Page 1

FPF+ 3SS

Embracing Challenge

Front panel mounting ne lter

series FP®

Version FPF+

Special Features

Corrosion resistant

Large lter elements

Big variety of lter element materials

with dierent porosities possible

Compact liquid alarm sensor as option

Low stagnant space

Simple construction

Simple assembly

Easy change of lter element

Universal usability

Application

The M&C front panel mounting extra-fine

filters reliably separate solids, in particular very

fine particles, occurring in analysis techniques

in gas filtration, using very fine, deep-acting

filter elements. The large filter surface of the

cylindrical filter element with 75mm length

guarantees reliable extra-fine filtration and a

long service life with low pressure drop.

The optional integrable liquid alarm sensor

LA3 is used in gas sample conditioning systems for monitoring gas cooling and condensate drain-off devices in order to provide protection for downstream analysis instruments.

This simple monitoring device reliably signals

the penetration of condensate in the event of

cooling or condensate drain-off equipment

being defective and thus avoids expensive

down times as well as high repair costs for

analysis instruments.

In the event of alarm, the power for the

sample gas pump or a solenoid valve is to be

switched off in the gas sample conditioning

system.

Description

Special features of the M&C FPF+ front panel

mounting filter are large filter surface, big

variety of different filter element materials

and porosities, integrable liquid alarm sensor,

low stagnant space, simple construction and

assembly as well as universal usability.

The condition of the filter can be seen immediately from outside through the filter glass

without opening the filter fitting. No tools

are needed for changing the filter element;

here, the optimum positioning of the sealing O-ring always guarantees reliable sealing

between filter glass and filter body.

The gas connections are located at the back

in the filter body. If no liquid sensor is used,

the inlet of the measuring gas can be turned

by 90° steps at the front ring attachment so

that a flexible adjustment to local conditions

is possible when assembling.

Corresponding tube connectors can be

optionally supplied (see data sheet 11.6).

The optional integrable liquid sensor LA3

works on the principle of electrical conductivity from 50 µS/cm conductance. In order

to avoid electrolytic effects on the sensor

surface, the sensors are powered with alternating current.

The liquid sensor is located in the sample gas

inlet that any droplets of liquid in the sample

gas are attracted under gravity to the sensor

surface and even the smallest liquid droplets

trigger a sure and rapid alarm.

The required electronic controller LA-1.. is

available in various versions and is described

in the separate data sheet 8.2.

Technical specications and illustrations are without

obligation, subject to modications. 09.96/11.06

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

7.2a

Page 2

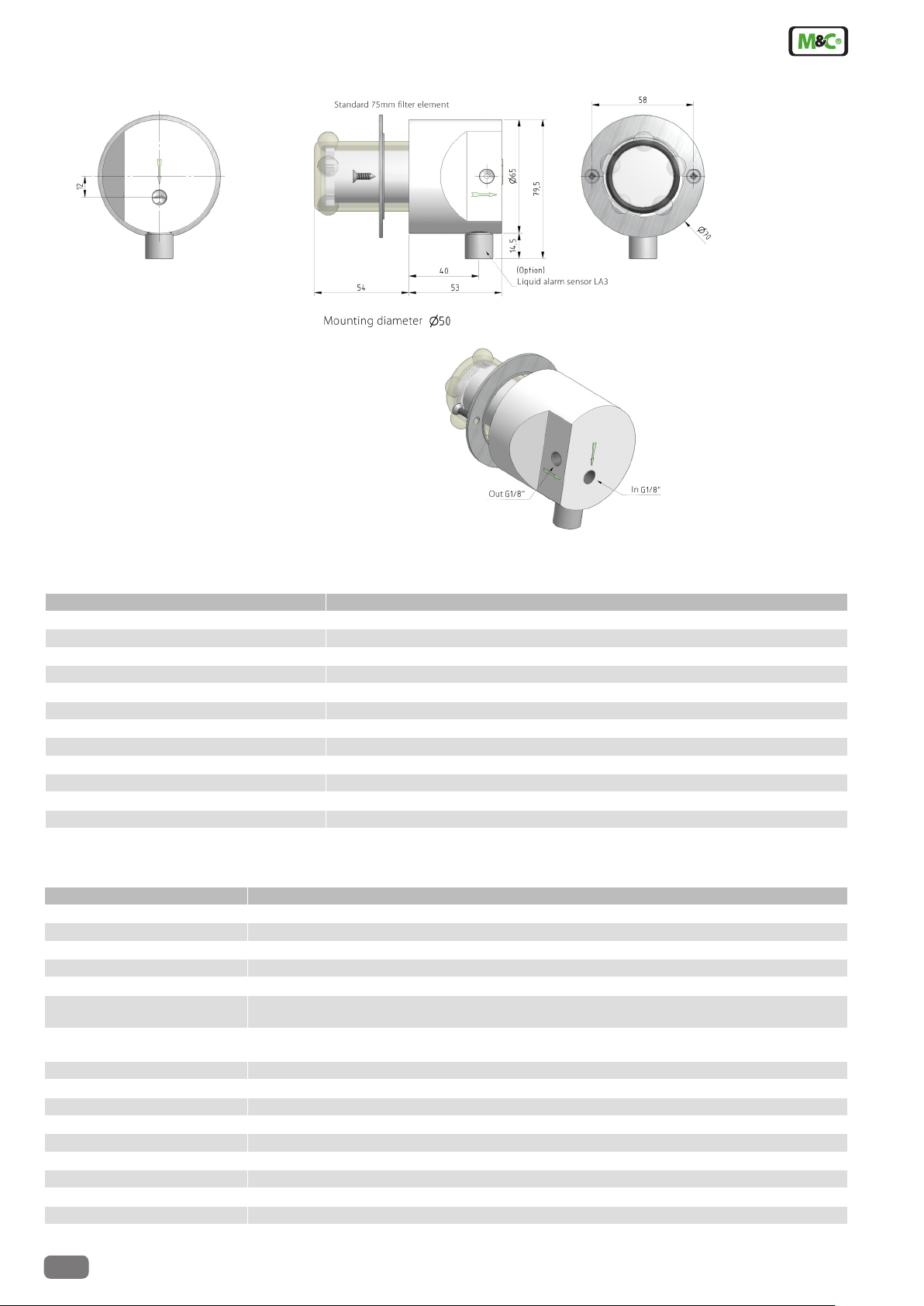

Design and dimensions

Dimensions in mm

Technical Data

Front panel-mounting filter series FP

Part No. 04 F 2100

Filter element without, see options

Liquid alarm sensor without, see options

Sample gas connections G1/8" i* DIN ISO 228/1

Pressure max. 4 bar g

Sample temperature max. 80 °C

Ambient temperature max. 80 °C

Filter surface 70 cm

Dead volume 50 ml

Weight 330 g (without filterelement, with liquid alarm sensor LA3)

Type of mounting Front panel mounting

Material of sample contacting parts PTFE, glass, FPM

* Appropriate ttings see data sheet 11.6

®

version FPF+

2

Options

Part No. Description

03E1300 Liquid alarm sensor type LA3**, for conductive media. For mounting in FPF+, material: 1.4571, PTFE, FPM

90F0002 Filter element type F-2T. Length: 75mm, material: PTFE, porosity: 2µm

90F0004 Filter element type F-20T. Length: 75mm, material: PTFE, porosity: 20µm

90F0003 Filter element type F-50T. Length: 75mm, material: PTFE, porosity: 50µm

90F0005 Filter element type F-3G. Length: 75mm, material: Glas, porosity: 3µm

90F0011 Filter element type F-2GF. Length: 75mm, material: glass fibre, porosity: 2µm. VE = 25 pcs. (for mounting 2 x adapter ring

90F0016 Filter element type F-0,1GF. Length: 64mm, material: glass fibre, porosity: 0,1µm. (for mounting 2 x adapter ring part no.

90F0550 Filter element type F-0,05SIC. Length: 75mm, material: ceramic, porosity: 0,05µm.

90F0006 Filter element type F-2K. Length: 75mm, material: ceramic, porosity: 2µm

90F0007 Filter element type F-20K. Length: 75mm, material: ceramic, porosity: 20µm

90F0008 Filter element type F-3SS. Length: 75mm, material: SS316L, porosity: 3µm

90F0010 Filter element type F-20SS. Length: 75mm, material: SS316L, porosity: 20µm

90F0115 Spun glass cartridge FW-1 for universal filter, without filling. Material: SS316Ti

90F0117 Spun glass cartridge FW-2 for universal filter, without filling. Material: PVDF

93S2083 Spec. spun glass, high temperature resistant for spun glass cartridge FW. Content:1000g

93S0050 Adapter ring for filter element F-0,1GF and F-2GF. Material: PTFE (1 pc.)

** Appropriate electronic controller see data sheet 8.2

7.2a

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

part no. 93S0050 is necessary)

93S0050 is necessary)

Technical specications and illustrations are without

obligation, subject to modications. 09.96/11.06

Loading...

Loading...