Page 1

LA 1S

Embracing Challenge

Liquid alarm sensors series LA®

for conductive media

Version LA 1S, LA 25S and ow chambers LS, LS 25 as well as

LA 1 and LA 25 for use in hazardous aereas

Special Features

Sure detection even of minimal liquid

quantities

line break monitoring for LA 1S and LA

25S

Integrable in M&C-Universal lters and

ow chambers

Also versions for higher pressure and

temperatures

No electrolytic eects on the sensor

surface

High chemical resistance

Cable length up to 100 meters

Application

Liquid alarm sensors are used in gas sample conditioning systems for monitoring gas

cooling and condensate drain-off devices in

order to provide protection for downstream

analysis instruments. This simple monitoring

device reliably signals the penetration of condensate in the event of cooling or condensate

drain-off equipment being defective and thus

avoids expensive down times as well as high

repair costs for analysis instruments.

In the event of alarm, the power for the

sample gas pump or a solenoid valve is to be

switched off in the gas sample conditioning

system.

Description

The M&C liquid sensors LA..S works on the

principle of electrical conductivity from 50

µS/cm conductance. In order to avoid electrolytic effects on the sensor surface, the sensors

are powered with alternating current.

The required electronic controller LA-1.. is

available in various versions and is described

in the separate data sheet 5-5.1.2.

Only the newly developed electronic controllers as described in the afore mentioned

data sheet from date of construction 04/2006

onwards can be used for the M&C liquid sensors LA..S.

The M&C LA..S liquid sensors are constructed

in such a way that any droplets of liquid in the

sample gas are attracted under gravity to the

sensor surface and even the smallest liquid

droplets trigger a sure and rapid alarm.

The LA 1S sensor is defined for operating

pressure up to 4 bar and LA 25S for up to 25

bar. The sensor protection corresponds to

type IP65 EN 60529.

The LA 1S sensor with its 12 mm diameter

glass body is mounted in the GL connection

of a F..-..-D universal filter or in the LS flow

chamber.

The LA 25S sensor has got a 1/4» special male connector for mounting in the

FSS..-D universal filter or for mounting in

8 mm tubes using a special union tee connector LS 25.

When mounting the universal filters and the

flow chamber, the gas inlet and gas outlets

can be rotated through 180° during assembly.

For hazardous areas the sensors LA 1 and LA

25 of the former series without line break

monitoring can be used because they are

«simple components». However the sensors

than may only be used with certified control

electronics, e.g. ER142 Exi (part no. 03E2009

for 230V or 03E2009a for 115V) for intrinsically

safe supply of the sensors.

Technical specications and illustrations are without

obligation, subject to modications. 09.96/11.06

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

8.1

Page 2

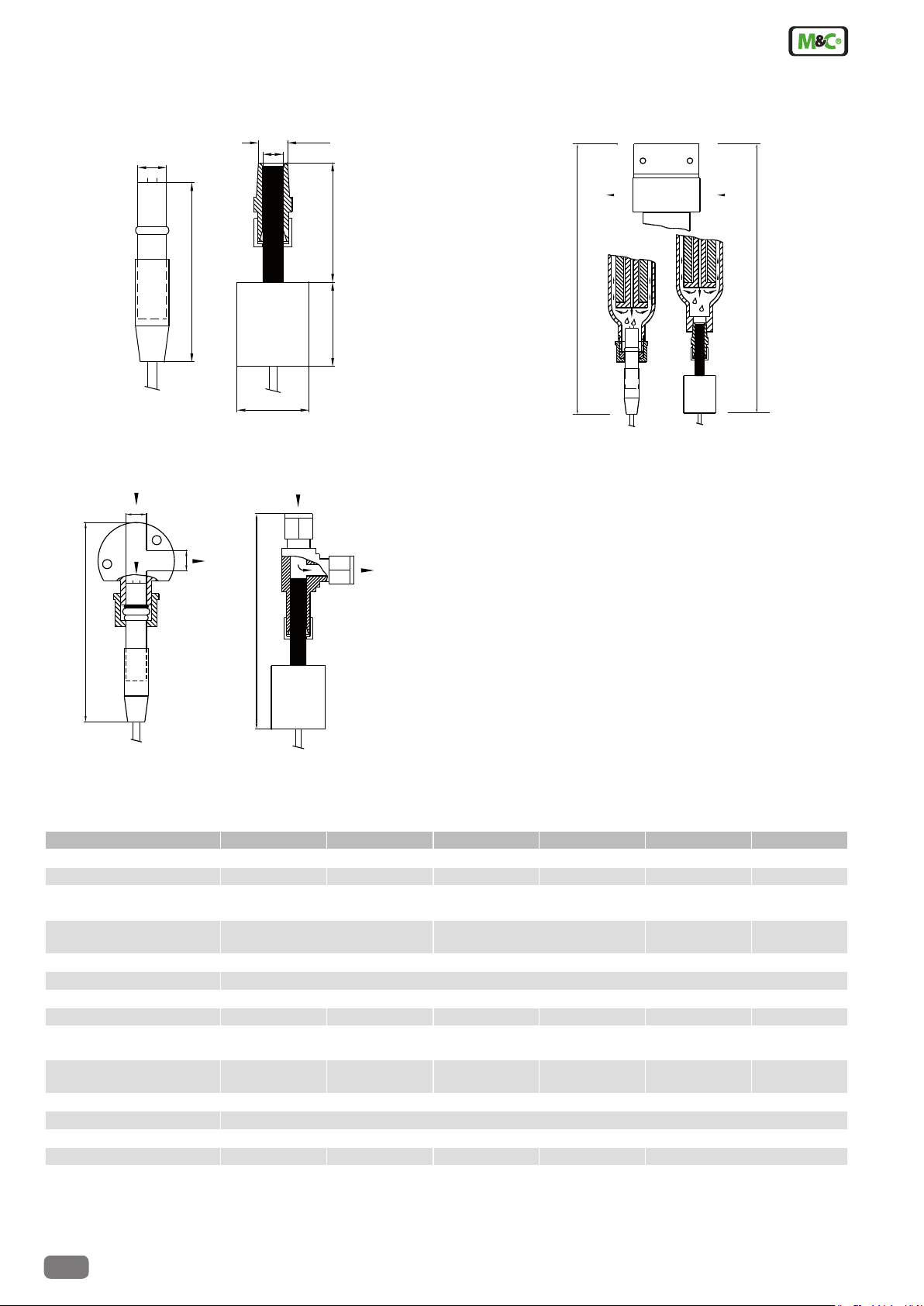

Dimensions

Liquid sensors LA 1S, LA 25S, LA 1 and LA 25

1/4"NPT

ø 12

ca.80

ø 8

LA 1S

LA 25S

ø 30

35 50

Liquid alarm sensors LA 1S and LA 25S with flow

chamber LS and LS 25

sample gas

G1/4"

sample gas

Liquid sensors LA 1S and LA 25S in universal

filter F..-..-D and FSS-..-D

sample gas

universal filter

F-..-D/FSS-..-D

LA1

sample gas

290

LA 25S

LA 1S

sample gas

G1/4"

sample gas

120

LA 25S

LS/LA

115

Dimensions in mm

Technical Data

Sensor series LA

Flow chamber LS LS 25

Part Number 03 E 1001 03 E 3100 03 E 1111 03 E 1120 03 E 1000 03 E 1110

Connection cable

ø 4,2 mm, 2-core

Pressure 0-4 bar g**** 0-25 bar g* (up to 100 bar g*) 0-4 bar g**** 0-25 bar g* (up

Flow 0-1000 l/hr

Operating temperature +80 °C ***

Gas connections ø12 mm G 1/4" i 1/4" NPT a ø8 mm** ø12 mm 1/4" NPT a

Stagnant space, approx. ca. 3 ml ca. 3 ml

Material of sample

contacting parts***

Type of mounting clamping attach-

Mounting position vertical

Electrical conductivity >50 µS/cm

Weight 50 g 60 g 140 g 100 g 50 g 140 g

Line break monitoring yes yes no

Operating in ex-areas no yes no yes

* other pressure ranges -, ** other dimensions -, *** other materials or temperatures on request

**** max. 2 bar when mounted in universal lter

Article numbers for combined lters or ow chamber sets including sensor and electronic controllers can be taken from the current article lists.

®

LA 1S LA 25S LA 1 LA 25

4 m

each additional meter of connection cable = part No. 03E 9001 (03 E 9000 for LA 1 and LA 25), total max. 100 meters

to 100 bar g*)

glass, platinium PVDF,

FPM

wall screw on pipe clamping attach-

ment

SS 316Ti

PVDF

SS 316Ti glass, platinium SS 316Ti

PVDF

screw on

ment

8.1

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 09.96/11.06

Loading...

Loading...