Page 1

SP2000-H320/S

Embracing Challenge

Gas Sample Probe Series SP®

Version SP2000-H320/S heated to 320°C

with separator vessel

Special Features

Special probe behind DENOX (SCR)

Heated to 320 °C

No salt formation in the heated lter

part

Condensate vessel in the gas outlet with

glass globe lling for extension of the

reaction surface

Optional heated condensate vessel

ntegrated peristaltic pump

Connection for test gas feeding

Easy maintenance and operation

Application

M&C has developed a special sampling technique for continuous gas sampling of waste

gas in DENOX plants (SCR) where NH3 is

added to the flue gas in order to reduce the

NOx content. This new sampling technique

has also proved to be suitable for processes

with very high pollutant concentrations.

In these applications, a big problem

is the measurement of NOx, SO2 and

O2-concentrations. With temperatures of <

300 °C, ammonium salts are produced due to

the chemical reaction of NH3 and SO2/SO3 in

the flue gas.

This salification blocks up filters and sample

lines in a short time.

The special M&C gas sample probe SP2000H320/S represents a good solution for these

problems. In order to prevent a blocking

due to salification, the probe temperature is

adjusted above 300 °C.

Description

The M&C gas sample probe SP2000-H320/S is

based on the standard sample probe.

The gas sample probe SP2000-H320/S is temperature controlled via an integrated capillary

sensor thermostat adjustable from 50 to 320

°C and including over temperature limiter and

low temperature alarm.

As an option, the gas sample probe is available with a FeCu-Ni thermoelement instead of

the thermostat controller. For this version, an

external temperature controller is necessary.

Due to the modular design the M&C gas sample probe SP2000-H320/S can be equipped

with the wide range of different sample tubes

and pre-filters respectively options.

At the sample gas outlet of the probe, the

gas passes a heated adapter to a non-heated condensate vessel of glass. It is filled

with glass balls to extend the surface for

the salification. The salt deposits and can

be washed out with the condensate.

A peristaltic pump SR25.1G removes the condensate with the solved ammonium salts.

The temperature of the vessel is higher than

the ambient temperature because of the hot

gas stream and the heated adapter. Therefore

a loss of measured components is negligible

because of warm condensate. In case of

DENOX application with a small content of

NH3 (normally only a few ppm) it is possible to

analyse SO2 and NOx without great losses (only

some ppm which normally can be neglected).

To determine the loss, it is possible to give

test gas via the probe to the analyser(s).

A measuring fault can be found and calibrated.

As an option the vessel can be heated as

well to suppress chemical reactions of the

measured component below a defined temperature.

To the sample outlet of the vessel a heated sample line 3/4-M for max. 200 °C

operating temperature can be connected.

Technical specications and illustrations are without

obligation, subject to modications. 03.97/06.06

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

2.6

Page 2

Technical Data

option:

20S908120S9065 ....

option: sample tube or pre-lter

345

20S5000

Gas Sample Probe SP2000-H320/S

Reset

320°C

9101112

L'L

7

6

5

8

N

12 3

Tu<-30 C

4

Tsoll

Netz/Power

To>+30 C

0-320 C

110

tube ø 6 mm

340

Output

DN4/6

230V,50Hz

(115V,60Hz)

condensate

93F0145

340

650

03B1000 bis 03B5050

heated sample line max. 200 C

DN4/6

SP2000-H320/S

Part No. 20S5000 (a) 20S5000 (a) + 20S9027

Temperature regulation Thermostat adjustable 50-320 °C,

with over temperature limiter

and low temperature alarm

as contact output alarm point ∆T30 °C,

contact rating 250V 3A~ 0,25A =

Probe heating max. 320 °C

Ambient temperature +5 °C to +60 °C** optionally with polyester protective housing -20 °C to +60 °C

Volume of filter chamber 120 ml

Sample pressure 0.4 to 2 bar abs.

Filter element ceramic, type S-2K 150*, filter porosity 2 µm

Condensate vessel glass (optional SS 316Ti, Hastelloy®), volume 0.4l (0,15l glass ball filling)

Adapter flange for condensate vessel Hastelloy

®

Peristaltic pump SR25.1G, 230/115V 50/60Hz

Ready for operation after 2h

Connections sample gas outlet / condensate outlet hose fitting DN4/6

Connection test gas inlet tube connection ø 6 mm with blind plug, option: ø 1/4" (a)

Power supply 230V 50Hz, 800W, option: 115V 60Hz (a)

Electrical connection terminals max 2.5mm2, 2x PG11 cable glands

Electrical equipment standard EN 61010, EN 60519-1

Degree of protection IP54, EN 60529

Mounting flange DN65 PN6, B, stainless steel 316 / 316Ti, option: 3"ANSI 150lbs RF (a)

Connection sample tube G3/4"i

Material of sample contacting parts stainless steel 316Ti, graphite, ceramic, Hastelloy, glass, FPM, PTFE, PVDF

Weight 17 kg

Options

Part-No.: 20 S 9053 2-way ball valve for shut off to process side /VA320

Part-No.: 20 S 9330 3-way ball valve for shut off to process side /3VA320

Part-No.: 20 S 9044 test gas inlet via check valve 0.7 bar /R

Part-No.: 20 S 9065 and following test gas inlet via check valve 0.7 bar /R

Part-No.: 01 B 8350 electronic temperature controller in wall mounting housing

Part-No.: on request heating of the condensate vessel to max. 180 °C

Part-No.: 20 S 9410 protection case of polyester

* Standard

** In case of higher ambient temperatures use option PT100 (Part No. 20S9025) or thermocouple Fe-CuNi respectively Ni-CrNi (Part No. 20S9027 resp. 20S9028) instead of the thermostate

controller. Then, an additional electronic temperature controller (see data sheet 2-5.1) is necessary.

Part-No. ....(a) = Execution power 115V 60Hz, ange 3"150 lbs, test gas connection ø 1/4".

For further technical data please see data sheet SP2000.

with FeCu-Ni thermoelement,

(instead of thermostat)

option: external electronic temperature

controller necessary

e.g. Part No. 01B8350

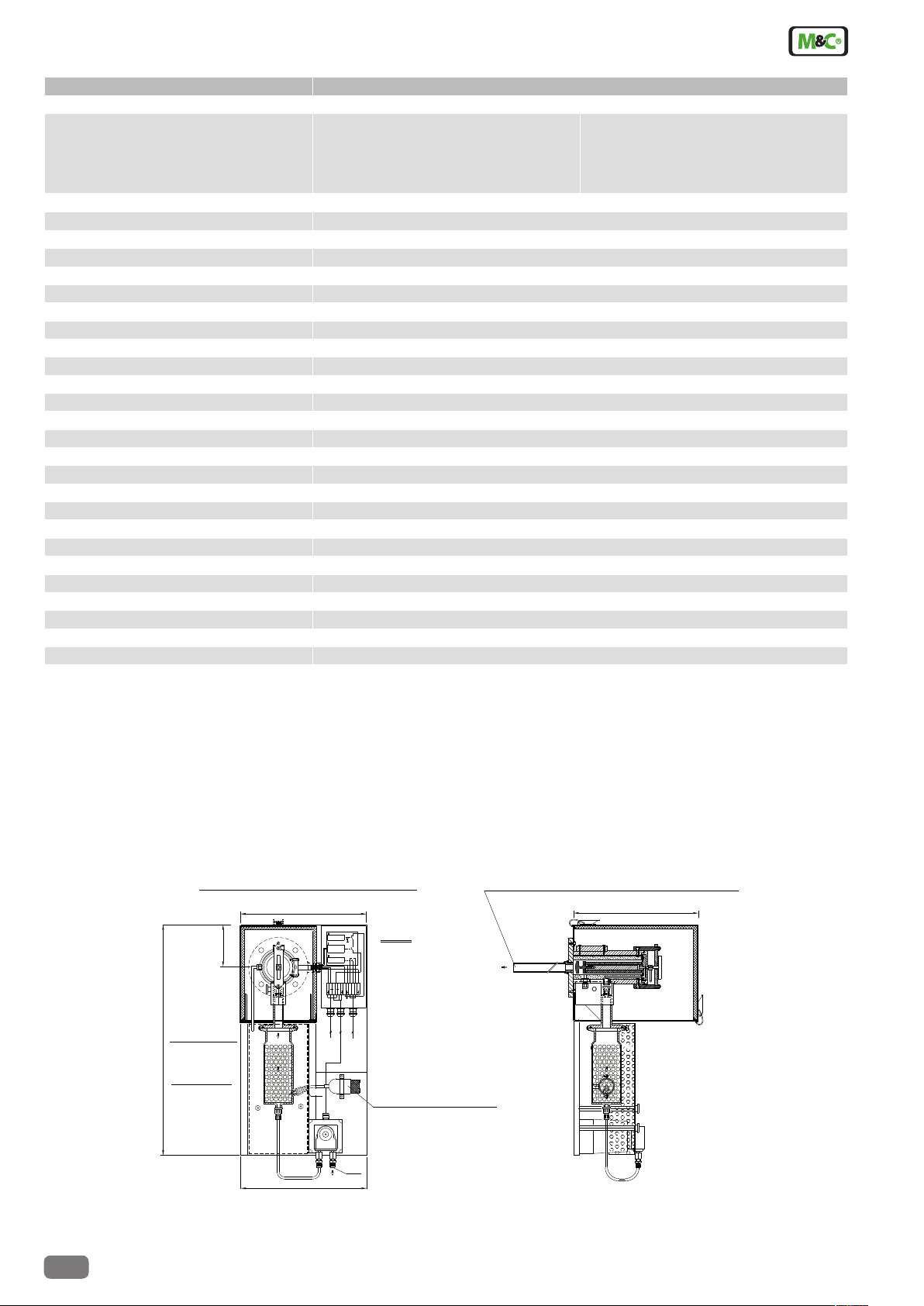

Dimensions

Gas Sample Probe SP2000-H320/S

Dimensions in mm

2.6

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 03.97/06.06

Loading...

Loading...