Page 1

SP2500-H/C/I/BB/F/1K190

Embracing Challenge

Gas Sample Probe Series SP®

Version SP2500-H, SP2500-H/C/I/BB, SP2500-H/C/I/BB/F

Special Features

Extractable sample tube or prelter,

without dismounting the probe

Integrated back purge possibility with

closing o the sample gas outlet

Optimum operational reliability

Universal applicability

Adaption to nearly all process condi-

tions due to its compact and modular

design

Easy mounting

Problem-free maintenance

Small stagnant space

Application

The gas sample probes M&C type SP2500...,

based on version SP2000-H (see data sheet

2.2.2), are used for continuous gas sampling

in processes with gases of high dust content, high temperatures and/or high humidity. They make it possible to remove e.g. for

cleaning purposes the preliminary filter or

the sample tube out of the process without

dismounting the complete gas sample probe.

The probes type SP2500-H/C/I/BB and

SP2500-H/C/I/BB/F with special back purge

possibility are used in case of very high dust

content. For this purpose, they are equipped

with an additional back purge valve and a

pneumatic check valve in the sample gas

outlet.

Description

The M&C gas sample probes are designed for

easy installation, reliable operation, troublefree maintenance and universal applicability. Depending on the application, different

sample tubes or prefilters (see data sheets

2-1.1.0.6 and 2-1.1.0.8), not included in the

scope of delivery of the probe, are screwed

into the thread (G3/4”i) of the filter housing.

The large surface ceramic filter element (also

glass fiber elements or spun glass fillings

are available) is placed in a housing with low

stagnant space outside the process.

The M&C gas sample probes are designed

so that changing a filter element does not

involve the use of tools. In this operation the

sample line does not need to be removed,

thus avoiding contamination of the clean gas

path and also maintaining the integrity of the

system.

The cleaning of the sample tube or the preliminary filter can be effected by extracting

the filter from the probe.

The special design of the heating element of

the SP2500... (with protective hood) permits

controlled heating of the complete filter

housing, including the mounting flange up

tp 180 °C. This ensures reliable operation

external to the process preventing the temperature falling

below the dew-point.

The temperature of the standard probe is

controlled by an integral compact design

capillary sensor thermostat with an excess

temperature limit switch and an alarm

function for temperature failure. The probe

SP2500-H provides the possibility to feed the

test gas /C optionally via a check valve.

Additional functions of the probe SP2500H/C/I/BB(/F):

• Calibration gas will be injected into

the probe through a check valve /C

directly to the sample outlet. No calibration gas is lost into the stack.

• An isolation valve with pneumatic control /I shuts off the sample outlet from the

internal filter area.

• Through a high flow rate check valve /

BB, which is fixed to the internal probe

area, blow back of the filter housing

area and the insitu probe tube will be

done.

• Through a high flow rate check valve

/BB/F, which is fixed to the filter housing wall, blow back of the incorporated ceramic filter will be done incl. the

filter area and the insitu probe tube.

Technical specications and illustrations are without

obligation, subject to modications. 03.03/06.06

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

2.4

Page 2

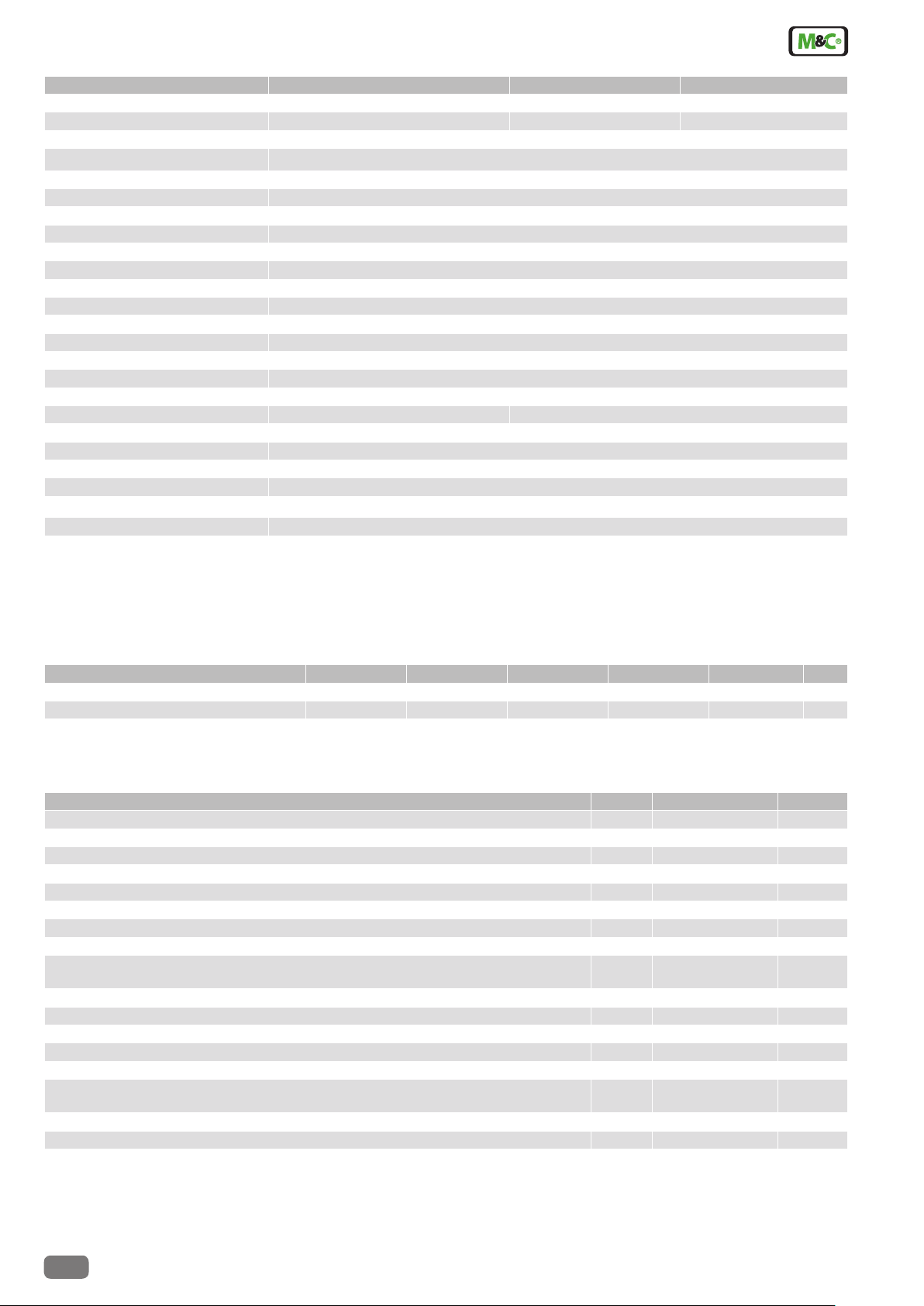

Technical Data

Gas Sample Probe Version SP2500-H SP2500-H/C/I/BB SP2500-H/C/I/BB/F

Part No. 20S3510 20S3520 20S3530

Integrated backflush no via filter chamber via filter element

Protective cover yes

Terminal box IP54 EN60529

Filter housing material Stainless steeel 316 / 316Ti*

Sealing materials FPM*

Probe flange sealing material Novapress

Insitu probe tube/prefilter Optional

Sample pressure max. 0,4-6 bar* abs.

Ambient temperature -20 °C to +60 °C*** /PT100, /Fe-CuNi, /Ni-CrNi** = -20°C to +80°C

Filter chamber volume 280 cm

Filter element, porosity S-2K150= Ceramic*, 2micron, /F-0, 1GF150= Glass fibre**, 0,1 micron, /FW= Spun glass**

Thermostat, Temperature adjustment 0-180°C* /PT100** /Fe-CuNi** /Ni-CrNi**

Ready for operation after 40min

Low temperature alarm contact Change-over contact Contact rating: 250V, 3A~, 0,25A= Alarm point: ∆T 30°C

Sample gas outlet connection 1x 1/4“ NPTi* tube connectors ø 6, 8 or 10 mm**

Backflush/Test gas connection 1/4“ NPTi* /C**= tube ø 8mm backflush: tube Ø 8mm, span: tube Ø 6mm

Shut off valve connection /I 1/8” NPT i

Pressure range contol air /I 3 - 10 bar

Power supply 230V 50/60 Hz, 800W /115V** = 115V 60Hz, 800W (fuse protection 10A)

Electrical connections Terminals max. 4mm2, 2x PG 13,5 cable gland

Electrical equipment standard EN 61010, EN 60519-1

Mounting flange DN65 PN6-B, SS316Ti* >DN or ANSI possible**

Weight 17kg*

* Standard

** Options

*** In case of higher ambient temperatures use option PT100 (Part No. 20S9025) or thermocouple Fe-CuNi respectively Ni-CrNi (Part No. 20S9027 resp.

20S9028) instead of the thermostate controller. Then, an additional electronic temperature controller (see data sheet 2-5.1) is necessary.

3

Differential pressure and T90-time

∆P and T90 at flow of: 100 200 500 1000 1500 Nl/hr

∆P with new filter element S-2K150/GF150 0,007 0,011 0,02 0,035 0,040 bar

T90-time for SP2500-H.. without tube 8 5,5 3 1 0,5 s

Versions and options (extract)

Executions Data s. Version Part-No.

Basic execution, heated to 0-180 °C ,with weather protection shield, material SS 316Ti 2-1.1.5 SP2500-H 20 S 3510

Basic execution, heated to 0-180 °C ,with weather protection shield, material SS 316Ti 2-1.1.5 SP2500-H/C/I/BB 20 S 3520

Basic execution, heated to 0-180 °C ,with weather protection shield, material SS 316Ti 2-1.1.5 SP2500-H/C/I/BB/F 20 S 3530

Options (Extract)

Execution with power supply 115V/60Hz /115V 20 S 9030

Execution with second outlet for sample gas 1/4" NPTi* /2x* 20 S 9015

Execution with back purge/calibration gas valve, opening pressure 0,7 bar, pipe 8 mm o.d.* /C* 20 S 9435

Execution with fiber glass filter element 0,1GF150, filter porosity 0,1 µm, sealing PTFE /GF150 20 S 9020

Execution with spec. filter housing lid and unscrewed cartridge

incl. spun glass filling, sealing FPM, Novapress

Execution with with PT00 sensor instead of the thermostat, without temp. controller /PT100 20 S 9025

Execution with thermoelement FE-CuNi ( type J ) instead of thermostat, without temp. controller /Fe-CuN 20 S 9027

Execution with thermoelement Ni-CrNi (type K) instead of thermostat, without temp. controller /Ni-CrNi 20 S 9028

Execution with second PT100 sensor /2-PT100 20 S 9026

Execution with special adapter flange size DN..PN6 or ANSI..150 lbs /DN 20 S 9004

Supporting adapter type SP2500H/SA500 to support long probe tubes and prefilters with extension tube,

including flange gasket, material 1.4571

Execution with gas pre-heater GVW1, material SS304 2-1.2.5 /GVW1 20 S 9058

Execution with connection of the gas pre-heater to valve ”BB” and to gas inlet 2-1.2.5 /GVW 20 S 9062

Execution with steam heating, without controller and valves /D 20 S 9033

* only SP2500-H

/FW 20 S 9047

/SA500 20 S 9433

2.4

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 03.03/06.06

Page 3

SP2600-H/C/I/BB/F/0,1GF190

Alarm contact

Power

Prefilter

Insitu sample tube

Dismounting

Control inSample out

Cal. gas in

Blowback in

Blow back in

Sample in

Blowback Control Cal.gas

Sample out

tube 6mm

340

110

260

207

345

(115V,60Hz

)

230V,50Hz

NL 'L

721 634 5

Tu <-30°C

8 9

To >+30°C

0-180°C

Tref.

1/8" NPTi

2-6bar

3-10bar

>0,7bar

1/4" NPTi

tube 8mm

optional: extension tube

Alarm contact

Power

Prefilter

Insitu tube

Dismounting

Sample out

Option: 2x

Cal. gas in

Cal. gas in

Sample in

Cal.gas

Sample out

Second Sample out

tube 8mm

340

110

260

207

345

(115V,60Hz)

230V,50Hz

NL 'L

721 634 5

Tu <-30°C

89

To >+30°C

0-180°C

Tref.

>0,7bar

Option: Option:

2x

Option: C

Option: C

Option: C

1/4" NPTi

optional: extension tube

Dimensions in mm

SP2500-H/C/I/BB

Dimensions in mm

Technical specications and illustrations are without

obligation, subject to modications. 03.03/06.06

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

2.4

Page 4

Alarm contact

Power

Prefilter

Insitu sample tube

Dismounting

Control inSample out

Cal. gas in

Blowback in

Blow back in

Sample in

Blowback Control Cal.gas

Sample out

tube 3/8"

tube 6mm

340

110

260

207

345

(115V,60Hz)

230V,50Hz

NL 'L

721 63 4 5

Tu <-30••C

8 9

To >+30••C

0-180••C

Tref.

1/8" NPTi

2-6bar

3-10bar

>0,7bar

1/4" NPTi

optional: extension tube

SP2500-H/C/I/BB/F

Dimensions in mm

2.4

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 03.03/06.06

Loading...

Loading...