Page 1

KS 2

Embracing Challenge

Liquid alarm sensor KS 2 / KS 2.Ex

for non-conductive and conductive media

Special Features

Sure detection even of minimal liquid

quantities

Integrable in M&C-universal lters and

ow chamber

Explosion proof version according to

ATEX for zone 0

Application

Liquid alarm sensors are used in gas sample conditioning systems for monitoring gas

cooling and condensate drain-off devices in

order to provide protection for downstream

analysis instruments. This monitoring device

KS 2/KS 2.Ex reliably signals the penetration

of non conductive (e.g. alcohol) and conductive (e.g. water) liquid in the event of cooling

or condensate drain-off equipment being

defective, thus avoiding expensive down time

as well as high repair costs for analysis instruments.

In the event of an alarm, power for the sample

gas pump must be switched off or a solenoid valve must be switched idle in the sample conditioning system.

Description

The M&C liquid sensor KS 2/KS 2.Ex works on

the principle of capacitive measurement and

is suitable for non-conductive and conductive media. A pre-amplifier is integrated in the

sensor housing and is connected with the

necessary external electronic controller via

2- resp. 3-wire. For KS 2 the required electronic controller is available in various versions,

FA1.1; FA1.4 and is described in the separate

data sheet 9.5.

The M&C liquid sensor KS 2.Ex for use in

hazardous areas and media should only be

applied in connection with electronic controller WE77.Ex1 or KFA6-SR2-Ex1W.

The M&C KS 2/KS 2.Ex liquid sensor is constructed in such a way that any droplets of

liquid in the sample gas are attracted directly

to the active sensor surface. Even the smallest

liquid droplets will trigger a sure and rapid

alarm.

The sensors are mounted with the 16mm ø

stainless steel body in the GL-25 connector

of the universal filter F..-..-D or the condensate

pot TG1 or in the flow chamber LS/KS.

Technical specications and illustrations are without

obligation, subject to modications. 04.99/11.06

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

8.3

Page 2

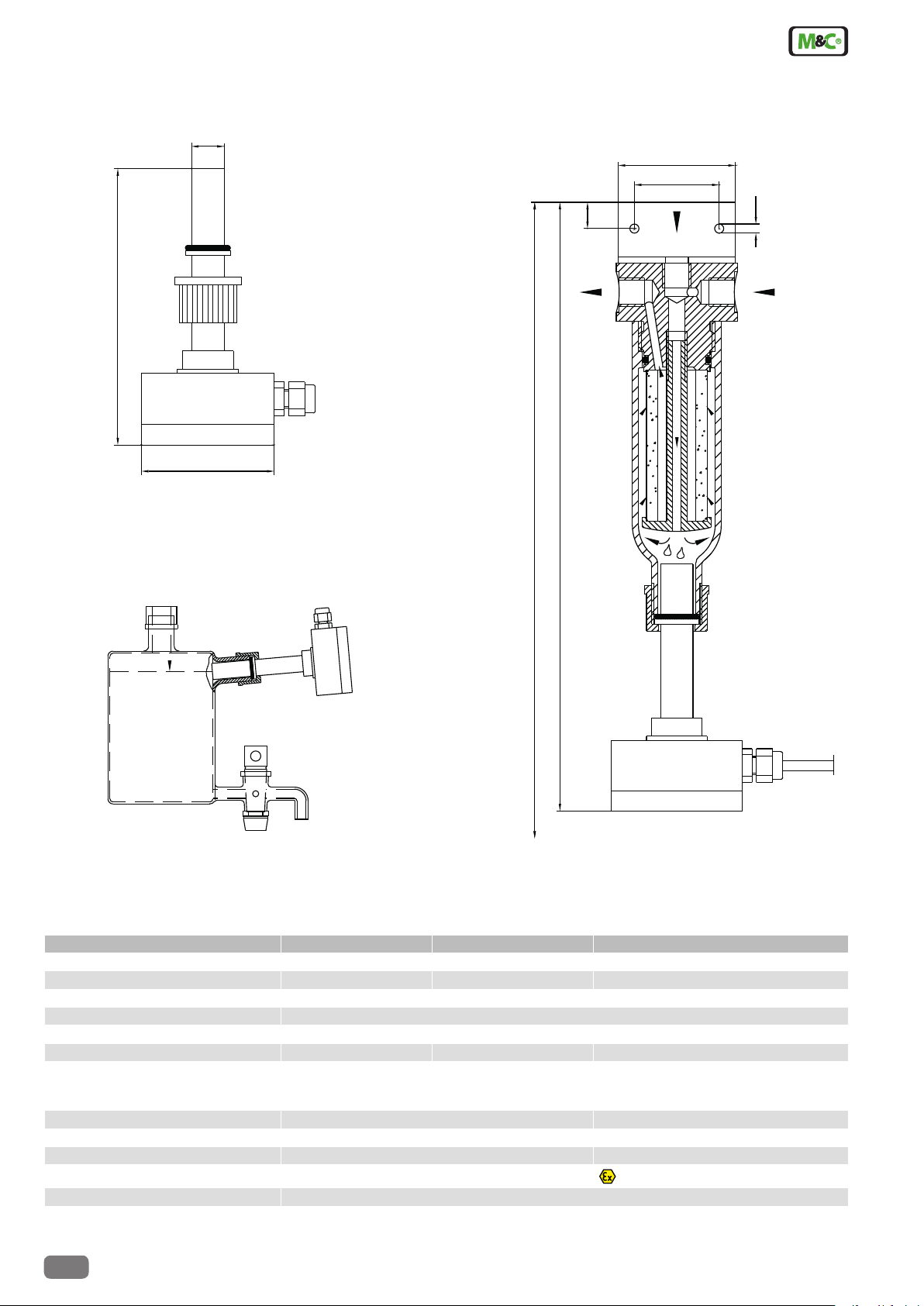

Dimensions

KS 2 / KS 2.Ex liquid sensor

Ø16

135

KS2

65x50

* Chemraz is a trade mark of Greene Tweed

Chemraz* O-Ring 15

Sleeve nut GL25/18

PG 7

Liquid alarm sensor KS 2 / KS 2.Ex

in a universal filter F..-..-D

58

42

13

G1/4"

G1/4" G1/4"

305

Ø 5

KS 2..liquid sensor for level

monitoring in condensate pot TG1

max.

KS2

TG1

KS 2

*

* constructional size 410mm

Dimensions in mm

In the event of condensate penetration, the lter housing acts as a buer vessel

preventing immediate liquid penetration.

Technical Data

Sensor KS 2 KS 2 Peek KS 2.EX

Part No. 03E4100 03E4110 03E4200

Pressure max. 2 bar abs. max. 11 bar abs. max. 2 bar abs.

Max. operating temperature 0 bis +60 °C 0 bis +50 °C

Liquid alarm limit 1,5 ml

Material of sample contacting parts PTFE, Chemraz*, SS316Ti Peek, Chemraz*, SS316Ti PTFE, Chemraz*, SS316Ti

Sample connection ø 16 mm ø 18 mm ø 16 mm

Option sample connection ø 18 mm,

Part No.. 03E9400 (fitting for mounting: Part

No. 09V2317 GE SS 1/2“NPT-18mm)

Power supply 8-12VDC, feeding via FA1.1 or FA1.4 8VDC, max. 2,4mA / operating: <1,4mA = Alarm

Method of mounting / mounting position clamping attachment / any position

Connection cable, length 1,5 m standard 3x 0,25 mm

System of protection IP 54 EN 60529

Weight 190 g

Electronic controller FA1.1 or FA1.4 (see data sheet 9.5) KFA6-SR2-Ex1W

for mounting in

stainl. steel filter

FSS...-D 1/2“NPT

2

for mounting in stainl. steel

filter

FSS...-D 1/2“NPT

2x 0,25 mm

2

II 1 G EEx ia IIC T6, KEMA 03ATEX1006

part no. 01U2501 (230V ) / 01U2501A (115V)

8.3

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications.04.99/11.06

Loading...

Loading...