Page 1

PAS

Embracing Challenge

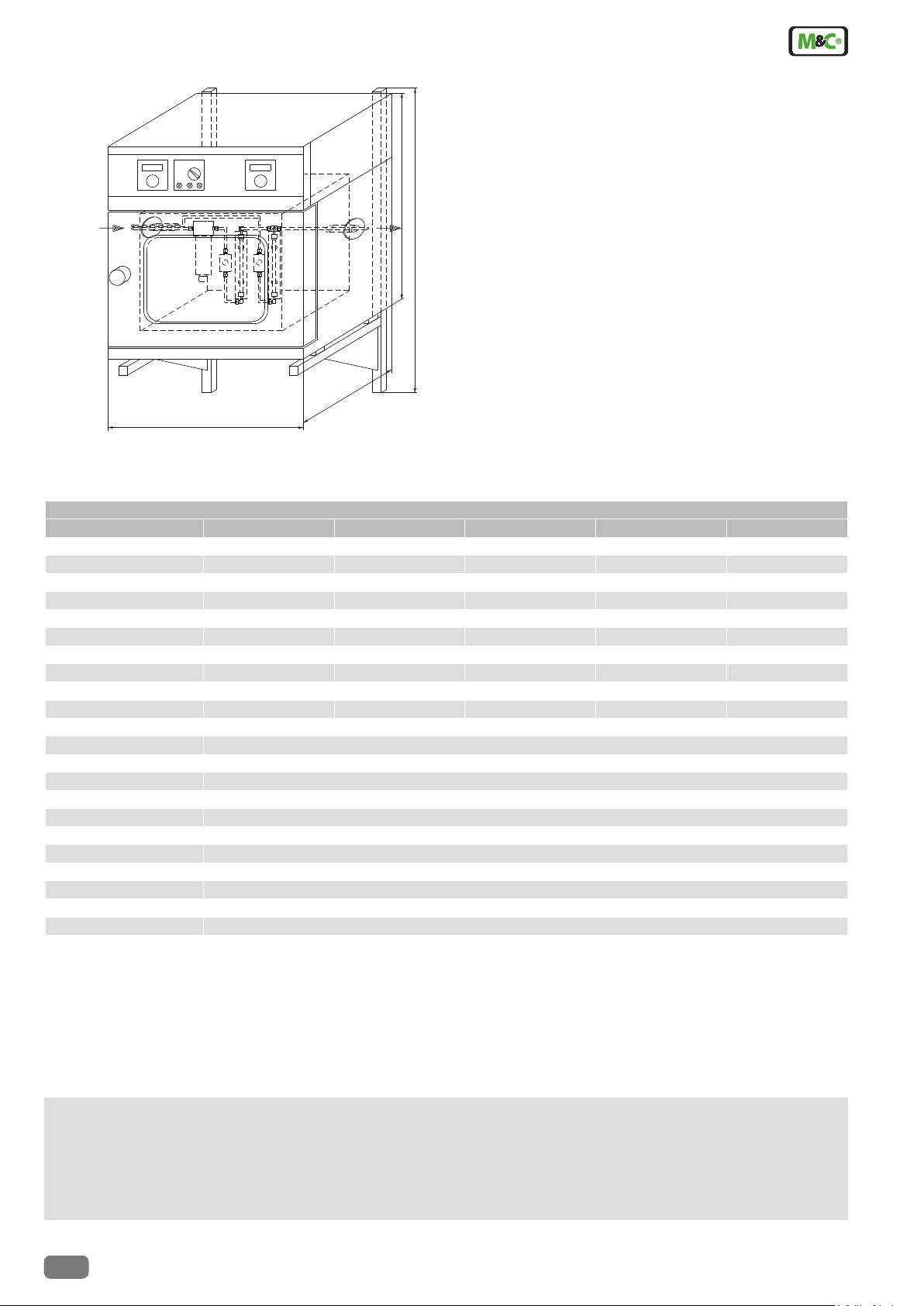

Heated, protective housing

Series PAS

enclosing customized components for

sample conditioning system

Special Features

Compact design

Electronically controlled heating

Digital temperature display

Twofold safety temperature limiter

Mounting of customized components

Easy-to-service tting of customized

components on a mounting plate

Individual designs possible

Bushings for sample pipes

Application

Heated M&C sample conditioning systems are

used where increased and constant operating

temperatures are necessary for the analysis of

gases or liquids.

The large M&C product range of heatable

components, in connection with the heated

PAS-... protective housing, allows you to solve

problems specific to your applications.

Description

The conditioning components are housed

in the protective cabinet (wall mounting) made of stainless steel, which is heat

insulated on all sides. The front door with

its single-knob lock enables easy access

to the accommodated components.

An observation window made of triple safety

glass is available as an option.

The heating of the cabinet is selectable within

the range of +20 to +200 °C. An exact, electronic control unit keeps the temperature

constant at ±1 °C. The temperature is displayed digitally. Two monitoring devices (temperature selection control and temperature

limiter), which are fitted additionally, ensure

safe operation. In order to distribute the temperature, a ventilator is fitted additionally into

models of size PAS-400 and above.

Depending on individual requirements the

following components can be installed:

• Filters

• Solenoid valves

• Valves, manually or pneumatically operated

• Ball valves, manually or pneumatically

operated

• Flowmeters with a needle valve and a

monostable flow control

• Pumps (pump head inside heated part,

motor outside)

• Customized parts

Suitable bushings into the heated interior are

provided for the heated sample lines.

Designs with European standard explosionproof heating up to 120 °C operating temperature or with steam heating as well as larger

cabinets are available on request.

Technical specications and illustrations are without

obligation, subject to modications. 09.96/01.07

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

14.7

Page 2

Dimensions

Technical Data

205 °C200 °C

H

( H )

T

B

Heated sample conditioning housing

Series PAS PAS-100 PAS-200 PAS-300 PAS-400 PAS-500

Assembly interior:

Width mm 320 400 480 400 560

Height mm 240 320 320 400 480

Depth mm 175 250 250 330 400

External dimensions:

Width B mm 470 550 630 550 710

Height H mm 520 (720)* 600 (800)* 600 (800)* 680 (880)* 760 (960)*

Depth T mm 325 400 400 480 550

Weight empty kg 20 28 30 35 50

Ventilator no no no yes yes

Power consumption 600 W 1100 W 1200 W 1400 W 2000 W

Power supply 230V 50/60Hz other voltages on request

Electrical connection 3 m mains cable with an earthing-pin plug; a suitable terminal box is provided for built-in components

Material of cabinet Stainless steel 304

Mounting Wall-mounting with optional wall console

Temperature control Electronically, microprocessor controlled, incl. a solid-state relay

Temperature display Digital LED display

Temperature limit Temperature selection control and limiter in accordance with DIN 12880, protective classification 3.1

Temperature selection Lockable rotary button, Range +20 to +200 °C (Standard)

Operating temperature > 5 °C above ambient temperature up to +200 °C

Ambient temperature max. +40 °C

Case protection IP20 EN 60529

Options: Observation window in door

External temperature control (2 x PT100 internal)

Min. temperature monitoring, status alarm contact, potential free, contact rating 250VAC 16A

EEx explosion-proof heating up to +120 °C inner operating temperature

Steam heating

Wall bushings for sample pipes

Built-in components specific to the system

* Dimensions in ( ) are corresponding to the total height incl. the wall console

Data required to submit an offer:

• Size

• Number, position and size of the bushings

• Details on built-in components

• Flow sheet, assembly drawing

• Required inner operating temperature

14.7

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 09.96/01.07

Loading...

Loading...