INSTALLATION GUIDE EN

PELLET STOVE

TOBA HYDRO

HYDRO 22

HYDRO 22 WITH HIGH EFFICIENCY PUMP

HYDRO 22 WITH EXCHANGER

PART 2 - OPERATION AND CLEANING

Instructions in English

TABLE OF CONTENTS

TABLE OF CONTENTS ...................................................................................... II

9 PRECAUTIONS BEFORE STARTUP ................................................................ 3

10 CONTROL PANEL ..................................................................................... 4

11 FIRST STARTUP ...................................................................................... 5

12 MENU STRUCTURE................................................................................... 7

13 MENU INFORMATION ..............................................................................11

14 MENU SETTINGS ....................................................................................14

15 TECHNICAL MENU ..................................................................................32

16 SAFETY DEVICES AND ALARMS .................................................................33

17 RECOMMENDATIONS FOR A SAFE USE ........................................................38

18 MAINTENANCE AND CLEANING .................................................................39

19FAULTS/CAUSES/SOLUTIONS .....................................................................47

20 CIRCUIT BOARD .....................................................................................50

II

9 - PRECAUTIONS BEFORE START-UP

GENERAL PRECAUTIONS

Remove any objects that may burn from the brazier (manual, various adhesive labels or any remaining polystyrene).

Check that the brazier is positioned correctly and rests properly on the base.

The rst start-up may not be successful as the feed screw is empty and does not always manage to load the required

amount of pellets in time to light the ame.

CANCEL THE ALARM FOR THE LIGHTING FAILURE BY HOLDING DOWN BUTTON 1 (ESC). REMOVE THE PELLET LEFT IN THE

BRAZIER AND REPEAT THE START-UP.

If after repeated attempts, the ame fails to ignite, despite a regular ow of pellets in the brazier, check that the brazier is seated correctly:

it must rest snugly against the slots and be clean of any ash incrustations. If no anomaly is found during this inspection, there

may be a problem with the product components or installation may not be correct.

REMOVE THE PELLETS FROM THE BRAZIER AND CONTACT AN AUTHORISED TECHNICIAN.

Do not touch the boiler during the rst lighting, as it is during this phase that the paint sets.

If necessary, touch up the paint with the aerosol spray in the original colour (see ''Accessories for pellet stoves'').

It is good practice to ensure eective ventilation in the room during the initial start-up, as the boiler will emit some

smoke and smell of paint.

ATTENTION!

Please ensure the brazier is clear of ALL pellets and ash build up following any failed ignitions. Failure to clear out

the brazier prior to resetting may result in further failed ignitions or in certain conditions an explosive ignition.

Do not stand close to the stove and, as mentioned, air the room. The smoke and smell of paint will disappear after about an hour of

operation, however, they are not harmful in any case.

The boiler will be subject to expansion and contraction during the lighting and cooling down stages, and may therefore make slight

creaking noises.

This is absolutely normal as the structure is made of laminated steel and must not be considered a defect.

It is extremely important to make sure the boiler does not reach high temperatures straight away, but to increase the temperature

gradually using low power at rst.

This will prevent damaging the ceramic or serpentine stone tiles, the welds and the steel structure.

DO NOT EXPECT HEATING EFFICIENCY IMMEDIATELY!!!

ATTENTION!

If during operation or initial ignition you encounter smoke spillage in to the room from the appliance

or the ue then please switch o the appliance, ventilate the room and contact the installation / service

engineer immediately.

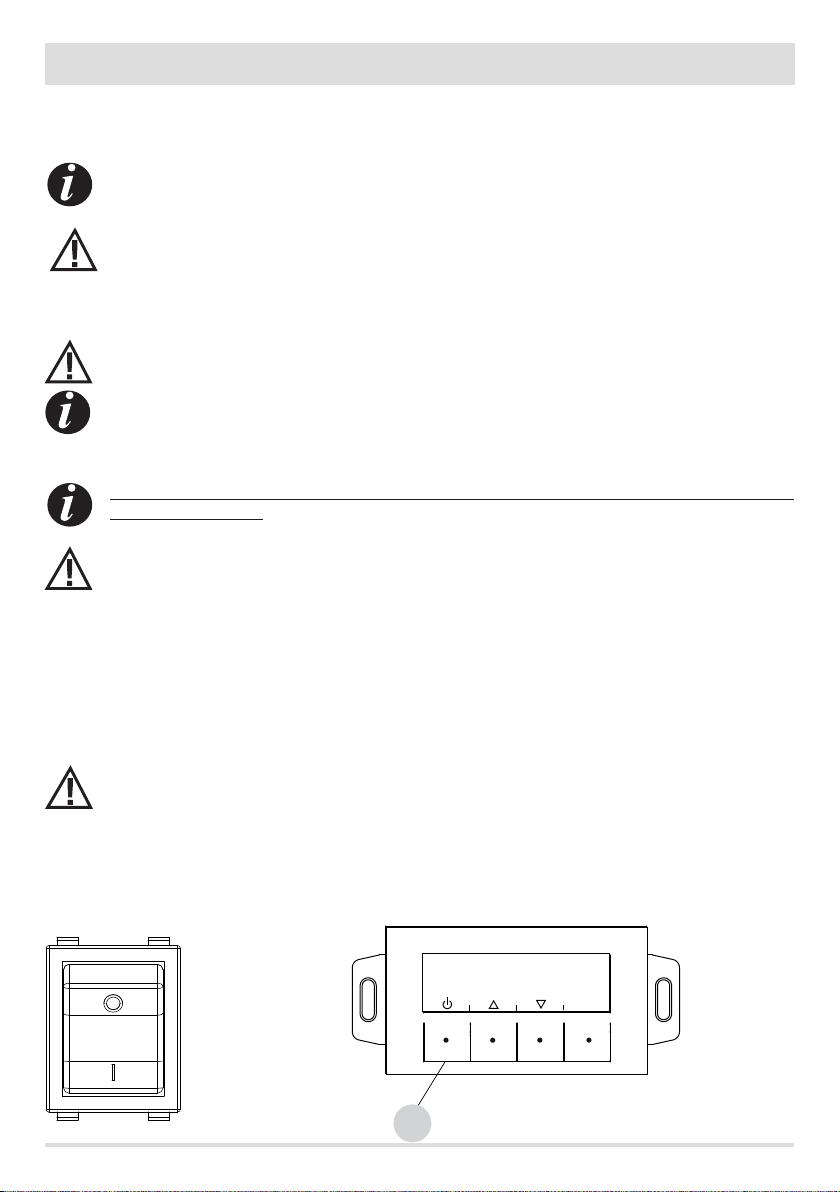

SETTINGS TO BE CARRIED OUT BEFORE THE INITIAL START-UP

After connecting the power cable to the electrical socket, turn the power switch to the (I) position. To turn the stove on or o, press the

button “B” on the control panel.

OFF

ON

Technical Dept. - All rights reserved - Reproduction is prohibited

MENU

B

3

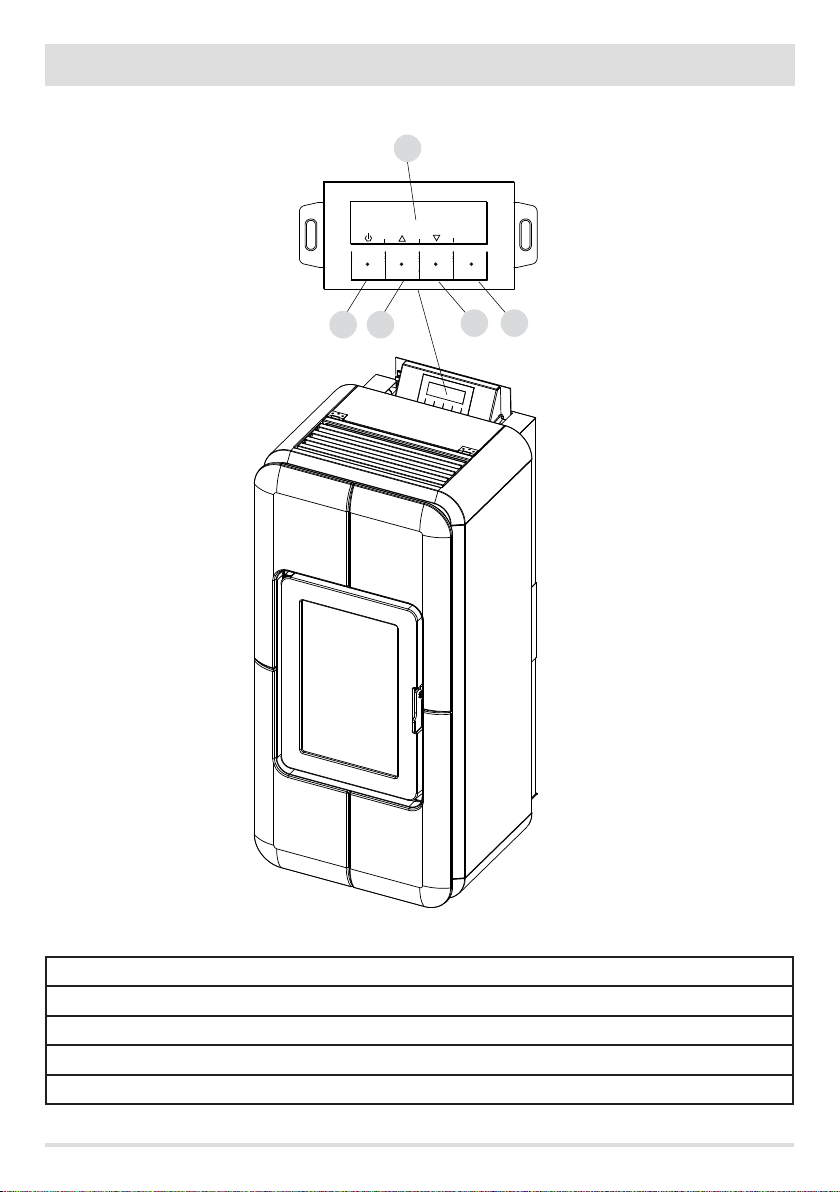

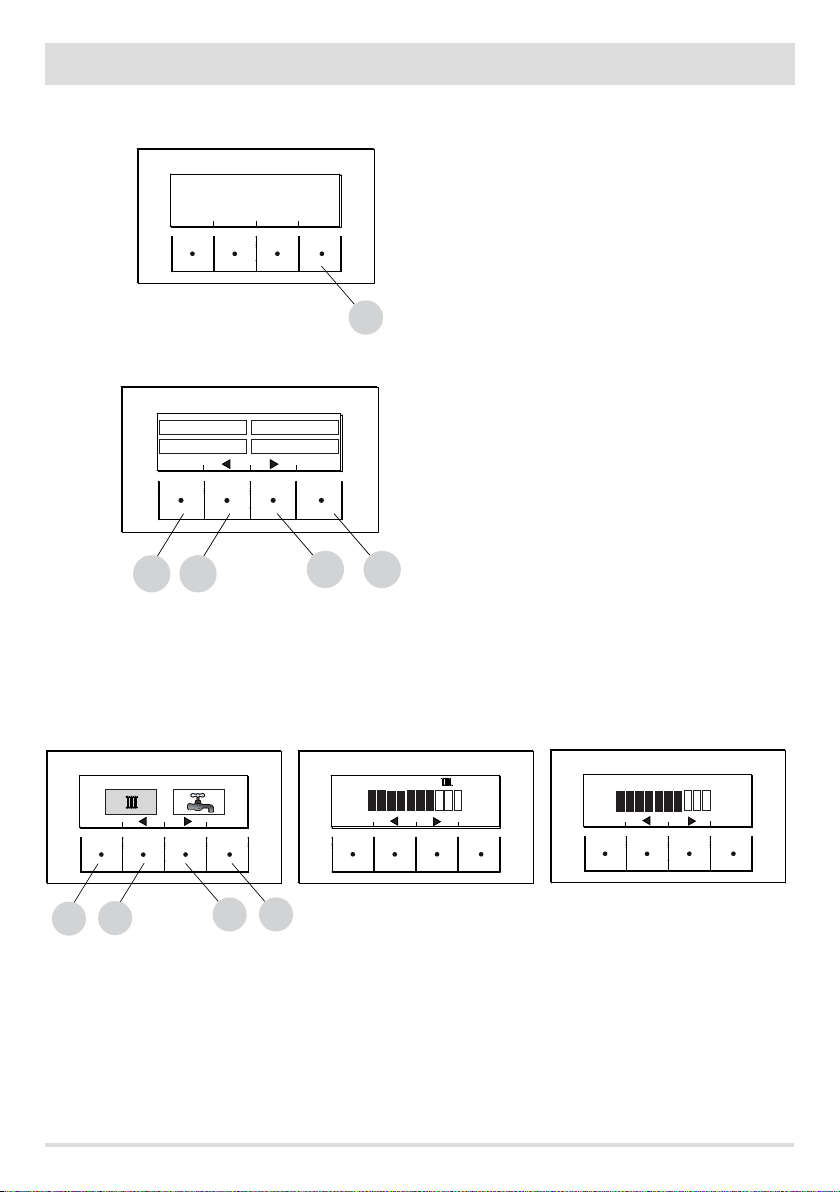

10 - CONTROL PANEL

CONTROL PANEL DISPLAY

B C

A

MENU

E

D

KEY

A - DISPLAY; indicates a series of information on the stove, as well as the identication code of any malfunction.

B - Function selection key indicated by the upper display (i.e. start-up/shutdown)

C - Function selection key indicated by the upper display (i.e. increase/scrolling)

D - Function selection key indicated by the upper display (i.e. decrease/scrolling)

E - Function selection key indicated by the upper display (i.e. menu)

4

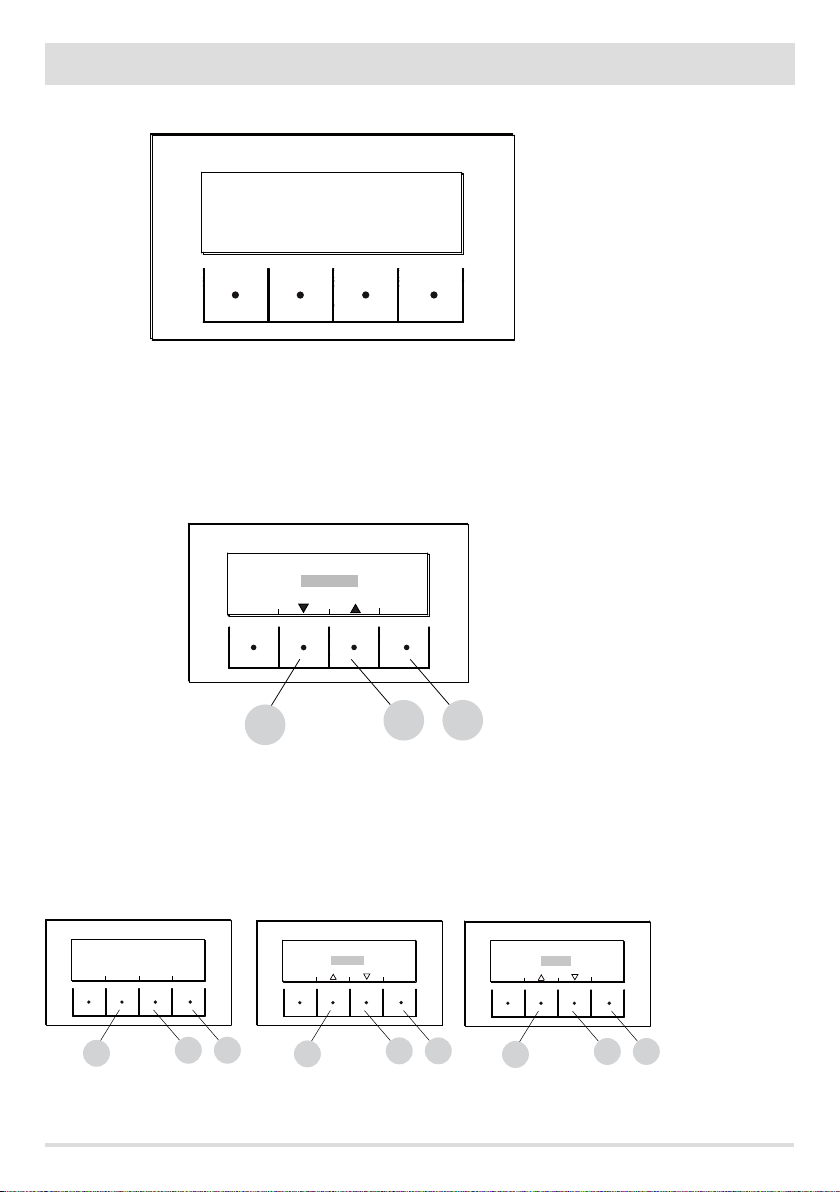

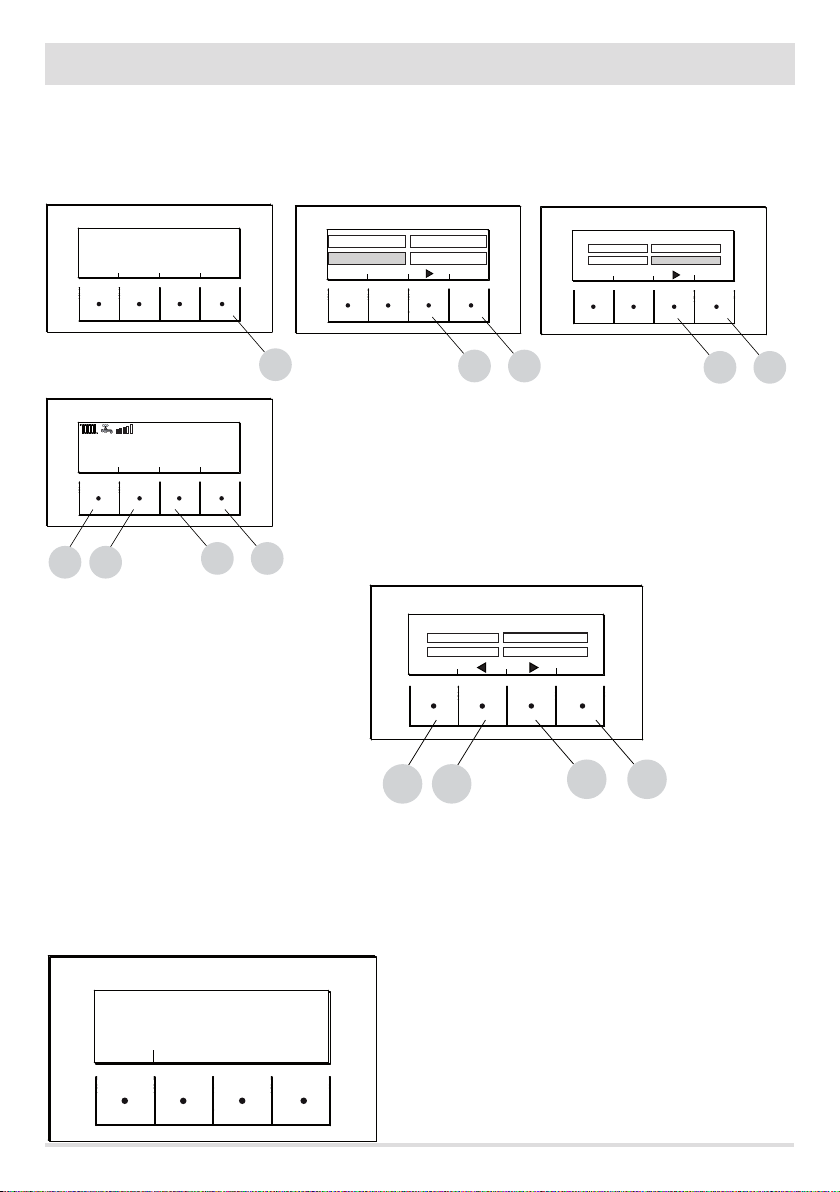

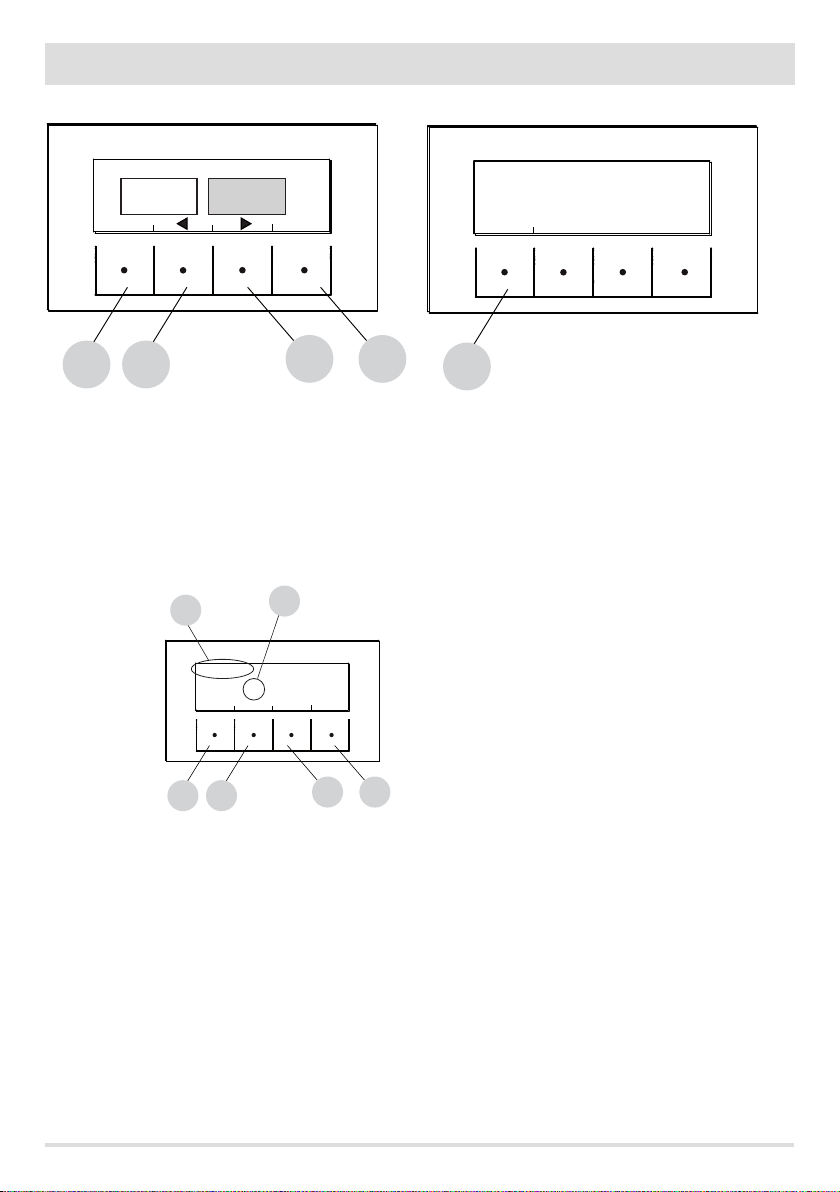

11 - FIRST START-UP

START BUTTON

PRODUCT TYPE VERSION

At initial start-up, after connecting the power cable and pressing the I/O button, the stove display will show wording for the software

version and database number (after a few seconds it will move on to the next screen).

If the language has already been set, the next screen will be OFF, otherwise one enters the following parameter.

SELECT LANGUAGE

At initial start-up, if it has never been set, the LANGUAGE choice screen appears.

LANGUAGE

ITALIANO

ENGLISH

ESPANOL

C

The system displays all possible languages.

Using the arrow keys (C, D) scroll the languages and conrm the desired language using the “E” (OK) key.

OK

D

E

SETTING TIME AND DAY

The keys that are active for this function are: “B”,“C”, “D”, “E”. The C-D keys are used to choose time or day while the E key is used to conrm.

TODAY IS MONDAY AND IT IS

21.25

CHANGE

CHANGE

DAY

C

OK

TIME

E

D

Technical Dept. - All rights reserved - Reproduction is prohibited

TODAY IS MONDAY AND IT IS

21.25

C

TODAY IS MONDAY AND IT IS

OK

E

D

21.25

C

OK

E

D

5

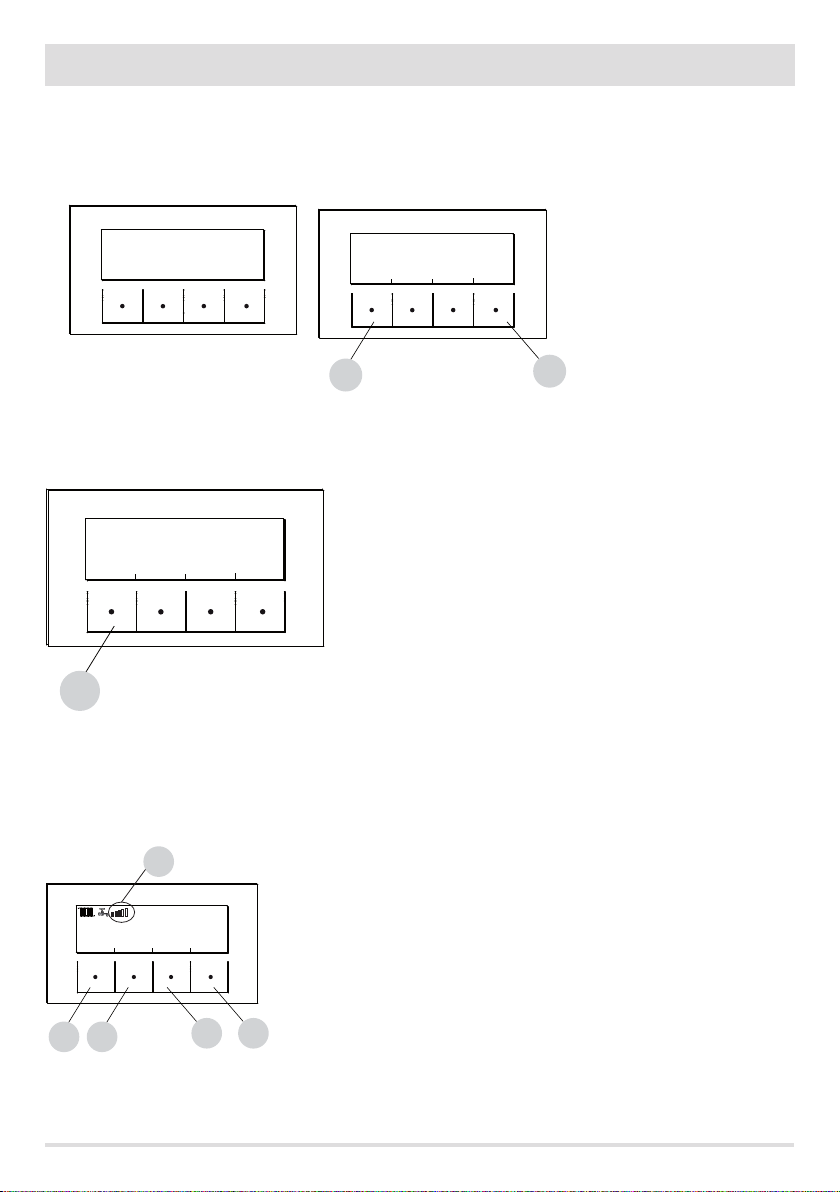

10 - CONTROL PANEL

SCREEN OFF

If a LANGUAGE has already been set, the display will go to OFF.

By pressing any one of the keys (B, C, D, E) the rst screen will appear with the wording OFF displayed. From this screen, pressing keys "B"

and "E" (respectively corresponding to ON and MENU) will make it possible to access the panel or the menu. If no key is pressed, the display

will once again show OFF after 5 seconds.

OFF

ON

B

OFF-DISPLAY OFF OFF-DISPLAY ACTIVE

ECO

MENU

E

Lighting the stove

To switch on the stove, keep the "B" (ON) key on the panel pressed. The stove starts an ignition procedure that brings the ame to a

suitable level to Supply Power.

ECO

OFF

ON

MENU

B

Supplying power

The power supply of the stove is indicated by “power level bars”: one bar corresponds to minimum power, 5 bars to maximum power;

this level is determined by the heating system heat requirements, the stove adjusts pellet loading parameters, fumes extraction, and

combustion air ow to comply with this requirement.

1

10:13 TIMER1 ECO

25°

23° AUTO

OFF

TEMP VENT

C

B

MENU

D

E

UPPER BAR: active requirements, active programmes, power bar, functions

CENTRAL BAR: room temperature, room set, room fan bar

LOWER BAR/KEYS: shut-o “B”, temperature set modify “C” and menu “E''

1 = power level bars

6

12 - MENU STRUCTURE

MENU STRUCTURE

To enter MENU press the "E" key (MENU).

OFF

ON

ECO

MENU

E

Next, this screen with the following functions is displayed:

TEMPERATURES

INFORMATION

EXIT

C

B

TEMPERATURE

When accessing this function, the main screen makes it possible to set heating and sanitary water temperature (if the boiler with probe

is congured - see menu settings input aux).

Select what is to be set and then using the C and D keys increase/decrease the temperature, use the E key to conrm while the B key is

used to exit and return to the main MENU.

PROGRAMS

SETTINGS

OK

Sub-menu

TEMPERATURE

PROGRAMMES

INFORMATION

SETTINGS

D

E

TEMPERATURE BUFFER

EXIT

EXIT

TEMPERATURES

71°

OK

TEMPERATURES

EXIT

C

B

OK

E

D

PROGRAMMES

In this case it is possible to choose the programme to be set.

Programme selection makes it possible to choose between one of the following options (one choice excludes the other):

TIMER 1

TIMER 2

MANUAL

TEMP. LEVELS

SLEEP FUNCT.

Technical Dept. - All rights reserved - Reproduction is prohibited

50°

OK

7

12 - MENU STRUCTURE

B

C

TEMPERATURES

INFORMATION

EXIT

PROGRAMS

SETTINGS

OK

D

E

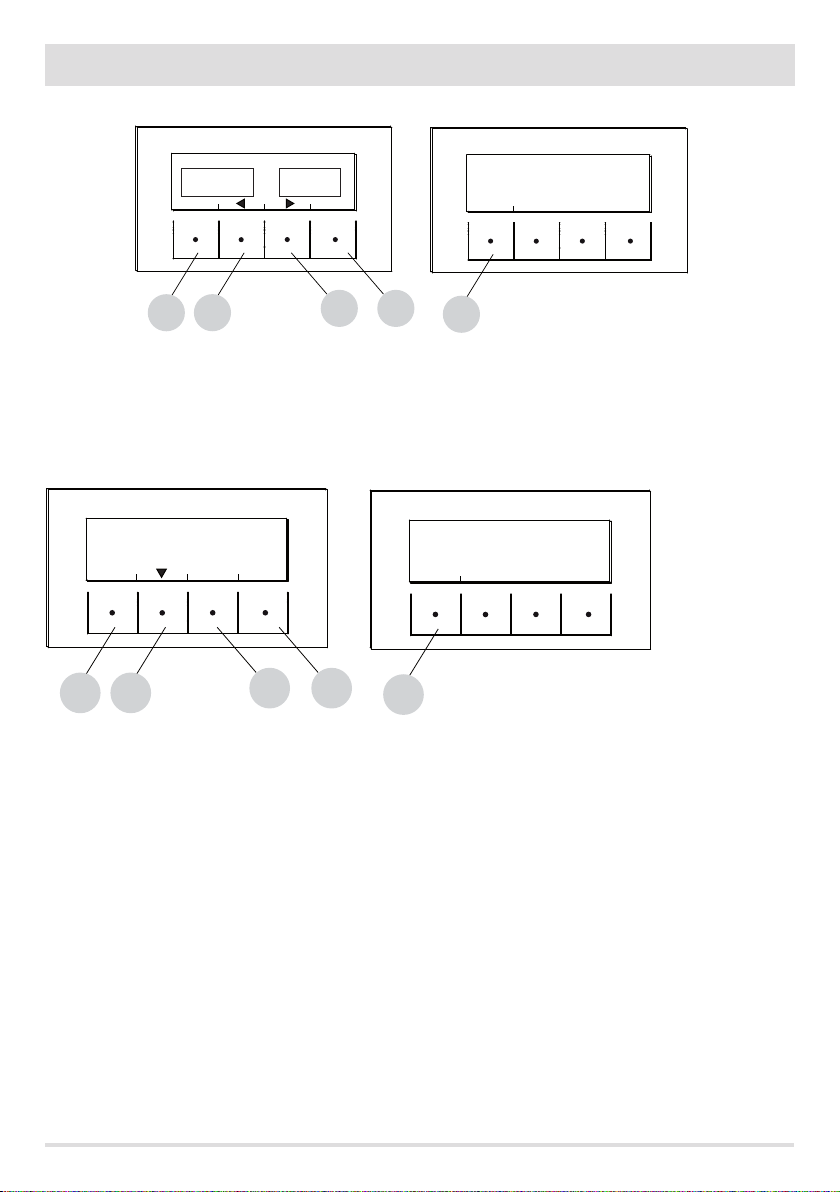

PROGRAM SELECTION

TIMER 1 TIMER 2

TEMP.LEVELS FUNCT. SLEEP

ACTIVATE

EXIT ENTER

MANUAL

In the MENU screen, move the cursor with arrows "C"-"D" and select PROGRAMS, press ok "E" to conrm. Next select the programme you

wish to set.

Once completed, always press “ACTIVATE” to conrm the choice of programme.

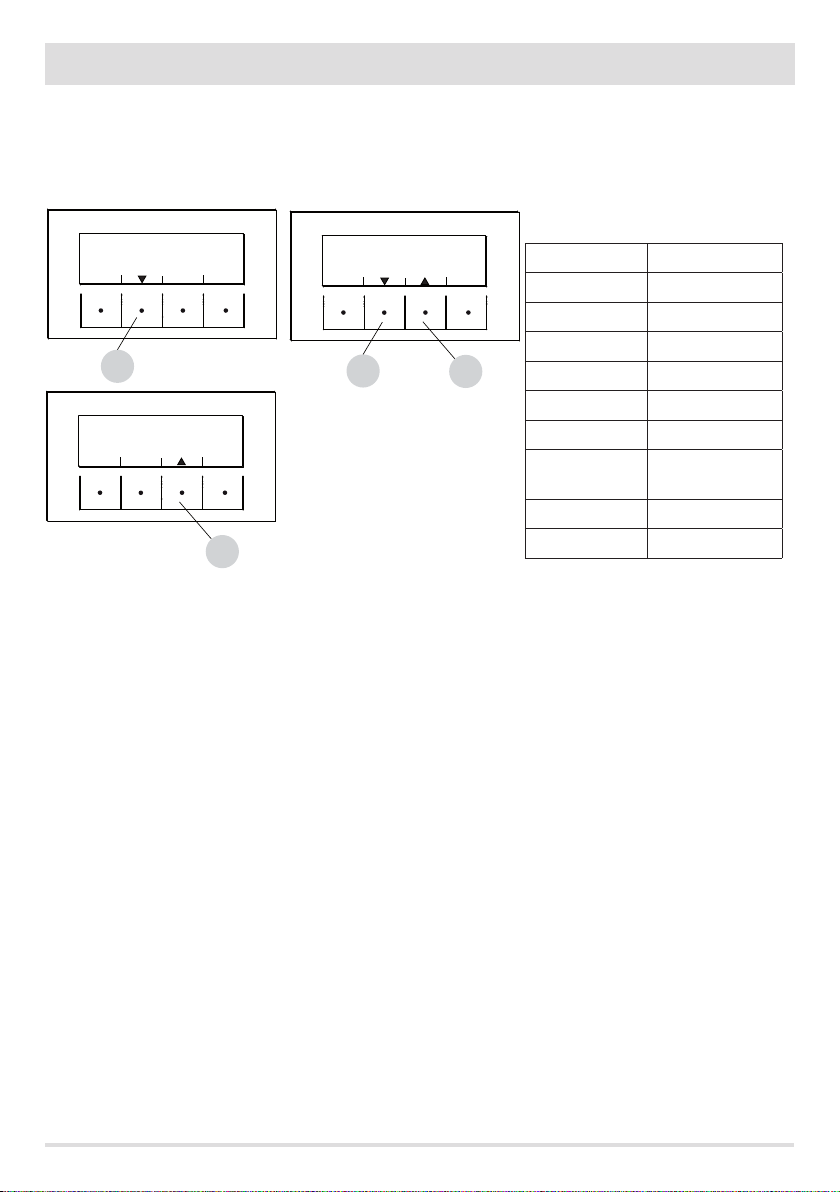

The TIMER 1 and 2 programs are freely programmable for each 1/2 hour of the day on three dierent temperature indicators (T1-T2-T3)

and in dierent ways for each day of the week. The OFF level requires that the stove is switched o in that interval.

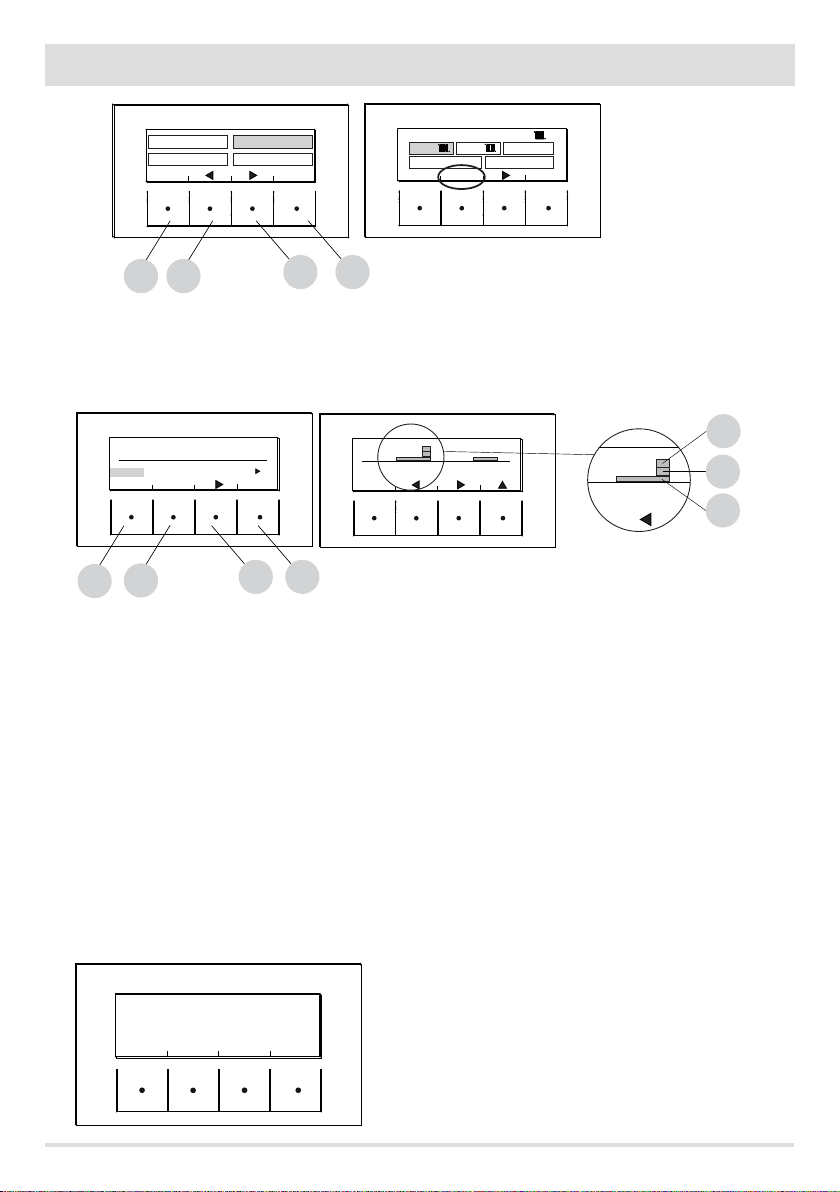

TIMER 1

0 246 12 18

MONDAY TUESDAY WEDNESDAY

COPY

EXIT

C

B

TIMER 1

0 246 12 18

MONDAY

OK

E

D

10:00 20°C

SAVE

6 12

10:00

T3

T2

T1

Example of temperature programming for Monday.

Select the TIMER 1 item from the PROGRAM menu and press the ENTER “E” key, using arrow “D” highlight Monday and press OK (“E”) to

enter programming.

Using the centre arrow keys “C” and “D” select the half hour interval to be selected and use the “E” key to set the temperature T1-T2-T3

(depending on whether the key is pressed 1-2-3 times, the corresponding temperature can be read in the bottom right of the display).

Once temperature programming for Monday is complete press the ''B'' SALVA (SAVE) key. If the same temperature scale of Monday is

desired for other weekdays, after saving ("E" key) press the "C" key (COPIA-COPY), select the day where the programme is to be copied

using the "D" key and press the "C" key (INCOLLA-PASTE). Repeat the same procedure until the programmes for all weekdays are complete.

At this point the stove is programmed according to your temperature needs, which can be modied at any time.

CAUTION:

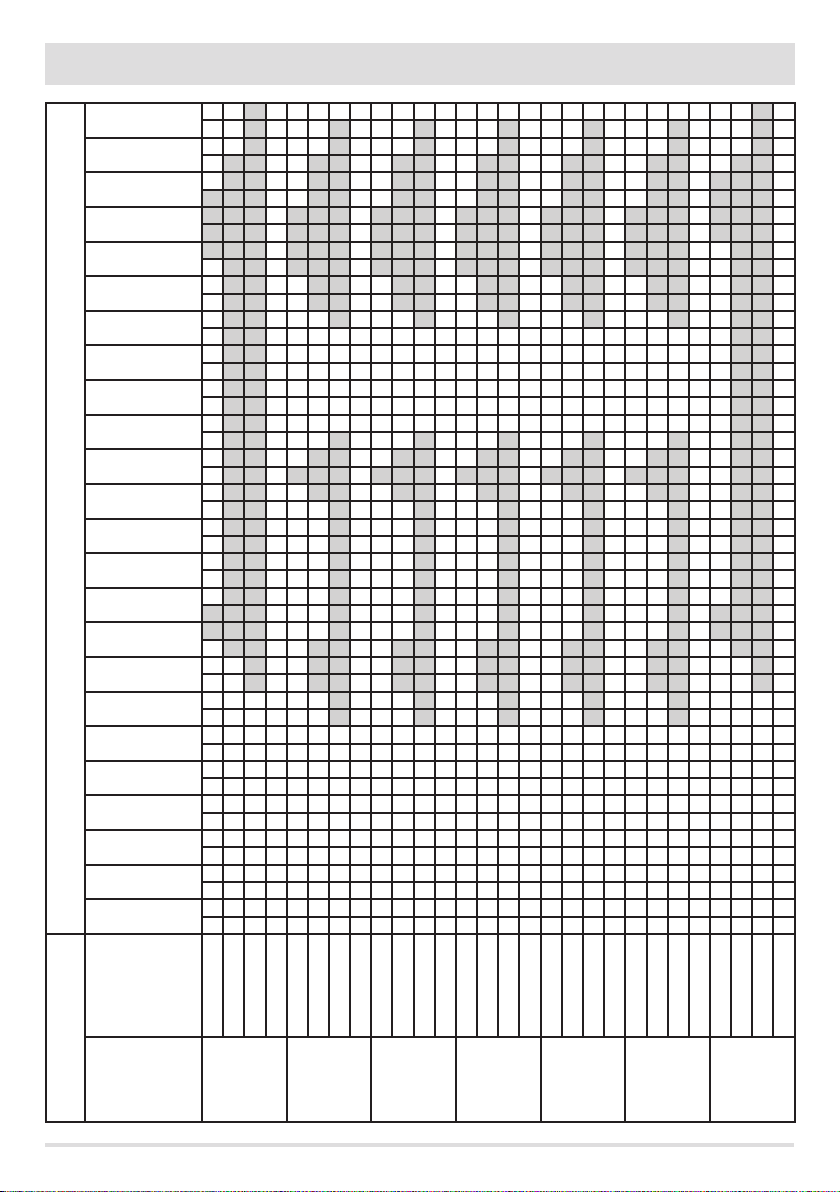

In order to make stove use easier, MCZ supplies Timer 1 with preset weekly temperatures and times (according to the table below), while

Timer 2 is empty. In any case, it is possible to change times and temperatures of Timer 1 at any time.

PANEL OFF DISPLAY FROM TIMER

When timer 1 (for example) has no set temperature, the panel highlights that the stove is in OFF position.

If the stove is o by MANUAL command, the timer will

OFF

03:33 TIMER 1

16° OFF

MENU

have no eect.

For the stove to come on with the timer, the panel must

display the image shown on the side; if this should not

be the case, it may be necessary to press the ON (“B”)

key.

8

12 - MENU STRUCTURE

23:00

22:00

21:00

20:00

19:00

18:00

17:00

16:00

15:00

14:00

13:00

12:00

11:00

Time table

10:00

09:00

08:00

07:00

06:00

05:00

04:00

03:00

02:00

01:00

00:00

T3T2T1

OFF

T3T2T1

OFF

Temperatures*

Weekly programmes

Days

Sunday

Monday

* T1=16°C T2=20°C T3=22°C OFF=switched o

Technical Dept. - All rights reserved - Reproduction is prohibited

T3T2T1

Tuesday

OFF

T3T2T1

Wednesday

OFF

T3T2T1

Thursday

OFF

T3T2T1

Friday

OFF

T3T2T1

Saturday

OFF

9

12 - MENU STRUCTURE

MANUAL

This function can be activated from the menu PROGRAMME by pressing the key "C" ACTIVE. When this function is activated, the stove no

longer follows time programming of TIMER 1 or 2 programs, but it keeps the temperature set in the main screen throughout the 24-hour

time period. It is possible to switch to programmes at any time.

TEMPERATURE LEVELS

TEMP. LEVELS

T1

T2

T3

It is possible to change the 3 temperature levels referenced by timers in this menu.

From the PROGRAMS menu use arrow key "D" to move and select TEMP LEVELS, press the "E" key, and enter the temperature settings

screen. With the centre arrow keys "C" and "D", it is possible to increase/decrease the temperature value, while the "B" key is used to move

to the next temperature. With the "E" key (OK), the set values are conrmed.

SLEEP FUNCTION

The sleep function is only activated when the stove supplies power and makes it possible to programme a stove shut-o time. Shut o can

be delayed up to a maximum of 8 hours from current time and with a 10-minute resolution.

To activate, enter the PROGRAM menu, scroll using arrow key "D" up to Funct. SLEEP press the ATTIVA (ACTIVATE) "C" key. In the next

screen, using keys "C" and "D", increase or decrease the minutes (10 minutes each time the key is pressed) and press OK ("E" key) to

conrm the stove shut o time.

NOTE: If the stove is not supplying power the display shows the wording "NOT AVAILABLE".

16°

20°

22°

OK

10

13 - MENU INFORMATION

INFORMATION

To enter the INFORMATION menu, proceed as follows:

from the main/initial screen, press the "E" Menu button, scroll using the "D" arrow key, up to the Information item, press the "E" ok key,

scroll again using the "D" arrow key up to software/data memory/all.memory/stove state and select the desired item, press OK using the

"E" key to enter the chosen information menu.

OFF

ON

MENU

TEMPERATURES

INFORMATIONS

EXIT

PROGRAMS

SETTINGS

E

10:13 TIMER1 ECO

25°

23° AUTO

OFF

TEMP AIR

C

B

MAIN SCREEN

The available information is:

• Software

MENU

D

E

SOFTWARE

ALARM HYSTORY

EXIT OK

• Data memory

• All. memory

• Stove state

B

SOFTWARE INFORMATION

The available data in this function are:

CODE

FIRMWARE

DATABASE

INTERFACE

It is information that can be used to identify the electronic part of the stove.

OK

D

INFORMATIONS

C

E

DATA HYSTORY

STOVE STATE

INFORMATIONS

SOFTWARE

ALARM HYSTORY

EXIT OK

D

DATA HYSTORY

STOVE STATE

E

D

E

INFORMATIONS-SOFTWARE

CODICE = MDUO

FIRMWARE = 140.7.08.08 [07]

DATABASE = 000.022

CONTROL PANEL = 14040613A/1000313B

EXIT

Technical Dept. - All rights reserved - Reproduction is prohibited

EXAMPLE

11

13 - MENU INFORMATION

DATA MEMORY-INFORMATION

INFORMATIONS-DATA HYSTORY

WORKING HOURS = 100

TOTAL IGNITIONS = 20

TEST DATE = 15/01/2013

EXIT

The available data in this function are:

WORKING HOURS

TOTAL IGNITIONS

TEST DATE

ALARM MEMORY-INFORMATION

It gives information about the last alarms detected.

INFORMATIONS-ALARM HYSTORY

ALARM 02 - 28/06/13 13:44 1

ALARM 02 - 21/06/13 08:03 2

ALARM 02 - 21/06/13 08.02 3

ALARM 02 - 21/06/13 09.46 4

EXIT

12

13 - MENU INFORMATION

STOVE STATE-INFORMATION

This menu is particularly useful if one wants to verify the stove work condition (State).

From the OFF screen, press the "E" Menu button, scroll with the "D" arrow key, up to the Information item, press the ok "E" key, scroll again

with the "D" arrow key up to stove state, press OK with the "E" key and one enters the stove State-information menu.

The items available within STOVE-STATE INFORMATION can be viewed using the "C" and "D" arrow keys and are:

INFORMATIONS-STOVE STATE

STATE = 0-OFF

WATER TEMP = -43°C SET = 70°C

ACTIVE+ = 471 SET = 400

SMOKE FAN = 0 SET = 0

EXIT

C

INFORMATIONS-STOVE STATE

MODBUS COM. = OFF IND.=4

EXIT

INFORMATIONS-STOVE STATE

FEED SCREW = 0 SET = 0

SMOKE TEMP = 30°C REQ = BOLL

AIR FAN = 0% POMP. = OFF

3 WAY VALVE = NO HY. CAND. =OFF

EXIT

C

D

• The main stove states that can be read on the display are:

STATE 1-9 various ignition phases

STATE 20-40 work state (power supply)

STATE 60-79 alarm state

STATE 80-84 shut o/cooling/autoeco state

STATE 85-93 auxiliary functions

STATE 94-95 cleaning state

state

water temp. set

aux sensor set

active+ set

D

fumes fan set

feed screw set

fumes temp. req

air vent. (not

pump

available)

relay aux spark plug

modbus com add.

• WATER TEMP.: Water temperature detected by the probe inside the stove and related SET

• AUX: PROBE: detects the value measured by the aux sensor (external/boiler/puer)

• ACTIVE+.: Value read by the Active Plus system and related SET

• FAN FUMES: Number of fumes fan revolutions and related SET

• FEED SCREW: number of feed screw revolutions and related SET

• FUMES TEMP.: temperature value read by the probe inside the stove

• REQ: (Heating/Sanitary) signals if system requires heat

• AIR FAN: Room fan operation level (not available)

• PUMP: signals if the stove's internal pump is turned on (ON) or turned o (OFF)

• AUX: RELAY: signals activation (ON) or the OFF state of Aux relay

• SPARK PLUG: Signals if spark plug is turned on or o

• MODBUS COM. External interface communication state

• ADD.: Address for communicating with modbus

Technical Dept. - All rights reserved - Reproduction is prohibited

13

14 - MENU SETTINGS

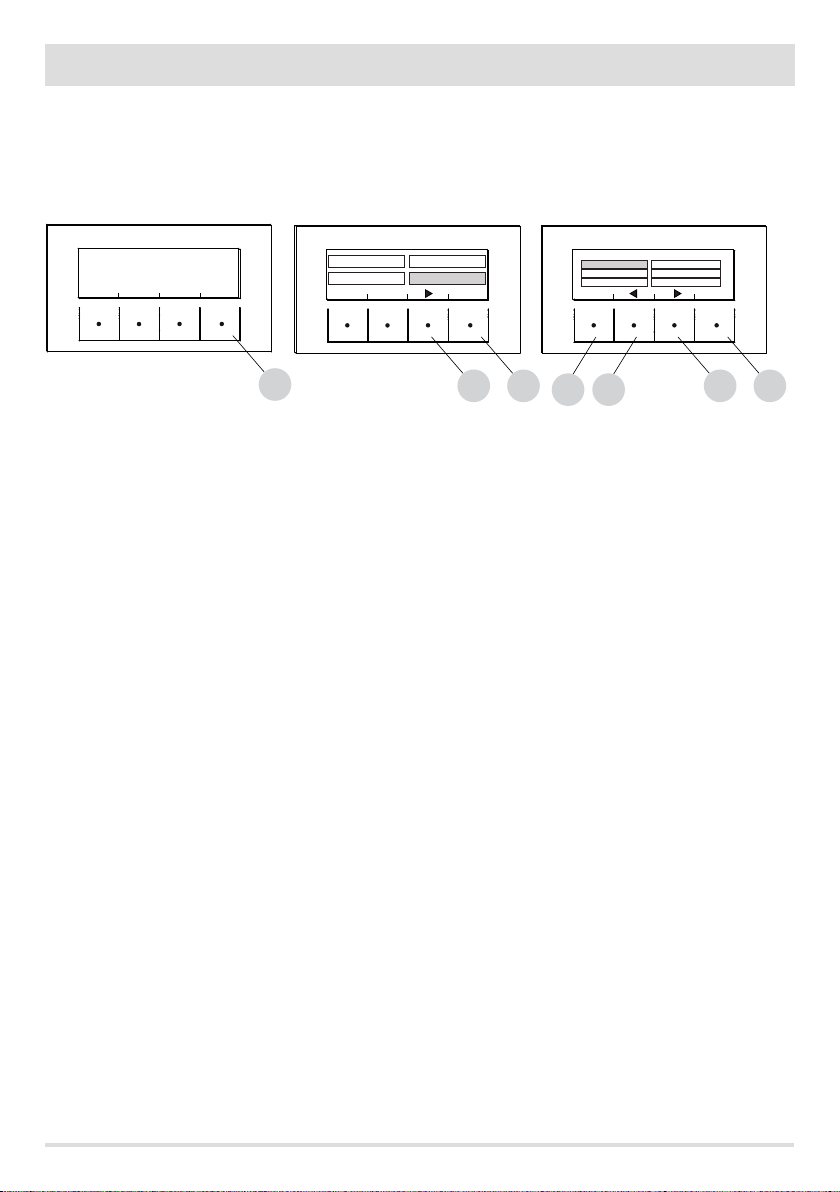

SETTINGS

To enter the menu SETTINGS, proceed as follows:

from the OFF screen, press the "E" Menu key, scroll with the "D" arrow key up to Settings item, press the ok "E" key, scroll again with the

"D" and/or "C" arrow key up to the chosen setting, press OK with the "E" key to enter the chosen menu.

It is possible to set the listed parameters from this screen. Each parameter has an info key to obtain brief information about the chosen

function.

OFF

ON

MENU

TEMPERATURES

INFORMATIONS

EXIT

E

PROGRAMS

SETTINGS

OK

D

• SETTINGS

• Auto Eco (default activated)

• Hydro Air (not available)

• Feed screw loading

• Pellet recipe

• Active +

• Cleaning cycle

• Language

• date - time

• Aux Input

• aux output

• Room Input

• T. on Pump

• Pump pwm

• Antifreeze function

• Plt sensor (not available)

• Modbus com.

• Display

• Technical menu (accessible by a specialised MCZ technician - password required)

• Active +

• Fume Analysis F

• Calib.Active

• Calib.S.fumes

• Diagnostics

• Parameters

• Boll advance

• Hour reset

SETTINGS

AUTOECO

FEED SCR LOAD

ACTIVE PLUS

EXIT

E

B

HYDRO-AIR

LOAD-RECIPE

CLEANING

OK

D

C

E

14

14 - MENU SETTINGS

AUTOECO (Factory activated)

SETTINGS-AUTOECO

DEACTIVATE

AUTOECO

INFO

C

B

The Auto eco mode turns the stove o when heating the system does not require heat, depending on the menu-settings-input aux

conguration.

AUTO ECO ACTIVE

The AutoEco active parameter (factory settings) is shown on the top right on the control panel display in the main screen. If heat is not

required, the stove turns o after the set time, switching to Auto Eco (State 84 - it is possible to see Auto eco in the Information Menu,

stove state).

NOTE: With the stove o, if T is set less than T room, or other heat request settings are fullled, the stove does not turn on.

ACTIVATE

AUTOECO

1

22° 18° AUTO

OFF

2

15:28 ECO

TEMP AIR

OK

D

E

MENU

IF YOU ACTIVATE THE AUTOECO, THE

STOVE GOES OFF WHEN THERE ARE

NO MORE HEAT REQUESTS

EXIT

B

1 = no heat request (T room > T set)

2 = T set

D

C

B

The stove turns on due to a request for heat when the set temperature is greater than the room temperature or there is a request for heat

from room thermostat 2 (see chapter on “aux input”).

AUTO ECO DEACTIVATED

With the stove on, if Auto eco is deactivated and there are no heat requests (dierent based on menu-settings-aux input settings) the

stove operates at minimum power.

The required condition for restarting is for there to be heat request for at least consecutive 10''; it is possible to restart if:

• at least 5 s have elapsed from when shutdown began

• the TH2O in the stove is < T set H2O

To modify the function:

from the Settings menu - using the arrow keys, select the AUTOECO function, press ok (E key) and press D or C key (arrow key) and select:

Activate = to modify the set time from 0 to 30 minutes (factory default 5 minutes)

Deactivate = to deactivate Auto Eco

Technical Dept. - All rights reserved - Reproduction is prohibited

E

15

14 - MENU SETTINGS

FEED SCREW LOADING (only with the stove o )

DEACTIVATE

INFO

B

SETTINGS-FEED SCR LOAD

LOAD

C

ACTIVATE

LOAD

OK

D

E

USE THE 'FEED SCREW LOADER' WHEN

THE FEED SCREW IS EMPTY AND

YOU MUST LOAD IT QUICKLY

EXIT

B

This function is for lling the pellet loading system. It can only be activated with the stove o.

To enter the function:

from the Settings menu - press OK (E key), press the D key (arrow key) and scroll up to load feed screw, press OK (E key) and activate the

function, press ok (''E'' key) to conrm. To interrupt the function, go back to the load feed screw menu, press OK (“E” key), arrow key “C”,

disable load and press OK (“E” key).

PELLET RECIPE (PLT RECIPE)

INFO

B

SETTINGS-LOAD-RECIPE

+15%

C

OK

D

E

CHANGE BY PERCENT THE FEED SCREW

SPEED TO ADAPT THE STOVE TO THE TYPE

OF PELLET

EXIT

B

This function is for adapting the stove to the type of pellet in use. As there are many types of pellet available on the market, stove

operation can vary considerably according to the quality of the fuel. When the pellets clog up the brazier due to excess loading of fuel,

vice-versa if the ame has a tendency to shut-o, it is possible to decrease/increase the amount of pellets in the brazier:

The available values compared to factory settings are:

+15% +10% + 5%; 0%; -10% -20% -30%

To modify the pellet recipe, in sequence, press:

from the Settings menu - press ok (E key), press the D key (arrow) scroll up to plt recipe and press OK (E key) and enter the function, using

the “C” and “D” keys to modify the parameter and press OK (“E” key).

ACTIVE +

The pellet type is not a problem because the stoves are equipped with the Active system and automatically adapt to pellet of any length

with a diameter of 6-8 mm. Eective and ecient combustion is independent from any type of connection to the ue which, with

traditional systems, may constitute a problem during the installation phase.

Thanks to an internal sensor, the stove is extremely reliable and precise, combustion air is constantly adjusted based on the quantity of

pellets present in the brazier, thus guaranteeing an eective and ecient combustion that is translated into decreased consumption,

emissions, and less frequent cleaning.

Thanks to Active plus, it is possible to control and communicate with the stove, even by way of Smartphone and tablet. Since it is possible

to manage more evolved gear motors (with continuous operation), the new pellet stoves equipped with active plus are more silent.

This function is used to adjust combustion air if the ame is too high or too low.

It can be activated from the SETTINGS menu, scroll using the “D” arrow key up to the “ACTIVE +” function, press OK using the “E” key, and,

16

14 - MENU SETTINGS

SETTINGS-SMOKE FAN

0%

INFO

B

using the “D” arrow key modify the parameter and press “ok” “E” key.

The xed parameters that can be set are: +10; +5; -5; -10

OK

D

E

CORRECT THE LEVEL OF

COMBURENT AIR

EXIT

B

CLEANING

This function can only be activated while the power supply is in the following mode:

SETTINGS-CLEANING

DEACTIVATE

CLEANING

INFO

C

B

from the Settings menu- press ok (E key), press the D key (arrow key), scroll up to the “ciclo pulizia” (cleaning cycle) press OK (E key)Activate/deactivate cleaning.

This procedure activates the fumes extraction fan at the maximum level in order to clean the brazier and expel soot.

ACTIVATE

CLEANING

OK

E

IMMEDIATELY ACTIVATE A CLEANING

CYCLE OF THE BRAZIER

EXIT

B

LANGUAGE

This function is used to choose the desired language among those set in the control panel.

To enter the function, from the Settings menu - press OK (E key), press the D key (arrow key) and scroll up to language item, press OK (E

key) and choose the language among the various ones set and nally press OK (“E” key) to conrm.

The available languages are: Italian/English/French/German/Spanish/Dutch/Danish

SETTINGS-LANGUAGE

ITALIANO

ENGLISH

FRANCAIS

C

B

Technical Dept. - All rights reserved - Reproduction is prohibited

OK

D

E

17

14 - MENU SETTINGS

TIME-DATE

This function is used to set date and time.

To enter the function, from the Settings menu - press ok (E key), press the D key (arrow key) and scroll up to the date-time item, press OK

(E key) to enter the function. Next, press the "E" (ok) key again to modify day/month/year/hour and minutes. To modify the parameters,

use the “C” and “D” (arrow keys) keys and press the "E" key to conrm.

SETTINGS-TIME-DATE

TODAY IS MONDAY

AND IT IS

EXIT

C

B

AUX INPUT (using one of the following parameters excludes the other)

The auxiliary input allows you to choose the system conguration type based on which the stove is connected.

To enter the function press:

from the Settings menu- press ok (E key), press the D (arrow) key and scroll up to the Aux Input item and press OK (E key). Using the “C”

and “D” keys select the desired heating system type and press ok with the “E” key.

It is possible to connect the following to the auxiliary input:

SETTINGS-INPUT AUX

THERM.AMB.2

W.CYLIN.PROB.

BUFFER PROBE

INFO

EXT.SENSOR

W.CYLIN.THERM.

BUFFER THERM.

24/06/13

14:14

OK

OK

D

E

D

C

B

E

Room thermostat 2

External probe

Boiler probe

Boiler thermostat

Puer probe

Puer Thermostat

Note: The boiler probe/thermostat choice implies the three-way aux output designation (contacts 7-8-9 on the rear terminal board).

The puer probe/thermostat choice implies the pump aux output designation (contacts 7-8-9 on the rear terminal board).

• Room Therm.2

The stove heat request may take place from any part of the room probe or from the “Termostato Amb 2” (Room thermostat 2) installed in

a room that is dierent from the one where the stove is positioned and is connected to terminals 1 and 2 of the back terminal board. The

stove's request for heat may be due to the closure of the contacts on the terminals and, simultaneously, to the stove's ambient probe (it is

not a case of either or). If you only want the external thermostat, please see “Ambient inlet”.

Notes: Installation of this thermostat is optional, the stove can also operate without it. Since the contact is N.O., the room probe is the only

heat request command.

Possible active weekly programming does not act on Room Thermostat 2 but rather on the probe on board the stove.

18

14 - MENU SETTINGS

• External probe

It makes it possible to work with system temperature adjustment. If installing an external probe on terminals 1 and 2 (NTC 10KOhm at

25°C b=3435) water temperature is automatically calculated by the electronics based on external temperature according to the curves

shown below:

The external probe must be installed on an external wall exposed towards North or North-West. If necessary, it is possible to correct the

value read by the probe by + 5 -5°C.

• Boiler probe

To activate this option, connect a probe (NTC 10KOhm at 25°C b=3435) to points 1 and 2 of the back 9-pole terminal board.

The heat request occurs when the boiler probe reads a temperature that is 2°C below the one set by the accumulation temperature marked

by a tap in the temperature menu.

In this conguration, the aux output is congured as a potential free contact to control the 3-way valve (contact 7-8-9 of the back 9-pole

terminal board)

• Boiler thermostat

To activate this option, connect a Normally Open (N.O.) contact thermostat to points 1 and 2 of the back 9-pole terminal board.

The heat request occurs when the boiler thermostat closes the contact.

Even with this conguration, the Aux output is congured as a potential free contact to control the 3-way valve (contact 7-8-9 of the back

9-pole terminal board).

• Puer probe

To activate this option, connect a probe (NTC 10KOhm at 25°C b=3435) to points 1 and 2 of the back 9-pole terminal board.

The heat request occurs when the boiler probe reads a temperature that is 2°C below the one set by the accumulation temperature marked

by a radiator in the temperature menu.

During installation with the puer, stove operation is only and exclusively determined by the puer probe and not by the room probe. The

purpose of the room probe on the stove is only to control the heating system pump controlled by the potential free contact N.O.: (max 5

ampere, not suitable for brushless pumps with upper start-up current) on terminals 8-9.

Technical Dept. - All rights reserved - Reproduction is prohibited

19

14 - MENU SETTINGS

• Puer thermostat

To activate this option, connect a Normally Open (N.O.) contact thermostat to points 1 and 2 of the back 9-pole terminal board.

Even with this conguration the purpose of the room probe on the stove is only to control the heating system pump controlled by the

potential free contact on terminals 7-8-9.

INPUT AUX

1 2 3

POS.1-2 EXTERNAL THERMOSTAT/THERMOSTAT/BOILER/PUFFER

(AUX INPUT) BOILER PROBE/PUFFER

POS.3-4 ROOM PROBE (ROOM INPUT) POS.7-8-9 AUX OUTPUT RELAY

The terminal block is at the back of the stove. Remove the two screws and protective cover to access it

4

5

6

POS.5-6 HOME AUTOMATION

NC

7

NO

8 9

C

20

14 - MENU SETTINGS

HYDRO AIR STOVE PRINCIPLE DIAGRAMS

The following diagrams are to be used only as a guideline. For proper connection, always follow the notes of the

plumbing and heating installer. The plumbing system must meet local, regional, or national requirements in

force. Installation and verication of operation is to be performed only by specialised, authorised personnel. The

manufacturer will not be held liable for non-compliance with the provisions listed above.

HEATING ONLY CONFIGURATION

CONFIGURATION WITH HEATING AND DOMESTIC HOT WATER

Technical Dept. - All rights reserved - Reproduction is prohibited

21

14 - MENU SETTINGS

BOILER CONFIGURATION

NO

NC

POS.1-2 = BOILER

1 2 345

PROBE/THERMOSTAT

HYDRO STOVE WITH PUFFER CONFIGURATION

6

7

8 9

C

POS.1-2 = PUFFER PROBE/

THERMOSTAT

22

1 2 345

C

NO

NC

6

7

8 9

14 - MENU SETTINGS

ONLY FOR UK

TOBA HYDRO

Technical Dept. - All rights reserved - Reproduction is prohibited

1 2 345

C

NO

NC

6

7

8 9

23

14 - MENU SETTINGS

ONLY FOR UK

TOBA HYDRO

C

NO

NC

6

7

1 2 345

8 9

24

14 - MENU SETTINGS

ONLY FOR UK

TOBA HYDRO

Technical Dept. - All rights reserved - Reproduction is prohibited

1 2 345

C

NO

NC

6

7

8 9

25

14 - MENU SETTINGS

ONLY FOR UK

TOBA HYDRO

C

NO

NC

6

7

1 2 345

8 9

26

14 - MENU SETTINGS

OUTPUT AUX

B

ALARM

REMOTE

INFO

SETTINGS-OUTPUT AUX

BOILER

AUX

C

EXIT

TEMP.

OK

D

E

SET AMBIENT INPUT AS A PROBE OR

THERMOSTAT.

(TERMINALS 3 - 4)

EXIT

B

The AUX output makes it possible to use a relay contact, based on the system conguration type chosen in the Aux Input menu.

It acts on contact 7-8-9 of the external terminal board.

The functions can only be selected if the boiler or puer conguration has not been chosen in the Aux Input menu, and

are:

• Remote alarm (9-8=C-NO)

• Auxiliary boiler (9-7=C-NC) (SEE DIAGRAMS ON THE NEXT PAGE)

• Auxiliary output in temperature (9-8-7=C-NO-NC)

To enter the function press:

from the Settings menu- press ok (E key), press the D (arrow) key and scroll up to the Aux Output item and press OK (E key). Using the “C”

and “D” keys to select the Remote Alarm/Aux boiler/Output in temp and press OK ("E" key).

• If the Aux output is set on Remote Alarm, the NO contact is closed when an alarm is present.

• If the Aux output is set to Auxiliary Boiler, the NC contact remains closed in all alarm states, in = "OFF" state, in 80 “Shutdown” state,

and in 51 “COOL” state. Under all conditions it remains open.

• Output temperature: the NO contact closes when the Boiler temperature exceeds the value set by the user. It can be set from 30 to 60,

it is used, for example, to disconnect the aux boiler above a certain temperature (using the NC contact) or to start an external pump

at temperature (using the NO contact)

• If the boiler conguration has been chosen, the Aux contact is set on “Three-way boiler valve”: the contact changes when there is a

heat request from the boiler.

• If the Puer conguration has been chosen, the Aux contact is set on “Pump control”: the NO contact closes when there is a heat

request from the Room PROBE

Technical Dept. - All rights reserved - Reproduction is prohibited

27

14 - MENU SETTINGS

EXAMPLE 1 - CONNECTION TO THE ROOM THERMOSTAT INLET OF THE AUX BOILER

Ingresso

termostato

7

1 2 345

6

NC

NO

EXAMPLE 2 - ROOM THERMOSTAT WITH DOUBLE CONTACT

• ROOM THERMOSTAT 2 TERMINALS 1-2

• ROOM PROBE TERMINALS 3-4

• AUX BOILER TERMINALS 7-9

8 9

C

N L

ambiente

CALDAIA AUX

7

8 9

1 2 345

6

C

NC

NO

EXAMPLE 3 - ROOM THERMOSTAT WITH DOUBLE CONTACT

• ROOM INLET TERMINALS 3-4 SET ON ROOM THERMOSTAT (SEE RELATIVE PARAGRAPH)

• AUX BOILER TERMINALS 7-9

N L

7

8 9

1 2 345

6

C

NC

NO

28

Ingresso

termostato

ambiente

CALDAIA AUX

Ingresso

termostato

ambiente

CALDAIA AUX

14 - MENU SETTINGS

INPUT AMB

The room input is used to set the probe or the thermostat at terminals 3-4 of the back terminal board of the stove.

The stove has the room probe set as default factory settings.

By selecting the thermostat, it is possible to replace the probe on the stove with a thermostat that requests heat when the contact is

closed.

B

SETTING-INPUT AMB

PROBE

AMB.

INFO

C

THERMOSTAT

AMB.

OK

D

E

SET AMBIENT INPUT AS A PROBE OR

THERMOSTAT.

(TERMINALS 3 - 4)

EXIT

B

To enter the function press:

from the Settings menu - press ok (E key), press the D key (arrow) and scroll up to Room Input, press OK (E key) and select room thermostat,

press E key to conrm.

Attention!!! If room temperature is selected, weekly hourly Programming will no longer be available.

PUMP ON T

This function enables adjustment of the pump activation temperature.

To enter the function press:

from the Settings menu- press ok (E key), press the C-D key (arrow) and scroll up to temp.On pump, press OK (E key)- Modify the

temperature using the central C and D keys, press the E key to conrm.

INFO

SETTINGS-T.ON PUMP

60°

OK

MINIMUM TEMPERATURE OF THE

WATER TO START THE PUMP

OF THE BOILER

EXIT

D

C

B

E

Technical Dept. - All rights reserved - Reproduction is prohibited

B

29

14 - MENU SETTINGS

PWM PUMP

This function is used to set high eciency pump speed.

To enter the function press:

from the Settings menu- press ok (E key), press the C-D key (arrow) and scroll up to PWM Pump, press OK (E key)- Modify the percentage

using the central C and D keys, press the E key to conrm.

INFO

B

SETTINGS-PUMP PWM

AUTO

C

OK

D

E

SET THE SPEED OF THE

MODULATING HIGH EFFICIENCY

PUMP

EXIT

B

FUNCT. ANTI-FREEZE

It consists in activating the pump (level 1) or the stove (level 2) and is automatically activated by the temperature read by the stove probe

and the temperature read by the external probe (if present and connected to the aux input).

The level 1 anti-freeze activation conditions (PUMP ON) are:

boiler temp < anti-freeze set +3°C

The level 2 anti-freeze activation conditions (PUMP and FLAME ON) are:

boiler temp = anti-freeze set

Anti-freeze activation conditions on external probe (if present) are:

ext_ltered temp < anti-freeze set -3°C

SETTINGS-ANTI FROZEN

DEACTIVATE

ANTI FROZEN

INFO

ACTIVATE

ANTI FROZEN

OK

SET THE ACTIVATION

TEMPERATURE OF THE

ANTIFREEZE FUNCTION

EXIT

D

C

B

E

B

To enter the function, press and adjust anti-freeze set:

from the Settings menu- press ok (E key), press the C-D key (arrow) and scroll up to Antifreeze function and press OK (E key)- Activate and

set (from 1 to 5°C) or Deactivate the function and press the E key to conrm.

PELLET SENSOR

Optional Function.

30

14 - MENU SETTINGS

MODBUS COM.

It is a communication system that makes it possible for the stove to receive commands from a Smartphone/tablet through a Web/Wi-Fi

interface.

To enter the function press:

from the Settings menu - press ok (E key), press the C-D key (arrow) and scroll up to Modbus com. and press OK (E key)- Set the address

and press E key to conrm.

SETTINGS-MODBUS COM.

ADDRESS

INFO

C

B

3

OK

D

E

SET THE ADDRESS MODBUS SLAVE

BAUD RATE 19.200 1 STOP BIT -

EVEN PARITY - 19200 8N1

EXIT

B

DISPLAY

Adjust display contrast and brightness. This function is found in:

from the Settings menu- press ok (E key), press the C-D key (arrow) and scroll up to Display, press OK (E key)- Modify the settings using the

B - C - D keys and press the E key to conrm.

SETTINGS-DISPLAY

CONTRAST

BRIGHTNESS

B

C

OK

D

E

Technical Dept. - All rights reserved - Reproduction is prohibited

31

15 - TECHNICAL MENU

TECHNICAL MENU

To access the technical menu you must contact the assistance centre as it requires a password.

To make changes in the technical menu, enter the SETTINGS menu, press the "E" (OK) key, scroll using the “C”-”D” arrows keys and select

Technical menu and press OK (E key)- Enter the password and press the E key to conrm.

SETTINGS-TECH. MENU

INSERT PASSWORD

0000

EXIT

OK

C

B

To enter the password:

using the C and D keys, set the numbers (1-2-3....9) with the E (OK) key conrm and move on to the next digit, once the four digits have

been entered, press the E key to enter the technical menu.

The technical menu displays the following parameters:

• ACTIVE +

• FUMES ANALYSIS F.

• CALIB.ACTIVE

• CALIB.S.FUMES

• DIAGNOSTIC

• PARAMETERS

• BOLL ADVANCE

• RESET HOURS

D

E

32

16 - SAFETY DEVICES AND ALARMS

SAFETY DEVICES

The product is tted with the following safety devices

ACTIVE +

Besides adjusting the stove operation, it also guarantees that the pellet loading feed screw is blocked if unloading is blocked or there is

signicant back pressure.

SMOKE TEMPERATURE PROBE

Detects the temperature of the smoke, thereby enabling start-up or stopping the product when the temperature drops

below the preset value.

CONTACT THERMOSTAT IN THE FUEL TANK

If the temperature exceeds the preset safety level, it immediately shuts down the running of the stove.

WATER THERMOSTAT

If the temperature exceeds the preset safety level, it immediately shuts down the running of the stove.

WATER TEMPERATURE SENSOR

When the water reaches the stop temperature (85°C), the probe automatically instructs the boiler to carry out

automatic "OFF Stand-by" shut-o.

ELECTRICAL SAFETY

The stove is protected against violent changes in current by a general fuse located in the control panel at the back of the

stove. Other fuses that protect the electronic boards are found on the latter.

SMOKE FAN

If the fan stops, the electronic board shuts o the supply of pellets in good time, and an alarm message is displayed.

GEAR MOTOR

If the reduction motor stops, the stove will continue to run until the ame goes out due to lack of fuel and until

a minimum level of cooling is reached.

TEMPORARY POWER CUT

When a power cut is less than 10", the stove returns to its previous operating state; if it is more, it executes a

cooling/re-ignition cycle.

FAILED START-UP

If during ignition no ame develops, the stove will go into alarm condition.

ANTI-FREEZE FUNCTION

If the probe in the boiler detects a water temperature of less than 5°C, the circulation pump is automatically activated to keep the system

from freezing.

PUMP ANTI-SEIZURE FUNCTION

If the pump is not used for prolonged periods, it is activated periodically for a few seconds to keep it from

seizing up.

Technical Dept. - All rights reserved - Reproduction is prohibited

33

16 - SAFETY DEVICES AND ALARMS

TAMPERING WITH THE SAFETY DEVICES IS PROHIBITED

If the product is NOT used as described in this instruction manual, the manufacturer declines all liability for any

damage caused to persons and property. In particular:

• All the necessary measures and/or precautions must be adopted when performing maintenance, cleaning and

repairs.

• Do not tamper with the safety devices.

• Do not remove the safety devices.

• Connect the product to an ecient smoke expulsion system.

• First, check that the environment where it is to be installed is properly ventilated.

Only after eliminating the cause of the intervention of the safety system is it possible to start the product back up.

This manual will help you understand which anomaly has occurred, and explain how to intervene according to the

alarm message displayed on the appliance.

Mechanical stove block

The following conditions may cause the mechanical stove block:

• Overheating of the structure and pellet tank

• Overheating of the water in the boiler

• High pressure of the outlet fumes (read on the pressure switch) and possible obstruction of the outlet.

The control panel will indicate the cause of the alarm and sound an acoustic warning.

In this situation, the automatic shut-down sequence is activated.

When this sequence is initiated, any attempt to restart the system will be ineective.

34

16 - SAFETY DEVICES AND ALARMS

ALARM ALERTS

If there is an operational anomaly, the stove enters the alarm phase displaying the problem that has taken place through a code, a brief

description of the alarm type and an acoustic warning.

The following table describes the possible alarms indicated by the stove, associated to the respective code that appears on the panel and

helpful tips to solve the problem.

B = RESET (cancels alarm)

C = INFO (provides information on the alarm type)

E = MENU

WRITTEN ON THE

DISPLAY

A01

NO IGNITION

A02

NO FLAME

A03

PLT SAFETY

TYPE OF PROBLEM SOLUTION

The re does not ignite.

(without acoustic alarm)

The re goes out abnormally.

(without acoustic alarm)

Pellet tank temperature is too high

A05

OBSTRUCTION

RESET

C

B

Check the level of pellets in the tank.

Check that the brazier rests correctly in its seat and has no

visible deposits or unburnt pellets.

Check whether the ignition plug becomes hot.

Empty and clean the brazier before relighting.

Check the level of pellets in the tank.

Check that the brazier rests correctly in its seat and has no

visible deposits of unburned pellets.

Wait for the cooling phase to end, cancel the alarm and

reduce pellet loading (SETTINGS MENU - Pellet recipe). If the

alarm persists, contact the service centre.

MENUINFO

E

A04

FUMES TEMP

A05

OBSTRUCTION

Technical Dept. - All rights reserved - Reproduction is prohibited

Fumes temperature is too high

Chimney ue clogged

Wait for the cooling phase to end, cancel the alarm and

reduce pellet loading (SETTINGS MENU - Pellet recipe). If the

alarm persists, contact the service centre.

Verify brazier clogging, smoke duct, lower compartment and

door closing. If the alarm persists, contact the service centre.

35

16 - SAFETY DEVICES AND ALARMS

WRITTEN ON THE

DISPLAY

A08

FLUE GAS FAN

A09

SMOKE TEMPERA

TURE PROBE

A11

GEAR REDUCER

A13

BOARD TEMP

A14

ACTIVE SENSOR

A18

WATER SIC

TYPE OF PROBLEM SOLUTION

Check that the lower compartment is clean (see the

Faulty smoke fan.

Smoke sensor fault.

Feed screw gear reducer fault.

Electronic board overheating

Active sensor anomaly

Water thermostat intervention

pages dedicated to stove cleaning) and verify that it is not

obstructed; clean it and cancel the alarm.

If the alarm persists, contact the service centre.

Contact an authorised service centre to have the component

checked and, if needed, replace the component.

The component is not working regularly.

Contact an authorised service centre to have the component

checked and, if needed, replace the component.

Wait for the cooling phase to end, cancel the alarm and

reduce pellet loading (SETTINGS MENU - Pellet recipe). If the

alarm persists, contact the service centre. .

Active Plus sensor operation anomaly. Contact an authorised

service centre to have the component checked and, if needed,

replace the component.

Water temperature is too high or thermostat operation

anomaly. If the alarm persists, contact the service centre.

A19

WATER PROBE

A20

AUX PROBE

Exiting the alarm conditions

NEVER open the appliance door whilst the stove is either in the initial startup or on its shut down cycle, pellets will

still be smoldering or therefore volatiles may be present.

ATTENTION!

If during operation or initial ignition you encounter smoke spillage in to the room from the appliance or the ue

then please switch o the appliance, ventilate the room and contact the installation / service engineer immediately.

36

Fault with water sensor.

Auxiliary probe fault

Possible fault in the safety component. Contact an authorised

service centre to have the component checked and, if needed,

replace the component.

Possible component fault.

Check that the probe inserted in the system respects the

characteristics specied in the instructions (see external

probe).

Contact an authorised service centre to have the component

checked and, if needed, replace the component.

16 - SAFETY DEVICES AND ALARMS

When the stove enters an alarm state, an automatic cooling/shut-o phase begins, at the end of which the cause of the alarm is displayed

on the small panel.

Before resetting the alarm, follow the controls indicated in the previous table, and them press the RESET key for a few seconds (or remove

power to the stove using the main ON/OFF switch on the back of the stove).

If the indicated actions do not solve the problem, the alarm condition will occur once again with dierent timing based on the alarm type:

in this case, contact technical assistance.

SHUT DOWN

If the shut-down key is pressed or one of the following conditions occurs:

• power request ends (Power = 0) for Ecostop, Timer, Sleep

• an alarm condition occurs

• water overheating occurs

the stove enters the shut down and thermal cooling phase that automatically includes the execution of the following phases:

• pellet loading stops

• the room fan maintains the set speed until it cools down

• the fumes extractor is activated at maximum speed and remains on for a xed period of 5 minutes, at the end of which the stove o

temperature is reached.

During the shut down phase, the small panel displays the wording OFF (see screen) but if it is in shut down due to an alarm condition, the

small panel displays the related code (See alarms table)

OFF

ON

ECO

MENU

EB

BLACKOUT WITH STOVE ON

If power is lost for less than 10" from stove start-up, it is repositioned in the phase where it was before the power failure.

If the loss of power exceeds 10", when the stove is powered once again, it goes back to the previous operational condition with the

following procedure it

• carries out a cooling phase, during which the panel displays OFF BLACKOUT

• restarts the stove

If the stove is in ignition phase when the blackout occurs, it will not turn back on once the power is restored (there is a risk that residual

pellet is present in the brazier) and the panel will display OFF BLACK-OUT.

If the ON key is pressed during the cooling phase, the stove stops executing the blackout restore state and it proceeds with ignition as

requested by the command. In the same way, pressing OFF is interpreted as a shut o command.

Technical Dept. - All rights reserved - Reproduction is prohibited

37

17 - RECOMMENDATIONS FOR A SAFE USE

RECOMMENDATIONS FOR A SAFE USE

ONLY A SUITABLE INSTALLATION ACCORDING TO THE UK BUILDING REGULATIONS (ADJ) AND A PROPER MAINTAINANCE

AND CLEANING OF THE PRODUCT CAN ASSURE YOU THE CORRECT FUNCTIONALITY AND A SAFE USE OF YOUR STOVE (ONLY

FOR UK).

We wish to notify you that we have been made aware of incidents involving domestic heating pellet stoves resulting from the stoves

having been incorrectly installed or inadequately maintained. In some cases the incident provoked an explosion that caused the glass

door on the stoves to shatter.

We would like to assure you that all of our products are very safe and are certied to the required European standards. The ignition

system has been tested carefully to increase the lighting eciency and avoid any trouble even in the worst working condition. Moreover

our structures are also provided with a safety device studied to discharge the eventual overpressure in combustion chamber, and avoid

any damage to the product and consequent risk for the nal user. However, like any stove, our stoves need to be properly installed and

maintained if they are to work safely.

Our studies suggest that these explosions are mainly caused by a combination of some or all of the following factors:

• Clogged brazier holes or a deformed brazier, resulting from insucient maintenance, creating the conditions for a delayed ignition

causing a build up of unburnt gases

• Insucient combustion air due to the stove not having a big enough air inlet or not having an air inlet at all

• The use of smoke connections or ue pipe assembly which don’t comply with UK regulations and which don’t create the draught

required to eectively suck the smoke outside (e.g. too many bends in the ue).

• Partially blocked ue pipes, which indicates poor maintenance, reducing the draw on the chimney making ignition dicult.

• The chimney terminal not complying with our installation instructions and failing to prevent potentially dangerous down-draught.

This component becomes essential when the stove is installed in windy areas like coastal zones.

Any of the above factors or any combination of them could generate unburnt gasses which in the worst cases could explosively ignite

when there becomes enough oxygen present.

To avoid this rare but not impossible inconvenient, rst of all the installation shall be done in compliance with UK building regulations and

the suggestions described in this manual.

Furthermore it’s absolutely important to respect the following simple rules:

• The brazier shall be always layed down in its proper position before any use of the product, removing completely the dirt if present

in the base plate

• Pellets must not be fed manually into the brazier, both before ignition and during the working condition.

• Eventual accumulated unburnt pellets in the burner after a failed ignitions must be removed before lighting

• If a failed ignition aects the product repeatedly, despite a clean brazier and a usual fuel loading, we recommend that you

immediately stop using the stove and contact a qualied technician to check the stove functionality.

The respect of these suggestions is absolutely enough to guarantee a safe ignition and to avoid any inconvenient to the product.

If the above precautions are not fullled, and the ignition shows an abnormal amount of pellet in the brazier and a consequent heavy

generation of unburned gas in the combustion chamber, respect carefully the following suggestions:

• Do not switch o the electrical power from the stove for any reason: this would arrest the gas exhaust blower with a consequent

spread of smoke into the room.

• Precautionally open the windows to ventilate the installation room from eventual smoke outlet in ambient (the ue gas outlet could

work not properly).

• Do not open the re door: this would aect the regular smoke evacuation from the chimney.

• Simply switch o the stove by pressing the on/o button in the control panel (not the rear button of power supply!), and wait till the

smoke has been evacuated completely.

• Before any re-lighting attempt, clean completely the brazier and its air passages from any dirt and unburned pellet; put it in the

proper position removing the dirt eventually present in the base plate. If a repeated failed ignition happens, stop using the stove and

contact a qualied technician to check the stove and chimney functionality

38

18 - MAINTENANCE AND CLEANING

Example of a clean brazier

Only a proper maintainance and cleaning of the product can assure you the correct functionality and a safe use of your stove (read chapter

12).

ATTENTION!

All the cleaning operations of all parts must be performed with the product completely cold and the plug

disconnected.

Disconnect the product from the 230V power supply before performing any maintenance operation.

The product requires little maintenance if used with certied high quality pellets.

Example of a dirty brazier

DAILY OR WEEKLY CLEANING PERFORMED BY THE USER

Brazier cleaning

Before ignition, always clean the “T” brazier and remove any ash or incrustation from it that might obstruct the air ow holes, paying

attention to hot ash. In the case of ignition failure, or if fuel in the tank runs out, unburned pellets may accumulate in the brazier. Always

empty the residue in the brazier before each start-up. Only if ash is completely cold may a vacuum cleaner be used to remove it. In this

case, use a suitable vacuum cleaner to remove small sized particles.

REMEMBER THAT ONLY A CORRECTLY POSITIONED AND CLEAN BRAZIER CAN GUARANTEE THE IGNITION AND OPTIMAL

OPERATION OF YOUR PELLET PRODUCT. IN CASE OF FAILED IGNITION AND AFTER ANY OTHER LOCK STATE OF THE

PRODUCT, IT IS ESSENTIAL TO EMPTY THE BRAZIER BEFORE PROCEEDING TO RESTART.

For the brazier to be cleaned properly, remove it from its housing completely and thoroughly clean all the holes and the grate on the

bottom. If good quality pellets are used, you will normally only need to use a brush to restore the optimal operating conditions of the

component.

Ash tray cleaning

Remove and empty the “U” ash tray. Wipe away any residual ash before reinserting the tray. Your experience and the quality of the pellets

will determine the ash tray cleaning frequency. However, it is recommended not to exceed 2 or 3 days.

CLEANING THE GLASS

It is recommended to clean the ceramic glass with a dry brush, or if it is very dirty, spray a little specic detergent and clean with a cloth.

ATTENTION!

Do not use abrasive products and do not spray the glass cleaning product on the painted parts and on the door

gaskets (ceramic bre cord).

Technical Dept. - All rights reserved - Reproduction is prohibited

39

18 - MAINTENANCE AND CLEANING

CLEAN THE EXCHANGER AND THE COMPARTMENT BENEATH THE BRAZIER EVERY 2/3 DAYS

Cleaning the exchanger and the compartment beneath the brazier is a simple operation but very important if the boiler is to maintain

optimal performance.

We therefore recommend cleaning the internal exchanger every 2-3 days, performing these simple operations in sequence:

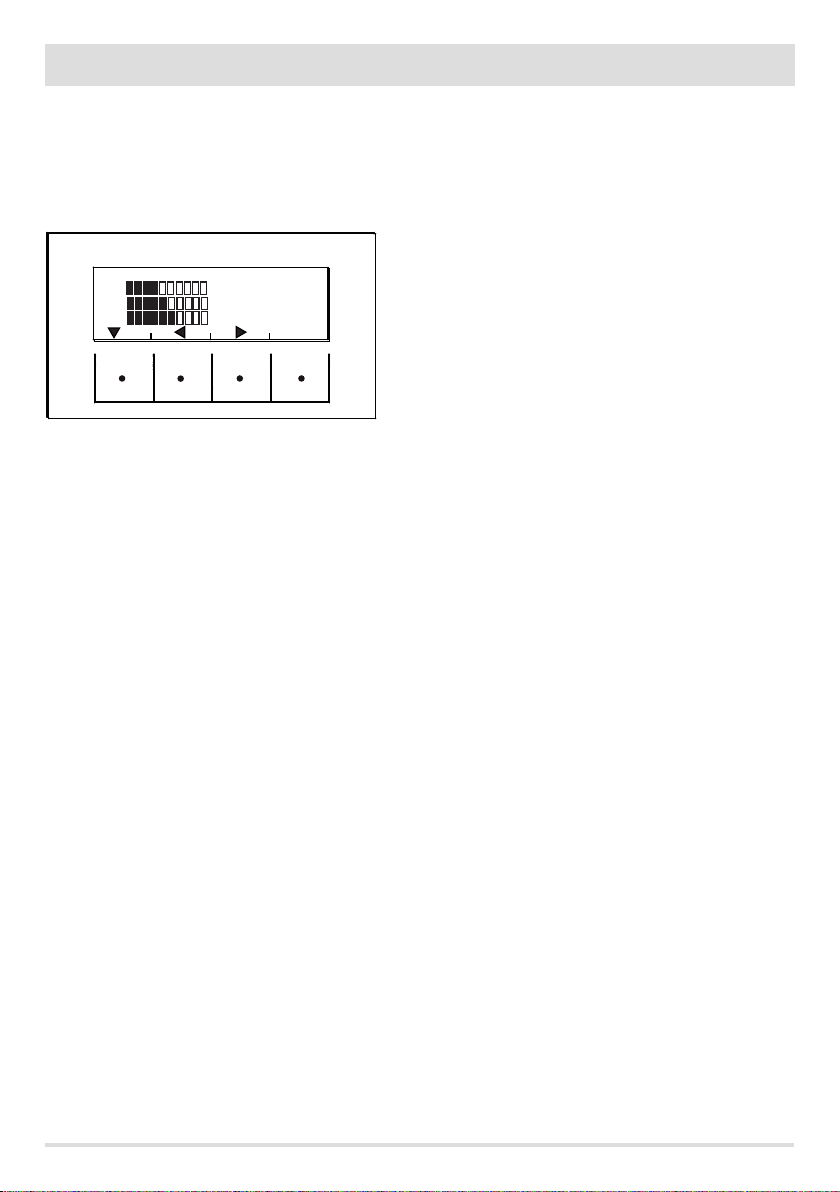

• Activate the “PULIZIA” (CLEANING) function – with the stove on press - menu (“E” key), select “IMPOSTAZIONI” (SETTINGS) using

the “C” and “D” keys and press OK (“E” key), scroll using the “C” and “D” keys and select “CICLO PULIZIA” (CLEANING CYCLE), conrm

pressing “OK” (“E” key), activate the “ATTIVA CICLO DI PULIZIA” (ACTIVATE CLEANING CYCLE) function, conrm by pressing OK (“E” key).

This procedure starts the smoke extractor on the maximum setting to expel the soot that becomes dislodged when the exchanger

is cleaned.

• Clean the pipe unit - Using the provided hook ”A”, shake the rods located beneath the top rmly for 5-6 times. This will remove any

soot that has deposited in the exchanger's smoke ducts during normal stove operation.

• Deactivate the “CICLO PULIZIA” (CLEANING CYCLE) function – this function is deactivated by pressing the “DISATTIVA CICLO

PULIZIA” (DEACTIVATE CLEANING CYCLE).

• Clean the smoke conveyor compartment (g. in following page) - The stove is equipped with a removable ash tray “G”, which

collects any accumulations of soot and ash.

• Once cleaning is nished, reposition the top and the ash tray“G”.

If cleaning is not done every 2-3 days, the boiler could go into alarm caused by ash clogging after several hours of

operation.

A

TEMPERATURES

INFORMATION

EXIT

C

B

PROGRAMS

SETTINGS

OK

D

E

B

AUTOECO

FEED SCR LOAD

ACTIVE +

EXIT

C

SETTINGS

HYDRO-AIR

PELLET RECIPE

CLEANING

OK

D

E

40

18 - MAINTENANCE AND CLEANING

CLEANING THE LOWER COMPARTMENT

Clean the area around brazier “C”; take out “D” and empty it. If necessary, using the nozzle of a vacuum cleaner, remove any ash and soot

that may have built up in the lower exchanger indicated by the arrow.

Before removing ash using a vacuum cleaner, it is recommended to clean the internal walls of the stove using the supplied scraper.

SCRAPER

C

D

Technical Dept. - All rights reserved - Reproduction is prohibited

41

18 - MAINTENANCE AND CLEANING

PERIODIC CLEANING PERFORMED BY A QUALIFIED TECHNICIAN

CLEANING THE EXCHANGER AND PIPE UNIT

CLEANING THE UPPER COMPARTMENT

In order to clean the exchanger and the pipe unit, while the stove is cold, proceed in the following manner:

• Remove the top “B”

• Remove front panel “A” (follow the instruction in the dedicated paragraph)

• Remove the four screws “C” and the two screws “D”

• Take out prole “E”

• Now remove the two screws “F”

• Lift cover “G” with turbulators “T” and put it somewhere safe to remove the ash.

B

C

D

F

G

C

E

D

F

T

H

A

42

18 - MAINTENANCE AND CLEANING

At this point, using a rod or a brush for cleaning bottles, clean inside the pipe unit and the pipes, removing any ash deposits.

Check the gasket of cover “G” and replace it if necessary (see gure on the previous page).

CAUTION: the exchanger must be cleaned at the end of the season by an authorised and qualied technician so that

any worn seals may be replaced.

After cleaning the tube bundle open door “R”, extract the ash pan and empty it of any ash that has dropped while cleaning.

Clean the turbulators and return all the pieces to their seats.

R

Technical Dept. - All rights reserved - Reproduction is prohibited

P

43

18 - MAINTENANCE AND CLEANING

CLEANING OF SMOKE DUCT AND GENERAL CHECKS:

Clean the smoke extractor duct, especially around the T joints, bends and any horizontal sections. For information on

cleaning the ue, contact a chimney sweep.

Check the seal of the ceramic bre gaskets on the door of the stove. If necessary, order new replacement seals from the retailer or contact

an authorized service centre to carry out this task.

CAUTION:

The frequency with which the smoke outlet system is cleaned depends on the use of the boiler and the type of

installation.

We recommend relying on an authorized service centre for end-of-season cleaning and maintenance, they will carry

out all of the previously mentioned work and make a general check of the stove's components.

END-OF-SEASON SHUTDOWN

At the end of each season, before switching the product o, it is recommended to remove all the pellets from the tank with a vacuum

cleaner with a long pipe.

When not in use the appliance must be disconnected from the mains power supply. It is recommended to remove the

power cable for additional safety, especially in the presence of children.

The service fuse may have to be replaced if the control panel display does not switch on when the product is switched on again by pressing

the main switch on its side.

There is a fuse compartment on the back of the product, under the power socket. After having disconnected the plug from the socket, use

a screwdriver to open the cover of the fuse compartment and, if necessary, replace them (3.15 A delayed).

CLEANING THE CONTROL PANEL DISPLAY

ATTENTION!!

THE PANEL DISPLAY IS VERY DELICATE, IT IS SUPPLIED WITH A PROTECTIVE FILM.

RECOMMENDATIONS FOR CLEANING:

Clean using a soft cotton cloth, which should be dry or slightly moist.

Do not use aggressive detergents or polyester materials.

Do not use abrasive sponges or powder detergents nor solvents such as alcohol and petrol, since they may damage the surface of the

device.

44

18 - MAINTENANCE AND CLEANING

REPLACEMENT OF OVERPRESSURE SILICON DAMPER FOR COMBUSTION CHAMBER

The overpressures sillicon damper “G” for combustion chamber (g. A) shall be replaced with a new one yearly (during the periodical

maintainance) in order to keep the overpressure safety system ecient.

For replacement use the following instructions

• remove the top

• remove the rst lateral ceramic covering / metal covering (in accordance with the model)

• unscrew the screw-washer-damper-spacer shown in g. A/C (operate same way on both sides)

Install the new kit as follows:

• Prepare the screw-washer-damper-spacer alligned as shown in g.C and screw them in the structure.

• screw it completely

Check now the proper compression of dampers, using the gauge included in the kit:

• lay the gauge on the lid (g.B); the gauge has to lay completely, while the head of the screw has to be in contact with the gauge. If

it’s not the case, register the screw accordingly.

A

G

C

Technical Dept. - All rights reserved - Reproduction is prohibited

B

45

18 - MAINTENANCE AND CLEANING

CHECKING THE INTERNAL COMPONENTS

ATTENTION!

The internal electromechanical components must only be checked by qualied personnel whose technical expertise

includes combustion and electricity.

We recommend that an annual maintenance service is carried out with a scheduled ser vice contract. This service is essentially a visual and

functional inspection of the following components: The following is a summary of the checks and/or maintenance that are indispensable

for the correct operation of the product.

PARTS/INTERVAL EVERY DAY 7 DAYS 15 DAYS 1 YEAR

Brazier*

Ash pan

Glass

Lower compartment

Complete exchanger

Smoke duct

Door gasket

.

.

.

.

.

.

.

Internal parts

Flue

Circulation pump

A plate heat exchanger

Plumbing components

Electro-mechanical components

Overpressure silicon damper for combustion

chamber

* The frequency of cleaning should be increased if the pellets are of poor quality.

46

.

.

.

.

.

19-FAULTS/CAUSES/SOLUTIONS

CAUTION:

All repairs must be carried out exclusively by a specialised technician, while the boiler is completely cold and the

electric plug is disconnected.

ANOMALY POSSIBLE CAUSES SOLUTIONS

The pellets are not fed into the combustion

chamber.

The pellet tank is empty Fill the tank with pellets

Sawdust has blocked the feed screw Empty the tank and remove the sawdust

from the feed screw by hand

Faulty gear motor Replace the gear motor

Faulty electronic board Replace the circuit board

The re goes out or the stove stops

automatically

The pellet tank is empty Fill the tank with pellets

The pellets are not fed See the previous anomaly

The pellet temperature safety probe has

been triggered

Chrono active. Check if the chrono setting is active.

The door is not closed properly or the

gaskets are worn

Unsuitable pellets Change the type of pellets with those

Low pellet supply Check the ow of fuel following the

The combustion chamber is dirty Clean the combustion chamber, following

Clogged outlet Clean the smoke duct

Faulty smoke extraction motor Check the motor and replace it, if neces-

Let the stove cool down, reset the

thermostat until the problem is resolved

and switch the stove back on. If the

problem persists, contact technical

assistance.

Close the door and replace the gaskets

with original ones

recommended by the manufacturer

instructions in the booklet.

instructions in the manual

sary

Water tank temperature too high Check correct operation of the water

Technical Dept. - All rights reserved - Reproduction is prohibited

circulation pump and the hydraulic system

in general.

47

19-FAULTS/CAUSES/SOLUTIONS

ANOMALY POSSIBLE CAUSES SOLUTIONS

The stove runs for a few minutes and then

goes out

Start-up phase is not completed Repeat start-up

Temporary power cut Wait for the automatic restart

Clogged smoke duct Clean the smoke duct

Faulty or malfunctioning temperature

probes

Pellets accumulate in the brazier, the glass

of the door gets dirty and the ame is

weak

The smoke evacuation motor does not

work

The stove does not run No power supply Check that the plug is inserted and the

Insucient combustion air Make sure that the air inlet in the room is

Damp or unsuitable pellets Change the type of pellets

Faulty smoke evacuation motor Check the motor and replace it, if neces-

No electrical supply to the stove Check the mains voltage and the

Motor block caused by clogging. Perform a general cleaning of the

The motor is faulty Check the motor and capacitor and

Defective motherboard Replace the electronic board

Control panel broken Replace the control panel

Pellet or water probe fault Wait for the pellet or water tank to cool

Blown fuse Replace the fuse.

Check and replace the probes

tted and clear. Check that the combustion

air lter on the Ø 5 cm air inlet pipe is not

clogged. Clean the brazier and check that

all the holes are clear. Perform a general

cleaning of the combustion chamber and

the smoke duct. Check the condition of the

door gaskets.

sary

protection fuse

combustion chamber and the smoke duct.

replace them, if necessary

main switch is in the “I” position.

down and restart the stove

Faulty spark plug Check the spark plug and replace it, if

necessary

48

19-FAULTS/CAUSES/SOLUTIONS

ANOMALIES RELATED TO THE HYDRAULIC CIRCUIT

ANOMALY POSSIBLE CAUSES SOLUTIONS

No increase in temperature with stove in

operation

Incorrect combustion adjustment. Check recipe

Boiler / system dirty. Check and clean the boiler.

Insucient stove power Check that the stove is properly sized for the

requirements of the system

Poor pellet quality Using pellets from the producer

Condensation in boiler Incorrect boiler or pump temperature

setting

Insucient fuel consumption. Check recipe

Radiators cold in winter Room thermostat (local or remote) set

too low. If remote thermostat, check if it

is defective.

Circulator does not run because it is

blocked.

Circulator does not go round. Check the electrical connections of the

Radiators have air in them Vent the radiators

Hot water is not provided Circulator (pump) blocked Free the circulator (pump)

If the stove is NOT used as described in this instruction booklet, the manufacturer declines all responsibility for

damage to persons and property that may arise. The manufacturer furthermore refuses to accept responsibility for

damage to persons and property arising from the failure to observe all the rules contained in the manual and in

particular:

• The operations in italics must be carried out by specialised personnel from the manufacturer

• All the necessary measures and/or precautions must be adopted when performing maintenance, cleaning and

repairs.

• Do not tamper with the safety devices.

• Do not remove the safety devices.

• Connect the stove to an ecient smoke extraction system.

• First, check that the environment where it is to be installed is properly ventilated.

Set the stove or the pump to a higher

temperature

Set to higher temperature or replace. (if

remote)

Free up the circulator by removing

the plug and turning the shaft with a

screwdriver.

circulator; replace if necessary.

Technical Dept. - All rights reserved - Reproduction is prohibited

49

20 - CIRCUIT BOARD

6

8

10

1

2

3

4

5

7

9

25

24

23

22

21

20

21 bis

18

17

13

14 15

1612

MOTHERBOARD WIRING KEY

1. AUX RELAY (C-NO-NC)

2. HOME AUTOMATION CONTACT

3. ROOM PROBE

4. INPUT AUX

5. SMOKE FAN ENCODER

6. GEAR MOTOR ENCODER

7. PRESSURE TRANSDUCER

8. WATER PROBE

9. SMOKE TEMPERATURE PROBE

10. PELLET LEVEL SENSOR (OPTIONAL)

11. ---------------------------------------------

12. SOFTWARE UPDATE

13. EXPANSION

PLEASE NOTE The electrical wiring of individual components is tted with pre-wired connectors of dierent sizes.

50

14. SERIAL COMMUNICATION

15. PWM PUMP CONTROL

16. CONTROL PANEL

17. WATER TEMPERATURE OVERLOAD CUT-OUT

18. TANK OVERLOAD CUT-OUT

19. ------------------------------------

20. 3-WAY VALVE

21. PWM PUMP SUPPLY

21bis. STANDARD PUMP

22. GEAR MOTOR

23. SMOKE FAN

24. SPARK PLUG

25. SWITCH

Via La Croce n°8

33074 Vigonovo di Fontanafredda (PN) – ITALY

Telephone: +39 0434/599599 r.a.

Fax: +39 0434/599598

Internet: www.mcz.it

e-mail: mcz@mcz.it

REV. 28901406600 12/01/2015

Loading...

Loading...