Page 1

Prefilters for series SP®

Embracing Challenge

Prelters for Gas Sample Probes

Series SP®

Version SP2000/V20.. with G 3/4”-connection,

SP2000/V12 with ange connection,

Version SP2000/20SS 150 with tube connection

Special Features

For dust loading up to 2g/m

Point selective sampling

Sampling after wet scrubber up to 90 °C

Sampling temperature up to max.

1800°C

Dierent lengths

Great variety of materials

Easy mounting

3

Application

The M&C-prefilters are used together

with M&C gas sample probes series SP®

for continuous gas sampling in processes

with increased dust loading.

Description

The large active surface of the M&C prefilter

guaranties a long moulding time. Even in case

the flow rate of the sample gas is increased,

there is only a small difference pressure on the

filter matrix between clean gas and crude gas

side. Therefore, the solid particles do not get

into the filter’s pore structure. They are deposited as filter cake on the filter’s surface and

cause a prolonged moulding time in its property as prefilter. The M&C-prefilters SP2000 /

V20.. /V12.. /20SS are selected according to

the specific application. The basis for selection are the process parameters, i.e. the gas

compounds, dust loading, grain sizes, water

vapure saturation, temperature, pressure and

gas velocity.

The M&C prefilters /V20.. are equipped

with a welded thread connector for

mountage into the mounting flange of

the M&C gas sample probe. For an optimal sampling position in the process, the

prefilters /V20.. can be mounted to the

sample probe via an extension tube /Vm...

In case of a high velocity of the process gas,

shape protection plates /AB.. are used in

order to protect the prefilters /V20.. against

abrasion.

The prefilters /V12-... have got a mounting flange adapter of stainless steel,

executed with 4 threaded bolts for

easy mounting. The prefilter versions

/V12-.. /SS, /V12-.. /IC are equipped with

a welded protection tube of stainless

steel or Incoloy on the mounting flange

adaptor. The feeding of process gas is made

via the three longitudinal slots distributed on

180° tube periphery. The special double-ply

construction of the prefilter /V12-1, /V12-3

is granting a particularly high back purging

efficiency.

Depending on fabrication, the prefilters /V20..,

/V12.. are partially made of different material

combinations. See table. For reduction of the

delay time in case of a small sample gas flow,

prefilters with volume displacer have to be

used.

The M&C tube prefilter /V20-T of PTFE cloth

with interweaved metal filaments for reduction of the surface resistance (in order to

avoid frictional electricity) disposes over an

excellent back purging quality. It is used for

example in case of gas sampling out of coal

bunkers with a high content of superfine

dust.

The prefilter /20SS 150 is used for direct

mounting on the M&C sample tubes SP2000/

SS. It is supplied with a shape protection plate

and a tube fitting with double cutting ring.

If there are problems eg. in case the depth

for assembling is too small or the flow velocity is too high, or the dust content or the

temperature are too high, then the electrical

heated adapter tube /AR should be used. It is

equipped with a flange connection at both

sides and is to be mounted on the plant’s

connection flange.

Technical specications and illustrations are without

obligation, subject to modications. 09.96/03.09

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

2.17

Page 2

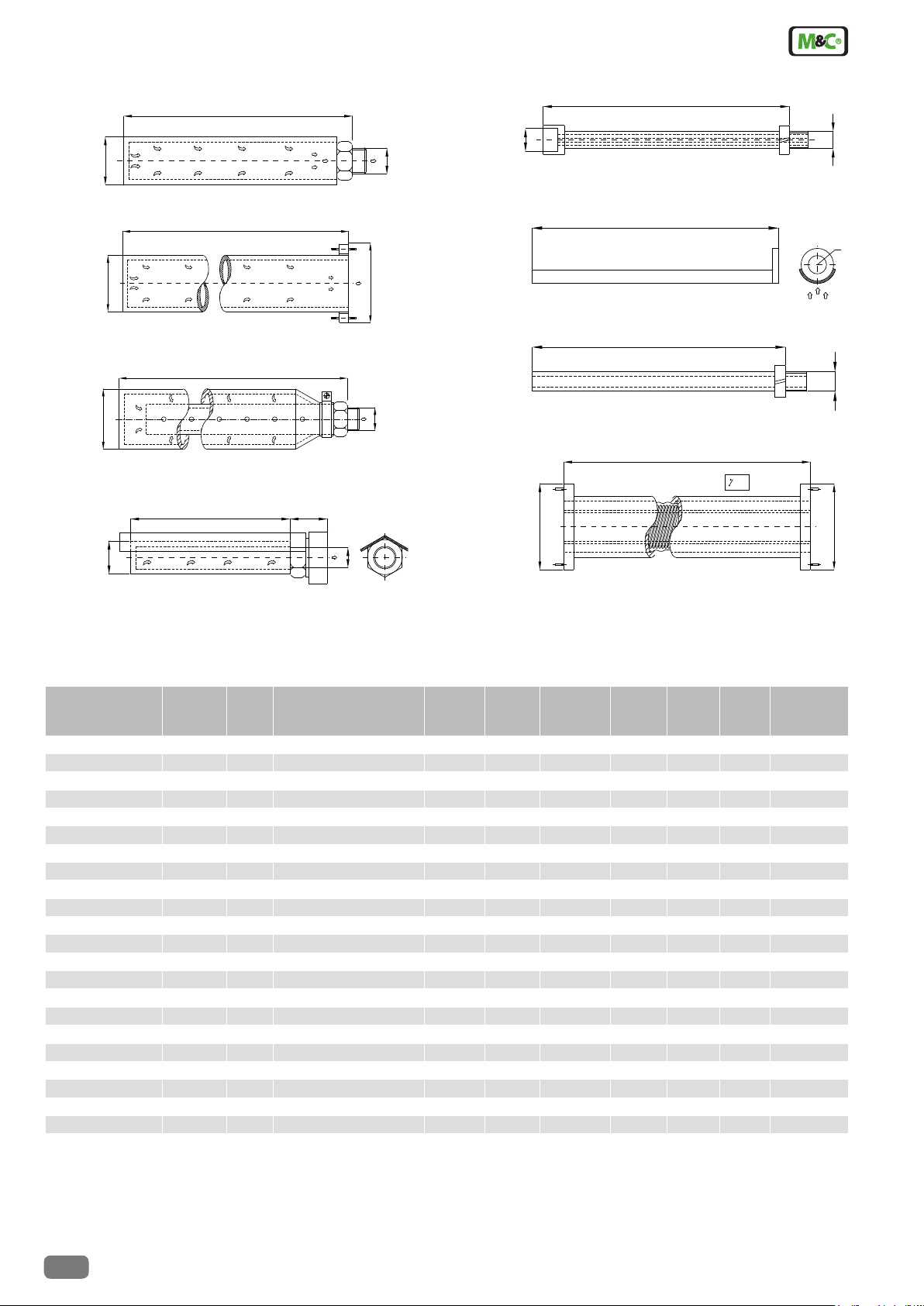

DImensions

C

Heated adaptor tube SP2000-H/AR

G

G

L1

Prefilter SP2000/20SS 150 with tube fitting and shape protection plate

G

35L1

d1

L1

Extension tube SP2000/Vm...

G

G

Shape protection plate SP2000/AB..

L1

G

Prefilter SP2000/V12... with mounting flange adaptor

G

L1

d1

L1

d1

G

Tube prefilter SP2000/V20-T including support tube with thread connection

Prefilter SP2000/V20 -0-1-2-3-4-5-6 with welded thread connection

d1

L1

G

Volume displacer V12-2/3

L1

G

Dimensions in mm

Technical Data

M&C Probe

Prefilters

Type

SP2000/20SS 150 20S9160 600 stainl. steel 316/316Ti 20 2-10 yes 150 31 ø 25

SP2000/V20 20S9085 600 stainl. steel 316/316Ti 2 2-10 yes 220 46 G 3/4"a

SP2000/V20-0 20S9105 600 stainl. steel 316/316Ti 2 2-10 X yes 220 46 G 3/4"a

SP2000/V20/HC 20S9095 900 Hastelloy-C 2 2-10 yes 220 46 G 3/4"a

SP2000/V20-0/HC 20S9115 900 Hastelloy-C 2 2-10 X yes 220 46 G 3/4"a

SP2000/V20-T 20S9315 200 PTFE / stainl. steel 316TI 3 > 10 yes

SP2000/V20-2 20S9125 600 stainl. steel 316/316Ti 2 > 10 yes 520 60 G 3/4"a

SP2000/V20-1 20S9145 600 stainl. steel 316/316Ti 2 > 10 X yes 520 60 G 3/4"a

SP2000/V20-2/HC 20S9135 900 Hastelloy-C 2 > 10 yes 520 60 G 3/4"a

SP2000/V20-1/HC 20S9155 900 Hastelloy-C 2 > 10 X yes 520 60 G 3/4"a

SP2000/V20-4

SP2000/V20-3

1)

1)

SP2000/V20-5 20S9127 500 stainl. steel 316/316Ti 3 2-10 yes

SP2000/V20-6 20S9128 500 stainl. steel 316/316Ti 3 > 10 yes

SP2000/V12-1 20S9500 1000 ceramik5)/stainl. steel 316Ti 1 > 10 yes

SP2000/V12-3 20S9510 1000 ceramik5)/stainl. steel 316Ti 1 > 10 optional yes

SP2000/V12-2 20S9505 1000 ceramik5)/stainl. steel 316Ti 2 > 10 optional yes 1000 60 DN65 PN6

SP2000/V12-1/SS

SP2000/V12-3/SS

SP2000/V12-2/SS

SP2000/V12-1/IC

SP2000/V12-3/IC

SP2000/V12-2/IC3)20S9545 1000 ceramik5) / Incoloy - 316Ti 2 > 10 optional yes 1000 60 DN100 PN6

1)

Prelter V20-3, V20-4 optional up to 1000 mm length available.

2)

With protection tube V12-1.

3)

With protection tube V12-2/3.

4)

Prelter with special construction for ecient back purge.

5)

Please pay attention to the characteristic feature of ceramic in case of high and changing temperatures!

2.17

Part-No. Temp.

20S9290 600 stainl. steel 316/316Ti 2 2-10 yes

20S9300 600 stainl. steel 316/316Ti 2 2-10 X yes

2)

20S9525 600 ceramik5)/stainl. steel 316Ti 1 > 10 yes

3)

20S9535 600 ceramik5)/stainl. steel 316Ti 1 > 10 optional yes

3)

20S9530 600 ceramik5)/stainl. steel 316Ti 2 > 10 optional yes 1000 60 DN100 PN6

2)

20S9540 1000 ceramik5) / Incoloy - 316Ti 1 > 10 yes

3)

20S9550 1000 ceramik5) / Incoloy - 316Ti 1 > 10 optional yes

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

max.

°C

Material

Filter / Connection

Filter

porosity

micron

Dust

content

3

g/m

Inside

volume

displacer

Backpurging

Length

„L1“

mm

4)

400 65 G 3/4"a

1)

1)

4)

220 50 G 3/4"a

4)

520 60 G 3/4"a

4)

500 40 DN65 PN6

4)

1000 60 DN65 PN6

4)

500 40 DN65 PN6

4)

1000 60 DN100 PN6

4)

500 40 DN65 PN6

4)

1000 60 DN100 PN6

Filter

ø „d1“

mm

300 31 G 3/4"a

300 31 G 3/4"a

Technical specications and illustrations are without

obligation, subject to modications. 09.96/03.09

Connection

„G“

Page 3

Options

Type Part-No. Temperature

max. °C

Material Length

„L1“ mm

Connection

„G“

Extension tubes for /V20...

SP2000/Vm 500 mm 20S9165 600 stainl. steel 316Ti 500 G 3/4"i/a

SP2000/Vm 1000 mm 20S9170 600 stainl. steel 316Ti 1000 G 3/4"i/a

SP2000/Vm 1500 mm 20S9175 600 stainl. steel 316Ti 1500 G 3/4"i/a

SP2000/Vm 2000 mm 20S9176 600 stainl. steel 316Ti 2000 G 3/4"i/a

SP2000/VmHC 500 mm 20S9180 900 Hastelloy-C 500 G 3/4"i/a

SP2000/VmHC 1000 mm 20S9185 900 Hastelloy-C 1000 G 3/4"i/a

SP2000/VmHC 1500 mm 20S9190 900 Hastelloy-C 1500 G 3/4"i/a

Shape protection plates for /V20(/HC), /V20-0(/HC), /V20-5:

SP2000/AB-SS 20S9250 600 stainl. steel 316Ti 220 ø 3/4"i

SP2000/AB-HC 20S9260 900 Hastelloy-C 220 ø 3/4"i

Shapeprotection plates for /V20-1(/HC), /V20 -2(/HC), V20-6:

(not for SP2500-H...)

SP2000/AB1-SS 20S9255 600 stainl. steel 316Ti 520 ø 3/4"i

SP2000/AB1-HC 20S9265 900 Hastelloy-C 520 ø 3/4"i

Volume displacer for /V12-2(/IC), /V12-3(/IC):

V12-2/3 20S9515 600 stainl. steel 316Ti 950 G 3/4"a

V12-2/3IC 20S9520 1000 Incoloy 950 G 3/4"a

Electrically heated adaptor tube for reception of /V12-1

SP2000-H/AR-500-R 230V 20S9398 max. 200 stainl. steel 316Ti 500* DN65 PN6

SP2000-H/AR-500-R 115V 20S9398a max. 200 stainl. steel 316Ti 500* DN65 PN6

Heated sampling tubes SP30, SP35 in case of decrease under dew point on process side, see data sheet 2-1.9.5.

Automatice back purging, other materials or executions on request.

Further technical information see sample probes SP 210/2100/2000.

* Others on request

Technical specications and illustrations are without

obligation, subject to modications. 09.96/03.09

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

2.17

Loading...

Loading...