Page 1

Liquid stop LB-1PV and LB-1SS

for protecting gas analysers and gas-phase

chromatographs against liquids

LB-1PV, LB-1SS

Special Features

Sure protection against liquid inrush

Reliable removal of liquid coming

through

Also suitable for high pressures

Available in stainless steel and PVDF

Easy change of the hydrophobic

protective membrane

With wall mounting holder

Application

The M&C liquid-stop LB-1.. is suitable for

protecting analysers against inrush of liquids

out of the gas conditioning unit which is

mounted before the analyser. This avoids

major damages of the analyser.

The most useful position of the liquid stop

LB-1.. is behind the gas conditioning unit,

directly before the flowmeter of the analyser.

5-1.10.9

Description

The hydrophobic protective membrane of

the liquid-stop LB-1.. is placed between the

two parts of the housing which are screwed

together. It is lined with a porous glass filter

frit in order to secure stable proportions.

The pore sizes of the protective membrane

are designed in such a way that gas molecules and steam can pass through but liquid

molecules are retained.

The gas inlet and outlet are positioned in

an horizontal line inside the housing. The

liquid outlet shows downwards when being

mounted.

Due to the horizontal flow direction of the

gases and because possible liquids are draining off on the protective membrane due to

its gravity, the leaking through of liquids to

the analyser is avoided.

Eventually occuring liquid can be let off via

a peristaltic pump SR25.1, separator and

automatic liquid drain ADS-SS or a condensate vessel TG1 (dip tank). The LB-1 has got a

respective connection possibility.

Changing the membrane is easy to handle.

The optimum positioning of the sealing

O-rings guarantees always a sure sealing of

both housing parts.

The filter inlet and outlet can be turned by

180° on the wall mounting holder so that a

flexible adaption to local circumstances is

possible during mountage.

10.03/11.06

M&C | TechGroup Germany GmbH

Rehhecke 79, D-40885 Ratingen

info@mc-techgroup.com

www.mc-techgroup.com

Fon +49 (0)2102 935-0

Fax +49 (0)2102 935-111

1

Page 2

2

5-1.10.9

M&C | TechGroup Germany GmbH

Rehhecke 79, D-40885 Ratingen

info@mc-techgroup.com

www.mc-techgroup.com

Fon +49 (0)2102 935-0

Fax +49 (0)2102 935-111

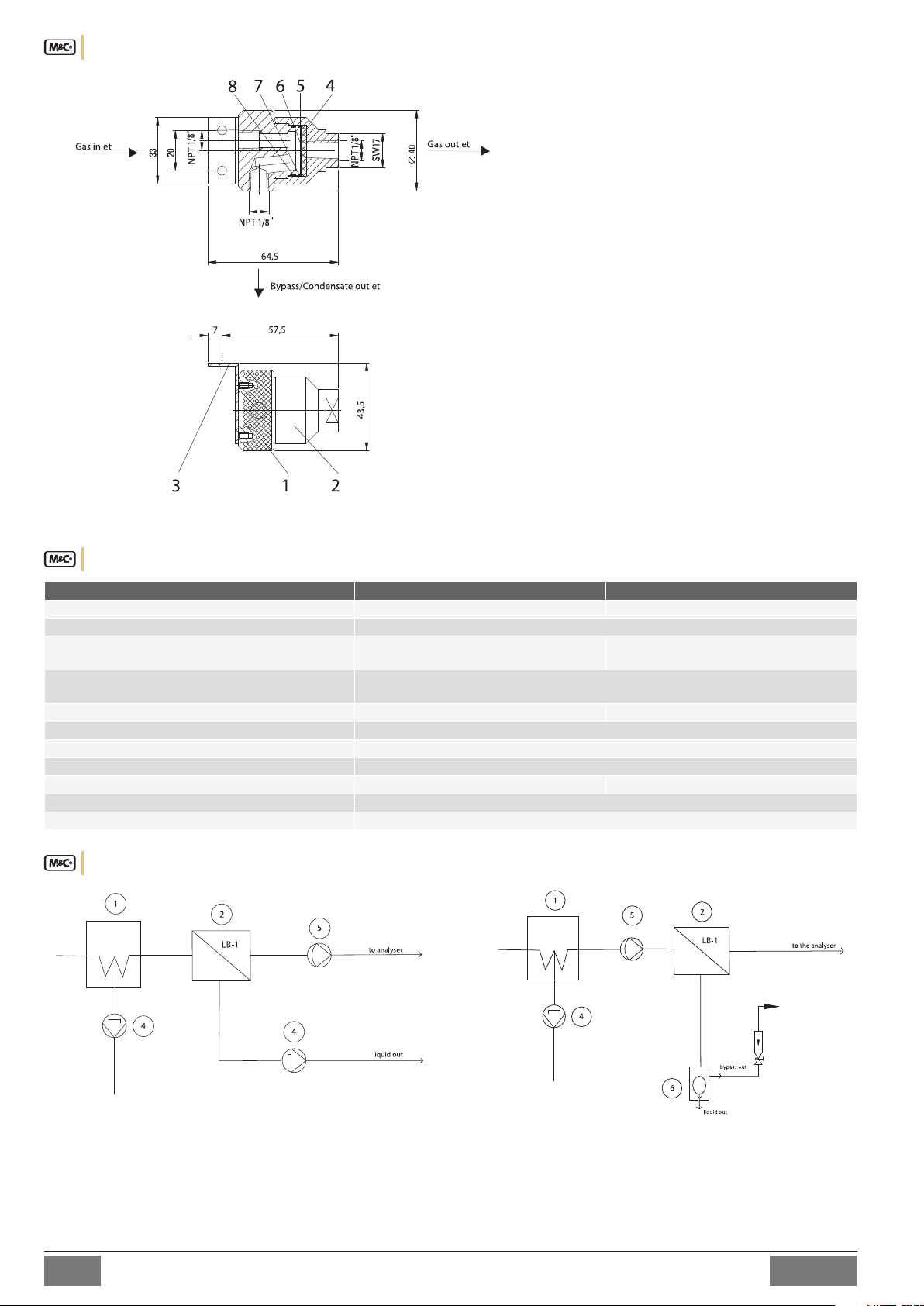

Dimensions

Dimensions in mm

1 Upper part of housing

2 Lower part of housing

3 Holding angle

4 Glass filter frit

5 Hydrophobic protective membrane

6 Flat ring of Teflon

7 O-ring FPM

8 O-ring FPM

Technical Data

Liquid-stop LB-1PV LB-1SS

Part No. 03F4005 03F4000

Gas flow max. 200 Nl/h

Gas pressure 0,3-2 bar abs.

∆P max. 0,5 bar

Differential pressure with clean

protection membrane, medium air, 20°C

Temperature sample gas max. +80 °C max. +100 °C

Ambient temperature 0 °C to +60 °C

Storage temperature -25 °C to +80 °C

Stagnant space 4 ml

Material of gas bearing parts PVDF, FPM, PTFE, Polyester, glass 1.4571, FPM, PTFE, Polyester, glass

Sample gas / drain connections NPT 1/8"i DIN ISO 228/1

Mounting / weight wall mounting / approx. 0,3 kg

50 100 mbar

100 200 Nl/hr

0,3 -10 bar abs.

∆P max. 0,5 bar

Examples for application

1 Gas cooler

2 Liquid-stop LB-1

4 Liquid drain with peristaltic pump SR25.1

5 Gas sample pump

6 Seperator and automatic liquid drain ADS-SS

Page 3

Upper part of housing

Lower part of housing

O-ring FPM

Glass filter frit

Flat-ring PTFE

Hydrophobic

protective membrane

Glass fibre surface

to be layed onto

glass filter frit

Attention: Do not touch on

the protective membrane!

O-Ring

Smooth side

Mounting bracket

Part No.:90F4010

Part No.:90F4005

Part No.:90F3515

Part No.:90F3510

Part No.:90F4000

Part No.:90F3520

Part No.:90F3525

Part No.:90F4020

Connection of the gas sample line

The connections (3 x 1/8”NPT i) for the gas sample lines are marked on the type plate and in the above drawing. They are executed with

respective screw fittings (see also data sheet 7-1.1) which are screwed gastight into the LB-1 with the aid of PTFE tape.

Changing the protection membrane

In case the hydrophobic protection membrane is dirty or overflowed so that the required flowrate is too short, it is advisable to exchange the

protective membrane incl. glass frit, PTFE flat ring and Viton O-ring (set I of spare parts, Part-No. 90F3530).

In case of interruption of the flow, the system has to be checked immediately!

During mountage attention must be paid to absolute cleanliness because impurities may impair the function of the LB-1!

By touching the surface with your hand, the protection membrane will be destroyed!

Aggressive condensate possible. Wear safety glasses and protective clothes!

For changing the protective membrane, unscrew the lower part of the liquid stop with the aid of an open-jawed spanner SW17. After this,

take out the O-rings and the glass frit, clean the housing parts and remount the LB-1 as shown below.

For a perfect function it is necessary that the protective membrane is positioned with its surface with fibre glass structure

onto the flat side of the glass frit! When changing the O-ring on the upper part of the LB-1 (Part-No. 90F4020), it is important

to draw up and not to roll up the O-ring. This way, a twisting and a respective leakage are avoided.

Part No. Description

90F4020 FPM O-ring for upper part LB-1

90F3515 FPM O-ring for CLF-5, CG-2 und LB-1

90F3525 PTFE flat ring for CLF-5 and LB-1

90F3510 Hydrophobic protective membrane for CLF-5 and LB-1

90F3520 Glass filter frit for CLF-5 and LB-1

90F4030 Spare part set LB-1 consisting of glass filter frit, protective membrane, flat ring PTFE, O-rings FPM

Recommended spare parts

Spare part set I Part No. 90F4030

including:

Protective membrane Part No. 90F3510

Glass filter frit Part No. 90F3520

Flat-ring PTFE Part No. 90F3525

O-ring FPM Part No. 90F3515

O-ring FPM Part No. 90F4020

5-1.10.9

M&C | TechGroup Germany GmbH

Rehhecke 79, D-40885 Ratingen

info@mc-techgroup.com

www.mc-techgroup.com

Fon +49 (0)2102 935-0

Fax +49 (0)2102 935-111

3

Loading...

Loading...