from a storage cover. Perishable fittings such as rubber seals and

plastic will be protected from UV radiation. Paint and gelcoat finishes will oxidise less and this will extend the service

life of these finishes.

Stone Protection

There are proprietary devices available that assist in protecting your trailer from stones thrown up by the tow vehicle.

Rock Tamer and Stone Stomper are two of the most commonly used.

28

Page 30

1300 4X4 4X4

Problem

Possible Cause

Remedy

No power from control panel

Check circuit breaker

Flat Battery

Charge battery

Replace pump, Contact dealer for

Check connections with multimeter

Turn on tap and hold finger over

Water tank is empty

Fill water tank

Check hoses ensuring none are

Damaged / worn pump diaphragm

Repair or replace pump

Problem

Possible Cause

Remedy

Gas bottle empty

Fill gas bottle

Gas bottle not turned on

Turn on valve on gas bottle

Check bayonet is securely

Check regulator is not blocked with

Check hose is not twisted and

• Remember that first use after connecting gas will take a little while for the gas to purge the line to the

Trouble Shoong

Water

Pump not working (no noise)

Pump working but no water flow

Gas

Faulty pressure switch

Bad electrical connection

Airlock in water lines

Kinked hose

replacement

or test light

nozzle for 5 seconds and release.

Repeat several times. If this fails, fill

water tank and use mains pressure

to pressurize tank

fouled

Cooker not igniting

cooktop. Hold the control knob down for up to 4 minutes

Gas hose on cooker not connected

Regulator blocked

Kinked hose

connected into receiver

dirt, wasps nests etc

kinked

29

Page 31

1300 4X4 4X4

Electrical

30

Page 32

1300 4X4 4X4

Problem

Possible Cause

Remedy

Open Circuits

Find and correct

Severe under adjustments

Adjust brakes

Faulty controller

Test and correct/replace

Short circuits

Find and correct

Great or oil on linings or magnets

Clean or replace

Corroded connection

Clean or replace connectors

Worn lining or magnets

Replace

Scored or grooved brake drums

Machine or replace

Poor Synchronisation

Correct Controller setting

Poor Brake adjustment

Adjust Brakes

Glazed brake Linings

Re-burnish or replace linings

Correct loading. Check at

Poor Synchronising with controller

Adjust controller

Poor Adjustment

Adjust brakes as per instructions

Faulty controller

Test and rectify or replace

Loose, bent or broken components

Inspect and replace components

Out-of-round brake drums

Machine or replace

Insufficient wheel load (dual Axle)

Correct trailer level to even load

Faulty controller

Test and Correct

Broken Wires

Repair or replace

Loose connections

Find and repair

Faulty ground

Find and repair

Brakes

No Brakes

Weak Brakes

Brakes Locking

Intermittent brakes

Overloaded trailer

weighbridge

31

Page 33

1300 4X4 4X4

Handy Tips

Driving Off Road

Towing your caravan off road adds many dimensions to the driver’s responsibilities and factors to be considered.

When travelling remote always carry enough spare parts and supplies to cater for a “worst case scenario.”

Always perform preventative maintenance and daily checks. Minimum trailer spares would consist of:

• Wheel Bearings

• Seals

• Wheel studs and nuts

These are available from Market Direct Campers

Wildlife

Australian outback roads are notorious for wandering stock and native wildlife which can be a serious danger to

motorists. Due care must always be taken, and the possibility of an animal strike considered in regard to speed and

time of day you are driving. Most animals in the outback are more active at night which greatly increases the likelihood

of an animal strike between dusk and dawn. Towing a camper or caravan increases braking distance and has inherent

risk associated with aggressive and defensive manoeuvring to avoid a collision.

Corrugations & rough road

Corrugations are arguably the most taxing and damaging road conditions to vehicles. Constant vibration can loosen

vehicle components and as a stress dynamic to vehicles and drivers well in excess of normal road driving. In these

conditions take regular breaks to reduce driver fatigue and fatigue to vehicles. Shock absorbers can become

extremely hot on corrugated roads which can cause damage to seals resulting in shock absorber fade (reduction in

damping effect) and in extreme cases failure of the seal completely. On rough and corrugated roads, it’s important to

adjust tyre pressures on your car and trailer to soften the effect and extend the contact patch of the tyre on the road.

Bulldust

This phenomenon is common on outback roads. Fine dust can settle in large holes obscuring them from unsuspecting

drivers. It is important to reduce speed in these conditions and drive carefully to avoid the possibility of damage or an

accident.

Sand

When driving on sand it is important to lower tyre pressures on both the vehicle and trailer. By lowering the pressure

you will effectively create a larger footprint for the tyre which will reduce how far it sinks in sand. Sand shape and

compaction will vary around the country so necessary reduction in tyre pressure will vary. Always keep in mind the

lower the pressure the lower the speed you should travel. When lowering pressures to 20psi or less you also increase

the chance of rolling the bead of the tyre off the rim so sharp turns should be avoided. When driving these conditions,

it is strongly advised you carry a tyre pressure gauge/deflator and a portable compressor to reinflate when back on the

highway.

Causeways

Outback roads often have causeways to control water runoff and prevent erosion of the road. When travelling at speed

these causeways can be a danger to motorists and vehicles so due care should be taken to reduce speed when

approaching them. In very remote areas these often won’t have signposts so special care should be taken in these

areas.

Creek and River Crossings

These crossings can be extremely dangerous even in low water levels and should never be attempted in times of even

mild flooding. Towing a camper or caravan greatly elevates the risk in this situation and should never be attempted

unless you are completely assured it is safe to do so. If there is any doubt about access in flood prone areas, you

should contact the local authorities to find out conditions and dangers before you proceed.

32

Page 34

1300 4X4 4X4

Protecting the environment

Remote areas and National Parks are sensitive areas and all precautions should be taken not to damage tracks,

interfere with flora and fauna and not to contaminate the area. In sensitive areas it is advisable to use grey water tanks

and contained toilets. If your camper or caravan isn’t fitted with such, both toilets and grey water tanks are available as

portable self-contained units. Always store food, food scraps and rubbish in secure containers, native animals can be

quite resourceful in scavenging for scraps. Dingos have been known to open locked eskies to get to food so don’t

chance it, always secure these items when travelling.

Trip Planning

* When planning remote trips always consider where you will resupply for fuel, food and water. Some remote fuel

stations may run out of fuel during busy periods or times when large fuel trucks are unable to access the area due to

road conditions and closures or simply close outside of the season. Always check conditions and availability of fuel

before setting out to remote areas.

Shire Councils

There are many resources available for planning your trip away. Every state has a tourism website as so regional

councils which will give you extensive information on camping sites, things to do and see, events happening in the

area and contact information for booking sites or activities.

National Parks

Each state’s national parks organisation have a website to assist in finding campsites and provide specific information

about each parks unique qualities. As a planning resource these are extremely good. All contact information will be

available.

Wikicamps

This smartphone app is an excellent resource for finding all kinds of camping across Australia. If you are looking for

free camping you won’t find a better resource. There is an app add on that even assists in finding fuel stops with user

updates on fuel prices.

Facebook

These days there are numerous Facebook groups dedicated to travelling with campers and caravans and also groups

dedicated to travel in specific areas. The area specific groups have many locals as members and are a great way to

find out local track closures, conditions and research the area in general.

33

Page 35

1300 4X4 4X4

Warranty Statement

The following information relates to warranties offered by MDC. Please read all the information carefully, and should

you have any questions relating to any aspect of this section, then please contact MDC. By purchasing an item from

MDC, you hereby agree to all terms and conditions of warranty as set out herein.

Validity of Claims

• Warranties are only valid to the original purchaser of the item in question and are valid from the original date

of purchase only.

• Warranties apply only to items sold as "new" and do not extend to any items sold via auction, or deemed to be

"factory seconds", "ex-demonstration" or "damaged" unless specifically stated otherwise by MDC in writing.

(Please see further on this page for more information).

• Warranties are not transferable under any circumstances. Similarly, if an item is sold to a third party by the

original purchaser, then all warranties become null and void, and the original purchaser shall make no claims

or be eligible for any claims on behalf of the new owner.

• Warranties do not apply to products purchased from MDC and then used in hire schemes or as rentals.

• MDC does not cover damage due to unauthorised modifications, misuse, abuse, incorrect assembly, improper

and irregular maintenance, or accident or collision.

• Any work performed under an authorised warranty claim approved by MDC must be performed by MDC, or an

authorised representative of MDC and only with the express written permission of MDC.

• Any affiliates, representatives, associates, agents, suppliers, resellers or similar of MDC shall have no

authority to authorise or deny warranty claims on behalf of MDC.

MDC shall not be liable, (in part or whole) for any warranties, either express or implied, made by agents or resellers on

behalf of MDC without the knowledge or express written permission of MDC. Such unauthorised claims shall be the

responsibility of the agent or reseller only.

Caravans & Camper Trailers

Unless stated otherwise, caravans & trailers only are covered by a 12 month limited manufacturer’s warranty from the

original date of purchase.

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law.

You are entitled to a replacement or refund for a major failure and for compensation for any other reasonably

foreseeable loss or damage.

You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure

does not amount to a major failure.

Items not covered under warranty include:

• Rust

• Wheels and Tyres

• Paint

• Travel Covers and Straps

• General consumables (eg bearings, light bulbs etc)

• Zips and mesh or screens are not covered.

In addition to MDC warranty, the consumer may also be covered by other rights and remedies of Consumer Law in

relation to the goods and or services to which this warranty relates

Tents

Tents are guaranteed to be in new merchantable condition at the time of purchase. A limited manufacturer’s warranty

period of 12 Months applies to MDC and Wax Converters canvas components, poles and fittings. General wear and

tear excepted.

34

Page 36

1300 4X4 4X4

Factory Seconds, Ex-Demonstration and Damaged Goods

From time to time, MDC may offer for sale items deemed to be "factory seconds", "ex-demonstration", or "damaged".

Any items sold as "factory seconds", "ex-demonstration" or "damaged" items are sold on an "as is" basis.

There are no warranties, refunds, credits, exchanges or similar associated with such items. In the sale of such items,

Market Direct Campers will attempt to provide all relevant information regarding the item, including faults, defects, or

similar, however, there may be instances where minor defects or imperfections have been overlooked. This is

PURELY UNINTENTIONAL and in no way alters the nature of the sale.

Due to the nature of such items, i.e being "ex-demonstration", "factory seconds" or "damaged", it is reasonable to

expect that some imperfections or flaws may exist even where it is not initially apparent. By purchasing such an item,

you agree to this statement in full and accept that there are no warranties implied or expressed.

Goods Bought at Auction

From time to time, MDC, may, at its discretion, offer items for auction, either independently or via a third party. Whilst

every effort will be made to provide all relevant information regarding the item on auction, as per Australian law, any

and all goods bought at auction subsequently do not carry any statutory warranty. Unless specifically stated in writing,

and goods sold at auction by, or on behalf of MDC shall carry no warranty.

Lodging a Claim

All warranty claims MUST BE LODGED through our website using our online Warranty Claim Form.

Contact

If you have any further questions relating to warranties, or are unsure about any aspect of this section, then please

contact us.

Phone: 1300 865 397

Maintenance

Maintenance is essential to keep your caravan in a safe and usable condition. Caravans are no different to any other

motor vehicle and require servicing at regular intervals which may vary according to use and the environment in which

it is used. The service schedule outlines the service intervals for safe travelling and your owner obligations under our

warranty policy. Servicing should always be carried out by a competent person with relevant experience.

WARNING:

• Never work beneath the caravan while suspended on a jack. Always use “Jack Stands” with an adequate SWL.

• Always use dedicated jacking points

• 240volt appliances and wiring must only be serviced and repaired by a qualified tradesperson.

• Gas plumbing must only be serviced and repaired by a qualified gas fitter

35

Page 37

1300 4X4 4X4

Maintenance Schedule

36

Page 38

1300 4X4 4X4

Inspect condition and torque to 125Nm (12mm studs)

(140Nm 14mm studs alloy rims) (200Nm 14mm studs steel rims)

Inspect condition and torque to 125Nm (12mm studs)

(140Nm 14mm studs alloy rims), (200Nm 14mm studs steel rims)

500KM FIRST SERVICE

Hitch Check hitch bolts to 76Nm. Lubricate with high temp bearing grease

Handbrake Inspect and adjust handbrake

Brakes Inspect and adjust brakes

Wheel nuts

Tyres Inspect for abnormal wear, damage and pressure

General fixings Ensure no loose fittings

Date: Service Person:

Dealer Stamp:

6 MONTHS / 5,000KM SERVICE

Hitch Check hitch bolts to 76Nm

Handbrake Check cable and adjust if necessary

CHECKED

CHECKED

Hand winch Check brake function and webbing

Suspension Lubricate and check bushes for excess movement. Torque bolts to 190Nm

Brakes Inspect and adjust. Check lining thickness and drum wear

Wheel bearings Remove, clean and re-lubricate. Inspect for wear and replace if necessary

Wheel Nuts

Tyres Inspect for abnormal wear, damage and pressure

Lights Check all lights are functioning

Battery Check terminals and voltage at full charge

Seals Check condition and correct latch/lock adjustment for correct 30-50% compression

General fixings Check all structural fixing are secure.

Date: Service Person:

Dealer Stamp:

37

Page 39

1300 4X4 4X4

Replace bearings, seals and lubricate. Check stub axle condition and wear.

Replace split pin.

Inspect condition and torque to 125Nm (12mm studs)

(140Nm 14mm studs alloy rims) (200Nm 14mm studs steel rims)

Replace bearings, seals and lubricate. Check stub axle condition and wear.

Replace split pin.

Inspect condition and torque to 125Nm (12mm studs)

(140Nm 14mm studs alloy rims) (200Nm 14mm studs steel rims)

12 MONTHS / 10,000KM SERVICE

Hitch Inspect for damage and lubricate. Check bolt Torque to 76Nm

Jockey Wheel Inspect for condition and operation

Hand winch Check brake function and webbing

Suspension Lubricate and check bushes for excess movement. Torque bolts to 190Nm

Brakes Inspect and adjust. Check lining thickness and drum wear

Wheel bearings

Wheel Nuts

Tyres Inspect for abnormal wear, damage and pressure

Lights Check all lights are functioning

Battery Check terminals and voltage at full charge

Seals Check condition and correct latch/lock adjustment for correct 30-50% compression

General fixings Check all structural fixing are secure.

Date: Service Person:

CHECKED

Dealer Stamp:

18 MONTHS / 15,000KM SERVICE

Hitch Inspect for damage and lubricate. Check bolt Torque to 76Nm

Jockey Wheel Inspect for condition and operation

Hand winch Check brake function and webbing

Suspension Lubricate and check bushes for excess movement. Torque bolts to 190Nm

Brakes Inspect and adjust. Check lining thickness and drum wear

Wheel bearings

Wheel Nuts

Tyres Inspect for abnormal wear, damage and pressure

Lights Check all lights are functioning

Battery Check terminals and voltage at full charge

Seals Check condition and correct latch/lock adjustment for correct 30-50% compression

CHECKED

General fixings Check all structural fixing are secure.

Date: Service Person:

Dealer Stamp:

38

Page 40

1300 4X4 4X4

Replace bearings, seals and lubricate. Check stub axle condition and wear.

Replace split pin.

Inspect condition and torque to 125Nm (12mm studs)

(140Nm 14mm studs alloy rims) (200Nm 14mm studs steel rims)

Inspect condition and torque to 125Nm (12mm studs)

(140Nm 14mm studs alloy rims) (200Nm 14mm studs steel rims)

24 MONTHS / 20,000KM SERVICE

Hitch Inspect for damage and lubricate. Check bolt Torque to 76Nm

Jockey Wheel Inspect for condition and operation

Hand winch Check brake function and webbing

Suspension Lubricate and check bushes for excess movement. Torque bolts to 190Nm

Brakes Inspect and adjust. Check lining thickness and drum wear

Wheel bearings

Wheel Nuts

Tyres Inspect for abnormal wear, damage and pressure

Lights Check all lights are functioning

Battery Check terminals and voltage at full charge

Seals Check condition and correct latch/lock adjustment for correct 30-50% compression

General fixings Check all structural fixing are secure.

Date: Service Person:

CHECKED

Dealer Stamp:

30 MONTHS / 25,000KM SERVICE

Hitch Inspect for damage and lubricate. Check bolt Torque to 76Nm

Hand brake Check cable and adjust if necessary

Hand winch Check brake function and webbing

Suspension Lubricate and check bushes for excess movement. Torque bolts to 190Nm

Brakes Inspect and adjust. Check lining thickness and drum wear

Wheel bearings Remove, clean and re-lubricate. Inspect for wear and replace if necessary

Wheel Nuts

Tyres Inspect for abnormal wear, damage and pressure

Gas System Leak, test, check stove operation and hose/coupling condition

Battery Check terminals and voltage at full charge

Seals Check condition and correct latch/lock adjustment for correct 30-50% compression

CHECKED

General fixings Check all structural fixing are secure.

Date: Service Person:

Dealer Stamp:

39

Page 41

1300 4X4 4X4

Replace bearings, seals and lubricate. Check stub axle condition and wear.

Replace split pin.

Inspect condition and torque to 125Nm (12mm studs)

(140Nm 14mm studs alloy rims) (200Nm 14mm studs steel rims)

Inspect condition and torque to 125Nm (12mm studs)

(140Nm 14mm studs alloy rims) (200Nm 14mm studs steel rims)

36 MONTHS / 30,000KM SERVICE

Hitch Inspect for damage and lubricate. Check bolt Torque to 76Nm

Jockey Wheel Inspect for condition and operation

Hand winch Check brake function and webbing

Suspension Lubricate and check bushes for excess movement. Torque bolts to 190Nm

Brakes Inspect and adjust. Check lining thickness and drum wear

Wheel bearings

Wheel Nuts

Tyres Inspect for abnormal wear, damage and pressure

Lights Check all lights are functioning

Battery Check terminals and voltage at full charge

Seals Check condition and correct latch/lock adjustment for correct 30-50% compression

General fixings Check all structural fixing are secure.

Date: Service Person:

CHECKED

Dealer Stamp:

42 MONTHS / 35,000KM SERVICE

Hitch Inspect for damage and lubricate. Check bolt Torque to 76Nm

Hand brake Check cable and adjust if necessary

Hand winch Check brake function and webbing

Suspension Lubricate and check bushes for excess movement. Torque bolts to 190Nm

Brakes Inspect and adjust. Check lining thickness and drum wear

Wheel bearings Remove, clean and re-lubricate. Inspect for wear and replace if necessary

Wheel Nuts

Tyres Inspect for abnormal wear, damage and pressure

Gas System Leak, test, check stove operation and hose/coupling condition

Battery Check terminals and voltage at full charge

Seals Check condition and correct latch/lock adjustment for correct 30-50% compression

CHECKED

General fixings Check all structural fixing are secure.

Date: Service Person:

Dealer Stamp:

40

Page 42

1300 4X4 4X4

Replace bearings, seals and lubricate. Check stub axle condition and wear.

Replace split pin.

Inspect condition and torque to 125Nm (12mm studs)

(140Nm 14mm studs alloy rims) (200Nm 14mm studs steel rims)

Inspect condition and torque to 125Nm (12mm studs)

(140Nm 14mm studs alloy rims) (200Nm 14mm studs steel rims)

48 MONTHS / 40,000KM SERVICE

Hitch Inspect for damage and lubricate. Check bolt Torque to 76Nm

Jockey Wheel Inspect for condition and operation

Hand winch Check brake function and webbing

Suspension Lubricate and check bushes for excess movement. Torque bolts to 190Nm

Brakes Inspect and adjust. Check lining thickness and drum wear

Wheel bearings

Wheel Nuts

Tyres Inspect for abnormal wear, damage and pressure

Lights Check all lights are functioning

Battery Check terminals and voltage at full charge

Seals Check condition and correct latch/lock adjustment for correct 30-50% compression

General fixings Check all structural fixing are secure.

Date: Service Person:

CHECKED

Dealer Stamp:

54 MONTHS / 45,000KM SERVICE

Hitch Inspect for damage and lubricate. Check bolt Torque to 76Nm

Hand brake Check cable and adjust if necessary

Hand winch Check brake function and webbing

Suspension Lubricate and check bushes for excess movement. Torque bolts to 190Nm

Brakes Inspect and adjust. Check lining thickness and drum wear

Wheel bearings Remove, clean and re-lubricate. Inspect for wear and replace if necessary

Wheel Nuts

Tyres Inspect for abnormal wear, damage and pressure

Gas System Leak, test, check stove operation and hose/coupling condition

Battery Check terminals and voltage at full charge

Seals Check condition and correct latch/lock adjustment for correct 30-50% compression

CHECKED

General fixings Check all structural fixing are secure.

Date: Service Person:

Dealer Stamp:

41

Page 43

1300 4X4 4X4

Replace bearings, seals and lubricate. Check stub axle condition and wear.

Replace split pin.

Inspect condition and torque to 125Nm (12mm studs)

(140Nm 14mm studs alloy rims) (200Nm 14mm studs steel rims)

Inspect condition and torque to 125Nm (12mm studs)

(140Nm 14mm studs alloy rims) (200Nm 14mm studs steel rims)

60 MONTHS / 50,000KM SERVICE

Hitch Inspect for damage and lubricate. Check bolt Torque to 76Nm

Jockey Wheel Inspect for condition and operation

Hand winch Check brake function and webbing

Suspension Lubricate and check bushes for excess movement. Torque bolts to 190Nm

Brakes Inspect and adjust. Check lining thickness and drum wear

Wheel bearings

Wheel Nuts

Tyres Inspect for abnormal wear, damage and pressure

Lights Check all lights are functioning

Battery Check terminals and voltage at full charge

Seals Check condition and correct latch/lock adjustment for correct 30-50% compression

General fixings Check all structural fixing are secure.

Date: Service Person:

CHECKED

Dealer Stamp:

66 MONTHS / 55,000KM SERVICE

Hitch Inspect for damage and lubricate. Check bolt Torque to 76Nm

Hand brake Check cable and adjust if necessary

Hand winch Check brake function and webbing

Suspension Lubricate and check bushes for excess movement. Torque bolts to 190Nm

Brakes Inspect and adjust. Check lining thickness and drum wear

Wheel bearings Remove, clean and re-lubricate. Inspect for wear and replace if necessary

Wheel Nuts

Tyres Inspect for abnormal wear, damage and pressure

Gas System Leak, test, check stove operation and hose/coupling condition

Battery Check terminals and voltage at full charge

Seals Check condition and correct latch/lock adjustment for correct 30-50% compression

CHECKED

General fixings Check all structural fixing are secure.

Date: Service Person:

Dealer Stamp:

42

Page 44

1300 4X4 4X4

MASTERCLASS Tutorials

43

Page 45

1300 4X4 4X4

Dometic

Thetford Australia

Cruisemaster

Statewide Bearings

Coopers Plains

Cairns

Virginia

Mackay

Rockhampton

Townsville

Beresfield

Smithfield

Wollongong

Kewdale

Albany

Email: albany@statewidebearings.com.au

Bibra Lake

Email: bibralake@statewidebearings.com.au

Belmont

Bunbury

Supplier Contact Details

https://www.dometic.com/en-au/au/contact-us

Address: 352B Bilsen Road, Geebung QLD 4034

Phone: (07) 3624 3800

Email: sales@cruisemaster.com.au

Address: 902 Beaudesert Rd Coopers Plains QLD 4108

Phone: (07) 3717 4444

Email: coopersplains@statewidebearings.com.au

Unit 2, 90 Pritchard Rd Virginia QLD 4014

Phone: (07) 3265 2666

Email:

67 Denham Street Rockhampton, QLD 4700

Ph: (07) 4927 2677

Email: rockhampton@statewidebearings.com.au

virginia@statewidebearings.com.au

Address: 41 Lara Way, Campbellfield VIC 3061

Phone: (03) 9358 0700

Email: infoaus@thetford.com.au

Unit3, 49 Cook St Cairns QLD 4870

Phone: (07) 4035 1800

Email: cairns@statewidebearings.com.au

59 Central Park Drive, Paget QLD 4740

Ph: (07) 4952 6660

Email: mackay@statewidebearings.com.au

Unit 2, 502 Woolcock Street, Garbutt QLD 4814

Ph: (07) 4758 8855

Email: townsville@statewidebearings.com.au

11 Yilen Close, Beresfield NSW 2322

Ph: (02) 4041 6444

Email: beresfield@statewidebearings.com.au

Unit 4, 222 Berkeley Road, Unanderra NSW 2526

Ph: (02) 4272 2377

Email: wollongong@statewidebearings.com.au

80 Chester Pass Road, Albany WA 6330

Ph: (08) 9842 2488

5 Hargreaves Street, Belmont WA 6104

Ph: (08) 9478 2444

Email: belmont@statewidebearings.com.au

Unit 4, 8 Cooper Street Smithfield, NSW 2164

Ph: 02 9616 0000

Email: smithfield@statewidebearings.com.au

67 Kewdale Road, Kewdale WA 6105

Ph: (08) 9352 2200

Email: kewdale@statewidebearings.com.au

Unit 6, 30 Salpietro Street, Bibra Lake WA 6163

Ph: (08) 9434 9555

42 McCombe Road, Davenport, WA 6230

Ph: (08) 9724 9100

Email: bunbury@statewidebearings.com.au

44

Page 46

1300 4X4 4X4

Collie

Geraldton

Karratha

Kalgoorlie

Wangara

Wingfield

Dandenong South

Somerton

Traralgon

Hobart

96 Forrest Street, Collie WA 6225

Ph: (08) 9734 1624

Email: collie@statewidebearings.com.au

51 Orkney Road, Karratha WA 6714

Ph: (08) 9144 2333

Email:

70 Distinction Road, Wangara, WA 6065

Ph: (08) 9303 6900

Email: wangara@statewidebearings.com.au

84 Greens Road, Dandenong South VIC 3175

Ph: (03) 8710 9777

Email: dandenong@statewidebearings.com.au

Unit 7, 4-14 Rocla Road, Traralgon VIC, 3844

Ph: (03) 5172 3000

Email: traralgon@statewidebearings.com.au

karratha@statewidebearings.com.au

Unit 1, 75 Flores Road, Geraldton WA 6530

Ph: (08) 9964 4655

Email: geraldton@statewidebearings.com.au

5 Darcy Lane, Kalgoorlie WA 6430

Ph: (08) 9091 4111

Email:

Grand Jct Rd & South Rd Wingfield SA 5013

Ph: (08) 8260 6299

Email: wingfield@statewidebearings.com.au

15-17 Somerton Road, Somerton VIC 3061

Ph: (03) 9308 0055

Email: somerton@statewidebearings.com.au

39 Sunderland Street, Derwent Park TAS 7009

Ph: (03) 6216 6999

Email: Hobart@statewidebearings.com.au

kalgoorlie@statewidebearings.com.au

45

Loading...

Loading...