Page 1

Instruction Manual

Gas Sample Probes Series SP

Versions SP2000H/DIL, SP2000H/DIL/B, SP2000H/DIL/BR

®

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 2

2

This Operating Manual does not claim completeness and may be subject to technical modifications.

© 01/2003 M&C TechGroup Germany GmbH. Reproduction of this

document or its content is not allowed without permission from M&C.

4th Edition: 04/2004

Dear customer,

we have made up this operating manual in such a way that all necessary information about the product can be found and understood quickly and easily.

Should you still have any question, please do not hesitate to contact M&C directly or go through your

appointed dealer. Respective contact addresses are to be found in the annexe to this operating manual.

Please also contact our homepage www.mc-techgroup.com for further information about our products. There, you can read or download the data sheets and operating manuals of all M&C products as

well as further information in German, English and French.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 3

3

Content

1 General information ...................................................................................................................... 5

2 Declaration of conformity ............................................................................................................ 5

3 Safety instructions ........................................................................................................................ 6

4 Warranty ........................................................................................................................................ 6

5 Used terms and signal indications .............................................................................................. 7

6 Introduction ................................................................................................................................... 8

7 Description .................................................................................................................................... 8

7.1 Variations ............................................................................................................................... 12

8 Technical Data ............................................................................................................................. 13

9 Dilution principle ......................................................................................................................... 14

10 Dimensions .................................................................................................................................. 15

11 Receipt and storage .................................................................................................................... 15

12 Installation information .............................................................................................................. 15

13 Installation ................................................................................................................................... 16

13.1 Installation of the sample probe ............................................................................................. 16

13.2 Connection of diluted sample outlet tubing ............................................................................ 17

13.3 Connection of supply tubes for dilution bypass gas ............................................................... 18

13.4 Connection of calibrating gas ................................................................................................ 19

13.5 Electrical connection .............................................................................................................. 19

13.5.1 Types with internal capillary tube hermostat .................................................................. 20

13.5.2 Types with external temperature controller ................................................................... 20

14 Initial use ..................................................................................................................................... 21

14.1 Calibration .............................................................................................................................. 23

15 Decommissioning ....................................................................................................................... 23

16 Maintenance ................................................................................................................................ 24

16.1 Replacement of filter element and seals ................................................................................ 25

16.2 Dismantling the dilution cross ................................................................................................ 27

16.2.1 Change and cleaning of the critical orifice (180°C version) ............................................ 28

16.2.2 Changing the packing at the critical orifice ( 320°C-Version) ......................................... 29

16.2.3 Change and cleaning of the injector ............................................................................... 30

16.2.4 Change of the o-ring at the injector (180°C-Version) ..................................................... 30

16.2.5 Change the packing at the injector (320°C-Version) ...................................................... 30

16.3 Removing the Bypass-T using option ..B/..BR (180°C version) ............................................. 31

16.3.1 Change and cleaning of the bypass injector (180°C version) ......................................... 32

16.3.2 Change of the O-ring at the bypass injector (180°C-Version) ........................................ 32

16.3.3 Change of the graphite packing at the bypass injector (320°C version) ......................... 33

17 Spare parts .................................................................................................................................. 34

18 Appendix ...................................................................................................................................... 35

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 4

4

List of illustrations

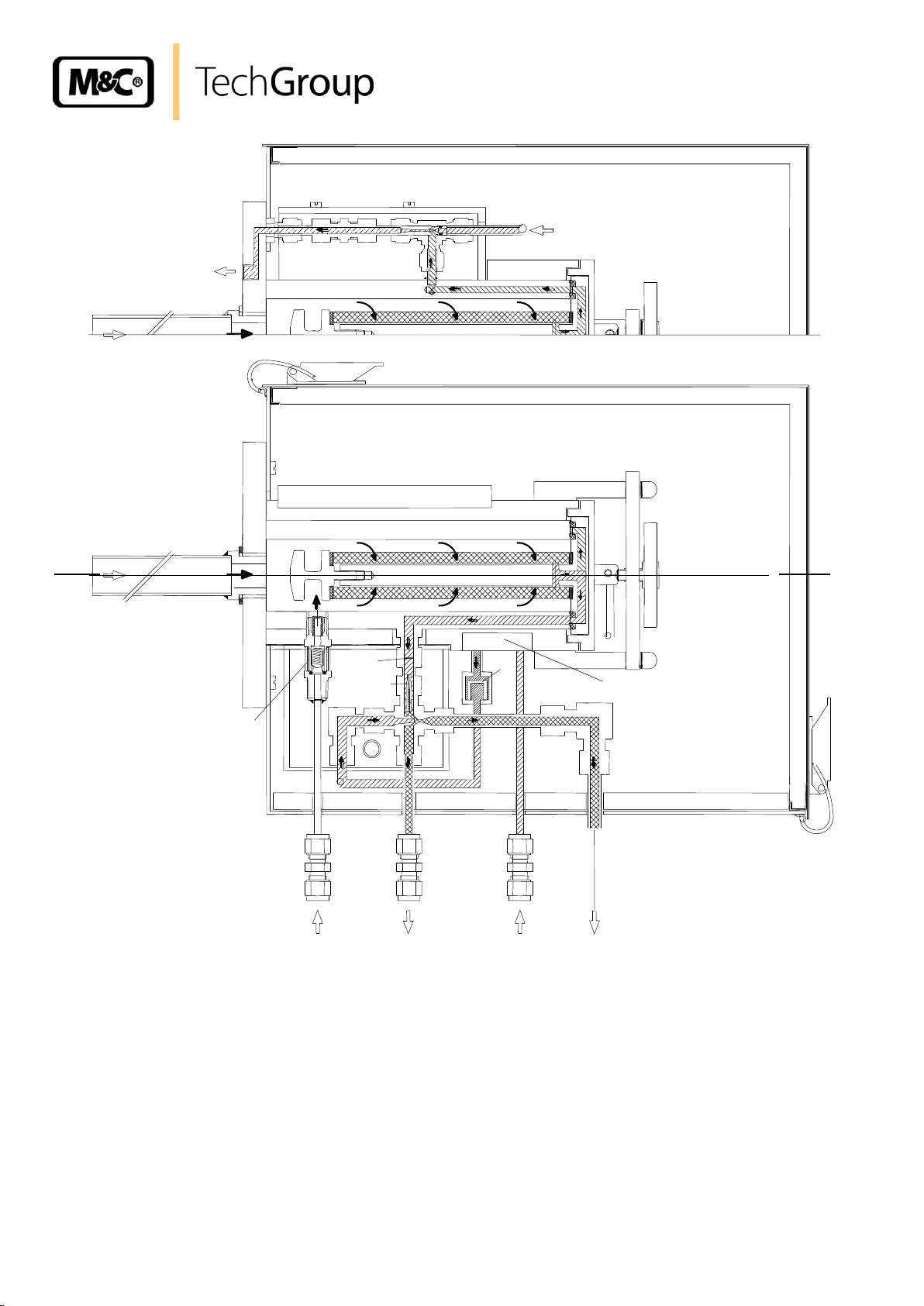

Figure 1 Probe type SP2000H/DIL/2x wit second sample outlet (undiluted) ................................... 8

Figure 2 Probe type SP2000H/DIL/VA/B ......................................................................................... 9

Figure 3 Probe type SP2000H/DIL/BR .......................................................................................... 10

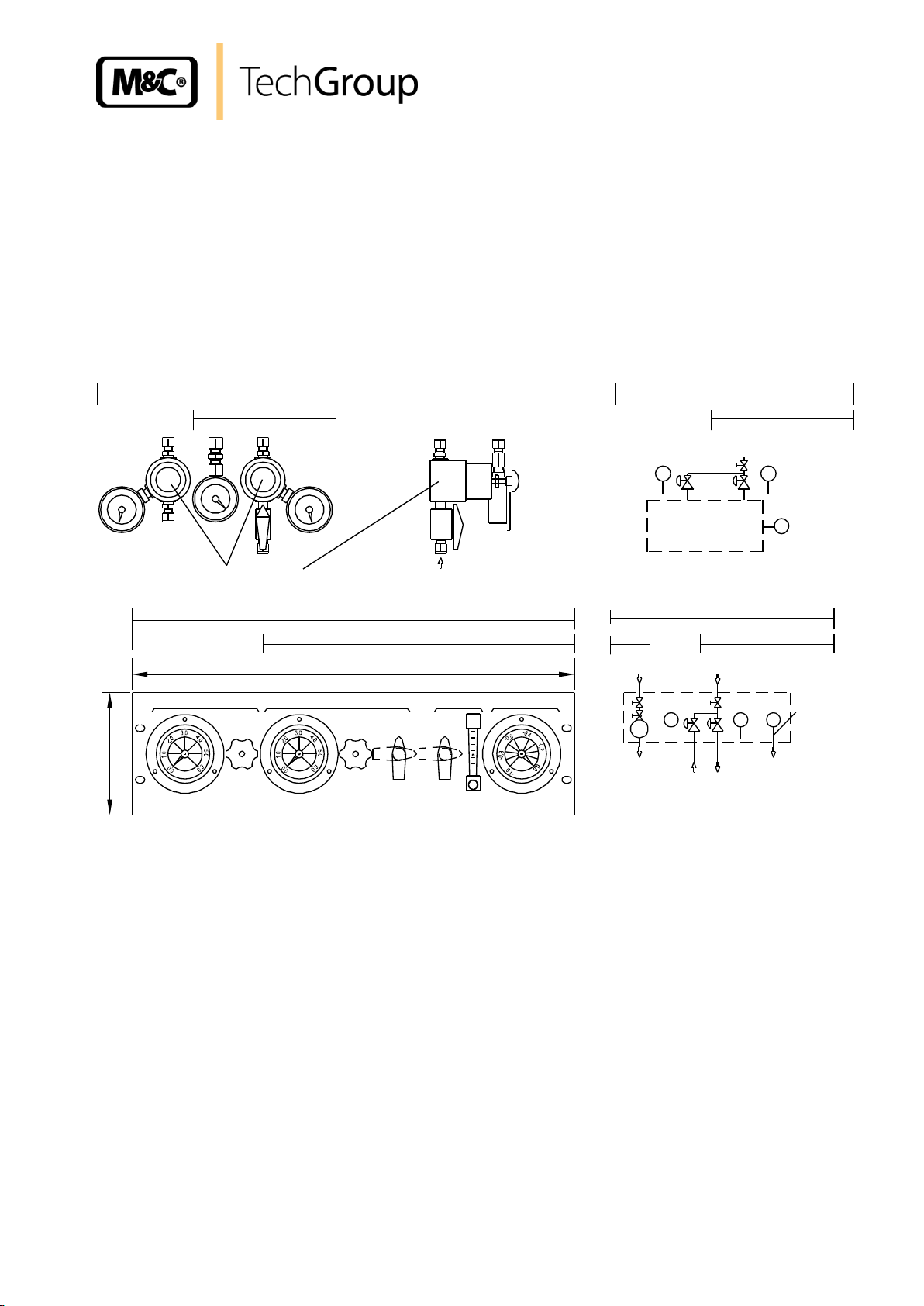

Figure 4 Installation set and control panel ..................................................................................... 11

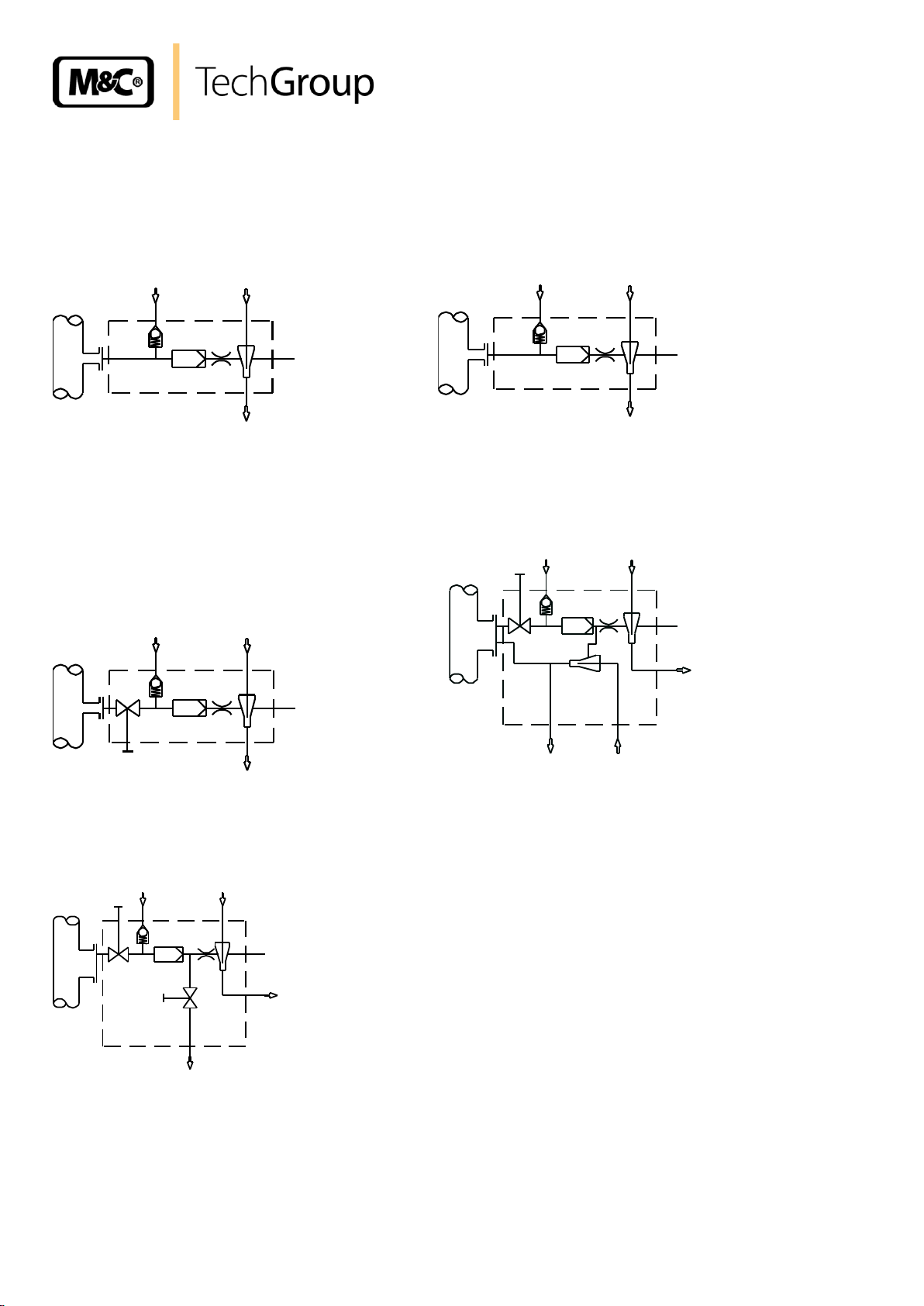

Figure 5 Gas flow pattern of available probe variants ................................................................... 12

Figure 6 Dilution principle .............................................................................................................. 14

Figure 7 Dimensions (mm) of SP2000H/DIL probe ....................................................................... 15

Figure 8 SP2000H/DIL/B with control panel DIL/S1 ...................................................................... 18

Figure 9 Extract from an injector data sheet .................................................................................. 22

Figure 10 Bypass injector data sheet ........................................................................................... 22

Figure 11 Cross-sectional drawing SP2000-H ............................................................................. 25

Figure 12 Removing the new filter housing lid ............................................................................. 26

Figure 13 Exploded drawing of dilution unit ................................................................................. 27

Figure 14 Crosspiece with critical orifice and o-ring seals (180°C version) ................................. 28

Figure 15 Dilution cross with graphite packing (320°C-Version) .................................................. 29

Figure 16 Injector 320°C version with graphite packing ............................................................... 30

Figure 17 Bypass-T with Injector and o-ring (180°C version) ...................................................... 31

Figure 18 Bypass Injector unit with o-ring ( 180°C-Version ) ....................................................... 32

Figure 19 Bypass Injector unit with graphite packing (320°C version) ......................................... 33

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 5

5

Head Office

M&C TechGroup Germany GmbH Rehhecke 79 40885 Ratingen Germany

Telephone: 02102 / 935 - 0

Fax: 02102 / 935 - 111

E - mail: info@mc-techgroup.com

www.mc-techgroup.com

1 GENERAL INFORMATION

The product described in this operating manual has been examined before delivery and left our works

in perfect condition related to safety regulations. In order to keep this condition and to guarantee a

safe operation, it is important to heed the notes and prescriptions made in this operating manual. Furthermore, attention must be paid to appropriate transportation, correct storage, as well as professional

installation and maintenance work.

All necessary information a skilled staff will need for appropriate use of this product are given in this

operating manual.

2 DECLARATION OF CONFORMITY

CE - Certification

The product described in this operating manual complies with the following EC directives:

EMV-Instruction

The requirements of the EC directive 2004/108/EC “Electromagnetic compatibility“ are met.

Low Voltage Directive

The requirement of the EC directive 2006/95/EC “Low Voltage Directive“ are met.

The compliance with this EC directive has been examined according to DIN EN 61010.

Declaration of conformity

The EU Declaration of conformity can be downloaded from the M&C homepage or directly requested

from M&C.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 6

6

3 SAFETY INSTRUCTIONS

Please take care of the following basic safety procedures when mounting, starting up or operating this equipment:

Read this operating manual before starting up and use of the equipment. The information and warnings given in this operating manual must be heeded.

Any work on electrical equipment is only to be carried out by trained specialists as per the regulations

currently in force.

Attention must be paid to the requirements of VDE 0100 (IEC 364) when setting high-power electrical

units with nominal voltages of up to 1000 V, together with the associated standards and stipulations.

Check the details on the type plate to ensure that the equipment is connected to the correct mains

voltage.

Protection against touching dangerously high electrical voltages:

Before opening the equipment, it must be switched off and hold no voltages. This also applies to any

external control circuits that are connected.

The device is only to be used within the permitted range of temperatures and pressures.

Check that the location is weather-protected. It should not be subject to either direct rain or moisture.

The device must not be used in hazardous areas.

Installation, maintenance, monitoring and any repairs may only be done by authorized personnel with

respect to the relevant stipulations.

4 WARRANTY

If the equipment fails, please contact M&C directly or else go through your M&C authorised dealer.

We offer a one year warranty as of the day of delivery as per our normal terms and conditions of sale,

and assuming technically correct operation of the unit. Consumables are hereby excluded. The terms

of the warranty cover repair at the factory at no cost or the replacement at no cost of the equipment

free ex user location. Reshipments must be send in a sufficient and proper protective packaging.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 7

7

DANGER!

This means that death, severe physical injuries and/or important material damages will occur in case the respective safety measures

are not fulfilled.

WAR NI NG !

This means that death, severe physical injuries and/or important material damages may occur in case the respective safety measures

are not fulfilled.

CARE!

This means that minor physical injuries may occur in case the respective safety measures are not fulfilled.

CARE!

Without the warning triangle means that a material damage may occur in case the respective safety measures are not met.

AT TEN TI ON!

This means that an unintentional situation or an unintentional status

may occur in case the respective note is not respected.

NOTE!

These are important information about the product or parts of the

operating manual which require user’s attention.

SKILLED STAFF

These are persons with necessary qualification who are familiar with

installation, use and maintenance of the product.

5 USED TERMS AND SIGNAL INDICATIONS

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 8

8

Sample out

diluted

Pressure gauge

-1…0bar

Cal gas

Dil. gas

6x1mm o.

Tube 8x1mm * (Inj. I)

Sample out

not diluted

option 2x

1/4"NPT

Dilution gas in

Tube

6x1mm o.

Tube

Dilution cross

6 INTRODUCTION

Dilution probes are used wherever dilution of the sample gas is necessary for the measurement of one

or several sample gas components. Examples are the measurement of toxic gas components, moisture measurements or adjustment of the sample gas concentration to the analyser measuring range.

M&C dilution probes type SP2000H/DIL... are based on the modular probe type SP2000-H. The diverse variants, filter techniques and materials available ensure optimal adjustment to the particular

process conditions.

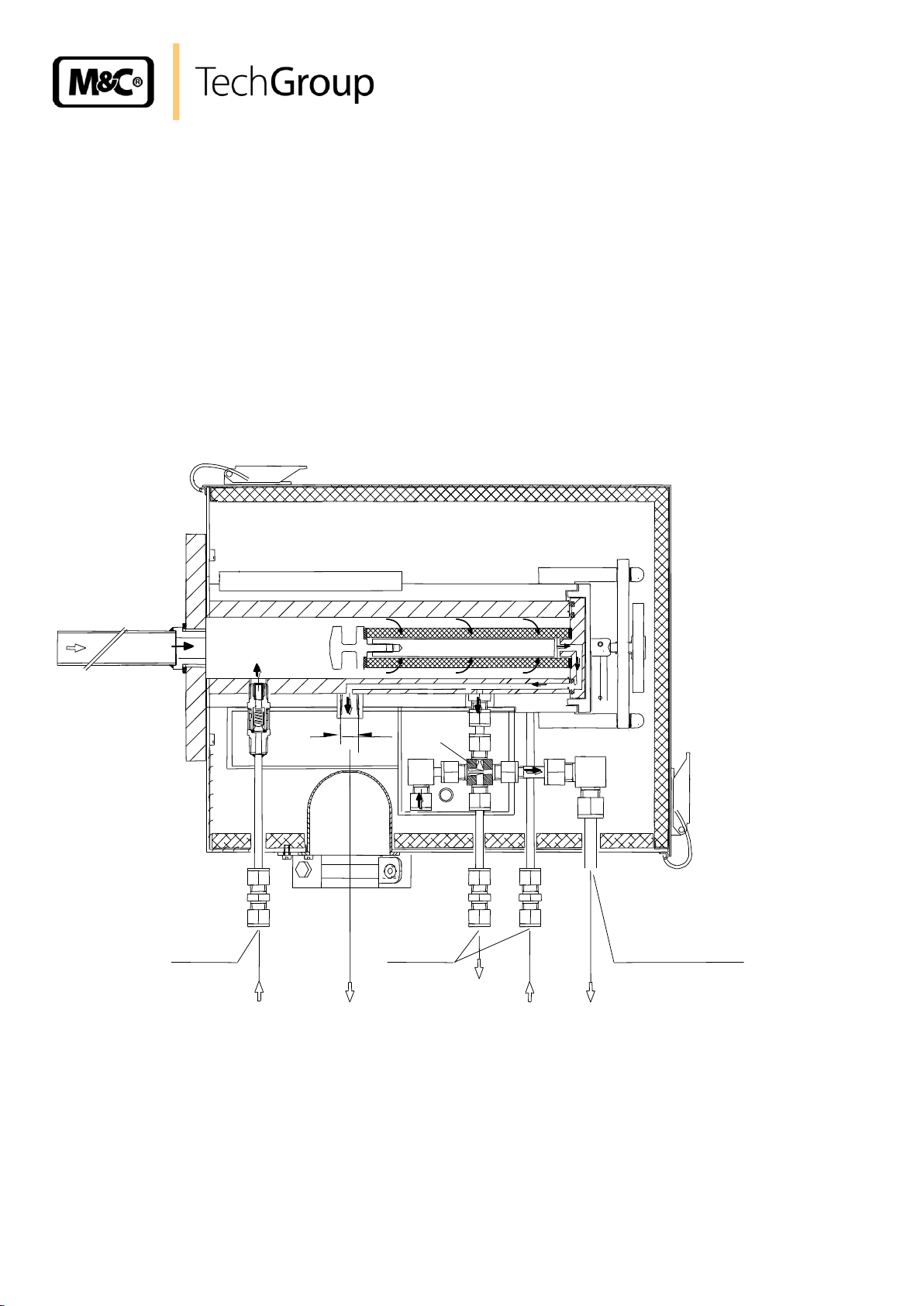

7 DESCRIPTION

The probe types SP2000H/DIL/2x, .../DIL/VA/B, .../DIL/BR are shown below.

Figure 1 Probe type SP2000H/DIL/2x wit second sample outlet (undiluted)

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 9

9

Sample out

diluted

Pressure gauge

-1...0bar

Cal gas

Dil gas

Check valve

Pre-heater

Filter

Crit. orifice

Bypass gas

View "A"

Bypass out

Bypass gas

Ball valve

Option VA

Filter

Bypass-T

A

A

Figure 2 Probe type SP2000H/DIL/VA/B

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 10

10

Sample out

diluted

Pressure gauge

-1…0bar

Cal gas

Dil gas

Check valve

Pre-heater

Filter

Filter

Crit. orifice

Bypass back to

The process

Bypass gas

View "A"

A

A

Figure 3 Probe type SP2000H/DIL/BR

To prevent cooling below dew point at the dilution point, the dilution unit with critical orifice is installed temperature-stable in the heated part of the gas sample probe directly in the clean gas outlet.

A gas pre-heater heats the dilution gas to probe temperature. With the option ..B/..BR wit bypass injector the bypass gas is pre-heated as well (double pre-heater). The probe is available with heating to

maximum 180°C or 320°C.

Test gas can be supplied to the probe for analyser calibration via the integrated test gas feed connection .

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 11

11

Pressure regulator

-A

-A1-A1

-A

-1...0 bar

measuring point

SP2000H/DIL...

0-6bar PI

Dilution gas

0-6barPI

PI

Underpressure

Bypass Dilution gas

Vacuum pressure

-1...0 bar

132 (3HE)

19" (84TE)

SP2000H/DIL...

-S1

-S

-S

Open

Test gas Inj.-low pressure

Open

Dilution gasBypass-Injector

-S

-S1

Bypass gas

measurement

PI

0-6 bar

15-150Nl/h

-1..0 bar

0-6 bar

FI

PI PI

Low pressure

Test gas Dilution gas/Bypass

Dilution gas

The probe can also be provided with an optional hand-operated, heated shut-off ball valve in the inlet VA (see Fig. 2) for the purpose of sealing off the filter space from the sampling process during filter

replacement. Another option is the second sample outlet for undiluted gas (..2x, see Fig.1)

A precision pressure regulator with pressure gauge serves for adjustment of the necessary dilution

gas supply pressure. The function of the dilution injector is monitored via a vacuum pressure gauge.

The pressure regulator and pressure gauge necessary for the dilution function must be ordered separately. Set -A is mounted directly on the probe. Control panel -S is designed for external installation

and is additionally provided with a shut-off valve and flow meter for test gas volume adjustment. The

options -A1 and -S1 include an additional pressure regulator for the bypass injector –B or bypass

injector with process return –BR (see Fig. 1).

Figure 4 Installation set and control panel

The dilution probe can be used for standard dilution factors from 10:1 to 500:1 (Injector I). Higher dilution rates in a ratio of 50:1 to 2000:1 are possible (Injector II).

Where a correspondingly small sample gas volume is taken from the process with large dilution factors, an optional heated bypass injector that is integrated directly upstream of the dilution part is available for reducing the response time in atmospheric respectively small vacuum operation. The bypass

option is available without gas return –B or with gas return to the process –BR . In vacuum operation, a bypass needle valve –BV serves for bypass volume adjustment (see Fig. 3).

The dilution unit is designed for problem-free operation independent of the process temperature and

process pressure (see technical data) as well as for easy maintenance.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 12

12

Dilution gas

measuring point

sample gas out

Underpressure

180° C

Test gas

Underpressure

measuring point

Test gas

320°C

Dilution gas

sample gas out

180° C

Test gas Dilution gas

measuring point

Sample gas out

Underpressure

not present

with type *

-B

-BR

Bypass gas in

*

Sample gas Dilution gas

Underpressure

measuring point

180°C

Sample gas out

Underpressure

measuring point

Sample gas

180°C

Dilution gas

Sample gas out

Bypassgas out

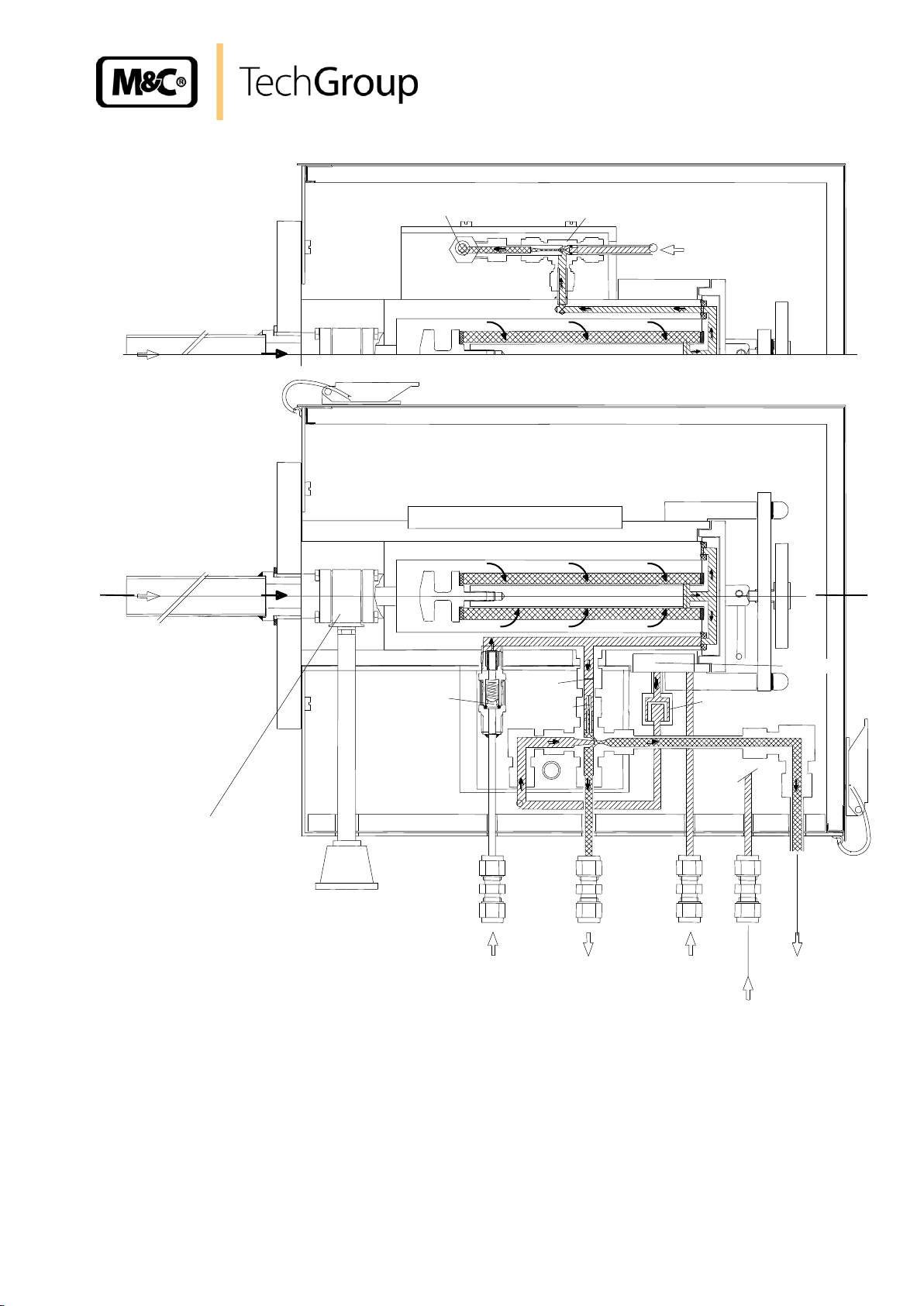

7.1 VARIATIONS

The gas flow patterns of the available probe variants are shown in the following figure.

SP2000-H/DIL SP2000-H320/DIL

SP2000-H/DIL-VA SP2000-H/DIL-VA-B

SP2000-H/DIL-B* (-BR*)

SP2000-H/DIL-VA-BV

Figure 5 Gas flow pattern of available probe variants

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 13

8 TECHNICAL DATA

Technical data SP series

®

Dilution probe version SP2000H/DIL ..

Weather protective cover

Yes

Electrical connection

Terminals; max. 4 mm²

Degree of protection of terminal box

IP54 EN60529

Mains supply

230V 50/60Hz, 800W or 115V 60Hz, 800W (fuse 10A)

Material of medium contacted parts

Stainless steel 1.4571, 1.4404, quartz glass, FPM, graphite

Ambient temperature

Thermostat: +5°C to 60°C

PT100, thermocouple: +5°C to 80°C

Operating temperature

0-180°C* alternatively 0-320°C

Ready

after 2 h

Temperature status alarm

/30°C to T

NOMINAL

*

Alarm contact rating

250V 3A AC, 0:25A DC

Sample gas outlet connection

1/4"-NPT internal, for max. 10mm pipe union

for version /H320 = pipe union øi 6mm*

Test gas back-flushing connection

for version /R pipe 6mm o.d.*

Filter space volume

120 ml

Weight

about 20 kg

Orifice type

a b c d e f g

Dilution factors1)

500:1

200:1

100:1

50:1

30*:1

20:1

10:1

Sample gas volume [Nl/hr]2)

1.4

2.7

5.5

11

19*

28

55

Dilution factor adjustment range

with dilution gas supply pressure setting -5% - +30%3)

Dilution gas volume injector version I or II

I: 480-600 Nl/hr*, optional II: 1800–3000 Nl/hr

Dilution gas supply pressure upstream of pressure regulator

Min. 4.5 bar, max. 16 bar

Bypass injector/B/BR:

Supply pressure – gas consumption – sample

gas volume

about 2 bar : Propellant ca. 300 l/hr : Sample gas about 150

l/hr

Process pressure

0.9 to 2 bar abs. at constant pressure

Influence of process temperature variations

No influence due to operation independent of process temperature

Influence of pressure change

Influence negligible at pressure changes ≤ 200mbar otherwise proportional to pressure changes.

Calibration of probe must be performed under process conditions or pressure correction must be implemented. Optional connection for pressure measurement / compensation

1/4“ NPT i.

13

* Standard, specify other values when ordering, intermediate values can also be specified.

1)

Values with injector I (higher dilution rates with injector II possible),

2)

at about 3 bar (downstream of supply pressure regulator) dilution gas,

3)

-5% however, not for orifice “g”

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 14

14

Orifice type

a b c d e f g

Dilution ratio

500:1

200:1

100:1

50:1

30:1

20:1

10:1

Volume flow through the critical orifice [Nl/h]

1.4

2.7

5.5

11

19

28

55

9 DILUTION PRINCIPLE

The functional principle of the dilution probe is based on ultrasonic flow through a critical orifice (see

Fig. 4). The flow through the orifice is constant when the differential pressure via the orifice is higher

than 500mbar. For the atmospheric inlet pressure (Poin = 1020mbar), this means a pressure at the

orifice outlet (P

The necessary vacuum at the orifice outlet is produced by an injector operated with dilution gas.

Depending on the critical orifice selected, dilution rates can be between 10:1 and 500:1. The table below gives an overview of the dilution factor and sample gas volume using the injector I (480 –

600Nl/h):

* With injector II 50:1 up to 2000:1

) of less than 520mbar absolute.

out

Figure 6 Dilution principle

Checking the dilution rates and exact adjustment of the pressure conditions are described in Chapter

14.1.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 15

15

Power

230V,50Hz

(115V,60Hz)(a)

Low temperature

alarm contact

Sample out

Dil gas

8x1mm o

Tube

Tube

6x1mm o

Tube

Sample

diluted

Pressure gauge

-1…0bar

Cal gas

Dil gas

Tube 8x1mm * (Inj. I)

Sample out

undiluted

1/4"NPT

Dil gas in

6x1mm o

Tube

6x1mm o

260

345

340

1) Implementation of the cal gas valve only with 180°C version; With 320°C version assembling in the angular sheet.

2) Tube connection 8mm (3/8”) o; With injector I connection DN6/8mm or DN8/10mm and with injector II DN8/10mm-DN12/14mm.

1)

2)

NOTE!

The probe should be stored in a protected, frost-free room.

10 DIMENSIONS

The dimensions of the SP2000H/DIL/2x probes are shown below.

Figure 7 Dimensions (mm) of SP2000H/DIL probe

11 RECEIPT AND STORAGE

Carefully remove the probe and any accessories from the transport packaging immediately upon

receipt and check the delivery against the delivery note.

Check the contents for possible transport damage and immediately notify the transport insurer of

any damage.

12 INSTALLATION INFORMATION

The safety rules and regulations for the prevention of accidents must be observed during installation

and also subsequent operation. The information in Chapter 3‚ “Important safety information” must be

observed.

The following also applies:

Select the optimal sampling point according to the generally applicable directives or co-ordinate

with the responsible departments.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 16

16

NOTE!

The probe must be checked for its suitability for use with the available operating parameters prior to installation (see type plate).

NOTE!

Check pipe unions for tightness.

Place the sampling point so that sufficient space is available for installation and removal of the

probe, taking into account the insertion length of the sample pipe.

Ensure good access to the probe for ease of maintenance.

Dimension the local sample connection so that the temperature of the connection is always above

the acid dew point to prevent corrosion and blockage problems. If this is not possible, a heated

sample pipe type SP35/SP30 is recommended for a cold orifice.

If the ambient temperature in the connection area is >60°C due to the radiated heat, a radiant heat

reflection plate must be provided locally for protection of the probe.

The mounting flange connection of the orifice should be DN65 PN6 or 3“ANSI (115V version). For

other required connection dimensions, an optional adapter intermediate flange is available. Instead of fitting a flanged orifice, the probe can also be fitted with an available R2" connection

adapter to an appropriate pipe coupling connection. The necessary, minimum flange size or

minimum connection diameter depends on the sample pipe used or pre-filter diameter.

It is recommended to fit the probe horizontally with an angle of inclination of 10° towards the proc-

ess.

13 INSTALLATION

M&C SP2000H/DIL... probes are designed for stationary use. With correct selection of the sample

point and proper installation, they will give many years of service with minimum maintenance required.

13.1 INSTALLATION OF THE SAMPLE PROBE

Remove probe cover after opening two toggle-type fasteners.

Turn stirrup bolt at the top end of the filter holder several times anticlockwise until the retaining

bracket can be turned laterally to the left.

Remove filter holder from the probe and check that the filter element is screwed tight. Subse-

quently refit filter holder.

Bring retaining bracket into previous position and tighten stirrup bolt hand-tight.

Remove heat conducting plates at sample gas outlets after loosening knurled screw. For connec-

tion of the sample pipe, screw in an appropriately dimensioned pipe union with 1/4"-NPT threaded

connection using PTFE sealing tape.

Screw supplied sample pipe or pre-filter directly or using an extension pipe into the 3/4" internal

thread in the probe flange with 3/4" flat gasket and tighten.

If the heated sample pipe type SP30/35 or ceramic pre-filter type V12 is used, the probe must be

bolted to its flange (with welded threaded studs). The flange seal must previously be placed between both flanges.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 17

17

NOTE!

When using the heated sample pipe or pre-filter V12 in conjunction with

probes with the bypass return option ..BR, a short-circuit between the bypass gas and sample inlet in the centre of the probe flange must be prevented or low sample gas readings will be obtained. Make sure that the gasket for the mounting flange does not block the bypass return connection or

the probe will not function properly.

NOTE!

For the preferred probe mounting position, the sample gas outlet points

downward (unnecessary for perfect functioning).

It is recommended to install the probe with a slight downward inclination

towards the process. This is essential for sampling, e.g. downstream of wet

scrubber (sample pipe type SP32), so that produced drops flow back into the

process.

NOTE!

Excess backpressure on the sample outlet of the probe can result in poor

performance. The maximum recommended tube length for common inside

tube diameters are as follows:

Injector type I:

i

6mm max. 50m

i

8mm max. 150m

Injector type II:

i

8mm max. 15m

i

10mm max. 40m

i

12mm max. 80m

NOTE!

When connecting hose pipes to stainless steel fittings, a supporting sleeve

must always be used.

The connection must be checked for tightness.

If the sample connection does not correspond with the flange connection DN65 PN6, the supplied

optional adapter flange must be fitted to the probe in the same way.

Position flange seal on sample connection.

Insert process-internal sample part of complete probe unit into sample connection.

Bolt mating and probe flange with supplied nuts and bolts.

13.2 CONNECTION OF DILUTED SAMPLE OUTLET TUBING

Provided on the probe side for connection of the sample outlet tubing is an elbow union with the di-

mension DN6/8mm (3/8“

for 115V version; optional also DN 8/10mm) in the space below the insu-

o

lating cover.

The sample tube is installed as follows:

Loosen toggle-type fasteners of insulating cover and remove the cover.

Insert tube through corresponding opening in base plate of the probe.

Connect tube to union.

Refit probe cover and lock with toggle-type fasteners.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 18

18

Test gas

njector-vacuum

Dilution gas

Bypass injector

Open

Open

500 l/h

Check valve

Calibration gas

Dilution gas

Vacuum pressure gauge

Bypass

Control panel DIl/S1

Dilution gas

Cal gas

Sample out

Bypass

Analyser

Back pressure max. 1,2 bar abs.

Option –A/A1

When ordering option –A or -A1, the sets, consisting of pressure regulators and pressure gauges, are

mounted directly on the probe (see Fig.2). Connection of the sample pipe takes place at the elbow

union of the probe (see above).

Option –S/S1

For option –S or - S1, the necessary pressure regulators, pressure gauge, shut-off valves and flow

meter are installed externally in a 19“ control panel (see Fig. 4). Connection of the sample or supply

pipes to the probe and downstream analyser system must be established by the customer. Appropriately marked connections are provided at the rear of the 19“ unit.

Figure 8 SP2000H/DIL/B with control panel DIL/S1

13.3 CONNECTION OF SUPPLY TUBES FOR DILUTION BYPASS GAS

Available for connection of the supply tubes are probe-sided tube unions with the dimension

DN4/6mm (1/4“

for 115V version). The tube unions are located outside the probe cover and can

o

be connected without disassembly.

When using option –A (only dilution gas) or –A1 (dilution and bypass gas), the supply tubes are con-

nected to the unions of the precision pressure regulator.

When using the 19“ control panels, corresponding connections for the supply gases are provided at

the rear of the unit.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 19

19

WAR NI NG !

An incorrect mains voltage can damage the unit. Check the rating

plate for the correct voltage prior to connection!

The probe must be installed so that contact with live parts is excluded!

In any case we recommend the use of temperature resistant cable !

The alarm contact for under-temperature must be displayed!

In case of an under-temperature alarm (failure of probe heating or

sensor), the dilution gas and bypass gas supply (if equipped) must

be interrupted or serious probe damage will result. We recommend

that external solenoid valves to perform this function be wired into

the probe’s under-temperature alarm circuitry automatically.

Damage the probe’s internal components from plugging or corro-

sion resulting from the lack of use of the probe’s under-

temperature alarm are not covered by warranty.

NOTE!

For the erection of power installations with rated voltages up to

1000V, the requirements of VDE 0100 and its associated standards

and specifications must be observed.

A main switch must be provided externally.

The supply circuit of the unit must be protected by a fuse with the

correct rating (over-current protection); the electrical values are

shown in the technical data.

When installing the capillary regulator or PID controller at the sample point, the maximum permissible ambient temperature must be

observed (see 8.). If this limit is exceeded, a PID controller must be

installed externally and outside the temperature critical zone.

13.4 CONNECTION OF CALIBRATING GAS

The dilution heated probe is provided with a check valve as standard, opening at pressures above

0.7bar.

In both versions, a pipe union DN4/6mm (1/4“

for 115V version) is available for connection of the

o

calibrating gas.

13.5 ELECTRICAL CONNECTION

Temperature setting of the SP2000H/DIL... probes takes place with a capillary regulator as standard.

The probe can also be provided with an optional PT100 or thermocouple. This requires the connection

of an external temperature controller.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 20

20

WAR NI NG !

For connecting use temperature resistant cable!

WAR NI NG !

Use corresponding compensating lines with thermocouples !

Power 230V 50Hz

or 115V 60Hz

Alarm output

1

2

1

2

+30°C

-30°C

Power 230V 50Hz

or 115V 60Hz

PT100 or

thermocouple

1

2

1

2

13.5.1 TYPES WITH INTERNAL CAPILLARY TUBE HERMOSTAT

Remove cover of connection box. The electrical wiring

diagram is located in the cover.

Insert mains cable (min. 3x1.5mm2) through cable gland

and connect to appropriate terminals.

Insert signal cable (under-temperature alarm) through ca-

ble gland and connect to appropriate terminals (the contact

Tu shows the alarm event).

Screw cover back in place.

13.5.2 TYPES WITH EXTERNAL TEMPERATURE CONTROLLER

Remove cover of connection box. The electrical

wiring diagram is located in the cover.

Insert mains cable (min. 3x1.5mm2) through cable

gland and connect to appropriate terminals.

Insert temperature sensor cable through cable

gland and connect to appropriate terminals.

Screw cover back in place.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 21

21

WAR NI NG !

The air supply to the injectors should not be turned on until the

probe is at operating temperature (see. technical data). Or damage

to the probe or/and inconsistent initial dilution ratio can result.

Prior to initial use, it must be ensured that the mains voltage corresponds with the voltage on the rating plate!

Caution: Do not touch the probe surface during use as this can

cause burns due to the high surface temperatures. Protective

gloves must be worn and the probe protected against unauthorised

access!

NOTE!

If the set temperature on the capillary controller should be reduced

by more than 30°C in one step during operation, the thermostat

over-temperature cut-out will operate (for re-starting press the reset button).

NOTE!

The total heating time is about two hours. After about one hour, the

lower alarm threshold value (30°C below set value) is exceeded.

NOTE!

For safety reasons, the vacuum pressure gauge must show a vacuum reading of >-0.6 bar. With a vacuum reading of < -0.6 bar, the

critical orifice will not function properly. If the necessary vacuum is

not reached, the dilution gas supply pressure must be increased.

14 INITIAL USE

Prior to initial use, system and process-specific safety measures must be observed.

For the media to be transported, the relevant safety requirements and measures must be taken into

account.

The following step-by-step procedure is recommended:

If available, close ball valve via pneumatic actuator or manually (turn twist handle fully to the right)

Check set temperature on installed thermostat or external controller.

Switch on the mains voltage.

After heating the complete probe (about two hours), open the ball valve for the dilution gas. If a ball

valve is installed operate the pneumatic actuator or turn the twist handle fully to the left manually.

Set the precision pressure reducer to the pressure specified on the enclosed injector data sheet (see

Fig. 6).

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 22

22

Injektortyp

I

Injektor-Nr.

689

Für Sonden-Nr.

8652/222835

Typ

SP2000-H/DIL/BR

Injector type

Injector No.

For probe No.

Type

Betriebsdruck

Operating pres-

sure

[bar]

Durchfluss

Flow

[l/h]

Unterdruck ohne kritische Düse

Vacuum without critical orifice

[bar]

Unterdruck mit kritischer Düse

Vacuum with critical orifice 5,1l/h

[bar]

2,4

415

-0,62

-0,61

2,6

435

-0,65

-0,64

2,8

460

-0,68

-0,67

3,0

490

-0,80

-0,77

3,2

510

-0,79

-0,77

3,4

535

-0,79

-0,77

3,6

560

-0,78

-0,76

3,8

585

-0,77

-0,76

4,0

605

-0,77

-0,75

Überprüfung des Verdünnungsfaktors

Check of the dilution ratio

Messgasdruck atmosphärisch

Sample gas pressure atmospheric

Kritische Düse

Critical nozzle

Verd.gas

Dilution gas

Verdünnungsgasdruck

Dilution gas pressure

Messgas

Sample

Verdünnung

Dilution

Messwert d. verd. Gases

Meas. value of the dil.

gas

5,1 l/h

100% N2

3,1 bar

100% O2

100:1

1,0 % O2

NOTE!

The gas pressure must be higher than 0.7 bar, as the vacuum valve

mounted on the probe has an opening pressure of 0. 7 bar.

When using the control panel, the respective ball valve for the test

gas supply must be opened and the flow rate set on the flow meter.

Bypass- Injektor

I

Ser.-Nr.

526

Für Sonden-Nr.

8652/222835

Typ

SP2000-H/DIL/BR

Bypass injector

Ser. No.

For probe No.

Type Bypassgas / Bypass gas

Prozessgas / Sample gas

Betriebsdruck

Operating pressure

[bar]

Durchfluss

Flow

[l/h]

Ansaugvolumenstrom bei 1bar

abs. Suction flow at 1bar abs.

[l/h]

Ansaugvolumenstrom bei 0,9bar abs.

Suction flow at 0,9bar abs.

[l/h]

0,5

110

45

-

1,0

155

115

-

1,5

190

200

65

2,0

235

250

135

2,5

270

300

200

3,0

310

350

250

3,5

355

370

270

4,0

395

390

305

4,5

430

425

350

An extract from an injector data sheet is shown below.

Injektor-Datenblatt / Injector data sheet

Figure 9 Extract from an injector data sheet

For the operation of an installed bypass injector, the necessary pressure must be set on the pressure

regulator provided (on left next to precision pressure regulator).

Figure 10 Bypass injector data sheet

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 23

23

WAR NI NG !

In the event of under-temperature (failure of probe heating), the dilution gas supply must be interrupted!

NOTE!

The gas pressure must be higher than 0.7 bar, as the vacuum valve

mounted on the probe has an opening pressure of 0. 7 bar.

When using the control panel, the respective ball valve for the test

gas supply must be opened and the flow rate set on the flow meter.

NOTE!

Calibrate systems analysers directly with zero gas and low concentration sample gas.

14.1 CALIBRATION

Calibration of the downstream analyser system or checking the dilution factor must always take place

under process conditions.

An appropriate calibration gas can be supplied via the cal gas valve.

The procedure for calibration or checking the dilution ratio is as follows:

Supply test gas of a known concentration to probe.

Check dilution ratio on downstream analyser and correct pressure on dilution gas supply pressure

regulator.

Test gas supply without bypass injector

To ensure that sufficient test gas is available in the filter space of the probe, the To test gas volume

should be minimum three times the flow through the critical orifice (see injector data sheet).

Test gas supply with bypass injector

The test gas volume must be about 10% higher than the volume flow through the probe produced by

the bypass and the volume flow via the critical orifice (see Fig. 7).

15 DECOMMISSIONING

Prior to decommissioning, i.e. switching off the heating, the probe should be purged with inert gas or

air to prevent the condensation of aggressive components from the process gas.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 24

24

WAR NI NG !

Aggressive condensation possible. Safety goggles and appropriate protective clothing should be worn!

Caution: Do not touch the probe surface during use as this can

cause burns due to the high surface temperatures. Protective

gloves must be worn and the probe protected against unauthorised

access!

Before carrying out maintenance work on electrical components,

the mains voltage must be disconnected in all poles. This applies

similarly to any connected alarm and control circuits!

NOTE!

The probe does not need to be removed for repairs or maintenance.

The probe will need to be removed for replacement of the process-

sided sample pipe.

16 MAINTENANCE

Prior to maintenance and repairs, system and process-specific safety measures must be observed.

No recommendations for maintenance intervals can be given. Maintenance intervals must be determined depending on the particular process conditions and specific application.

Probe maintenance is limited mainly to replacement of the filter elements, inspection of the seals and

maintenance of the dilution systems.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 25

25

WAR NI NG !

Before carrying out any maintenance or repairs, it must be ensured

that no health-endangering contaminants remain in the probe. A

suitable measure is, e.g. purging the probe with inert gas.

The bypass respectively primary injector air supply should be

turned off before the probe filter lid assembly is removed. Otherwise the critical orifice will be blocked by dust !

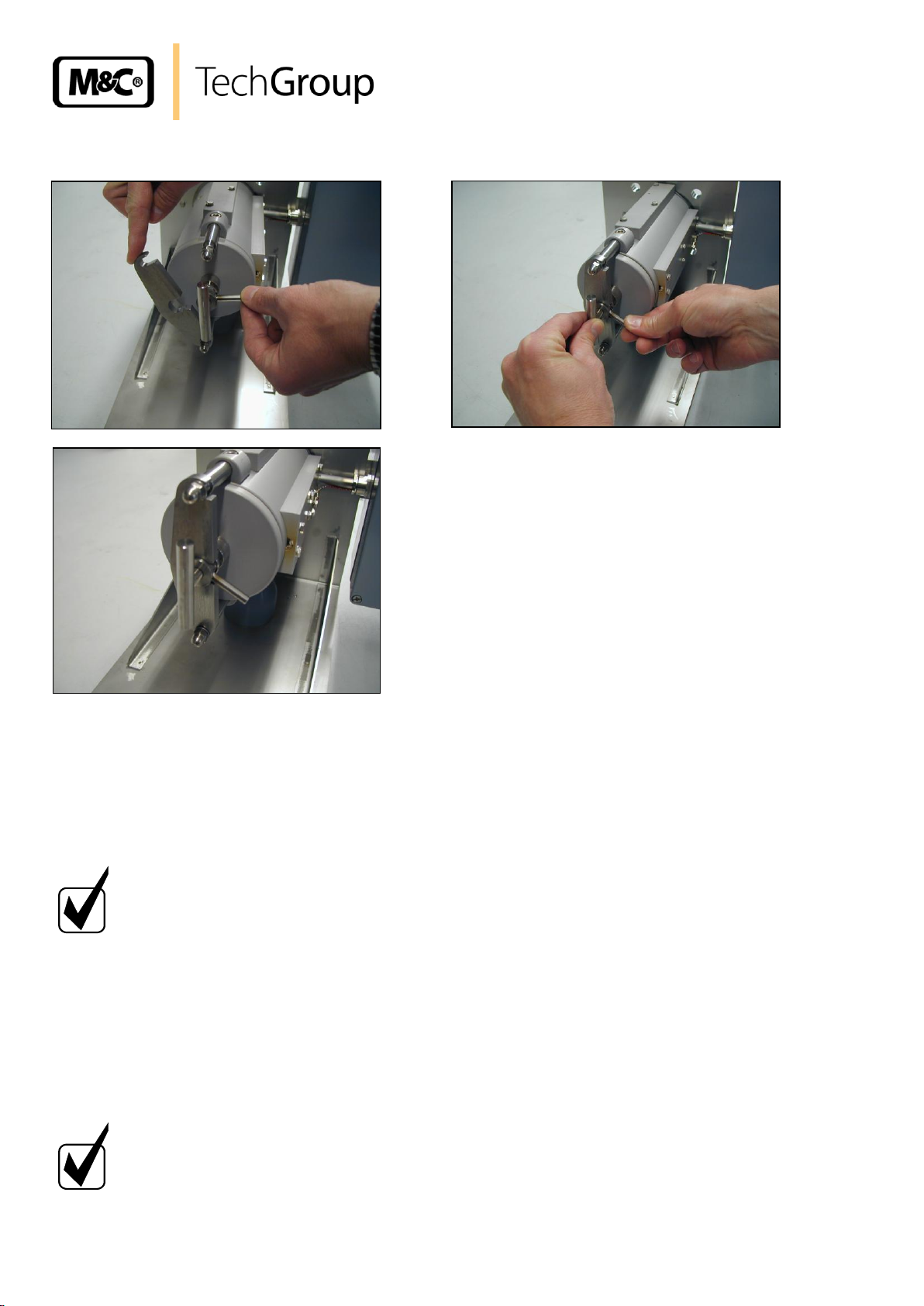

16.1 REPLACEMENT OF FILTER ELEMENT AND SEALS

For change of the filter element respectively gaskets carry out the following steps:

Close ball valve (if available).

Close dilution gas supply and, if available, bypass gas supply.

Remove protective cover after loosening toggle-type fasteners.

Loosen stirrup bolt, swing retaining bracket to the left, grip filter holder by the ring and withdraw.

From serial no. 10283:

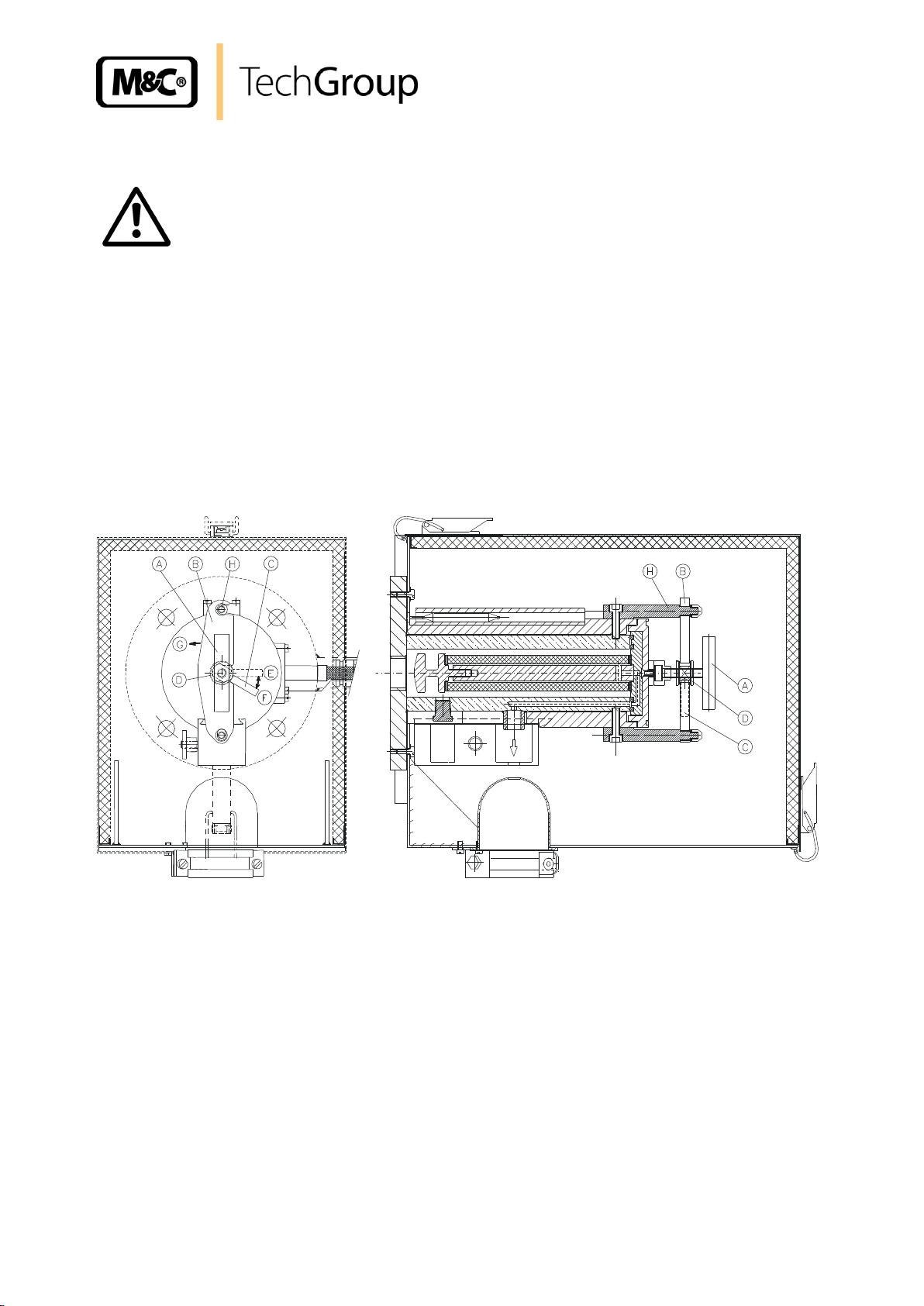

Figure 11 Cross-sectional drawing SP2000-H

The following steps are recommended removing the filter housing lid:

Turn toggle screw „A“ approx. 1 turn counter-clockwise, that the filter housing lid will lift up;

Turn handle „C“ in position „E“;

Turn clamp „B“ counter-clockwise in direction „G“;

Take toggle screw „A“ an pull out the filter housing lid;

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 26

26

NOTE!

It is now also possible to clean the sample pipe to remove deposits.

Caution ceramic probe tubes. Increased risk of breakage!

NOTE!

Graphite gaskets in combination with the highly heated probe can

only be used once. To be noted is that after inserting the filter

holder, the stirrup bolt must tightened hand-tight in a cold condition and retightened after reaching operating temperature.

The following pictures should explain the above mentioned steps.

Figure 12 Removing the new filter housing lid

Unscrew filter knurled screw, inspect filter element and replace if necessary.

Inspect filter element seals and replace if necessary.

Inspect O-rings (for /320H.. flat graphite gasket, for /7aT PTFE sealing rings) in cover and re-

place if necessary.

Clean filter space.

Turn clamp „B“ clockwise and turn with the handle „C“ the ringsscrew „D“ in position „E“, that

the clamp „B“ will latch into the ringscrew „D“ and the threaded bolt „H“. It could be neccessary

to move the filter housing lid a little bit forward and backward;

Turn handle „C“ in position „F“ and fasten the filter housing lid by turning the toggle screw „A“

clockwise by hand.

Fit protective cover.

Open ball valve (if available).

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 27

27

Nut 1

Nut 2

Nut 3

Nut 4

Nut 5

Nut 6

Critical orifice

Mark

Injector

Mark

Mark

Tube sample gas

out

Block

180°C Version

O-rings

WAR NI NG !

Do not remove nut 2 until the dilution cross is removed from the

probe or the orifice will be broken !

16.2 DISMANTLING THE DILUTION CROSS

Figure 11 shows an exploded drawing of the dilution unit.

Figure 13 Exploded drawing of dilution unit

The following step-by-step procedure is recommended:

Remove probe insulating cover (see 16.1).

Loosen knurled screw for fixing heat conducting plates.

Remove heat conducting plates.

Remove all pipe connections on dilution unit (crosspiece). These are:

- vacuum pressure gauge nut 6

- dilution gas inlet nut 4

- sample gas outlet nut 5 (remove sample gas out pipe at upper elbow union. Do not remove

pipe connected to crosspiece)

- nut 1.

The dilution cross is now ready for further maintenance and repair work.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 28

28

WAR NI NG !

Do not clean the critical orifice mechanically.

Cleaning should take place in an ultrasonic bath!

Jet pipe

2

1

Orifice

Sucking pipe

Pos. 2:

Sealing set for critical orifice

consisting of 2 o-rings

Part No.: 93 S 4009

Orifice

Seat

O-rings

Mounting tool

Part No.: 93S4040

3

Nut 3

Injector

WAR NI NG !

The Swagelok® fittings must be carefully tightened to avoid damaging the internal components. Tightening too far will damage the

cross.

Use a mating gauge to make sure that the fittings are not too tight.

If a fitting is believed to be leaking, do not tighten the fitting to re-

move the leak. Disassemble the piece completely and reassemble it

making sure that the nut is not tightened too far.

16.2.1 CHANGE AND CLEANING OF THE CRITICAL ORIFICE (180°C VERSION)

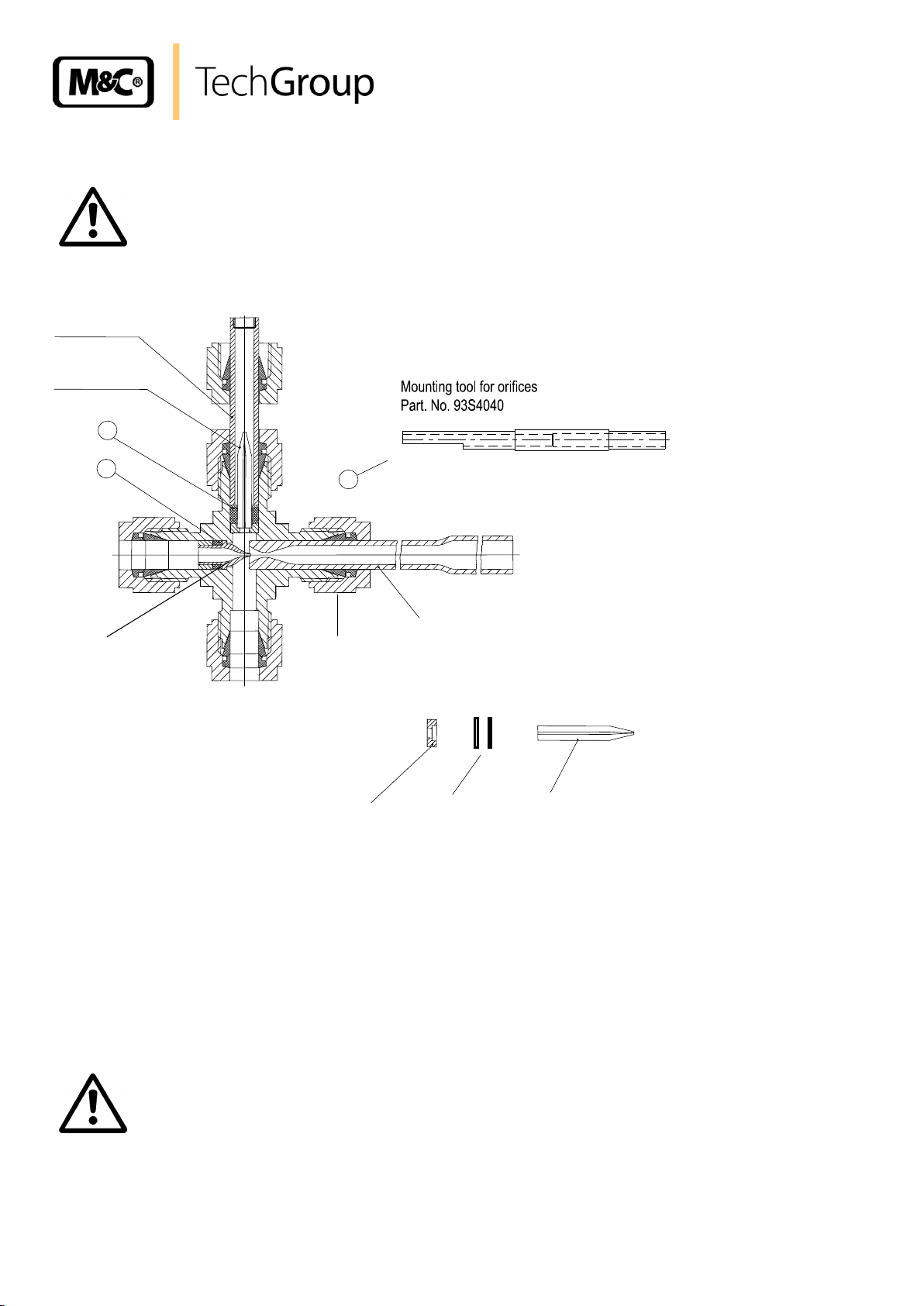

Figure 14 shows the position of the orifice in the crosspiece and the o-ring seals (180°C version).

Figure 14 Crosspiece with critical orifice and o-ring seals (180°C version)

Please dismantle as follows:

Loosen union nut 3 and remove the jet pipe;

Push the injector out with the mounting tool (pos. 3, Fig. 14). Carry it out from the opposite

side;

Push the critical orifice, orifice seat and o-rings carefully out of the crosspiece (with the tool

from the opposite side) ;

Check the o-rings and change them if necessary;

Re-fit the new respectively cleaned orifice into the o-rings (180°C-Version) up to block.

Re-install the dilution unit in the opposite way.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 29

29

Jet pipe

2

1

Orifice

Sucking pipe

Pos. 2:

Packing for critical orifice

consisting of 4 graphite seals

3,2/ 6 – 1,5mm thickness

plus plain washer 3,3/ 6

Part No.: 93 S 4005

Orifice

Seat

Graphite rings

Plain washer

Mounting tool

Part No.: 93S4040

3

Nut 3

Injector

WAR NI NG !

The Swagelok® fittings must be carefully tightened to avoid damaging the internal components. Tightening too far will damage the

cross.

Use a mating gauge to make sure that the fittings are not too tight.

If a fitting is believed to be leaking, do not tighten the fitting to re-

move the leak. Disassemble the piece completely and reassemble it

making sure that the nut is not tightened too far.

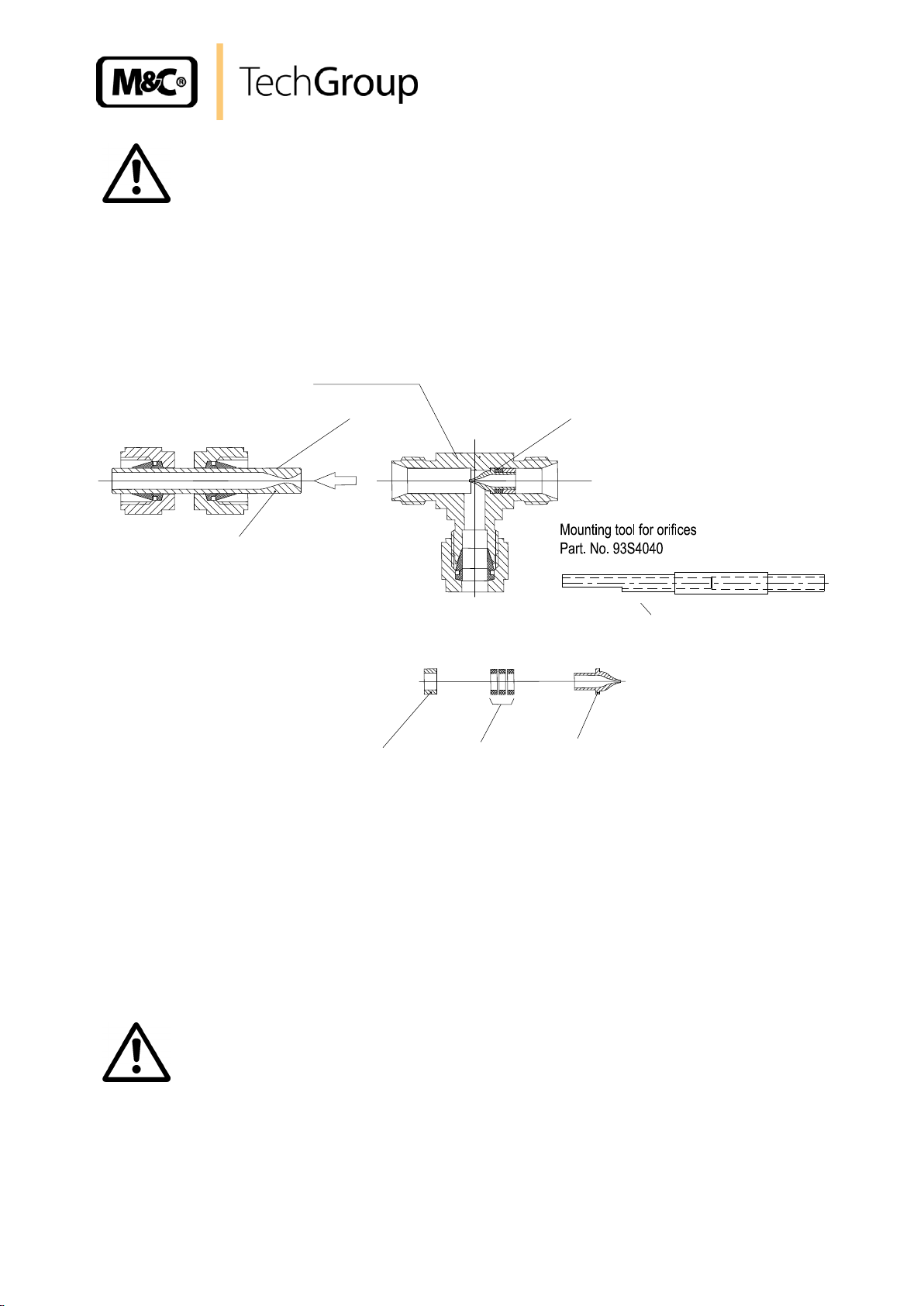

16.2.2 CHANGING THE PACKING AT THE CRITICAL ORIFICE ( 320°C-VERSION)

When the orifice is removed please change the packing (320°C- version) as well.

Figure 15 shows the dilution cross with the orifice and the packing (320°C version).

Figure 15 Dilution cross with graphite packing (320°C-Version)

The stepwise change of the graphite packing is as follows:

Remove the dilution cross as described in 16.2;

Loosen nut 3 and dismount the jet pipe;

Push out the injector with the mounting tool (Pos.3, Fig. 15) from the jet pipe side

Push out the orifice, the orifice seat and the graphite packing carefully from the opposite side

using the mounting tool (pos. 3, Fig. 15);

Remove the graphite sealing;

Push 4 new graphite rings and the plain washer on the orifice (dimension see Fig.15);

Place the orifice seat in the crosspiece;

Put the orifice in the seat;

Push the graphite packing with the tool into the cross up to block and press;

Re-fit the jet pipe.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 30

30

NOTE!

For cleaning the injector it is not necessary to remove it out of the

dilution cross. Clean the nozzle mechanically. For the 180°Cversion the complete cross can be cleaned up in an ultrasonic

bath.

WAR NI NG !

The complete cross of the 320°C-version can not be cleaned in an

ultrasonic bath. Otherwise the graphite packing will be damaged !

Before cleaning the nozzle with compressed air remove the critical

orifice first (s. 16.3) !

WAR NI NG !

The Swagelok® fittings must be carefully tightened to avoid damaging the internal components!

Thrust collar

Nozzle

Graphite rings

Part No.: 93S4002

Injector complete, DIL-H320

16.2.3 CHANGE AND CLEANING OF THE INJECTOR

16.2.4 CHANGE OF THE O-RING AT THE INJECTOR (180°C-VERSION)

Please change the o-ring as follows:

Loosen union nut 3 and remove the jet pipe;

Loosen nut 4 and remove the dilution tube connection;

Push out the injector with the tool (Pos. 3) from the opposite side (jet pipe);

Remove the o-ring from the nozzle;

Push on the o-ring on the nozzle;

Re-install the injector with the tool. Push it up to block and press it tightly.

16.2.5 CHANGE THE PACKING AT THE INJECTOR (320°C-VERSION)

All the time when the injector is removed please change the packing (320°C- version).

Figure 14 shows the injector with the graphite packing.

Figure 16 Injector 320°C version with graphite packing

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 31

31

WAR NI NG !

The Swagelok® fittings must be carefully tightened to avoid damaging the internal components!

Injector nozzle

O-ring

Bypass-T

Jet pipe

Union nut 2

Nut 1

Nut 3

Sample gas

Dilution gas

Please change the packing as follows:

Loosen union nut 3 and remove the jet pipe;

Loosen nut 4 and remove the dilution tube connection;

Push out the injector with the tool (Pos. 3) from the opposite side (jet pipe);

Remove the thrust collar from the nozzle;

Remove the graphite rings;

Push on the nozzle and the 3 new graphite rings;

Replace the thrust collar;

Re-install the injector with the tool. Push it up to block and press it tightly.

16.3 REMOVING THE BYPASS-T USING OPTION ..B/..BR (180°C VERSION)

For maintenance and cleaning the Bypass-T can be dismantled completely. The figure below shows

the scheme of the Bypass-T.

Figure 17 Bypass-T with Injector and o-ring (180°C version)

Dismantle the Bypass-T as follows:

Remove probe insulating cover (see 16.1);

Remove all pipe connections on Bypass-T. These are:

- Bypass inlet union nut 1

- union nut 2 (sample outlet side)

- union nut 3 (sample inlet).

The Bypass-T is now ready for further maintenance and repair.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 32

32

NOTE!

For cleaning the injector of the 180°C-vesion it is not necessary to remove it

out of the Bypass-T. Clean the nozzle mechanically or put the complete

cross into an ultrasonic bath. For the 320°C-version do not clean the complete cross in an ultrasonic bath because the graphite packing could be destroyed.

A cleaning with compressed air has to be carried out from the sample outlet

side (jet pipe).

nozzle

O-Ring

Part No.: 93S4000

Injector complete, SP2000-H/DIL

Mounting tool

Part No.: 93 S 4040

Jet-pipe

Bypass-T

Pos.1:

O-Ring for nozzle

16.3.1 CHANGE AND CLEANING OF THE BYPASS INJECTOR (180°C VERSION)

We recommend the following steps for the change of the bypass injector:

Unscrew the jet pipe (pos. 2) from the Bypass-T;

Push out the injector nozzle from the opposite side (tool pos. 3, Fig. 18) and change it with

sealing;

Push the injector into the T up to the block and press it tightly. Use the mounting tool.

16.3.2 CHANGE OF THE O-RING AT THE BYPASS INJECTOR (180°C-VERSION)

Figure 18 shows the injector in the 180°C-version.

Figure 18 Bypass Injector unit with o-ring ( 180°C-Version )

We recommend the following steps:

Unscrew the jet pipe (pos. 2) from the Bypass-T;

Push out the injector nozzle from the opposite side (tool pos. 3, Fig. 18);

Remove the thrust collar and the o-ring;

Push new o-ring on the nozzle;

Put on the thrust collar;

Push the injector into the T up to the block and press it tightly. Use the mounting tool.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 33

33

WAR NI NG !

The Swagelok® fittings must be carefully tightened to avoid damaging the internal components!

Thrust collar

Nozzle

Graphite rings

Part No.: 93S4003

Injector complete, DIL-H320-BR

Mounting tool

Part No.: 93 S 4040

Jet pipe

Bypass-T

Pos.1:

Packing for injector nozzle

consisting of 3 graphite rings

4/ 6 – 1,5mm thickness

Part NO.: 93 S 4010

WAR NI NG !

The Swagelok® fittings must be carefully tightened to avoid damaging the internal components!

16.3.3 CHANGE OF THE GRAPHITE PACKING AT THE BYPASS INJECTOR (320°C

VERSION)

When changing the injector the packing (320°C version) must be changed as well.

Figure 16 shows the bypass injector unit of a 320°C version.

Figure 19 Bypass Injector unit with graphite packing (320°C version)

We recommend the following steps:

Unscrew the jet pipe (pos. 2) from the Bypass-T;

Push out the injector nozzle from the opposite side (tool pos. 3);

Remove the thrust collar and the graphite rings;

Push 3 new rings on the nozzle;

Put on the thrust collar;

Push the injector into the T up to the block and press it tightly. Use the mounting tool.

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 34

34

Recommended Spare Parts

Article

Description

90 S 0020

Spare filter element S-2K150, ceramic, 2µm, 150mm

93 S 0045

Spare flat packing (30), Viton , for filter element S-2K150

93 S 0020

Spare O-ring (39), Viton , for lid SP2000H

93 S 0025

Spare O-ring (55), Viton , for lid SP2000H

93 S 0055

Spare flat packing (30), graphite, for filter element S-2K150, 320°C

93 S 0030

Spare flat packing (69), graphite, for lid SP2000H,320°C

90 S 2077

Flange packing DN65 PN6B (67), for SP2000

93 S 0010

Spare thermostat 0-180°C

93 S 0011

Spare thermostat 0-320°C

93 S 0015

Spare heater cartridge HLP, 230V 630W

93 S 0017

Spare heater cartridge HLP, 115V 630W

93 S 0018

Heat conductivity paste for heater cartridge

20 S 4300

Complete set SP2000H/DIL critical orifice incl. 2x O-ring. Material: glass

# please indicate ratio with the order.

20 S 4301

Complete set SP2000H/DIL critical orifice incl. 2x O-ring Dilution Ratio 100:1, Flow rate

6,2L/h, Material: glass

93 S 4000

Eductor for SP2000-H/DIL incl. O-ring.

93 S 4002

Eductor for SP2000-H320/DIL, incl. gasket.

93 S 4003

Eductor for SP2000-H320/DIL-BR, incl. gasket.

93 S 4006

Dilution cross 180°C/320°C empty, without any inserts, Material SS316

93 S 4010

Gasket set for eductor of probe SP2000-H320/DIL, 3x graphite-ring. 1x SS-ring 4/6x1,5

93 S 4015

Eductor for SP2000-H/DIL-B, incl. O-ring.

93 S 4016

Bypass T-piece 180°C/320°C empty, without any inserts, Material SS316

93 S4005

Sealing set for critical orifice of SP2000-H320/DIL: 4 pcs. Graphite ring 3/6x1,5mm,

1pc. washer 3,3/6x0,5mm

93 S 4009

Gasket set for critical orifice of probe SP2000-H/DIL and SP2006-H/DIL, Viton.

93 S 4020

Dilution cross complete for SP2000-H/DIL. DIL-ratio to be specified with the order.

93 S 4022

Dilution cross complete for sample probe SP2000-H320/DIL. DIL-ratio to be specified

93 S4025

Bypass-T-piece complete for SP2000-H/DIL-BR.

93 S 4027

T-piece complete for SP2000-H320/DIL-BR.

17 SPARE PARTS

Wear, tear and replacement part requirements depend on specific operating conditions.

The following table gives an extract of recommended spares for the dilution probes type

SP2000H/DIL... .

Gas sampling and gas conditioning technology 2-1.1.7-ME

Page 35

18 APPENDIX

More product documentation is available on our Internet catalogue:

www.mc-techgroup.com.

35

Gas sampling and gas conditioning technology 2-1.1.7-ME

Loading...

Loading...