Page 1

PMA 50 EEX

Embracing Challenge

Oxygen Analyser Series PMA®

Thermostated version PMA 50 EEX

in a wall mounting explosion-proof housing

SIL

DIN EN 61508

Special Features

Explosion proof according to ATEX and

NEPSI for Zone 1

SIL approval according to DIN EN 61508

Thermostated, in an explosion-proof

housing

Accurate and reliable, small space

requirement

Analogue/Digital indicator

Five linear measuring ranges

Physical measuring principle

Small stagnant volume, fast response

time

Remote range indication and control

Flow alarm sensor

Status alarm, safety in operation

Application

Due to the extremely fast response time

of the M&C magneto-dynamic measuring

cell with no stagnant volume as well as the

negligible cross sensitivity from other sample

gas components, the M&C oxygen analyser

PMA 50 EEX is a suitiable and reliable instrument for monitoring oxygen concentrations

in various gas analytical process control applications.

Description

The M&C oxygen analyser PMA 50 EEX is a

temperature controlled instrument which has

been designed for continuous measurements

of oxygen concentrations in particle-free and

dry sample gas with a flow rate between 0-60

Nl/hr.

The PMA 50 EEX is a reliable and easy-tooperate instrument. It is built into an

explosion-proof EEX d e IIC T5 wallmounting housing with stainless steel tubing

and certified ventilate arrestors at sample gas

inlet and outlet. The transducer unit maintains a constant operating temperature of 55

°C and a flashing LED on the control panel

indicates the proper operating temperature

of the analyser. The five measuring ranges

are displayed on the analogue meter with

30/100% scale and the 100% range on the

digital meter. The selected measuring range

is displayed on the front panel by LED’s. Two

output signals are available. The terminals

for the incoming power supply, two output

signals, remote range indication and control

and status alarm are located inside the EEX

e box. The sample gas enters the analyser via

a ventilate arrestor after it passed through an

external sample conditioning system with at

least a protective fine filter and flowmeter

with needle valve for adjusting the required

flow rate of the sample gas (also available

with M&C). After passing the M&C measuring cell and the flow sensor, the sample gas

leaves the instrument via the certified outlet

ventilate arrestor.

Measuring principle of M&C oxygen analyser

The PMA 50 EEX utilises the paramagnetic

principle of operation to measure oxygen

concentrations. The analyser measures the

paramagnetic susceptibility of the oxygen

in the sample gas by means of the M&C

magneto-dynamic measuring cell. The physical propertys which distinguishes oxygen

from other gases is its paramagnetism. It is

significantly higher comparing to other common gases. This operation principle is one of

the most accurate and reliable procedures to

determine the oxygen concentration in a gas

mixture from 0 to 100 Vol.%.

The robust M&C cross-flow cell has no

stagnant volume. Advantages are the fast

response time, the flow rate up to 60 l/hr,

the small volume of 2 ml, the extremely low

drift, the absolute linearity and the negligible

cross sensitivity against other sample gas

components. With a proper sample conditioning and pressure, the M&C cell will never

need replacing. The dumbbell with a small

mirror at its centre is mounted in a strong

inhomogenous magnetic field. The paramagnetic oxygen strengthens the forces on the

diamagnetic dumbbell and causes a shifting

which is detected by a system consisting of

light beam, mirror and a photo cell.

A compensation current is induced via the

feedback coil on the dumbbell and leads to

a reset of the dumbbell into its zero-position.

The required current is linearly proportional to

the oxygen concentration.

Technical specications and illustrations are without

obligation, subject to modications. 02.95/01.07

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

13.7

Page 2

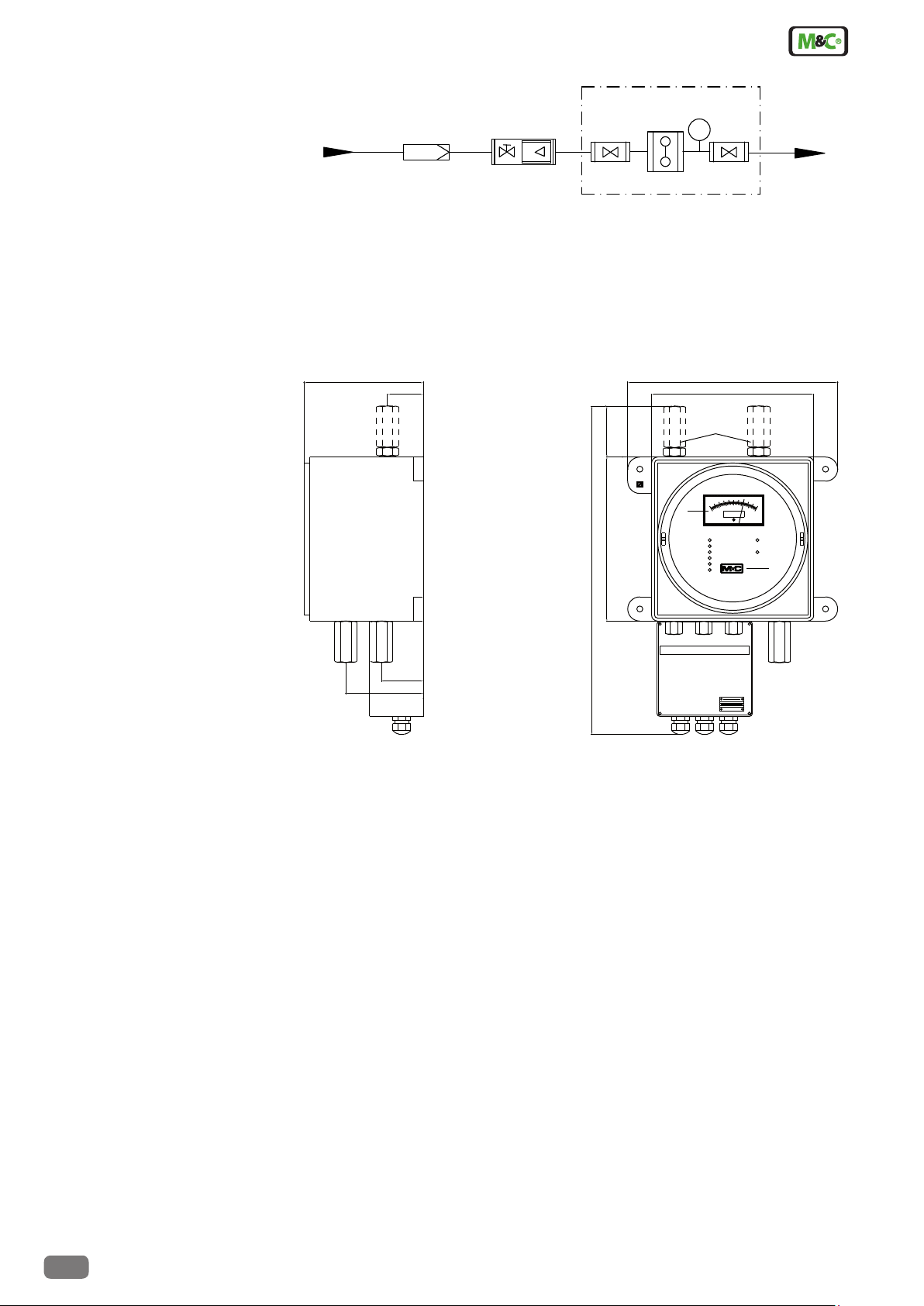

Gas flow diagram PMA 50 EEX

1. External fine filter

2. External flowmeter with needle valve

3. Ventilate arrestor

4. Oxygen measuring cell PMA

5. Flow alarm sensor

(and at version #:with

pressure sensor)

Dimensions

1. Sample gas in/out with certified

ventilate arrestors

2. Cable glands 2x PG 13,5; 1x PG 16

3. Zero control

4. Measuring range select

5. Span control

6. Optional purging with certified venti-

late arrestors

1 2

3

5

4

FLA

(P)

3

Front view Side view

200

60

70

275

355

275

6

60

40

80

20

0

15

20

10

25

5

30

0

20.9

100

Dimensions in mm

130

O -Analyser

535

70

2

PMA 50 Ex

53 4

1

2

13.7

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 02.95/01.07

Page 3

Technical Data

Version PMA 50 EEX thermostated oxygen analyser in explosion-proof housing

Part No. 05A1000 :

05A2500 :

05A2505 :

Measuring ranges selectable for 0-1, 0-3, 0-10, 0-30 and 0-100 vol.% O2 linear and position EXTERNAL

External range indication externally: Potentialfree contact for all measuring ranges. Capacity 48V DC 200mA DC, Minimum contact rating

Remote range control Measuring ranges selectable via external potential free contacts 30V DC 3mA DC

Combined analogue/digital indicator analogue meter with a scale of 0-30 and 0-100% for each selected range

Output signals 0-10V DC, burden >100 KΩ for range 0-100 % isolated.

Response time for 90% FSD < 5 seconds at 60 Nl/hr air

Accuracy after calibration deviation: analogue signal output = ± 1% of span at range 3 - 100% / digital indicator = ±0,1 vol.% O

Reproducibility deviation: analogue signal output = < 1% of span / digital indicator = ±0,1 vol.% O

Influence of ambient temperature no influence up to 50 °C

Influence of barometric pressure The oxygen reading varies in direct proportion to changes of the barometric pressure

Influence of sample gas flow Variation in gas flow between 0-60 Nl/hr air will cause a difference of < 0,2 vol.% O

Sample gas inlet pressure 0,01-0,1 bar g standard or # in case of purging up to 0,5 bar g

Sample gas outlet pressure outlet of analyser must discharge freely into atmosphere

Flow rate of sample gas max. 60 Nl/hr (no flowmeter inside)

Temperature of sample gas -10 °C up to +50 °C dry gas

O2-transducer temperature fixed at +55 °C

Ambient-/ Storage temperature -10 °C up to +50 °C / -20 °C up to +60 °C, relative humidity 0-90% RH

Power supply internal power unit for 230VAC standard or 115VAC (a)* +/-10%, 40-60Hz, 35,5VA

Electrical connections terminals 2,5 mm2, 3x PG cable glands (mains supply, signals, range indication, remote ranging , status alarm)

Materials in contact with sample gas Platinum, Glass, Stainless Steel 316Ti, Epoxy resin, PTFE, PVDF

Sample gas connection

Flow alarm thermo-conductive flow sensor downstream mounted after measuring cell

Status alarm Change-over contact, switching capacity 250 V AC 2A AC, 48V DC 200mA DC minimum contact rating 50mW for

Protection / classification

Certificate No. KEMA 03 ATEX 2215X

Temperature cutoff at 72°C via thermal fuse, non-reversible

Housing / colour wall mounted explosion-proof housing / blue

Dimension / weight 475 (535) x 275 (355) x 200 mm / h x w x d / approx. 22 kg

Options Part-No. 05A9000: purging the enclosure via two certified ventilate arrestors, for pressures up to max. 1,5 bar abs.

* Please specify with order.

PMA 50 EEX, power supply 230V 40-60Hz, signal 0-1V and 0-20mA

PMA 50 EEX/P/PD-1-50, power 230V 40-60Hz, 0-1V / 0-20mA, pressure compensation 0,6 - 1,5 bar abs. with purging

the enclosure via two certified ventilate arrestors in the in- and outlet NPT1/4“i

PMA 50 EEX/P/PD, power 230V 40-60Hz, 0-1V / 0-20mA, pressure compensation 0,6 - 1,1 bar abs.

05A1000a / 05A2505a / 05A2505a = 115V 40-60Hz

(variations of +10% to -15% have no influence on the function of the analyser), 40-60Hz, 35,5VA, power supply via

EEx e connecting box, diameter of cable: 5mm - 9mm (PG13,5), 7mm - 12mm (PG16)

5V/1mA; internally : LED indication

digital meter 3

1

/

digit 9 mm high LCD-indicator for 0-100% O2 reading, selectivity 0,1vol.% O

2

2

0/4-20mA burden 270 Ω for every measuring range, electrically isolated; output voltage max. 15V (ex works).

Switchable max. burden 800 Ω, output voltage max. 30V.

Output current limiting adjustable 20mA-22mA (20,5mA ex works)

= ± 2% of span at range 1%

2

2

# no influence from 0,5-1,5 bar abs. at PMA 50 EEX/P/PD-1-50 with process pressure compensation

2

(PMA 50 EEX required admission pressure for competent flow rate, no pump inside)

or 0,6-1,5 bar abs. at version # PMA 50 EEX/P/PD-1-50 with process pressure compensation

1

/

" NPTi

4

temperature <+45°C / >+60°C, defect light beam, measuring cell not coupled, flow alarm <10 / >70Nl/h, power

supply error control, mains voltage breakdown

IP 54 EN 60529 / II2G EEX d e IIC T5 or II1/2G EEX d e [ia] IIC T5

and/or corrosive gases, connection

1

/

" NPTi, purge gas inlet pressure max. 100 mbar, flow rate 10-60 Nl/hr

4

Part-No. 05A9005: purging the enclosure via one certified ventilate arrestor, for pressure range > 1,1 bar - 1,5 bar abs.

and non-corrosive gases, connection

1

/

4

" NPTi

Part-No. 05A9015: Zero suppressing type SD-1/50 for PMA-50 pressurerange 0,5-1,5bar abs. Lowest range 97-100%

material: SS316, PVDF, Viton. mounted in the PMA-50Ex. Only in connection with PMA50EEx/P/PD-1/50.

Externally switchable via potential free contacts, 30V DC 3mA DC

Part-No. : Transmitter for measurements of gases from ex-zone 0 II 1/2 G Eex de [ia] IIC T5

Part-No. 90A0009: Measuring cell type PMC-1LB, solvent resistant.

Part-No. 90A0006: Measuring cell PMC-1G with glass solder. O-ring made of Chemraz

W A R N I N G ! I M P O R T A N T !

An external fine filter must always be used at the gas inlet of the analyser. Depending

on the composition of the sample gas, it may be necessary to use a sample conditioning system.

Technical specications and illustrations are without

obligation, subject to modications. 02.95/01.07

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

13.7

Loading...

Loading...