Page 1

PSS-5/3

Embracing Challenge

Portable Gas Conditioning Unit

series PSS®

Version PSS-5 for 150 Nl/h gas ow rate

Version PSS-5/3 für 350 Nl/h gas ow rate

Special Features

Low maintenance and self-monitoring

Outlet dew point adjustable from +2 °C

to +15 °C

Dew point stability ± 0,1 °C

Operational in 10 minutes

Compact construction

Light weight

Optimum reliability

Jet Stream heat exchangers in 3 stand-

ard materials

Universal equipment possible

Application

The M&C portable gas conditioning unit

PSS-5... is designed to carry out precise

gas analyses at different locations. The entire

gas conditioning unit is housed in a robust

aluminium-frame case to enable the user to

carry out a rapid gas analysis, which is safe

with little maintenance work.

The PSS-5... gas conditioning unit is suitable

for variable, discontinuous use as well as for

continuous operation. The components built

into the PSS-5... gas conditioning unit can be

used for standard applications. If you have

special problems please ask us for other solutions.

Description

The PSS-5... gas conditioning unit is

equipped with an ECP... gas cooler

with Jet-Stream heat exchanger which

cools the sample gas to constant +5 °C

independent of the ambient temperature.

As soon as the operating temperature of

< +8 °C is reached after start-up, the gas

pump N...KPE is switched on automatically via

the status contact of the gas-cooler. The SR

25.1 peristaltic pump ensures a constant condensate removal which makes a long-term

measurement possible without problems.

The corresponding particle filtration is carried

out by a 2µm filter type FP-2T.

This makes the PSS5... unit a complete gas

conditioning system suitable for most of the

analysers.

Technical specications and illustrations are without

obligation, subject to modications. 09.95/12.11

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

14.5

Page 2

255

540

440

4

3

2

4

32

1

1

max.1800VA

Kondensat

AUS

AUS

Messgas

EIN

3

6

7

5

4

Electr. terminals

GL25

GL18

< °C

ON

> °C

ECP

Cooler

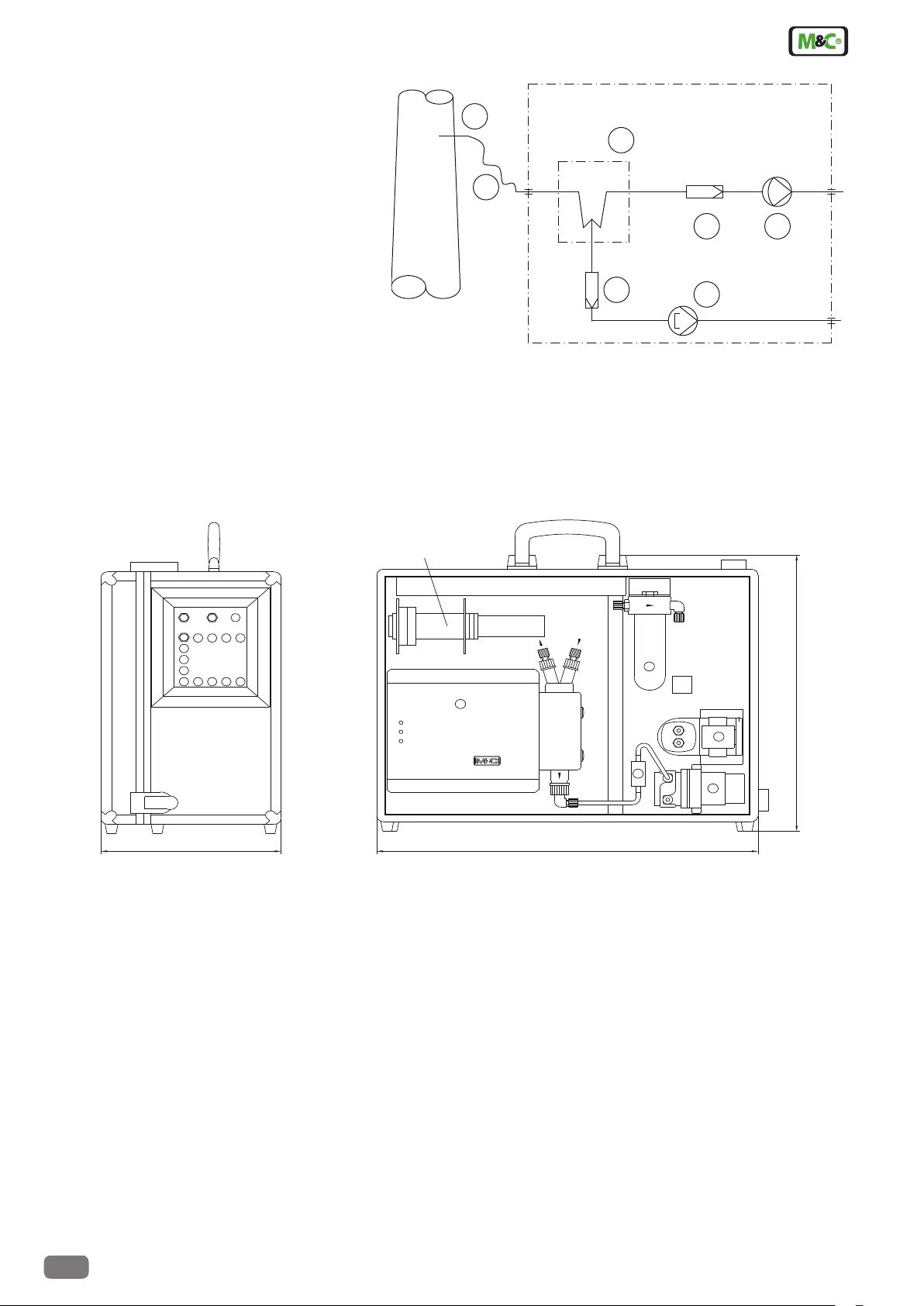

Flow scheme PSS-5 und PSS-5/3

1 Gas sample probe

2 Sample line, 3 m PVC hose

3 Gas cooler ECP 1000 or ECP 3000

4 Fine lter FP-2T, lter porosity 2 µm

5 Gas diaphragm pump N3KPE or N9KPE

6 Pre-lter PF2

7 Peristaltic pump SR25.1

1

3

2

54

Dimensions

6

7

Dimensions in mm

14.5

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 09.95/12.11

Page 3

Technical Data

Gas Conditioning Unit series PSS

Part No. for 230V 50Hz version 01G1100 01G1500

Part No. for 115V 60Hz version 01G1100a 01G1500a

Sample outlet dew point range of adjustment: +2 °C ..... +15 °C, factory setting: +5 °C

Dew point stability at constant conditions < ±0,1 °C

Sample inlet temperature **max. 80 °C optional: **max.180 °C with stainless steel bulkhead union

Sample inlet dew point **max.+80 °C

Gas flow rate **max. 150 Nl/hr **max. 350 Nl/hr

Ambient temperature **+5 °C up to +40 °C

Storage temperature -25 °C up to +65 °C

Pressure 0,7 bar up to 1,4 bar abs.

Total cooling capacity ** max. 50 kJ/hr max. 90 kJ/hr

Number of gas inlets 1

Number of gas outlets 1 optional: max. 4

Medium connections tube connection 4/6 mm

Material of sample contacting parts stainless steel, glass, PPH, PVC, PVDF, PTFE, Novoprene® optional: FDM for gas sample line, part no.: 01G9025

Ready for operation approx. 10 min.

Power supply 230V 50Hz or 115V 60Hz

Power consumption max. 240VA; with option temperature controller and heated sample line 230V: max. 1620VA 115V: max. 920VA

Fuse protection 4A t, 5x 20 mm, with option temperature controller: 10A t

Electrical connection Cold appliance plug with 2 m of cable

Case protection IP20 (DIN 40050. IEC 529)

Housing portable aluminium-frame case

Housing dimensions 440 mm x 540 mm x 255 mm (H x W x D)

Electrical equipment standard EN61010

Weight approx. 18,5 kg approx. 20,0 kg

®

version PSS-5 version PSS-5/3

Options Type Part No

Further sample gas outlet Parallel samplegas outlet, tubing via T-piece on lateral PVDF bulkhead fitting, DN4/6, max. 4 pieces 01G9065

Flowmeter, max. 4 pieces FM40 7-70 l/hr air, mounted in sample gas outlet

FM40 15-150 l/hr air , mounted in sample gas outlet

FM40 25-250 l/hr air , mounted in sample gas outlet

FM40 50-500 l/hr air, mounted in sample gas outlet

01G9070

01G9075

01G9080

01G9085

Fittings out of PVDF Fittings out of PVDF instead of PP and 3m FPM sample tube DN4/6 01G9025

Sample tube Sample tube out of Kanthal® ø 6 mm, length 1 m, sampling temperature max. 1300 °C 01G9030

Liquid alarm Liquid alarm LA 1/1.4, consisting of: liquid alarm sensor LA1, controller LA1.4, filter glass

01G9035

F120G-D with GL connection incl. mountage/wiring. In case of condensate inrush,

the sample gas pump is automatically switched of.

3-way ball valve 3L/PV-1 for switching over from test gas to sample gas, in the inlet of the sample gas

01G9046

conditioning unit, mounted with mounting brackets, fitting PVDF

5-way ball valve 5L/PV-1 for switching over from test gas to sample gas, in the inlet of the sample gas

01G9045

conditioning unit, mounted with mounting brackets, fitting PVDF

Electronic temperature controller

for max. 12 m heated sample line

701 control range 0-200 °C, inlet PT100, power 230V 50Hz,

Contact capacity 250V AC max. 10A, completely mounted incl. 7-pin plug 10A

01G9055

100W/m

Electronic temperature controller

for max. 6 m heated sample line 100W/m

Connecting adapter DN4/6 for heated

sample line

701 control range 0-200 °C, inlet PT100, power 115V 60Hz,

Contact capacity 250V AC max. 10A, completely mounted incl. 7-pin plug 10A

PSS-5 connecting adapter with bending protection for rigid mountage of heated sample line with interchangeable PTFE tube DN4/6, consisting of special Swagelok fitting with 4mm cartridge, material:

01G9055a

01G9060

SS316Ti.

Connecting adapter DN6/8 for heated

sample line

PSS-5 connecting adapter with bending protection for rigid mountage of heated sample line with interchangeable PTFE tube DN6/8, consisting of special Swagelok fitting with 6mm cartridge, material:

01G9060

SS316Ti.

PPH = Polypropylene

PTFE = Polytetrauoroethylene (Teon®)

PVC = Polyvinylchloride

PVDF = Polyvinylidenuoride

** Maximum values in technical data’s must be rated in consideration of total cooling capacity at 25 °C ambient temperature and 5 °C outlet dew point.

Other versions on request.

Technical specications and illustrations are without

obligation, subject to modications. 09.95/12.11

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

14.5

Loading...

Loading...