Page 1

Operating Manual

Diaphragm-sample pump series MP

®

Version MP47, MP47/R, MP47-Z, MP47-Z/R, MP47/D

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 2

2

List of content

1 General information ................................................................................................................ 4

2 Declaration of conformity ....................................................................................................... 4

3 Safety instructions .................................................................................................................. 5

4 Warranty ................................................................................................................................... 5

5 Used terms and signal indications ........................................................................................ 6

6 Introduction .............................................................................................................................. 7

7 Description ............................................................................................................................... 7

8 Ambient conditions ................................................................................................................. 8

8.1 Safety ..................................................................................................................................... 8

9 Technical data .......................................................................................................................... 9

10 Version MP47/R and MP47-Z/R with integrated needle valve type .../R for flow .................

adjustment ............................................................................................................................. 10

11 Version MP47 .../D with a double diaphragm safety system/ diaphragm ............................

breakage monitoring system ................................................................................................ 11

11.1 Application ........................................................................................................................ 11

11.2 Description ....................................................................................................................... 11

12 Flow sensor LPH 125-1-A-SPST incl. connection set MP47 .../D mounted on ....................

pump MP47 .../D ................................................................................................ ..................... 12

13 Receipt of goods and storage .............................................................................................. 12

14 Installation instructions ........................................................................................................ 13

14.1 Mechanical ....................................................................................................................... 13

14.2 Electrical ........................................................................................................................... 14

14.3 Pneumatic ........................................................................................................................ 15

15 Supply line connections ....................................................................................................... 16

15.1 Hose-/tube connections .................................................................................................... 16

16 Start up ................................................................................................................................... 16

17 Closing down ......................................................................................................................... 17

18 Maintenance ........................................................................................................................... 17

18.1 Exchange of the diaphragm ............................................................................................. 18

18.2 Exchange of the valve plates ........................................................................................... 19

18.3 Cleaning ........................................................................................................................... 19

19 Trouble shooting ................................................................................................................... 20

20 Spare parts list ....................................................................................................................... 21

21 Annexe .................................................................................................................................... 22

List of illustrations

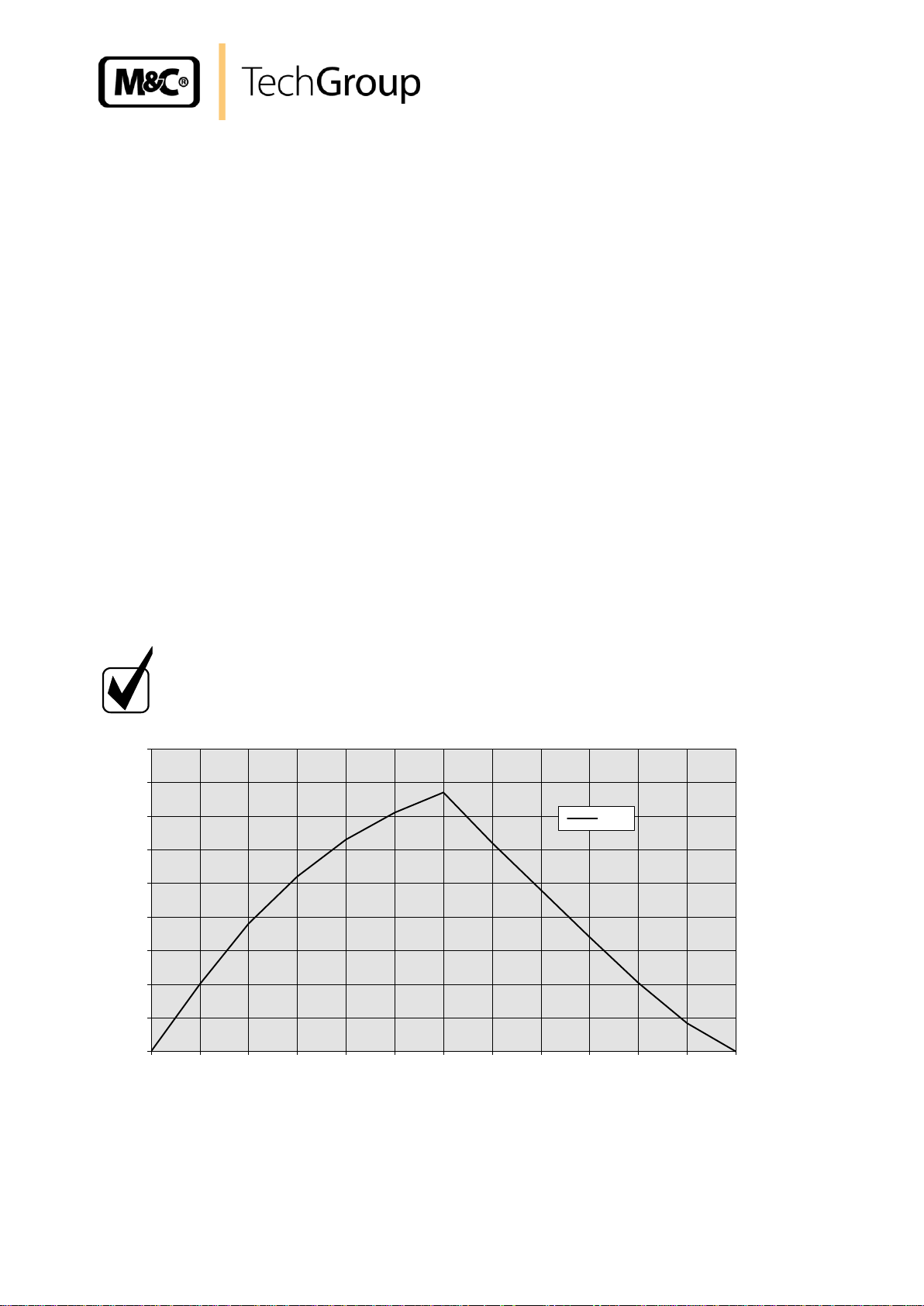

Figure 1 Pump capacity MP47 ........................................................................................................ 7

Figure 2 Pump type MP47/R ......................................................................................................... 10

Figure 3 Flow capacity type MP47/R ............................................................................................. 10

Figure 4 Flow capacity type MP47-Z/R ......................................................................................... 10

Figure 5 Pump MP47 .../D with the standard motor ...................................................................... 11

Figure 6 Pump MP47 .../D with flow sensor .................................................................................. 12

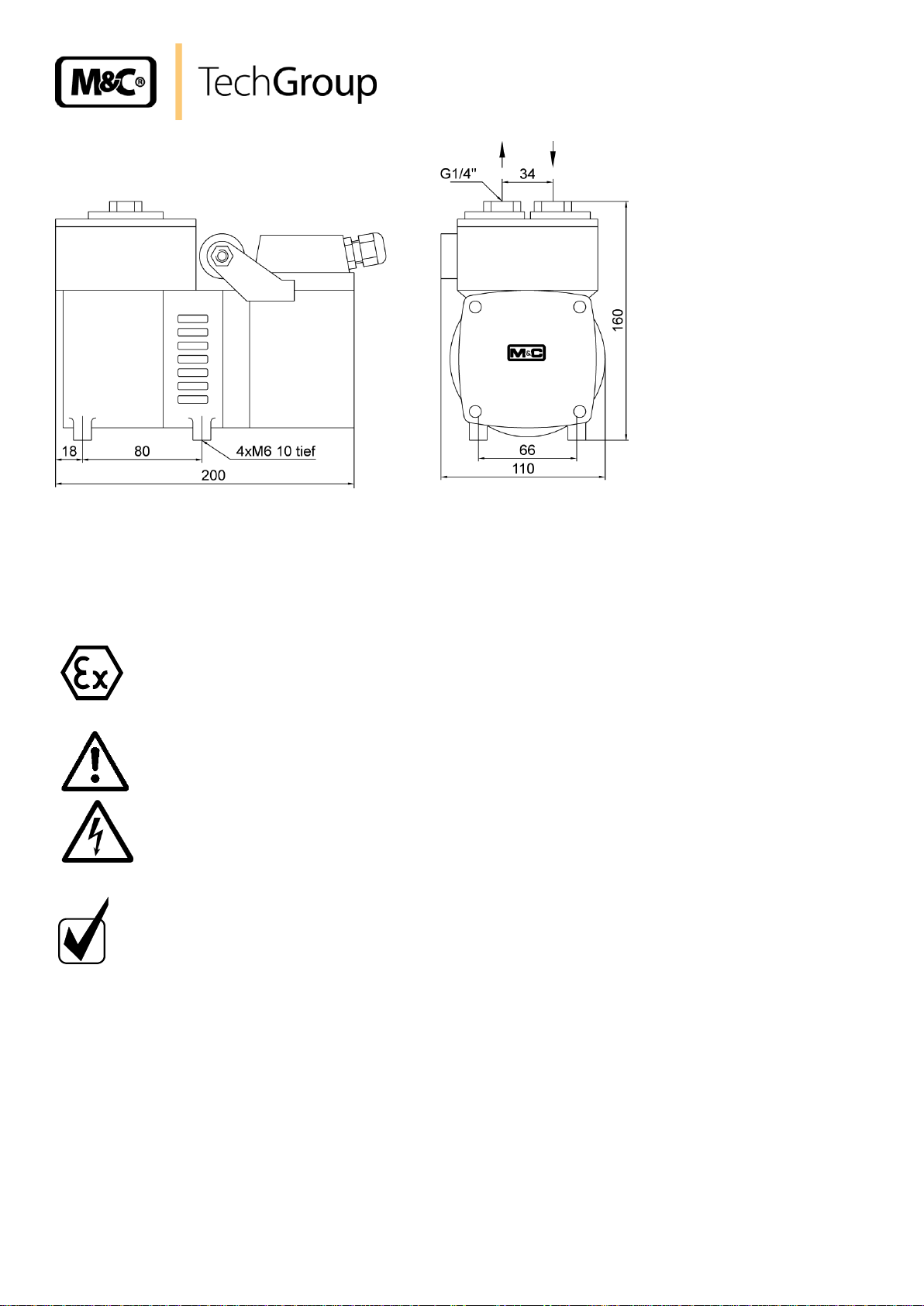

Figure 7 Dimensions (mm) pump MP47 ........................................................................................ 14

Figure 8 Electrical connection of the pump ................................................................................... 15

Figure 9 Sectional drawing pump MP47 ........................................................................................ 18

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 3

3

This Operating Manual does not claim completeness and may be

subject to technical modifications.

© 12/2001 M&C TechGroup Germany GmbH. Reproduction of this

document or its content is not allowed without permission from M&C.

MP® is a registered trade mark.

4th Edition: 03/2011

Dear customer,

we have made up this operating manual in such a way that all necessary information about the product can be found and understood quickly and easily.

Should you still have any question, please do not hesitate to contact M&C directly or go through your

appointed dealer. Respective contact addresses are to be found in the annexe to this operating manual.

Please also contact our homepage www.mc-techgroup.com for further information about our products. There, you can read or download the data sheets and operating manuals of all M&C products as

well as further information in German, English and French.

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 4

4

Head Office

M&C TechGroup Germany GmbH Rehhecke 79 40885 Ratingen Germany

Telephone: 02102 / 935 - 0

Fax: 02102 / 935 - 111

E - mail: info@mc-techgroup.com

www.mc-techgroup.com

1 GENERAL INFORMATION

The product described in this operating manual has been examined before delivery and left our works

in perfect condition related to safety regulations. In order to keep this condition and to guarantee a

safe operation, it is important to heed the notes and prescriptions made in this operating manual.

Furthermore, attention must be paid to appropriate transportation, correct storage, as well as professional installation and maintenance work.

All necessary information a skilled staff will need for appropriate use of this product are given in this

operating manual.

2 DECLARATION OF CONFORMITY

CE - Certification

The product described in this operating manual complies with the following EC directives:

EMV-Instruction

The requirements of the EC directive 2004/108/EC “Electromagnetic compatibility“ are met.

Low Voltage Directive

The requirement of the EC directive 2006/95/EC “Low Voltage Directive“ are met.

The compliance with this EC directive has been examined according to DIN EN 61010.

Declaration of conformity

The EU Declaration of conformity can be downloaded from the M&C homepage or directly requested

from M&C.

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 5

5

3 SAFETY INSTRUCTIONS

Please take care of the following basic safety procedures when mounting, starting up or operating this equipment:

Read this operating manual before starting up and use of the equipment. The information and warnings given in this operating manual must be heeded.

Any work on electrical equipment is only to be carried out by trained specialists as per the regulations

currently in force.

Attention must be paid to the requirements of VDE 0100 (IEC 364) when setting high-power electrical

units with nominal voltages of up to 1000 V, together with the associated standards and stipulations.

Check the details on the type plate to ensure that the equipment is connected to the correct mains

voltage.

Protection against touching dangerously high electrical voltages:

Before opening the equipment, it must be switched off and hold no voltages. This also applies to any

external control circuits that are connected.

The device is only to be used within the permitted range of temperatures and pressures.

Check that the location is weather-protected. It should not be subject to either direct rain or moisture.

The Diaphragm-sample pumps MP47, MP47/R, MP47-Z, MP47-Z/R, MP47/D must not be used in

hazardous areas.

Installation, maintenance, monitoring and any repairs may only be done by authorized personnel with

respect to the relevant stipulations.

4 WARRANTY

If the equipment fails, please contact M&C directly or else go through your M&C authorised dealer.

We offer a one year warranty as of the day of delivery as per our normal terms and conditions of sale,

and assuming technically correct operation of the unit. Consumables are hereby excluded. The terms

of the warranty cover repair at the factory at no cost or the replacement at no cost of the equipment

free ex user location. Reshipments must be send in a sufficient and proper protective packaging.

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 6

6

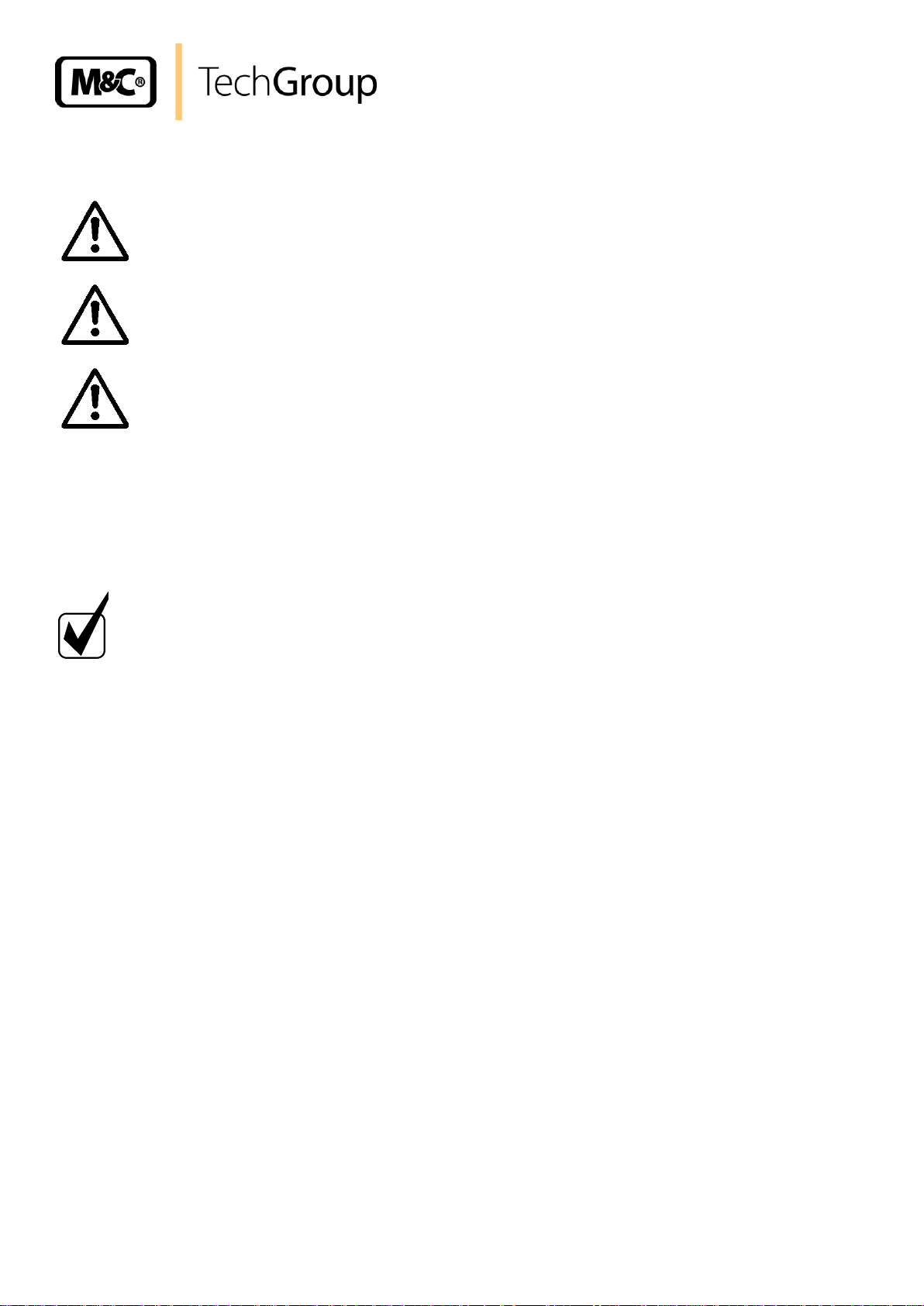

DANGER!

This means that death, severe physical injuries and/or important

material damages will occur in case the respective safety measures

are not fulfilled.

WA R NI N G!

This means that death, severe physical injuries and/or important

material damages may occur in case the respective safety measures are not fulfilled.

CARE!

This means that minor physical injuries may occur in case the

respective safety measures are not fulfilled.

CA R E!

Without the warning triangle means that a material damage may

occur in case the respective safety measures are not met.

AT T EN T IO N !

This means that an unintentional situation or an unintentional status

may occur in case the respective note is not respected.

NOTE!

These are important information about the product or parts of the

operating manual which require user’s attention.

SKILLED STAFF

These are persons with necessary qualification who are familiar with

installation, use and maintenance of the product.

5 USED TERMS AND SIGNAL INDICATIONS

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 7

7

0

50

100

150

200

250

300

350

400

450

0,4

0,5

0,6

0,7

0,8

0,9 1 1,2

1,4

1,6

1,8 2 2,2

l/hr

MP47

bar abs.

NOTE!

The diaphragm pump series MP47 ... are not allowed for liquid medium.

6 INTRODUCTION

This diaphragm pump MP47 ... is suitable for corrosive gases. It is constructed especially for problems in the analysis technique.

7 DESCRIPTION

The pump MP47 has a PTFE-head. All sample contacting parts are out of PTFE. The pump works

absolutely lubricant free, so gases remain analytically unchanged. Due to a special diaphragm and

valve system, the pump operates maintenance-free.

The MP47 ... is available in 230 V or 115 V and can be equipped with an EEx motor for applications in

hazardous areas as well.

The standard MP47 ... is designed for normal applications at a maximum gas flow of 6 l/min. Up to

flow rates of 17 l/min we recommend the type MP47-Z.

With the option MP .../R a needle valve is build into the pump-head to adjust the flow rate (see data

sheet 6-1.1.3).

M&C provides for the series MP47 ... pump as option a diaphragm breakage monitoring. MP47 .../D is

equipped with a special double-membrane safety system (see 6-1.1.5).

Maximum temperature for medium during operating: -30 °C ... +80 °C.

The pump must be protected from the effectes of dust and water.

Before use please check the compatibility of the material.

Figure 1 Pump capacity MP47

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 8

8

WA R NI N G!

It is therefore essential to provide protection for persons against

contact with live parts (e.g. electrical connections, motor windings) and moving parts (e.g. fan). Protection against the entry of

foreign bodies must also be provided.

WA R NI N G!

Aggressive medium is possible.

Wear protective glasses and proper protective clothing during

disassembly, repair or cleaning!

NOTE!

Components connected to the pump must be designed according

to the pneumatic performance of the pump (see technical data).

Take care that safety regulations are observed when connecting

the pump to the power supply. Specific safety instructions con-

cerning sample must be observed.

8 AMBIENT CONDITIONS

When the pump is operating the following ambient conditions must be maintained:

• Ambient temperature during operating: -10 °C .... + 40 °C.

• The pump must be protected from the effects of dust and water.

• During operating an adequate supply of air for cooling must be provided.

8.1 SAFETY

The protection class of the pumps MP47/MP47-Z is IP20 and so offer no protection against contact or

foreign bodies.

The pumps have no protection against water. In this case too, as far as is relevant, measures to protect the pump must be taken before start-up.

The pumps may only be used for their intended purpose.

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 9

9 TECHNICAL DATA

Diaphragm pump

MP47 /230V

MP47 /115V

MP47-Z /230V

MP47-Z /115V

Part No.

02 P 1000

02 P 1000a

02 P 1100

02 P 1100a

Power supply

230V 50Hz

115V 60Hz

230V 50Hz

115V 60Hz

Degree of protection

IP 20 - DIN 40050

Capacity max.

6,0 l/min* without pressure

0,85 / 1,25 bar abs., on suc-

tion/pressure side: 2,5 l/min

17 l/min* without pressure

Operating pressure

0,4 to 2,2 bar abs.

0,1 to 2,5 bar abs.

Sample temperature

-30 to +80°C

Ambient temperature

-10 to +40°C

Storage temperature

-15 to +60°C

Power consumption

110W

Current consumption

0,75A

1,7A

0,75A

1,7A

Gas connections

G1/4" i DIN ISO 228/1

Electrical standard

EN 61010 part 1

Material of sample contacting parts

PTFE

Weight

4,4 Kg

Material mark according to ISO 1629 and 1043.1

* Litre at standard conditions

9

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 10

10

Needle valve

Pump head

Sample gas

10 VERSION MP47/R AND MP47-Z/R WITH INTEGRATED NEEDLE VALVE TYPE

.../R FOR FLOW ADJUSTMENT

The integrated needle valve in the pump head is an internal bypass and allows to adjust the flow

capacity . In case of the optimal needle form, flow adjustment in a wide range is possible. All parts in

contact with sample are made from PTFE and PVDF. No O-rings are necessary.

Figure 2 Pump type MP47/R

Figure 3 Flow capacity type MP47/R Figure 4 Flow capacity type MP47-Z/R

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 11

11

66

18

80

20

110

180

G1/4"

4xM6 10 tief

34

124

G1/8

11 VERSION MP47 .../D WITH A DOUBLE DIAPHRAGM SAFETY SYSTEM/

DIAPHRAGM BREAKAGE MONITORING SYSTEM

11.1 APPLICATION

There are some applications - for example when processing with strong aggressive, high toxic or

hydrocarbon contaminated gases, it is necessary to install a high level safety system. For these applications, it is important to monitore continuously the tightness of the pump diaphragm.

11.2 DESCRIPTION

M&C provides for the series MP47... pump as option a diaphragm breakage monitoring. Below the

pump diaphragm, a monitoring area integrated as a pressure close area with a second diaphragm.

Both diaphragms form a sealed safety area. Via an optional flow sensor and an external compressed

medium, i.e. air or N2, it is possible to monitore continuously the tightness of the diaphragm.

Dimensions of analytical diaphragm pump with a double diaphragm safety system type MP47.../D.

Figure 5 Pump MP47 .../D with the standard motor

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 12

12

ø 28

51

NOTE!

The equipment should be stored in a protected, frost-free room!

LPH-7 l/hr

1/8“ NPT f

12 FLOW SENSOR LPH 125-1-A-SPST INCL. CONNECTION SET MP47 .../D

MOUNTED ON PUMP MP47 .../D

The optional available flow sensor LPH is provided with a mounting clip, 2x male connectors 1/8”- 2

mm and 0,5 m PTFE tube 1 x 2 mm.

Figure 6 Pump MP47 .../D with flow sensor

Fitting position: vertical

Alarm level: 7 l/hr

Switching function: NC or NO depending on mounting position

NC = lead of flow sensor in position at the top

Contact rating: DC max. 200 V, 50 W, 1 A; AC max. 150 V, 70 VA, 0,7 A

Material: Acrylic, PTFE, nickel-plate brass

As monitoring gas, it can be used N2 or with max. 1,7 bar,

depending on the application (at least, however, sample pressure plus 0,2 bar compressed air).

In case of a correctly functioning diaphragm pump, no monitoring gas will be consumed.

13 RECEIPT OF GOODS AND STORAGE

Please take the sample pump and possible special accessories carefully out of the packaging

material immediately after arrival, and compare the goods with the items listed on the delivery

note!

Check the goods for any damage caused during delivery and, if necessary, notify your trans-

port insurance company without delay of any damage discovered.

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 13

13

NOTE!

The pump must only be used in the conditions specified in the

technical data. The pump should be installed away from heat

sources and freely ventilated to prevent any accumulation of heat.

For outdoor installation, the pump must be installed in a housing

protected from frost in the winter and sufficiently ventilated in

summer. Exposure to direct sunlight must be avoided.

WA R NI N G!

It is therefore essential to provide protection for persons against

contact with live parts (e.g. electrical connections, motor windings)

and moving parts (e.g. fan). Protection against the entry of foreign

bodies must also be provided.

NOTE!

Pumps have mechanical moving parts that can induce vibrations.

To prevent damages at the pump or at peripheral components /

facilities as well as minimizing noise development an appropriate

vibration decoupling is necessary. For this M&C can deliver e.g.

anti-vibration pads.

This explicit is also valid for the connection of the sample lines at

the pump head.

14 INSTALLATION INSTRUCTIONS

When installing the pump make certain that accident prevention regulations and safety instructions

including those for subsequent operation are observed. The safety instructions in section 6.2 must be

observed.

The protection class of the pumps MP47, MP47-Z, MP47/R, MP47-Z/R, MP47D is IP20 and so offer

no protection against contact or foreign bodies.

14.1 MECHANICAL

The dimensions of the mountings are given in figure 7 and figure 8.

The pump is provided for assembly and therefore it has to be fastened with screws.

Install the pump so that the fan can draw in sufficient cooling air.

Install the pump so that accidental finger contact with the fan is impossible.

Mounting the pump at the highest place in system and/or with pump head downside so that

condensate cannot be assembled inside the head.

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 14

Figure 7 Dimensions (mm) pump MP47..

The diaphragm pumps type MP47, MP47/R, MP47-Z, MP47-Z/R,

MP47/D must not be used in hazardous areas.

WA R NI N G!

When connecting the equipment, please ensure that the supply

voltage is identical with the information provided on the model

type plate. The supply voltage is only allowed to deviate max. +6

% respectively -10 % from the indication on the model type plate.

NOTE!

Attention must be paid to the requirements of IEC 364 (DIN VDE

0100) when setting high-power electrical units with nominal voltages of up to 1000 V, together with the associated standards and

stipulations. Check the details on the type plate to ensure that the

equipment is connected up to the correct mains voltage. A main

switch and matching fuse must be provided externally (EN 60335-

1)! The main circuit of the pump type MP47 ... (230 V) must be

equipped with a protective motor switch 0,63 - 1 A corresponding

to the nominal current (over current protection) (EN 60335-1);

The main circuit of the pump type MP47 ... (115 V) must be

equipped with a protective motor switch 1 - 1,6 A corresponding

to the nominal current (over current protection) (EN 60335-1);

14.2 ELECTRICAL

14

When making the electrical installation the safety regulations must be observed. In particular make

sure that the electricity supply is isolated before trying to connect the pump.

The earthwire (ground) must be connected to the motor.

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 15

15

NOTE!

The pump must only be used in the conditions specified in the technical

data. The pump should be installed away from heat sources and freely ventilated to prevent any accumulation of heat. For outdoor installation, the pump

must be installed in a housing protected from frost in the winter and suffi-

ciently ventilated in summer. Exposure to direct sunlight must be avoided.

The pump must be installed so that contact with live parts (connections, possibly windings) is

impossible.

Figure 8 Electrical connection of the pump

Unscrew the cover of the connection box with the PG cable glands;

Put the cable through the cable gland and connect it according to figure 8; Connections are

marked in the connection box.

14.3 PNEUMATIC

Remove the protection plugs from the port threads (thread size G1/4”).

Accessories like hose connections are screwed into the port threads by sealing tape (using

M&C connectors sealing tape is not necessary).

Connect the suction and pressure lines.

Arrange the suction and pressure lines so that condensate cannot run into the pump.

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 16

16

NOTE!

The valve body must be fixed while mounting the fittings because moving

may change the pump capacity. Do not confuse hose-/tube connections for

sample gas inlet and outlet; the connections are labeled accordingly! Check

for tightness of all sample lines after connection! The tightness of the connections can only be guaranteed if the end section of the connection

hose/tube is flat (use a hose-cutter)!

15 SUPPLY LINE CONNECTIONS

15.1 HOSE-/TUBE CONNECTIONS

The gas inlet and outlet hoses/tubes are connected on the top of the pump. Standard G1/4" threaded

joints are available for the connection of the gas sample lines.

When connecting the sample gas supply hoses or tubes to the corresponding threaded connections,

pay attention to the following points:

Loosen the sleeve nut of the clamping-ring threaded joint by turning to the left. Take care that

the nut is removed carefully from the body of the threaded joint to avoid losing the clamping

ring which is mounted loose in the nut.

Push the sleeve nut over the connection hose/tube.

Push the clamping ring onto the connection hose/tube with the thicker bulge pointing to nut.

Push the hose/tube onto the supporting nipple in the threaded joint.

Tighten the sleeve nut by hand. The hose/tube is now mounted in such a way that it cannot

slip and is resistant to pressure.

The appropriate tube or hose threaded joint connections are available optionally from M&C.

16 START UP

Specific safety instructions for media being handled must be observed. Before pumping a medium,

the compatibility of materials of pump head, diaphragm and valves with the medium must be checked

(for pump materials: see technical data). The following steps should be carried out before initial startup:

The pump must not start against pressure or vacuum. When it is switched on the pressure in

the suction and pressure lines must be atmospheric. This must be so even when the pump restarts after the power has been cut off for a short period.

The maximum permissible operating pressure (see technical date) must not be exceeded,

even when the flow is restricted.

To prevent the maximum permissible operating pressure being exceeded, restriction or control

of the air or gas flow should only be carried out in the suction line.

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 17

17

NOTE!

The area in which the pump is situated when not in use must be

kept free of frost at all times!

WA R NI N G!

Aggressive medium is possible.

Wear protective glasses and proper protective clothing during

disassembly, repair or cleaning!

WA R NI N G!

It is necessary to take the pump off the mains before any assembly,

maintenance or repair work is carried out!

WA R NI N G!

Aggressive medium is possible.

Wear protective glasses and proper protective clothing during

disassembly, repair or cleaning!

If restriction or control of the air or gas flow is made on the pressure side ensure that the

maximum permissible operating pressure is not exceeded.

When the pump is at a standstill the inlet and exhaust must be at normal atmospheric pres-

sure.

Diaphragm and valve plates are the only parts subject to wear. Wear is usually indicated by a

drastic reduction in the pneumatic performance. When replacing parts proceed as described in

section 18.

Ambient conditions: see technical data.

17 CLOSING DOWN

If the pump is putting out of action for a short time no particular measures need to be taken.

18 MAINTENANCE

Before the maintenance work is carried out, it is necessary that the specific safety procedures pertaining to the system and operational process are observed!

Diaphragm and valve plates are the only parts of the pump subject to wear. They are simple to

change.

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 18

18

NOTE!

Always change valve plates, diaphragm and sealing rings at the same time.

Valve, suction side

Valve, pressure side

Figure 9 Sectional drawing pump MP47

Parts and tools required:

Valve plates and structured diaphragm (see spare part list , chapter 20)

Change the diaphragm and valve plates in the following sequence:

18.1 EXCHANGE OF THE DIAPHRAGM

Mark the position between housing A , diaphragm B and pressure plate C ;

Loosen the 4 hexagon screws H and remove the pressure plate C and the diaphragm head B ;

Unscrew the diaphragm K by hand out of the tapping hole of the rod L (counterclockwise);

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 19

19

WA R NI N G!

Aggressive medium is possible.

Wear protective glasses and proper protective clothing during

disassembly, repair or cleaning!

Loosen the 4 screws M and remove the cover N ;

Screw the new diaphragm K into the rod L hand-tight;

Turn the flywheel P until the rod L is in a central position. Control that the bulge of the dia-

phragm K fits to the groove of housing A ;

Fix the diaphragm head B and the pressure plate C according to the mark;

Fix the 4 hexagon scews H constantly over cross until the plate springs R are flat;

Turn the flywheel P and check whether it works proper;

Mount the cover N ;

18.2 EXCHANGE OF THE VALVE PLATES

Loosen the 6 hexagon screws D and remove the pressure ring E ;

Change the o-ring S at the valve body F on the pressure side;

Change the valve plate T . Check whether the protection ring U is in the right position and the

6 layers of the valve plate T point to the top;

Screw in the valve bodies F and tighten them in a moderate way;

Change the o-ring S on the sucking side;

Remove the valve plate T and change it with a new one. Check whether the protection ring U

is in the right position and the 6 layers of the valve plate T point to the bottom;

Screw in the valve bodies G and tighten them in a moderate way;

Put on the pressure ring E and tighten the 6 hexagon screws.

18.3 CLEANING

When changing valve plates and diaphragm, inspect all parts for dirt before assembling the

pump head and clean them if necessary.

As far as possible clean the parts with a dry cloth. Solvents should not be used as they can

attack the plastics and synthetic rubber parts. If a compressed air line is available, blow the

parts out with it.

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 20

20

Problem/Indication

Possible cause

Check/Action

Pump produces no

flow

No main supply

Check power supply; Check plug for correct

fit

Connections or lines are

blocked

Remove blockade

An external valve is closed or

a filter is blocked

Open valve or clean dirty/blocked filter

Liquid (condensate) has collected in the pump head

Let the pump for a few minutes pumping air;

Flow, pressure or

vakuum too low

Diaphragm or valves are

weared out

Change diaphragm or/and valves

Compare the actual perfor

mance with the figures in

the technical data

The pump is not designed for this condition

There is pressure on the

pressure side and at the same

time vacuum or a pressure

above atmospheric on the

suction side

The pump is not designed for this condition

The cross-section of the

pneumatic lines or connected

components is too small, or

they are restricted

To measure the performance, disconnect the

pump from the system (smaller diameter

tubing or a valve can significantly affect

performance)

A leak at a connector, in a

diaphragm/valve plate is

damaged or pump heads

dirty

Insulate the leak, tighten the screws, clean

or exchange dirty parts

NOTE!

If the pump does not operate properly and you cannot find any of the above

mentioned faults, send it back to M&C.

If you have been handling dangerous or highly aggressive gases please

clean the pump before dispatch.

For recommended spare parts please see section 20.

19 TROUBLE SHOOTING

Before working on the pump isolate the power supply securely, then check that the lines are not live.

The following tips for fault-finding are best employed in the sequence shown.

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 21

21

Diaphragm pump MP47, MP47/R, MP47-Z,

MP47-Z/R, MP47/D

(C) Consumable parts (R) Recommended spare parts (S) Spare parts

Recommended quantity

being in operation [years]

Part No.

Description

C/R/S

1 2 3

90P1108

Ring type U for valve chamberr MP47

R - -

1

90P1105

Diaphragm type K for MP47 Material: FPM,

PTFE coated

R 1 2

3

90P1113

O-Ring 25 f. MP47/Z/R, Material: FPM

R 1 2

3

90P1110

Valve type T f. MP47, 1 pc.

Material: PTFE (required 2 pcs.)

R 2 4

6

90P1111

Valve body type F/G 1/4”i for MP47

Material: PTFE

R 1 2

3

90P1112

Valve type F/G 1/4”i for MP47/R, MP47-Z/R

Material: PTFE

R 1 2

3

90P3025

Connecting rod for MP47 Type L

S - -

1

90P3027

Pump head top part for MP47 Material: PTFE

S - -

1

90P3028

Pump head top part for MP47/R, MP47-Z/R

with boring for needle valve Material: PTFE

S - -

1

90P6000

Needle from PTFE with screw part out of PTFE

for needle valve MP47-Z-NV (until 9.93)

S - -

1

90P6005

Needle from PTFE

for needle valve MP47-Z-NV (until 9.93)

S - -

1

90P6010

Seal ring out of PTFE

for needle valve MP47-Z-NV (until 9.93)

S - -

1

90P6030

Needle valve for MP47/R, MP47-Z/R (from

10.93) seal ring and needle out of PTFE

S - -

1

90P6015

Needle out of PTFE for MP-Z/R (from 10.93)

S - -

1

90P6020

Seal ring out of PTFE

for needle valve MP47-Z/R (from 10.93)

S - -

1

20 SPARE PARTS LIST

Wear, tear and replacement part requirements depend on specific operating conditions.

The recommended quantities are based on experience and they are not binding.

Gas sampling and gas conditioning technology 6-1.1.1-ME

Page 22

90P6025

Adapter out of PTFE

for needle valve MP47-Z/R (from 10.93)

S - -

1

PVDF Male connectors with G-thread (ISO 1010031)

05V1045

Male connector DN 4/6-G1/8” Material: PVDF

S - -

2

05V1050

Male connector DN 6/8-G1/8” Material: PVDF

S - -

2

05V6600

Verrule DN 4/6, PVDF

S 2 2

4

05V6602

Verrule DN 6/8, PVDF

S 2 2

4

05V6605

Union nut DN 4/6, PVDF

S 2 2

4

05V6607

Union nut DN 6/8, PVDF

S 2 2

4

21 ANNEXE

22

Further product documentation can be seen and downloaded from our home page:

www.mc-techgroup.com

Gas sampling and gas conditioning technology 6-1.1.1-ME

Loading...

Loading...