Page 1

Operating Manual

Oxygen Analyser Series PMA

Version PMA 50 Ex

Gas sampling and gas conditioning technology 9-3.15-ME

Page 2

2

This Operating Manual does not claim completeness and may be

subject to technical modifications.

© 04/1996 M&C TechGroup Germany GmbH. Reproduction of this

document or its content is not allowed without permission from M&C.

PMA® is a registered trade mark.

6th Edition: 12/2011

Dear customer,

we have made up this operating manual in such a way that all necessary information about the

product can be found and understood quickly and easily.

Should you still have any question, please do not hesitate to contact M&C directly or go through

your appointed dealer. Respective contact addresses are to be found in the annexe to this operating manual.

Please also contact our homepage www.mc-techgroup.com for further information about our

products. There, you can read or download the data sheets and operating manuals of all M&C

products as well as further information in German, English and French.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 3

3

List of Contents

1 General information ......................................................................................................... 5

2 Declaration of conformity ................................................................................................ 5

3 Electrical standards ......................................................................................................... 6

4 Safety instructions ........................................................................................................... 6

5 Information and safety instructions for using the Analyser in hazardous areas ......... 7

6 Warranty ........................................................................................................................... 7

7 Used terms and signal indications .................................................................................. 8

8 Introduction ...................................................................................................................... 9

8.1 Serial number ............................................................................................................... 9

8.2 Power supply ................................................................................................................ 9

9 Application ....................................................................................................................... 9

10 Technical Data ................................................................................................................ 10

10.1 Options ....................................................................................................................... 11

11 Description ..................................................................................................................... 12

11.1 PMA 50 Ex/P/PD-1-50 with pressure compensation and enclosure purging (without

SIL-certification) .......................................................................................................... 13

11.2 PMA 50 Ex/P/PD with pressure compensation (without SIL-certification) .................... 14

11.3 Option zero suppression (without SIL-certification) ..................................................... 14

11.4 Option enclosure purging or ventilation ....................................................................... 14

12 Measuring principle ....................................................................................................... 15

13 Gas flow diagram ........................................................................................................... 16

14 Receipt of goods ............................................................................................................ 18

15 Installation ...................................................................................................................... 18

16 Supply connections ....................................................................................................... 19

16.1 Sample gas inlet and sample gas outlet ...................................................................... 19

16.2 Option purging enclosure or ventilation ....................................................................... 19

16.3 Electrical connection ................................................................................................... 20

17 Starting up ...................................................................................................................... 21

18 Calibration ...................................................................................................................... 21

18.1 Zero calibration ........................................................................................................... 22

18.2 Span calibration .......................................................................................................... 23

19 Measuring ....................................................................................................................... 25

20 Cross sensitivities ......................................................................................................... 26

21 Closing down .................................................................................................................. 29

22 Storage and Transport ................................................................................................... 29

23 Maintenance ................................................................................................................... 29

23.1 Removal of the measuring cell .................................................................................... 30

23.2 Mechanical zero point adjustment ............................................................................... 33

24 Spare parts list ............................................................................................................... 34

25 Appendix......................................................................................................................... 35

Gas sampling and gas conditioning technology 9-3.15-ME

Page 4

4

List of Illustrations

Figure 1 PMA 50 Ex Oxygen Analyser ................................................................................. 12

Figure 2 Scheme of the measuring cell and optical signal processing .................................. 15

Figure 3 Gas flow diagram ................................................................................................... 16

Figure 4 Gas conditioning .................................................................................................... 17

Figure 5 Electrical connection in the connection box of the PMA 50EX EEX e ..................... 20

Figure 6 Schematic view of the internal layout of the analyser ............................................. 30

Figure 7 Transmitter unit ........................................................................................................ 32

Figure 8 Schematic view of the transmitter unit .................................................................... 33

Figure 9 Circuit diagram front board PMA50ex 10.2008 ....................................................... 38

Figure 10 Assembly front board PMA50ex 10.2008 ............................................................... 39

Figure 11 Circuit diagram mains adapter PMA50ex 10.2008 .................................................. 40

Figure 12 Assembly / connection mains adapter PMA 50ex 10.2008 ..................................... 41

Figure 13 Cut-out magnification front board for adjustment of temperature alarm (TP10,

P19) (TP11: actual temperature) und flow alarm threshold (P20) ............................ 42

Figure 14 Cut-out magnification front board couple sensor bridge for application of a

transmitter without couple sensor ........................................................................... 42

Figure 15 Cut-out magnification front board for adjustment of reference voltage ,

amplification and offset of the O2-signal .................................................................. 43

Figure 16 Cut-out magnification mains adapter for adjustment of the temperature, current

and voltage output .................................................................................................. 44

Figure 17 Cut-out magnification mains adapter for adjustment of burden and limitation of

the current output ................................................................................................... 44

Gas sampling and gas conditioning technology 9-3.15-ME

Page 5

5

Head Office

M&C TechGroup Germany GmbH Rehhecke 79 40885 Ratingen Germany

Telephone: 02102 / 935 - 0

Fax: 02102 / 935 - 111

E - mail: info@mc-techgroup.com

www.mc-techgroup.com

1 GENERAL INFORMATION

The product described in this operating manual has been examined before delivery and left our

works in perfect condition related to safety regulations. In order to keep this condition and to

guarantee a safe operation, it is important to heed the notes and prescriptions made in this operating manual. Furthermore, attention must be paid to appropriate transportation, correct storage,

as well as professional installation and maintenance work.

All necessary information a skilled staff will need for appropriate use of this product are given in

this operating manual.

2 DECLARATION OF CONFORMITY

CE - Certification

The product described in this operating manual complies with the following EC directives:

ATEX-Directive

The product described in this manual is produced in accordance with the EC directive for devices and

protection systems for appropriate use in hazardous areas 94/9/EG appendix II.

EMV-Instruction

The requirements of the EC directive 2004/108/EG “Electromagnetic compatibility“ are met.

Low Voltage Directive

The requirement of the EC directive 2006/95/EG “Low Voltage Directive“ are met.

Declaration of conformity

The EU Declaration of conformity can be downloaded from the M&C homepage or directly requested from M&C.

The SIL –declaration of conformity can be requested directly at M&C.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 6

6

3 ELECTRICAL STANDARDS

The electrical standard of electrical equipment corresponds to the safety regulations concerning

the EN61010 and to the safety requirements of the European standards EN 61508; EN 50014 :

1997, EN 50018 : 2000, EN 50019 : 2000, EN 50020 : 2002 and EN 50284 : 1999 for operation of

the equipment in hazardous areas group II category 2. Attention must be paid to the Certificate of

Conformity KEMA 03 ATEX 2215X (see appendix).

4 SAFETY INSTRUCTIONS

Please note the following basic safety procedures when using this equipment:

Read these operating instructions carefully before start-up and use of the equipment! The

information and warnings given in these operating instructions must be heeded.

Attention must be paid to the requirements of the certificate of conformity (see appendix):

KEMA 03 ATEX 2215X.

Work on electrical equipment is only to be carried out by trained specialists as per the

regulations currently in force.

Attention must be paid to the requirements of VDE 0100 when setting high-power electri-

cal units with nominal voltages of up to 1000V, together with the associated standards

and stipulations.

For use in hazardous area observe the relevant national and international instructions and

regulations.

Check the details on the type plate to ensure that the equipment is connected up to the

correct mains voltage.

Protection against touching dangerously high electrical voltages. Before opening the

equipment, it must be switched and hold no voltages. This also applies to any external

control circuits that are connected.

The equipment is only to be set within the permitted range of temperatures and pres-

sures.

Check that the location is weather-protected. It should not be subjected to either direct

rain or moisture.

Installation, maintenance, monitoring and any repairs may only be done by authorised

personnel with respect to the relevant stipulations.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 7

7

5 INFORMATION AND SAFETY INSTRUCTIONS FOR USING THE ANALYSER

IN HAZARDOUS AREAS

The Oxygen Analyser PMA 50 Ex is suitable for use in hazardous area group II category 2.

The explosion proof protection is:

II 2G EEx de IIC T5 or II 1/2 G EEx de [ia] IIC T5 KEMA (appr.-no.: 03 ATEX 2215X)

The analyser has been certified through KEMA, authorized company for official approval of electric

equipment in the Netherlands. Detailed information and a copy of the certificate are attached to this

operating manual.

Installation and operation of the analyser has to be done corresponding to the conditions in the Excertificate (see appendix). Only in this case, the reliability of operation in hazardous area can be guaranteed.

All changes of the standard analyser with parts which are not specified or approved by M&C as well as

repair and service with not specified parts mean a loss of the Ex-certificate.

In case of doubt, please turn directly to M&C respectively to your M&C franchised dealer.

6 WARRANTY

If the equipment fails, please contact M&C directly or else go through your M&C authorised

dealer.

We offer a one year warranty as of the day of delivery as per our normal terms and conditions of

sale, and assuming technically correct operation of the unit. Consumables are hereby excluded.

The terms of the warranty cover repair at the factory at no cost or the replacement at no cost of

the equipment free ex user location. Reshipments must be se nd in a sufficient and proper p rote ctive packaging.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 8

8

DANGER!

This means that death, severe physical injuries and/or important material

damages will occur in case the respective safety measures are not fulfilled.

W ARN I NG !

This means that death, severe physical injuries and/or important material damages may occur in case the respective safety measures

are not fulfilled.

CARE!

This means that minor physical injuries may occur in case the respective safety measures are not fulfilled.

CA R E!

Without the warning triangle means that a material damage may occur in case the respective safety measures are not met.

AT T ENT ION !

This means that an unintentional situation or an unintentional status

may occur in case the respective note is not respected.

NOTE!

These are important information about the product or parts of the

operating manual which require user’s attention.

SKILLED STAFF

These are persons with necessary qualification who are familiar with

installation, use and maintenance of the product.

NOTE!

These are important information about the product or parts of the

instruction manual referring to operating in hazardous areas.

7 USED TERMS AND SIGNAL INDICATIONS

Gas sampling and gas conditioning technology 9-3.15-ME

Page 9

9

8 INTRODUCTION

8.1 SERIAL NUMBER

The type plate with the serial number is fixed on the left side of the analyser’s housing.

Please indicate always this serial number in case of questions or when purchasing spare parts.

8.2 POWER SUPPLY

The internal power supply of the Oxygen Analyser PMA 50 Ex is reversible 115/230V AC, with

40Hz to 60Hz. Exact indications are to be found on the type plate. Variations of the power supply

of -15% to +10% do not effect the function of the analyser.

9 APPLICATION

The Oxygen Analyser PMA 50 Ex is suitable for the continuous measurement of oxygen in particle-free and dry sample gases with a maximum dew point of 5°C.

The features of the anaylser are safe operation, accuracy and low maintenance.

The measurement is based on the physical principle of the magneto-dynamic oxygen measuring

cell and is one of the most exact quantitative methods of oxygen determination within the range

of 0-100 Vol.% oxygen.

There is a direct flow against the measuring cell which has got a low volume of only 2 ml (small

stagnant volume). Further characteristics are robustness, extremely small drift, fast response

time (T90 < 5 sec.) and negligible cross sensitivities to other sample gas components.

Flow variations within a range of 0 Nl/h to 60 Nl/h air result in a changement of the oxygen indication which is smaller than 0,2 Vol % O2.

Measurements in flue gases and in inerting installments are some typical applications for the

PMA 50 Ex within a great variety of other measurement tasks.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 10

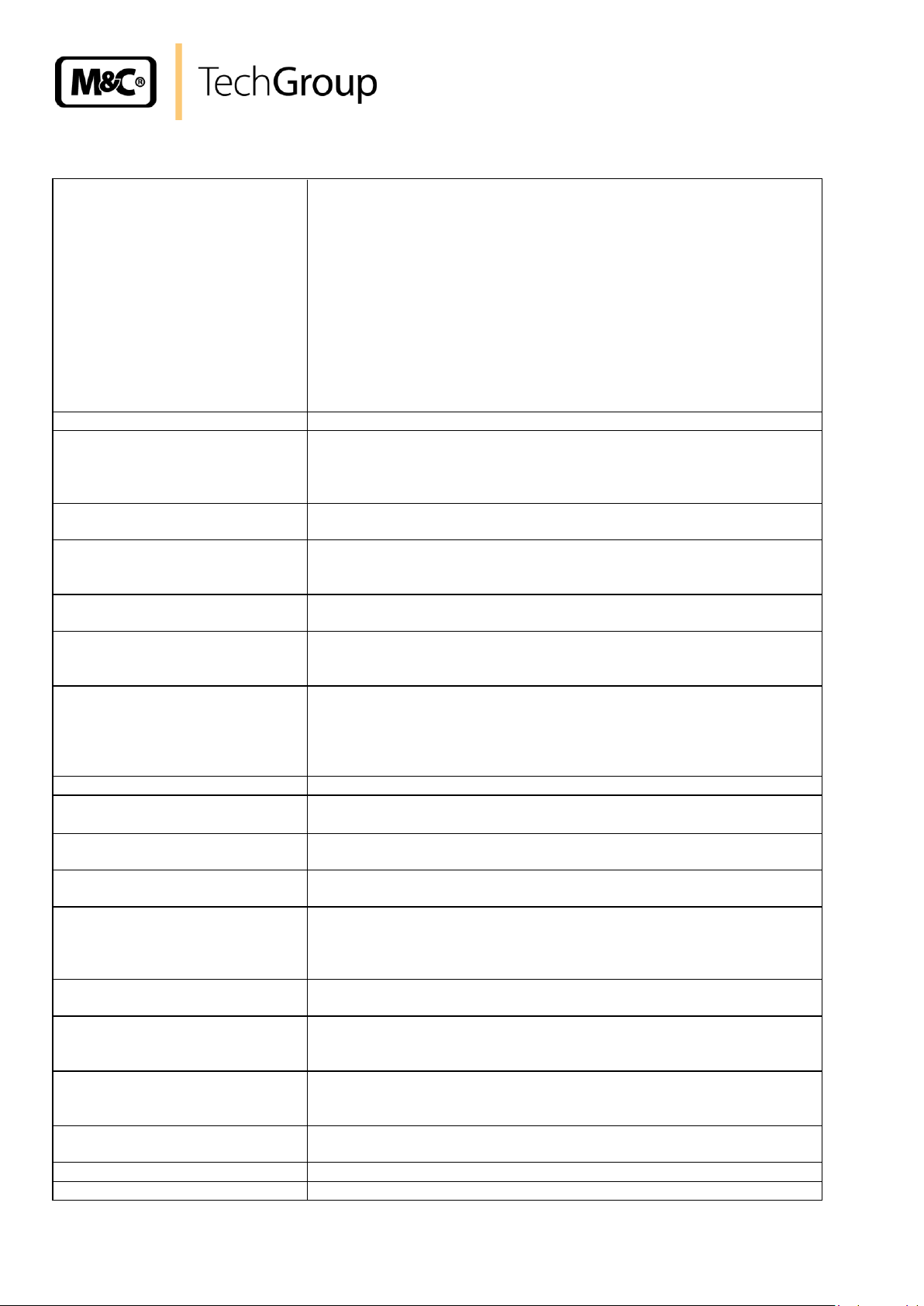

10 TECHNICAL DATA

Part Number

05A1000 :

05A1000a :

05A2500 :

05A2500a

05A2505 :

05A2505a :

PMA 50 EX, power supply 230V

PMA 50 EX, power supply 115V

PMA 50 EX/P/PD-1-50, power 230V, (not with SIL-certification)

pressure compensation 0,6 - 1,5 bar abs. with purging the enclosure via

two certified ventilate arrestors in the in- and outlet NPT1/4“i

PMA 50 EX/P/PD-1-50, power 115V, (not with SIL-certification)

pressure compensation 0,6 - 1,5 bar abs. with purging the enclosure via

two certified ventilate arrestors in the in- and outlet NPT1/4“i

PMA 50 EX/P/PD, power 230V, (not with SIL-certification)

pressure compensation 0,6 - 1,1 bar abs.

PMA 50 EX/P/PD, power 115V, (not with SIL-certification)

pressure compensation 0,6 - 1,1 bar abs.

Power supply

230VAC (standard) or 115VAC (a) -15% to +10%, 40-60Hz, 35,5VA

Electrical connections

via EEx e connection box 3x PG-cable gland

cable diameter : 6mm - 13mm (M20x1,5), 10mm - 17mm (M25x1,5)

terminals 2,5mm2,

(power, signals, range position and remote choice, status signal)

Measuring ranges

selectable for 0-1, 0-3, 0-10, 0-30 and 0-100 vol.% O2 linear

choice via rotary selection switch at PMA 50 or remote switching

External range indication

Potential free contact for all measuring ranges.

Capacity 48V DC 200mA DC,

Minimum contact rating 5V/1mA

Remote range selection

Measuring ranges selectable via potential free contacts max. 30V DC

3mA DC. The function is displayed at the PMA 50 via LED.

Combined analogue/digital indicator

analogue meter with a scale of 0-30 and 0-100% for each selected range

digital meter 4 1/2 digit 9 mm high LCD-indicator for 0-100% O2 reading,

selectivity 0,01vol.% O2

Output signals

0/4-20mA burden 270 Ω for every measuring range, electrically isolated;

output voltage max. 15V (ex works).

Switchable max. burden 800 Ω, output voltage max. 30V.

Output current limiting adjustable 20mA-22mA (20,5mA ex works)

0-10V DC, burden >100 KΩ for range 0-100 % isolated.

Response time for 90% FSD

< 5 seconds at 60 Nl/hr air

Accuracy after calibration

1% of the span value of measuring range after calibration or 0,02%O

2

depending on which value is the higher one

Reproducibility

Analogue output = < 1% of measuring range / digital indication =

± 0,01 Vol.% O2

Influence of ambient temperature

No influence up to 50 °C

Influence of barometric pressure

The oxygen reading varies in direct proportion to changes of the barometric pressure.

No influence from 0,6-1,5 bar abs. at PMA 50 EEX/P/PD-1-50 with

process pressure compensation

Influence of sample gas flow

Variation in gas flow between 0-60 Nl/hr air will cause a difference of

< 0,2 vol.% O2

Sample gas inlet pressure

0,01-0,1 bar g standard or in case of purging up to 0,5 bar g

(PMA 50 EEX required admission pressure for competent flow rate, no

pump inside)

Sample gas outlet pressure

outlet of analyser must discharge freely into atmosphere

or 0,6-1,5 bar abs. at version PMA 50 EEX/P/PD-1-50 with process pressure compensation

Flow rate of sample gas

Min. 10 Nl/hr up to max. 60 Nl/hr adjustable externally via flow meter (no

flowmeter inside)

Temperature of sample gas

-10 °C up to +50 °C dry gas

O2-transmitter temperature

fixed at +55 °C

10

Gas sampling and gas conditioning technology 9-3.15-ME

Page 11

Temperature cutoff

at 72°C via thermal fuse, non-reversible

Ambient temperature

During operation between -10° C to + 50° C

Storage temperature

-20°C to +60°C at relative air moisture of 0-90% r.h.

Medium touched material

Platine, glass, PTFE, PVDF, stainl. steel 1.4571, Epoxy

Connections measuring gas

Ventilate arrestors at inlet and outlet, NPT 1/4" i

Flow failure

thermo-conductive flow sensor downstream mounted after measuring cell

Status signal outlet

Change-over contact, switching capacity 250 V AC 2A AC, 48V DC

200mA DC minimum contact rating 50mW for temperature <+45°C /

>+60°C, defect light beam, measuring cell not coupled, flow failure

<5 / >80Nl/h, power supply error control, mains voltage breakdown,

failure measuring range selection

Housing / colour

EEX-d e wall mounted explosion-proof housing / blue

Dimensions/Weight

475 (535mm with ventilate arrestors) x 355mm x 200mm (HxWxD) / 22kg

Classification/Protection

II 2G EEx de IIC T5 or II 1/2 G EEx de [ia] IIC T5

IP54 DIN 60529

Certificate No.

KEMA 03 ATEX 2215X

Part

number

Options

05A9015

Zero suppression in range of 1%-97%; Only in connection with part no. 05A2500(a)

PMA50EEx/P/PD-1/50. Externally switchable via potential free contacts, 30V DC 3mA DC

(not with SIL-certification)

05A9005

Extra charge for one ventilate arrestor for PMA-50Ex... for pressure range up to 1500mbar abs.

and non-corrosive gases, connection NPT1/4"i.

05A9000

purging the enclosure via two certified ventilate arrestors, for pressures up to max. 1,5 bar abs.

and/or corrosive gases, connection 1/4" NPTi, purge gas inlet pressure max. 100 mbar, flow

rate 10-60 Nl/hr

Transmitter for measurements of gases from ex-zone 0 II 1/2 G EEx de [ia] IIC T5

90A0009

Measuring cell type PMC-1LB, solvent resistant.

90A0006

Measuring cell PMC-1G with glass solder. O-ring made of Chemraz

10.1 OPTIONS

11

Gas sampling and gas conditioning technology 9-3.15-ME

Page 12

12

130

70

60

200

355

520

2

3

4

571

6

8

9

10

111213

141516

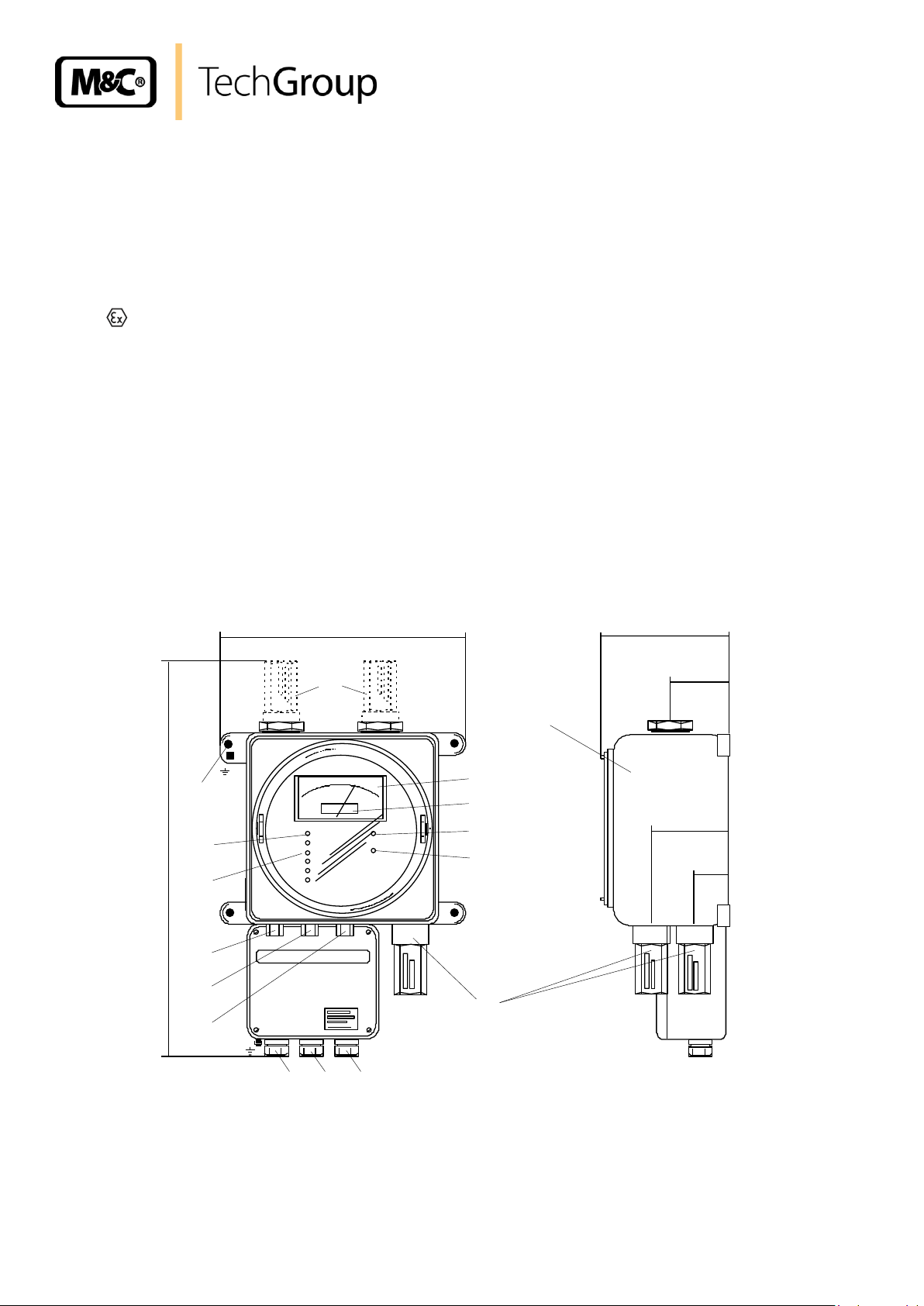

11 DESCRIPTION

The main part of the PMA 50 Ex is the magneto-dynamic oxygen measuring cell.

This measuring principle is one of the most precise quantitative methods for determination of the

oxygen contents in the range of 0-100 Vol.% O2.

The Oxygen Analyser PMA 50 Ex is destined for stationary operation. The mounting into a EEx

de IIC T5 housing 1 with ventilate arrestors in the sample gas inlet and outlet 6 makes it possible

to install the analyser in hazardous area of group II category 2. Equipment with protection (s. type

plate) II 1/2 G EEx de [ia] IIC T5 (option) is suitable to measure explosive gases of group II

category 1.

The analyser is thermostated and regulated to a transmitter temperature of +55°C. The temperature controller is built in that way that the low-voltage part is separated from the 230V capacity

part via an optoelectronic coupler with no-voltage releasing magnet.

A fast and homogeneous conduction of temperature is guaranteed by large-surface heating elements mounted on the transmitter surface.

An overheating of the transmitter to more than 72°C is avoided by a non-reversible thermal fuse.

The transmitter is equipped with an isolating cap in order to accumulate the heat and isolate the

transmitter.

Figure 1 shows the Oxygen Analyser PMA 50 Ex in front view and side view.

Figure 1 PMA 50 Ex Oxygen Analyser

A window in the housing of the analyser enables you to control the indications of the measured

value 2, the status LEDs 4 and 5 as well as the measuring range LEDs 13 and 14.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 13

13

NOTE!

The enclosure purging has to flow off atmospherically free!

Every operational control is accessable from outside and guarantees a simple and user-friendly

handling during calibration and change-over of the measuring range.

The operational controls are:

Adjustment of measuring range span value 10,

Range switch 11 and

Adjustment zero point 12.

The oxygen display of the PMA 50 Ex is effected by a two-scale analogue instrument 2, with

ranges of 0-30 Vol% and 0-100 Vol % O2. A digital display 3 is integrated into the analogue display. Here, the oxygen value is indicated in a range of 0-100Vol% with a resolution of 0,1Vol%.

The change-over of the measuring range is to be done via the range switch 11. The measuring

range chosen is displayed by a respective LED 13 on the front plate of the PMA 50 Ex and via a

potential free contact (see Fig. 5) to external.

The selection of the measuring range can also be effected externally. The LED 14 on the front

plate of the analyser signals the remote measuring range control in connection with a respective

measuring range LED.

The functioning of the analyser heating is indicated by the flashing LED 5.

The PMA 50 Ex has got a collective status output as standard. This is a potential-free change-

over contact in ‘Safety-First’ switching. The breaking capacity is 200mA with 48V DC or 2A with

250V AC. The state is displayed via status-LED 4. The following status signals are given:

Light source defective,

measuring cell not coupled,

flow failure <5 / >80Nl/h,

power supply error control,

mains voltage breakdown,

transmitter temperature <+45°C / >+60°C,

failure measuring range selection

11.1 PMA 50 EX/P/PD-1-50 WITH PRESSURE COMPENSATION AND ENCLOSURE PURGING (WITHOUT SIL-CERTIFICATION)

In case of barometric or process originated pressure variations, the PMA 50 Ex can be equipped

with a special pressure compensation. The compensation can be effected within a pressure

range of 0,6 – 1,5 bar abs.. Thereby errors in measurement caused by pressure variations can

be eliminated.

Additionally the analyser is equipped with an enclosure purging via ventilate arrestors in the inlet

and outlet. The enclosure purging is necessary in case of corrosive sample gas and / or pressure

above 1,1 bar abs.. In case of a leackage in the analyser pressure can not be built up and in case

of additionally corrosive sample gas the analyser will not be damaged. The necessary purge gas

quantity is 10 – 60 Nl/hr corresponding to the adjusted sample gas quantity and the purge gas

inlet pressure is max. 100 mbar.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 14

14

NOTE!

For excess pressure operation (>100 mbar) an enclosure ventilation according to the ex-certificate is necessary. For additionally corrosive

sample gas an enclosure purging is necessary. Both have to flow off

atmospherically free!

11.2 PMA 50 EX/P/PD WITH PRESSURE COMPENSATION (WITHOUT SILCERTIFICATION)

In case of barometric or process originated pressure variations, the PMA 50 Ex can be equipped

with a special pressure compensation. The compensation can be effected within a pressure

range of 0,6 – 1,1 bar abs.. Thereby errors in measurement caused by pressure variations can

be eliminated.

11.3 OPTION ZERO SUPPRESSION (WITHOUT SIL-CE RTIFICATION)

A zero suppression is possible for devices with pressure compensation within a range of 1% to

97% O2. The suppressed measuring range depending on the suppression is lying on the position

of a standard measuring range. The factory provided adjusted suppression can be switched on

and off via an actuator at the terminals 22 resp. 23 inside of the connection box of the analyser

(see Fig. 5). After switching off the original measuring range again is active.

11.4 OPTION ENCLOSURE PURGING OR VENTILATION

For measurement of corrosive gases it is recommandable to equip the analyser with an enclosure

purging. This reduces the risk of a destruction of the analyser by corrosion in case of leaky gas

ways. For this please choose option part number 05A9000 ( 2 x ventilate arrestors). The necessary purge gas quantity is 10 – 60 Nl/hr corresponding to the adjusted sample gas quantity and

the purge gas inlet pressure is max. 100 mbar.

In case of elevated inlet pressure of 1,1bar up to max. 1,5bar abs. also one ventilate arrestor

according to the ex-certificate (see appendix) is required. For this choose option with part number

05A9005. For elevated inlet pressure of 1,1bar up to max. 1,5bar abs. and corrosive sample gas

the analyser has to be equipped with option part number 05A90000 (enclosure purging). The

necessary purge gas quantity is 10 – 60 Nl/hr corresponding to the adjusted sample gas quantity

and the purge gas inlet pressure is max. 100 mbar.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 15

15

2 4 3

1

GAS INLET

GAS OUTLET

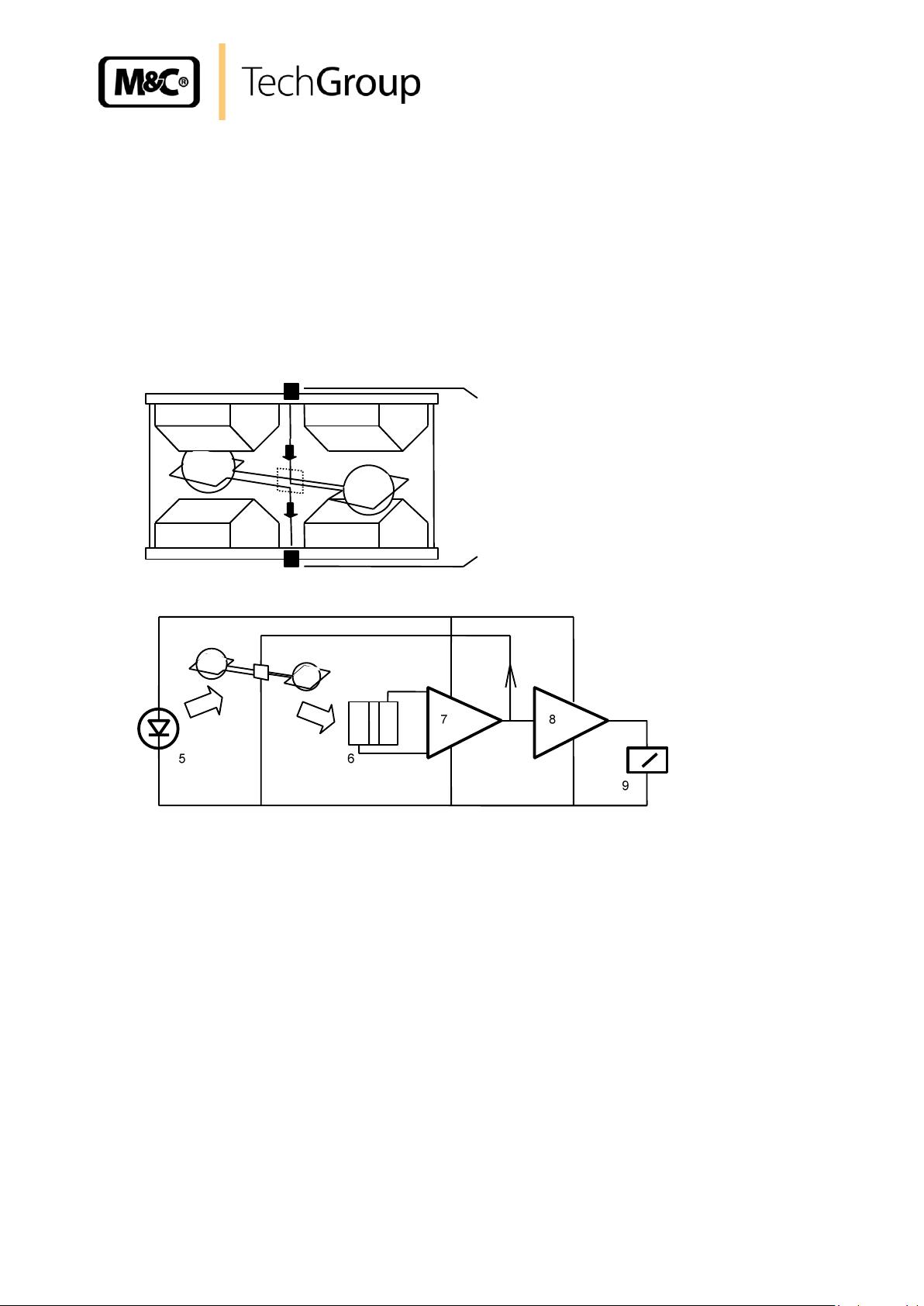

12 MEASURING PRINCIPLE

Oxygen is a gas with a significant paramagnetic susceptibility. The molecules of oxygen are attracted much more strongly by a magnetic field than the molecules of other gases.

The measuring principle shown in the following is benefitting from these characteristics of the

oxygen. The great advantage of the paramagnetic measuring principle is the highly reduced cross

sensitivity of the measurement to other components in the sample gas.

Figure 2 shows the diagram of the measuring cell as well as the optical system for the detection

of the dumbbell’s movement.

Figure 2 Scheme of the measuring cell and optical signal processing

The measuring cell consists of two nitrogen-filled spheres which are arranged in the form of a

dumbbell. In the dumbbell’s central point of rotation, a small mirror is placed. The dumbbell is

surrounded by a wire coil needed for the compensation procedure. The described system is fixed

rotationally symmetrical inside a glass tube via a tightening strap out of platinum and is srewed

up with two pole pieces .

Two permanent magnets are producing an inhomogeneous magnetic field. When oxygen is flowing in, the molecues of the oxygen are drawn into the magnetic field. In consequence, the lines of

electric flux on the cuneiform pole pieces are compressed. The nitrogen-filled diamagnetic

sheres are pushed out of the magnetic field. This causes a rotation of the dumbbell. The rotation

is detected via an optical system consisting of mirror , projection LED and photoelectric cell

.

In case the dumbbell is pushed out of the magnetic fieild, the tension of the photoelectric cell is

immediately changed. The measuring amplifiers and are producing a respective current

which develops via the wire coil on the dumbbell an electro-magnetic load moment. The load

moment is resetting the dumbbell into its zero position.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 16

16

1 : External fine filter

2 : External flow meter

3 : Ventilate arrestor

4 : Measuring cell

5 : Flow alarm sensor

6 : Ventilate arrestor

3

4

5

6 2 1

Every change of the oxygen concentration produces a lineary proportional change of the compensation current and can be read directly in % O2 as oxygen value on the display .

Due to its very small stagnant volume (2 cm3) and the direct flow of the M&C measuring cell, an

extremely fast response time (T90-time) of 1 second for a high gas flow can be realized.

13 GAS FLOW DIAGRAM

Figure 3 shows the gas flow diagram of the Oxygen Analyser PMA 50 Ex.

Figure 3 Gas flow diagram

The measuring cell 4 must absolutely be protected against dust particles. Therefore, the preceding external gas conditioning system should be equipped with a fine filter 1 of at least 2 micron

filter porosity (eg. type FP-2T).

The maximum gas flow of 60Nl/h is adjusted via an externally mounted flow meter 2 with needle

valve.

The sample gas enters the measuring cell 4 via the inlet ventilate arrestors 3.

A flow sensor 5 in the outlet of the measuring cell is controlling the gas flow through the cell ac-

cording to the measuring principle of thermal conductivity. In case the minimum gas flow is decreased, an alarm is automatically given and is available as status alarm on the the collective

status output. Furthermore, an alarm state is shown by a colour change of the LED 4 (see figure

1) on the front plate of the analyzer.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 17

17

1 4 5 9 2

3

8

10 7 6

1

2

5 3 10

Sample

gas outlet

Sample gas

Condensate

I Atmospheric pressure

II Overpressure

Max 100 mbar

Max 100 mbar

8

1 Gas cooler 7 Pressure display

2 Fine filter 8 Overflow valve

3 Flow meter 6-60Nl/h 9 Condensate pump

4 Sample gas pump 10 Analyser PMA50 Ex

5 Filter 11 Condensate removal

6 Pressure reduction

Sample

gas outlet

11

Figure 4 shows the construction of the conditioning system according to above mentioned specification.

Figure 4 Gas conditioning

Gas sampling and gas conditioning technology 9-3.15-ME

Page 18

18

NOTE!

The oxygen analyser PMA 50 Ex must be stored in a wheather - protected and frost-proof area !

W ARN I NG !

The sample gas must be dry (dew point 5°C), free from dust and the

sample gas temperature is not allowed to exceed 50°C. Otherwise

an upstream sample gas cooler with automatic condensate removal

is necessary.

A preceding fine filter of at least 2 micron is absolutely necessary.

The sample gas has to flow off atmospherical freely at the sample gas outlet, because a pressure rise at the sample gas outlet

and therefore in the measuring cell falsifies the oxygen indication.

The maximum inlet pressure is 1,1 bar abs. For the standard device

and 1,5 bar abs. for devices with purging enclosure or ventilation.

NOTE!

The analyser is suitable for use in explosive atmosphere group II

category 2. Equipment with protection II 1/2 G EEx de [ia] IIC T5

is suitable to measure explosive gases of group II category 1.

Equipment with protection II 1/2 G Eex de IIC T5 is suitable to

measure explosive gases of group II category 2.

14 RECEIPT OF GOODS

The analyser PMA 50 Ex is a completely pre-installed unit.

Please take the analyser and possible special accessories carefully out of the packaging mate-

rial immediately after arrival, and compare the goods with the items listed on the packing list;

Check the goods for any damage caused during delivery and, if necessary, notify your trans-

port insurance company without delay of any damage discovered.

15 INSTALLATION

The analyser PMA 50 Ex is designed for stationary wall mounting. All electrical connections are

located inside the connecting box below the analyser housing.

Accurate and proper installation as well as a preceding optimal sample gas conditioning system

will result in a long operatability and a minimum maintenance.

When using the analyser outdoors, it must be protected against atmospheric influences.

The installation should be done in constant climatic ambient conditions if possible.

The ideal installation site should be free from vibration. If this is not possible, rubber-metal con-

nections must be mounted in order to decouple the housing.

The analyser must not be installed in direct proximity of heat sources.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 19

19

W ARN I NG !

The Ex-approval of the oxygen analyser is only valid in connection

with the approved ventilate arrestors. For this reason, it is not allowed to remove them or to use other types of ventilate arrestors !

NOTE!

Please mount the ventilate arrestors with LOCTITE™ type 270 to

anticipate unwanted loosening of the devices !

16 SUPPLY CONNECTIONS

16.1 SAMPLE GAS INLET AND SAMPLE GAS OUTLET

The sample gas inlet and outlet are placed on the lower side of the analyzer. Both are equipped

with ventilate arrestors type MC 95 A. The certified ventilate arrestors are executed with 1/4“ NPT

inside thread.

The sample gas must be dry and free from dust. The sample gas inlet temperature should not

exceed 40°C. Otherwise, a preceding gas cooler with automatic condensate collection is recommended.

The sample gas should escape atmospherically from the outlet if possible, because a pressure

increase inside the measuring cell would falsify the oxygen indication. The maximum inlet pressure is 100mbar.

The sample gas quantity should be adjusted according to local circumstances between 6Nl/h and

60 Nl/h air (external flow meter).

16.2 OPTION PURGING ENCLOSURE OR VENTILATION

According to the Ex-Certificate (see annexe) purging of the enclosure is also requested in case of

increased inlet pressures of 1,1 to max. 1,5 bar. Please choose option part no. 05A9005 respectively with increased pressure and corrosive gases option purging enclosure part no. 05A9000.

When measuring corrosive gases, it is advisable to equip the analyser with the possibility of purging enclosure. This reduces the risk of distruction of the analyser due to corrosion in case of

leaky gas ways. For this please choose option part no. 05A9000 (2 x ventilate arrestor).

The flush gas inlet and outlet are placed on the upper side of the analyser housing. They too, are

both equipped with ventilate arrestors of type MC 95 A with 1/4“ NPTi-connections 16 (see figure

1, broken line).

Dry air or nitrogen has to be used for purging the enclosure. The purge gas flow rate has to be

adjusted between 10Nl/h and 60Nl/h.

Please indicate the option ‘purging enclosure’ with your order !

For a retrofitting of the analyser with the option purging enclosure, the following components are

necessary:

two ventilate arrestors type MC95A, part number 90A5150

1 x male connector DN4/6-1/4““NPTi, part number 05V2060 for the purge gas connection.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 20

20

W ARN I NG !

If you do not use the correct supply voltage, the equipment may be

destroyed. Please take care of the correct supply voltage as indicated on the type plate.

The equipotential bonding terminals of the analyser housing and

the terminal box must always be connected in case of installation

in hazardous area.

Take care of sufficient connection to ground of the housing !

NOTE!

When setting high-power electrical units with nominal voltages

of up to 1000V, attention must be paid to the requirements of

IEC 364 (DIN VDE 0100) together with the associated standards

and stipulations and ElexV!

L

1

1%2 3%3 10%4 30%

5

100%

6

com7 0

8

1%9 3%10 10%11 30%

12

100%

N

13

014 0

15

+

16

0

17

+

18

0

19

NC20 MC21 NO

22

IN

23

0

24

external measuring range

selection

external measureing range

indication

Recorder outlet mA +

Recorder outlet mA 0

Recorder outlet V +

Recorder outlet V 0

Outlets

dc-isolated

0 or 4-20mA for

measuring range

0 - 10V

for 0 -100% O2

Power IN L

Power IN N

Status

contact

PE

Power IN PE

Option zero suppression ON

16.3 ELECTRICAL CONNECTION

A main switch and a respective protection must be provided by the client.

All possible electrical connections are placed inside the connector box below the analyser’s hou s-

ing. After loosening the cover screws, the following terminal items are accessible:

Figure 5 Electrical connection in the connection box of the PMA 50EX EEX e

Gas sampling and gas conditioning technology 9-3.15-ME

Page 21

21

NOTE!

The temperature is stable after approx. 3 hours. Now, the analyser can be

calibrated according to the following instructions. For controlling the

stable status, a further calibration should be effected after 24 hours !

NOTE!

In principle, a calibration should be effected under measuring conditions,

holding the flow quantities, the room temperature and the barometric

pressure to a constant value. Avoid vibrations!

17 STARTING UP

The following steps have to be executed when starting up the analyser:

Before starting the equipment for the first time, check that the electrical connections and the

gas connections have been executed as requested. The voltage indicated on the type plate

must correspond to the mains supply.

Any zero point deviation of the analogue display can be set right via the adjusting screw below

the digital dispay. For this purpose, the housing of the analyzer must be opened in a voltagefree status.

Set the range switch to 30% and switch on the analyser by using the main switch. Now, the

display of the analyser shows an oxygen value of less than 21% with ambient air.

The warming up status is displayed by the permanently beaming temperature control LED on

the front plate (figure 1). After approximately 30 minutes, the PMA 50 Ex has reached its operating temperature. This is signalized by the flashing of the temperature control LED.

18 CALIBRATION

Before executing the calibration, the safety instructions relating to the instalment and the process

must be heeded !

The precision of the measurement depends on the precision of the analysers calibration.

The linearity of the measuring ranges allows a two-point calibration, the zero calibration and the

span calibration.

A weekly calibration of the analyser guarantees the required precision of the measurements.

Due to the direct proportional dependance of the oxygen indication to the barometric respectively

process pressure, the calibration interval may be decreased to one day in case there are great

variations of pessure.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 22

22

W ARN I NG !

The pressure reducer should have a maximum outlet measuring

range of 0-1,5 bar abs. and should always be adjusted to a low

outlet pressure of max. 0,1 bar. This protects the measuring cell

against destruction due to high pressure!

NOTE!

Always calibrate at the gas flow used for the measurement too.

Ouput signal

Signal to be measured

0-1 V DC

0 V

0-20 mA

0 mA

4-20 mA

4 mA

NOTE!

Analysing a gas mixture the single components have to be checked according to a possible cross sensitivity and to be considered for zero calibration (see chapter 20).

18.1 ZERO CALIBRATION

The calibraiton of the zero point is to be effected with a gas free of oxygen, eg. Nitrogen (N2) 5.0.

The following steps have to be executed:

Connect the flexible PVC or Viton tube with the bottle’s pressure reducer of the N2-zero gas

bottle;

First of all, open the bottle valve, then open the outlet valve of the pressure regulator;

The pressure regulator and the tubing have to be flushed for about 5 seconds;

Check adjusted control pressure and reduce to ≤ 0,1bar if necessary then shut the outlet valve

of the pressure regulator again;

Connect the free tube end of the zero gas bottle connection with the external flow meter or, if

available, with the external calibration valve;

Open the outlet valve of the pressure regulator slowly, in order to avoid pressure peaks;

Adjust the zero gas volume flow with the needle valve of the flow meter to max. 60 l/h. The

volume flow of the calibration gas should always be adapted to the sample gas volume flow;

Wait approx. 30 seconds until stabilisation of the display;

Set the range switch to 0-1% O2;

If necessary, adjust the zero point to 0 % via the zero point potentiometer 12 (figure 1) (with a

screw driver);

Check the analogue output signals at 0% O2;

Gas sampling and gas conditioning technology 9-3.15-ME

Page 23

23

NOTE!

After zero calibration the span has to be calibrated too.

NOTE!

In case the oxygen concentration of the sample gas is below 30% O2, the

calibration can be effected with dry air. Should the concentrations be

higher, ideally, the test gas should correspond to the span value !

W ARN I NG !

The pressure reducer should have a maximum outlet measuring

range of 0-1,5 bar abs. and should always be adjusted to a low

outlet pressure of max. 0,1 bar. This protects the measuring cell

against destruction due to high pressure!

NOTE!

Always calibrate at the gas flow used for the measurement too.

Shut the output valve of the pressure regulator and bottle valve and separate the tube connec-

tion to the analyser.

18.2 SPAN CALIBRATION

Before calibrating the span value, always check the zero point.

The following calibration procedure has to be carried out:

Adjust measuring range selection switch to the range in which the calibration will be carried out.

Connect the flexible PVC or Viton tube with the bottle pressure reducer of the test gas bottle, if

necessary with ambient air or instrument air.

First open the bottle valve, then open the closed output valve of the pressure regulator;

Flush the pressure regulator and the tubing for about 5 seconds;

Check adjusted control pressure and reduce to ≤ 0,1bar if necessary then shut the outlet valve

of the pressure regulator again.

Connect the free tube end of the test gas bottle connection with the gas inlet of the analyser

or, if available, the external calibration valve;

Open slowly the output valve of the pressure reducer in order to avoid pressure peaks;

Set the test gas volume flow to max. 60 l/h by means of the needle valve of the flow meter.

The volume flow of the calibration gas should always correspond to the sample gas volume

flow;

Gas sampling and gas conditioning technology 9-3.15-ME

Page 24

24

Output signal

Signal to be measured with span value

100 %

0-10 V DC

2,09 V

Output signal

Signal to be measured with span value

30 %

100 %

0-20 mA

13,95 mA

4,19 mA

4-20 mA

15,16 mA

7,35 mA

NOTE!

The mA-signal depends on the adjusted measuring range. Therefore, it is important to check the correctness of the measuring

range chosen !

AT T ENT ION !

After completion of calibration set measuring range selection

switch to desired measuring range again.

The mA-output signal is dependend on the measuring range!

Wait approx. 30 seconds until the display is stable. If necessary, adjust the O2-value of the test

gas via the span potentiometer 10 (figure 1) (with a screw driver at air 20,93%);

Check the analog output signals;

The signal to be measured can be calculated as follows:

(max. signal output - min. signal output) x Concentration [%]

Measured value = + min. Signal output

Measuring range span value [%]

A test gas concentration of 20,9% (air) would result in the following:

Shut the output valve of the pressure regulator and the bottle valve and separate the tube

connection to the analyser.

The span calibration has been completed.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 25

25

DANGER!

The sample gas must be free from all liquid or solid particles, i.e.

the dew point of the gas must be significantly below the equipment

temperature so that no condensate will occur inside the equipment. If necessary, lower the dew point by means of a cooler or

dryer. For dust filtration use a filter of 2 micron porosity !

NOTE!

Basically measurements should be carried out only with flow quan-

tity and room temperature held constant.

19 MEASURING

For the first starting up at a new location, the afore mentioned steps have to be performed.

The interval of the new calibration is defined by the requirements of precision.

After having chosen the desired measuring range, the analyser is ready to operate.

We will be pleased to inform you about an optimal gas conditioning!

Gas sampling and gas conditioning technology 9-3.15-ME

Page 26

26

20 CROSS SENSITIVITIES

The following table shows the cross sensitivities of the most important gases at 20°C and 50°C.

All values are based on a zero calibration with N2 and a span calibration with 100 Vol.% O2. The

deviations are each valid for 100 Vol.% of the respective gas.

Gas Molecular formula 20°C 50°C

Acetaldehyde C2H4O - 0,31 - 0,34

Acetone C3H6O - 0,63 - 0,69

Acetylene C2H2 - 0,26 - 0,28

Ammonia NH3 - 0,17 - 0,19

Argon Ar - 0,23 - 0,25

Benzene C6H6 - 1,24 - 1,34

Bromine Br2 - 1,78 - 1,97

Butadiene C4H6 - 0,85 - 0,93

n-Butane C4H10 - 1,10 - 1,22

Iso Butylen C4H

7

Chlorine Cl2 - 0,83 - 0,91

Diacetylene (CHCl)2 - 1,09 - 1,20

Nitrous monoxide N2O - 0,20 - 0,22

Ethane C2H4 - 0,43 - 0,47

Ethylbenzene C8H10 - 1,89 - 2,08

Ethylene C2H4 - 0,20 - 0,22

Ethylene glycol (CH2OH)2 - 0,78 - 0,88

Ethylene oxide C2H4O2 - 0,54 - 0,60

Furan C4H4O - 0,90 - 0,99

Helium He + 0,29 + 0,32

n-Hexane C6H14 - 1,78 - 1,97

Hydrogen chloride HCL - 0,31 - 0,34

Hydrogen fluoride HF + 0,12 + 0,14

Hydrogen sulfide H2S - 0,41 - 0,43

Carbon dioxide CO2 - 0,27 - 0,29

Carbon monoxide CO - 0,06 - 0,07

Krypton Kr - 0,49 - 0,54

Methane CH4 - 0,16 - 0,17

Methanol CH4O - 0,27 - 0,31

Methylen chloride CH2Cl2 - 1,00 - 1,10

Methyl propene C4H8 - 0,94 - 1,06

Monosilan SiH4 - 0,24 - 0,27

Neon Ne + 0,16 + 0,17

n-Octane C8H18 - 2,45 - 2,70

Phenol C6H6O - 1,40 - 1,54

Propane C3H8 - 0,77 - 0,85

Propylene C3H6 - 0,57 - 0,62

Propylene chloride C3H7Cl - 1,42 - 1,44

Propylene oxide C3H6O - 0,90 - 1,00

Oxygen O2 +100,00 +100,00

Sulfur dioxide SO2 - 0,18 - 0,20

Sulfur fluoride SF6 - 0,98 - 1,05

Monosilane SiH

4

Nitrogen N2 0,00 0,00

Nitrogen dioxide NO2 + 5,00 + 16,00

Nitrogen monoxide NO + 42,70 + 43,00

Styrene C8H8 - 1,63 - 1,80

Toluene C7H8 - 1,57 - 1,73

Vinyl chloride C2H3Cl - 0,68 - 0,74

Vinyl fluoride CH3F - 0,49 - 0,54

Water (Steam) H2O - 0,03 - 0,03

Hydrogen H2 + 0,23 + 0,26

Xenon Xe - 0,95 - 1,02

- 0,94 - 1,06

- 0,24 - 0,27

Gas sampling and gas conditioning technology 9-3.15-ME

Page 27

27

The selectivity of the above mentioned measuring principle is based on the high susceptibility of

oxygen to other gases (see table).

The following examples shall show how cross sensitivities can be considered for the zero calibration.

Example 1: Determination of the rest content of oxygen in a 100% carbon dioxide (CO2)

protective atmosphere at 20°C

In the table of cross sensitivities you can read the value for CO2 at 20°C of –0,27. This means

that for calibration with nitrogen the zero point must be set to +0,27% in order to compensate the

deviation of the display in good approximation.

In this example, the atmosphere contains exclusively CO2 and O2. For this reason, the influence

of cross sensitivity can be eliminated without problem by using carbon dioxide (CO2) instead of

nitrogen for the zero calibration.

Example 2: Determination of the oxygen content of a gas mixture at 20°C

1 Vol.% C2H6 (Ethane);

5 Vol.% O2;

40 Vol.% CO2;

54 Vol.% N2.

Zero point calibration with nitrogen (N2).

The cross sensitivity values of above table are based on 100 Vol.% of the respective gases.

Therefore, a conversion must be maid to the effective volume concentration. In princi ple, the fo llowing is valid:

Table value * Volume concentration

Effective cross sensitivity = [Vol.%]

100

For the components of the gas mixture, the following values are found:

C2H6 : -0,0043 Vol.%;

CO2 : -0,1080 Vol.%;

N2 : 0,0000 Vol.%.

= -0,1123 Vol.%

To determine the sum of cross sensitivity as exactly as possible, a correction factor has to be

determined, because the sum of cross sensitivities relates not on 100% but on 100% minus the

oxygen concentration (here 95%).

Gas sampling and gas conditioning technology 9-3.15-ME

Page 28

28

NOTE!

After zero calibration the span has to be calibrated too.

The correction factor is calculated as follows:

100

Correction factor =

(100 – O2-concentration)

It is incidental:

100

= 1,0526

(100 – 5)

For the gas mixture the rectified sum cross sensitivity then is calculated in good approximation for

0 Vol.% oxygen:

1,0526 x -0,1123 Vol.% = -0,1182 Vol.%

The rectified sum cross sensitivity with change of sign now can be used for the correction of the

zero calibration. In this case zero had to be adjusted at +0,12 Vol.%.

In case the cross sensitivities should be ignored in the above mentioned example, this would result in a relative error of approximately 2%.

If the span is not calibrated with 100 Vol.% oxygen here eventually it is also a correction of the

cross sensitivities necessary.

Example: span calibration with air

The correction factor is calculated as follows:

(100 – O2-concentration)

Correction factor =

100

It is incidental:

100 – 20,93

= 0,7907

100

Gas sampling and gas conditioning technology 9-3.15-ME

Page 29

29

NOTE!

The analyser should be stored in a protected frost-proof area !

W ARN I NG !

Dangerous voltage. Before carrying out any maintenance work,

take the analyser and all external switching circuits in connection

with the analyser off the mains.

For use in hazardous areas it is absolutely necessary to observe

the ex-instructions !

NOTE!

Only original spare parts and those corresponding to M&C

specifications must be used !

For the gas mixture in example 2 the rectified sum cross sensitivity then is calculated in good

approximation for 20,93 Vol.% oxygen:

0,7907 x -0,1182 Vol.% = -0,0935 Vol.%

The rectified sum cross sensitivity with change of sign now can be used for the correction of the

span calibration. In this case span has to be adjusted at:

20,93 Vol.% + 0,0935 Vol.% = 21,02 Vol.%.

21 CLOSING DOWN

In case of a short time closing down of the process control system, the analyser should remain

„ON“. No further precautions are required.

In case of a closing down of the analyser for a longer period, it is recommended to flush the analyser with dry and clean inert gas (eg. ambient air) in order to prevent a damage of the measuring

cell by aggressive and corrosive liquid gases.

22 STORAGE AND TRANSPORT

23 MAINTENANCE

Before carrying out any maintenance activities, the safety requirements specific to the instalment

and the process must be heeded!

The physical measuring principle and the special design of the analyser are minimizing the maintenance requirements.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 30

30

The preceding components necessary for the sample gas conditioning are to be maintained according to the respective operating manuals.

The calibration of zero point and span value is to be effected with the corresponding test gases

according to instruction.

Recommended interval of calibration for standard applications: 1 x per week.

23.1 REMOVAL OF THE MEASURING CELL

Figure 6 shows the schematic internal construction of the analyser PMA 50 Ex.

1 Sample gas inlet 6 from 08.2009 the line-filter is dropped out

2 Sample gas outlet 7 Flexible tube

3 Electrical connections 8 Power supply and temperature board

4 Hex screws 9 Front controller board

5 Transmitter type 1.07.X. 10 Flow sensor, stainl. steel

Figure 6 Schematic view of the internal layout of the analyser

Gas sampling and gas conditioning technology 9-3.15-ME

Page 31

31

W ARN I NG !

NOTE!

For any work with the analyser it must be ensured that the ambience as well as the analyser itself are free from explosive or flammable gases !

W ARN I NG !

Dangerous voltage. before carrying out any maintenance or repair

activities, take the analyser and all external switching circuits in

connection with the analyser off the mains !

W ARN I NG !

Hot transmitter surface up to 55°C. Touching may lead to burnings.

Wear safety gloves !

W ARN I NG !

Strong magnetic field. Before dismounting the transmitter unit, remove all sensible parts (eg. wrist watch etc.)!

For dismounting the measuring cell, the following procedure is recommended:

Loosen the inside hex screws of the housing window;

Unscrew the window lid of the analyser;

Loosen the fastening screws (4 x M4) of the inside front plate;

Pull out the front plate and fold it to the right side;

Remove carefully the black isolating cap from the transmitter unit;

Loosen the threaded hose coupling of the sample gas inlet 1 (see figure 6) and the sample gas

outlet 2;

Gas sampling and gas conditioning technology 9-3.15-ME

Page 32

32

Pull off the green 2-, 3- and 4-pole plug-in connections from the power supply board;

Loosen the earth connection (green-yellow) of the transmitter unit (3 see figure.6);

Loosen the hex screws 4 (see figure 6) on the top of the transmitter mounting plate;

Loosen union nuts 1 at sample in- and outlet 7 (see figure 6);

Now, the complete transmitter unit can be taken out of the housing. All further procedures should be

executed on a clean work bench outside the hazardous area. Put the transmitter unit in a position as

shown in figure 7 (18-pole plug must show to the right side).

Electrical connections meas. cell Heater element

Gas outlet measuring cell Transmitter board

Gas inlet measuring cell Temperature cut out at 72

O

C

Fastening screw for measuring cell Temperature sensor

Figure 7 Transmitter unit

Unsolder the brown and yellow cable from the terminals 1 (see figure 7) on the back side of the

measuring cell; do not overheat the terminals; mark the cables accordingly;

Disconnect the tubing for the sample gas outlet 2 and sample gas inlet 3;

Loosen the fastening screw of the measuring cell 4 with a screw driver and pick carefully the cell;

Exchange only with measuring cells of the same type;

Turn the transmitter as shown in figure 8 and loosen the fastening screw of the photocell 4.

The mountage of the measuring cell is to be effected in reverse order; take care of the correct dumpbell

position!

In case there are minimally different positions of the dumpbells inside the measuring cells when

mounting a new cell, it is absolutely necessary to adjust the zero point mechanically.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 33

33

23.2 MECHANICAL ZERO POINT ADJUSTMENT

The mechanical zero point adjustment has to be done as described in the following.

1 IR LED 5 Heater element

2 Temperature cut out (72°C) 6 Adjustment screw photocell

3 Sample gas heating coil 7 Measuring cell

4 Fastening screw photocell 8 Photocell

Figure 8 Schematic view of the transmitter unit

Before switching on the analyser, set the range selector to 30%. Control the zero point of the analogue

display and adjust it if necessary to 0% via the adjustment screw below the digital display;

Switch on the analyser via the external switch. Normally, the analogue display will indicate a value of

21% oxygen because the cell is filled with ambient air;

The warming up is indicated by the permanently beaming LED in the front plate of the analyser; after

approx. 30 minutes, the flashing display signalizes that the required operating temperature has been

reached;

Set the potentiometer for zero point and span value in the mid position; you can do this by turning the

potentiometer with a screw driver fully to the left and then turn it five turns back to the right;

Charge the analyser with a zero gas volume flow of approx. 40 l/h;

With a precise adjustment of the zero point, the analogue display should indicate 0.0 Vol.% oxygen;

If this does not happen, please execute the following steps:

Open the housing of the analyser (see 23.1);

Remove carefully the isolating cap of the transmitter unit; now, all screws of the photocell fixing are

visible (see figure 8);

Set the range switch to 3%;

Turn the adjustment screw 6 (see figure 8) of the photocell as long clockwise or anticlockwise as on

the display appears a value of nearly 0,0 Vol.% oxygen;

After the mechanical zero point adjustment, the fixing screw of the photocell fixing 4 must be screwed

down again;

Now, the zero point adjustment has been done;

Place carefully the isolating cap on the analyser and close it according to 23.1.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 34

34

O2 Analyser PMA 50 Ex

(C) Consumable parts

(R) Recommended spare parts

(S) Spare parts

Recommended piece number for

use (years)

Part-No.

Description

C/R/S

1 2 3

90 A 0020

Zero potentiometer / span potentiometer 5K

S - -

-

90 A 0080 +

90 A 0083

Digital-analog panel, 4 1/2 digit 9 mm high LCD-

indicator

S - -

-

90 A 0010

Measuring cell PMC-1

S - -

-

90 A 0009

Special measuring cell PMC-1 LB, solvent-resistent,

with O-rings Kalrez

S - -

-

90 A 0035

Projection-LED

S - -

-

90 A 0040

Photocell unit

S - -

-

90 A 3010

Solid-State-Relais A3P-202N

S - -

-

90 A 3015

Temperature cut out 72°C

S 1 2

3

90 A 3020

Temperature sensor

S - -

-

90 A 3030

Heater element 50mm x 40mm

S - -

-

90 A 5150

Ventilate arrestor EX PMA 50

R - 1

1

24 SPARE PARTS LIST

The need of wearing and spare parts depends on the specific operating conditions. The recommended quantities of wearing and spare parts are based on experience and are not binding.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 35

35

25 APPENDIX

Safety handbook according to SIL

Circuit diagram front board PMA50ex 02.2010

Assembly front board PMA50ex 02.2010

Circuit diagram mains adapter PMA50ex 02.2010

Assembly / connection mains adapter PMA 50ex 02.2010

Cut-out magnification front board for adjustment of temperature alarm (TP10, P19) (TP11: ac-

tual temperature) und flow alarm threshold (P20)

Cut-out magnification front board couple sensor bridge for application of a transmitter without

couple sensor

Cut-out magnification front board for adjustment of reference voltage , amplification and offset

of the O2-signal

Cut-out magnification mains adapter for adjustment of the temperature, current and voltage

output

Cut-out magnification mains adapter for adjustment of burden and limitation of the current out-

put

Ex-Certificate of Conformity No.: KEMA 03 ATEX 2215X

SIL-declaration of conformity

Further product documentation can be seen and downloaded from our home page:

www.mc-techgroup.com.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 36

36

Single channel 1oo1

Redundant 1oo2

Single channel 1oo1

Redundant

1oo2

Safety function

Mesurement of the oxygen

concentration

Mesurement of the oxygen

concentration

Dangerous error

Oxygen signal too low

Oxygen signal too big

Measuring range

Depending on the measuring task

Depending on the measuring task

Device type

B

(but without µP and software)

B

(but without µP and software)

Proof test interval

1 year

1 year

MTTR

24 hr

24 hr

SFF

91,3 %

96,4 %

HFT 0 1 0 1

SIL–ability

2 2

factor

—

5 %

—

5 %

PFD

3,83 × 10-4

1,93 × 10-5

1,66 × 10-4

8,34 × 10-6

du

8,44 × 10

-8

(per hr)

3,52 × 10

-8

(per hr)

dd

4,62 × 10

-7

(per hr)

4,62 × 10

-7

(per hr)

su

4,25 × 10

-7

(per hr)

4,74 × 10

-7

(per hr)

sd

5,70 × 10

-11

(per hr)

5,70 × 10

-11

(per hr)

Safety handbook according to SIL

Contemplated devices

It was contemplated the PMA 50 EX with part no. 05A1000(a) and the following options:

- Ventilation equipment and enclosure purging (part no. 05A9005 and 05A9000),

- Measuring cell solvant resistant or with glass solder (part no. 90A0009 u. 90A0006)

- Transmitter for measurements of gases from ex-zone 0 II 1/2 G EEx de [ia] IIC T5

Excluded are the PMA 50 EX/P/PD… with pressure compensation, part no. 05A2500(a) as well

as the options 0-20mA outlet, part no. 05A2505(a) resp. zero suppression, part no. 05A9015.

Device description and safety function

The safety function of the device is the measurement of the oxygen concentration in the measuring cell which is provided as linear current signal 4-20mA. The status relay as transmission of a

summary fault indication is element of the safety function. Current signals <3,2mA and > 20,5mA

as well as an open status contact have to be evaluated as failure from a downstream device.

The SIL-qualification is valid for all adjustable measuring ranges. It applies for alarm of rising oxygen concentration (dangerous fault: oxygen signal is to small) as well as for alarm of decreasing

oxygen concentration (dangerous fault: oxygen signal is too big).

For one channel and two channel operation of the oxygen analyser PMA 50 Ex the following parameters have been determined.

Gas sampling and gas conditioning technology 9-3.15-ME

Page 37

37

Operating conditions

Ambient conditions:

Temperature: -10 °C bis +50 °C

Pressure: 0.9- 1.1 bar abs.

Vibrations have to be avoided.

The sample gas has to be dry (dew point 5°C) and dust free and the sample gas inlet temperature is not allowed to exceed 50°C. The maximum inlet pressure is 1,1 bar abs. for the standard

device and 1,5 bar abs. for devices with encosure purging or ventilation equipment. Generally a

fine filter with min. 2µm has to be installed upstream.

Sample gas has to discharge freely into atmosphere at the sample gas outlet because a pressure

rise at the outlet and therefore in the measuring cell will result in false readings.

Especially the accuracy of the adjusted measuring range has to be observed, because the current outlet 4-20mA is dependent on the measuring range. If the measuring range is choosen externally it is mandatory necessary to interpret the external measuring indication (see Fig. 5).

The analyser has to be maintained and calibrated regularly expertly according to the manufacturer’s data.

The maintenance intervals for monitoring of inertization processes have to be specified according

to leaflet BGI 518 of the Main Association of Trade Associations (= leaflet T 023 of the trade association chemistry) edition 07/2009. For other applications the leaflet BGI 836 of the Main Association of Trade Associations (= leaflet T 021 of the trade association chemistry) edition 07/2009

has to be applied.

Yearly proof test

Minimum once a year a proof test for the whole safety chain has to be performed. Thus also the

yearly system check according to the Industrial Safety Regulation is covered.

For the analyser the prooftest comprises the regular calibration / adjustment as well as triggering

and test of the switch function of the status relay (fail safe relay).

Gas sampling and gas conditioning technology 9-3.15-ME

Page 38

38

Figure 9 Circuit diagram front board PMA50ex 10.2008

Gas sampling and gas conditioning technology 9-3.15-ME

Page 39

39

Figure 10 Assembly front board PMA50ex 10.2008

Gas sampling and gas conditioning technology 9-3.15-ME

Page 40

40

Figure 11 Circuit diagram mains adapter PMA50ex 10.2008

Gas sampling and gas conditioning technology 9-3.15-ME

Page 41

41

Figure 12 Assembly / connection mains adapter PMA 50ex 10.2008

Gas sampling and gas conditioning technology 9-3.15-ME

Page 42

42

Figure 13 Cut-out magnification front board for adjustment of temperature alarm (TP10, P19) (TP11:

actual temperature) und flow alarm threshold (P20)

Figure 14 Cut-out magnification front board couple sensor bridge for application of a transmitter with-

out couple sensor

Failure indication:

B15: Flow-min, Flow-max failure

B14: Transmitter LED-Strom failure

B11: Transmittertemperatur max failure

B12: Transmittertemperatur min failure

B13: Powersupply +UB failure

B10: Powersupply -UB failure

(Couple sensor failure and failure range-selector internal are not displayed optical.)

Gas sampling and gas conditioning technology 9-3.15-ME

Page 43

43

Figure 15 Cut-out magnification front board for adjustment of reference voltage , amplification and

offset of the O2-signal

Gas sampling and gas conditioning technology 9-3.15-ME

Page 44

44

Figure 16 Cut-out magnification mains adapter for adjustment of the temperature, current and voltage

output

Figure 17 Cut-out magnification mains adapter for adjustment of burden and limitation of the current

output

Gas sampling and gas conditioning technology 9-3.15-ME

Page 45

45

Gas sampling and gas conditioning technology 9-3.15-ME

Page 46

46

Gas sampling and gas conditioning technology 9-3.15-ME

Page 47

47

Gas sampling and gas conditioning technology 9-3.15-ME

Page 48

48

Gas sampling and gas conditioning technology 9-3.15-ME

Loading...

Loading...