Page 1

Operating Instructions

Electrically-heated and portable gas sample probes

Series PSP4000-H, PSP4000-H/C, PSP4000-H/C/T

Gas sampling and gas conditioning technology 2-2.1-ME

Page 2

2

This Operating Manual does not claim completeness and may be

subject to technical modifications.

© 03/1996 M&C TechGroup Germany GmbH. Reproduction of this

document or its content is not allowed without permission from M&C.

SP® is a registered trade mark.

2nd Edition: 03/2007

Dear customer,

we have made up this operating manual in such a way that all necessary information about the

product can be found and understood quickly and easily.

Should you still have any question, please do not hesitate to contact M&C directly or go through your

appointed dealer. Respective contact addresses are to be found in the annexe to this operating

manual.

Please also contact our homepage www.mc-techgroup.com for further information about our

products. There, you can read or download the data sheets and operating manuals of all M&C

products as well as further information in German, English and French.

Gas sampling and gas conditioning technology 2-2.1-ME

Page 3

3

Contents

1 General information ....................................................................................................................... 4

2 Declaration of conformity ............................................................................................................. 4

3 Safety instructions ........................................................................................................................ 5

4 Warranty ......................................................................................................................................... 5

5 Used terms and signal indications .............................................................................................. 6

6 Introduction .................................................................................................................................... 7

7 Serial numbers ............................................................................................................................... 7

8 Power supply ................................................................................................................................. 7

9 Technical Data ............................................................................................................................... 8

9.1 Options ..................................................................................................................................... 9

10 Applications ................................................................................................................................. 10

11 Description ................................................................................................................................... 10

12 Receipt of goods .......................................................................................................................... 11

13 Preparation and installation ....................................................................................................... 11

14 Supply connections ..................................................................................................................... 12

14.1 Connecting the heated sample line ........................................................................................ 12

14.2 Electrical connection .............................................................................................................. 13

14.3 Calibration-gas discharge ....................................................................................................... 13

14.4 Temperature measurement .................................................................................................... 14

15 Starting ......................................................................................................................................... 14

16 Maintenance ................................................................................................................................. 15

16.1 Changing the filter element .................................................................................................... 15

17 Switching off ................................................................................................................................ 15

18 Spare parts list ............................................................................................................................. 16

19 Appendix ...................................................................................................................................... 17

List of illustrations

Figure 1 Connection of the heated sample line ................................................................................. 12

Figure 2 Sample facilities .................................................................................................................. 18

Figure 3 Wiring plan .......................................................................................................................... 19

Figure 4 Basic version ....................................................................................................................... 20

Figure 5 Carrying case to transport sample probe ............................................................................ 21

Figure 6 Filter unit and connection of the heated sample line ........................................................... 22

Figure 7 High temperature sample tube aluminium oxide ................................................................. 23

Figure 8 Electrically heated sample tube SP34-H ............................................................................. 24

Gas sampling and gas conditioning technology 2-2.1-ME

Page 4

4

Head Office

M&C TechGroup Germany GmbH Rehhecke 79 40885 Ratingen Germany

Telephone: 02102 / 935 - 0

Fax: 02102 / 935 - 111

E - mail: info@mc-techgroup.com

www.mc-techgroup.com

1 GENERAL INFORMATION

The product described in this operating manual has been examined before delivery and left our works

in perfect condition related to safety regulations. In order to keep this condition and to guarantee a

safe operation, it is important to heed the notes and prescriptions made in this operating manual.

Furthermore, attention must be paid to appropriate transportation, correct storage, as well as

professional installation and maintenance work.

All necessary information a skilled staff will need for appropriate use of this product are given in this

operating manual.

2 DECLARATION OF CONFORMITY

CE - Certification

The product described in this operating manual complies with the following EC directives:

EMV-Instruction

The requirements of the EC directive 2004/108/EC “Electromagnetic compatibility“ are met.

Low Voltage Directive

The requirement of the EC directive 2006/95/EC “Low Voltage Directive“ are met.

The compliance with this EC directive has been examined according to DIN EN 61010.

Declaration of conformity

The EU Declaration of conformity can be downloaded from the M&C homepage or directly requested

from M&C.

Gas sampling and gas conditioning technology 2-2.1-ME

Page 5

5

3 SAFETY INSTRUCTIONS

Please take care of the following basic safety procedures when mounting, starting up or

operating this equipment:

Read this operating manual before starting up and use of the equipment. The information and

warnings given in this operating manual must be heeded.

Any work on electrical equipment is only to be carried out by trained specialists as per the regulations

currently in force.

Attention must be paid to the requirements of VDE 0100 (IEC 364) when setting high-power electrical

units with nominal voltages of up to 1000 V, together with the associated standards and stipulations.

Check the details on the type plate to ensure that the equipment is connected to the correct mains

voltage.

Protection against touching dangerously high electrical voltages:

Before opening the equipment, it must be switched off and hold no voltages. This also applies to any

external control circuits that are connected.

The device is only to be used within the permitted range of temperatures and pressures.

Check that the location is weather-protected. It should not be subject to either direct rain or moisture.

The device must not be used in hazardous areas.

Installation, maintenance, monitoring and any repairs may only be done by authorized personnel with

respect to the relevant stipulations.

4 WARRANTY

If the equipment fails, please contact M&C directly or else go through your M&C authorised dealer.

We offer a one year warranty as of the day of delivery as per our normal terms and conditions of sale,

and assuming technically correct operation of the unit. Consumables are hereby excluded. The terms

of the warranty cover repair at the factory at no cost or the replacement at no cost of the equipment

free ex user location. Reshipments must be send in a sufficient and proper protective packaging.

Gas sampling and gas conditioning technology 2-2.1-ME

Page 6

6

DANGER!

This means that death, severe physical injuries and/or important

material damages will occur in case the respective safety measures

are not fulfilled.

W ARN IN G !

This means that death, severe physical injuries and/or important

material damages may occur in case the respective safety

measures are not fulfilled.

CARE!

This means that minor physical injuries may occur in case the

respective safety measures are not fulfilled.

CAR E!

Without the warning triangle means that a material damage may

occur in case the respective safety measures are not met.

ATT ENT ION !

This means that an unintentional situation or an unintentional status

may occur in case the respective note is not respected.

NOTE!

These are important information about the product or parts of the

operating manual which require user’s attention.

SKILLED STAFF

These are persons with necessary qualification who are familiar with

installation, use and maintenance of the product.

5 USED TERMS AND SIGNAL INDICATIONS

Gas sampling and gas conditioning technology 2-2.1-ME

Page 7

7

6 INTRODUCTION

M&C gas sample probes provide direct insitu ultra-fine filtration during continuous gas sampling for

analytic measurements. In this way, part of the necessary maintenance work for a system is

concentrated on a single point. This filter technology has the major advantage that dust mixtures

consisting of ultra-fine and coarse dusts can be optimally retained with the least possible maintenance

work.

Optimal adaptation of the sample probe to processing conditions and to measurement work is a

necessary condition for a measurement system to work smoothly. Basically, the gas sample should be

kept to a necessary minimum. This is made possible thanks to optimised downstream gas processing

using M&C components. Only in this way is it possible to reduce maintenance to a minimum while

ensuring maximum availability.

7 SERIAL NUMBERS

The nameplates bearing the serial number are located on the side of the electrical connection box.

Always quote the device's serial number when making enquiries and ordering replacement parts.

8 POWER SUPPLY

Depending on the version, the probe is operated with 115 or 230 V AC. Precise details can be found

on the device's nameplate.

Gas sampling and gas conditioning technology 2-2.1-ME

Page 8

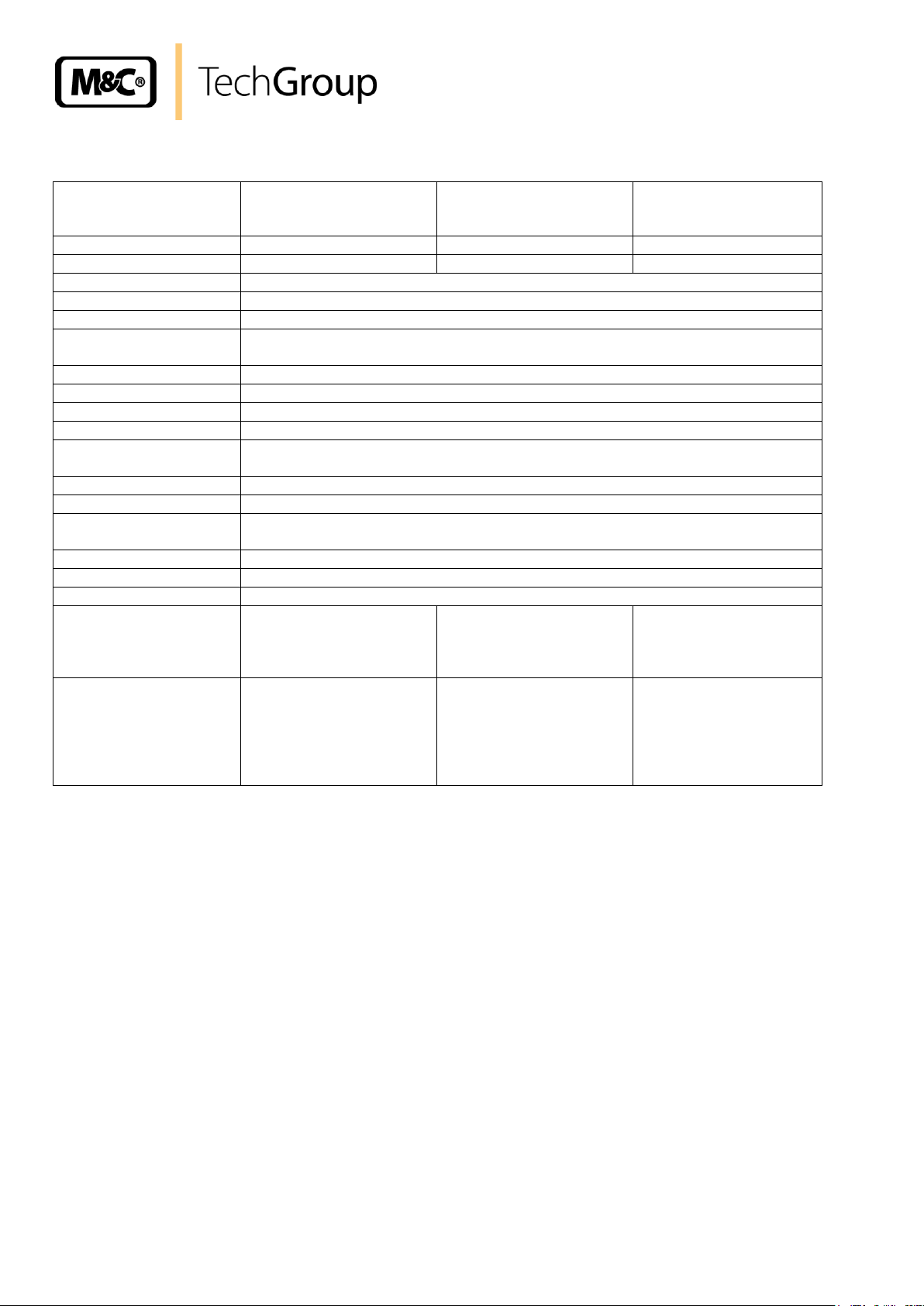

9 TECHNICAL DATA

Probe series SP®

portable version

PSP4000

PSP4000-H

PSP4000-H / C

PSP4000-H /C /T

Part No. 230V

40S1000

40S1005

40S1015

Part No. 115V

40S1000a

40S1005a

40S1015a

Sample temperature

max. 600 °C *standard

Sample pressure

max. 1 bar

Ambient temperature

-20 °C to +60 °C

Filtration chamber

volume

40 cm

3

Filter element

S-2K ceramic, 2 μm

Probe temperature

Adjustable between 100-180 °C, pre-set at works to 180°C

Ready for operation

After approximately 30 minutes

Gas inlet

Basic connection G 3/8"i, probe tube or adapters optional

Gas outlet

1/8" NPT + tube connector ø 6 mm (optional ø 8 mm)

and pipe clamp for attachment of heated sample line

Power supply

220-240V 50/60Hz, 200 W or 115V 60Hz

Electrical connection

Plug and socket connector 7 pin with 4 meter connection cable

Electrical equipment

standard

EN 61010, EN 60519-1

System of protection

IP40, EN 60529

Material

Stainless steel 316Ti, ceramic, FPM

Weight

3 kg

Calibration gas

connection for

SS-tube/Plastic

hose ø 6 mm

no

yes

yes

Temperature

measurement with

Thermocouple sensor

FeCuNi, length 600 mm

with 4 m connection

cable and standard plug.

no

no

yes

8

Gas sampling and gas conditioning technology 2-2.1-ME

Page 9

9.1 OPTIONS

Part No.

40S9130

extra price for PSP4000-H.. with sample outlet ø 8 mm tube connector

40S9100

extra price for PSP4000-H /FW with special filter cartridge filled with special spun glass with

M12-connection, material SS316Ti, FPM

sample adapter with variable probe tube length:

40S9005

3/8" adapter fitting with gasket and 8 mm PTFE sealing ring

40S9000

adapter with cone-shaped part for openings of ø 10-20 mm and ø 8 mm probe tube out of

stainless steel 316, extensible 80-200 mm

40S9010

ø 8 mm probe tube out of stainless steel 316Ti with position indication, for extensible probe

length of 190-300 mm.

fixed probe tubes with male connector G 3/8", length 1 m:

40S9020

Material: stainless steel SS316Ti, ø 6 mm, max. 600 °C

40S9030

Material: stainless steel SS316Ti, ø 8 mm, max. 600 °C

40S9040

Material: stainless steel SS316Ti, ø 10 mm, max. 600 °C

40S9050

Material: stainless steel SS316Ti, ø 12 mm, max. 600 °C

40S9108

Material: Titane, ø 6mm, max. 400 °C

40S9109

Material: Hastelloy® C, ø 6/8 mm, max. 900 °C

40S9112

Material: Inconell® 625, ø 12 mm, max. 1200 °C

40S9106

Material: Kanthal®, ø 15 mm, max. 1300 °C

40S9110

Material: Ceramic-Aluminium-Oxyd 1), ø 12 mm, max. 1800 °C, for mounting tube adapter

PSP4000H/AO Art. Nr. 40S9111 is necessary

40S9111

Tube adapter PSP4000H/AO, material: stainless steel SS316Ti

heated sample probe tubes SP34-H...:

40S9115

heated sample probe tube SP34-H with incorporated thermostate

40S9120

heated sample probe tube SP34-H1.1 with thermocouple sensor FeCuNi

40S9125

heated sample probe tube SP34-H2 with PT100 sensor

equipment, out of stainless steel SS316Ti for placing the probe stationary:

40S9060

intermediate connection adapter G3/4"o - G3/8"i / 8 ø with gasket 3/8".

40S9070

connection mounting nipple of R 2"o. DIN 2999/1 with G 3/4"i und G 3/8"i

40S9080

mounting flange DN65 PN6 B with thread connection 3/4"i ISO and gasket

90S2075

flange gasket set for DN65 PN6 B consisting of Klingerit gasket and screws M12

heated sample line PSP4M4/6 spec. made for probe PSP4000H:

01B4034

beginning connection part I with pipe end, for interchangeable tube 4/6, incl. PT100 and 1,5 m

extension cable axial at the back, with 7 pins plug

01B4037

end connection part K with spec. pipe end, for interchangeable tube 4/6, 0,5 m extension cable

axial at the back, with 7 pins connector

01B4036

per meter heated sample line PSP4M4/6, operating temperatures max. 200 °C with

exchangeable PTFE hose 4/6 mm to jut out 0,5 m (cold end), incl. 3 extra wire for the probe

heater, PT100 position 0,6 m mounted from electrical inlet Silicone foam heat insulation with

Nylon net, power 220-240V 50/60Hz, 110W/m

Max. 12 meter length at 230V/50Hz and 6 meter length at 115V/60Hz for PSS-5..-conditioing

system with internal temperature regulator

01B4034W

beginning connection part I for sample line PSP-W4M4/6 with pipe end, for interchangeable tube

4/6, incl. PT100 and 1,5 m extension cable axial at the back, with 7 pins plug

01B4037W

end connection part K for sample line PSP-W4M4/6 with spec. pipe end, for interchangeable

tube 4/6, 0,5 m extension cable axial at the back, with 7 pins connector

01B4036W

per meter heated sample line PSP-W4M4/6, operating temperatures max. 200 °C with

exchangeable PTFE hose 4/6 mm to jut out 0,5 m (cold end), incl. 3 extra wire for the probe

heater, PT100 position 0,6 m mounted from electrical inlet. Silicone foam heat insulation with

corrugated hose envelope out of PA, power 220-240V 50/60Hz, 110W/m.

Max. 10 meter length at 230V/50Hz and 6 meter lenfth at 115V/60Hz for PSS-5..-conditioing

system with internal temperature regulator

40S9090

aluminium-composite carrying case PSP to take portable gas sample probe PSP4000H... and

max. 5 m heated sample line PSP4M4/6 or max. 8 m PSP-W4M4/6, dimension 530 x 420 x 300

mm

9

Gas sampling and gas conditioning technology 2-2.1-ME

Page 10

10

NOTE!

The max. length of heated sample lines for PSS-5 gas conditioning systems

with integrated temperature controller is 12m for 230V/50Hz resp. 6m for

115/60Hz.

10 APPLICATIONS

The PSP4000-H... gas sample probes are used for extraction of gases from dust loaded, high-

temperature or humid processes.

Due to its compact design and low weight, the device is envisaged particularly for mobile uses. The

basic probe including the compact sample adapter with variable probe tube lengths enable rapid and

centric gas sampling from, for example, exhaust gas pipes with diameters of between 150 mm and

600 mm.

A probe tube with a fixed length of 1 meter extends the range of potential applications.

With version PSP4000-H/C/T, parallel to gas sampling it is also possible to measure the process

temperature at the end of the probe tube using an integrated thermo-couple sensor.

To avoid cooling and condensation of sample gas in the extraction area, a heated sample probe tube

SP34-H.. is available.

Appropriate accessories are available for mounting the probes directly at the flange or threaded

sleeve-mounting brackets.

The specially designed, electrically-heated sample lines PSP 4M4/6 or PSP-W4M4/6 with reduced

outer diameter can be connected to the PSP4000-H... for transporting gas to the gas sample

conditioning system.

If unheated sample lines are used, this should be conducted on a descending gradient to the gas

sample conditioning system.

11 DESCRIPTION

The standard version is as follows:

The stainless steel filter chamber (SS316Ti) with an integrated 2µm ceramic depth filter element is

inserted completely into an electrically heated aluminium heating jacket with a heat-insulated

protective casing.

The temperature is adjusted to + 180°C via an integrated and adjustable capillary tube thermostat.

The green control lamp glows during the heat-up phase and is extinguished when the heating element

temperature is reached. It then comes on and off as the heating element is switched on and off.

By changing the internal wiring, the sample probe can be operated at 230V 50 Hz or 115V 60 Hz. The

standard wiring is for 230V.

Electrical connection is effected at the connection socket on the probe via the power cable provided

with a 7-pin adapter jack or via an additional cable conducted within the heated sample line PSP

4M4/6 resp. PSP-W4M4/6 , also with a 7-pin adapter jack.

The adapter jack's pins are wired as follows:

Pin 3: L - Mains power line conductor.

Pin 4: N - Mains power neutral conductor.

Pin 7: PE - Protective earthing conductor.

The probe's sample gas outlet connection has a 1/8" NPT inner thread. A temperature resistant 6 mm

tube connector is fitted gas-tight into this to connect the sample line. Once the electrically-heated

sample line PSP 4M4/6 resp. PSP-W4M4/6 has been mounted, the connection is enclosed in special

heat-conducting jaws in order to avoid temperatures falling below the required level in the critical

connection areas.

Gas sampling and gas conditioning technology 2-2.1-ME

Page 11

11

The heated sample line is rapidly and safely mechanically coupled with a tightening bracket including

integrated quick-coupling.

To ensure simple filter changes, the complete filter unit including the connected sample line can be

drawn out of the heat-insulated protective casing.

In the PSP400H/C special version, calibration-gas into the probe is possible without disassembling

the probe via a special threaded connecting joint.

The special version PSP4000H/C/T allows the process temperature to be measured by way of a

thermo-element which is introduced into this threaded connecting joint. Its length can be adjusted up

to the end of the sampling tube. The standard length of this thermocouple sensor is 600 mm.

Optionally available is the PSP transport case for transporting the PSP4000-H... gas-sample probe

including a maximum 5 m heated sample line PSP 4M4/6 resp. max. 8m for type PSP-W4M4/6.

12 RECEIPT OF GOODS

The gas sample probe PSP4000-H... is normally delivered in two packaging units:

1. Basic gas-sample probe with optional mounting accessories.

2. Optional sample tubes.

The gas sample probe should be removed carefully from the packaging and checked immediately for

completeness against the delivery note.

Check the goods for any damage incurred during transport and if necessary inform your transport

insurer of any damage.

13 PREPARATION AND INSTALLATION

Select the optimal sampling point in accordance with the generally applicable guidelines or consult the

competent persons.

The sampling point should be easily accessible.

Locate the probe connections in such a way that the connections' temperature is always above the

acid dew point in order to avoid corrosion and blockage problems.

If the ambient temperature in the area of the connections is >80°C as a result of radiated heat, then a

radiated-heat deflector must be mounted to protect the probe.

The probe can also be mounted with an optional mounting flange or R2" threaded mounting fitting.

Before mounting, the probe must be adjusted to the existing operating conditions.

Gas sampling and gas conditioning technology 2-2.1-ME

Page 12

12

Under / over pressure situation

mbar

bar

Process temperature

°C,

Min.

°C,

Max.

Dust loading

g/m³

Dust composition - grain size

µm

Gas composition

corrosive

toxic

explosive

Which parameters should be

measured, e.g. O2, CO, SO2, NOX,....,

Vol.%

mg/Nm³

ppm

Required amount of gas

l/h,

Min.

l/h,

Max.

Necessary T90 time

sec.

Heated sample line

PTFE-tube DN 4/6

The existing operational parameters are to be checked accordingly prior to commencing mounting

work.

14 SUPPLY CONNECTIONS

14.1 CONNECTING THE HEATED SAMPLE LINE

Remove the aluminium heat-conducting jaws at the probe's filter head by loosening the 4

screws from the gas outlet's threaded connection. The outlet's threaded connection is provided

for the connection of a tube with an external diameter of 6 mm (optionally 8 mm).

Before connecting a sample line not specified by M&C, the tube connection should be

prepared according to the following sketch.

M&C's heated sample lines type PSP 4M4/6 and PSP-W4M4/6 are manufactured to fit the

mechanical and electrical connections to the PSP4000-H... gas sample probe and already contain an

internal line for the probe's power supply.

Figure 1 Connection of the heated sample line

Push the insert into the PTFE tube in order to avoid the tube being compressed and slide the

red silicon protective ring up to the end of the heated sampling tube.

Introduce the PTFE tube into the threaded connection joint with the double-cutting ring system

to ensure sealing.

Gas sampling and gas conditioning technology 2-2.1-ME

Page 13

13

After tightening the connecting nuts by hand, tighten them a further 1 1/4 turns using a flat

spanner.

Push the end of the heated sample line as far as the end of the threaded connection joint and

clamp with the aluminium heat-conducting jaws.

Mount the aluminium heat-conducting jaws in the longitudinal axis of the filter chamber in such

a way that they fit into the aperture in the heat-insulated protective casing.

Remove the front part of the tension clip for holding the heated sampling tube to the probe and

push the filter chamber including the heated sampling probe into the heat-insulated protective

casing.

Screw on the front part of the tension clip again.

In the case of the PSP4000-H screw down the black knob on the rear side of the protective

casing and tighten by hand.

In the case of the PSP4000-H/C, PSP4000-H/C/T, the flat nut and the dummy bolt of the

threaded connecting joint on the rear side are to be screwed on again and after tightening the

dummy bolt by hand, this is then to be tightened further by turning precisely 1 1/4 turns with a

flat spanner.

14.2 ELECTRICAL CONNECTION

Plug in the 7-pin plug (power supply) and switch on the power. During the heating up phase,

the green control lamp glows. When the operating temperature is reached (180°C), the green

control light is extinguished and then lights up when the heating element is switched on to

adjust the temperature.

For safety reasons, we recommend switching the gas pump on only after another fifteen

minutes has elapsed in order to ensure that the sampling probe heats up completely.

When using the SP34-H... heated sample tube, the electrical connection should be made separately

using the built-in connection socket. The SP34-H sample tube has a built-in capillary tube thermostat

which adjusts the temperature in a range between 100°C and 180°C. (Factory setting 180°C).

When using the heated sample tube SP34-H1.1 and SP34-H2, an external temperature controller is

to be used for adjusting the temperature.

14.3 CALIBRATION-GAS DISCHARGE

In the case of the probe version PSP400-H/C with integrated calibration-gas connection, test gas can

be conducted directly into the probe during the entire sampling procedure for the calibration of

connected gas-analysis devices.

Remove the threaded connection's dummy bolt on the rear side of the probe.

Connect the 6 mm stainless steel tube provided or a temperature resistant tube DN4/6 (PTFE,

viton, silicon) using the nut provided and the double clamping ring. When connecting the tube,

prior to assembly the 4 mm stainless steel insert must be pushed into the tube.

Introduce the tube or the hose into the threaded connection until it clicks in.

Tighten the threaded connection's nuts by hand and then exactly 1 1/4 turn using a flat

spanner.

Gas sampling and gas conditioning technology 2-2.1-ME

Page 14

14

ATT ENT ION !

The protective housing's surface temperature is around 50°C.

NOTE!

Push the sample tube into the connecting adapter up to the marking as

otherwise the conical seal ring will not have a sealing effect.

14.4 TEMPERATURE MEASUREMENT

In the case of the probe version PSP4000-H/C/T, after removing the dummy bolt, the thermo-

element is pushed into the threaded connection on the rear side of the probe and fixed and

sealed using the connecting nut and the PTFE conical ring seal.

The thermo-element can be adjusted to the length of the sampling tube by sliding it backwards

and forwards accordingly.

Tighten the nut by hand and then carefully tighten further using an open-end wrench until the

thermo-element sits firmly.

The external measuring amplifier or an extension compensation lead is to be connected to the

compensating lead's standard plug.

15 STARTING

If a transport case is in use, remove the probe along with the heated sample line connected. Connect

the sample line to the gas sample conditioning system.

1. Connection of the PTFE tube connection

2. Connection of the 7-pin plug.

When using the device for the first time and when connecting the heated sample line, proceed as

follows:

In the case of the PSP4000-H, draw the probe's filter chamber forwards out of heat-insulated

protective casing by loosening and removing the black knob (rear side).

In the case of the PSP4000-H/C, PSP4000-H/C/T, the dummy bolt and the flat nut located on

the rear side of the threaded connection must be loosened and removed to do this.

Then mount the desired probe option at the filter chamber's G3/8" inlet:

In case of option "probe with adjustable tube length", screw the connecting adapter including

its integrated PTFE conical ring seal 40S9005 with washer into the probe's G3/8" inlet thread.

Push the heat-insulated adapter with its cone connector 40S9000 over the connection

adapter's pressure nut and fix it to the nut with the clamping screw.

Push the 8 mm sample tube through the conical connection into the filter chamber.

By turning the adapter to the right, the PTFE conical ring seal is pressed together and thus

seals the sampling tube.

When using a SP34H... heated sample tube, this should be screwed into the probe's G3/8" inlet

threaded connection. Additional unheated sample tubes or pre-filters can be screwed into the G3/8"

threaded connection at the other end as the need arises.

When mounting the probe in conjunction with the threaded fitting 40S9070, and flange 40S9080, the

connecting adapter with the PTFE conical ring seal 40S9005 and the intermediate adapter G3/4" 8mm 40S9060 are to be used.

Gas sampling and gas conditioning technology 2-2.1-ME

Page 15

15

ATT ENT ION !

High surface temperatures! Wear protective gloves!

ATT ENT ION !

In case of a hot probe wear protective gloves when changing the filter

element.

16 MAINTENANCE

It is difficult to give any recommendations as to a particular maintenance cycle. Depending on your

process conditions, a meaningful maintenance cycle must be elaborated for the specific application.

An indication that probe-maintenance may be necessary could be shown by a constant decline in the

amount of sample gas in the analysis system.

Probe maintenance is restricted essentially to replacing filter elements and checking seals.

16.1 CHANGING THE FILTER ELEMENT

As far as possible, the filter element should be changed when the probe is cold.

To do this in the case of the PSP4000-H, screw off the black knob on the rear side.

In the case of the PSP400-H/C with sample-gas connection and PSP4000-H/C/T with temperature

measurement the dummy bolt on the rear side is first to be removed and the thermo-element drawn

out. Then loosen and remove the threaded connection's hexagon nut.

Now loosen the rapid coupling for the heated sample line holder by pressing down on the outside

coupling ring and draw the complete filter unit out of the heat-insulated protective casing.

Screw the screw-on sleeve off the filter head.

Screw off the filter element holder and replace the filter element.

Check the filter element seals and the O-ring at the filter head and replace if necessary.

Clean filter chamber.

Clean or rod through the sampling tube in order to remove any deposits.

Then re-assemble in reverse order.

17 SWITCHING OFF

Before switching off, i.e. switching off the heating, the probe should be flushed with inert gas or air in

order to avoid condensation of aggressive components from the process gas.

Gas sampling and gas conditioning technology 2-2.1-ME

Page 16

16

Portable gas sample probe PSP4000-H..

(C) Consumables parts

(R) Recommended spare parts

(S) Spare parts

Recommended quantity being in

operation [years]

Part No.

Description

C/R/S

1 2 3

90 S 0015

Filter element S-2K,ceramic 2µm [4]

C

6 12 24

94 S 0005

Spun glass cartridge FW for PSP4000

S

- 1 1

93 S 2083

Filter spun glass, pure, temp. resistant up to 690°C, 500g

C

1 2 3

93 S 0045

Viton-gasket [3] for PSP4000

R

4 8 12

90 F 0040

Viton-O-ring 26 [2]

R

2 4 8

94 S 0045

Novapress gasket 3/8" (blue), max. 600°C

R

3 6 9

90 S 2078

Ceramic fibre gasket 3/4“, max. 1250°C

R

1 1 1

90 S 2080

Novapress gasket 3/4" (blue), max. 600°C

R

1 1 1

90 S 2077

flange gasket DN65 PN6 B, Novapress (67mm i.d.)

S

- - -

94 S 0040

PTFE fix ring, for 3/8“ fitting P.No. 40 S 9005

R

2 4 5

94 S 0050

Thermostat 100-180°C with 6mm sensor tube

R

- 1 1

93 S 0018

Temperature resistant heat sink compound,

max. 200°C, 100 g tube

R 1 1

1

94 S 0010

Cartridge heater 230V 160W, PSP4000 up to S.No. 118

R 1 1 2 94 S 0015

Cartridge heater 115V/230V 100W

R 2 2 4 94 S 0025

Tube connection 6mm for PSP4000-H/C

S - -

-

94 S 0020

Blind cap compl. for PSP4000-H/C

S - - - 94 S 0030

VITON o-ring 3 for PSP4000-H/C blind cap

R 2 4 6 94 S 0035

PTFE fix ring for PSP4000-H/C/T thermoelement connection

R 2 4

6

18 SPARE PARTS LIST

Wear, tear and replacement part requirements depend on specific operating conditions.

The recommended quantities are based on experience and they are not binding.

Gas sampling and gas conditioning technology 2-2.1-ME

Page 17

17

19 APPENDIX

Sample facilities, PSP4000-H/C and PSP4000-H/C/T

Wiring plan

Basic version

Carrying case to transport sample probe

Filter unit and connection of the heated sample line

High temperature sample tube aluminium oxyde

Electrically heated sample tube SP34-H

Further product documentation can be seen and downloaded from our home page:

www.mc-techgroup.com

Data sheet – portable heated sample probe PSP4000-H

Document: 2-2.1

Data sheet - electrically heated sample probe tube SP34-H

Document: 2-2.2

Gas sampling and gas conditioning technology 2-2.1-ME

Page 18

18

Figure 2 Sample facilities

Gas sampling and gas conditioning technology 2-2.1-ME

Page 19

19

Figure 3 Wiring plan

Gas sampling and gas conditioning technology 2-2.1-ME

Page 20

20

Figure 4 Basic version

Gas sampling and gas conditioning technology 2-2.1-ME

Page 21

21

Figure 5 Carrying case to transport sample probe

Gas sampling and gas conditioning technology 2-2.1-ME

Page 22

22

Figure 6 Filter unit and connection of the heated sample line

Gas sampling and gas conditioning technology 2-2.1-ME

Page 23

23

Figure 7 High temperature sample tube, aluminium oxide

Gas sampling and gas conditioning technology 2-2.1-ME

Page 24

24

Figure 8 Electrically heated sample tube SP34-H

Gas sampling and gas conditioning technology 2-2.1-ME

Loading...

Loading...