Page 1

TM

MX-2100/2104

Data, Voice, Fax and LAN Integrating

Modular Multiplexer

Installation and Operation Manual

NOTICE

This manual contains information that is proprietary to MICROWAVE DATA SYSTEMS, INC.

No part of this publication may be reproduced in any form whatsoever without prior written

approval by MICROWAVE DATA SYSTEMS, INC.

No representation or warranties for fitness for any purpose other than what is specifically

mentioned in this manual is made either by MICROWAVE DATA SYSTEMS, INC. or its

agents.

MICROWAVE DATA SYSTEMS, INC. reserves the right to revise this publication and make

changes without obligation to notify any person of such revisions or changes.

For further information contact MICROWAVE DATA SYSTEMS, INC. at the address below or

contact your local distributor.

MICROWAVE DATA SYSTEMS, INC.

175 SCIENCE PARKWAY

ROCHESTER, NY 14620-4261 U.S.A.

Tel: General Business: +1 (716) 242-9600

Customer Service: +1 (800) 474-0964

Fax All Services: +1 (716) 242-9620

Internet E-mail: techsupport@microwavedata.com

World Wide Web: http://www. microwavedata.com

2002 Microwave Data Systems, Inc. Pub. No. 8011130000

Page 2

Page 3

SAFETY WARNINGS

Always observe standard safety precautions during installation, operation and maintenance of this

product. Only qualified and authorized service personnel should carry out adjustment,

maintenance or repairs to this instrument. No adjustment, maintenance or repairs should be

performed by either the operator or the user.

WARRANTY FOR PRODUCTS MANUFACTURED BY

MICROWAVE DATA SYSTEMS, INC.

A. MICROWAVE DATA SYSTEMS, INC. (MDS) products, except as stated otherwise in an

applicable price list, are warranted against defects in workmanship and material for a period

of one (1) year from date of delivery as evidenced by MDS's packing slip or other

transportation receipt.

B. MDS’s sole responsibility under this warranty shall be to either repair or replace, at its

option, any component which fails during the applicable warranty period because of a defect

in workmanship and material, provided PURCHASER has promptly reported same to MDS

in writing. All replaced Products or parts shall become MDS's property.

C. MDS will honor the warranty at MDS's repair facility in Rochester, New York. It is

PURCHASER's responsibility to return, at its expense, the allegedly defective Product to

MDS. PURCHASER must obtain a Return Material Authorization (RMA) number and

shipping instructions from MDS prior to returning any Product under warranty.

Transportation charges for the return of the Product to PURCHASER shall be paid by MDS

within the United States. For all other locations, the warranty excludes all costs of shipping,

customs clearance and other related charges. If MDS determines that the Product is not

defective within the terms of this warranty, PURCHASER shall pay MDS all costs of

handling, transportation and repairs at the then prevailing repair rates.

D. All the above warranties are contingent upon proper use of the Product. These warranties

will not apply (i) if adjustment, repair or parts replacement is required because of accident,

unusual physical, electrical or electromagnetic stress, neglect, misuse, failure of electric

power, environmental controls, transportation, not maintained in accordance with MDS

specifications, or abuses other than ordinary use; (ii) if the Product has been modified by

PURCHASER or has been repaired or altered outside MDS's repair facility, unless MDS

specifically authorizes such repairs or alterations; (iii) where MDS serial numbers, warranty

data or quality assurance decals have been removed or altered.

E. MDS also reserves the right to make product improvements without incurring any obligation

or liability to make the same changes in Products previously manufactured or purchased. In

no event shall MDS be liable for any breach of warranty in an amount exceeding the net

selling price of any defective Product. No person, including any dealer, agent or

representative of MDS is authorized to assume for MDS any other liability on its behalf

except as set forth herein. Non-payment of any invoice rendered within the stated payment

terms automatically cancels any warranty or guarantee stated or implied. If any payment is

due MDS for services performed hereunder, it shall be subject to the same payment terms as

the original purchase.

F. EXCEPT FOR THE EXPRESS WARRANTIES STATED HEREIN, MDS DISCLAIMS

ALL WARRANTIES ON PRODUCTS FURNISHED HEREUNDER, INCLUDING,

WITHOUT LIMITATION, ALL IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS; and the stated express warranties are in lieu of all obligations or liabilities

on the part of MDS arising out of or in connection with the performance of the Products.

Page 4

WARRANTY FOR PRODUCTS MANUFACTURED BY OTHERS

A. For products not manufactured by MDS, the original manufacturer's warranty shall be

assigned to PURCHASER to the extent permitted and is in lieu of any other warranty,

expressed or implied.

B. For warranty information on a specific product, a written request should be made to MDS.

FCC-15 User Information

This equipment has been tested and found to comply with the limits of the Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to the radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

Page 5

Foreword

This manual describes the MX-2100/2104 family of data, voice, fax and

LAN integrating modular multiplexers. The manual covers the general

system characteristics, presents typical system applications, and provides

installation, operating procedure and configuration information for the

modules that are part of the basic MX-2100/2104 system configuration.

This release of the manual covers the characteristics of equipment

equipped with the Common Logic Module running software version 3.1

and above.

Manual Organization

This manual is organized as follows:

Chapter 1. General Information

presents the main features and typical applications of the MX-2100/2104

family, describes the various equipment versions, and lists the technical

characteristics of the MX-2100/2104 systems.

Preface

Chapter 2. Installation

provides detailed installation and operation instructions for MX-2100/2104

systems.

Chapter 3. Configuring MX-2100

provides general instructions for using and managing MX-2100/2104

systems by means of terminals and Telnet hosts.

Chapter 4. Operation

provides typical configuration procedures for MX-2100/2104 systems.

Chapter 5. Diagnostics

describes the diagnostic and performance monitoring functions supported

by MX-2100/2104 systems.

Appendix A. Connection Data

provides connection data for the basic modules used in the MX-2100/2104

system.

Appendix B. Alarms

explains the alarms and configuration error messages generated by the

MX-2100/2104 system.

Page 6

Appendix C. SNMP Management

describes the SNMP and IP environments, and provides background

information regarding the handling of management traffic.

Appendix D. Software Download

provides instructions for the installation of new software releases.

Appendix E. Configuration Parameters

lists the various parameters that can be used to configure MX-2100/2104.

Appendix F. Command Set Description

describes MX-2100/2104 commands.

Conventions

Note

Caution

A note draws attention to a general rule for a procedure, or to exceptions to

a rule.

A caution warns of possible damage to the equipment if a procedure is not

followed correctly.

A warning alerts to the presence of important operating and maintenance

(servicing) instructions in the literature accompanying the equipment. If

Warning

these instructions are not followed exactly, bodily injury may occur.

Related Documentation

In addition to this system manual, separate Installation and Operation

Manuals are available for each of the modules that are used in the

MX-2100/2104 systems. Each module’s Installation and Operation Manual

presents the technical characteristics, applications and specific

configuration information for that module.

Note that when the module manual refers to the respective MX-2000 or

MX-2004 system Installation and Operation Manual, refer to the

corresponding section of

this

system manual.

Page 7

Quick Start Guide

This Quick Start Guide is a brief step by step guide to setting up and using your

MX-2100. It is a supplement to the MX-2100/2104 Installation and Operation

Manual.

1. Installing MX-2100

To install MX-2100 (for more detailed instructions refer to the System Installation

and Setup chapter):

1. Unpack the equipment.

2. Check that your site conforms to the equipment requirements (refer to Site

Requirements in the System Installation and Setup chapter).

3. Check the power supply rating considerations (refer to Power Supply Rating

Considerations in the System Installation and Setup chapter).

4. Install the MX-2100 enclosure (refer to Installation and Setup in the System

Installation and Setup chapter).

5. Install an additional KPS module if necessary (refer to Installation and Setup in

the System Installation and Setup chapter).

6. Install the KM-Ringer module (refer to Installation and Setup in the System

Installation and Setup chapter).

7. Connect the power cable, the KM-Ringer module, the Supervisory Port (KCL.2

module), the KML module, option modules and I/O modules (refer to

Interfaces and Connections in the System Installation and Setup chapter).

8. Set the IP address using the DEF AGENT (refer to DEF AGENT in the Command

Set Description appendix).

2. Operating MX-2100

To operate MX-2100 (for more detailed instructions refer to Operating Instructions

in the Operation chapter):

1. If MX-2100 includes a KM-Ringer module, set the KM-Ringer module power

switch to OFF.

2. Turn on MX-2100 by setting the ON/OFF switches (on the rear panels) to ON.

3. Check the front-panel indications (refer to Operating Instructions in the

Operation chapter).

Operating MX-2100 1

Page 8

Quick Start Guide MX-2100/2104 Installation and Operation Manual

4. If MX-2100 includes a KM-Ringer module, turn it on by setting its POWER

switch to ON. Verify that the RING VOLTAGE and BATTERY VOLTAGE

indicators light.

5. Check the MX-2100 configuration (refer to Checking Current Operating

Configuration in the Operation chapter).

6. Check the normal MX-2100 operating indications (refer to Normal Indications

in the Operation chapter).

7. MX-2100 has diagnostic functions which can be used to test the proper

operation of the MX-2100 system and identify the faulty components. For an

explanation of the MX-2100 diagnostic functions refer to the Diagnostics

chapter.

8. Turn off MX-2100 as follows:

- If MX-2100 includes a KM-Ringer module, then turn off the

KM-Ringer before MX-2100.

- For the MX-2100’s KPS modules and MX-2104,

set the ON/OFF switches (on the rear panels) to OFF.

3. Setting-Up the Local Configuration

To set-up the MX-2100 local configuration (for more detailed information refer to

Setting Configuration Parameters in the Configuring MX-2100 chapter):

1. Set the system parameters refer to Configuring the System Parameters in the

Configuring MX-2100 chapter).

2. Select the main link parameters (refer to Configuring the Main Link Parameters

in the Configuring MX-2100 chapter).

3. Select the channel parameters (refer to Configuring the Channel Parameters in

the Configuring MX-2100 chapter).

4. Controlling MX-2100 from a Supervisory Port

To control MX-2100 from a supervisory port (for more detailed instructions refer to

Operating Instructions in the Operation chapter):

1. Start a session for MX-2100 (refer to Starting a Session - Single MX-2100 and

Starting a Session - Multiple MX-2100 in the Operation chapter).

2. Type the desired commands after the working prompt and press Enter to

execute the command. Refer to the Command Set Description appendix for a

list of commands available.

3. End the control session by typing EXIT. You can now control MX-2100 from

the front panel (refer to General Front Panel Operating Instructions in the

Configuring MX-2100 chapter).

2 Controlling MX-2100 from a Supervisory Port

Page 9

Contents

Chapter 1 General Information

UNCTIONAL DESCRIPTION

1.1 F

Main System Features ..............................................................................................1-1

System Supervision and Configuration......................................................................1-4

Diagnostic Capabilities.............................................................................................1-6

HYSICAL DESCRIPTION

1.2 P

MX-2100, General Description ................................................................................1-6

MX-2100 Rear Panel................................................................................................1-7

MX-2100 Front Panel...............................................................................................1-8

MX-2104, General Description ................................................................................1-8

MX-2104 Rear Panel................................................................................................1-9

MX-2104 Front Panel.............................................................................................1-10

Common Logic Modules........................................................................................1-10

Main Link Modules................................................................................................1-10

Power Supply Modules ..........................................................................................1-11

Option Modules (not for MX-2104)........................................................................1-12

I/O Modules ..........................................................................................................1-12

PPLICATION CONSIDERATIONS

1.3 A

Basic MX-2100 System...........................................................................................1-16

Redundancy (not for MX-2104)..............................................................................1-20

Dual Link Operation (not for MX-2104) .................................................................1-22

Priority Bumping (not for MX-2104) .......................................................................1-27

Switched Backup Operation (not for MX-2104)......................................................1-28

Switch Mode .........................................................................................................1-30

System Management..............................................................................................1-32

System Timing Considerations................................................................................1-38

Data Channel Clock Modes ...................................................................................1-45

Timing Modes of ISDN Channels ...........................................................................1-46

Sub Link Timing.....................................................................................................1-47

Main Link Interface Characteristics.........................................................................1-47

1.4 I/O M

1.5 T

ODULE APPLICATIONS

ECHNICAL SYSTEM CHARACTERISTICS

......................................................................................................1-6

.................................................................................................1-1

.........................................................................................1-16

.............................................................................................1-50

................................................................................1-50

Chapter 2 Installation

NTRODUCTION

2.1 I

ITE REQUIREMENTS AND PREREQUISITES

2.2 S

Input Power Requirements.......................................................................................2-2

Grounding...............................................................................................................2-2

Channel Connection Considerations ........................................................................2-3

Front and Rear Panel Clearance ...............................................................................2-3

Ambient Requirements ............................................................................................2-3

Electromagnetic Compatibility Considerations ..........................................................2-3

Current and Power Requirements of MX-2100 Power Supply Modules.....................2-3

Current and Power Capabilities of MX-2100 Power Supply Modules ........................2-6

Ratings of Ring and Feed Voltage Supplies................................................................2-7

QUIPMENT NEEDED

2.3 E

Terminal Characteristics...........................................................................................2-8

Software Requirements ............................................................................................2-8

MX-2100/2104 Installation and Operation Manual i

................................................................................................................2-1

...............................................................................2-2

..........................................................................................................2-8

Page 10

Table of Contents

Supervisory Port Interface Characteristics .................................................................2-8

Connection of Supervision Terminal.........................................................................2-9

ACKAGE CONTENTS

2.4 P

NSTALLATION AND SETUP OF

2.5 I

MX-2100...............................................................................................................2-12

MX-2104...............................................................................................................2-12

KPS Module...........................................................................................................2-13

KCL.2 Module .......................................................................................................2-14

NTERFACES AND CONNECTIONS

2.6 I

KPS Module...........................................................................................................2-16

KCL.2 Module .......................................................................................................2-17

Connections to KML, Options, I/O Modules, and Ringers .......................................2-19

MX-2104...............................................................................................................2-19

NITIAL SETUP AND CONFIGURATION

2.7 I

........................................................................................................2-11

Chapter 3 Configuring MX-2100

NTRODUCTION

3.1 I

ONTROL OF

3.2 C

General ...................................................................................................................3-1

Front Panel Operating Instructions ...........................................................................3-2

Front Panel Menu....................................................................................................3-2

ETTING CONFIGURATION PARAMETERS

3.3 S

General Configuration Procedure.............................................................................3-7

Configuring the System Parameters ..........................................................................3-9

Configuring the Main Link Parameters....................................................................3-11

Configuring the Channel Parameters ......................................................................3-11

Configuring the SP Parameters .................................................................................3-12

................................................................................................................3-1

MX-2100 O

PERATION

MX-2100.............................................................................2-12

........................................................................................2-16

..................................................................................2-21

...................................................................................3-1

................................................................................3-7

Chapter 4 Operation

ENERAL

4.1 G

4.2 MX-2100 S

4.3 F

4.4 O

..........................................................................................................................4-1

UPERVISION LANGUAGE

Command Language Syntax.....................................................................................4-1

Command Options ..................................................................................................4-2

Command Protocol..................................................................................................4-3

Index of Commands ................................................................................................4-4

RONT PANEL CONTROLS AND INDICATORS

Organization of MX-2100 Display............................................................................4-9

Using the Front Panel Push-buttons.......................................................................... 4-9

Checking Current Operating Configuration.............................................................4-10

Normal Indications ................................................................................................4-12

PERATING INSTRUCTIONS

Supervision Terminal .............................................................................................4-12

Front Panel............................................................................................................4-16

Chapter 5 Diagnostics

LARMS

5.1 A

5.2 D

...........................................................................................................................5-1

IAGNOSTIC TESTS

MX-2100 TEST OPTIONS, General..........................................................................5-1

Test Options Operating Instructions .........................................................................5-3

MX-2100 Diagnostic Functions, General ..................................................................5-7

Main Link Loops ......................................................................................................5-8

I/O Module Loops and Tests ..................................................................................5-12

.....................................................................................4-1

..........................................................................4-7

...............................................................................................4-12

............................................................................................................5-1

ii MX-2100/2104 Installation and Operation Manual

Page 11

Table of Contents

Appendix A Connection Data

COPE

A.1 S

A.2 S

A.3 MNG C

A.4 A

A.5 DC P

Appendix B Alarms

B.1 A

B.2 C

.......................................................................................................................... A-1

UPERVISORY PORT CONNECTOR

ONNECTOR

LARM RELAY CONNECTOR

OWER INPUT CONNECTOR

LARM MESSAGES

ONFIGURATION ERROR MESSAGES

........................................................................................................ A-3

.............................................................................................................B-1

Appendix C SNMP Management

COPE

C.1 S

C.2 SNMP E

C.3 IP E

C.4 SNMP T

............................................................................................................................ C-1

NVIRONMENT

General .................................................................................................................. C-1

SNMP Principles ..................................................................................................... C-1

Management Domains Under SNMP ...................................................................... C-3

NVIRONMENT

General .................................................................................................................. C-4

IP Environment....................................................................................................... C-5

Automatic IP Traffic Routing.................................................................................... C-6

RAPS

.................................................................................................................. C-8

...................................................................................................... C-1

............................................................................................................ C-4

...................................................................................... A-1

.............................................................................................. A-4

....................................................................................... A-4

...................................................................................B-10

Appendix D Software Download

COPE

D.1 S

D.2 C

D.3 W

.......................................................................................................................... D-1

OLD (LOCAL

Preparations ...........................................................................................................D-1

Downloading Procedure - MX-2100 with Single KCL.2............................................ D-2

ARM INSTALLATION (UPGRADING

Preparations ...........................................................................................................D-3

Downloading Procedure .........................................................................................D-3

NSTALLATION PROCEDURE

) I

Appendix E Configuration Parameters

ENERAL

E.1 G

..........................................................................................................................E-1

System Configuration Parameters .............................................................................E-1

Main Link Configuration Parameters.........................................................................E-3

Supervisory Port Configuration Parameters............................................................... E-7

Appendix F Command Set Description

ENERAL

F.1 G

F.2 C

..........................................................................................................................F-1

OMMANDS

.....................................................................................................................F-2

BYE .........................................................................................................................F-2

CLR ALM.................................................................................................................F-2

CLR LOOP .............................................................................................................. F-3

CLR MONITOR .......................................................................................................F-4

CONNECT SWITCH................................................................................................ F-4

DATE....................................................................................................................... F-5

DEF AGENDA.......................................................................................................... F-6

DEF AGENT............................................................................................................. F-7

ROCEDURE

) P

......................................................................... D-1

INDOWS-BASED STATIONS

- W

..................... D-3

MX-2100/2104 Installation and Operation Manual iii

Page 12

Table of Contents

DEF ALM DEBOUNCE.............................................................................................F-9

DEF CALL................................................................................................................ F-9

DEF CH................................................................................................................. F-12

DEF CON.............................................................................................................. F-12

DEF DB FLIP..........................................................................................................F-14

DEF DP ................................................................................................................. F-15

DEF FRAME........................................................................................................... F-17

DEF MANAGER LIST..............................................................................................F-18

DEF ML .................................................................................................................F-19

DEF ML CALL........................................................................................................ F-20

DEF NAME ............................................................................................................F-24

DEF NODE............................................................................................................ F-24

DEF NP .................................................................................................................F-25

DEF PWD.............................................................................................................. F-26

DEF ROUTE ..........................................................................................................F-27

DEF SP .................................................................................................................. F-28

DEF SYS.................................................................................................................F-29

DISCONNECT SWITCH ........................................................................................F-32

DSP AGENT ..........................................................................................................F-33

DSP ALM............................................................................................................... F-34

DSP BERT.............................................................................................................. F-34

DSP CH CON........................................................................................................ F-35

DSP FLIP ............................................................................................................... F-36

DSP HDR TST .......................................................................................................F-37

DSP MANAGER LIST .............................................................................................F-37

DSP KVF5 or DSP PBX...........................................................................................F-38

DSP KVF6.............................................................................................................. F-39

DSP SIGNALING or DSP SIG .................................................................................F-40

DSP PRBS_INJ .......................................................................................................F-40

DSP REM AGENT .................................................................................................. F-41

DSP REV................................................................................................................ F-41

DSP ST FRAME...................................................................................................... F-42

DSP ST ML ............................................................................................................F-44

DSP ST SLOT......................................................................................................... F-46

DSP ST SYS............................................................................................................ F-48

EDIT DB................................................................................................................ F-50

EXIT.......................................................................................................................F-50

F............................................................................................................................F-51

FLIP ML................................................................................................................. F-51

HELP..................................................................................................................... F-52

INIT DB................................................................................................................. F-52

INIT F.................................................................................................................... F-53

LOAD DB 1\2........................................................................................................ F-54

LOAD IO............................................................................................................... F-54

LOOP.................................................................................................................... F-55

ML RECOVERY...................................................................................................... F-56

MONITOR ............................................................................................................F-56

REBUILD FRAME................................................................................................... F-56

RESET LOC............................................................................................................ F-57

RESET IO............................................................................................................... F-57

RESET ML.............................................................................................................. F-57

TIME .....................................................................................................................F-58

UPDATE DB 1\2.................................................................................................... F-58

iv MX-2100/2104 Installation and Operation Manual

Page 13

Table of Contents

List of Figures

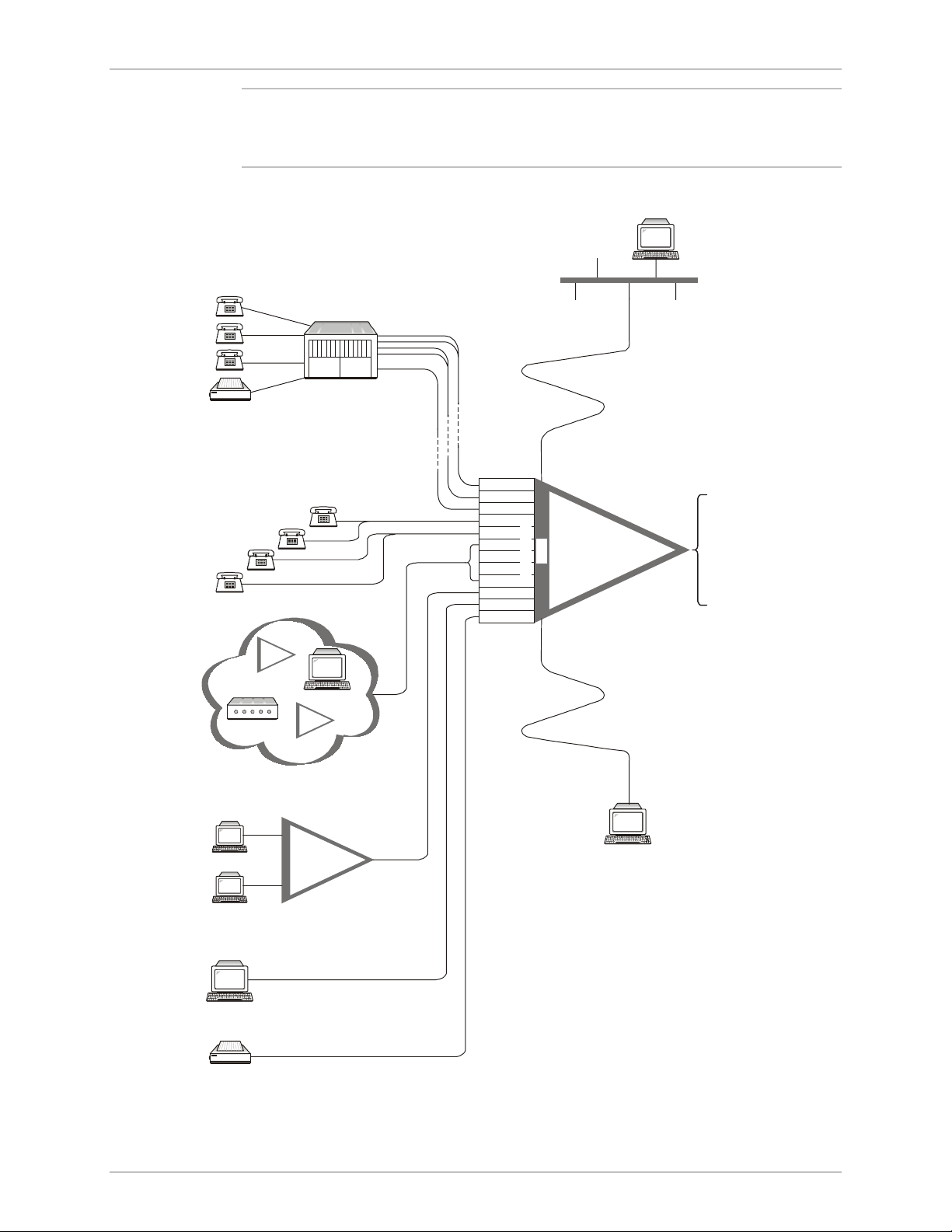

Figure 1-1. MX-2100 System Applications.......................................................................... 1-2

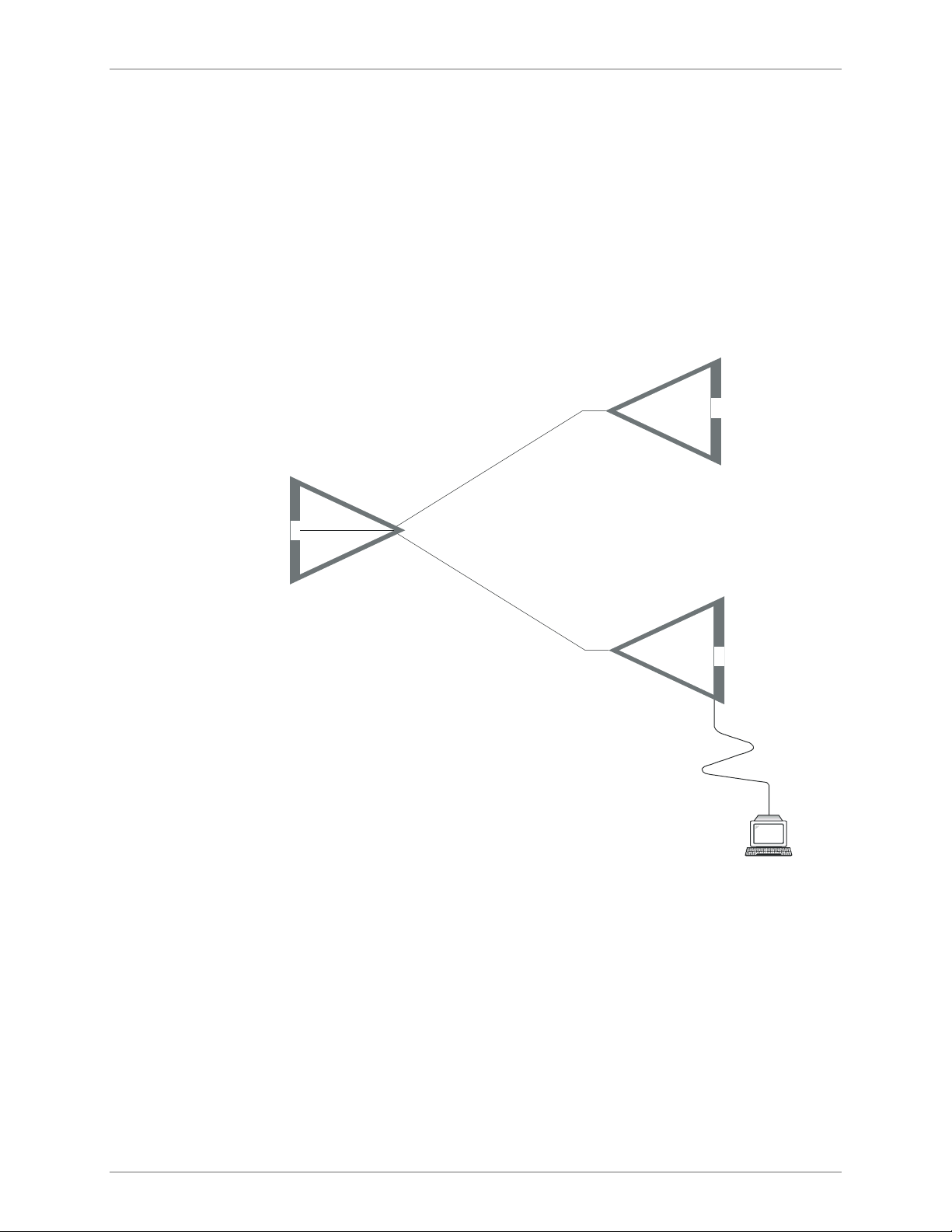

Figure 1-2. “V” Configuration ............................................................................................ 1-5

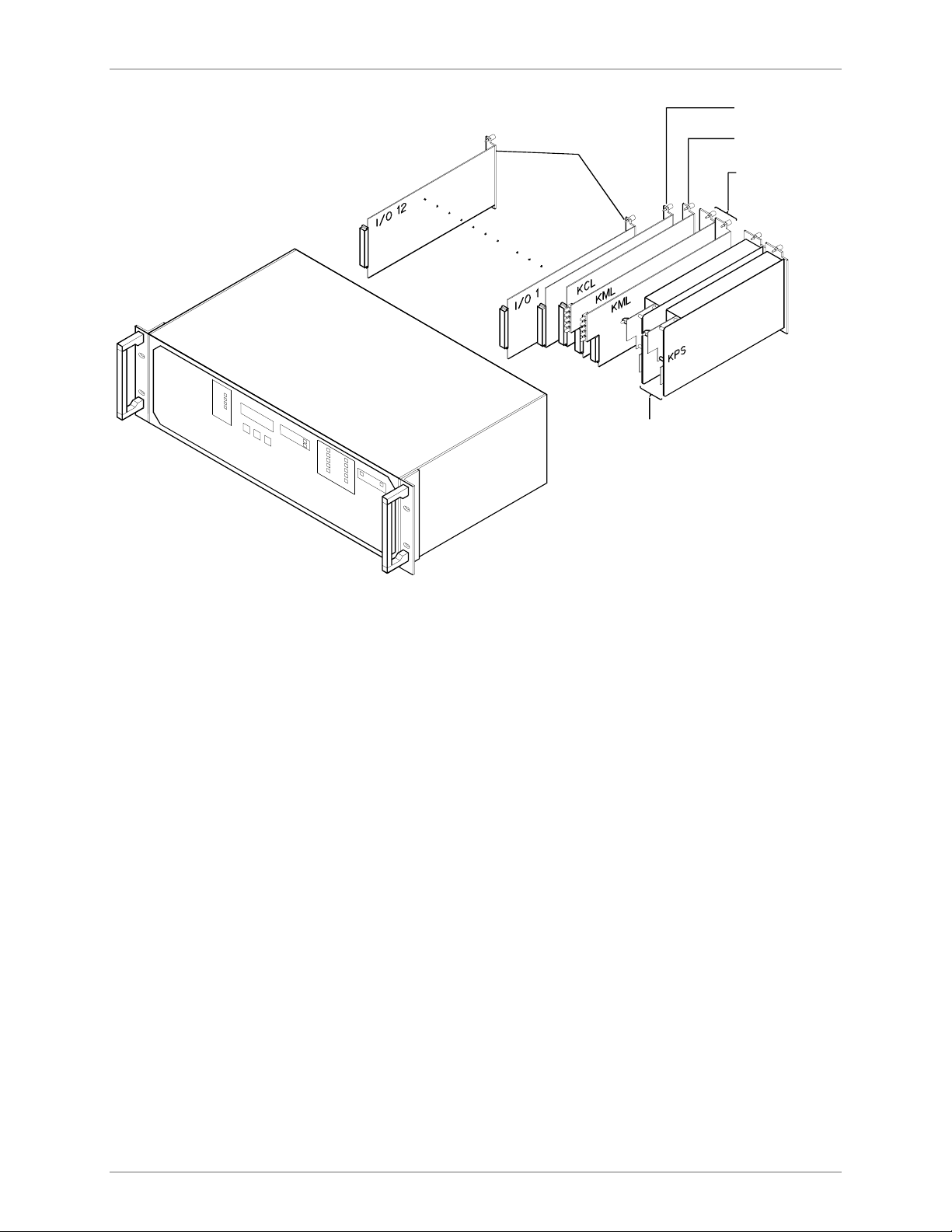

Figure 1-3. MX-2100 Enclosure with Modules, General View............................................. 1-7

Figure 1-4. MX-2100 Enclosure, Rear View........................................................................ 1-8

Figure 1-5. MX-2100 Enclosure Front Panel ....................................................................... 1-8

Figure 1-6 MX-2104 Enclosure, General View................................................................... 1-9

Figure 1-7. MX-2104 Enclosure, Rear View........................................................................ 1-9

Figure 1-8. MX-2104 Enclosure Front Panel ..................................................................... 1-10

Figure 1-9. Basic MX-2100 System Structure.................................................................... 1-16

Figure 1-10. Redundant MX-2100 System ....................................................................... 1-21

Figure 1-11. Dual Link, High Capacity Point-to-Point Application .................................... 1-22

Figure 1-12. Dual Link System, Independent Link Application ......................................... 1-23

Figure 1-13. Basic Bypassing Configuration ...................................................................... 1-24

Figure 1-14. Bypassing Parameters................................................................................... 1-25

Figure 1-15. Typical Bypassing Application ...................................................................... 1-26

Figure 1-16. Typical KDI Bypassing and Multidrop Application ........................................1-27

Figure 1-17. Typical Switched Backup Configuration .......................................................1-29

Figure 1-18. Typical ISDN Switched Backup Application ................................................. 1-30

Figure 1-19. Single Switch Mode ..................................................................................... 1-31

Figure 1-20. Dual Switch Mode ....................................................................................... 1-31

Figure 1-21. Single and Switch Mode............................................................................... 1-32

Figure 1-22. Remote Management: In-Band .................................................................... 1-34

Figure 1-23. Using the Data Frame ..................................................................................1-34

Figure 1-24. Remote Management: Out-of-Band............................................................. 1-35

Figure 1-25. Local Neighbor Management ....................................................................... 1-36

Figure 1-26. Remote Neighbor Management ................................................................... 1-36

Figure 1-27. Network Configurations Using DTE Timing .................................................. 1-39

Figure 1-28. Typical External DCE Timing Application ..................................................... 1-41

Figure 1-29. Typical DCE (KML.1–4) Timing Application.................................................. 1-42

Figure 1-30. Typical Internal Timing Mode Application.................................................... 1-42

Figure 1-31. Typical Loopback Timing Application........................................................... 1-43

Figure 1-32. Typical DCE from I/O Timing Mode Application (KML.7, KML.8, KML.F) .... 1-43

Figure 1-33. Typical DCE from ML Timing Mode Application (KML.7, KML.8, KML.F) ..... 1-44

Figure 1-34. Clock Mode 1 (DCE).................................................................................... 1-45

Figure 1-35. Clock Mode 2 (DTE1) .................................................................................. 1-45

Figure 1-36. Clock Mode 3 (DTE2) .................................................................................. 1-46

Figure 2-1. Attachment of Brackets .................................................................................. 2-12

Figure 2-2. Typical KPS Module, Location of Internal Jumper........................................... 2-13

Figure 2-3. Module KCL.2, Internal Switch and Jumpers .................................................. 2-14

Figure 2-4. KPS Modules, Rear Panels.............................................................................. 2-17

Figure 2-5. Module KCL.2, Rear Panel ............................................................................. 2-18

Figure 2-6. MX-2104 Enclosure, Typical Rear View.......................................................... 2-19

MX-2100/2104 Installation and Operation Manual v

Page 14

Table of Contents

Figure 3-1. Organization of Front Panel Menu (Part I) ........................................................ 3-4

Figure 3-2. Organization of Front Panel Menu (Part II) ....................................................... 3-5

Figure 3-3. Organization of Front Panel Menu (Part III) ...................................................... 3-6

Figure 4-1. MX-2100 Front Panel....................................................................................... 4-7

Figure 4-2. MX-2104 Front Panel....................................................................................... 4-7

Figure 4-3. Indicator Functions ..........................................................................................4-8

Figure 5-1. Local Main Link Loop, Signal Path.................................................................... 5-9

Figure 5-2. Remote Main Link Loop, Signal Paths ............................................................ 5-10

Figure 5-3. Main Link Modem Loop 3, Signal Path........................................................... 5-11

Figure 5-4. Main Link Modem Loop 2, Signal Path........................................................... 5-12

Figure 5-5. I/O Module, Local Loop on Individual Channel.............................................. 5-13

Figure 5-6. I/O Module, Remote Loop on Individual Channel..........................................5-13

Figure 5-7. Voice I/O Module, Test Tone Injection Path................................................... 5-15

Figure C-1. IP Address Classes............................................................................................C-5

Figure C-2. Management System Topology Using Subnetting .............................................C-7

List of Tables

Table 1-1. MX-2100 Multiplexing Data............................................................................ 1-17

Table 1-2. Bandwidth Allocations .................................................................................... 1-19

Table 1-3. Example of Bandwidth Allocations ..................................................................1-20

Table 1-4. KML.F Fiber-Optic Interface Characteristics .................................................... 1-49

Table 2-1. Power Consumption of MX-2100 Modules ....................................................... 2-4

Table 2-2. Nominal Power Consumption of Power Supply Modules .................................. 2-6

Table 2-3. DCE and DTE Interfacing Mode - Control Lines ................................................ 2-9

Table 2-4. MNG Connector - Control Lines .....................................................................2-11

Table 2-5. Module KCL.2, Internal Switch and Jumper Functions..................................... 2-14

Table 2-6. KPS Modules, Rear Panels............................................................................... 2-16

Table 2-7. Module KCL.2, Rear Panel ..............................................................................2-18

Table 2-8. MX-2104, Rear Panel Components ................................................................. 2-20

Table 2-9. Typical Terminal Control Sequences ............................................................... 2-22

Table 3-1. MX-2100 Front Panel Configuration Parameters................................................ 3-3

Table 3-2. Procedure for Performing Configuration Activity ............................................... 3-8

Table 4-1. General Command Options .............................................................................. 4-2

Table 4-2. MX-2100 Command Set Index.......................................................................... 4-4

Table 4-3. MX-2100 Controls, Connectors, and Indicators ................................................. 4-8

Table 4-4. Instructions for Displaying Current Configuration Parameters .......................... 4-11

vi MX-2100/2104 Installation and Operation Manual

Page 15

Table of Contents

Table 5-1. Deactivating all the Tests................................................................................... 5-3

Table 5-2. Activating / Deactivating the Monitoring of a Selected Channel ......................... 5-4

Table 5-3. Activating / Deactivating a Main Link Loop........................................................ 5-5

Table 5-4. Activating / Deactivating a Channel Loop .......................................................... 5-6

Table A-1. Common Logic Module KCL.2, Supervisory Port Connector Pin Allocations

for DCE Emulation............................................................................................. A-1

Table A-2. Common Logic Module KCL.2, Supervisory Port Connector Pin Allocations

for DTE Emulation .............................................................................................A-2

Table A-3. Common Logic Module KCL.2, MNG Connector Pin Allocations ...................... A-3

Table A-4. Alarm Relay Connector Pinout......................................................................... A-4

Table B-1. LCD Alarm Messages ........................................................................................ B-1

Table C-1. IP Address Class................................................................................................C-5

Table E-1. System Parameters ............................................................................................ E-1

Table E-2. Main Link Parameters........................................................................................ E-4

Table E-3. Supervisory Port Parameters .............................................................................. E-7

Table F-1. Call-out Parameters......................................................................................... F-10

Table F-2. Dial-out Parameters ........................................................................................ F-16

Table F-3. Network Parameters....................................................................................... F-26

Table F-4. Terminal Programmed Parameters .................................................................. F-28

Table F-5. System Parameters .......................................................................................... F-30

Table F-6. MX-2100 Default Configuration Used with Supervision Terminal .................... F-53

Table F-7. Codes Used by Typical Terminals.................................................................... F-54

MX-2100/2104 Installation and Operation Manual vii

Page 16

Table of Contents

viii MX-2100/2104 Installation and Operation Manual

Page 17

Chapter 1 General Information

1.1 Functional Description

MX-2100/2104 is an advanced, highly versatile user-configurable modular TDM

(Time Division Multiplex) system. The MX-2100/2104 system provides an efficient

and cost-effective method for transmitting data, voice and fax over digital data

services. Access to these services is provided over a variety of standard interfaces

(V.35, RS-530/V.36, RS-232/V.24, X.21, Standard DDS, codirectional G.703,

ISDN, fiber optic, T1, and E1), at data rates ranging from 9.6 to 1536 kbps.

Bandwidth utilization efficiency is 98.5%.

Main System Features

The MX-2100/2104 system can be equipped with various types of input/output

(I/O) modules that provide the required interface for the user data, fax, and voice

channels. The series of I/O modules includes:

• High-speed synchronous data modules operating at a rate of 2.4 through

614.4 kbps – the KHS series of modules

• Low-speed data modules (300 bps to 57.6 kbps or 64 kbps) synchronous and

asynchronous data channels, including statistical multiplexing modules – the

KLS series of modules

• ISDN interface modules – the KHS.U series and KVF.4/S0 series

• 2W and 4W multiple voice channel interface modules that can directly

connect to PBX lines and two-wire telephone sets – the KVC series of modules

• 2W and 4W interface voice/fax low bit rate KVF.4 and KVF.8 modules

• T1 and E1 PBX trunk interface KVF.5 and KVF.6 modules

• Token ring extender module, KTRE

• Ethernet Bridge/Router module, KMBE

• Bypass and multidrop module, KDI (not applicable for MX-2104).

Detailed information on the specific MX-2100 modules can be found in the

separate module Installation and Operation Manuals.

The 3U high MX-2100 unit can be equipped with up to 12 I/O modules. 1U high

MX-2104 unit can be equipped with up to 4 I/O modules.

Functional Description 1-1

Page 18

Chapter 1 General Information MX-2100/2104 Installation and Operation Manual

Note

In this manual, the generic term MX-2100 is used when the information is

applicable to both MX-2100 and MX-2104 equipment versions. If the information is

applicable to only a particular equipment version, this will be specified.

Figure 1-1 illustrates the basic capabilities of the MX-2100 system.

Network

Management Station

Ethernet

Network

Fax

Modem

Stat

Mux

Terminal

SDM

Mux

PAB X

Trunk

Line

Tie Lines

KVF.4

KVF.4

KVF.5

KVC.1M

KVC.1M

KLS.1

KLS.1

KLS.1

KLS.2

KHS.1

KHS.1

KVF.4

SP Port

or SLIP

KCL

I/O Modules

Ethernet Port

MX-2100

KML

-V.35

-RS-530/V.36

-RS-232/V.24

-X.21

-G.703 Codirectional

-Standard DDS

-ISDN

-E1

-T1

-Fiber-Optic

CAD/CAM

Fax

1-2 Functional Description

MX-2100

Supervision Terminal

or TELNET

or SNMP

Figure 1-1. MX-2100 System Applications

Page 19

MX-2100/2104 Installation and Operation Manual Chapter 1 General Information

The MX-2104 system can be equipped with only one main link. The 3U high

MX-2100 system can be equipped with two main link modules. Two main link

modules in an MX-2100 system, can be used in several ways:

• To provide hot-standby redundancy (backup) for the main link, with automatic or

manual switchover in case one of the links fails. For maximum flexibility, MX-2100

allows the preparation of a different configuration for use on the backup link. The

backup link can also use a switched data circuit. The switched circuit can be

established on a PSTN line, using analog modems, or on an ISDN line using an S

or U interface.

• To provide two independent links from the same MX-2100 enclosure. The two

links can operate at different data rates. The dual-link mode can also be used

for providing the equivalent of hot standby protection to critical data channels

(by enabling the priority bumping feature).

• To provide multidrop and bypass capabilities (using a dedicated KDI module).

In addition to main link redundancy, the MX-2100 system reliability can be further

enhanced by installing an additional power supply unit in the enclosure. The

power supplies share the load current, therefore when one of them fails or its

input voltage is disconnected, the other takes over the full load without

disturbance to MX-2100 operation.

The MX-2100/2104 system provides flexible system timing options, with several

main link, and channel timing modes.

The main link timing modes are DTE, DCE, and external DCE. In the DCE and

external DCE modes, the timing reference source can be selected by the user:

• Internal oscillator

• External (timing locked to one of the data channels)

• The other main link module (provided a KDI module is installed).

In addition to the main timing source, a fallback source can be selected. When the

timing mode is DTE or external DCE, buffers are inserted in the main link signal

paths, to absorb the expected jitter and timing instabilities. Normal buffer size is

±8 bits; for operation over satellite links, the receive buffer size can be increased to

±256 bits.

The timing modes available for the data channels are programmable, thereby

permitting each channel to be configured as either DCE (supplies receive and

transmit clocks to the user's equipment), DTE1 (supplies the receive clock and

accept a transmit clock), or DTE2 (accepts receive and transmit clocks from the

user's equipment), with buffered retiming of the received data. Connection to the

national network and to common-carrier data lines is also supported, with the

external clock selectable as the source for system timing.

For modules with ISDN, T1, E1, and fiber-optic interfaces, a loopback timing

mode is available. This mode enables locking the MX-2100 timing to the accurate

timing provided by the network to which the interface is connected.

Functional Description 1-3

Page 20

Chapter 1 General Information MX-2100/2104 Installation and Operation Manual

System Supervision and Configuration

The MX-2100 system is designed for unattended operation. A complete collection

of operating parameters configures the MX-2100 system and each of its modules.

This collection of operating parameters is determined by a database. This database

is stored in the non-volatile memory of the MX-2100 control module. MX-2100

can store two different databases, and can be configured to switch automatically

between the databases, in accordance with a predetermined daily schedule

("day/night" operation), or to use one of the databases only in case of switching to a

backup link.

MX-2100 supervision and minimal configuration functions can be performed from

its front panel, using three push-buttons and an LCD display. For more detailed

information, refer to Local Management on page 1-33.

MX-2100 stores alarms detected during operation in a buffer. The buffer serving

the front panel LCD can store one alarm of each type. The buffer for alarms to be

sent to a supervision terminal can hold up to 100 alarms. During regular operation,

a front panel indicator lights to indicate if there are any alarms in the alarm buffer.

The local operator can then review the contents of the alarm buffer on the front

panel LCD display, and can delete old alarms related to events that are no longer

present in the system.

In addition to the alarm buffer, the front-panel LED indicators display in real time

the main link and power supply status and alert when test loops are present in the

system. The front panel LED indicators can also be used to monitor on-line a

selected user channel. The monitored functions are transmit and receive data

activity, and the state of the RTS and DCD control lines (or E and M lines for voice

channels).

Local MX-2100 Management

A local MX-2100 can be managed by any of the following:

• MX-2100 front panel using push buttons and an LCD

• ASCII terminal connection to the local MX-2100

• TELNET connection to the local MX-2100. The connection can be via SLIP or

via an Ethernet LAN. The local MX-2100 requires an IP address. For

information on assigning an IP address, refer to the DEF AGENT command in

the Command Set Description appendix.

• SNMP network management station connected to the local MX-2100. The

connection can be via SLIP or via an Ethernet LAN. The local MX-2100

requires an IP address. For information on assigning an IP address, refer to the

DEF AGENT command in the Command Set Description appendix.

Remote MX-2100 Management

A remote MX-2100 can be managed either in-band or out-of-band. For both, the

remote MX-2100 requires an IP address. For information on assigning an IP

address, refer to the DEF AGENT command in the Command Set Description

appendix.

1-4 Functional Description

Page 21

MX-2100/2104 Installation and Operation Manual Chapter 1 General Information

In-Band Management

In-band management of a remote MX-2100 is performed via the local MX-2100

and the data frame. A connection to the local MX-2100 can be made through:

• An Ethernet LAN

• A SLIP connection.

In both cases, management can be performed via TELNET. Some of the bandwidth

of the main link between the two MX-2100s is used to relay the management

information.

In a “V” configuration, any one of the three MX-2100s can be considered the local

MX-2100. The other two MX-2100s can be managed through the local MX-2100.

KCL

Remote

MX-2100

A

Main Link

Remote

MX-2100

A

B

Main Link

B

Local

MX-2100

KCL

KCL

Supervision Terminal

or TELNET

or SNMP

Figure 1-2. “V” Configuration

The main link between the local MX-2100 and the remote MX-2100 can also be

used to download software.

Out-of-Band Management

There are several options for managing a remote MX-2100 out-of-band:

• Using a network management station or TELNET over a LAN connected to the

remote MX-2100. The remote MX-2100 requires an IP address. For

information on assigning an IP address, refer to the DEF AGENT command in

the Command Set Description appendix.

Functional Description 1-5

Page 22

Chapter 1 General Information MX-2100/2104 Installation and Operation Manual

• Using a network management station or TELNET via a SLIP connection to the

remote MX-2100. The remote MX-2100 requires an IP address. For

information on assigning an IP address, refer to the DEF AGENT command in

the Command Set Description appendix.

• Using an ASCII terminal via a modem connection to the SP port.

Diagnostic Capabilities

The MX-2100 system provides extensive diagnostics, supervision and maintenance

capabilities for easy maintenance and rapid detection and location of faults.

MX-2100 diagnostics include automatic self-test upon power-up, and on-line

monitoring of critical functions. The system generates time stamped alarm

messages that cover all the significant system events. The time stamp is provided

by a real-time clock with battery backup. The system operator can then perform

comprehensive testing on each type of module, to determine the cause of the

alarm messages and return the system to normal operation.

Various types of test loops are provided, including modem loops 2 and 3 per

ITU-T Rec. V.54 for rapid isolation of the fault area, tone injection for rapid testing

of voice interface modules, and pseudo-random sequence transmission test for

checking the proper operation of data interface modules, and detection of bit

errors.

1.2 Physical Description

MX-2100, General Description

The MX-2100 system consists of a 19" (3U) enclosure that contains 18 module

slots. Five of the slots (slots 1 through 5) are assigned to the system modules:

• The control subsystem

• The main link (aggregate) interface subsystem

• The system power supplies.

Two slots each are assigned for KML and KPS modules, respectively, to provide

support for the redundancy option:

• Slots 1 and 2 - for KPS modules

• Slots 3 and 4 - for KML modules.

One slot (slot 6) is assigned for an options module (e.g., for the KDI or KAI

modules). The other 12 slots are intended for I/O modules. Each I/O slot can

accept any type of I/O module. All the modules are inserted through the rear

panel. The cable connections are also made through the rear panel.

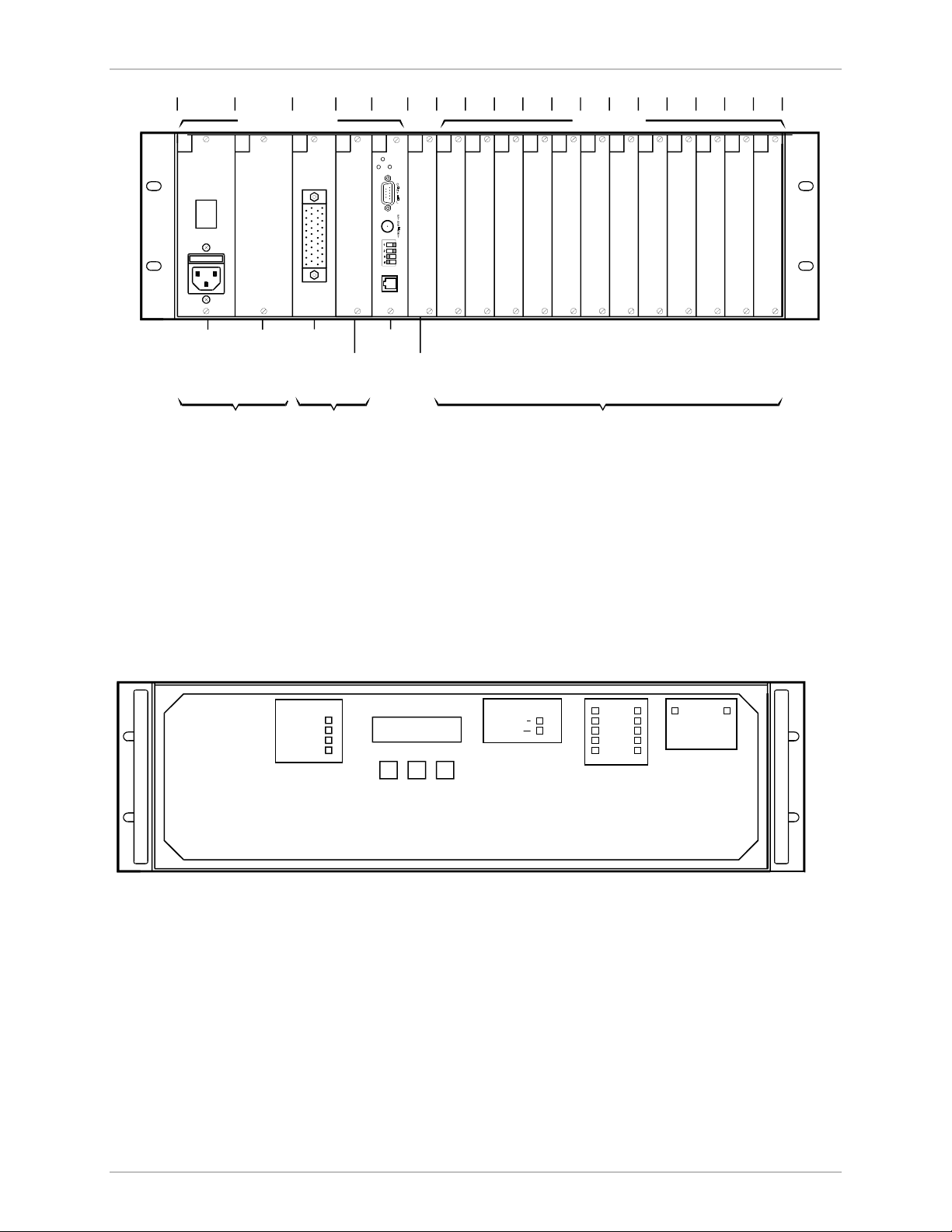

Figure 1-3 shows a general view of a MX-2100, and identifies the functions of the

enclosure slot.

1-6 Physical Description

Page 23

MX-2100/2104 Installation and Operation Manual Chapter 1 General Information

Options

Module

12 I/O

Modules

Power Supply

Sub-system

Common

Logic

Main Link

Interface

Sub-system

Figure 1-3. MX-2100 Enclosure with Modules, General View

MX-2100 Rear Panel

Figure 1-4 shows a typical rear panel of the MX-2100 enclosure and identifies the

slots and their use.

Note the labels which designate the type of module that can be installed in each

slot; in addition, each slot is keyed, therefore it is not possible to install the wrong

module type.

Physical Description 1-7

Page 24

Chapter 1 General Information MX-2100/2104 Installation and Operation Manual

Slot 1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

System Slots I/O Slots

1

PS-A

Power

Supply

2

PS-B

POWER

Redundant

Power

Supply

(Optional)

Power Supply

Sub-system

3

ML-AKPS

KML.1

KML

Module

Main Link Interface

Sub-system

MX-2100 Front Panel

The front panel of the MX-2100 enclosure includes an LCD, three push-buttons,

and labels for the show-through areas for the status indicators located on each

system module. Note that the indicators are arranged in groups (one group for

each system module), that are positioned before the corresponding module slot.

4

ML-B5CL6OP

Redundant

KML Module

(Optional)

KCL.2

RESET

ALARM

TEST

ALM RLY

KCL

Module

7

I/O18I/O29I/O310I/O411I/O512I/O6

Options

Module

I/O Modules

as Required

Figure 1-4. MX-2100 Enclosure, Rear View

13

I/O714I/O815I/O916I/O10

17

I/O1118I/O12

Figure 1-5 shows the front panel of the MX-2100 enclosure. Refer to the Operation

chapter for a description of the front panel functions.

DATAVOICE

TXD

RXD

RTSM-LEAD

E-LEAD DCD

CHANNEL

CURSOR SCROLL ENTER

Figure 1-5. MX-2100 Enclosure Front Panel

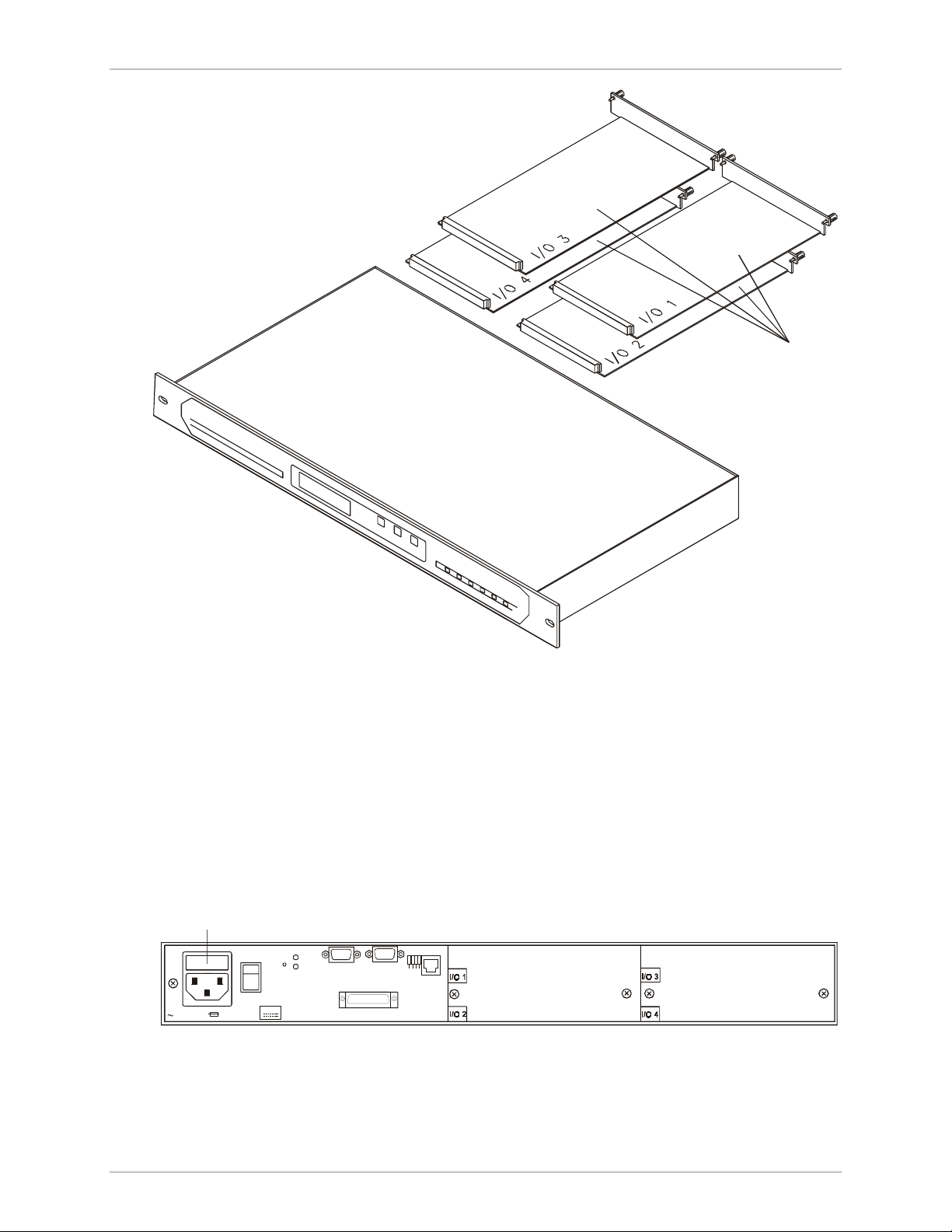

MX-2104, General Description

The MX-2104 system consists of a 19" 1U enclosure with 4 slots for the installation

of I/O modules. All the modules are inserted through the rear panel. The cable

connections are also made through the rear panel. The front panel includes a

control section with three push-buttons and a two-row LCD display

(16 characters per row), and status and alarm indicators.

STATUS

ALARM

TEST

SYSTEM

ON LINE

LOCAL LOS

REMOTE LOS

B

MAIN LINK

TXD

RXD

A

ON LINE

BA

POWER SUPPLY

The following figure shows a general view of a MX-2104 enclosure.

1-8 Physical Description

Page 25

MX-2100/2104 Installation and Operation Manual Chapter 1 General Information

4 I/O Modules

The MX-2104 enclosure contains the control sub-system, the main link (aggregate)

sub-system and the system power supply.

The main link sub-system performs main link interfacing, multiplexing and

demultiplexing functions, and provides the timing signals used by the I/O modules

installed in the enclosure.

MX-2104 Rear Panel

The following figure shows a typical rear view of the MX-2104 enclosure and

identifies the I/O slots.

FUSE

RST

ALM

TST

100-24 0VAC 0.8A T 25 0V

∼

Power

Figure 1-6 MX-2104 Enclosure, General View

ON

X.21

MNG

1234

ALM RLY

CONTROL

Figure 1-7. MX-2104 Enclosure, Rear View

Physical Description 1-9

Page 26

Chapter 1 General Information MX-2100/2104 Installation and Operation Manual

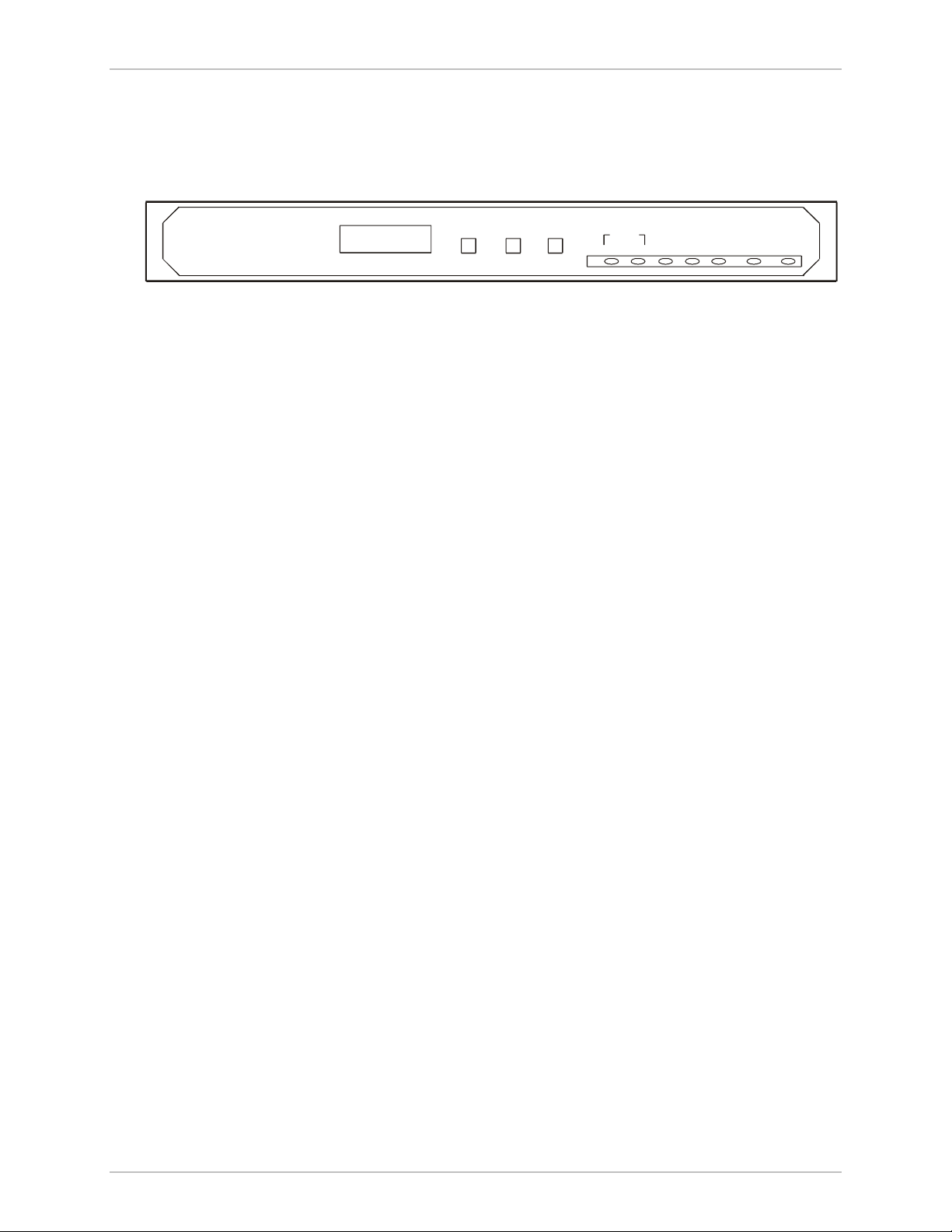

MX-2104 Front Panel

The following figure shows the front panel of the MX-2104 enclosure. The front

panel includes an LCD, three push-buttons, and status indicators. Refer to the

Operation chapter for a description of the front panel functions.

Common Logic Modules

The MX enclosure requires one KCL.2 type common logic module. The main

functions of the KCL.2 module are control of:

• Multiplexing/demultiplexing operations

• System management

• Interfacing with the optional external system management.

The KCL.2 module stores the MX-2100 database in non-volatile memory

(NVRAM). The configuration information stored in the NVRAM is downloaded to

the module installed in MX-2100 upon turn-on or after system reset. Therefore,

during troubleshooting activities, it is possible to temporarily remove the KCL.2

module from the MX-2100 enclosure without disrupting system operation. If it is

necessary to replace the KCL.2 module, the database can be transferred to a new

module by installing the NVRAM taken from the original module in the

replacement module.

CURSOR SCROLL ENTER

REM

LOS

LOC

Figure 1-8. MX-2104 Enclosure Front Panel

RX TX

ON

LINE

TEST

ALARM

Main Link Modules

The enclosure can accept one KML type main link interface module or, for

MX-2100, two KML type main link interface modules. In addition to main link

interfacing, the KML module performs the multiplexing and demultiplexing

functions and provides the timing signals used by the other modules installed in

the enclosure. Two KML modules are necessary for dual link configurations and for

main link redundancy.

The following main link interface modules are available:

KML.1 - V.35 main link interface module

KML.2 - V.24/RS-232 main link interface module

KML.3 - V.36/RS-422/RS-530 main link interface module

KML.4 - X.21 main link interface module

KML.5 - G.703 codirectional main link interface module

KML.6 - Standard DDS CSU/DSU main link interface module

KML.7 - T1 main link interface module

KML.8 - E1 main link interface module.

1-10 Physical Description

Page 27

MX-2100/2104 Installation and Operation Manual Chapter 1 General Information

KML.10 - ISDN main link interface module. The module can be ordered in two

versions:

• KML.10/S with ISDN S-type interface. The "S" interface operates as Terminal

Adapter (TE side), intended for connection to standard Network Termination

(NT) unit.

• KML.10/U with ISDN U-type interface. The "U" interface operates as Network

Termination (NT side) unit, intended for connection to standard Line

Termination (LT) unit.

KML.F - Fiber-optic main link interface module (not for MX-2104). The module

can be ordered with various types of optical interfaces (laser or LED transmitters

for single-mode and multi-mode fiber-optic cable).

For more information, see each main link module’s Installation and Operation

Manual.

Power Supply Modules

The MX-2100 enclosure can accept one or two KPS type power supply modules.

Several types of power supply modules are available:

KPS.3 - 25W power supply module for -48 VDC power

KPS.4 - 50W power supply module for 100 to 240 VAC mains

KPS.5 - 25W power supply module for -24 VDC power

KPS.6 - 56W power supply module for 100 to 240 VAC mains

KPS.7 - 56W power supply module for -48 VDC mains.

Two KPS modules are necessary for redundancy: when both modules are

operational, they share the load, whereas in case of failure or loss of input power

the remaining module continues to supply the power alone and there is no

redundancy. Switch-over is automatic and does not disturb normal operation.

The MX-2104 enclosure includes one power supply. The available types are:

• AC - 30W power supply for 100 to 240 VAC mains

• 48 - 40W power supply for -48 VDC mains.

In addition to power supply modules, the MX-2100 enclosure supports one

KM-Ringer module, for providing line feed and ring voltages for voice channels

and phantom feed for ISDN lines. This module is available in AC (115 to 230 VAC)

and DC (-24 VDC or -48 VDC) input voltage versions. The KM-Ringer can be

installed as a plug-in module for MX-2100, or located on shelves or desktops.

Physical Description 1-11

Page 28

Chapter 1 General Information MX-2100/2104 Installation and Operation Manual

Option Modules (not for MX-2104)

The 3U MX-2100 system can accept two types of options module:

KAI

Alarm indication module for installation in the options position, or in any I/O slot.

The KAI includes indicators similar to those located on the MX-2100 front panel.

These indicators repeat all the relevant MX-2100 front panel indications on the

rear panel, and thus complement the indicators available on the rear panels of the

other modules. Maintenance activities are thus expedited, as all the MX-2100

indications become readily available on one side of the equipment.

KDI

Bypass and multidrop module. The KDI module can be installed in the option slot,

or in any I/O slot. The KDI module enables direct transfer (bypassing) of a group of

main link frame bits, in both directions, between the two main links of MX-2100.

Channels that are not bypassed are connected to I/O modules of MX-2100.

The KDI module is available in two versions:

• KDI version: supports only the bypassing function

• KDI/M version: also includes a data channel interface for one multidrop channel.

The multidrop channel is compatible with the data channels of the KLS.1/NEW

low-speed data module, and supports data rates in the range of 0.3 to 64 kbps. As

is standard practice in a multidrop application, the receive path of the local

multidrop channel continuously receives the data transferred in its allocated

bandwidth on the desired main link (the same data is also bypassed to the other

link, to make it available downstream), but its transmit path is connected to the

main link only when the RTS line in the local interface is asserted.

I/O Modules

For more information, see the option module’s Installation and Operation Manual.

MX-2100 supports up to 12 user-selected I/O modules. MX-2104 supports up to 4

user-selected I/O modules. Both units can accept any combination of the following

types of I/O modules with power supply limitations.

KVC.1 - ADPCM or PCM voice interface module, provides two voice channels. For

more information, refer to the KVC.1 Installation and Operation Manual.

The following versions are available:

− KVC.1/E&M: four-wire or two-wire interface with E&M signaling per

RS-464 Types I, II, III and V, and British Telecom SSDC5

− KVC.1/FXS: two-wire interface for direct connection to a telephone set

− KVC.1/FXO: two-wire interface for direct connection to a PBX extension

line.

1-12 Physical Description

Page 29

MX-2100/2104 Installation and Operation Manual Chapter 1 General Information

• KVC.1M - ADPCM or PCM voice interface module, provides one or two voice

channels and support error-free fax transmission. For more information, refer

to the KVC.1M Installation and Operation Manual.

The following versions are available:

− KVC.1M/E&M: two voice channel with four-wire or two-wire interface with

E&M signaling per RS-464 Types I, II, III and V, and British Telecom SSDC5

− KVC.1M/E&M48: similar to the KVC.1M/E&M, except that it requires an

external -48 VDC source to supply the signaling voltage for increasing the

maximum allowed line length

− KVC.1M/FXS: two voice channels with two-wire interface for direct

connection to a telephone set

− KVC.1M/FXSP: similar to KVC.1M/FXS, except that it has an internal ringer

and line feed supply

− KVC.1M/FXO: two voice channels with two-wire interface and FXO loop

start signaling for direct connection to a PBX extension line.

• KVC.3 - Low-bit rate voice module, provides two high-quality compressed

voice channels. For more information, refer to the KVC.3 Installation and

Operation Manual.

The following versions are available:

− KVC.3/E&M: two voice channels with four-wire or two-wire interface with

E&M signaling per RS-464 Types I, II, III and V, and British Telecom SSDC5

− KVC.3/FXS: two voice channels with two-wire interface for direct

connection to a telephone set

− KVC.3/FXSP: similar to KVC.3/FXS, except that it has an internal ringer and line

feed supply

− KVC.3/FXO: two voice channels with two-wire interface and FXO loop start

signaling for direct connection to a PBX extension line.

• KLS.1 - Low-speed RS-232 data module. For more information, refer to the

KLS.1 Installation and Operation Manual.

• KLS.2 - Low-speed RS-232 four-channel asynchronous statistical data module.

For more information, refer to the KLS.2 Installation and Operation Manual.

• KHS.1 - High-speed data interface module, provides two high-speed V.35,

RS-530 or RS-449/RS-422 data channels. For more information, refer to the

KHS.1 Installation and Operation Manual.

• KHS.2 - Two-channel synchronous data module. For more information, refer

to the KHS.2 Installation and Operation Manual.

Physical Description 1-13

Page 30

Chapter 1 General Information MX-2100/2104 Installation and Operation Manual

• KHS.U - Data interface module, provides one or two ISDN basic access rate

type "U" interfaces. The KHS.U module enables the extension of ISDN lines

over non-ISDN facilities. For more information, refer to the KHS.U Installation

and Operation Manual.

The following versions are available:

− KHS.U/S with one "U" interface

− KHS.U/D with two "U" interfaces.

• KHS.703 – High-speed data module that provides two independent 64 kbps

codirectional data channels per ITU-T Rec. G.703. Each module is terminated

with an RJ-45 eight pin connector. For more information, refer to the KHS.703

Installation and Operation Guide, further on in this manual.

• KVF.4 - Voice/fax relay module using advanced digital signal processing (DSP)

techniques (MPMLQ in accordance with ITU-T Rec. G.723.1) to provide one

or two channels for transmission of voice and standard Group III fax signals

over the MX-2100 link with automatic switch-over between voice and fax

modes. For more information, refer to the KVF.4 Installation and Operation

Manual.

The following versions are available:

− KVF.4/E&M: two channels with four-wire or two-wire interface with E&M

signaling per RS-464 Types I, II, III and V, and British Telecom SSDC5

− KVF.4/E&M/E: similar to the KVF.4/E&M, except that it requires an external

-48 VDC source to supply the signaling voltage for increasing the maximum

allowed line length

− KVF.4/FXS: two voice channels with two-wire interface for direct

connection to a telephone set

− KVF.4/FXS3: similar to KVF.4/FXS, except that it supports pulse metering

and polarity reversal

− KVF.4/FXSP: similar to KVF.4/FXS, except that it has an internal ringer and

line feed supply

− KVF.4/FXSW: one channel similar to the channels of the KVF.4/FXS, and

one two-wire interface operating with FXO signaling, intended for

connection to the PSTN, or to a PBX extension line

− KVF.4/FXO: two channels with two-wire interface and FXO loop start

signaling for direct connection to a PBX extension line