Page 1

Congratulations on your purchase of an MDS engine. MDS engines are

noted for their excellent power, robust character, and efficient operation.

All MDS engines are designed to precise tolerances and should be handled

with care. The following information and recommendations are presented

to help you become more familiar with the assembly and operating

characteristics of your new MDS engine. For best results, please closely

follow the break-in procedures and adjustment suggestions. Also, be sure

to read the enclosed safety instructions and warranty information prior

to operation.

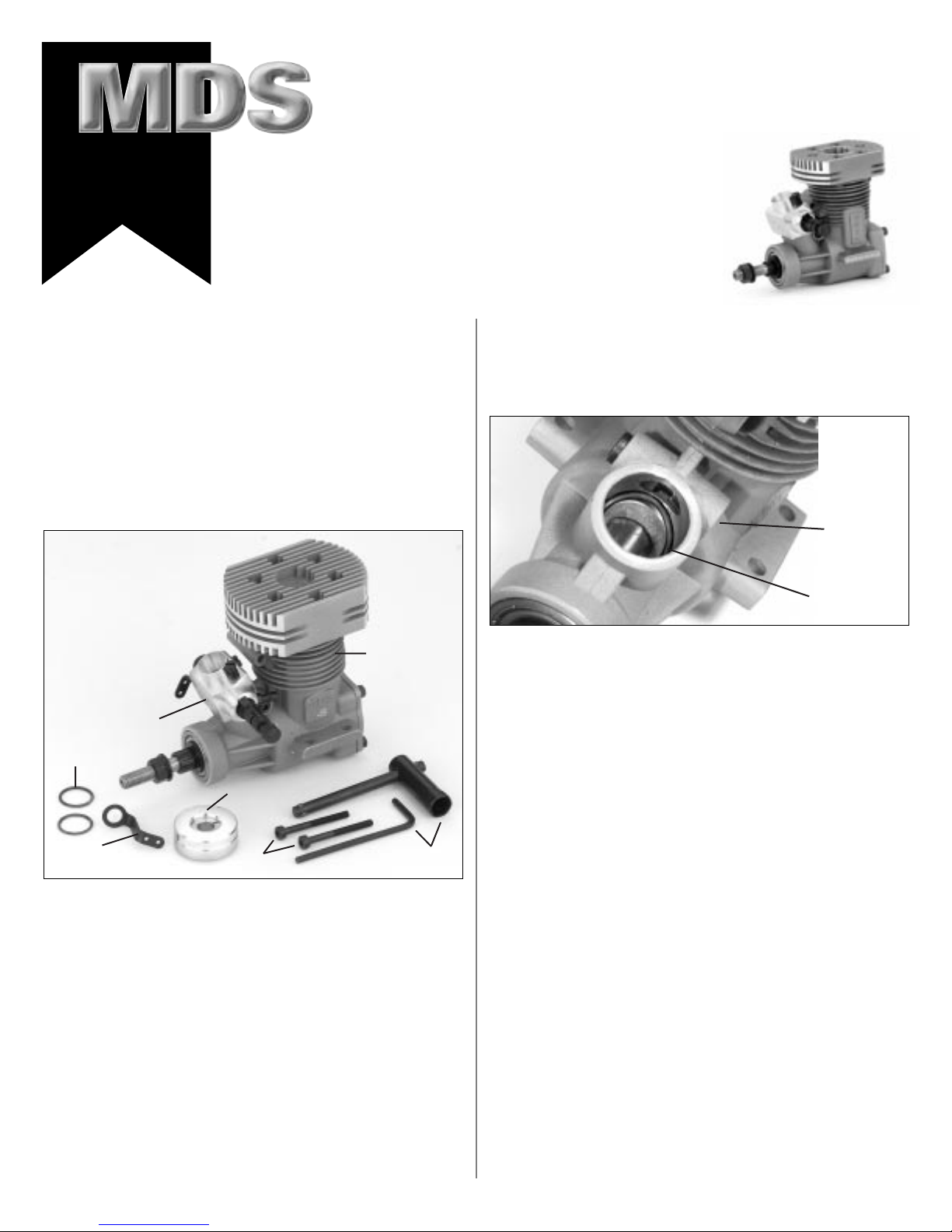

A. Assembly

Inside the MDS engine box you should find one each of the

following items as shown in Photo 1:

To assemble your new engine, please follow these simple steps:

1. Remove the individual plastic bags from the box and place

them on a table or workbench in front of you. Remove the

engine from its plastic wrapper. Note: Some engines may

already have the carburetor installed. If so, it will be necessary to remove the carburetor at this time. If the carburetor

assembly does not remove easily, it may be necessary to

loosen the carburetor retaining bolt slightly (see Photo 2)

using the Allen wrench supplied in the parts/tool bag. Next,

rotate the carburetor back and forth slightly while pulling

upward to remove the carburetor.

2. Remove the two O-rings from the parts bag. Install the first

O-ring into the cavity of the air intake port of the crankcase,

as shown in Photo 2, making sure that the O-ring is seated

evenly at the bottom of the cavity and cannot come in

contact with the engine crankshaft. The second O-ring is a

spare.

3. It is now time to re-attach the carburetor to the engine.

Before inserting the carburetor, inspect the carburetor

retainer

to insure that the curved portion of the carburetor retainer

drawbar matches the inside wall of the air intake port. If it

does not, simply place it in position with your finger. Before

tightening the carburetor to the engine, it’s suggested that a

downward pressure be applied to the carburetor to create an

airtight seal to the O-ring. Align the carburetor so the needle

valve is 180 degrees to the crankshaft of the engine and

secure if using the provided Allen wrench.

Note: The carburetor is correctly positioned when the

throttle arm is located on the right side of the engine when

viewed from the rear.

CAUTION: Do not overtighten; doing so could damage the

carburetor body.

4. Move the carburetor barrel to its full idle position and adjust

the barrel stop screw so the air passage of the carburetor barrel is completely closed as shown in Photo 3 on the next

page. This will allow for the engine to be shut off by moving

the throttle trim of your transmitter to the full low position

during operation. Note: It’s important to do this procedure

at this time as the barrel stop screw is not accessible once the

engine is installed in the helicopter.

A. Engine assembly

B. Aeromix

™

carburetor

(may be pre-installed)

C. Complete accessory and

tool set (included tools

may vary slightly with

different engines)

D. Two muffler mounting

bolts (.38 & .48 only)

E. Tapered collet and

knurled prop washer

(.38 & .48 only)

F. Extended heli throttle arm

(.38 & .48 only)

G. Two carburetor O-Rings

• Instructions and

warranty card

Pro Heli Engine Operating Instructions

™

Photo 1

Photo 2

A

Carb

Retaining

Bolt

O-Ring

B

C

D

(.38 & .48 only)

E

(.38 & .48 only)

F

(.38 & .48 only)

G

Version 1.1

Page 2

5. In many helicopter installations, it will be necessary to

replace the existing throttle arm with the extended heli

throttle arm provided in the parts bag (.38 & .48 only). In

most cases, it’s suggested that the throttle arm be positioned

once the engine has been installed in the helicopter to

achieve proper alignment and to accomodate each engine

installation. Prior to attaching the throttle arm, it’s also

suggested that you first test fit the desired control linkage to

the throttle arm to insure that the attachment holes in the

throttle arm are of the correct size. In some cases, it may be

necessary to enlarge the attachment holes using a drill for

proper fit. Note: The holes are already enlarged in the .68

heli engine.

6. Attach the appropriate fan/flywheel assembly included with

your helicopter kit per the kit manufacturer’s instructions. A

tapered collet and knurled prop washer, as well as a stepped

spacer, have been included with this engine to facilitate

fan/flywheel assemblies which require this arrangement

(.38 & .48 engines only). If the tapered collet/knurled

prop washer are to be used, it will first be necessary to

remove the stepped spacer from the engine prior to attachement. Note: When attaching and tightening the fan/flywheel assembly to the engine, it’s suggested that a piston

locking tool be used to achieve proper tightness. We recommend the Revolution Piston Locking Tool (RVO1003) or similar item.

7. Install the engine into the helicopter per the kit manufacturer’s recommendations.

B. Understanding Your MDS Aeromix

™

Carburetor

The MDS Aeromix™carburetor is designed for use with the

Pro series of MDS helicopter engines. This carburetor provides

the proper air-fuel mixture necessary for helicopter flying and

provides smooth performance throughout the throttle operating range.

Note: If this is your first attempt at operating a model engine,

we suggest you seek the advice of an experienced modeler for

help, if possible. Your local hobby dealer may be able to help or

put you in contact with an experienced modeler who would be

willing to help you.

CAUTION: Before making any adjustments to the carburetor,

please consider the following: In helicopters, engine failure in

flight is a serious problem, especially for modelers who do not

have much flying experience. Such a failure will usually result

in loss of control of the helicopter and a resulting crash.

To ensure safe, reliable control of the helicopter in flight, you

must adjust the engine to achieve a throttle response that’s

quick and reliable. This means the carburetor adjustment is

very important for proper helicopter performance and must be

done with great care in order to obtain reliable throttle

response. Initial test flights are recommended at a very low

altitude (approximately 1 foot or less from the ground) until

reliable operation is achieved.

When the helicopter is in flight, accurate and reliable throttle

response in the medium speed hover range is very important!

This is because most initial helicopter flying (hovering) is done

at the medium speed position.

On this carburetor, there are two adjustable needle valves for

fuel flow control.

High Speed Needle V

alve

1. The High Speed Needle Valve (located on the left side of

carburetor as you look at the engine from the rear forward)

controls the mixture of the engine speed range from half

(midstick) to fully opened throttle.

Low Speed Needle V

alve

2. Low (idle) Speed Needle Valve (located in the throttle barrel

in right side with throttle arm) controls the mixture of

the engine speed range from idling to half open throttle

(midstick). Note: The idle needle valve is recessed into the

throttle arm extension on the .68 heli engines.

Note that the best mixture around half (midstick) throttle is

obtained by balancing the High Speed Needle Valve and the

Low Speed Needle Valve Settings.

Suggested Initial Needle V

alve Settings:

High Speed Needle Valve: 2-1/2 turns

Low Speed Needle Valve: 2-1/2 turns

Please note that all settings are established by turning the

respective needle valve clockwise until it stops, then backing

out counterclockwise to the desired position.

C. Engine Break-in

Your new MDS helicopter engine can be broken-in either in the

helicopter or on an engine test stand. Most helicopter pilots

choose to break-in their new engines while in the helicopter.

This is an acceptable practice, provided that the engine is run

in a low rpm condition, with a rich needle setting for a minimum of 6–8 tanks of fuel. Once this has been completed, the

engine can be leaned down in small increments and taken to

full power as needed. Note: If the engine is used in a lean or

full power condition during the first 6–8 flights, possible damage can occur, voiding the warranty.

D. Initial Test Flights and Adjustments

To start the engine, you will need the following items:

• We recommend a high quality, 2-cycle heli fuel

containing 15% to 30% nitromethane.

• Fuel pump

• Electric starter with appropriate extension

• Glow driver or power panel

• Glow plug (HAN3020 recommended)

• In-line fuel filter

The following adjustment procedures are recommended:

Initial Carburetor Adjustments

(Range from idle to 1/2 open throttle)

1. Start the engine with the transmitter throttle stick fully

down and the throttle trim lever set in the center position.

Be sure to hold the rotor blades firmly while starting in case

of clutch engagement.

2. Set the throttle trim lever so the engine runs with the highest idling rpm possible, without engaging the clutch. Let the

engine run for 1–2 minutes in this condition to warm up.

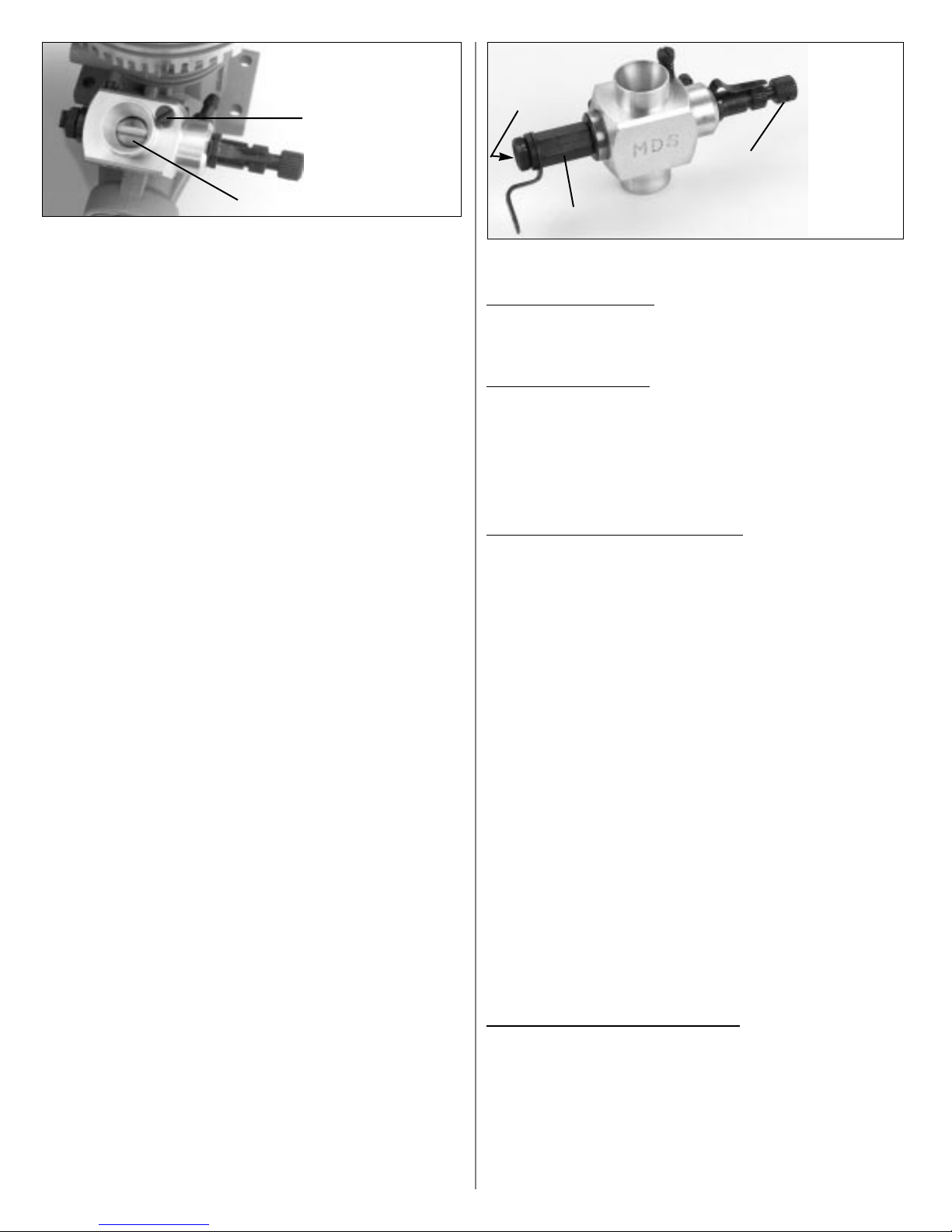

Photo 3

Carburetor barrel fully closed

Idle stop screw

Photo 4

Low Speed

Needle Valve

recessed inside

(.68 only)

High Speed

Needle Valve

Throttle Arm Extension

(.68 only)

Page 3

3. Pinch the fuel intake line between your fingers to restrict fuel

flow, while listening to the engine rpm. If the rpm increases

immediately, this may indicate that the low speed needle

valve is set too lean. Richen as necessary. Adjust the low

speed needle valve until a reliable idle is achieved and a hesitation of 2–3 seconds is established once the fuel line is

pinched.

4. Test hover the helicopter by advancing the transmitter throttle stick gradually until the helicopter just lifts up (floats)

from the ground. Warm up the engine while maintaining a

low level floating hover for approximately 10 seconds, then

slowly reduce the engine speed and allow the engine to idle

for a while. If the engine remains at a high idle for a few

seconds, then settles down (loses rpm), this may indicate

that the engine is running too lean. Adjust the low speed

needle valve in small 1/8 turn increments until the engine

will return to a low idle directly after hovering.

5. Repeat the above procedure several times. If the engine tends

to hesitate or cut-out as the throttle is increased, this may

indicate that the low (or high) speed needle valve is set too

rich. Lean the low speed needle valve slightly and re-test

until an acceptable throttle response is achieved. On the

contrary, if the low speed needle valve is set too lean, the

engine may hesitate longer and exhibit a weaker exhaust

tone. It may also be possible that the engine will run roughly

and produce a “missing” or inconsistent exhaust sound.

Richen the low speed needle valve as needed until the proper

adjustment is achieved.

6. If the engine runs with hesitation but does not stop, try to

hover the helicopter, maintaining an altitude of approximately 1 foot from the ground and carefully watching the

exhaust smoke. If the mixture is too rich, you may observe

an excess of exhaust smoke and the throttle response will be

very soft. If the mixture is too lean, the engine will run with

a higher pitched exhaust sound, lose power gradually, and

little smoke will be produced, showing an overheating tendency. It will be difficult to maintain a hover or keep the

helicopter flying. CAUTION: Do not continue to fly the

helicopter in this condition as this could cause severe damage to your engine. Re-adjust the fuel mixture as needed.

Note: In most cases, the higher the nitro content of the fuel,

the more the engine will smoke due to increased oil content

in the fuel.

Maximizing High Speed Performance

This setting will depend on the individual characteristics of the

helicopter engine/muffler configuration, the fuel used, and the

atmospheric conditions. The high speed needle valve should be

gradually closed (leaned out) in 1/8 turn increments until the

highest performance is obtained in flight at full power.

CAUTION: Do not close the high speed needle valve to a lean

setting and risk overheating the engine during the first 6–8

tankfuls of operation during the initial break-in process.

Operating the engine at too lean a setting in pursuit of maximum performance is not recommended and can cause damage

to the engine. Note: Do not attempt these adjustments until a

reliable fuel mixture setting in the initial hovering position has

been achieved. If you are not proficient in forward flight, seek

the help of a more experienced pilot for these adjustments.

Maximizing Middle Range of Performance

(Hovering speed)

In helicopter flight, throttle response at hovering speeds is very

important. If the low speed needle valve and high speed needle

valve are properly adjusted (balanced) the mixture will be correct through the middle range of performance. If, however,

minor re-adjustments are necessary for the best possible throttle

response, use the following symptoms to make the necessary

corrections:

1. If the mixture at the middle range of operation is too lean,

gradually increased engine speed is accompanied by diminished exhaust smoke and a high-pitched exhaust sound

while maintaining a hover. In some extreme cases, the

engine will overheat and begin to lose power to a point

where a hover cannot be maintained. In this situation, open

both the high speed and low speed needles valve 1/8 turn

counterclockwise (richer) and retest.

2. If the mixture at middle range of operation is too rich, positive and quick throttle response will not be possible to

obtain. Exhaust smoke will be dense, and the exhaust sound

will be lower, accompanied sometimes by a considerably

reduced rotor speed. When this occurs, close both the high

speed and low speed needle valves clockwise (leaner) 1/8 of a

turn and re-test.

Note: Make any needle valve adjustments in small increments

of not more than 1/8 of a turn when trying to make adjustments to the middle range of operation. Excessive re-adjustment will upset either the low or high speed performance. Be

patient when making re-adjustments so you can find the best

balance of idle, hover and high speed performance. You want

the engine to respond quickly and positively to the throttle

control. Throttle response at hovering speeds is also affected by

the relationship of the main rotor pitch curves and engine

throttle curves. If the optimum middle range throttle response

cannot be obtained using the carburetor adjustments described

above, try adjusting the helicopter’s pitch and throttle curves to

achieve the desired response.

E. Engine Care

D

os

Fuel

Always use clean, fresh fuel. Because dirt is the number one

enemy of any engine, we highly recommend the use of an

in-line fuel filter between the tank and the carburetor. Also,

place one between your fuel pump and the tank filler line.

After-Run Oil

Because model fuel contains methanol, it has the property of

drawing moisture from the atmosphere. Exposure to moisture

can cause corrosion to such vital engine parts as the bearings

and crankshaft. Therefore, we strongly urge that after every

flying session you drain all fuel from the tank and then put

approximately 1 oz. of after-run fuel into the fuel tank. We

recommend Hangar 9 Final Run (HAN3100). Start the engine

and let it run for 1–2 minutes at idle. Drain the excess after-run

fuel from the tank. Your engine will now be protected against

corrosion.

Glow Plug

Proper glow plug selection is extremely important if you are to

achieve maximum performance from your MDS heli engine.

We recommend the use of the Hangar 9 #3 heli performance

plug (HAN3020).

Inspection

Periodically remove the muffler and inspect the piston

through the exhaust port. Any signs of scoring may be an

indication that the engine has been overheated and run in a

lean condition.

Don’ts

Don’t dismantle the engine unnecessarily as doing so can

cause damage to the precision fit parts, such as the piston and

sleeve. If it’s necessary to clean the interior of the engine (such

as after a crash), remove only the muffler, carburetor, cylinder

head and backplate. You should be able to clean all foreign

matter from the engine without disturbing the fit of the precision parts. Any further disassembly could result in voiding the

manufacturer’s warranty.

F. MDS Safety Instructions and Warnings

See the enclosed safety instruction card for details.

G. Service and Warranty

See the enclosed registration card for details.

Page 4

MDSMAN4 Version 1.1

8

5

6

18

4

3

2

1

16

7

19

15

9

10

11

12

13

14

15

17

11

1

2

3

4

5

6

7

8

9

10

11

28

12

No. Description .38FSH Pro .48FSH Pro .68FSH Pro

1 High Speed Needle Valve Assembly 04600250 04600250 04600250

2 Idle Stop Screw & Spring 04600240 04600240 04600240

3 Carburetor Body 03800201 03800201 04600201

4 Fuel Inlet Nipple & Gasket 04000230 04000230 04000230

5 Throttle Barrel Retaining Screw 04600212 04600212 04600212

6 Throttle Barrel Spring 04000211 04000211 04000211

7 Throttle Barrel 04000210 04000210 06100210

8 Low Speed Needle Valve 04600215 04600215 04600215

9 Throttle Lever Arm 04000220 04000220 —

10 Throttle Lever Arm Extended (Heli) 03830220 03830220 03830220

11 Throttle Lever Nut & Washer 04000221 04000221 03830221

12 Throttle Arm Extension — — 06830225

28 Carburetor O-Ring 03800092 03800092 06800092

No. Description .38FSH .48FSH Pro .68FSH Pro

1 Prop Nut & Washer 03830002 03830002 06800002

2 Top Hat/Sleeve/Stepped Spacer 03830008 04830008 N/A

3 Prop Washer/Tapered Collet 03830006 04830006 06800006

4 Front Ball Bearings 03800021 03800021 06800021

5 Rear Ball Bearing 04000022 04600022 06800022

6 Crankcase 03800060 04830060 06800060

7 Crankshaft 03830030 04830030 06830030

8 Backplate 03800061 04001061 06800061

9 Connecting Rod 03800031 04800031 06800031

10 Wrist Pin 03800033 04800033 06800033

11 Wrist Pin Clips 03800034 06800034 06800034

12 Piston & Cylinder Assembly 03800040 04800040 06830040

13 Head Gasket 03800053 04800053 06800053

14 Cylinder Head 03830050 04830050 06830050

15 Screw Set 02800091 04001091 06800091

16 Muffler Screw Set 03800304 04600304 06800304

17 Carburetor Retainer & Nut 04600090 04600090 04600090

18 F/R Gasket 03800062 04600062 06800062

19 Carburetor 03800200 03800200 06830500

Aeromix™Carburetor Parts Diagram

Dimensions (mm) A B C D E F G

MDSE03830 .38 Heli 30 39 15 37 77 65 1/4 x 28

MDSE04830 .48 Heli 36 44 17.5 55 87 100 1/4 x 28

MDSE06830 .68 Heli 40 52 24 55 100 120 5/16 x 24

Engine Parts Diagram

B

A

C

D

E

F

G

=HEIGHT

=LENGTH

=CRANKSHAFT

Loading...

Loading...