Page 1

Operating instructions

®

Gas sample probe series SP

Versions SP2500-H, SP2500-H/C/I/BB

SP2500-H/C/I/BB/F

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 2

2

Contents

1 General information ....................................................................................................................... 4

2 Declaration of conformity ............................................................................................................. 4

3 Safety instructions ......................................................................................................................... 5

4 Warranty ......................................................................................................................................... 5

5 Used terms and signal indications ............................................................................................... 6

6 Introduction .................................................................................................................................... 7

7 Description ..................................................................................................................................... 7

7.1 Options ................................................................................................................................... 10

8 Technical data .............................................................................................................................. 11

9 Dimensions ................................................................................................................................... 12

10 Receipt and storage ..................................................................................................................... 12

11 Installation information ............................................................................................................... 12

12 Installation .................................................................................................................................... 13

12.1 Probe assembly ...................................................................................................................... 13

12.2 Fitting preliminary filter or sample tube ................................................................................... 14

12.3 Connection of sample line ...................................................................................................... 16

12.4 Connection of backflushing and calibration gas line ............................................................... 17

12.5 Electrical connection ............................................................................................................... 17

12.5.1 Versions with internal capillary tube thermostat .............................................................. 18

12.5.2 Version with external thermostat ..................................................................................... 18

13 Starting ......................................................................................................................................... 19

14 Closing down ............................................................................................................................... 20

15 Maintenance ................................................................................................................................. 20

15.1 Replacement of filter element and seals ................................................................................ 21

16 Spare parts list ............................................................................................................................. 22

17 Annex ............................................................................................................................................ 22

List of illustrations

Figure 1 Probe type SP2500-H ...................................................................................................... 8

Figure 2 Probe type SP2500-H/C/I/BB ........................................................................................... 8

Figure 3 Probe type SP2500-H/C/I/BB/F ........................................................................................ 9

Figure 4 Dimensions (mm) of SP2500-H.. probe ......................................................................... 12

Figure 5 Schematic diagram of filter housing cover ..................................................................... 14

Figure 6 Removal of filter housing cover ...................................................................................... 15

Figure 7 Fitting preliminary filter or sample tube .......................................................................... 15

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 3

3

This Operating Manual does not claim completeness and may be

subject to technical modifications.

© 06/2004 M&C TechGroup Germany GmbH. Reproduction of this

document or its content is not allowed without permission from M&C.

SP® is a registered trade mark.

1st Edition: 06/2004

Dear customer,

we have made up this operating manual in such a way that all necessary information about the

product can be found and understood quickly and easily.

Should you still have any question, please do not hesitate to contact M&C directly or go through your

appointed dealer. Respective contact addresses are to be found in the annexe to this operating

manual.

Please also contact our homepage www.mc-techgroup.com for further information about our

products. There, you can read or download the data sheets and operating manuals of all M&C

products as well as further information in German, English and French.

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 4

4

Head Office

M&C TechGroup Germany GmbH Rehhecke 79 40885 Ratingen Germany

Telephone: 02102 / 935 - 0

Fax: 02102 / 935 - 111

E - mail: info@mc-techgroup.com

www.mc-techgroup.com

1 GENERAL INFORMATION

The product described in this operating manual has been examined before delivery and left our works

in perfect condition related to safety regulations. In order to keep this condition and to guarantee a

safe operation, it is important to heed the notes and prescriptions made in this operating manual.

Furthermore, attention must be paid to appropriate transportation, correct storage, as well as

professional installation and maintenance work.

All necessary information a skilled staff will need for appropriate use of this product are given in this

operating manual.

2 DECLARATION OF CONFORMITY

CE - Certification

The product described in this operating manual complies with the following EC directives:

EMV-Instruction

The requirements of the EC directive 2004/108/EC “Electromagnetic compatibility“ are met.

Low Voltage Directive

The requirement of the EC directive 2006/95/EC “Low Voltage Directive“ are met.

The compliance with this EC directive has been examined according to DIN EN 61010.

Declaration of conformity

The EU Declaration of conformity can be downloaded from the M&C homepage or directly requested

from M&C.

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 5

5

3 SAFETY INSTRUCTIONS

Please take care of the following basic safety procedures when mounting, starting up or operating this

equipment:

Read this operating manual before starting up and use of the equipment. The information and

warnings given in this operating manual must be heeded.

Any work on electrical equipment is only to be carried out by trained specialists as per the regulations

currently in force.

Attention must be paid to the requirements of VDE 0100 (IEC 364) when setting high-power electrical

units with nominal voltages of up to 1000 V, together with the associated standards and stipulations.

Check the details on the type plate to ensure that the equipment is connected to the correct mains

voltage.

Protection against touching dangerously high electrical voltages:

Before opening the equipment, it must be switched off and hold no voltages. This also applies to any

external control circuits that are connected.

The device is only to be used within the permitted range of temperatures and pressures.

Check that the location is weather-protected. It should not be subject to either direct rain or moisture.

The equipment must not be used in hazardous areas.

Installation, maintenance, monitoring and any repairs may only be done by authorized personnel with

respect to the relevant stipulations.

4 WARRANTY

If the equipment fails, please contact M&C directly or else go through your M&C authorised dealer.

We offer a one year warranty as of the day of delivery as per our normal terms and conditions of sale,

and assuming technically correct operation of the unit. Consumables are hereby excluded. The terms

of the warranty cover repair at the factory at no cost or the replacement at no cost of the equipment

free ex user location. Reshipments must be send in a sufficient and proper protective packaging.

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 6

6

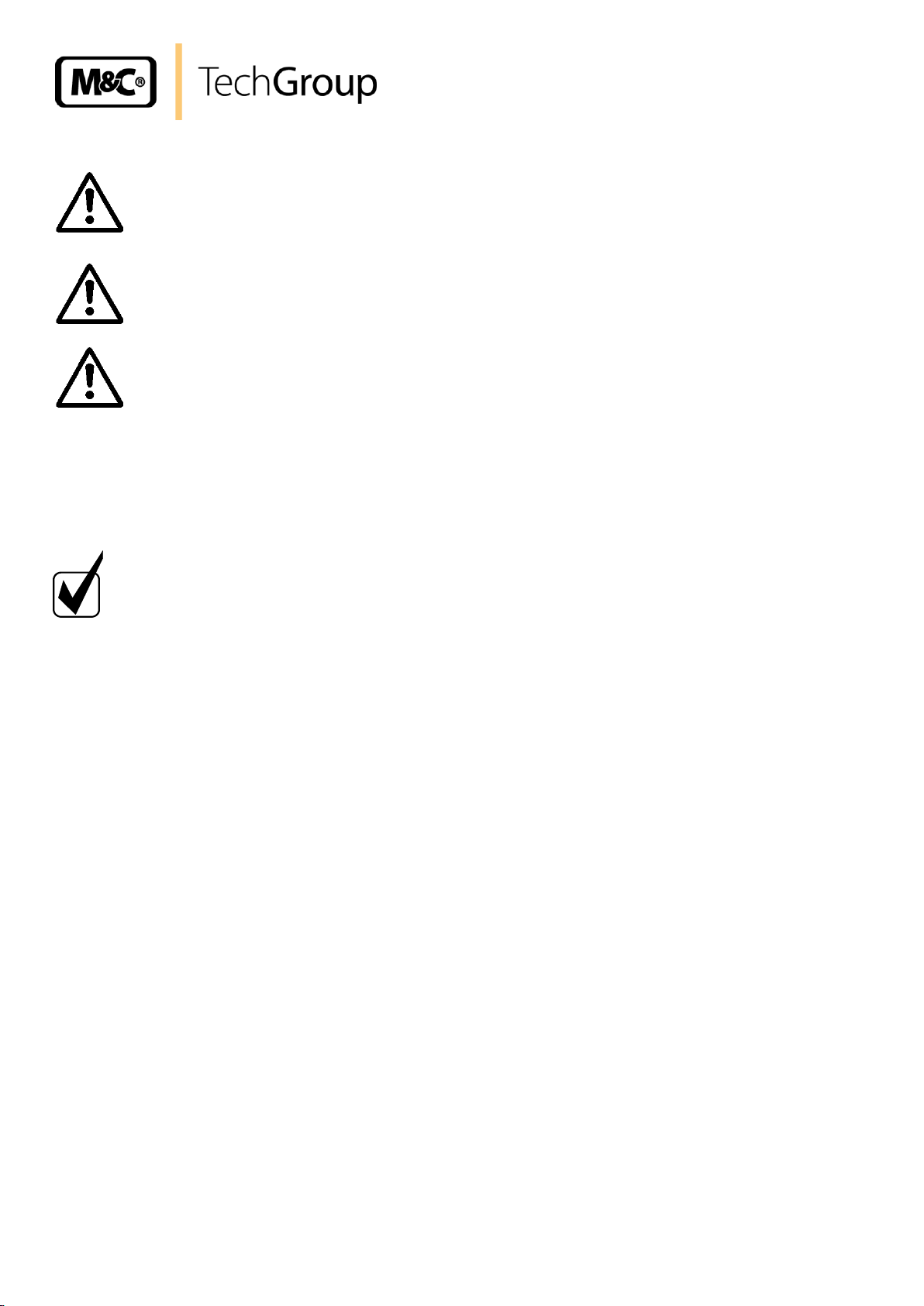

DANGER!

This means that death, severe physical injuries and/or important

material damages will occur in case the respective safety measures

are not fulfilled.

W ARN ING !

This means that death, severe physical injuries and/or important

material damages may occur in case the respective safety

measures are not fulfilled.

CARE!

This means that minor physical injuries may occur in case the

respective safety measures are not fulfilled.

CAR E !

Without the warning triangle means that a material damage may

occur in case the respective safety measures are not met.

ATT E NTI ON!

This means that an unintentional situation or an unintentional status

may occur in case the respective note is not respected.

NOTE!

These are important information about the product or parts of the

operating manual which require user’s attention.

SKILLED STAFF

These are persons with necessary qualification who are familiar with

installation, use and maintenance of the product.

5 USED TERMS AND SIGNAL INDICATIONS

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 7

7

6 INTRODUCTION

M&C SP2500-H.. series probes are used for continuous gas sampling in dust-loaded processes at

high temperatures and high gas moisture.

The probe offers the possibility to remove the preliminary filter or sample tube in the process without

having to remove the probe head for cleaning purposes.

H/C/I/BB and ..-H/C/I/BB/F series probes are used in highly dust-loaded processes. The additionally

installed backflushing valve and pneumatic isolating valve in the sampled gas outlet ensure highly

efficient backflushing of the filter space in the in the probe head and used preliminary filter.

For further information or personal advice, please do not hesitate to contact us or visit us online to

view our wide range of products at:

7 DESCRIPTION

The probe has been designed for easy installation, safe operation, easy maintenance and diversity in

application.

Depending on the particular problem, various sample tubes or preliminary filters (see data sheets 2-

1.1.0.6 and 2-1.1.0.8), which are not included in the scope of supply of the probe, are screwed into the

G3/4"i thread in the filter holder.

The large, ceramic deep-bed filter element (optional glass fibre elements or glass wadding fillings

available) is arranged in a housing with minimal dead space outside the process area.

The probes are designed for replacement of the filter element without the need for tools; as the sample

line does not need to be removed, contamination of the clean gas side is avoided.

Cleaning of the sample tube or preliminary filter takes place by withdrawing the filter part from the

probe without having to remove the probe head.

Owing to the special design of the heating element of SP2500... series probes, the entire probe head

including mounting flange can be heated adjustable to 180°C, thus ensuring reliable operation without

cooling below the dew point externally. Temperature control with the standard version takes place by

means of an integrated capillary sensor thermostat with excess temperature limiter and alarm function

in a compact arrangement directly on the probe.

With the SP2500-H, backflushing or calibration gas supply takes place via an optional check valve

(option C).

Additional functions of the SP2500-H/C/I/BB(/F):

The calibration gas can be supplied directly at the check valve/C to the probe outlet.

Calibration gas supply at the probe is possible without any expensive gas loss via the

otherwise open probe inlet.

The isolating valve /I isolates the gas outlet of the heated filter chamber.

The filter space, sample tube or preliminary filter can be backflushed via the check valve /BB

projecting into the heated filter chamber.

The filter element, and via this indirectly, the filter space and sample tube or preliminary filter

can be backflushed via the check valve /BB/F installed in the heated chamber wall.

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 8

8

340

(115V,60Hz)

110

260

207

230V,50Hz

Option: 2x

Sample

OUT

Pre-filter

Sample tube

Power

Low temperature

Test gas IN

Test gas

Sample IN

180°C

Sample OUT

>0,7bar

Option:

Option:

2x

Option:

Option: C

alarm

2. sample OUT

Test gas IN

Option: C

345

1/4" NPTi

340

(115V,60Hz)

110

260

207

230V,50Hz

Test gas

IN

Control

IN

Sample

OUT

Pre-filter

Sample tube

Power

Low temperature

alarm

Backflush IN

Tube 6x1

1/8" NPTi

Backflush

Sample IN

180°C

2-6bar

Test gas

Control

Sample OUT

3-10bar

>0,7bar

Backflush IN

1/4" NPTi

Tube 8x1

345

The following figures show the probe types SP2500-H, ...H/C/I/BB, ...H/C/I/BB/F.

Figure 1 Probe type SP2500-H

Figure 2 Probe type SP2500-H/C/I/BB

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 9

340

(115V,60Hz)

110

260

207

230V,50Hz

Test gas

IN

Control IN

Sample

OUT

Pre-filter

Sample tube

Power

Low temperature

alarm

Backflush

IN

Tube 6x1

1/8" NPTi

Backflush

Sample IN

180°C

2-6bar

Test gas

Control

Sample OUT

3-10bar

>0,7bar

Backflush

IN

1/4" NPTi

Tube 8x1

345

Figure 3 Probe type SP2500-H/C/I/BB/F

9

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 10

10

Description

Article No.

Basic typeSP2500H, heated to 0-180°C, with weatherproof cover,

Material stainless steel 1.4571

20 S 3510

Basic type SP2500-H/C/I/BB, heated to 180°C, with weatherproof cover,

Material stainless steel 1.4571

20 S 3520

Basic type SP2500-H/C/I/BB/F, heated to 0-180°C, with weatherproof cover,

Material stainless steel 1.4571

20 S 3500

.

Power supply 115V/60Hz/115V

20 S 9030

Type with second sampled gas outlet 1/4" NPTi*/2x*

20 S 9015

Type with backflushing/calibration gas supply valve (C*), opening pressure 0.7 bar,

tube 8 mm*

20 S 9435

Type with glass filter element 0.1GF150, filter fineness 0.1 µm,

seal PTFE/GF150

20 S 9020

Type with special filter housing cover with spun glass cartridge

Including spun glass filling, seal FPM, Novapress/FW

20 S 9047

Type with PT100 sensor instead of capillary controller,

without thermostat/PT100

20 S 9025

Type with thermocouple Fe-CuNi (type J) instead of capillary controller,

without thermostat/Fe-CuNi

20 S 9027

Type with thermocouple Ni-CrNi (type K) instead of capillary controller,

without thermostat/Ni-CrNi

20 S 9028

Type with second PT100 sensor/2-PT100

20 S 9026

Type with special intermediate flange adapter DN..PN6 or ANSI..150 lbs/DN

20 S 9004

Support tube adapter type SP2500H/SA500 for supporting the installation of long sample

tubes and preliminary filters with extension tube, including flange gasket, material 1.4571

20 S 9433

Type with gas pre-heater GVW1, material stainless steel 2-1.2.5/GVW1

20 S 9058

Connection of gas pre-heater to connection “BB“ and gas inlet/GVW

20 S 9062

Type with steam heating without regulating and valves

Instead of capillary controller/D

20 S 9033

7.1 OPTIONS

The following list shows the options available. The diversity of options and modular design of M&C

gas sample probes ensure optimum probe selection to suit the particular process and ambient

conditions.

* only SP2500-H

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 11

11

Technical data SP

®

series

SP2500-H

SP2500-H/C/I/BB

SP2500-H/C/I/BB/F

Article number

20 S 3510

20 S 3520

20 S 3530

Integrated backflushing

No

Via filter space

Via filter element

Weatherproof cover

Yes

Electrical connection

Terminals; max. 4 mm², 2 x PG13.5 cable gland

Degree of protection of terminal box

IP54 EN60529

Power supply

230V 50/60Hz, 800W or 115V 60Hz, 800W (fuse 10A)

Material of medium contacted parts

Stainless steel 1.4571, 1.4404, FPM*, Graphite**

Ambient temperature

-20°C to +60°C*** /PT100, /Fe-CuNi,/Ni-CrNi** = -20°C to +80°C

Operating temperature

0-180°C* /PT100** /Fe-CuNi** /Ni-CrNi**

Process pressure

0.4 to 6 bar abs.

Ready for operation

after 40min

Alarm contact rating

250V 3A~, 0.25A=, operating point: ΔT 30°C** to T

nominal

Sample gas outlet connection

1/4"-NPT* internal, for tube connection Ø6, 8 or 10mm**

Calibration gas backflushing

connection

1/4“ NPTi*/C**

Backflushing: tube 8mm, calibration gas: tube

6mm

Isolating valve/I connection

1/8“ NPTi

Control air pressure range

3 – 10bar

Filter space volume

280 cm3

Filter fineness

S-2K150= ceramic*, 2µ,/F-0,1GF150= glass fibre**, 0.1µ,/FW= glass

fibre/spun glass**

Mounting flange

DN65 PN6, Form B, 1.4571* >DN or ANSI possible**

Weight

approx. 17kg*

Electrical equipment standard

EN 61010, EN 60519-1

8 TECHNICAL DATA

* Standard

** Optional

*** At high ambient temperatures, the PT100 (Art. No. 20S9025) or thermocouple Fe-CuNi or Ni-CrNi (Art. No. 20S9027 or

20S9028) option should be selected instead of the thermostat. The use of an additional electronic thermostat is

necessary (see also data sheet 4.3).

**** Option only for SP2500-H

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 12

12

340

110

260

207

345

NOTE!

The probe should be stored protected from frost.

9 DIMENSIONS

The following illustration shows the dimensions of the SP2500-H.. probe.

Figure 4 Dimensions (mm) of SP2500-H.. probe

10 RECEIPT AND STORAGE

The probe and any special accessories should immediately be unpacked carefully upon delivery

and against the delivery note.

The delivery should be checked for any transport damage and the transport insurer immediately

notified of any damage.

11 INSTALLATION INFORMATION

When carrying out installation, the safety rules and regulations for the prevention of accidents must be

observed – this applies similarly to subsequent operation. The information in Chapter 3 “Important

safety information” must be observed in particular.

The following applies:

Select an optimal sample point according to the general guidelines or agree on a sample point

with the responsible authorities.

The sample point should be arranged so that sufficient space for installation and removal of the

probe is available; the insertion length of the sample tube should be taken into account.

Easy access to the probe must be ensured for any necessary maintenance.

The sample nozzle locally should be dimensioned so that the nozzle temperature is always above

the acid dew point to prevent corrosion and blockages.

If the ambient temperature in the area of the nozzle is higher than 60°C due to the radiated heat,

a radiant heat reflective plate must be installed in the area of the nozzle locally to protect the

probe.

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 13

13

NOTE!

The suitability of the probe must be verified prior to installation by

comparison with the available operating parameters (see rating plate).

NOTE!

In the preferred probe mounting position, the sample gas outlet points

downwards (does not make any difference to the function of the probe).

It is recommended to mount the probe with a slight downward inclination

with respect to the process to enable any precipitated droplets to flow back

to the process.

CAR E !

The fittings must be tightened carefully to avoid damaging the internal

components. The fittings must not be overtightened.

In the event of leaks, the fittings must not be tightened further. The

respective fitting should be removed completely and retightened.

Check unions for leaks.

The nozzle mounting flange connection should be DN65 PN6 or 3“ANSI (115V version). For other

connection dimensions, an optional intermediate flange adapter is available. The necessary,

minimum flange sizes or minimal nozzle diameter depends on the sample tube used or the

preliminary filter diameter.

It is recommended to mount the probe horizontally with an angle of inclination of 10° with respect

to the process.

12 INSTALLATION

M&C SP2500-H.. probes are designed for stationary use and with correct selection of the sample point

and proper installation, they will give many years of trouble-free service with minimum maintenance.

12.1 PROBE ASSEMBLY

Remove the probe cover after opening the two toggle-type fasteners.

Place the flange gasket on the sample nozzle.

Bolt together the mounting support and probe flange with the supplied nuts and bolts.

When using the support tube adapter (for supporting the installation of long sample tubes or

preliminary filters when the probe is installed in a horizontal position), bolt the same between the

nozzle flange and special flange with the threaded bolts.

The supplied sliding segment must be screwed to the sample tube or extension tube of the preliminary

filter about 450mm away from the G3/4“t connecting thread.

If the sample nozzle does not correspond to the standard flange connection DN65 PN6, the optional

supplied adapter flange must be fitted to the probe in the same manner.

Remove the heat conducting plates at the sample gas outlet after loosening the knurled screw.

For connection of the sample line, screw in an appropriately dimensioned union with 1/4"-NPT

connecting thread using PTFE sealing tape.

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 14

14

12.2 FITTING PRELIMINARY FILTER OR SAMPLE TUBE

The SP2500-H.. probe offers the possibility of fitting or removing the preliminary filter or sample tube in

the process without having to remove the probe head.

For this purpose, the filter housing covers must be removed as follows:

Figure 5 Schematic diagram of filter housing cover

Turn handle A about one full turn anticlockwise, so that the cover is lifted.

Place handle C in position E.

Swing out clamp B to the left (in the direction of G);

Remove the filter housing cover with handle A.

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 15

15

The following figures show the described steps.

Figure 6 Removal of filter housing cover

Fitting of the preliminary filter or sample tube takes place as follows:

Unscrew the mounting adapter for the preliminary filter or sample tube from the filter housing

cover .

Figure 7 Fitting preliminary filter or sample tube

The filter element is now visible.

Check that the filter element is screwed tight and then screw on the mounting adapter again.

Screw the preliminary filter or sample tube with appropriate seal into the ¾“ thread of the

mounting adapter ;

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 16

16

NOTE!

When connecting hose assemblies to stainless steel unions, a supporting

sleeve must always be used.

The connection must be checked for leaks.

Push the filter housing cover with preliminary filter or sample tube into the filter space in the

probe head.

Swing clamp B to the right and with handle C bring eye bolt D in position E, so that the clamp

engages in eye bolt D and threaded bolt H; if necessary, push in or pull out the filter housing cover

slightly with the clamping screw A;

Turn handle C into position F and tighten handle A hand-tight by turning clockwise.

12.3 CONNECTION OF SAMPLE LINE

Provided on the probe side for connection of the sample line is a ¼“ NPTi thread. This thread can be

used for screwing in appropriate connecting unions for lines with the sizes Ø6mm (standard), 8mm or

10mm.

The sample line is connected as follows:

Loosen the toggle-type fasteners on the insulating cover and hood and remove.

Screw the appropriate threaded union into the probe head with sealing tape.

Insert the line through the respective opening in the probe base plate and silicone holder.

Connect the line to the union. For Swagelok® fittings:

- Fully insert the liner with support sleeve into the union.

- Tighten the union nut finger-tight.

- Prior to tightening, mark the union nut in the 6 o’clock position.

- Grip the body with a spanner and tighten the union nut with 11/4 turns; after a full turn, the mark

must be turned further to the 9 o’clock position.

Refit the special hood and close with clamps.

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 17

17

ATT E NTI ON!

The backflushing pressure must be higher than the process pressure.

Pay attention to the maximum pressure level (see technical data).

DANGER!

An incorrect system voltage can damage the device. Ensure that the

system voltage corresponds to the voltage shown on the rating plate

prior to connection!

The probes must be mounted so that any contact with live parts is

impossible!

The use of heat-resistance cable is recommended in any event!

The alarm contact excess temperature must be monitored!

In the event of an excess temperature alarm (failure of the probe

heating or sensor) the sample gas supply must be interrupted to

avoid damaging the probe or subsequent components.

NOTE!

For the erection of power installations with rated voltage up to 1000V,

the requirements of VDE 0100 as well as relevant standards and

specifications must be observed.

An external main switch must be provided.

The supply circuit of the device must be protected with a fuse

corresponding to the rated current (overvoltage protection); electrical

values are shown in the technical data.

When fitting a capillary or PID controller at the sample point, the

maximum permissible ambient temperature must be observed (see

8.). If this temperature is exceeded, a PID controller must be provided

externally and outside the temperature-critical zone.

12.4 CONNECTION OF BACKFLUSHING AND CALIBRATION GAS LINE

SP2500-H:

For option “C”, a check valve is fitted (see Figure 1, opening pressure 0.7bar). Connection of the

backflushing or calibration gas line takes place on the underside of the probe. Provided for this

purpose is a tube with the dimensions Ø8 x 1mm.

The connection for the optional second sample gas outlet is ¼“ NPTi. The thread is closed with a

cover.

SP2500-H/C/I/BB(/F):

In the versions SP2500-H/C/BB and SP2500-H/C/BB/F, separate connections are available for

calibration and backflushing gas (see Figures 2 and 3):

Backflushing gas tube connection Ø8 x 1mm, und

Calibration gas tube connection Ø6 x 1mm.

Control of the isolating valve I takes place separately within a pressure range of 3 to 10bar. This valve

has a 1/8“ NPTi connecting thread.

12.5 ELECTRICAL CONNECTION

Temperature adjustment of the SP2500-H/.. series probes generally takes place with a capillary

controller. The probe can also be provided with an optional PT100 or thermocouple. This requires the

connection of an external thermostat.

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 18

18

NOTE!

The use of temperature-resistant cable is recommended!

NOTE!

Use appropriate compensating cables for thermocouples!

Power 230V 50Hz

or 115V 60Hz

Alarm output

1

2

1

2

+30

-30

800W

Power 230V 50Hz

or 115V 60Hz

PT100 or

thermocouple

1

2

1

2

800W

12.5.1 VERSIONS WITH INTERNAL CAPILLARY TUBE THERMOSTAT

Remove the connection box cover. The electrical wiring

diagram shown is contained in the cover.

Insert the mains cable (min. 3 x 1.5 mm2 ) through the

cable gland and connect to the appropriate terminals.

Insert the signal cable (low temperature alarm) through

the cable entry and connect to the appropriate terminals

(contact position Tu indicates alarm).

Screw the cover back in place again.

12.5.2 VERSION WITH EXTERNAL THERMOSTAT

Remove the cover of the connection box. The

electrical wiring diagram shown is contained in

the cover.

Insert the mains cable (min. 3 x 1.5 mm2)

through the cable gland and connect to the

appropriate terminals.

Insert the temperature sensor cable through

the cable entry and connect to the appropriate

terminals.

Screw the cover back in place again.

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 19

19

W ARN ING !

Prior to starting the device, it must be verified that the system

voltage corresponds with the voltage shown on the rating plate!

NOTE!

If the set temperature on the capillary controller should be reduced

in one step by more than 30°C, the excess temperature circuit

activates the thermostat (press reset button to switch on again).

W ARN ING !

Caution: Do not touch the probe surface when in use. The high

surface temperatures that prevail are liable to cause burns.

Protective gloves must be worn and the probe must be protected to

prevent unauthorised access!

NOTE!

The total heating time is about 40 minutes. The probe is ready to

use after exceeding the lower alarm threshold value (30°C below

the set value).

CAR E !

In the event of low temperature (failure of the probe heating), the

sample gas supply must be interrupted by suitable measures!

13 STARTING

Prior to starting the device, the system and process-specific safety measures must be observed.

For the media to be supplied, the relevant safety requirements and measures must be taken into

account.

The following step-by-step procedure is recommended:

Check the set temperature on the built-in thermostat or on the external controller.

Switch on the power.

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 20

20

W ARN ING !

Beware of aggressive condensate. Wear safety goggles and

appropriate protective clothing!

W ARN ING !

Caution: Do not touch the probe surface when in use. The high

surface temperatures that prevail are liable to cause burns.

Protective gloves must be worn and the probe must be protected to

prevent unauthorised access!

W ARN ING !

Prior to carrying out maintenance on electrical components, the

power supply must be disconnected in all poles. This applies

similarly to any connected alarm and control circuits!

NOTE!

The probe can remain mounted for maintenance or repairs.

Replacement of the process-sided sample tube can take place with the

probe head mounted.

14 CLOSING DOWN

Prior to closing down, i.e. switching off the heating, the probe should be flushed with inter gas or air in

order to prevent the condensation of aggressive components from the process gas.

15 MAINTENANCE

Prior to carrying out maintenance and repairs, the system and process-specific safety measures must

be observed.

Maintenance intervals cannot be recommended. These must be determined depending on the specific

application.

Maintenance of the probe is limited mainly to replacement of the filter mats and inspection of the seals

and gaskets.

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 21

21

W ARN ING !

Prior to carrying out maintenance and repairs, it must be ensured

that no health-endangering contaminants remain in the probe. An

appropriate measure is to flush the probe with inert gas, for

example.

Before replacing the filter element, the sample gas supply must be

interrupted!

NOTE!

Graphite seals in combination with the highly heated probe can

only be used a single time. Important to note after fitting the filter

housing cover that the U-bolt is tightened hand-tight in a cold

condition and retightened when the operating temperature is

reached.

15.1 REPLACEMENT OF FILTER ELEMENT AND SEALS

For replacement of the filter element or seals, the following procedure is recommended:

Remove protective cover after opening toggle-type fasteners.

Remove filter housing cover as described under 12.2.

Unscrew preliminary filter or sample tube from mounting adapter (see Figure. 7).

Unscrew mounting adapter.

Unscrew filter knurled screw, inspect filter and replace if necessary.

Inspect filter element seals and replace if necessary.

Inspect O-tings in cover and replace if necessary.

Clean filter space.

Refit filter housing cover in reverse order and insert probe head.

Lock filter housing cover as described under12.2.

Fit protective cover.

Gas sampling and gas conditioning technology 2-1.1.5-ME

Page 22

22

Recommended spare part

Article No.

Description

90 S 0020

Spare filter element S-2K150, ceramic, 2µm, 150mm

93 S 0045

Spare gasket (30), Viton

, for filter element S-2K150

93 S 1000

Spare O-ring (68), Viton

, for cover SP2500-H

93 S 1005

Spare O-ring (86), Viton

, for cover SP2500-H

93 S 1010

Spare O-ring (105), Viton

, for cover SP2500-H

93 S 0057

Gasket 11/2“, Novapress, for filter holder SP2500..

90 S 2077

Flange gasket DN65 PN6B (67), for SP2000

93 S 0010

Spare thermostat 0-180°C

93 S 0015

Spare heating cartridge HLP, 230V 800W

93 S 0017

Spare heating cartridge HLP, 115V 800W

93 S 0018

Heat transfer compound for fitting heating cartridge

16 SPARE PARTS LIST

The wearing and spare parts required depend on the specific operating conditions.

The following table contains some recommended spare parts for SP2500-H/.. . series probes

17 ANNEX

Further product documentation can be viewed and selected on our online

catalogue at: www.mc-techgroup.com.

Sample tubes series SP

Document: 2-1.1.0.6

Prefilter series SP

Document: 2-1.1.0.8

Gas sampling and gas conditioning technology 2-1.1.5-ME

Loading...

Loading...