Page 1

Operating Manual

Liquid alarm sensors for conductive media Series LA

Version LA 1S and LA 25S

and flow chambers LS and LS 25

with electronic controllers LA 1.1, LA 1.4

®

Gas sampling and conditioning technology 5-5.1.1-ME

Page 2

2

This Operating Manual does not claim completeness and may be

subject to technical modifications.

© 01/2006 M&C TechGroup Germany GmbH. Reproduction of this

document or its content is not allowed without permission from M&C.

LA® is a registered trade mark.

2nd Edition: 05/07

Dear customer,

we have made up this operating manual in such a way that all necessary information about the

product can be found and understood quickly and easily.

Should you still have any question, please do not hesitate to contact M&C directly or go through your

appointed dealer. Respective contact addresses are to be found in the annexe to this operating

manual.

Please also contact our homepage www.mc-techgroup.com for further information about our

products. There, you can read or download the data sheets and operating manuals of all M&C

products as well as further information in German, English and French.

Gas sampling and conditioning technology 5-5.1.1-ME

Page 3

3

Contents

1 General information .................................................................................................................... 4

2 Declaration of conformity ........................................................................................................... 4

3 Safety instructions ...................................................................................................................... 5

4 Warranty ....................................................................................................................................... 5

5 Used terms and signal indications ............................................................................................ 6

6 Introduction .................................................................................................................................. 6

7 Application ................................................................................................................................... 7

8 Technical Data ............................................................................................................................. 7

9 Description ................................................................................................................................... 8

10 Receipt of goods and storage .................................................................................................... 8

11 Installation instructions and Dimensions ................................................................................ 9

12 Mounting .................................................................................................................................... 11

12.1 Pre-assembly at works in case of complete control units .................................................. 11

12.2 Mounting of the sensor LA 1S into the universal filter ........................................................ 12

12.3 Mounting of the sensor LA 1S into the flow chamber LS .................................................... 12

12.4 Mounting of the Sensor LA 25S onto the Universal filter .................................................... 13

12.5 Mountage of the Sensor LA 25S into the flow chamber LS 25 ........................................... 13

13 Supply connections .................................................................................................................. 14

13.1 Electrical connections ......................................................................................................... 14

13.1.1 Electronic controller LA-1.1 ....................................................................................... 14

13.1.2 Electronic controller LA-1.4 ....................................................................................... 16

13.2 Pneumatical connections ................................................................................................... 17

14 Starting ....................................................................................................................................... 17

14.1 Starting with a dry sensor ................................................................................................... 17

14.2 Function test ....................................................................................................................... 18

14.3 Adjustment of sensitivity ..................................................................................................... 18

14.4 Adjustment of alarm holding function ................................................................................. 19

15 Closing down ............................................................................................................................. 19

16 Maintenance and repair ............................................................................................................ 20

17 Spare parts list ........................................................................................................................... 21

18 Appendix .................................................................................................................................... 21

List of illustrations

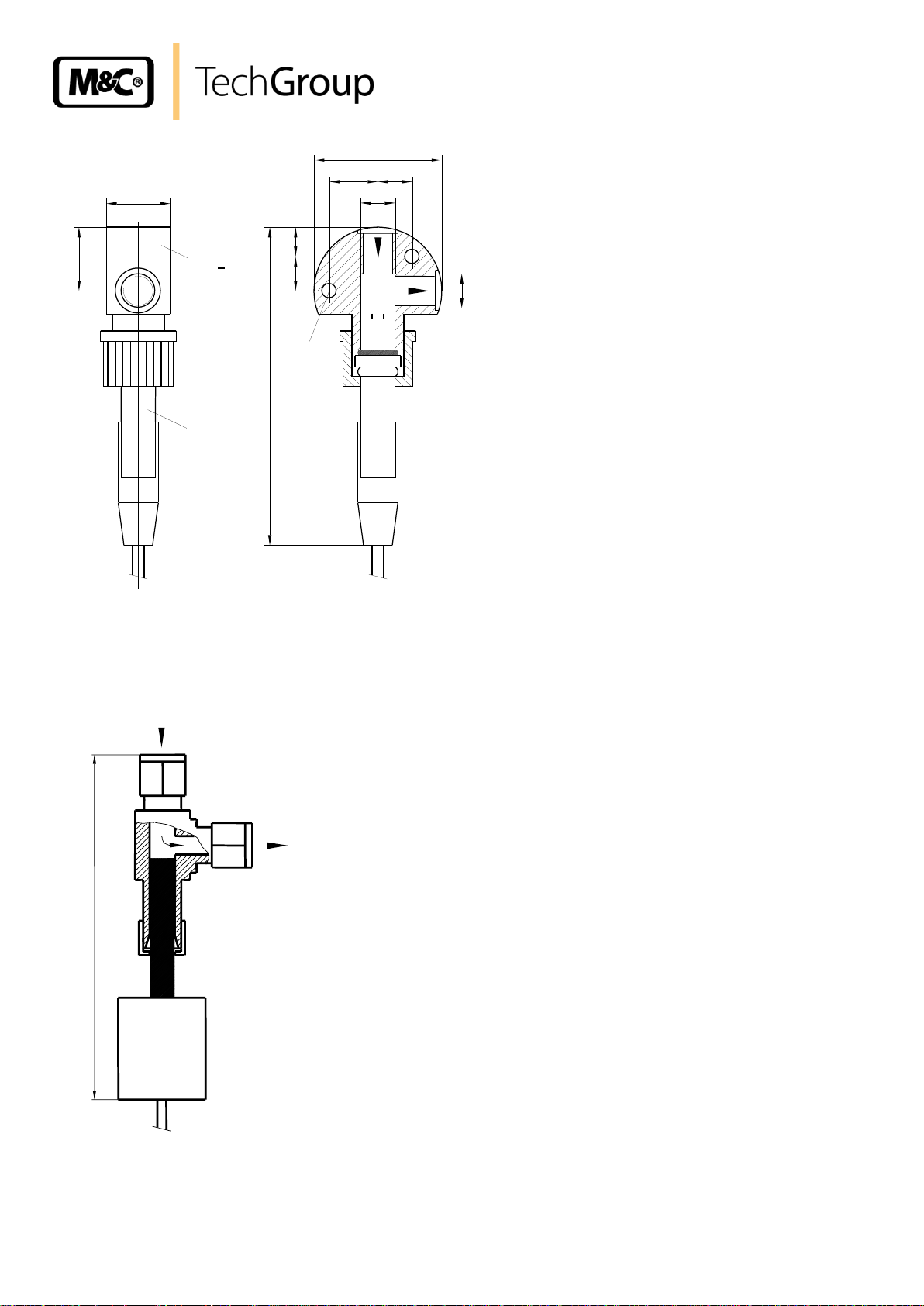

Figure 1 Flow chamber LS with liquid sensor LA 1S .................................................................... 10

Figure 2 Flow chamber LS 25 with liquid sensor LA 25S ............................................................. 10

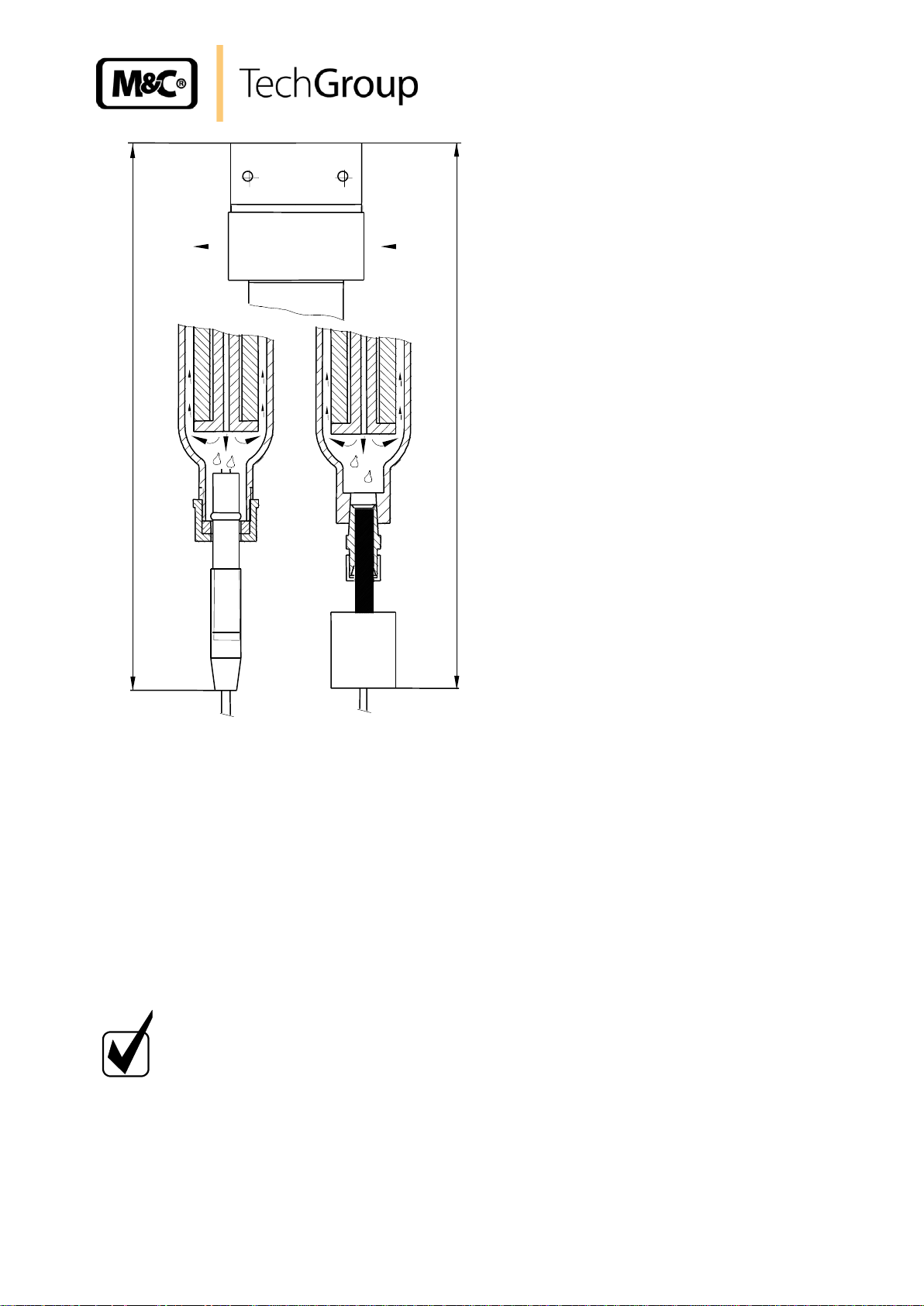

Figure 3 Liquid alarm sensor LA 1S and LA 25S with universal filter F..-..D and FSS-..-D .......... 11

Figure 4 Mounting of the sensor LA 1S into flow chamber LS ...................................................... 13

Figure 5 Electrical connection and dimensions LA-1.1 ................................................................. 15

Figure 6 Electrical connection and dimensions LA-1.4 ................................................................. 16

Figure 7 Insertion plan of the LA-1.4 ............................................................................................ 17

Figure 8 Flow diagram LA1.1, 115/230V 50/60Hz ........................................................................ 22

Figure 9 Flow diagram LA1.1, 24V AC/DC ................................................................................... 23

Figure 10 Flow diagram LA1.4, 115/230V 50/60Hz ........................................................................ 24

Figure 11 Flow diagram LA1.4, 24V AC/DC ................................................................................... 25

Gas sampling and conditioning technology 5-5.1.1-ME

Page 4

4

Head Office

M&C TechGroup Germany GmbH Rehhecke 79 40885 Ratingen Germany

Telephone: 02102 / 935 - 0

Fax: 02102 / 935 - 111

E - mail: info@mc-techgroup.com

www.mc-techgroup.com

1 GENERAL INFORMATION

The product described in this operating manual has been examined before delivery and left our works

in perfect condition related to safety regulations. In order to keep this condition and to guarantee a

safe operation, it is important to heed the notes and prescriptions made in this operating manual.

Furthermore, attention must be paid to appropriate transportation, correct storage, as well as

professional installation and maintenance work.

All necessary information a skilled staff will need for appropriate use of this product are given in this

operating manual.

2 DECLARATION OF CONFORMITY

CE - Certification

The product described in this operating manual complies with the following EC directives:

EMV-Instruction

The requirements of the EC directive 2004/108/EC “Electromagnetic compatibility“ are met.

Low Voltage Directive

The requirement of the EC directive 2006/95/EC “Low Voltage Directive“ are met.

The compliance with this EC directive has been examined according to DIN EN 61010.

Declaration of conformity

The EU Declaration of conformity can be downloaded from the M&C homepage or directly requested

from M&C.

Gas sampling and conditioning technology 5-5.1.1-ME

Page 5

5

3 SAFETY INSTRUCTIONS

Please take care of the following basic safety procedures when mounting, starting up or

operating this equipment:

Read this operating manual before starting up and use of the equipment. The information and

warnings given in this operating manual must be heeded.

Any work on electrical equipment is only to be carried out by trained specialists as per the regulations

currently in force.

Attention must be paid to the requirements of VDE 0100 (IEC 364) when setting high-power electrical

units with nominal voltages of up to 1000 V, together with the associated standards and stipulations.

Check the details on the type plate to ensure that the equipment is connected to the correct mains

voltage.

Protection against touching dangerously high electrical voltages:

Before opening the equipment, it must be switched off and hold no voltages. This also applies to any

external control circuits that are connected.

The device is only to be used within the permitted range of temperatures and pressures.

Check that the location is weather-protected. It should not be subject to either direct rain or moisture.

The electronic controllers LA-1.1 and LA-1.4 as well as the liquid sensors LA 1S and LA 25S in

combination with this electronic controllers must not be used in hazardous areas.

Installation, maintenance, monitoring and any repairs may only be done by authorized personnel with

respect to the relevant stipulations.

4 WARRANTY

If the equipment fails, please contact M&C directly or else go via your appointed M&C dealer.

We offer a one year warranty as of the day of delivery as per our normal terms and conditions of sale

and assuming technically correct operation of the device. Consumables are hereby excluded. The

terms of the warranty cover repair at the factory at no cost or the replacement at no cost of the

equipment free ex user location. Reshipments must be sent in a sufficient and proper protective

packaging.

Gas sampling and conditioning technology 5-5.1.1-ME

Page 6

6

DANGER!

This means that death, severe physical injuries and/or important

material damages will occur in case the respective safety measures

are not fulfilled.

WA R N ING !

This means that death, severe physical injuries and/or important

material damages may occur in case the respective safety

measures are not fulfilled.

CARE!

This means that minor physical injuries may occur in case the

respective safety measures are not fulfilled.

CA R E !

Without the warning triangle means that a material damage may

occur in case the respective safety measures are not met.

AT T E NT I O N!

This means that an unintentional situation or an unintentional status

may occur in case the respective note is not respected.

NOTE!

These are important information about the product or parts of the

operating manual which require user’s attention.

SKILLED STAFF

These are persons with necessary qualification who are familiar with

installation, use and maintenance of the product.

5 USED TERMS AND SIGNAL INDICATIONS

6 INTRODUCTION

The M&C liquid alarm units series LA® are designed for a continuous and stationary operation and

guarantee a long service life and a minimum maintenance work provided a perfect installation.

Gas sampling and conditioning technology 5-5.1.1-ME

Page 7

Sensor Series LA

®

LA 1S

LA 25S

Flow chamber

LS LS 25

Part Number

03 E 1001

03 E 3100

03 E 1111

03 E 1120

Connection cable

2 m 2 m

ø 4,2 mm, 2-core

each additional meter of connection cable = part No. 03E 9001, total max. 100 meters

Pressure

0 - 4 bar g****

0 - 25 bar g (up to 100 bar g*)

Flow

0 - 1000 l/h

Operating temperature

+80 °C ***

Gas connections

ø 12 mm

G 1/4" i

1/4" NPT a

ø 8 mm **

Stagnant space approx.

3 ml 3 ml

Material of sample

contacting parts ***

glass, platinum

PVDF,

FPM

SS316Ti,

PVDF

SS316Ti

Type of mounting

clamping attachment

wall

screw on

pipe

Mounting position

vertical

Electrical conductivity

>50 µS/cm

Weight

50 g

60 g

140 g

100 g

Electronic Controller Series LA® Type

LA-1.1

LA-1.4

Part Number

230V 50/60Hz

115V 50/60Hz

24V DC

24V AC

03 E 2001*

03 E 2001*

03 E 2001* d

03 E 2001* b

03 E 2006

03 E 2006 a

03 E 2006 d

03 E 2006 d

Mounting

Wall mounting housing Rail mounting housing EN 50022

Sensor inlets

1

Power consumption

2 VA

1VA

Alarm-relay (2x MC/NC/NO)

contact rating

250V DC/AC

DC=50W, AC=500VA, 3A

250V DC/AC

DC=45W, AC=500VA, 2A

Cable inlet

1x terminal range 3mm - 6,5mm

2x terminal range 5mm - 10mm

Electrical connection

Terminals max. 2,5 mm

2

Adjustment of switching point

Via potentiometer after opening of housing

Via potentiometer in the housing front

Distance between sensor and

electronic LA-1..

max. 100m

Line break supervision

yes

Alarm reset**

yes

Protection type

IP65 EN60529

IP20 EN60529

Housing material

Polycarbonate

Polyamide PA 6.6 combustibility class VO

(UL94)

Ambient temperature

-25 °C to +60 °C

Dimensions

B 80xL 160xH 55 mm

B 22,8 x L 100 x H 111 mm

Weight

0,31 kg

0,23 kg

7

7 APPLICATION

Liquid alarm sensors LA 1S and LA 25S are used in gas sample conditioning systems for monitoring

gas cooling and condensate drain-off devices in order to provide protection for downstream analysis

instruments. This simple monitoring device reliably signals the penetration of condensate in the event

of cooling or condensate drain-off equipment being defective and thus avoids expensive down times

as well as high repair costs for analysis instruments.

The electronic controllers LA-1.1 and LA-1.4 are used for feeding and signal processing of the liquid

alarm sensors LA 1S and LA 25S.

In the event of alarm, the power for the sample gas pump or a solenoid valve is to be switched off in

the gas sample conditioning system.

8 TECHNICAL DATA

* other pressure ranges -, ** other dimensions -, *** other materials or temperatures on request

**** max. 2 bar when mounted in universal filter

A Electronic controllers type LA-1.1 LA-1.4

Reversible distribution voltage 230V 50Hz / 115V 60Hz, at works adjusted to 230V 50Hz.

** at works deactivated

Gas sampling and conditioning technology 5-5.1.1-ME

Page 8

8

NOTE!

Only the newly developed electronic controllers as described in the afore

mentioned data sheet from date of construction 04/2006 onwards can be

used for the M&C liquid sensors LA..S.

AT T E NT I O N!

The special electronic controller ER142 Exi (without line break controller)

(Part No.: 03E2009 (a)) must only be used for the intrinsically safe feeding

of the old sensor versions LA 1 or LA 25 being installed in the EX-zone.

For application in combination with the new sensor versions LA 1S and

LA 25S no explosion protection is provided!

9 DESCRIPTION

The M&C liquid sensors LA..S works on the principle of electrical conductivity from 20 µS/cm

conductance. In order to avoid electrolytic effects on the sensor surface, the sensors are powered with

alternating current.

The M&C LA..S liquid sensors are constructed in such a way that any droplets of liquid in the sample

gas are attracted under gravity to the sensor surface and even the smallest liquid droplets trigger a

sure and rapid alarm.

The LA 1S sensor is defined for operating pressure up to 4 bar and LA 25S for up to 25 bar. The

sensor protection corresponds to type IP65 EN 60529.

The LA 1S sensor with its 12 mm diameter glass body is mounted in the GL connection of a F..-..-D

universal filter or in the LS flow chamber. The LA 25S sensor has got a 1/4" special male connector

for mounting in the FSS..-D universal filter or for mounting in 8 mm tubes using a special union tee

connector LS 25.

When mounting the universal filters and the flow chamber, the gas inlet and gas

outlets can be rotated through 180° during assembly.

Two mounting types are available, wall-mounting LA1.1 and rail-mounting LA1.4.

A line break supervision is integrated for sure operation. There are two LED’s for displaying

operational and fault status as well as two potential-free changeover contacts with "safety-first"

switching action for sure alarm signalling. The electronic controllers are equipped with an alarm reset

that may be activated or deactivated. During delivery, it is not activated.

By using one of the contacts, a pump or a solenoid valve in the gas conditioning system can be

switched directly and the second contact can be used as a status alarm.

The switching point of the electronic controller LA-1.. is adjustable via a potentiometer. At works, a

standard alignment is made for a conductivity of 100µS/cm.

10 RECEIPT OF GOODS AND STORAGE

The liquid alarm series LA® are normally delivered in 2 packing units:

1. Universal filter F.-..-D or flow chamber LS and liquid sensor LA ..S

2. Electronic controller LA-1...

Please take the liquid alarm units LA... and eventual special accessories carefully out of the

packaging material immediately after arrival, and compare the goods with the items listed on the

packing list.

Check the goods for any damage caused during delivery and, if necessary, notify your transport

insurance company without delay of any damage discovered.

Gas sampling and conditioning technology 5-5.1.1-ME

Page 9

NOTE!

The liquid alarm components should be stored in a protected frost-free

area !

NOTE!

NOTE!

During mounting, the gas inlet and gas outlet of the universal filters and

the flow chamber can be turned by 180°.

9

11 INSTALLATION INSTRUCTIONS AND DIMENSIONS

The liquid alarm sensor LA ..S is used for detecting liquids and is to be installed behind the gas

dehydration devices, e.g. behind a gas cooler, but always on the deepest point of the installation. This

is provided by the universal filters F.-..-D and the flow chambers LS or LS 25.

The filters F.-..D and the flow chambers LS are designed for wall mounting and are mounted by using

the 2 fastening screws.

The operating position is exclusively vertical, only then an immediate alarm is given in case of liquids

breaking through.

When mounting the devices outside, no special protecting measures are necessary provided that in

winter the ambient temperature does not fall below the dew point temperature of the measuring gas.

The gas inlet and outlet can be positioned on the left side or the right side of the filter, all you need to

do is to shift the blue angle bracket. Another inlet connection – supplied with a blind plug - is vertically

available. The flow chamber has got the gas inlet on the vertical position and the gas outlet according

to the fastening on the right side or the left side.

The flow direction is marked with arrows.

The standard gas connections of the universal filters F.-..-D and the flow chamber LS are G1/4" i.

The gas connections can be selected depending on the application, either soft and flexible tubes out

of PVC, Novoprene, FPM etc. or rigid tubes out of synthetic material like PTFE or metal e.g. stainless

steel.

For the suitable connection fittings please look into our range of products.

Gas sampling and conditioning technology 5-5.1.1-ME

Page 10

10

G1/4"

115

LA1

25

12

13

ø50

G1/4"

17 12

ø5

25

LS

Sample gas

Sample gas

LA 25S

LS 25

DN 8

DN 8

120

LA 1S

LS

Figure 1 Flow chamber LS with liquid sensor LA 1S

Figure 2 Flow chamber LS 25 with liquid sensor LA 25S

Gas sampling and conditioning technology 5-5.1.1-ME

Page 11

Universal filter

F..-..D / FSS-..-D

Sample gas

Sample gas

LA 25S

LA 1S

290

290

NOTE!

Please check before assembling that the clamping ring GL25-12 of

PTFE/silicone is not defect and is placed on the sensor, the white PTFE

surface pointing to the viewer (medium side). Only then, the necessary

leak-proofing is guaranteed.

11

Figure 3 Liquid alarm sensor LA 1S and LA 25S with universal filter F..-..D and FSS-..-D

12 MOUNTING

12.1 PRE-ASSEMBLY AT WORKS IN CASE OF COMPLETE CONTROL UNITS

In case you order a complete control unit consisting of liquid sensor, universal filter or flow chamber

and electronic controller, the mounting of the sensor into the respective installation device is effected

at works as far as possible.

For transportation, the sensor LA 1S of the universal filters F.-..-D is pre-assembled. The only thing

left to do is to mount the sensor LS 1S hand-tight by clockwise rotation of the red union nut GL25 into

the below GL connection of the filter.

The sensor LA 25S is to be screwed with the pre-assembled G1/4“ fitting into the thread of the

stainless steel filter body by using a tape of Teflon.

If the sensors are delivered in connection with a flow chamber, both are completely pre-assembled.

Gas sampling and conditioning technology 5-5.1.1-ME

Page 12

12

NOTE!

The PTFE/Silicone clamping ring GL25-12 must not be defective. Only then,

the necessary tightness is guaranteed.

NOTE!

The O-ring must not be defective. Only then, the necessary tightness is

guaranteed.

12.2 MOUNTING OF THE SENSOR LA 1S INTO THE UNIVERSAL FILTER

In case the client has selected single components, the mounting of the sensor has to be effected as

follows:

Dismount the red GL25 union nut incl. the inside GL25-12 clamping ring from the filter.

Tear the red anti-kink socket of the cable on the sensor LA 1S by slight swinging movements

backwards in direction of the connection cable of the sensor body.

Push the GL25 union nut on the sensor body with its inside thread showing to the sensor

beginning (platinum electrodes) backwards in direction of the red cable anti-kink.

Push the GL25-12 clamping ring with the white PTFE surface showing to the sensor beginning

(medium side) over the swelling on the sensor body.

Push the red union nut with clamping ring against the swelling on the sensor body.

Push the red anti-kink socket of the cable by slight swinging movements onto the sensor body

again.

Screw the red GL25 union nut with sensor onto the GL connection thread of the filter.

12.3 MOUNTING OF THE SENSOR LA 1S INTO THE FLOW CHAMBER LS

If the client has selected single components, the mounting of the sensor has to be effected as follows:

Dismount the union nut incl. the inside O-ring and the pressing ring from the chamber body.

Tear the red anti-kink cable socket by slight swinging movements from the sensor body over

the connecting cable.

Push the union nut with its inside threading showing to the sensor beginning (platinum

electrodes) over the connection cable onto the sensor body.

Push the PVDF pressing ring and afterwards the black FPM O-ring on the electrodes’ side up

to the swelling on the sensor body.

Push the union nut on the sensor body up to the swelling.

Put the sensor connection cable again through the black anti-king cable socket and push the

socket by slight swinging movements approx. 15 mm onto the sensor body.

Mount the sensor with union nut into the below connection of the flow chamber.

Gas sampling and conditioning technology 5-5.1.1-ME

Page 13

Union nut

Antikink

Item

Part-No.

Description

1

90 E 1000

FPM O-ring 14

2

90 E 1010

PVDF – pressing ring 16

3

03 E 1001

Liquid sensor LA 1S

with 4m connection cable

4

03 E 3100

Flow chamber LS

with union nut

13

Figure 4 Mounting of the sensor LA 1S into flow chamber LS

12.4 MOUNTING OF THE SENSOR LA 25S ONTO THE UNIVERSAL FILTER

If the client hat selected single components, the mounting of the sensor has to be effected as follows:

Screw the attached mounting fitting with a Teflon tape into the filter body.

Put the sensor with pre-assembled union nut and the pre-assembled pressing and cutting ring

into the fitting and draw up the union nut hand-tight. Then draw the union nut with a flat key

exactly 1 ¼ rotations. Now, it is mounted correctly.

12.5 MOUNTAGE OF THE SENSOR LA 25S INTO THE FLOW CHAMBER LS 25

If the client has selected single components, the mounting of the sensor has to be effected as follows:

Put the sensor with pre-assembled union nut and the pre-assembled pressing and cutting ring

into the flow chamber and draw the union nut hand-tight. Then draw the union nut with a flat

key exactly 1 ¼ rotations. Now, it is mounted correctly.

Gas sampling and conditioning technology 5-5.1.1-ME

Page 14

14

W A R NI N G !

Incorrect supply voltage may destroy the equipment. Please take

care of the correct voltage as indicated on the type plate!

The supply voltage may vary from the indication on the type plate

by max. ± 10%.

NOTE!

When setting high-power electrical units with nominal voltages of

up to 1000V, attention must be paid to the requirement of IEC 364

(DIN VDE 0100) as well as the associated standards and

stipulations!

NOTE!

Only the sensor types LA 1S and LA 25S provide a line break

control.

NOTE!

The connection cables of the sensors LA 1S and LA 25S are

normal 2-wire lines and can be extended up to 100m via usual

terminals if necessary.

The connection cables of the old sensors LA 1, LA 25 and LA 1-H

are special HF lines that must not be lead and extended via

normal terminals because those terminals interrupt the protective

cover of the line.

13 SUPPLY CONNECTIONS

13.1 ELECTRICAL CONNECTIONS

The electronic controllers LA-1.1 are equipped with a mains selector switch S3 for 230 / 115 V. At

works, this selector switch is adjusted to 230 V. Check the desired voltage before starting and, if

necessary, change the selector switch by using a screw driver.

The electronic controllers LA-1.4 in 24 V version are suitable for both, constant voltage and alternating

voltage.

When fixing the sensor cable to the installation, take care that the cable is not too short in order to be

able to dismount the sensor without problem for control or cleaning purposes.

13.1.1 ELECTRONIC CONTROLLER LA-1.1

For the electrical connection, the following steps are to be taken (see figure 4):

Loosen the 4 lid screws and remove the lid.

Lead the connection cables through the respective clamp fitting.

The electrical connection of the sensor LA 1S or LA 25S is made according the colours on the

terminals 5 = brown and 6 = white. All sensors of type LA 1, LA 25 and LA 1-H are to be

connected to terminals 5 = brown and 8 = white. In this case, a bridge must be installed

Gas sampling and conditioning technology 5-5.1.1-ME

between terminals 6 and 7.

Page 15

NOTE!

If the the old sensor LA 1, LA 25 or LA 1-H is connected the same way as

the new sensor LA 1S, the function of the electronic is inverted: no liquid =

alarm, liquid = o.K.

NOTE!

If a new sensor LA 1S is connected the same way as the old sensor LA 1,

LA 25 or LA 1-H no line break control is existing.

15

The voltage supply takes place on terminals 1 = L, 2 = N and 3 = PE.

The alarm is to be connected to terminals 11, 21 = centre contact, 12, 22 = alarm and 14, 24 =

o.k..

Figure 5 Electrical connection and dimensions LA-1.1

Gas sampling and conditioning technology 5-5.1.1-ME

Page 16

16

13.1.2 ELECTRONIC CONTROLLER LA-1.4

For the electrical connection, the following steps have to be carried out (see also figure 5):

The electrical connection of the sensor LA 1S or LA 25S is to be made on terminals 5 = brown

and 6 = white. Old sensors of type LA 1, LA 25 and LA 1-H are to be connected to terminals 5

= brown and 8 = white. In this case, you must install a bridge between terminals 6 and 7.

The voltage supply is to be effected on the terminals 1 = L, 2 = N and 4 = PE.

The alarms are to be connected on terminals 11, 21 = alarm, 12, 22 = centre contact and 14,

24 = o.k..

Figure 6 Electrical connection and dimensions LA-1.4

Gas sampling and conditioning technology 5-5.1.1-ME

Page 17

17

Figure 7 Insertion plan of the LA-1.4

13.2 PNEUMATICAL CONNECTIONS

For the connection of the measuring gas lines and when using the universal filters F..-..-D and the flow

chamber LS, you must use two fittings with thread G1/4“ a and the corresponding tube and pipe

connection. The screw fittings have to be screwed into the universal filter respectively the flow

chamber by using PTFE tape.

The flow chamber LS 25 is already equipped with screw fittings for 8mm tubes.

Regarding mounting of the tube and pipe lines:

Dismount the union nuts as well as the pressing and cutting rings from the fitting.

Push the union nut, then the pressing ring, then the cutting ring onto the tube resp. Pipe line.

Put the tube resp. Pipe into the fitting and draw up the union nut hand-tight.

Then the stainless steel nuts have to be drawn up by using a flat key by exactly 1 ¼ rotations

and it is correctly mounted.

14 STARTING

14.1 STARTING WITH A DRY SENSOR

Switch on the mains voltage, the green LED of the electronic controllers LA 1.1 resp. LA1.4 are

beaming.

The liquid alarm control is ready for work!

Gas sampling and conditioning technology 5-5.1.1-ME

Page 18

18

NOTE!

If the sensor is dry, the green LED indicates that the instrument is

in operating condition, the green LED is out when the red LED is on

and signalizes a liquid alarm.

NOTE!

If the alarm is not activated when executing the function test, the

sensor, the electronic controller and the connections must be

examined.

NOTE!

The sensor LA 1S is only able to detect condensate with a

conductance ration of min. 20 µS/cm.

Therefore, it is advisable to check the sensor function with the

eventually occuring condensate. For this purpose, dismount the

sensor and execute the above described function test with the

respective condensate.

W A R NI N G !

Aggressive condensate possible. Wear protective glasses and

protective clothes when dismounting, repairing or cleaning the

sensor!

In case the read alarm LED is beaming, there is liquid on the sensor, or there is a line break, or you

must do an adjustment of the sensitivity (see chapter 14.3).

14.2 FUNCTION TEST

The responsiveness of the sensors LA 1S and LA 25S should be examined before the first starting

and afterwards two times a year and is to be effected as follows:

Dismount the sensor LA 1S resp. LA 25S.

Make a short-circuit of the sensor electrodes by using a humid finger.

The electronic controller LA-1.1 resp. LA-1.4 indicates an alarm, i.e. the red LED is beaming.

After the function test, dry the electrodes with a cloth.

Remount the sensor into the receiver part.

For the sensors LA 1S and LA 25S, a parting of a cable can be simulated by disconnecting a

connection lead on the electronic controller. Also in this case, the electronic controller LA 1.1 resp.

LA1.4 must immediately indicate alarm, i.e. the red LED must beam.

14.3 ADJUSTMENT OF SENSITIVITY

At works, a standard adjustment of the electronic controllers LA-1.1 and LA-1.4 is executed for a

conducting capacity of 100µS/cm. Hereby, the length of the sensor’s connection cable does not

matter.

In case a permanent alarm is given and the red LED is permanently beaming after the initial starting in

spite of the fact that the sensor is dry, or in case the sensor is humid and no alarm is given, the

sensitivity of the sensor must be adjusted.

Gas sampling and conditioning technology 5-5.1.1-ME

Page 19

NOTE!

Should there be condensate with a low conducting capacity, do not shortcircuit the sensor. Moisten instead the sensor (that has be cleaned with

distilled water) with the respective condensate.

19

Range of adjustment on the electronic controllers: 50µS/cm … 1mS/cm.

For an adjustment of sensitivity, the following steps have to be executed:

Remove the 4 lid screws of the electronic controller LA-1.1 and remove the lid.

Dismount the sensor, clean and dry the electrodes.

In case of permanent alarm with a dry and clean sensor: Turn on the potentiometer P1 (LA-

1.1) resp. Sensitivity adj. (LA-1.4) anticlockwise (lower sensitivity) until the alarm is out. Then

make a short-circuit with a humid finger. Then, the electronic controller LA-1.. must

immediately indicate alarm, i.e. the red LED must be beaming.

In case the alarm is not activated while making the short-circuit of the sensor electrodes

with a humid finger: Turn on the potentiometer P1 (LA-1.1) resp. Sensitivity adj. (LA-1.4) in

clockwise direction (higher sensitivity) until the alarm is indicated, i.e. the red LED is beaming.

Screw again the 4 lid screws of the electronic controller LA-1.1.

Dry the electrodes with a cloth and mount the sensor again.

14.4 ADJUSTMENT OF ALARM HOLDING FUNCTION

Optionally, you can configure a self-holding of the alarm. For this purpose, you have to execute a

manual reset in the event of an alarm.

For configuration of the alarm holding function, you have to execute the following steps:

Remove first the 4 lid screws and then the lid of the electronic controller LA-1.1.

For the rail mounting version LA-1.4, loosen the above and below closing behind the terminals

by means of a screw driver. Then pull the printed board together with the housing front out of

the back housing part.

Plug the jumper on JP1 from position: 2-3 (no alarm memory function) to position 1-2 (see

figure 4 resp. 6).

Screw the lid again on electronic controller LA-1.1.

Push the printed board again into the housing of electronic controller LA-1.4.

The manual reset has to be released on the electronic controllers LA 1.1 and LA1.4 by actuating the

key button S1 resp. Al. Reset. In case of the electronic controller LA 1.1, you have to remover the

housing lid for this purpose (see figure 4). In case of electronic controller LA 1.4, you have to actuate

the key button in the housing front (Al. Reset).

15 CLOSING DOWN

No special measures have to be respected for closing down.

Gas sampling and conditioning technology 5-5.1.1-ME

Page 20

20

NOTE!

Please take care of the specific installation and process safety

measures before executing any maintenance and repair work!

AT T E NT I O N!

In case of liquid breaking through, the total conditioning unit

including the receiving part with sensor must be dried and

cleaned.

NOTE!

Aggressive condensate possible. Wear safety glasses and

respective protective clothes when dismounting, repairing or

cleaning the sensor!

16 MAINTENANCE AND REPAIR

The liquid control units series LA® are working maintenance-free during a long period of time.

It may be that the electrodes of the sensors LA 1S resp. LA 25S are dirty from deposits. Please use a

cloth for cleaning, eventually in connection with a solvent of cleaning material. For cleaning, the sensor

has to be dismounted.

In case of a defect of the electronic, please send the instrument for repair to M&C Products.

Gas sampling and conditioning technology 5-5.1.1-ME

Page 21

Liquid alarm sensor unit LA...

(V) Consumables, (E) Recommended spare parts, (T) Spare parts

Recommended quantity for

operation during a period of

xxx years

V/E/T 1 2

3

Sensor LA 1S / LS:

90 E 1000

FPM O-Ring (14)

E 2 4

8

90 E 1010

PVDF-Ring (16)

E 2 4

8

Sensor LA 1S / F.-..-D:

90 F 0025

PTFE Sealing ring GL25-12ø

E 2 4

8

91 F 0020

Union nut GL25 (read)

E 1 2

3

Sensor LA 1S, LA 25S:

03 E 1001

Liquid sensor LA 1S with 4m connection cable

T 1 1

1

03 E 1111

Liquid sensor LA 25S with 4m connection cable

T 1 1

1

03 E 9001

Connection cable LA.., per meter

T - -

-

21

17 SPARE PARTS LIST

The requirement of wear, tear and spare parts depend on specific operating conditions. The quantities

we recommend are based on experience and are not binding.

18 APPENDIX

Flow diagram LA1.1, 115/230V 50/60Hz

Flow diagram LA1.1, 24V AC/DC

Flow diagram LA1.4, 115/230V 50/60Hz

Flow diagram LA1.4, 24V AC/DC

For additional product documentation please look into our home page:

www.mc-techgroup.com

Gas sampling and conditioning technology 5-5.1.1-ME

Page 22

22

Figure 8 Flow diagram LA1.1, 115/230V 50/60Hz

Gas sampling and conditioning technology 5-5.1.1-ME

Page 23

23

Figure 9 Flow diagram LA1.1, 24V AC/DC

Gas sampling and conditioning technology 5-5.1.1-ME

Page 24

24

Figure 10 Flow diagram LA1.4, 115/230V 50/60Hz

Gas sampling and conditioning technology 5-5.1.1-ME

Page 25

25

Figure 11 Flow diagram LA1.4, 24V AC/DC

Gas sampling and conditioning technology 5-5.1.1-ME

Loading...

Loading...