Page 1

Operating Manual

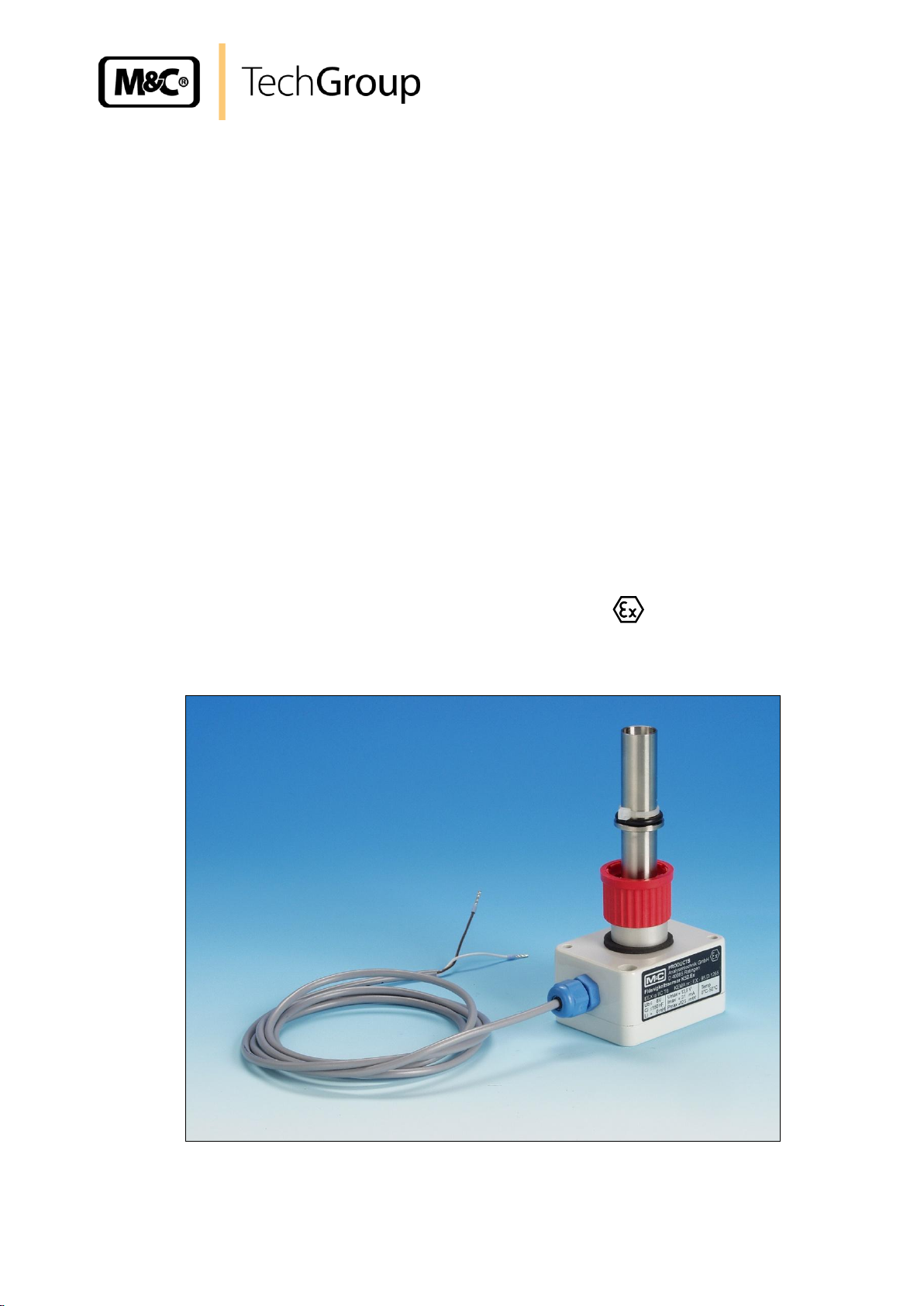

Liquid Alarm Sensor KS2 / KS2.Ex

for non-conductive and conductive media

Gas sampling and conditioning technology 5-5.3 ME

Page 2

2

This Operating Manual does not claim completeness and may be

subject to technical modifications.

© 10/2004 M&C TechGroup Germany GmbH. Reproduction of this

document or its content is not allowed without permission from

M&C.

2nd Edition: 02/2009

Dear customer,

we have made up this operating manual in such a way that all necessary information about the

product can be found and understood quickly and easily.

Should you still have any question, please do not hesitate to contact M&C directly or go through your

appointed dealer. Respective contact addresses are to be found in the annexe to this operating

manual.

Please also contact our homepage www.mc-techgroup.com for further information about our

products. There, you can read or download the data sheets and operating manuals of all M&C

products as well as further information in German, English and French.

Gas sampling and conditioning technology 5-5.3 ME

Page 3

3

Content

1 General information ....................................................................................................................... 4

2 Declaration of conformity ............................................................................................................. 4

3 Safety instructions ........................................................................................................................ 5

4 Warranty ......................................................................................................................................... 5

5 Used terms and signal indications .............................................................................................. 6

6 Application ..................................................................................................................................... 7

7 Technical data ................................................................................................................................ 8

8 Description ..................................................................................................................................... 9

9 Function ........................................................................................................................................ 10

9.1 Connection and Adjustment of the sensor type KS2 at the electronic FA1.1 ......................... 10

9.2 Connection and Adjustment of the sensor type KS2 at the electronic FA1.4 ......................... 10

9.3 Connection of the sensor type KS2.ex to the electronics WE77/Ex1 ..................................... 11

9.4 Connection of the sensor type KS2.ex to the electronics KFA6-SR2-Ex1.W ........................ 11

9.5 Adjustment of the Sensor type KS2.Ex ................................................................................... 12

10 Cleaning of the sensor ................................................................................................................ 13

11 Spare parts list ............................................................................................................................. 14

12 Appendix ...................................................................................................................................... 14

List of illustrations

Figure 1 KS2 / KS2.Ex Liquid-Sensor ............................................................................................... 7

Figure 2 KS2.. liquid sensor for level monitoring in the condensate pot type TG1 ............................ 9

Figure 3 Liquid alarm-sensor KS.2 / KS2.Ex in a Universal filter F..-..-D .......................................... 9

Figure 4 Electronic KFA6-SR2-Ex1.W (left) and terminal box KS2.Ex respectively WE77/Ex1 ....... 12

Figure 5 Wiring diagram KS2.Ex and KFA6-SR2-Ex1.W respectively WE77/Ex1 ........................... 12

Figure 6 Mounting of the sensor type KS2 ....................................................................................... 15

Gas sampling and conditioning technology 5-5.3 ME

Page 4

4

Head Office

M&C TechGroup Germany GmbH Rehhecke 79 40885 Ratingen Germany

Telephone: 02102 / 935 - 0

Fax: 02102 / 935 - 111

E - mail: info@mc-techgroup.com

www.mc-techgroup.com

1 GENERAL INFORMATION

The product described in this operating manual has been examined before delivery and left our works

in perfect condition related to safety regulations. In order to keep this condition and to guarantee a

safe operation, it is important to heed the notes and prescriptions made in this operating manual.

Furthermore, attention must be paid to appropriate transportation, correct storage, as well as

professional installation and maintenance work.

All necessary information a skilled staff will need for appropriate use of this product are given in this

operating manual.

2 DECLARATION OF CONFORMITY

CE - Certification

The product described in this operating manual complies with the following EC directives:

EMV-Instruction

The requirements of the EC directive 2004/108/EC “Electromagnetic compatibility“ are met.

Low Voltage Directive

The requirement of the EC directive 2006/95/EC “Low Voltage Directive“ are met.

The compliance with this EC directive has been examined according to DIN EN 61010 as well as DIN

57721 for the voltage test of heating elements.

Declaration of conformity

The EU Declaration of conformity can be downloaded from the M&C homepage or directly requested

from M&C.

Gas sampling and conditioning technology 5-5.3 ME

Page 5

5

3 SAFETY INSTRUCTIONS

Please take care of the following basic safety procedures when mounting, starting up or

operating this equipment:

Read this operating manual before starting up and use of the equipment. The information and

warnings given in this operating manual must be heeded.

Any work on electrical equipment is only to be carried out by trained specialists as per the regulations

currently in force.

Attention must be paid to the requirements of VDE 0100 (IEC 364) when setting high-power electrical

units with nominal voltages of up to 1000 V, together with the associated standards and stipulations.

Check the details on the type plate to ensure that the equipment is connected to the correct mains

voltage.

Protection against touching dangerously high electrical voltages:

Before opening the equipment, it must be switched off and hold no voltages. This also applies to any

external control circuits that are connected.

The device is only to be used within the permitted range of temperatures and pressures.

Check that the location is weather-protected. It should not be subject to either direct rain or moisture.

Only the especially marked liquid sensor KS2.EX is allowed to be operated in hazardous areas.

Installation, maintenance, monitoring and any repairs may only be done by authorized personnel with

respect to the relevant stipulations.

4 WARRANTY

If the equipment fails, please contact M&C directly or else go via your appointed M&C dealer.

We offer a one year warranty as of the day of delivery as per our normal terms and conditions of sale

and assuming technically correct operation of the device. Consumables are hereby excluded. The

terms of the warranty cover repair at the factory at no cost or the replacement at no cost of the

equipment free ex user location. Reshipments must be sent in a sufficient and proper protective

packaging.

Gas sampling and conditioning technology 5-5.3 ME

Page 6

6

DANGER!

This means that death, severe physical injuries and/or important

material damages will occur in case the respective safety measures

are not fulfilled.

W ARN IN G !

This means that death, severe physical injuries and/or important

material damages may occur in case the respective safety

measures are not fulfilled.

CARE!

This means that minor physical injuries may occur in case the

respective safety measures are not fulfilled.

CAR E!

Without the warning triangle means that a material damage may

occur in case the respective safety measures are not met.

ATT ENT ION !

This means that an unintentional situation or an unintentional status

may occur in case the respective note is not respected.

NOTE!

These are important information about the product or parts of the

operating manual which require user’s attention.

SKILLED STAFF

These are persons with necessary qualification who are familiar with

installation, use and maintenance of the product.

5 USED TERMS AND SIGNAL INDICATIONS

Gas sampling and conditioning technology 5-5.3 ME

Page 7

7

PG 7

ø16

135

65 x 50

Sleeve nut GL25/18

Chemraz* O-ring 15

KS 2

6 APPLICATION

Liquid alarm sensors are used in gas sample conditioning systems for monitoring gas cooling and

condensate removal devices in order to provide protection for downstream analysis instruments. This

monitoring device KS2 / KS2.Ex reliably signals the penetration of non conductive (e.g. alcohol)

and conductive (e.g. water) liquid in the event of cooling or condensate removal equipment being

defective, thus avoiding expensive down time as well as high repair costs for analysis instruments.

In the event of an alarm, we recommend to switch off the power supply for the sample gas or a

solenoid valve in the sample conditioning system.

* Chemraz is a Greene Tweed Trademark

Figure 1 KS2 / KS2.Ex Liquid-Sensor

Gas sampling and conditioning technology 5-5.3 ME

Page 8

7 TECHNICAL DATA

Sensor

KS2

KS2 Peek

KS2.Ex

Part No.

03E4100

03E4110

03E4200

Pressure

max. 2 bar abs.

max. 11 bar abs.

max. 2 bar abs.

Max. operating temperature

0°C to +60°C

0°C to +50°C

Liquid alarm limit

1,5ml

Material of sample

contacting parts

PTFE, Chemraz,

SS316Ti

Peek, Chemraz,

SS316Ti

PTFE, Chemraz, SS316Ti

Sample connection Standard

(Fitting for mounting in

stainless steel filter:

connector GE SS ½“NPT18mm Part No.. 09V2317)

ø16 mm for GL25

ø18 mm for

mounting in

stainless steel filter

FSS...-D1/2“NPT

ø16 mm for GL25

Option sample connection

ø18 mm, Part No..: 03E9400

(Fitting for mounting in

stainless steel filter:

connector GE SS ½“NPT18mm Part No.. 09V2317)

for mounting in

stainless steel filter

FSS...-D1/2“NPT

for mounting in stainless

steel filter FSS...D1/2“NPT

Method of mounting /

mounting position

clamping attachment / for liquid alarm vertical with opening

upwards

Max. voltage / current /

power consumption

13,5V / 31 mA / 125 mW

Inner capacity max.

150 nF

Inner inductivity max.

0 mH

Power supply

8-12VDC

feeding via FA1.4 or FA1.1

8V DC / max.2,4mA

operating: < 1,4 mA alarm

Connection cable, length 1,5

m standard

3 x 0,25mm²

2 x 0,25mm²

Cable

capacity

inductivity

200pF/m

1µH/m

Protection

IP 54 DIN 40050

II 1 G EEx ia IIC T6

KEMA 03ATEX1006

Weight

190 g

8

Gas sampling and conditioning technology 5-5.3 ME

Page 9

9

max.

TG 1

KS 2

42

58

ø5

13

305

*

G1/4" i.

G1/4" i.

G1/4" i.

* constructional size 410mm

KS 2

8 DESCRIPTION

The M&C liquid sensor KS2 / KS2.Ex works on the principle of capacitive measurement and is

suitable for non-conductive and conductive media. A pre-amplifier is integrated in the sensor housing

and is connected with the necessary external electronic controller via 2- resp. 3-wire. For the sensor

type KS2 the required electronic controller is available in various versions, FA1.1 or FA1.4 and is

described in a separate data sheet. The M&C liquid sensor KS2.Ex for applications in hazardous

areas and media should only be applied in connection with electronic controller WE77.Ex1, KFA6-

SR2-Ex1.W or an electronic with the same performance data (see chapter 9.4). For electronics with

the same performance data there is no guarantee for problemless operation. The M&C KS2 / KS2.Ex

liquid sensor is constructed in such a way that any droplets of liquid in the sample gas are attracted

directly to the active sensor surface. Even small liquid droplets will trigger a sure and rapid alarm. The

sensors can be mounted with the 16mm stainless steel body in the GL-25 connector of the

Universal filter

F..-..-D or the condensate pot TG1 or in the flow chamber LS/KS.

Figure 2 KS2.. liquid sensor for level monitoring in the condensate pot type TG1

In the event of condensate breakthrough, the filter acts as a buffer vessel preventing immediate liquid

penetration.

Figure 3 Liquid alarm-sensor KS.2 / KS2.Ex in a Universal filter F..-..-D

Gas sampling and conditioning technology 5-5.3 ME

Page 10

10

NOTE!

A sensor with high sensitivity can cause false alarms.

NOTE!

A sensor with high sensitivity can cause false alarms.

9 FUNCTION

9.1 CONNECTION AND ADJUSTMENT OF THE SENSOR TYPE KS2 AT THE

ELECTRONIC FA1.1

Link the sensor to the electronic FA1.1 (see also manual 5-6.10ME)

KS2 terminal X4/3 to FA1.1 terminal 15 (yellow)

KS2 terminal X4/2 to FA1.1 terminal 17 (white)

KS2 terminal X4/1 to FA1.1 terminal 18 (brown)

Adjustment with „dry“ sensor:

Turn the potentiometer to the left until the green LED is OFF and the red LED is ON.

Turn the potentiometer very slowly to the right. After the green LED is ON, turn the potentiometer

for another 0,5 rotations to the right.

Checking the sensibility:

Test the sensor with the condensate of your application, if possible. A condensate quantity of 1,5 ml

effects the alarm release. The sensor can be adjusted to a higher sensibility if the potentiometer is

turned to the left.

9.2 CONNECTION AND ADJUSTMENT OF THE SENSOR TYPE KS2 AT THE

ELECTRONIC FA1.4

Link the sensor to the electronic FA1.4 (see also manual 5-6.10ME)

KS2 terminal X1/3 to FA1.4 terminal 15 (yellow)

KS2 terminal X1/2 to FA1.4 terminal 17 (white)

KS2 terminal X1/1 to FA1.4 terminal 18 (brown)

Adjustment with „dry“ sensor:

Turn the potentiometer to the left until the green LED is OFF and the red LED is ON.

Turn the potentiometer very slowly to the right. After the green LED is ON, turn the potentiometer

for another 0,5 rotations to the right.

Checking the sensibility:

Test the sensor with the condensate of your application, if possible. A condensate quantity of 1,5 ml

effects the alarm release. The sensor can be adjusted to a higher sensibility if the potentiometer is

turned to the left.

Gas sampling and conditioning technology 5-5.3 ME

Page 11

11

NOTE!

The bridge between the connecting points 3 and 4 of the electronics

WE77/Ex1 guarantees a „safty-first“ alarm release (alarm in case of voltage

loss and parting of the cable).

NOTE!

If the bridge is missing or switched between the connecting points 4 and 5 of

the electronics WE77/Ex1 the alarm is not working in a „safty-first“ mode (no

alarm in case of voltage loss).

9.3 CONNECTION OF THE SENSOR TYPE KS2.EX TO THE ELECTRONICS WE77/EX1

The function is as follows:

dry sensor : LED „ON“ contact MC-NO terminal 7 and 9 closed Sensor current > 1,7 mA

wet sensor : LED „OFF“ contact MC-NC terminal 7 and 8 closed Sensor current < 1,4 mA

Brigde between connecting points 4 and 5 or missing bridge

The sensor current is on a very low level. Therefore we recommend to switch a resistance of 10k

parallel to the sensor to increase the level.

The function than is as follows:

dry sensor : LED „OFF“ contact MC-NC terminal 7 and 8 closed Sensor current > 1,7 mA

wet sensor : LED „ON“ contact MC-NO terminal 7 and 9 closed Sensor current < 1,4 mA

9.4 CONNECTION OF THE SENSOR TYPE KS2.EX TO THE ELECTRONICS

KFA6-SR2-EX1.W

Move all switches (S1-S3) on the front into position I (left).

The function is as follows:

dry sensor : left LED „OFF“ contact MC-NC terminal 7 and 8 closed Sensor current > 1,7 mA

wet sensor : left LED „ON“ contact MC-NO terminal 7 and 9 closed Sensor current < 1,4 mA

Gas sampling and conditioning technology 5-5.3 ME

Page 12

12

1-2

+

3

KFA6

1

2

3

Sensor KS2.Ex

-

+

Switching capacity AC 253V/2A

S1

S2

S3

14

N15L

Power supply

230V 50Hz

1W

13

7

8

9

Output

MC

NO

NC

Bridge

Left

Right

Electronics

WE77/Ex1

Poti

Sensor

1 - 2

+

3

4

5

6

7

MC 8 NC 9 NO

10

PE

11

L

12

N

WE77/Ex1

Power supply

230V 50Hz

3,5VA

Bridge

1

2

3

Sensor KS2/Ex

-

+

AC 250V/4A/500VA

DC 229V/0,1A; 60V/ 0,6A; 24V/4A

9.5 ADJUSTMENT OF THE SENSOR TYPE KS2.EX

Figure 4 Electronic KFA6-SR2-Ex1.W (left) and terminal box KS2.Ex respectively WE77/Ex1

Turn the potentiometer (figure 4) to the left until the LED is OFF.

Turn the potentiometer slowly to the right. After the LED is ON, turn the potentiometer for another

1,5 rotations to the right.

Figure 5 Wiring diagram KS2.Ex and KFA6-SR2-Ex1.W respectively WE77/Ex1

Gas sampling and conditioning technology 5-5.3 ME

Page 13

13

Evaluation for example by section switch amplifier KFA6-SR2-Ex1.W

Nominal revolutions according to DIN 19234 respectively Namur

Voltage UO

10,6 V

Current I0

19 mA

Power consumption P0

51 mW

Data according to certificate of conformity for KS2.Ex

Voltage max. UO

13,5V

Current max. IK

31mA

Power consumption Pmax

125mW

Permissible connection data

Class

EEx ia

IIB

EEx ia

IIC

Outer capacity max.

929nF

230nF

Outer inductivity max.

5mH

3mH

Permissible connection data

Class

EEx ib

IIB

EEx ib

IIC

Outer capacity max.

2929nF

609nF

Outer inductivity max.

115mH

31mH

Evaluation by section switch amplifier WE77/Ex1

Nominal revolutions according to DIN 19234 respectively Namur

No-load voltage UAO

approx. 8V DC

Locked motor current JAK

approx. 8mA

Forward break-over point JS

1,2mA - 2,1mA

Switching hysteresis JH

approx. 0,2mA

Data according to certificate of conformity

Voltage max. UO

13,5V

Current max. IK

31mA

Power consumption Pmax

125mW

Permissible connection data

Class

EEx ia

IIB

EEx ia

IIC

Outer capacity max.

929nF

230nF

Outer inductivity max.

5mH

3mH

Permissible connection data

Class

EEx ib

IIB

EEx ib

IIC

Outer capacity max.

2929nF

609nF

Outer inductivity max.

115mH

31mH

NOTE!

The plastic housing of the sensor has to be cleaned with a moist cloth.

Technical data for switch amplifiers (techn. data sensor see page 5)

10 CLEANING OF THE SENSOR

Gas sampling and conditioning technology 5-5.3 ME

Page 14

14

Liquid sensor type KS2 / KS2.Ex

(C) consumable parts and (R) recommended spare parts

recommended quantity

KS2/KS2.Ex beeing in

operation [years]

Part number

Description

C/R 1 2

3

91 E 4000

O-Ring 15x2,5mm for KS-Sensor

Material: Chemraz

R 1 1

1

91 E 4005

O-Ring 9x2mm for KS-Sensor

Material: Chemraz

R 1 1

1

91 E 4010

O-Ring 9x2mm for KS-Sensor

Material: Viton

R 1 1

1

91 E 4015

O-Ring 13x1mm for KS-Sensor

Material: Viton

R 1 1

1

90 F 0022

Union nut GL25/18

R 1 1

1

11 SPARE PARTS LIST

Wear, tear and replacement part requirements depend on specific operating conditions.

The recommended quantities are based on experience and are not binding.

12 APPENDIX

Mounting of the sensor type KS2

EC-Type Examination Certificate: KEMA 03ATEX1006

For additional manuals and data sheets please look on our home page

www.mc-techgroup.com

Manual flow alarm FA

Document: 5-6.10MD

Data sheet condensate vessel TK, TG

Document: 3-6.3.1

Data sheet universal filter FP, FT

Document: 5-1.1

Gas sampling and conditioning technology 5-5.3 ME

Page 15

15

O-Ring 9 Chemraz

Art.-No.: 91E4005

Art.-No.: 91E4010

O-Ring 9 Viton

Art.-No.: 91E4000

O-Ring 15 Chemraz

Mutter GL 25/18

Art.-No.: 90F0022

O-Ring 13 Viton

Art.-No.: 91E4015

Grub srew M3x10

Gasket Viton

Circuit board with sensor

PG7

Figure 6 Mounting of the sensor type KS2

Gas sampling and conditioning technology 5-5.3 ME

Page 16

16

Gas sampling and conditioning technology 5-5.3 ME

Page 17

17

Gas sampling and conditioning technology 5-5.3 ME

Loading...

Loading...