Page 1

Series 1

Embracing Challenge

Hose and Tube Fittings Series 1 - 3

out of plastics PP, PVDF, PTFE

Special Features

Corrosion resistant

Gas tight

Easy to handle

Dierent connection threads

Application

Hose and tube fittings as well as fittings of

series 1 to 3 out of plastics are indispensable

and well proven accessories in the analysis

technique in order to guarantee a safe and

gastight connection of equipment with hoses

and tubes.

Description

The hose fittings series 1 are used for connection of nonrigid flexible tubes with

a defined inside and outside diameter. The

sealing and clamp system of the tube fitting 1 is based on a special fittings body

with a centered hose nozzle. The tube

must be cut straightly before it is pushed

over the hose nozzle until the limit stop.

The tube is locked via the ferrule that is

pressed on the tube by a knurled nut.

This avoids shearing forces and torsion effects. For safety reasons the clamp

ring is equipped with a shoulder that pushes

against the fittings body during the installation. This guarantees a defined contact pressure of the tube.

Technical specications and illustrations are without

obligation, subject to modications. 09.96/12.06

Tube fittings series 2 are applicable for unflexible rigid hoses and tubes with given outside

diameter. Both hoses and tubes must be cut

straightly and burred before they are pushed

into the fitting until the limit stop. The tightness is guaranteed by the double cone ferrule

2 respectively the separate back and front ferrule 2N which are pressed on the line via the

hexagon nut. Thread fittings and flanges of

the series 3 complete the range of necessary

accessories.

For GL-connections please use the special

M&C GL-adapters. You can find corresponding

hoses and hose cutters in the M&C catalogue.

– See data sheet 11.5, 11.7. –

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

11.6

Page 2

The following fittings are preferred standard versions and available in stock.

Other executions, materials, dimensions (in inches as well) on request (minimum order quantity!).

Technical Data

Fitting Series 1-3 Material PVDF (Polyvinylidenefluoride) Material PP (Polypropylene)

Operating temperature -20 °C up to +80 °C -5 °C up to +60 °C

Storage temperature -30 °C up to +110 °C -20 °C up to +80 °C

Max. permitted operating pressure at 20 °C PN10, 10 bar

Connection thread G 1/8, 1/4, 3/8, 1/2 pipe thread, DIN ISO 228

1/8, 1/4, 3/8, 1/2 NPT-thread, USAS B2.1

M 10x 1,5 metric screw thread, DIN 13

Hose connection dimensions Series 1 DN 4/6, 6/8, 8/10, 10/12 mm inside-/outside diameter

Hose connection dimensions Series 2 6, 8, 10, 12 mm outside diameter

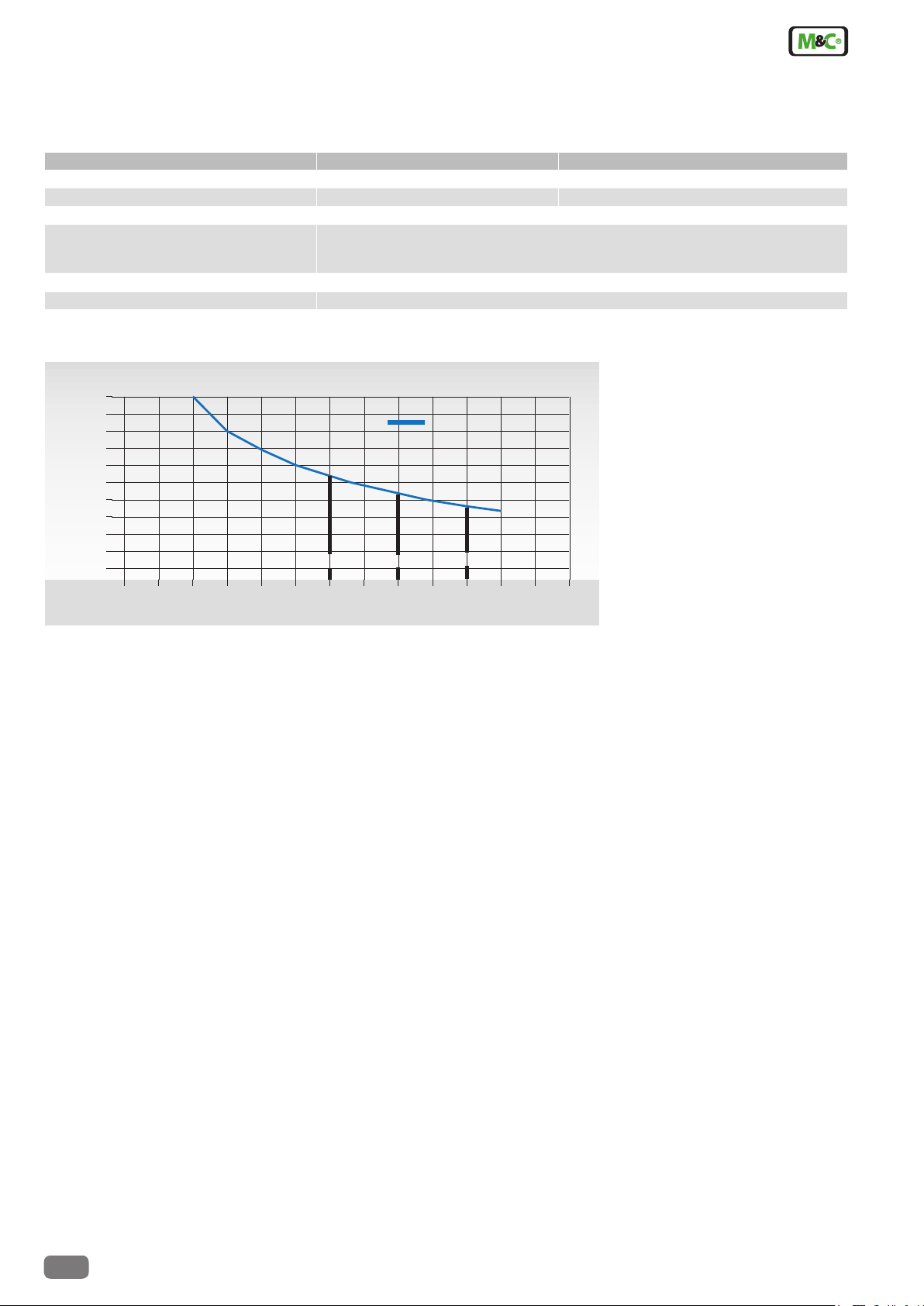

10

9

8

7

6

5

4

bar

3

2

1

0

0 90 110 13010 30 50 80 100 12070

20

PVDF / PP / PTFE

PP max. 60°C

40

60

°C

PVDF max. 80°C

PTFE max. 100°C

The max. operation pressure decreases with increasing temperature.

The temperature of 20 °C is related to air at 65 % humidity (DIN 50014).

11.6

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 09.96/12.06

Page 3

Male Connector Series 1

Example of order:

20 pieces of male elbows, G1/4"-DN10/12, PVDF. Part No. 05V4070.

Look at the table for male elbow. In the adjacent field you can see the

material PVDF. The corresponding part No. is written down in line ‘G1/4’ and

column ‘10/12’ - 05V4070.

Male Connector, Series 1, out of PVDF and PP

Please find the Part No. of all available standard versions in this list:

Dimension DN ..... mm, material PVDF Dimension DN ..... mm, material PP

Thread 4/6 6/8 8/10 10/12 4/6 6/8 8/10 10/12

G 1/8" 05V1045 05V1050 05V1055 05V1090 05V1095 05V1100

G 1/4" 05V1060 05V1065 05V1067 05V1070 05V1105 05V1110 05V1115

G 3/8" 05V1075 05V1080 05V1069 05V1085 05V1120 05V1125 05V1130

G 1/2" 05V1087 05V1135

1/8" NPT 05V2045 05V2050 05V2055 05V2090 05V2095 05V2100

1/4" NPT 05V2060 05V2065 05V2070 05V2105 05V2110 05V2115

3/8" NPT 05V2075 05V2080 05V2085 05V2120 05V2125 05V2130

1/2" NPT 05V2086 05V2087

M10 x 1,5 05V3000 99A1440

Male Elbow Connector, Series 1, out of PVDF and PP

Please find the Part No. of all available standard versions in this list:

Dimension DN ..... mm, material PVDF Dimension DN ..... mm, material PP

Thread 4/6 6/8 8/10 10/12 4/6 6/8 8/10 10/12

G 1/8" 05V4045 05V4050 05V4055 05V4090 05V4095 05V4100

G 1/4" 05V4060 05V4065 05V4070 05V4110 05V4115 05V4120

G 3/8" 05V4075 05V4080 05V4085 05V4125 05V4130 05V4135

G 1/2" 05V4087

1/8" NPT 05V6045

1/4" NPT 05V6060 05V6065 05V6110

Female Connector, Series 1, of PVDF and PP

Please find the Part No. of all available standard versions in this list:

Dimension DN ..... mm, material PVDF Dimension DN ..... mm, material PP

Thread 4/6 6/8 8/10 10/12 4/6 6/8 8/10 10/12

G 1/8" 05V3910 05V3805

G 1/4" 05V3900 05V3915 05V3800

G 3/8"

G 1/2"

Technical specications and illustrations are without

obligation, subject to modications. 09.96/12.06

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

11.6

Page 4

Union Connector, Series 1 out of PVDF and PP,

hose / hose,

hose / tube

Please find the Part No. of all available standard versions in this list:

Dimension DN ..... mm, material PVDF Dimension DN ..... mm, material PP

Ø DN bzw. D 4/6 6/8 8/10 10/12 4/6 6/8 8/10 10/12

4/6 05V3015 05V3505 05V3510 05V3515 05V3030 05V3500 05V3502

6/8 05V3505 05V3020 05V3520 05V3525 05V3500 05V3035

8/10 05V3510 05V3520 05V3022 05V3530

10/12 05V3515 05V3025 05V3040

6 05V3115 05V3190 05V3130

8 05V3119 05V3120 05V3135

10

12 05V3128 05V3125 05V3150 05V3140

Union Connector, Series 2,

tube / tube out of PVDF and PTFE

Please find the Part No. of all available standard versions in this list:

Dimension DN ..... mm, material PVDF Dimension DN ..... mm, material PTFE

Ø D 6 8 10 12 6 8 10 12

6 06V1000

8

10

12

Elbow Connector, Series 1 out of PVDF and PP,

hose / hose,

hose / tube

Please find the Part No. of all available standard versions in this list:

Dimension DN ..... mm, material PVDF Dimension DN ..... mm, material PP

Ø DN bzw. D 4/6 6/8 8/10 10/12 4/6 6/8 8/10 10/12

4/6 05V3350

6/8 05V3355

8/10

10/12

6 05V3180 05V3160

8

10

12 05V3185 05V3165

Tee-Connector, Series 1, out of PVDF and PP

Please find the Part No. of all available standard versions in this list:

Dimension DN ..... mm, material PVDF Dimension DN ..... mm, material PP

Ø DN 4/6 6/8 8/10 10/12 4/6 6/8 8/10 10/12

4/6 05V5015 05V5030

6/8 05V5020 05V5035

8/10 05V5045

10/12 05V5025 05V5040

11.6

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 09.96/12.06

Page 5

Bulkhead Connector, Series 1 out of PVDF and PP,

hose / hose,

hose / tube

Please find the Part No. of all available standard versions in this list:

Dimension DN ..... mm, material PVDF Dimension DN ..... mm, material PP

Ø DN

resp. D

4/6 05V3215 05V3216 05V3230

6/8 05V3220 05V3235

8/10 05V3222

10/12 05V3225 05V3240

6

8

10

12

4/6 6/8 8/10 10/12 4/6 6/8 8/10 10/12

Plug, Series 3,

out of PTFE, PVDF and PP

Please find the Part No. of all available standard versions in this list:

Thread: Thread:

Material G 1/8" G 1/4" G 3/8" G 1/2" 1/8" NPT 1/4" NPT 3/8" NPT 1/2" NPT

PTFE 06V7000 06V7005 06V7010

PVDF 06V7015 06V7020 06V7025

PP

Hose nozzle, Series 3,

out of PVDF and PP

Please find the Part No. of all available standard versions in this list:

Tube i. ø mm, material PVDF Tube i. ø mm, material PP

Thread 4 6 8 10 4 6 8 10

G 1/8" 06V8000 06V8010 06V8015

G 1/4" 06V8020 06V8025 06V8030

G 3/8" 06V8035 06V8040 06V8045

Spare parts, Series 1 and 2,

out of PVDF and PP

Please find the Part No. of all available standard versions in this list:

Dimension DN ..... mm, material PVDF Dimension DN ..... mm, material PP

Spare parts 4/6 6/8 8/10 10/12 4/6 6/8 8/10 10/12

Front ferrule 1 05V6600 05V6602 05V6604 05V6500 05V6502 05V6504

Nut 1 05V6605 05V6607 05V6609 05V6505 05V6506 05V6508

Front ferrule 2

Nut 2

Back ferrule 2N

Front ferrule 2N

Front ferrule 2 and back-/ front ferrule combination 2N are compatible.

Back ferrule 2N made of PTFE, front ferrule 2N made of PEEK.

Series 1

Nut 1 Ferrule 1

Series 2

Nut 2 Ferrule 2

Back/Front ferrule 2N

Technical specications and illustrations are without

obligation, subject to modications. 09.96/12.06

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

11.6

Loading...

Loading...