Page 1

- 1 -

INSTRUCTION MANUAL

Microprocessor controlled oxygen analyser PMA

Version PMA100 (V1.52)

®

9-3.12-ME M&C Products Analysentechnik GmbH

Page 2

Table of content

1. Electrical standards 3

2. Important safety informations 3

3. Warranty 3

4. Used terms and signal indication 4

5. Introduction 4

5.1 Analyser model ............................................................................................................................ 4

5.2 Patent references ..........................................................................................................................4

5.3 Serial number ...............................................................................................................................4

5.4 Power supply ...............................................................................................................................4

5.5 Mounting system .......................................................................................................................... 4

6. Application 5

7. Description 5

7.1 Measuring principle ......................................................................................................................5

7.2 Flow diagram ................................................................................................................................6

7.3 Dimensions and weight ................................................................................................................7

7.4 Front panel .................................................................................................................................... 7

7.5 Technical data............................................................................................................................... 8

8. Supply connections 9

8.1 Medium ........................................................................................................................................ 9

8.2 Electrical .......................................................................................................................................9

8.2.1 mA output ..................................................................................................................................10

8.2.2 In- and output contacts .............................................................................................................. 10

8.2.3 Connector for solenoid valves ...................................................................................................10

9. Receipt and storage 11

10. Installation 11

11. Starting up 11

12. Menu description 12

13. Calibration 27

13.1 Calibration ..................................................................................................................................27

13.2 Cross-sensitivity .......................................................................................................................... 27

14. Measuring 30

14.1 Automatically range switch ........................................................................................................30

14.2 Expanded measuring range........................................................................................................ 30

15. Function of in- and output contacts and alarms 31

16. Closing down 32

17. Maintenance and repair 33

18. Trouble shooting 34

19. Spare part list 35

20. Appendix 35

- 2 -

This instruction manual does not claim completeness and is subject to technical modifications.

©5/1999 M&C Products Analysentechnik GmbH. Reproduction of this document or its content is not allowed without permission

from M&C.

PMA® is a registered trade mark.

5th edition: 02/2003

M&C Products Analysentechnik GmbH 9-3.12-ME

Page 3

- 3 -

1. Electrical standards

The electrical standard corresponds to the safety regula–

tions concerning the low-voltage recommendation 73/23

EWG in version 93/68 EWG and the recommendation of

electromagnetic compatibility 89/336 EWG in version

93/68 EWG.

We meet the following standards:

EN 61010 part 1 / EN 50081 part 1 / EN 50082 part 1

EN 55014 / EN 60555 part 2 & 3 / EN 60335 part 1

2. Important safety informations

Please note the following basic safety procedures when

using this equipment:

• Work on electrical equipment is only to be carried

out by trained specialists as per the regulations

currently in force.

• Attention must be paid to the requirements of IEC 364

(DIN VDE 0100) when setting high-power electrical units

with nominal voltages of up to 1000 V, together with the

associated standards and stipulations.

• Check the details on the type plate to ensure that

the equipment is connected up to the correct mains

voltage.

• Protection against touching dangerously high electrical

voltages.

Before opening the equipment, it must be switched and

hold no voltages. This also applies to any external

control circuits that are connected.

• The equipment is only to be set within the permitted

range of temperatures and pressures.

• Check that the location is weatherprotected. It should

not be subject to either direct rain or moisture.

• The equipment may not be operated in an area at

risk from explosion.

• Installation, maintenance, monitoring and any repairs

may only be done by authorised personnel with respect

to the relevant stipulations.

3. Warranty

If the equipment fails, please contact M&C directly or else

go through your M&C authorised dealer.

We offer a one year warranty as of the day of delivery as

per our normal terms and conditions of sale, and assuming

technically correct operation of the unit. Consumables are

hereby excluded. The terms of the warranty cover repair at

the factory at no cost or the replacement at no cost of the

equipment free ex user location. Reshipments must be

send in a sufficient and proper protective packaging.

9-3.12-ME M&C Products Analysentechnik GmbH

Page 4

4. Used terms and signal indication

- 4 -

SKILLED STAFF

These are persons with necessary qualification, who are

familiar with installation, use and maintenance of the

product.

The signals are used according to DIN 4844 and

EU Recommendation 91/C53/06.

These are important informations about the product or

parts of the instruction manual which require user’s

attention.

5. Introduction

5.1 Analyser model

The Oxygen analyser type PMA100 is produced by M&C

Products Analysentechnik in Ratingen, Germany.

5.2 Patent references

The M&C paramagnetic measuring cell is patented in

Europe and the USA under the following patent numbers:

• Germany Pat.-Nr. 36 33 750

• France Pat.-Nr. 87 13 608

• United Kingdom Pat.-Nr. 21 96 127

• The Netherlands Pat.-Nr. 188 2449

• USA Pat.-Nr. 4,807,463

5.3 Serial number

The type plate with the serial number is located at the back

panel of the analyser. Whenever you call M&C regarding

questions or orders for spares please give us the serial

number of your PMA.

5.4 Power supply

The power supply for the oxygen analyser PMA100 is 230V,

50Hz or 115V, 60Hz (‘a’ added to the Serial-No.). For detailed

information please look at the type plate of your analyser.

Variations of the power supply in a range of +10% to - 15%

have no influence on the function of the analyser.

5.5 Mounting system

The analyser is build in a 19“ housing, for rack or tablemounting.

M&C Products Analysentechnik GmbH 9-3.12-ME

Page 5

- 5 -

➡➡

6. Application

The transducer of the PMA100 works at a stable temperature of +55°C. Therefore the analyser is suitable for continuous measurements of oxygen concentrations in particlefree and dry sample gases.

Safe operation, reliability and minimized maintenance are

the characteristic of the PMA100.

The operation of the instrument is based upon the principle

of the magneto-dynamic cell which is the most accurate

and reliable cell for determining the oxygen content in gas

mixtures in a range of 0 to 100 Vol.-%.

The patented M&C measuring cell has been improved in

order to achieve stability, minimum drift of temperature and

extremely fast response time. Due to this fast response

time and the negligible cross-sensitivity from other gases

the PMA100 is applicable in a wide range of processes,

like:

• monitoring of flue gases,

• inerting installations,

• fermentation processes,

• process- and lab-measurements, etc.

7. Description

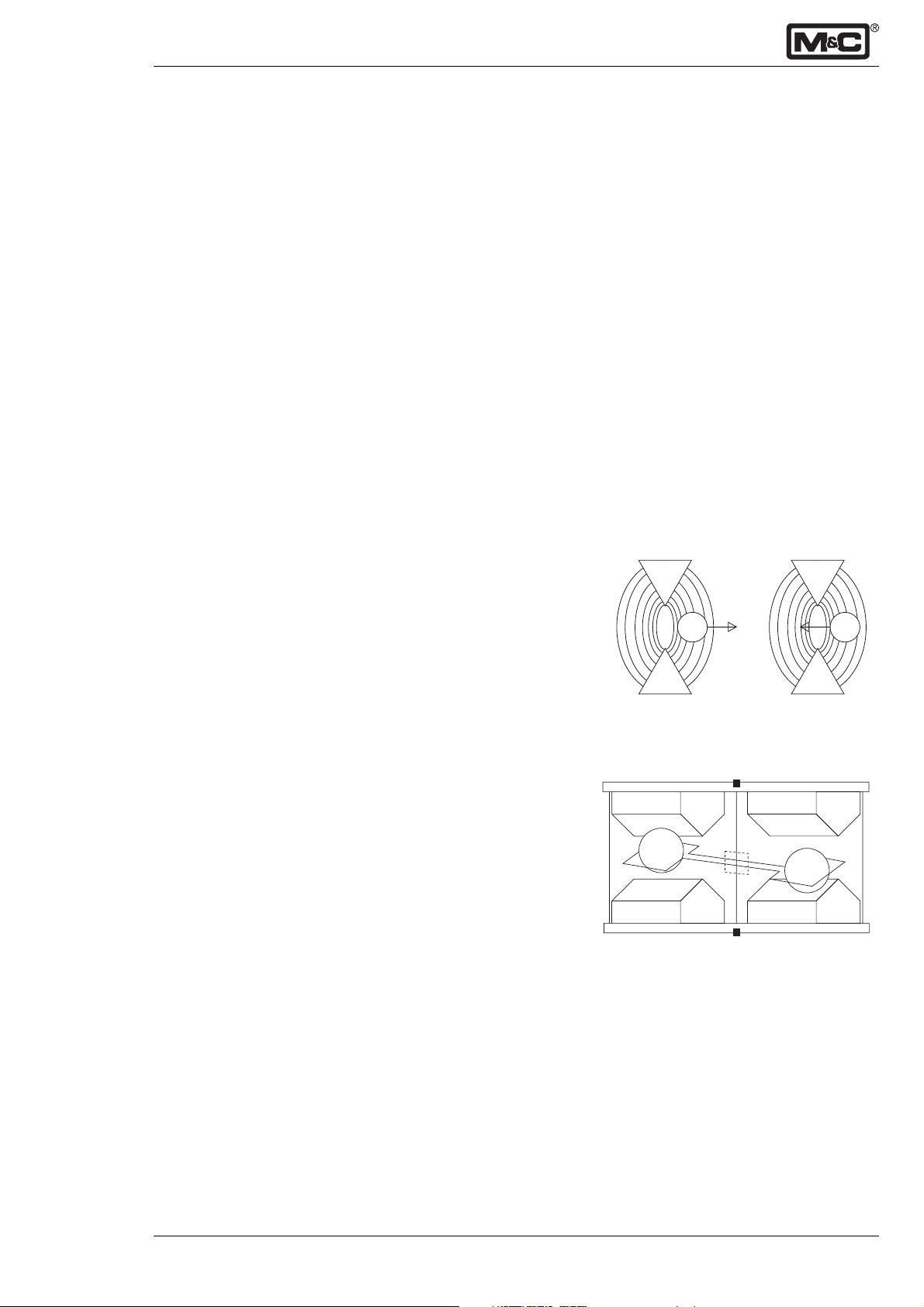

7.1 Measuring principle

The paramagnetic susceptibility of oxygen is significantly

greater than that of other common gases, and for this

reason the molecules of oxygen are attracted much more

strongly by a magnetic field than the molecules of other

gases. Most of the other gases are slightly diamagnetic,

e.g. the molecules are then repelled by a magnetic field.

The principle of the magneto-dynamic cell is based upon

Faraday’s method of determining the magnetic susceptibility of gas. The cell consists of two nitrogen-filled quarts

spheres arranged in the form of a dumb bell. A single turn

of platinum wire is placed around the dumb bell which is

suspended in a symmetrical non-uniform magnetic field.

When the surrounding gas contains oxygen, the dumb bell

spheres are pushed out of the magnetic field by the change

in the field which is caused by the relatively strong paramagnetic oxygen. The torque acting on the dumb bell will

be proportional to the paramagnetism of the surrounding

gas and consequently it can be used as a measure of the

oxygen concentration.

N

N

2

S

Nitrogen=Diamagnetic Oxygen=Paramagnetic

Fig. 1: Magnetic susceptibility of gases

2

1

1 : Quarts sphere dumb bell

2 : Platinum wire

3 : Mirror

4 : Magnetic pole pieces

Fig. 2: The measuring cell in theory

3

N

S

4

O

2

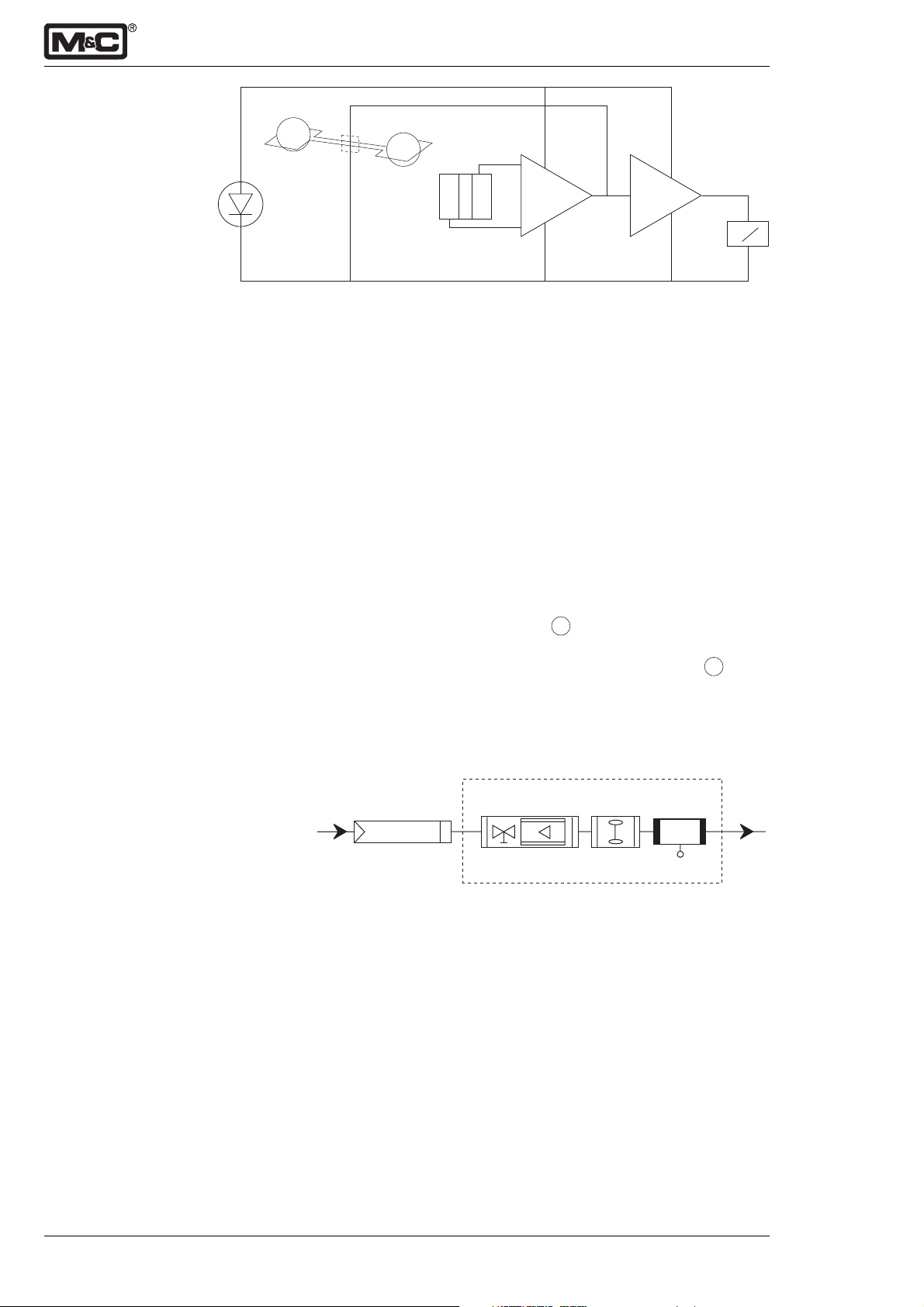

The distortion of the dumb bell is sensed by a light-beam

and projected on a mirror attached to the dumb bell whereof it is reflected to a pair of photo cells (Fig. 3). When both

photo cells are illuminated equally the output will be zero.

The output from the photo cells is connected to an amplifier,

which in turn is fed to the feedback coil of the measuring

cell. If the oxygen content of the gas sample changes,

9-3.12-ME M&C Products Analysentechnik GmbH

Page 6

- 6 -

1

1: Measuring cell

2: „LED“ light beam

3: Photo cell

4: Feed back amplifier

5: Output amplifier

6: Meter indication

Fig. 3: Principle of operation

➞

➞

23 54

the corresponding output of the amplifier, which is a current

and also proportional to the oxygen content, produces a

magnetic field in the feedback coil opposing the forces and

thereby causing the dumb bell to rotate.

Since the feedback current from the amplifier is proportional to the oxygen content of the gas sample, the output

signals produced by the amplifier will be accurate and

linear. The paramagnetic susceptibility of oxygen varies

inversely as the square of the absolute temperature. Therefore, a temperature sensitive element in contact with the

measuring cell assembly is included in the feedback

current circuit in order to provide compensation for

changes in analyser temperature.

7.2 Flow diagram

The flow can be adjusted in a range of 25 - 60Nl/h air at the

flowmeter with needle valve 2 built on the front panel of

the analyser.

The flow sensor at the outlet of the measuring cell 3 de–

tects the sample flow if it decreases under 25l/hr.

We recommend a conditioning system upstream the

analyser PMA100, e.g. consisting of a cooler and fine filter.

6

1: external filter

2: flowmeter with needle valve

3: patented M&C measuring cell PMA100

4: flow control

Fig. 4: Flow diagram of the analyser

1234

We like to inform you about suitable M&C equipment.

M&C Products Analysentechnik GmbH 9-3.12-ME

Page 7

- 7 -

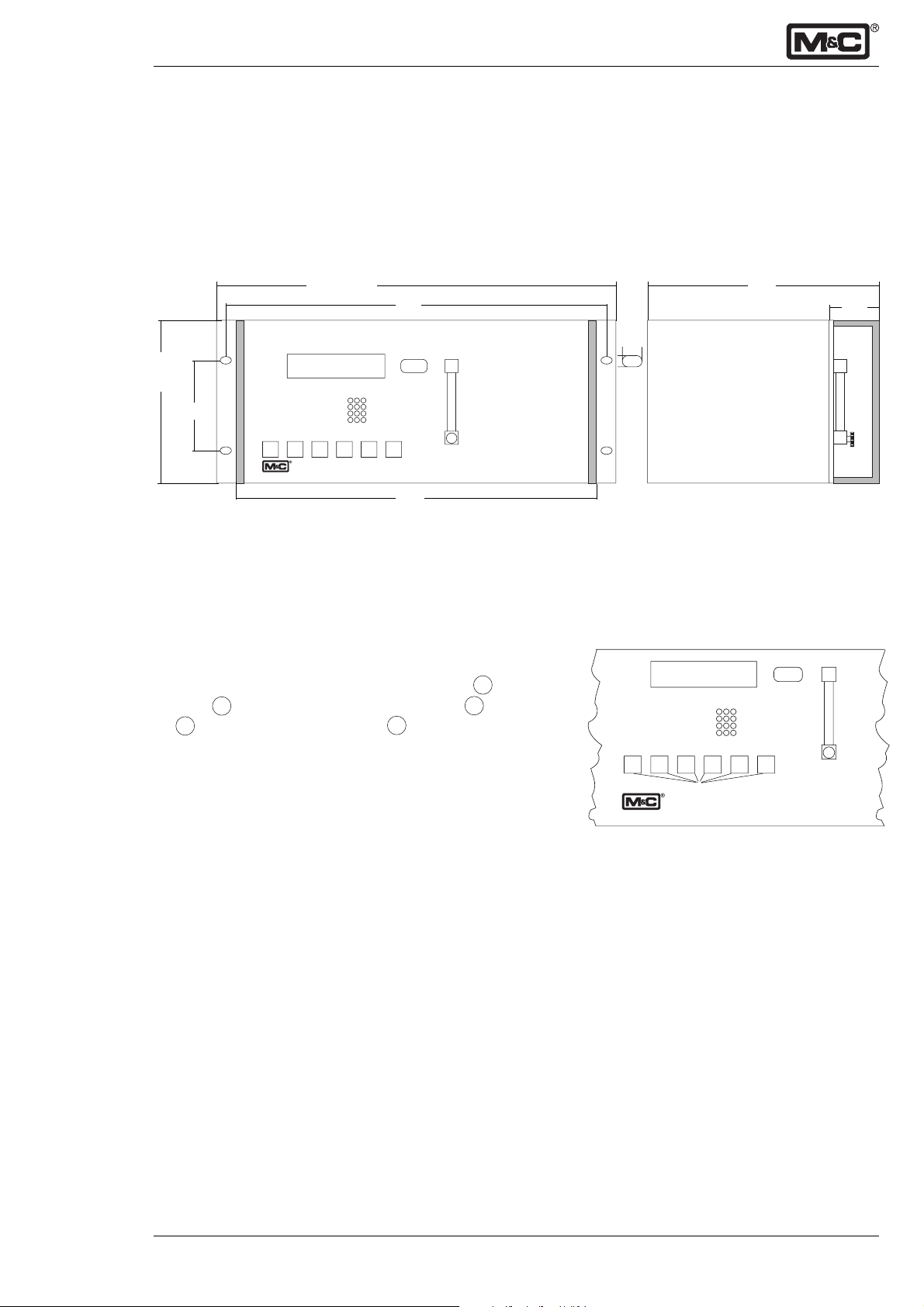

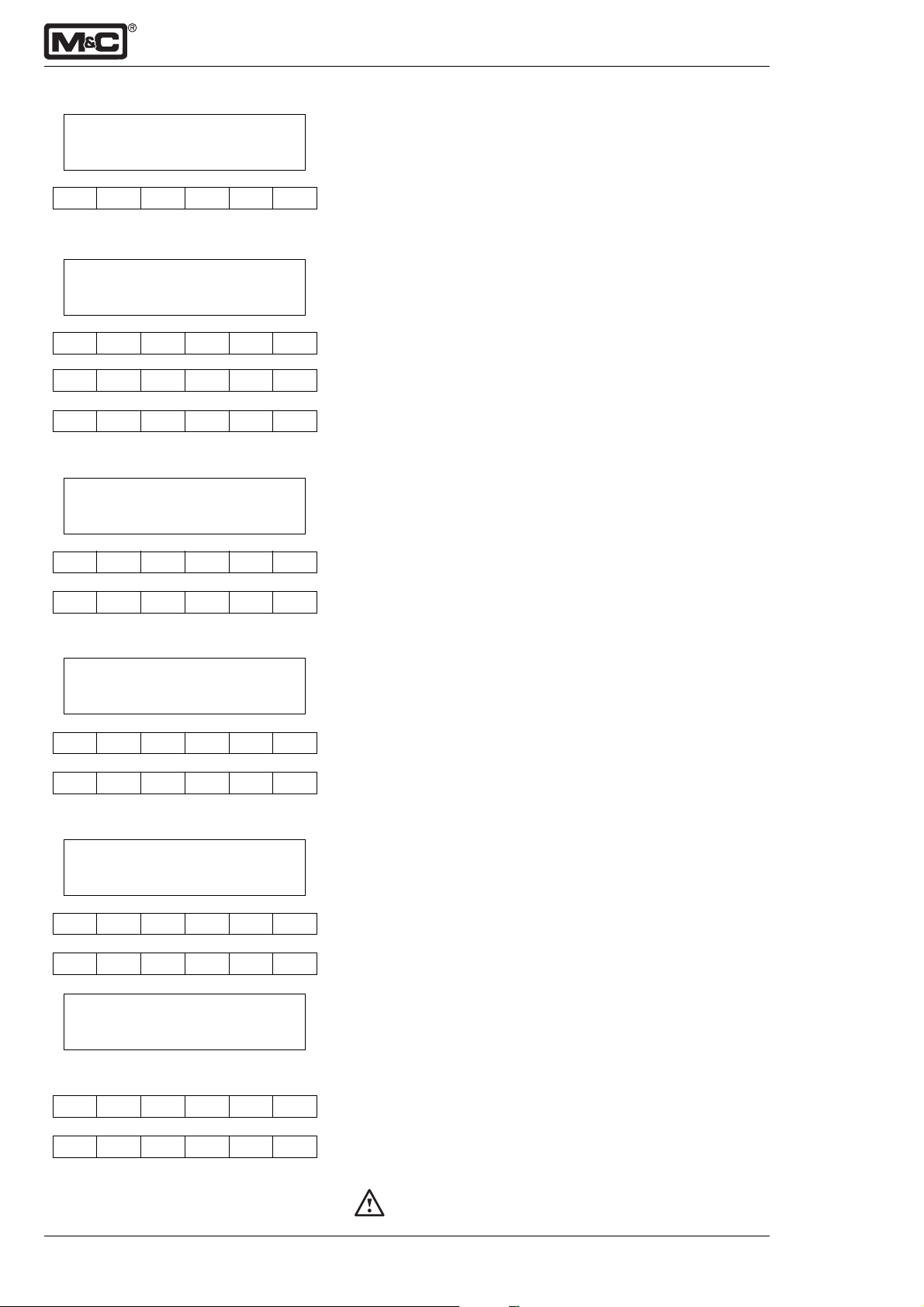

7.3 Dimensions and weight

The analyser is build in a 19” housing, also suitable for

table mounting. Fig. 5 shows the dimensions of the

PMA100. Please take additional 60mm fitting-depth into

consideration when installing the analyser.

The weight of the analyser is approx. 11 kg.

483

177

(4U)

(84HP)

20,9 V0l.% O

1010 mbar

102

⇑⇓

PMA100

465

2

Alarm

440

7.4 Front panel

The following figure shows the front panel of the oxygen

analyser PMA100.

You can see the double-lined LCD display 1 , the alarm

LED 2 , the flowmeter with needle valve 3 , status LEDs

4 and the six operating keys 5 .

The sample flow can be adjusted at the needle valve in a

range of 25-60Nl/hr.

The control panel refers to NAMUR standard and is

devided into:

• Select key

• Enter key

• Direction key

• Direction key

⇑⇑

⇑

⇑⇑

⇓⇓

⇓

⇓⇓

• Cal key

• Measuring key

(for more functional description see chapter 12)

341

50

10

7

Fig. 5: Dimensions of the PMA100

20,9 V0l.% O

1

1010 mbar

Selec Enter ⇑⇓Cal Meas

PMA100 O2-analyser

Fig. 6: Front panel with display, operating keys

and flowmeter

2

4

5

Alarm

2

3

9-3.12-ME M&C Products Analysentechnik GmbH

Page 8

- 8 -

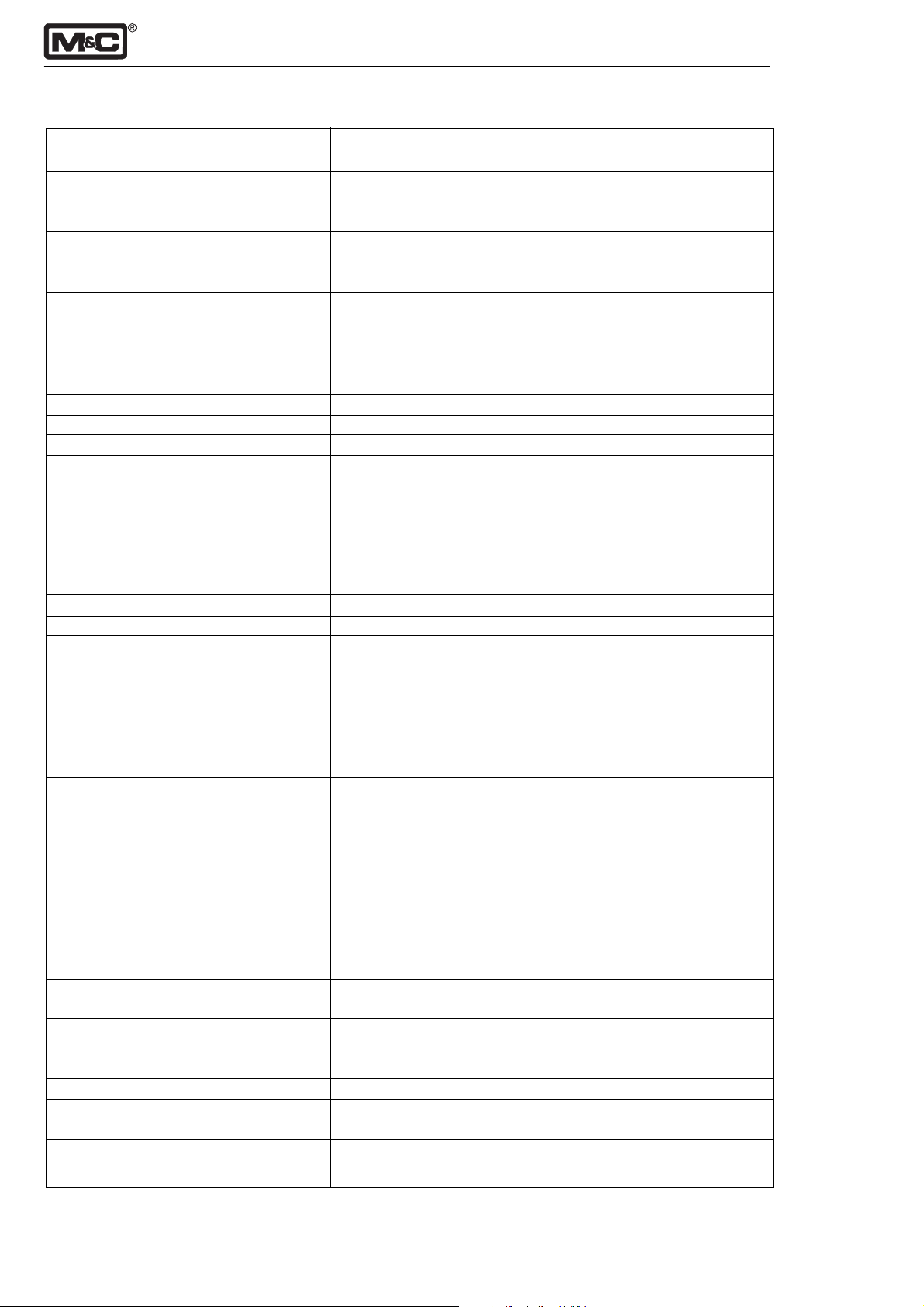

7.5 Technical data

Part No. 03A3000(a): PMA100, power supply 230VAC, 50Hz, 115VAC, 60Hz

signal: 4-20mA; (a)=115V

Measuring ranges 4 linear measuring ranges free selectable, lowest span 1%,

basis parameterizing: 0-1; 0-10; 0-25; 0-100Vol.% O2 *; manual, automatic

or remote range control and range indication is possible

Indication, suitable in German, English and French 2 line, 16-sign. LCD-display, resolution 0,01Vol.%O2, continuous

O2-indication and read off O2-transducer temperature, mA-signal, measuring range, time, date, error/alarm message, process pressure

Output signals selection: isolated 0-20, 2-20, 4-20*, 4-20.5mA for the selected range,

max. load 500Ω;

interface RS232, AK communication protocol, bi-directional,

option: interface RS485

Relay outputs, free configurable 4 potential free relay contacts NO, contact rating max. 48VDC, 500mA, 15W

Binary outputs 24VDC, max. 400mA, controlling of 3 external valves for calibration

Binary inputs, free configurable potential free, 4 x 12 - 24VDC, max. 20mA or internal 24V

Flow alarm caloric conductibility sensor in the outlet of the cell

Status alarm for min. flow, transducer temp. < 50°C, processor error,

pressure sensor: LED-indication and potential free contact output,NO,

max. 48VDC, 500mA, 15W and mA output signal, f.e. 22mA

Alarm contact for underflow or exeeding of the measuring range, termination of the

calibration, external alarm, concentration alarm: LED-indication and

potential free contact output, NO, max. 48VDC, 500mA, 15W

Response time for 90%-FSD < 3sec at 60 NI/hr air

Accuracy after calibration deviation ± 1% of 2-100% span, ±2% of 1% span

Reproducibility deviation < 1% of span

Influence of ambient temperature no influence up to 50°C

Influence of barometric or process pressure the oxygen reading varies in direct proportion to the baromatric or process

pressure variation

option: integrated process pressure compensation for the range 0,6 to

1,6bar abs., part no.: 03A9300

Influence of sample gas flow variation in gas flow between 0 and 60 Nl/hr air will cause a difference in

reading of < 0,1Vol.%O

2

Sample gas

- inlet pressure 0,01 up to 0,5bar g (PMA100 requires positive pressure for adequate flow

rate, no pump inside)

- outlet pressure outlet of analyser should discharge freely into atmosphere, or see option:

pressure compensation

- flow rate 25 - 60 Nl/hr air

- temperature -10°C up to +50°C dry gas

O2-transducer temperature fixed at +55°C

Ambient temperature -10°C up to +50°C

Storage temperature -20°C up to +60°C, rel. humidity 0-90% RH

Power supply internal power unit for 230VAC or 115VAC available, (a) +/-10%, 40-60 Hz, 35VA

Electrical connections mains supply: 3-pol. chassis plug with 2m cable; signals: 4 x Sub-D plug

Materials in contact with sample gas platinum, epoxy resin, glass, FPM, stainless steel 316, PTFE, PVDF

Sample gas connection 1/8“ NPT internal thread*, option with tube connector DN 4/6 PVDF

available part no.: 05V1045

Protection / Electrical standard IP40 (EN60529) / EN61010

Housing/ 19“ rack mounting with front handles

Front colour grey RAL 7032

Dimensions/ width: 84HP; hight: 4U; depth: 350mm + approx. 60mm installation space

Weight approx. 11 kg

supply voltage

DC

* standard/basis execution

M&C Products Analysentechnik GmbH 9-3.12-ME

Page 9

- 9 -

8. Supply connections

8.1 Medium

Note!

The oxygen analyser PMA100 is suitable for continuous

measurements of oxygen concentrations in particle-free

and dry sample gases. Therefore it is recommended to use

a gas conditioning system upstream the analyser, e.g.

equipped with a cooler and a particle filter.

We like to inform you about suitable M&C equipment.

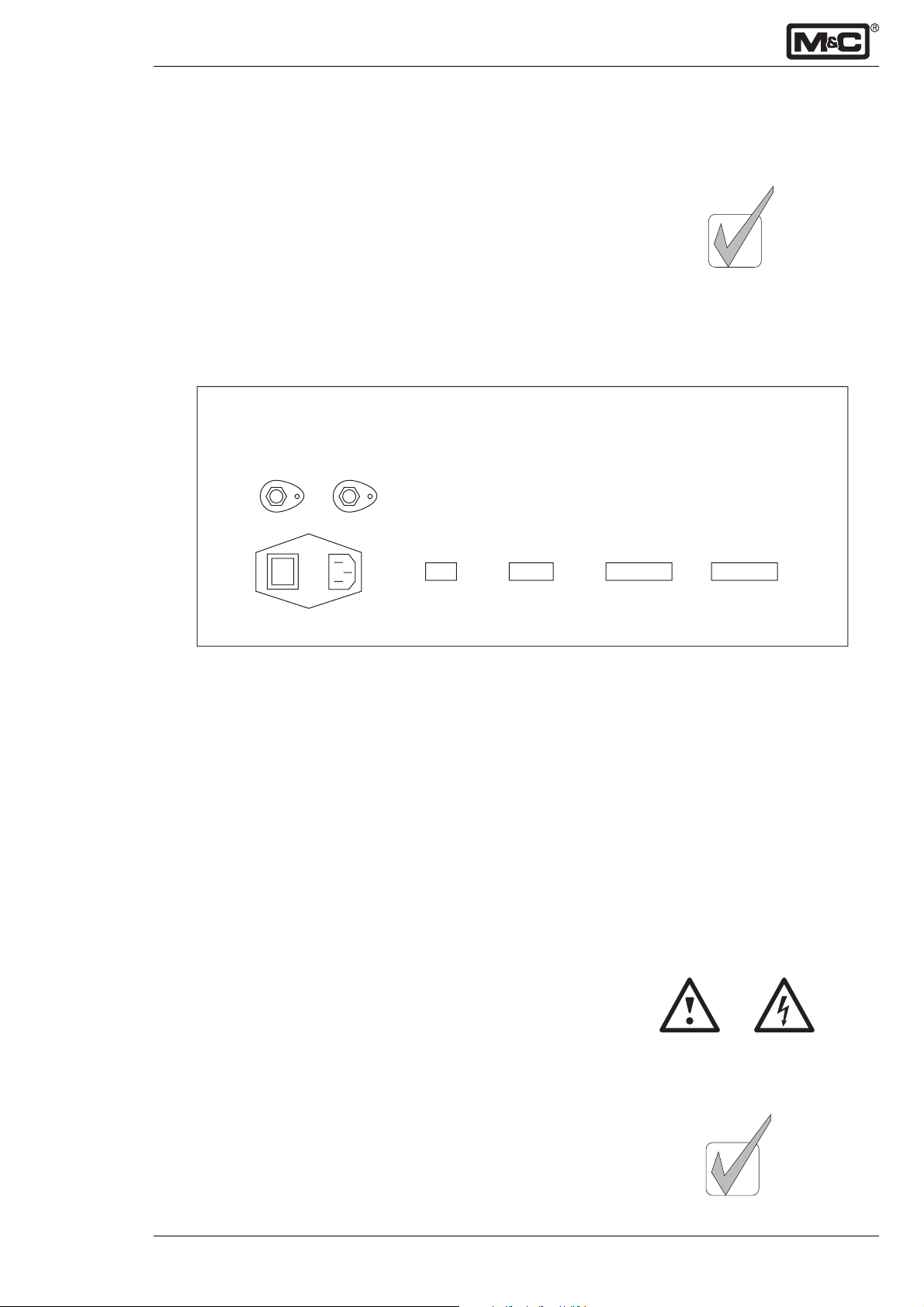

The following diagram shows the connections on the back

panel of the PMA100.

Sample in Sample out

Before opening the assembly cover

disconnect the electrical supply!

X1 X2 X3 X4 X5

Power in

Patented measuring cell

USA patent number 4807463

For connection of the sample gas in- and outlet use 1/8”

NPT male fittings.

We like to inform you about our range of tube and pipe

connectors.

8.2 Electrical

The analyser PMA100 is equipped with an internal power

switch. The 2m cable with 3-pole plug at the end is part of

the standard supply.

False supply voltage can damage the equipment. When

connecting the equipment, please ensure that the supply

voltage is identical with the information provided on the

model type plate!

Fig. 7: Connections on the back panel of the

PMA100

Note!

For the erection of power installations with rated voltages

up to 1000V, the requirements of VDE 0100 and relevant

standards and specifications must be observed!

The main circuit must be equipped with a fuse corresponding to the nominal current (over current protection); for

electrical details see technical data (chapter 7.5).

9-3.12-ME M&C Products Analysentechnik GmbH

Page 10

mA +

mA +

mA +

mA +

mA -

Fig. 8: 15-pole Sub-D socket X3

Out 4 MC

Out 3 NO

Out 2 MC

Out 1 NO

Alarm MC

Status MC

Out +24V

IN 1,2,4; GND

IN 3 (+24V)

In 1 (+24V)

In 4 (+24V)

1

9

10

11

12

13

14

15

14

15

16

17

18

19

20

21

22

23

24

25

mA -

mA -

mA -

mA -

mA -

mA -

mA -

Out 4 NO

Out 3 MC

Out 2 NO

Out 1 MC

Status NO

Out 0V

IN 3; GND

Alarm NO

In 2 (+24V)

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

10

11

12

13

- 10 -

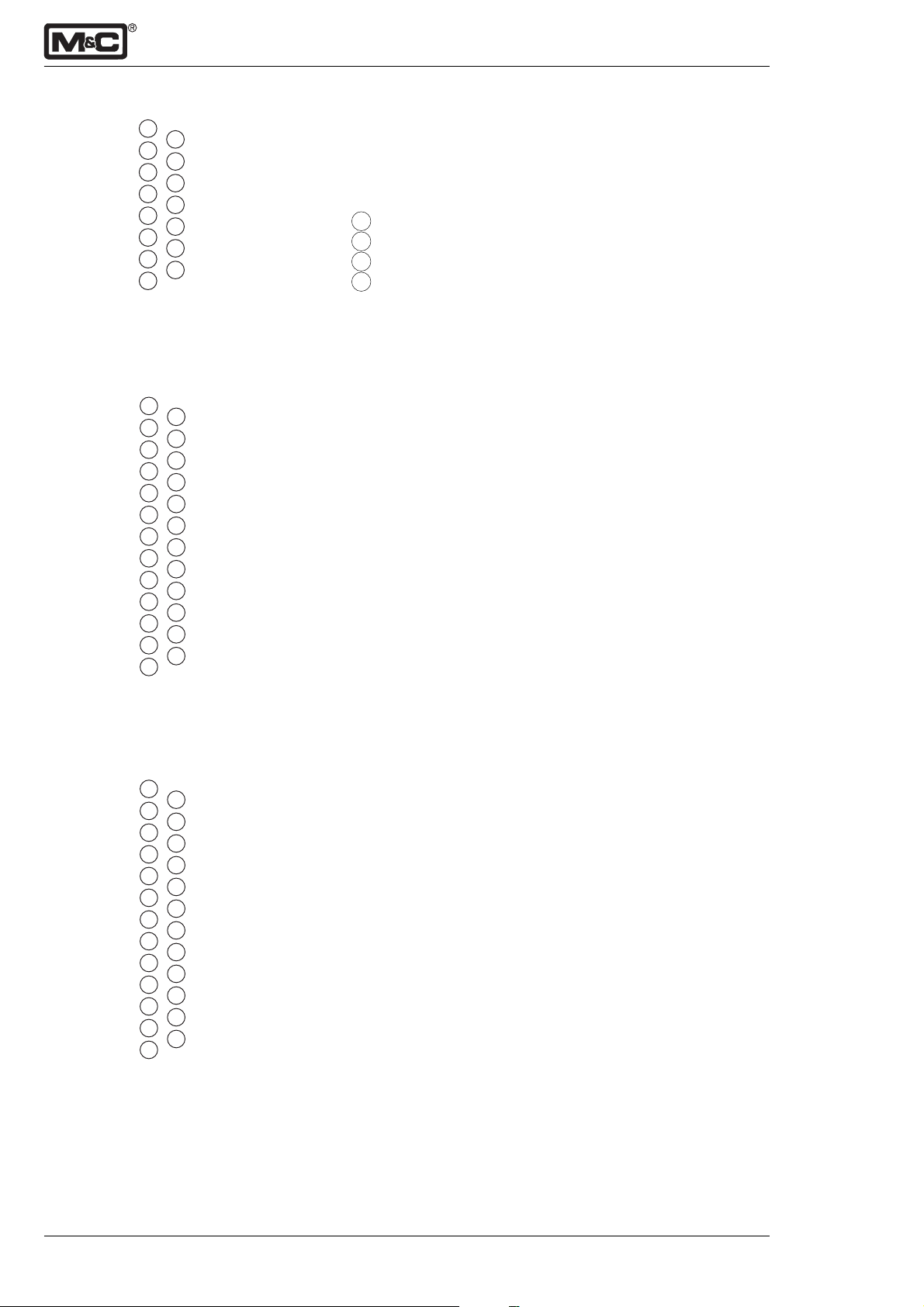

8.2.1 mA output

The mA output is available on the back panel of the

PMA100 (see fig.8) at the 15-pole Sub-D socket X3. The

following figure shows the configuration of the terminal.

For multichannel version the outputs are arranged as

follows:

1 channel 1,

2 channel 2,

3 channel 3,

4 channel 4.

The menu-driven handling of the mA outputs is described in

chapter 12.

8.2.2 In- and output contacts

Fig. 9 shows the configuration of the terminal X4. The

following connections are available at the 25-pole Sub-D

plug:

• four binary inputs, In1 to In4, with 12V - 24V, max. 20mA,

• four binary output contacts, Out1 to Out4, with 48V,

max. 500mA,

• one alarm contact, Alarm MC and Alarm NO, with 48V,

max. 500mA,

• one status contact output, Status MC and Status NO,

with 48V, max. 500mA. and

• one supply power contact, Out +24V and Out 0V, with

24V, max. 100mA.

Fig. 9: 25-pole Sub-D plug X4

24V

+0V Y1

+0V Y2

24V

+0V Y3

Option

24V

Option

Option

24V

Option

Option

24V

Fig. 10: 25-pole Sub-D socket X5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Option

Option

24V

Option

Option

24V

Option

Option

24V

Option

Option

24V

The menu-driven handling of the in- and outputs is

described in chapter 12.

8.2.3 Connector for solenoid valves

Fig. 10 shows the 25-pole Sub-D socket X5 with the supply

power to control three external solenoid valves. At the moment

three conections are available:

• pin 2 connection for the zero gas solenoid valve, 24V,

max. 400mA,

• pin 3 connection for the span gas solenoid valve, 24V,

max. 400mA, and

• pin 5 connection for the sample gas solenoid valve, 24V,

max. 400mA.

The menu-driven handling of the in- and outputs is

described in chapter 12.

M&C Products Analysentechnik GmbH 9-3.12-ME

Page 11

- 11 -

9. Receipt and storage

The PMA100 is completely pre-installed and normally delivered in one packaging unit.

• Please take the analyser and possible special accessories carefully out of the packaging material immediately after arrival, and compare the goods with the items

listed on the delivery note;

• Check the goods for any damage caused during delivery

and, if necessary, notify your transport insurance company without delay of any damage discovered.

Note!

The oxygen analyser PMA100 must be stored in a wheather-protected frost-free area!

10.Installation

The PMA100 is built in a 19“ housing, which is also suitable

for table mounting.

Accurate and proper installation of the PMA100 analyser

will not only minimize instrument breakdown, but it will also

result in reliable operation of the analyser.

The operator must be satisfied that the analyser installation

and positioning is safe for extremes of conditions which

could occur in the operating environment of the analyser.

Choose installation sites which are reasonable free from

vibration sources, and are not subjected to large temperature fluctuations outside the analyser specifications.

Without any precautions avoid any back pressure different

from barometric pressure at the gas outlet of the analyser.

Note that the PMA100 analyser is only suitable for

measuring of non-hazardous gas mixtures in non-hazardous areas!

11.Starting up

Before using the equipment for the first time, check that the

safety measures specific to the installation and process are

complied with.

Before connecting the analyser to the mains, compare

the mains voltage with the information on the type plate

of the analyser.

Note!

The working temperature of the analyser is 55°C. After

starting, the analyser warms up. The current temperature is

displayed.

During the warm-up time the menu of the analyser is locked

for use.

9-3.12-ME M&C Products Analysentechnik GmbH

Page 12

12.Menu description

12.1 Table of content

• Overview menu-drive and Overview operating keys ....................................................................................... 13

12.2 Warming up ....................................................................................................................................................... 14

12.3 Alarm log-book ................................................................................................................................................. 14

12.4 Parameterising level 1 ........................................................................................................................................ 15

12.4.1 Language ........................................................................................................................................................... 15

12.4.2 Select range ....................................................................................................................................................... 15

12.4.3 Set range ............................................................................................................................................................ 15

12.4.4 Set autorange hysteresis .................................................................................................................................... 15

12.4.5 Current output ................................................................................................................................................... 15

12.4.6 Status error mA .................................................................................................................................................. 16

12.4.7 Set date/time ..................................................................................................................................................... 16

12.4.8 Relay configuration ............................................................................................................................................ 16

12.4.9 Input configuration ............................................................................................................................................ 17

12.4.10 Average ............................................................................................................................................................. 17

12.4.11 Concentration alarm .......................................................................................................................................... 18

12.5 Parameterising level 2 ........................................................................................................................................ 19

12.5.1 Step into the menu ............................................................................................................................................ 19

12.5.2 LCD contrast ...................................................................................................................................................... 19

12.5.3 Calibration method ........................................................................................................................................... 19

12.5.4 Calibration interval ............................................................................................................................................. 19

12.5.5 Current signal with calibration ........................................................................................................................... 20

12.5.6 Calibration time ................................................................................................................................................. 20

12.5.7 Measuring time .................................................................................................................................................. 20

12.5.8 Pressure compensation ..................................................................................................................................... 20

12.6 Calibration of the pressure sensor ..................................................................................................................... 20

• Current pressure ................................................................................................................................................ 21

• Data output ........................................................................................................................................................ 21

• Memory clear .................................................................................................................................................... 21

12.7 Interface communication and passwords ........................................................................................................ 21

12.7.1 Baud rate (correlation with the ser. interface RS232) ........................................................................................ 21

12.7.2 Communication channel (communication with the ser. interface RS232/485) ................................................ 21

12.7.3 STX and ETX character ...................................................................................................................................... 22

12.7.4 Change password level 1 .................................................................................................................................. 22

12.7.5 Change password level 2 .................................................................................................................................. 22

12.8.1 Inquiry of the transducer channel ..................................................................................................................... 22

12.8.2 Read NV-Memory Editor ................................................................................................................................... 22

12.8.3 Device mode ..................................................................................................................................................... 23

12.8.4 Select channel ................................................................................................................................................... 23

12.8.5 Arrangement of the mA-outputs ....................................................................................................................... 23

12.8.6 Set active valve .................................................................................................................................................. 23

12.8 Zero- and span calibration ................................................................................................................................ 24

12.8.1 Zero gas concentration ..................................................................................................................................... 24

12.8.2 Span gas concentration ..................................................................................................................................... 24

12.8.3 Calibration ......................................................................................................................................................... 24

• Manual calibration ............................................................................................................................................. 24

• Manual calibration offset ................................................................................................................................... 25

• Autocalibration offset ....................................................................................................................................... 25

• Autocalibration ................................................................................................................................................. 25

12.8.4 Deviation from calibration ................................................................................................................................. 26

12.8.5 Calibration log-book ......................................................................................................................................... 26

- 12 -

M&C Products Analysentechnik GmbH 9-3.12-ME

Page 13

- 13 -

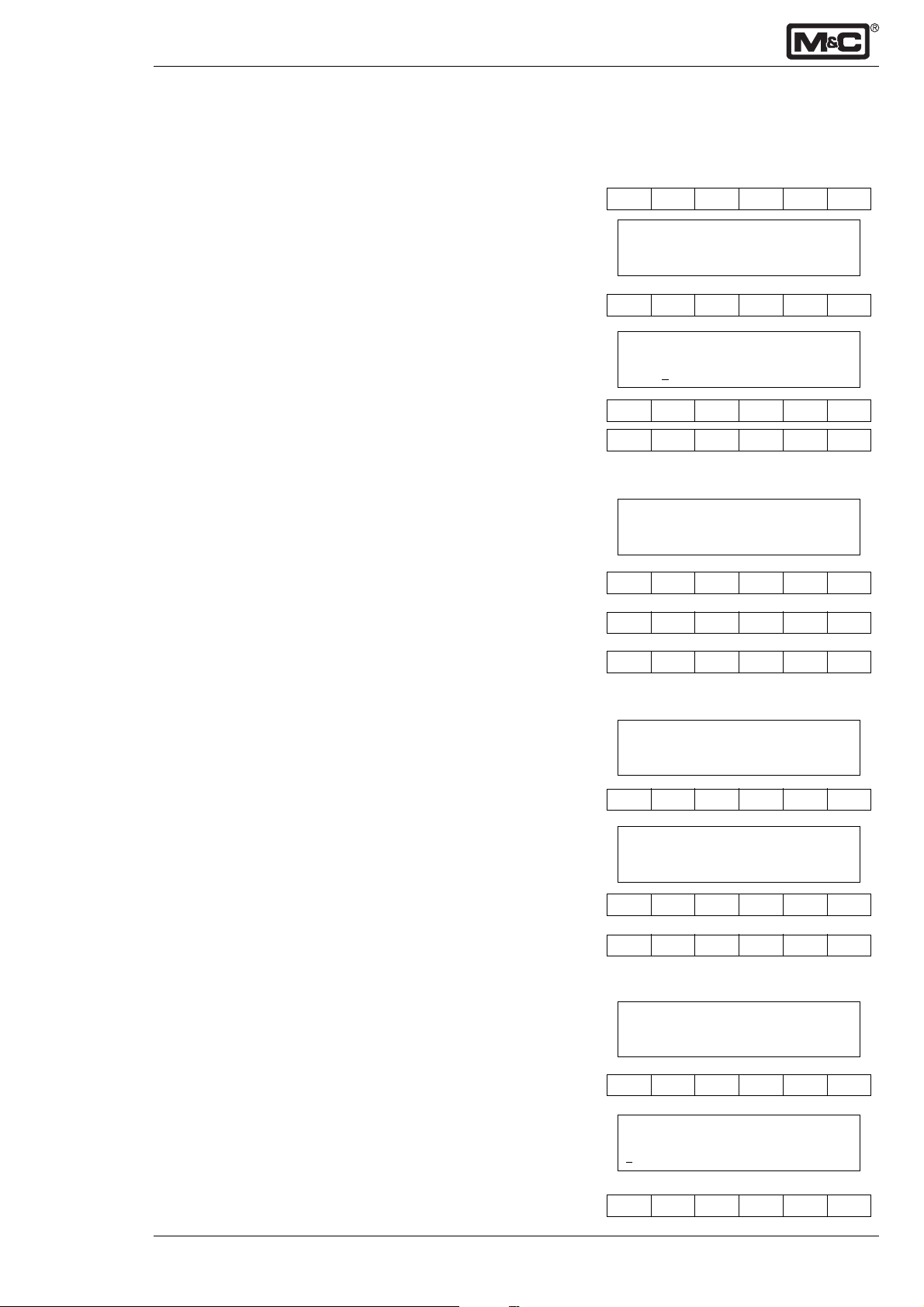

Overview menu-drive Overview operating keys

Display

Status

Alarm log-book

Entry code

Code 1

Language

Code 2

LCD contrast

Meas

Cal

Select

Enter

↑↓

Read only

see

code1

• Startup of measuring menu

• Function: to leave the actual menu

structure to the measuring display

• Startup of calibration

• Selection of menu points

• Selection of changeable positions

• Jump into submenu

• Confirmation of input

• Selection of submenu points if shown on

the display

Cal

Zerogas

concentration

Measuring

range

Current output

Date/Time

Relayconfiguration

Relay NC/NO

Keep alarm

yes/no

Inputconfiguration

Average

Concentrationalarm

Calibrationmethod

Calibrationpressure sensor

Current

pressure

Data output

Memory clear

Interface

communication

Password

NV-Memory

Device mode

Spangas

concentration

Calibration

Deviation from

calibration

Calibration

log-book

Alarm

range

Alarm signal

9-3.12-ME M&C Products Analysentechnik GmbH

Page 14

MC Para O

TM M&C Products

2

V 1.52

- 14 -

12.2 Warming up

After switching on the analyser type PMA100, the warmingup begins.

The following display appears for approximately 20 seconds:

• M&C logo

• current O2-concentration

• Software-version implemented in the PMA100

• and the trademark.

press: 1005 mbar

press: 1005 mbar

heating 22.5°C

Select

alarm log-book

Select

After further 20 seconds the display changes. Via the Direction keys ⇑⇓ the following current values can be indicated:

• measuring range,

• temperatur of the transducer,

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

• pressure in the measuring-cell,

• date/time,

• current output.

The second line displays the heating procedure.

The warming-up is finished by reaching a temperature of

54°C. The display shows either the current value (see

above) or an error message. The second line of the display

presents the current oxygen concentration (for multi-channel

version the concentration of the respective channel).

The Select key leads to the next menu point.

12.3 Alarm log-book

The starting time and the 9 last alarms are stored. The

Direction keys ⇑⇓ can be used going through the alarm logbook. The current alarm message is shown on the display

like E ....

The Select key leads to the entry of the access code.

enter to config.

Code: 0000

Enter

enter to config.

Code: 0000

Select

Enter

enter to config.

Level 1

Select

The Enter key opens the access code menu for the first,

second respectively read only level.

The first changeable position is underlined. With the Direction keys ⇑⇓ the value of the position can be changed in

between 0 and 9. A jump to the next position happens via

the Select key. The entry of the complete code has to be

confirmed by the Enter key and is shown in the second line

of the display.

The codes are preadjusted at the factory:

Code:0010 level 1

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

Code:1000 level 2

Code:0000 read only-level;

The read only-level allows a passage through all menu

points of level 1 via the Select key. In this level parameters

can not be changed.

The Select key leads to level 1 - measuring parameters,

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

relay-, input and output configuration.

M&C Products Analysentechnik GmbH 9-3.12-ME

Page 15

- 15 -

12.4 Parameterising level 1

12.4.1 Language

The following languages are selectable by the Direction

keys ⇑⇓ :

• English,

• German,

• French.

Enter confirms the choice.

The Select key leads to the next menu point.

12.4.2 Select range

After the entry of the code for level 1 the display opens to

the select range menu. Four variable ranges and the autorange are available. The functions can be selected by the

Direction keys ⇑⇓ . With the autorange always the favourable range is used.

In combination with the autorange function, unused measuring

ranges are requested to be set to 0 (see 12.4.3).

The Select key leads to the next menu point.

12.4.3 Set range

The desired ranges 1 to 4 or the autorange are selected by

the Direction keys ⇑⇓ . The display is opened for changes

by the Enter key. The first changeable position is

underlined and can be changed operating the Direction

keys ⇑⇓ . A jump to the next position happens via the

Select key. The entry of the complete measuring range has

to be confirmed by the Enter key.

language

English

Enter

Select

select range 1

r1(...4), autorange

Enter

Select Enter

Select

set range 1

xx%O2 - xxx,x%O

Enter

Select Enter

↑

↑

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

↑

↑

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

2

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

The Select key leads to the next menu point.

12.4.4 Set autorange hysteresis

This adjustment is important using the autorange function.

The %-value is related to the smallest span of the relevant

switching ranges and determines the interval switching into

the next lower range (see 14.1).

The entry starts with the Enter key. The first changeable

position is underlined and can be changed operating the

Direction keys ⇑⇓. A jump to the next position happens via

the Select key.

The entry has to be confirmed by the Enter key, and the

Select key leads to the next menu point.

12.4.5 Current output

Two adjustments are possible:

1. fixed output signal and

2. output signal with range of tolerance showing the

underflow respectively exceeding of the signal range.

The following ranges are preseted:

• 0 - 20mA • 0 - 20mA + 0,45mA

• 2 - 20mA • 2 - 20mA ± 0,45mA

• 4 - 20mA • 4 - 20mA ± 0,45mA

Select

set hyst. autor.

xx.xx%

Enter

Select Enter

Select

current output

0-20mA, 2-20mA, ...

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

↑

↑

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

9-3.12-ME M&C Products Analysentechnik GmbH

Page 16

- 16 -

Enter

Select

status error mA

no, 0mA, 2mA, 20,5mA, ...

⇑⇑

⇑

⇑⇑

Enter

Select

set date/time

MM-DD-YY hh:mm

Enter

Select

⇑⇑

⇑

⇑⇑

A selection is done by the Direction keys ⇑⇓ and confirmed

by the Enter key.

The Select key leads to the next menu point.

12.4.6 Status error mA

↑

↑

Using a permanent current output signal, status errors can

be identified. The output signal is selected via the Direction

keys ⇑⇓ and confirmed by the Enter key.

⇓⇓

⇓

⇓⇓

The following output signals are available:

• no output signal

• 0 mA • 2 mA

• 20,5 mA • 21 mA

• 22 mA • 22,5 mA

•23mA • 24mA

The Select key leads to the next menu point.

12.4.7 Set date/time

The Enter key enables the entry of the date/time values:

first month, day and year, then hour and minute.

The first changeable position is underlined and can be

changed operating the Direction keys ⇑⇓ .

⇓⇓

⇓

⇓⇓

A jump to the next position happens via the Select key.

The entry has to be confirmed by the Enter key, and

operating once more the Select key leads to the next menu

point.

relay config.

relay 1

Enter

relay config.

R1: span1...4,conc. alarm1...4

Enter

Select

relay nc = 1

1:0 2:0 3:0 4:0

Enter

Select Enter

Select

⇑⇑

⇑

⇑⇑

⇑⇑

⇑

⇑⇑

⇑⇑

⇑

⇑⇑

12.4.8 Relay configuration

↑

↑

This menu point determines the function of maximum four

relays, R1 to R4 (see 7.5 technical data). A selection of the

relays is done by the Direction keys ⇑⇓ .

⇓⇓

⇓

⇓⇓

The Enter key opens the Entry and the Direction keys ⇑⇓

select the desired function:

• allocation of the measuring ranges 1 to 4

• measuring span error

• concentration alarm (1 to 4)

• calibration

⇓⇓

⇓

⇓⇓

• flow alarm

• external alarm (see 12.4.9).

The Enter key confirms the selection.

The Select key leads to the next menu point.

This menu point selects whether the relay functions as:

0 normally open contact

1 normally closed contact

The entry starts with the Enter key. The first changeable

⇓⇓

⇓

⇓⇓

position is underlined and can be changed operating the

Direction keys ⇑⇓ . A jump to the next position happens via

the Select key.

The entry has to be confirmed by the Enter key, and the

Select key leads to the next menu point.

M&C Products Analysentechnik GmbH 9-3.12-ME

Page 17

- 17 -

An alarm situation can be kept. If yes, one input must be

configured as a reset (see 12.4.9).

The entry starts with the Enter key. The first changeable

position is underlined and can be changed operating the

Direction keys ⇑⇓ . A jump to the next position happens via

the Select key.

The entry has to be confirmed by the Enter key, and the

Select key leads to the next menu point.

12.4.9 Input configuration

Inputs 1 to 4 are selected by the Direction keys ⇑⇓ (see 7.5).

The Enter key opens the entry. The Direction keys ⇑⇓ select

one of the following input functions:

• external alarm (passing through an incoming signal),

• set span 1 to 4,

• autocalibration offset,

• autocalibration,

• alarm reset,

resets all alarms, which are setted to ‘keep alarm=1’ in

the previous menu point. The signal for the reset function

must be an impulse.

keep alarm = 1

1:0 2:0 3:0 4:0

Enter

Select Enter

Select

input config.

input 1...4

Enter

input config.

external alarm

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

↑

↑

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

The choice has to be confirmed via the Enter key.

The Select key leads to the next menu point.

12.4.10Average

This menu point opens the possibility to determine an

average value over a maximum measuring time of 100

seconds. This average value is displayed. The desired

value can be selected via the Direction keys ⇑⇓.

The Enter key operates the confirmation and the Select

key leads to the next menu point.

Enter

Select

average

no, 1, ..., 100 seconds

Enter

Select

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

↑

↑

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

9-3.12-ME M&C Products Analysentechnik GmbH

Page 18

conc. alarm 1...4

[< or >] xx.xx%

Enter

Select

Select

conc. alarm 1...4

alarm contact/ ...

Select Enter

Select

- 18 -

12.4.11Concentration alarm

↑

↑

The user is able to set maximum four threshold values in

Vol.-% O2 as a minimum or maximum alarm limit. The values

1 to 4 are selected by the Direction keys ⇑⇓ . The Enter key

opens the entry. The cursor jumps to the first changeable

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

position, the <-/>-sign for minimum respectively maximum

limit. A selection is operated via the Direction keys ⇑⇓ . A

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

jump to the next position happens via the Select key. The

entry has to be confirmed by the Enter key.

The Select key leads to the next menu point.

• Display concentration alarm

↑

↑

The following menu point determines whether a concentration alarm is displayed as:

• alarm contact,

• status contact, or

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

• no.

A selection happens via the Direction keys ⇑⇓, and is

confirmed by the Enter key. If ‘no’ is selected, the alarm

signal can be used as a relay control output (see 12.4.8).

The Select key leads to the next threshold value.

After reaching the 4th value the Select key leads to the next

menu point.

alarm hysteresis

xx.xx%

Enter

alarm hysteresis

xx.xx%

Select

Select Enter

set beep

off/on

Enter › fl

Select

• Alarm range

The alarm range is determined by a percentile of the alarm

threshold value.

The Enter key opens the menu for the entry of above

mentioned value. The first changeable position is under–

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

lined and can be changed operating the Direction keys ⇑⇓ .

A jump to the next position happens via the Select key.

The entry has to be confirmed by the Enter key, and operating once more the Select key leads to the next menu point.

• Set alarm beep

↑

↑

The optical alarm display can be supported by a beep

alarm signal. The function beep on or off is selected via the

Direction keys ⇑⇓ . The Enter key confirms the choice.

Operating the Select key leads to the beginning of the

menu.

Anytime you want to start up the menu anew press the

Meas

M&C Products Analysentechnik GmbH 9-3.12-ME

Measuring key.

Page 19

- 19 -

12.5 Parameterising level 2

12.5.1 Step into the menu

System parameters can be changed in level 2. Operating

the MEAS key leads back to the configuration level.

Operating two times the Select key leads from the measuring menu to the entry of the access code (see 12.2).

Select

Enter to config.

Code: 0000

The Enter key opens the menu. The first changeable

position is underlined and can be changed via the Direction

keys ⇑⇓ . Operating the Select key jumps to the next

position. The entry of the complete code (1000 preadjusted

at the factory) has to be confirmed by the Enter key.

The Select key leads to the next menu point.

12.5.2 LCD contrast

The display background gets darker with increasing

ambient temperatures. To get a better contrast, the letters

on the display can be changed to more light colour. The

Enter key opens the entry display. The desired contrast is

set by the Direction keys ⇑⇓ inbetween a range of 0 to 7

(light coloured letters). The Enter key confirms the entry.

The Select key leads to the next menu point.

12.5.3 Calibration method

It is possible to choose or enable the calibration methods

by the Direction keys ⇑⇓:

• manual calibration,

• manual calibration offset,

• autocalibration offset,

• autocalibration.

With Enter you step into the calibration menu.

The desired function is set by the Direction keys ⇑⇓ , and

confirmed by the Enter key.

Enter

Enter to config.

Code: 0000

Select Enter

Select

LCD-contrast

(0...7):0

Enter

Enter

Select

cal. menu point

manual cal.

Select Enter

manual cal.

yes/no

Enter

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

↑

↑

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

Select leads to the next menu point.

Select

12.5.4 Calibration interval

This menu point determines the time steps (in hours) using

cal. interval

the autocalibration function (see 13.).

t in hours: 001

Enter opens the display, and the data input is operated by

⇑⇑

the Direction keys ⇑⇓ .

Enter

cal. interval

001

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

↑

↑

The Enter key confirms the entry, and the Select key leads

to the next menu point.

9-3.12-ME M&C Products Analysentechnik GmbH

Select Enter

Page 20

cal. current

off/on

- 20 -

12.5.5 Current signal with calibration

During the calibration a mA-signal can be put out as:

off mA-signal of the last measuring value

on current signal of the respective calibration gas

Select

cal. time [s]

fill: 090 cal: 095

Enter

Select

Select

meas. time [s]

fill: 000 meas: 02

Enter

Select Enter

press compens.

on/off

Enter

⇑⇑

⇑

⇑⇑

⇑⇑

⇑

⇑⇑

⇑⇑

⇑

⇑⇑

The Select key leads to the next menu point.

12.5.6 Calibration time

This menu point sets the backflush respectively calibration

time in case of the autocalibration function. The entry of the

time steps happens in seconds and counts backwards

from the final value (see 13.3). Enter opens the display, and

the data input is operated by the Direction keys ⇑⇓ .

⇓⇓

⇓

⇓⇓

The Enter key confirms the entry, and the Select key leads

to the next menu point.

12.5.7 Measuring time

This menu point sets the backflush respectively measuring

time in case of the measuring point switch function. Enter

opens the display, and the data input is operated by the

Direction keys ⇑⇓ .

⇓⇓

⇓

⇓⇓

The Enter key confirmsthe entry, and the Select key leads

to the next menu point.

12.5.8 Pressure compensation

↑

↑

A pressure compensation is implemented in the oxygen

analyser type PMA100. The compensation is switched on

or off via the Direction keys ⇑⇓ , and confirmed by the

Enter key.

⇓⇓

⇓

⇓⇓

Select

cal. p.-sensor

. . . %O

20.21 %O

20.21 %O

Select

2

Enter

Enter

Enter

The Select key leads to the next menu point.

12.6 Calibration of the pressure sensor

Three steps are necessary to calibrate the pressure sensor:

1. Air is given to the analyser under normal ambient pres-

P: . . .

sure. Operating the Enter key starts the calibration procedure. The cursor jumps to the first changeable point. If ne-

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

cessary the value for the current pressure can be corrected

operating the Direction keys ⇑⇓ . After operating the Enter

key the display changes. The first line shows the O2-concen–

tration and the pressure on the low level.

2

2

P: 1022

P: 400

2. The pressure has to be increased by minimum 300 mbar

(max. pressure 0,6bar), throttling the flow at the sample

outlet of the analyser. The second line on the display shows

the variable pressure.

3. After compensation of the two O2- readings (first and

second line) the calibration is confirmed operating the

Enter key.

The Select key leads to the next menu point.

Zero and span calibration have to be carried out after

calibration of the pressure sensor.

M&C Products Analysentechnik GmbH 9-3.12-ME

Page 21

- 21 -

• Current pressure

The Enter key opens the display to change the value for

the current pressure. The corrected value has no influence

on the O2- reading. The modified pressure value is con–

firmed by the Enter key.

current pressure

.....mbar

Enter

The Select key leads to the next menu point.

• Data output

The measuring data can be handed as follows:

• no data output,

• stored on the internal RAM,

• send to a Printer, or

• stored on RAM and send to a Printer.

Data stored on the internal RAM are available via the serial

interface.

The functions can be selected via the Direction keys ⇑⇓ ,

and confirmed by the Enter key.

The Select key leads to the next menu point.

• Memory clear

It is possible to reset the data memory with the Enter key.

Select leads to the next menu point.

12.7 Interface communication and passwords

12.7.1 Baud rate (correlation with the ser. interface

RS232)

The desired baud rate can be selected via the Direction

keys ⇑⇓ . Available are:

2400

9600

19200

38400

Select

data output

no / . . .

Enter

Select

memory clear

Enter cleared

Select

baud rate

2400 . . . 38400

Enter

↑

↑

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

↑

↑

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

The Enter key confirms the choice and the Select key

Select

leads to the next menu point.

12.7.2 Communication channel (communication with

the ser. interface RS232/485)

com. channel No.

To communicate with the serial interface of an external

device the COM port No. of the PMA100 has to be adapted

000

to the external COM port No. .

Enter opens the display to put in the COM port No. via the

Enter

Direction keys ⇑⇓ .

com. channel No.

000

Repeatedly operating the Enter key confirms the data

⇑⇑

input.

Select leads to the following menu point.

9-3.12-ME M&C Products Analysentechnik GmbH

Select Enter

Select

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

Page 22

STX&ETX char.

STX: $02 ETX: $03

Enter

Select Enter

Select

password 1

Code: 0001

⇑⇑

⇑

⇑⇑

- 22 -

12.7.3 STX and ETX character

It is necessary to determine a start respectively stop signal

for the communication on the basis of an AK protocol.

Enter opens the submenu. The first changeable position is

underlined and can be changed operating the Direction

⇓⇓

⇓

⇓⇓

keys ⇑⇓ . A jump to the next position happens via the

Select key. The entry has to be confirmed by the Enter key.

Operating once more the Select key leads to the next

menu point.

12.7.4 Change password level 1

The preadjusted password can be changed by a four-digit

individual code.

Enter

password 1

Code: 0001

Select Enter

Select

Select

D:x.xxx P :xxxx

T:xx.xx ADC :0...7

Enter

Enter

Select

⇑⇑

⇑

⇑⇑

⇑⇑

⇑

⇑⇑

Enter opens the submenu. The first changeable position is

underlined and can be changed operating the Direction

keys ⇑⇓ . A jump to the next position happens via the

Select key.

The code must contain a figure > 0.

⇓⇓

⇓

⇓⇓

The entry has to be confirmed by the Enter key.

Operating once more the Select key leads to the next

menu point.

12.7.5 Change password level 2

Follow the steps in chapter 12.7.4

Attention! Password 1 and password 2 must be different.

With Select you leave level 2 to the measuring menu.

12.8.1 Inquiry of the transducer channel

The display shows on the first line the analogue value (D) of

the transducer channel in [mV] and optional the current

pressure (P) in [mbar]. The second line displays the current

transducer temperature (T) in [°C] and the selected transducer

⇓⇓

⇓

⇓⇓

channel (ADC) and a number to change the display from the

standard (1) to the configuration of the valves (2), respectively to the configuration of the relays and alarms (0).

Operating the Enter key enables the choice of the

transducer channel (0-7, only standard configuration).

The following are functional:

3 = current analogue value ‘pressure’,

6 = current analogue value ‘O2-concentration’, and

7 = current analogue value ‘temperature’.

A renewed operation of the Enter key confirms the entry,

and the Select key leads to the next menu point.

12.8.2 Read NV-Memory Editor

read NV-memory

The NV-Memory Editor describes the basic respectively the

programming level of the analyser. An access to this level is

..$.........0

Select

M&C Products Analysentechnik GmbH 9-3.12-ME

only possible with the approval of the manufacturer.

The Select key leads to the next menu point.

Page 23

- 23 -

12.8.3 Device mode

This menu point selects via the Direction keys ⇑⇓ whether

the analyser works as a single-channel version or as a

multi-channel (max. 4 channels) version.

The choice is confirmed by the Enter key. If single-channel

version is selected the Select key leads to the beginning of

the menu.

Operating the Select key with the multi-channel version

leads to the next menu point.

12.8.4 Select channel

The channels 1 to 4 can be activated or deactivated by the

Direction keys ⇑⇓ .

The Select key leads to the next channel.

After the 4th channel, the Select key leads to the next menu

point.

12.8.5 Arrangement of the mA-outputs

At this menu point max. 4 channels can be reserved via the

Direction keys ⇑⇓ with mA-signals for the following

functions:

•O2- value channel 1 to 4,

• process pressure channel 1 to 4, and

• cell temperature.

The jump into the submenu happens via the Enter key.

The respective function is selected via the Direction keys

⇑⇓ , and confirmed by the Enter key.

Select leads to the next menu point.

device mode

single-chan. mod

Enter

Select

select channel

channel 1: on/off

Select

Select

select DAC

current output 1

Enter

Enter

Select

↑

↑

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

↑

↑

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

↑

↑

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

12.8.6 Set active valve

Maximum 8 solenoid valves are pre-reserved with an

identification No.

The Select key leads to the beginning of the menu.

set active valve

(1-8): 65071000

Enter

Enter

Select

↑

↑

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

9-3.12-ME M&C Products Analysentechnik GmbH

Page 24

zero conc.

xx.xx%O

Enter

zero conc.

(-)xx.xx%O

Select Enter

Select

Enter

span-conc.

00.00% O

Select Enter

Select

- 24 -

12.8 Zero- and span calibration

Cal

Operating the Cal key leads to the display represented

beside.

A jump into the entry mode of the zero calibration happens

automatically.

2

12.8.1 Zero gas concentration

Enter opens the display. The Direction keys ⇑⇓ operate the

input of the zero gas concentration (cross sensitivities see

chapter 13.2). The first changeable position is underlined

and can be changed operating the Direction keys ⇑⇓ . A jump

2

to the next position happens via the Select key. The entry

has to be confirmed by the Enter key.

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

The value for the zero gas concentration must be

lower than the value for the span gas concentration

Operating once more the Select key leads to the next menu

point.

12.8.2 Span gas concentration

Enter opens the display. The Direction keys ⇑⇓ operate the

input of the span gas concentration. The first changeable

position is underlined and can be changed operating the

Direction keys ⇑⇓ . A jump to the next position happens via

2

the Select key. The entry has to be confirmed by the

Enter key.

⇑⇑

⇓⇓

⇑

⇓

⇑⇑

⇓⇓

The value for the span gas concentration must be

higher than the value for the zero gas concentration.

Operating once more the Select key leads to the next menu

point.

Manual cal.

press Enter

Enter

0 calibration

00.00 d: (-)00.00

Enter

span calibration

00.00 d: (-)00.00

12.8.3 Calibration

Four calibration modes are available and pre-selected in

menu point 12.5.3:

• manual calibration,

• manual calibration offset,

• autocalibration offset, and

• autocalibration.

• Manual calibration

The Enter key starts the calibration procedure.

After reaching a stable level for the zero gas concentration

(line 2 displays the current value) pressing the Enter key

leads automatically to the span calibration. The deviation in

%O2 to the last calibration is shown on the display (value „d“ ).

After reaching a stable level for the span gas concentration

(line 2 displays the current value) pressing the Enter key

closes the calibration procedure, and the analyser jumps

automatically into the measurement level. The deviation in

%O2 to the last calibration is shown on the display (value „d“ )

during the calibration procedure.

A fault during the calibration procedure is represented on

the display as E ... followed by the message: O2-calibration.

The fault is also stored in the calibration log-book.

M&C Products Analysentechnik GmbH 9-3.12-ME

Page 25

- 25 -

• Manual calibration offset

Enter starts the calibration procedure.

autocal. offset

press Enter

After reaching a stable level for the span gas concentration

(line 2 displays the current value), pressing the Enter key

closes the calibration procedure. The analyser jumps automatically into the measurement level.

A fault during the calibration is represented on the display

as E ... followed by the message: O2-calibration.

The calibration fault is also stored in the calibration logbook.

• Autocalibration offset

Enter starts the procedure.

The calibration procedure happens automatically.

The analyser is purged with span gas. The purging time

which counts backwards is setted in menu point12.5.6

The next step is calibrating the analyser with span gas. The

calibration time is setted in menu point 12.5.6.

The time counts backwards. After reaching a stable value

the time steps double.

In the following the analyser is purged with sample gas for

the time mentioned above.

When the calibration procedure is finished, the analyser

jumps automatically into the measurement level.

A fault during the calibration is displayed as:

E ... O2-calibration, and is also stored in the calibration

log-book.

Enter

autocal. offset

21.00 d: (-) 00.00

Enter

autocal. offset

press Enter

Enter

inflate gas . . . sec.

21,00 %O

cal ref. . . . sec.

21.00 d: (-) 00.00

inflate gas

21.00 d: (-) 00.00

2

• Autocalibration

Enter starts the calibration. The times for purging and

calibration are setted in menu point 12.5.6.

First the analyser is purged with zero gas.

Then the analyser is calibrated with zero gas.

The same procedure happens with span gas.

Autocalibration

press Enter

Enter

inflate gas . . . sec.

21,00 %O

Cal zero . . . sec.

00.00 d: (-) 00.00

inflate gas . . . sec.

00,00 d: (-) 00.00

Cal ref. . . . sec.

21.00 d: (-) 00.00

2

9-3.12-ME M&C Products Analysentechnik GmbH

Page 26

- 26 -

inflate gas . . . sec.

21.00 d: (-) 00.00

Select Cal

calib. diff.

ofs: (-)x.x% g: x.x%

Select

cal. log-book

M 10.11.99 11:o7

Afterwards the analyser is purged with sample gas.

After finishing the procedure the analyser jumps automatically into the measurement level.

A fault during the calibration is displayed as:

E ... O2-calibration, and is also stored in the calibration log-

book.

The next menu point can be reached stepping into the

calibration mode via the Cal key and passing the previous

menu points with the Select key.

12.8.4 Deviation from calibration

The display shows the deviation from the basic calibration

carried out in the factory. The offset is given of the possible

deviation (±100%).

Select leads to the following menu point.

12.8.5 Calibration log-book

It is possible to read back the data (date and time) of the

last 9 calibrations via the Direction keys ⇑⇓ .

The kind of calibration is marked as follows:

M manual calibration,

O manual calibration offset,

S autocalibration offset,

A autocalibration.

A fault during the calibration is displayed as (e.g.) :

E O 10.11.9911:07

Select

Select leads to the beginning of the calibration

M&C Products Analysentechnik GmbH 9-3.12-ME

Page 27

- 27 -

13.Calibration

13.1 Calibration

Four calibration modes are available with the analyser PMA100:

• manual calibration,

• manual calibration offset,

• autocalibration offset, and

• autocalibration.

The calibration gases are given to the ‘sample in’ connection, located on the back panel of the PMA100 (see 8.1, fig. 7).

In case of autocalibration two respectively three valves are

controlled by the analyser menu. The connection of the calibration valves is described in chapter 8.2.

A detailed description of the menu-driven handling is given

in chapter 12.

Faults during the calibration procedure are displayed in the

main menu like:

E ... O2-calibration.

The fault message is also stored in the calibration log-book

with an E ... followed by the shortcut for the calibration

mode, the date, and the time the calibration is carried out.

If the zero and the span gas concentration deviates more

than 5Vol.-% to the adjusted concentration, a calibration

cannot be carried out. The deviation is displayed as an

error message.

In case of autocalibration flow through the analyser is

necessary. Otherwise an error message is displayed and

the calibration cannot be carried out. The offset calibration

is a single-point calibration and can be carried out, e. g.

with ambient air only.

The calibration modell depends on the fact that in spite of a

drift the zero point remains nearly to zero, and the calibration of the span gives a proper accuracy.

It is recommended to use a span gas concentration very

close to the required measuring range.

13.2 Cross-sensitivity

The paramagnetic measuring principle is based on the very

high magnetic susceptibility of oxygen. In comparison to

oxygen, other gases have such a minor susceptibility, most

of them are not even worth mentioning. Exception to this

are the nitrogen oxides. However, as this gas is in most

cases present in a very low concentration, the error is still

negligible.

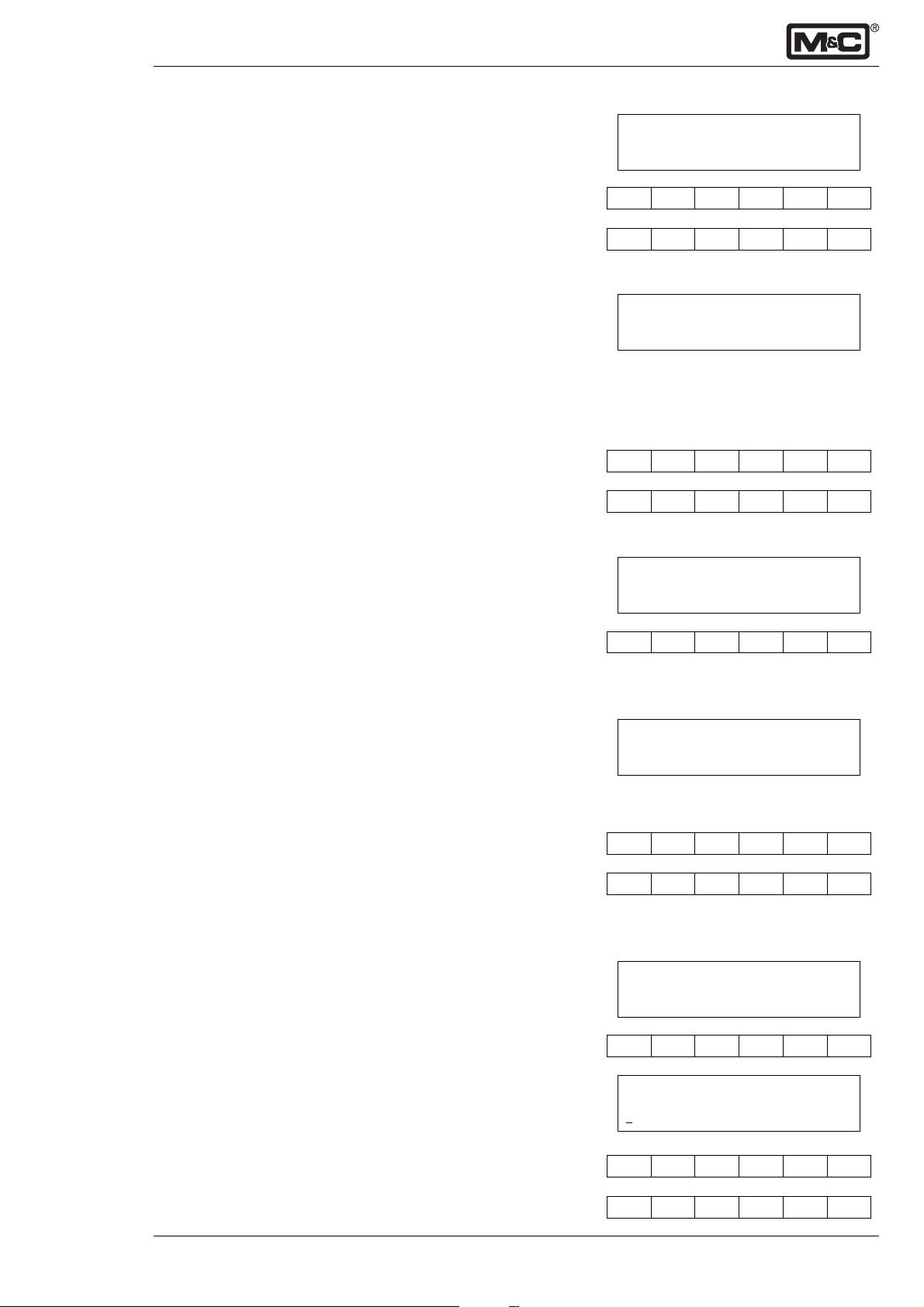

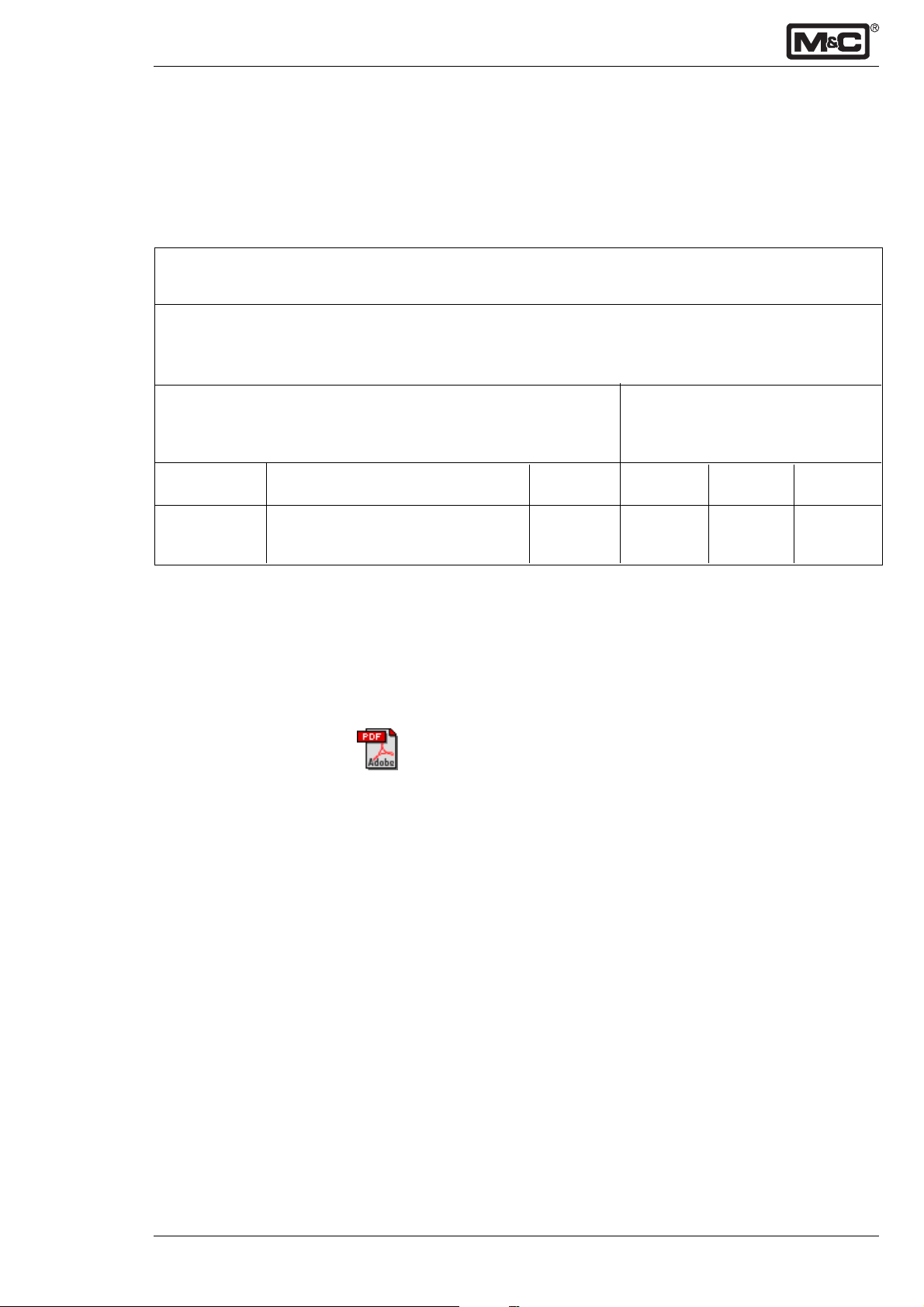

The next table shows a list of cross-sensitivities. All values

based on a zero calibration with 100 Vol.-% N2 and a span

calibration with 100 Vol.-% O2. The cross-sensitivities in the

table are valid for 100 Vol.-% of the corresponding gas.

9-3.12-ME M&C Products Analysentechnik GmbH

Page 28

- 28 -

Gas Formula + 20°C+50°C

Argon Ar - 0,23 - 0,25

Acetylene C2H

2

Acetone C3H6O - 0,63 - 0,69

Acetaldehyde C2H4O - 0,31 - 0,34

Ammonia NH

Benzene C6H

Bromine Br

Butadiene C4H

Methyl propene C4H

n-Butane C4H

Chlorine Cl

3

6

2

6

8

10

2

Hydrogen chloride HCL - 0,31 - 0,34

Nitrous oxide N2O - 0,20 - 0,22

Diacetylene (CHCl)

Ethane C2H

Ethylen oxide C2H4O

Ethylene C2H

Ethylene glycol (CH2OH)

Ethylbenzene C8H

2

4

2

4

2

10

Hydrogen fluoride HF + 0,12 + 0,14

Furan C4H4O - 0,90 - 0,99

Helium He + 0,29 + 0,32

n-Hexane C6H

14

Krypton Kr - 0,49 - 0,54

Carbon monoxide CO - 0,06 - 0,07

Carbon dioxide CO

Methane CH

Methylen chloride CH2Cl

2

4

2

Neon Ne + 0,16 + 0,17

n-Octane C8H

18

Phenol C6H6O - 1,40 - 1,54

Propane C3H

Propylene C3H

8

6

Propylene oxide C3H6O - 0,90 - 1,00

Propylene chloride C3H7Cl - 1,42 - 1,44

Monosilane SiH

Styrene C8H

Nitrogen N

4

8

2

Nitrogen oxide NO + 42,70 + 43,00

Nitrogen dioxide NO

Oxygen O

Sulphur dioxide SO

Silphur fluoride SF

2

2

2

6

Hydrogen sulphide H2S - 0,41 - 0,43

Toluene C7H

8

Vinyl chloride C2H3Cl - 0,68 - 0,74

Vinyl fluoride CH3F - 0,49 - 0,54

Water (steam) H2O - 0,03 - 0,03

Hydrogen H

2

Xenon Xe - 0,95 - 1,02

- 0,26 - 0,28

- 0,17 - 0,19

- 1,24 - 1,34

- 1,78 - 1,97

- 0,85 - 0,93

- 0,94 - 1,06

- 1,10 - 1,22

- 0,83 - 0,91

- 1,09 - 1,20

- 0,43 - 0,47

- 0,54 - 0,60

- 0,20 - 0,22

- 0,78 - 0,88

- 1,89 - 2,08

- 1,78 - 1,97

- 0,27 - 0,29

- 0,16 - 0,17

- 1,00 - 1,10

- 2,45 - 2,70

- 0,77 - 0,85

- 0,57 - 0,62

- 0,24 - 0,27

- 1,63 - 1,80

0,00 0,00

+ 5,00 + 16,00

+100,00 +100,00

- 0,18 - 0,20

- 0,98 - 1,05

- 1,57 - 1,73

+ 0,23 + 0,26

Fig. 10: Table of cross-sensitivities

M&C Products Analysentechnik GmbH 9-3.12-ME

Page 29

- 29 -

Example :

The residual oxygen percentage should be measured in a

closed 100% carbon dioxide (CO2) atmosphere. The „zerocalibration“ is done by means of Nitrogen (N2).

According to the list of cross-sensitivities the error for CO

at 20°C is -0,27%. In order to obtain a higher accuracy this

means for the calibration that the reading should be

adjusted at +0,27% with N2, in order to compensate the

error of CO2.

Since the values of cross-sensitivities are based on 100 Vol.-%

of that particular gas, the error at 50 Vol.-% CO2 and

50 Vol.-% N2 is -0,135%.

2

9-3.12-ME M&C Products Analysentechnik GmbH

Page 30

Meas. range 1

0 - 50Vol.-%

Meas. range 2

30 - 40Vol.-%

up

29 30 39 40 Vol.-%

0 1,82 18,12 20 mA

Fig. 11: Automatically range switch

hysteresis 10%

down

- 30 -

14.Measuring

The connections for sample gas inlet and outlet are located

on the back panel of the PMA100 oxygen analyser (see 8.1).

A detailed description of the menu-driven handling is given

in chapter 12.

Note!

The oxygen analyser PMA100 is suitable for continuous

measurements of oxygen concentrations in particle-free

and dry sample gases. Therefore it is recommended to use

a gas conditioning system downstream the analyser

equipped with a cooler and a particle filter.

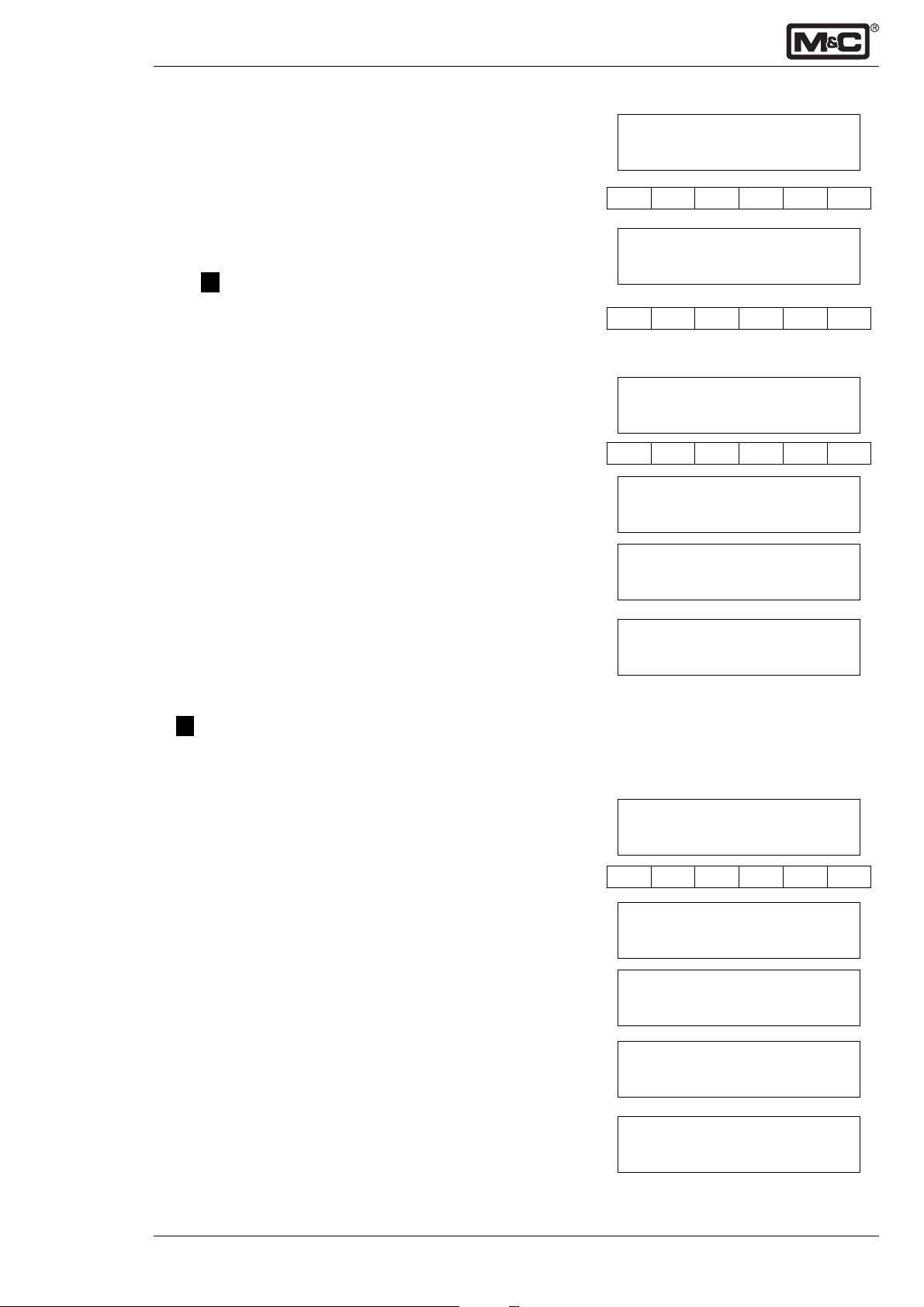

14.1 Automatically range switch

The function of the automatically range switch is pre-selected

in menu point 12.4.2 or via the serial interface. It is recommended to set unused measuring ranges to ‘0’ (see 12.4.3).

The analyser uses the suitable measuring range automatically.

Fig. 11 shows the switching between two overlapping

measuring ranges, 0 - 50Vol.-% and 30 - 40Vol.-%.

Going through the measuring ranges upward the analyser

switches exact at the range limits, in this example at 30Vol.-%

respectively 40Vol.-%.

Going down through the measuring ranges the autorange

hysteresis determines the interval switching into the next

lower range. The %-value, which is set in menu point 12.4.4,

is related to the smallest span of the switching relevant

ranges. The resultant value in Vol.-% O2 is added to the

respected range. The switching relevant range in the

example (30 - 40Vol.-%) is 10Vol.-%. This means a

switching interval of 1Vol.-% if the adjusted hysteresis is

10%. The switching points are at 39Vol.-% respectively

29Vol.-%.

The mA-output is related to the extended measuring range 2.

This means:

29Vol.-% - 0 mA, and

40Vol.-% - 20 mA .

14.2 Expanded measuring range

Expanded measuring ranges are selected in menu point 12.4.3.

The minimum range is 1Vol.-% O2. The selected mA-output

signal (see 12.4.5) is related to the respective span.

Example:

• measuring range 99 - 100Vol.-%,

• 4 - 20mA.

This means a resolution of 1/16Vol.-% O2 per mA.

Changing pressure can cause extremely high deviations using small measuring ranges without pressure

compensation.

M&C Products Analysentechnik GmbH 9-3.12-ME

Page 31

- 31 -

15.Function of in- and output contacts and

alarms

The following in- and output contacts are available at the

Sub-D socket X4 at the back panel of the analyser

(specification see 8.2.2):

• 4 binary inputs,

• 4 relay output contacts,

• 1 common relay alarm contact, and

• 1 common relay status contact.

The binary inputs can be reserved for the following funct–

ions (configuration see 12.4.9):

• external alarm: an external alarm signal, e.g. a cooler- or

liquid alarm from the conditioning system upstream the

analyser, can be locked on. This signal releases a respec–

tiv alarm message (alarm LED and display on the front

panel of the PMA100). If one of the output contacts is

locked on with ‘external alarm’ (see 12), the input signal

is passing through.

• set span: the measuring ranges 1 to 4 can be chosen

externally.

• autocalibration offset and autocalibration: starting signal

for the autocalibration functions.

• reset of stored alarms: alarms which are kept after the

release (see 12.4.8) can be resetted with a pulsed signal.

The function of the output contacts are as follows (configuration see 12.4.8):

• measuring range: this function gives a feedback about

the current active range. The ranges 1 - 4 can be selected.

• conc. alarm: it is possible to lock max. 4 concentration

alarms on the relay outputs (configuration see 12.4.11).

• calibration: a signal is given when the analyser works in

the calibration mode.

• flow alarm: in addition to the internal signals like alarm

LED, display or status contact the flow alarm can be

locked on one of the relay output contacts.

• external alarm: an external alarm signal can be passed

to one of the relay output contacts (see above).

Alarms are signalised via the alarm LED and the analyser

display. In addition to this a common alarm relay contact is

available. An exception is the concentration alarm. The

alarm limits are fixed in menu point 12.4.11. The display of

the concentration alarm (alarm LED, analyser display, common output or status alarm) must be confirmed separately

in menu point 12.4.11. An allocation of the concentration

alarm can be realised via the relay contact outputs (see

above).

9-3.12-ME M&C Products Analysentechnik GmbH

Page 32

The following alarm messages are available at the common

alarm output:

• concentration alarm 1 - 4 (if allocated, see above)