Page 1

PMA 100-L

Embracing Challenge

Oxygen Analyser Series PMA®

Version PMA 100-L

Microprocessor based,

19”-rack unit or table version

Special Features

Safe in operation

High accuracy and reliability

Physical measuring principle, linear

measuring ranges

Fast response time

Transducer unit temperature controlled

at +55 °C

Solid 19" metal housing

Large LCD- indicator with background

lighting

Selectable time constant for noise

damping if needed for unstable process

conditions

4 free selectable O2 measuring ranges,

incl. zero suppression, lowest span 1%

Manual, automatic or remote range

control

User friendly menu control correspond-

ing to NAMUR recommendations

Isolated output signal 0/4-20mA

4 congurable MIN. or MAX. oxygen

level alarms

4 free congurable isolated binary

inputs, for example: alarm conrmation,

measuring range control, autocal. start

Analogue signal memory during adjust-

ing and calibration

Application

Due to the extremely fast response time of the

patented M&C magneto-dynamic measuring

cell with no stagnant volume as well as the

negligible cross sensitivity from other sample

gas components, the M&C oxygen-analyser

PMA 100-L has a wide variety of applications.

The analyser is a suitable and reliable instrument for monitoring oxygen concentrations

in various gas analytical process control applications including flue gas measurements,

inert gas installations, fermentation processes

and laboratory process control installations.

Description

The M&C oxygen analyser PMA 100-L is a

temperature controlled instrument which has

been designed for continuous measurements

of oxygen concentrations in particle-free and

dry sample gas. The PMA 100-L is a reliable

and easy-to-operate instrument. It is built

into a housing for 19 inch rack mounting /

table version.

The transducer unit maintains a constant

operating temperature of 55 °C.

The programmable measuring ranges are displayed on the LCD display. Sample gas connections as well as connectors for incoming

power supply and all output / input signals

are located at the rear side of the analyser. The

sample gas enters the analyser via an external

protective fine-filter. The required flow rate

can be adjusted at the flow meter with needle

valve, mounted on the front panel upstream

the M&C measuring cell and the flow chamber with flow alarm sensor. The internal tubing is made of PTFE and PVDF.

Measuring principle of M&C oxygen analyser

The PMA 100-L utilises the paramagnetic

principle of operation to measure oxygen

concentration. The analyser measures the

paramagnetic susceptibility of the oxygen

in the sample gas by means of the M&C

magneto-dynamic measuring cell. The physical propertys which distinguishes oxygen

from other gases is its paramagnetism. It is

significantly higher comparing to other common gases. This operation principle is one of

the most accurate and reliable procedures to

determine the oxygen concentration in a gas

mixture from 0 to 100 Vol.%.

The robust M&C cross-flow cell has no

stagnant volume. Advantages are the fast

response time, the flow rate up to 60 l/hr, the

small volume of 2 ml, the extremely low drift,

the absolute linearity and the negligible cross

sensitivity against other sample gas components. With a proper sample conditioning

and pressure, the M&C cell will never need

replacing.

Manual / automatic calibration

3 code levels, access to 2 code levels

only with release code

Flow alarm monitoring

4 free congurable potential free relay

contact outputs, for example: oxygen

level alarm

Technical specications and illustrations are without

obligation, subject to modications.10.99/01.07

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

13.5

Page 2

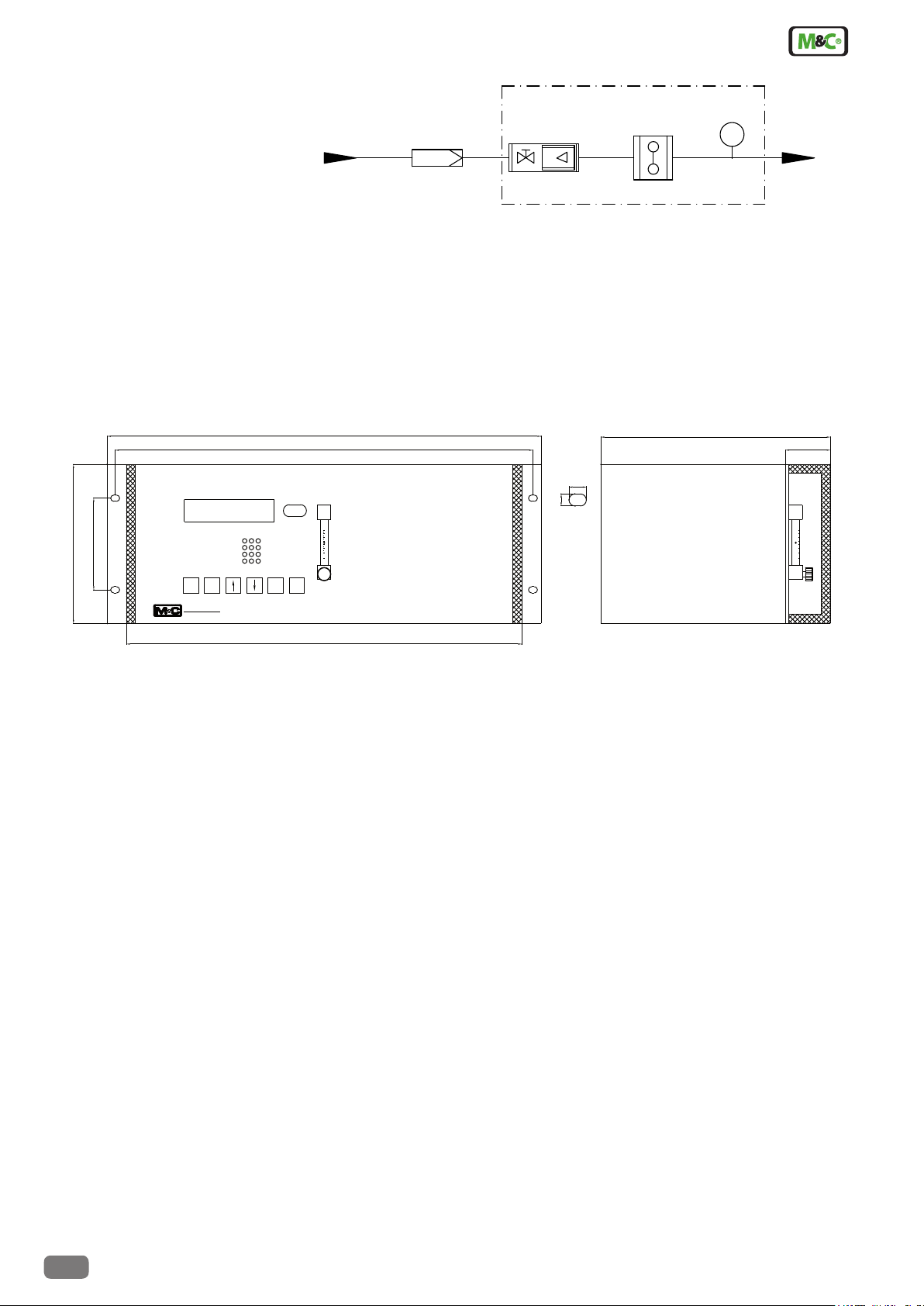

Gas flow diagram PMA 100-L

1. External fine filter

2. Flowmeter with needle valve

3. Oxygen measuring cell PMA

4. Flow alarm sensor

Dimensions

1 2

3

4

FLA

102

177 (4HE)

Dimensions in mm

1013 mbar

20,93 Vol% O

Select

O-Analyser

2

PMA 100

Enter

2

Front view

483 (84TE)

465

Alarm

MeasCal

440

Side view

341

50

10

7

13.5

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 10.99/01.07

Page 3

Technical Data

Version PMA 100-L microprocessor based oxygen analyser in 19"-housing

Part No. 03A3100 : PMA 100-L power supply 230V 50Hz, 4-20mA; 03A3100a = 115V 60Hz

Measuring ranges 4 linear measuring ranges free selectable, lowest span 1%,

basis selection* 0-1, 0-10, 0-25 and 0-100 vol. O2.

manual, automatic or remote range control and range indication is possible

Indication two line 16-sign LCD display, resolution 0,01vol.%O2, continuous O2 indication and call off

Text illustration optional in

English, French or German

Output signals selection: isolated 0-20, 2-20, 4-20*, 4-20,5mA for the selected range, max. load 500Ω.i

Relay outputs free configurable 4 potential free relay contacts NO, contact rating max. 48VDC, 500mA, 15W

Binary outputs 24VDC, max. 400mA

Binary inputs free configurable potential free, 4x 12-24VDC, max. 20mA or internal supply voltage 12 VDC

Flow alarm thermo-conductive sensor, mounted downstream O2-measuring cell

Status alarm for min. flow alarm, O2-transducer temperature < 50 °C, central processing unit failurer: LED indication and potenti-

Alarm contact for exceed/remain measuring range, truncate calibration, external alarm, alternatively oxygen level alarms: LED

Response time for 90% FSD < 3 seconds at 60 Nl/hr air

Accuracy after calibration deviation ± 1% of 2-100% span, ± 2% of 1% span

Reproducibility deviation < 1% of span

Influence of ambient temperature no influence up to 50 °C

Influence of barometric- or

process pressure

Influence of sample gas flow variation in gas flow between 0-60 Nl/hr air will cause a difference of < 0,1 vol.% O

Sample gas inlet pressure 0,01 up to 0,6 bar g, (PMA 100-L requires positive pressure for adequate flow rate, no pump inside)

Sample gas outlet pressure recommendation: discharge freely into atmosphere; however max. 0,6 to 1,6 bar abs.

Flow rate of sample gas 25-60 Nl/hr air

Temperature of sample gas -10 °C up to +50 °C dry gas

O2-transducer temperature fixed at +55 °C

Ambient temperature -10 °C up to +50 °C

Storage temperature -20 °C up to +60 °C, relative humidity 0-90% RH

Power supply internal power unit for 230VAC standard or 115VAC available (a) +/- 10%, 40-60Hz, 35VA

Electrical connections mains supply: 3-pole chassis plug with 2 m cable; signals: 4x Sub-D plug

Materials in contact with sample gas Platinum, Epoxy resin, glass, FPM, Stainless Steel 316Ti, PTFE, PVDF

Sample gas connection 1/8" NPT internal thread*, option with tube connector DN 4/6 /PVDF available,

Protection / electrical standard IP 40 EN 60529 / EN 61010

Housing / front colour 19 inch rack mounting with front handles / grey RAL 7032

Dimension / weight height 4U, width 84HP, depth 350 mm + approx. 60 mm installation space / approx. 11 kg

*standard

O2-transducer temperature, mA-signal, measuring range, time, date, failure-/alarm information

al free contact output, NO, max. 48VDC, 500mA, 15W and mA-output indication - example 22mA

indication and potential free contact output, NO, max. 48VDC, 500mA, 15W

no influence within the range of 0,6 up to 1,6bar abs. with integrated pressure compensation

2

Part No. 05V1045

W A R N I N G ! I M P O R T A N T !

An external fine filter must always be used at the gas inlet of the analyser. Depending

on the composition of the sample gas, it may be necessary to use a sample conditioning system. Without precautions, the analyser is only suitable for measuring of nonhazardous gases or gasmixtures in non-hazardous areas.

Technical specications and illustrations are without

obligation, subject to modications. 10.99/01.07

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

13.5

Loading...

Loading...