LTC-1

Embracing Challenge

Gas- and liquid coolers

Series LC, LT

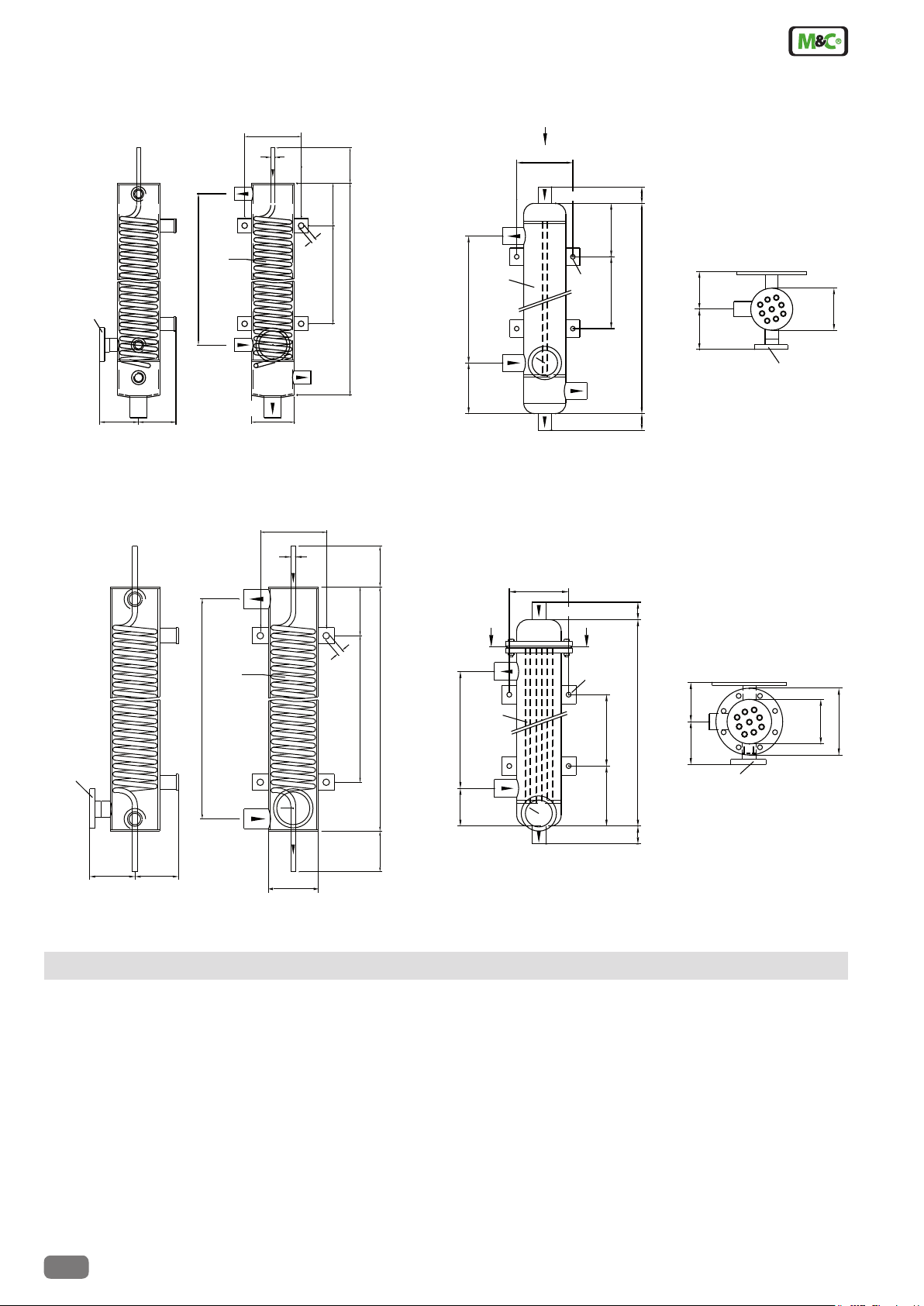

Jacket cooler with cooling coil

version LGC-1 (S), LC-1 (S)

Jacket cooler with bundle of tubes

version LGT-2, LTC-1

Special Features

Optimal cooling capacity

No stagnant space

Material stainless steel 316Ti

Dial thermometer

Wall mounting

Various connection sizes available

Other executions on request

Application

The M&C gas and liquid coolers series L... are

used in the analysis technique to decrease the

temperature of a liquid sample respectively to

cool down the dew point of a humid sample

gas.

The coolant for example is water. The countercurrent working principle guarantees an

optimised cooling process.

Description

The M&C gas coolers LGC-1 and the extended

version LGC-1S are equipped with a cooling

coil fixed in a completely welded steering

tube. An additional area at the bottom guarantees a sure separation of sample gas and

condensate.

The version LGT-2 is a tubular gas cooler with

a separation area as well.

The dial thermometer at the coolant inlet

indicates the approximate temperature of the

sample gas outlet dew point.

The condensate is removed by means of a

peristaltic pump, an automatic liquid drainer

or a collecting vessel.

The M&C liquid coolers LC-1 and the extended version LC-1S are equipped with a cooling

coil fixed in a completely welded steering

tube.

The version LTC-1 is a tubular liquid cooler.

Top and bottom of the cooler are designed as

distribution areas. The top of the cooler LTC-1

is removable.

The dial thermometer at the coolant inlet of

versions LC-1 and LC-1S respectively at the

bottom of version LTC-1 indicates the temperature of the sample outlet.

Liquid and gas coolers series L… are operating nearly maintenance-free.

The cooling effect and the stability of cooling are depending on the inlet temperature

of the coolant, the quantity of coolant, the

conditions of the sample inlet, the state of

aggregation of the sample, the ∆T between

coolant inlet temperature and sample outlet

temperature as well as the ambient temperature.

The quality of the coolant and the sample

must correspond to the material of the coolers.

Layout and calculation of the cooler are

effected in accordance with the specific application and operating data. Please specify all

available parameters along with your inquiry.

Technical specications and illustrations are without

obligation, subject to modications. 03.97/06.06

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

6.10

0

60

0-60°C

D

B

(6m)

E

A

(600)

(480)

(570)

6065

50

ø 6

80

60

ø 6,5

G3/8"i

3,5 m

300

180

C

270

G3/8"i

50

ø 60

Dimensions

Gas cooler LGC-1 (S)

210

0-60°C

65

60

Liquid cooler LC-1 (S)

G1/4"i

(510)

G1/4"i

E

3,5 m

(6 m)

D

G3/8"i

ø 6

80

ø 60

Gas cooler LGT-2

X

A

C

ø 6,5

B

50

150

G1/4"i

50

(450)

300

(600)

G3/8"i

0,6 m

560

G3/8"i

85

80

A

G3/8"i

E

D

G3/8"i

C

ø 6,5

B

G3/8"i

370

25

90

X

700

25

60

ø 60

65

0-60°C

Liquid cooler LTC-1

80

Dimensions in mm

460

A

G1/4"i

X

G3/8"i

E

0,53 m

G3/8"i

D

55

60

0

C

G1/4"i

B

ø 6,5

370

25

X

X-X

60

600

65

0-60°C

90

25

Connections: A: Sample IN B: Sample OUT C: Condensate OUT D: Coolant IN E: Coolant OUT

ø 60

ø 90

6.10

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 03.97/06.06

Technical Data

Coolant cooler Version L... LGC-1 (S) LC-1 (S) LGT-2 LTC-1

Part-No. 04K1000

S)

04K1500

Gas cooler with separation area yes no yes no

Liquid cooler no yes no yes

Cooling capacity approx. max. 900 kJ/hr / 1600 kJ/hr

Dimension cooling coil / bundle of pipes 1x 4/6 mm, length 3,5 m or 6 m

Sample connection INLET 1. tube ø 6mm o.d. tube ø 6 mm o.d. G3/8"i G1/4"i

Sample connection OUTLET 2. G1/4"i tube ø 6 mm o.d. G3/8"i G1/4"i

Condensate connection 3. G3/8"i G3/8"i

Coolant connection IN- and OUTLET 4./5. G1/4"i G3/8"i G3/8"i G3/8"i

Sample flow rate, recommended max. 500 l/hr 60 l/hr 700 l/hr 200 l/hr

Sample pressure max. 10 bar g max. 50 bar g max. 10 bar g max. 10 bar g

Coolant pressure max. 10 bar g max. 10 bar g max. 10 bar g max. 10 bar g

Coolant liquid flow rate 50-300 l/hr, depending on necessary cooling capacity, coolant temperature IN/OUT, etc.

Differential pressure ∆P sample side 30 mbar with 500 l/hr 0,7 bar with 60 l/hr 1 mbar with 500 l/hr 0,2 bar with 200 l/hr

Stagnant space sample side 175 ml / 210 m l

S)

Sample inlet temperature max. 300 °C max. 300 °C max. 300 °C max. 300 °C

Ambient temperature / Storage temperature +2 °C to +80 °C / -40 °C to +80 °C

Mounting / Material of medium touched parts Wall mounting / stainless steel 316Ti*

Dimensions (w x h x d) 110x400x125 mm / 110x700x125 mm

Weight 1,8 kg / 3,0 kg

S)

Options: Part-No.:

Pressure rating PN40 with certificate of conformity 04K9000

Bundle of pipes 10/12 mm 1) instead of 6/8 04K9010

Coolant connection G1/4"i instead of G3/8"i 4./5. 04K9015

Coolant connection G1/2"i instead of G3/8"i 4./5. 04K9020

Sample connection IN/OUT G3/8"i instead of G1/4"i 1./2. 04K9025

Sample connection IN/OUT G1/2"i instead of G1/4"i 1./2. 04K9030

Sample-, Condensate-, Coolant connection G1/4"i instead of G3/8"i

Sample-, Condensate-, Coolant connection G1/2"i intead of G3/8"i

04K2000

04K2500

S)

S)

S)

44 ml / 76 ml

S)

1,8 kg / 3,0 kg

04K4000 04K3000

max. 3600 kJ/hr / 6100 kJ/hr

1)

9x 6/8 mm, length LGT: 0,6 m LTC: 0,5 m

S)

370 ml 350 ml

120x750x125 mm 120x650x125 mm

S)

3,3 kg 3,6 kg

04K9035

04K9040

S)

= Extended version (S).

1)

= With option bundle of pipes 10/12 mm instead of 6/8 mm.

* Standard, others on request.

Maximum cooling capacity referring to super heated steam respectively liquid and sucient coolant.

Technical specications and illustrations are without

obligation, subject to modications. 03.97/06.06

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

6.10

Loading...

Loading...