Page 1

Instruction Manual

Ultra-fine filter series FP

Introduction

The M&C panel-mounting filter FPF-0,1 is equipped with an extra fine glass-fibre filter element with a filter

fineness of 0,1 µm. This guarantees an optimised protection of the analysers against solids.

Description

The filter FPF-0,1 consists of the following components:

c filter glass, d filter element holder, e filter element, f O-ring, g filter body, h hexagon screws and i front-

ring.

At the back of the FPF-0,1 filter the G1/8“i

outlet are marked accordingly. The filter element e is fixed with the filter element holder d on the filter body g.

The filter glass c is screwed in the filter body g and covers the filter area. The filter glass presses on the O-ring

f which guarantees the tightness of the device. The front-ring i with it’s hexagon screws fixes the filter FPF-0,1

in the front panel.

Function

The sample gas enters the filter via the gas inlet from the outer side of the filter element to the inner side and

leaves the filter via the outlet connection.

Maintenance

Before the maintenance work is carried out, it is necessary that the specific safety procedures

pertaining to the system and operational process be observed!

process conditions and have to be determined specifically. The maintenance work is focused on the check of the

filter element respectively the change of the element.

Change of the filter element

Please carry out the following steps:

• before changing the element shut off the gas way to the filter and if necessary sweep the filter with inert gas;

• unscrew by hand the filter glass anticlockwise (the direction is marked on the front-ring);

• unscrew by hand the filter element holder anticlockwise;

• dismantle the filter element;

•

Check the right position of the o-ring before assembling the filter

• clean the filter housing respectively the filter glass if necessary and re-install the new filter element in the

opposite turn

Spare parts

Wear, tear and replacement part requirements depend on specific operating conditions.

The recommended quantities are based on experience and are not binding.

Ultra-fine filter version FPF-0,1 (C) consumable parts, (R) recommended spare parts and (T) spare parts

Article-No. Description

90 F 0009

90 F 0097

90 F 0096

90 F 0118

90 F 0043

90 F 0044

90 F 0095

90 F 0094

*Option

Installation, maintenance, monitoring and any repairs may only be done by authorised personnel with respect to

the relevant stipulations.

Recommended quantity

Glass-fibre filter element F-0,1GF 50, fineness 0,1µm,

Glass-fibre filter element F-2GF 50, fineness 2µm,

Stainless steel filter element F-3SS50, 3µm*,

Filter glass F-45,

O-ring of Viton

O-ring of Viton

PVDF filter element holder FPF-GF,

PVDF filter element holder FPF-P,

®

, 41 for FPF-0,1 until 5.93, f R

®

, 35 for FPF-0,1 from 6.93, f R

®

, version FPF-0,1 for panel-mounting

(DIN ISO 228/1) connections for gas in- and outlet are located. In- and

Maintenance intervals depend on the

for operation [years]

V/E/T

e C

e C

e C

c R

for elements 0,1GF50 / 3SS 50 d S

for elements 2GF 50 * d S

1 2 3

12 24 36

12 24 36

2 4 6

1 2 2

1 2 2

1 2 2

- 1 1

- 1 1

Subject for technical modifications Reproduction of this document or its content is not allowed without permission of M&C

M&C TechGroup Germany GmbH z Rehhecke 79 z 40885 Ratingen z Germany z Tel.: (0)2102/935-0 z Fax: (0)2102/935-111 z www.mc-techgroup.com

© M&C 06.97/07.02 Gas sampling and gas conditioning technology 5 - 0.1 ME

Page 2

Instruction Manual

A

Ultra-fine filter series FP

2

®

, version FPF-0,1 for panel-mounting

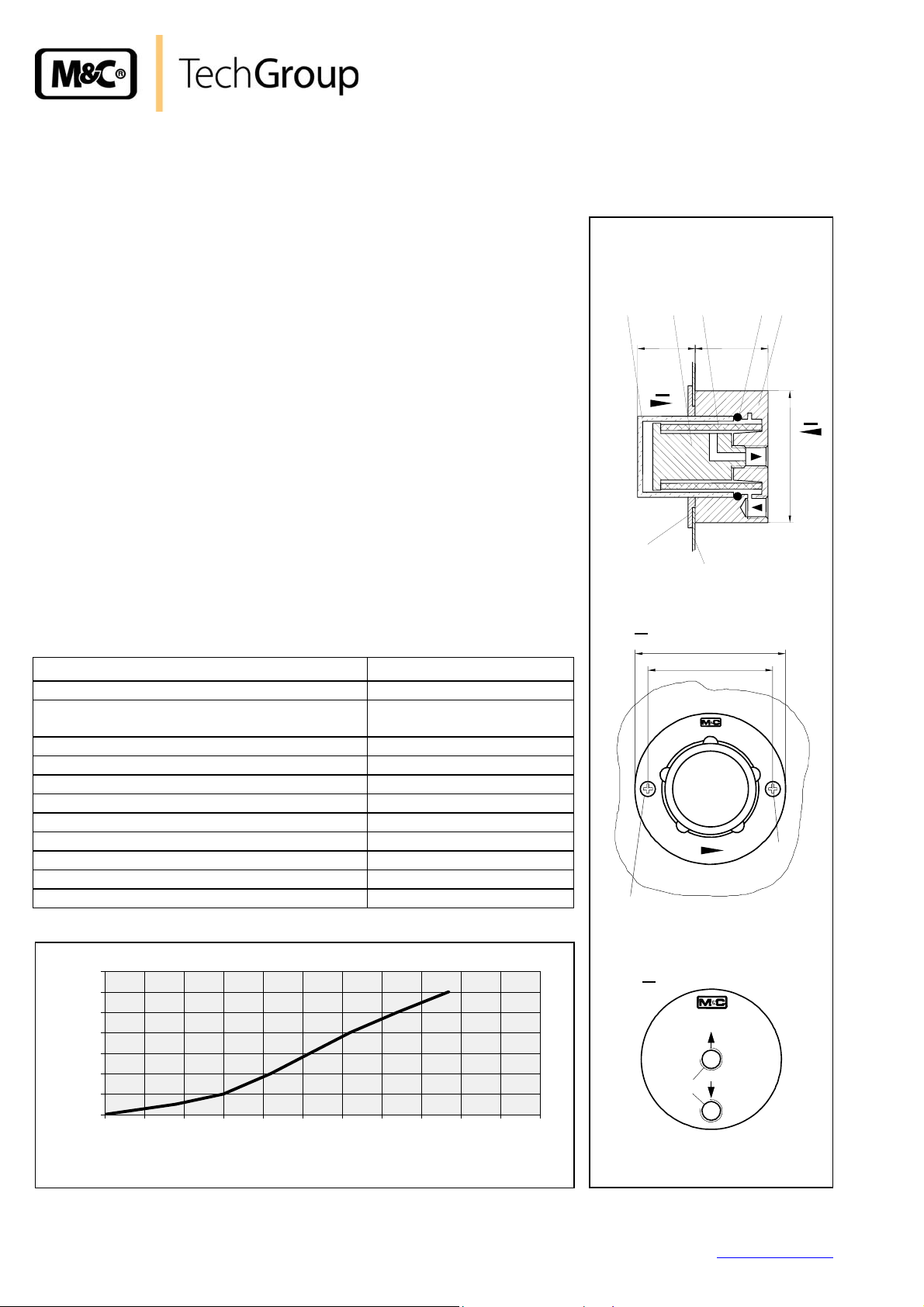

Application

Panel-mounting filter FPF-0,1

The M&C front panel-mounting extra-fine filters reliably separate solids, in

particular very fine particles, occurring in analysis techniques in gas filtration,

using very fine, deep-acting filter elements. The large filter surface of the

cylindrical filter element guarantees reliable extra-fine filtration and a long

1

2 3

service life with low pressure drop.

The 19" front-plate mounting equipment requires flat-design equipment for

30

which the FPF-0,1 extra-fine filter has primarily been developed.

Description

A

Special features of the M&C FPF-0,1 front panel-mounting filter are flat design,

low dead volume, simple construction and assembly as well as universal

usability.

The condition of the filter can be seen immediately from outside through the

filter glass without opening the filter fitting. No tools are needed for changing the

filter element; here, the optimum positioning of the sealing O-ring always

guarantees reliable sealing of the filter glass in respect of the filter body. The

7

gas connections are located at the back in the filter body. The inlet of the

measuring gas can be turned by 180° at the front ring attachment so that a

flexible adjustment to local conditions is possible when assembling.

Drilling in front panel ø50

Corresponding tube connectors can be optionally supplied.

Technical Data

Front panel-mounting fine filter series FP

Part N°.

®

version FPF-0,1

04 F 1000

Filter element Glassfibre 0,1µm (others on

request)

Connections G1/8" i DIN ISO 228/1

Pressure max. 4 bar

Sample temperature max. 80°C

Ambient temperature max. 80°C

Filter surface 50 cm²

Dead volume 30 ml

Open

Weight 280 g

Type of mounting Front panel mounting

Material of sample contacting parts PVDF, PTFE, glass, FPM

Air flow in Nl/hr and differential pressure in mbar with new filter element

6

ø70

ø58

FPF-0,1

36

Auf

4 5

M4

ø65

B

70

60

50

40

30

mbar

20

10

0

0 100 200 300 400 500 600 700 800 900 1000 1100

Nl/hr

Subject for technical modifications Reproduction of this document or its content is not allowed without permission of M&C

M&C TechGroup Germany GmbH z Rehhecke 79 z 40885 Ratingen z Germany z Tel.: (0)2102/935-0 z Fax: (0)2102/935-111 z www.mc-techgroup.com

5 - 0.1 ME sampling and gas conditioning technology © M&C 06.97/07.02

B

G 1/8"i

In

FPF-0,1

AusOut

Ein

dimensions in mm.

Loading...

Loading...