Page 1

ECP 20-2PV

Embracing Challenge

Peltier-Gas Cooler Series ECP®

Version ECP 20-2 for 500 Nl/hr gas ow rate

(single stream)

Special Features

Compact, self-controlling and mainte-

nance-free

With Jet-Stream heat exchanger avail-

able in 3 standard materials

Gas ow rate 1 stream 500 l/hr

Outlet dew point adjustable from +2 °C

to +15 °C

Dew point stability ± 0,1 °C

Status-Alarm contact standard

Small dimensions

Light weight

Optimum reliability

Application

The M&C gas cooler ECP 20-2 is used in gas

analysis to lower the dew point of humid gas

to avoid condensation in the analyser. An

extremely stable gas dew point avoids water

vapour cross-sensitivity and volumetric errors.

Description

The electronically controlled peltier cooler

produced by M&C incorporates the ‘’JetStream’’ design of heat exchanger. This design

induces condensate formation and guarantees optimum dew point reduction to a stable low value, eliminating the need for additional pre-drainage devices.

The condensate formed should be removed

with a small peristaltic pump, sample trap

or collection vessel. The simple construction

employed enables heat exchangers of different materials to be used depending on the

application.

The operating status of the cooler is displayed

by three LED’s, one each for over or under

temperature alarm and one which pulsates

indicating the cooler is functioning correctly.

The alarm status changes when the temperature deviates by +/-3 °C from the set point.

The gas cooler ECP 20-2 has got two EC-Jetstream heat exchangers which are best

employed using one as a pre-cooler and the

second as a main or final cooler with a flow

capacity max. of 500 Nl/hr.

The compact lightweight design of this

device makes it ideal for use in portable and

compact continuous sample conditioning

systems.

The gas cooler is self-controlling and maintenance-free.

Technical specications and illustrations are without

obligation, subject to modications. 05.97/06.06

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

6.2

Page 2

3872

226

PG 9PG 11

C

ON

C

385

280

60

90

95

210

Alarm contactPower -in

ø7

GL 25

2xGL 18

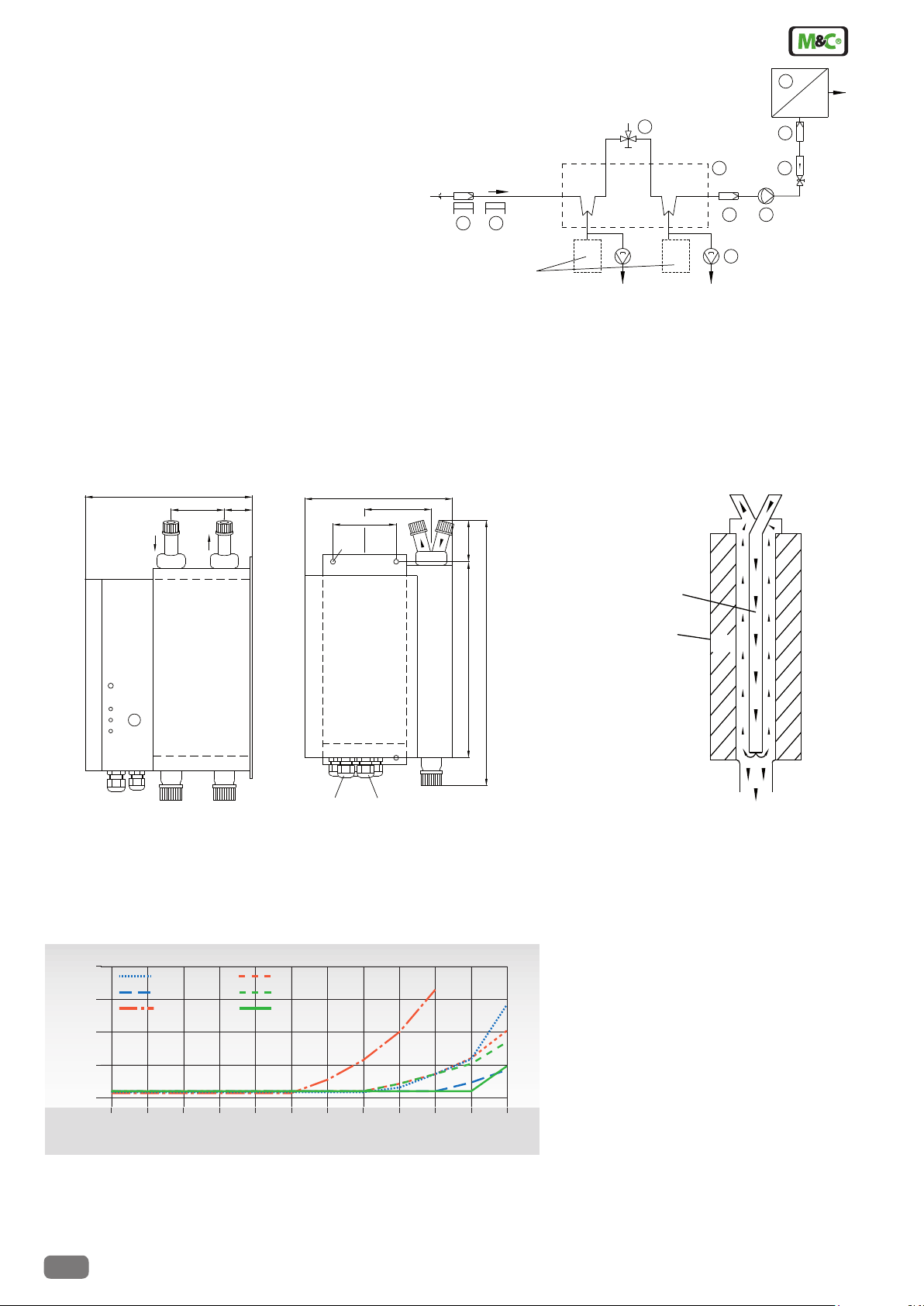

Example application for ECP 20-2

Alternative:

Trap with float or

condensate vessel

5

Condensate OUT

+5°C

4

3

10

9

8

7

ECP20-2

1 2

Sample Gass IN

Testgas

IN

6

M&C Jet-Stream

heat exchanger

Cooling block

Condensate - OUT

Sample gas - IN

Sample gas - OUT

+5°C

Sample gas flow rate Nl/hr

Sample outlet dew point °C

0 50 100 150 200 250 300 350 400 450 5004550

8

12

16

20

40 °C -2

60 °C -3

40 °C -3

60 °C -1

40 °C -1

60 °C -2

1 Heated lter sample probe SP2000-H

2 Heated sample line 4M4/6

3 Cooler ECP20-2

4 3-way ball valves 3L/PV-1

5 Peristaltic pumps SR25.1

6 Diaphragm pump MP47

7 Fine lter FP-2T-D with liquid alarm LA1

8 Aerosol lter CLF-5/W optional according to application

9 Flow meter FM10, 50-500 Nl/hr

10 Analyser, e. g. PMA1000

Dimensions

ECP 20-2

side view front view

Functioning diagram of M&Cheat exchanger

Dimensions in mm

6.2

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Sample outlet dew point difference

for the gas cooler ECP20-2 with heat exchangers out of:

1 Glass

2 PVDF

3 Stainless steel 316Ti

in dependence on the gas ow rate and

40 °C and 60 °C sample inlet dew point

at 25 °C ambient temperature.

Technical specications and illustrations are without

obligation, subject to modications. 05.97/06.06

Page 3

Technical Data

Gas Cooler series ECP

Part No. Gas Cooler ECP 20-2 01K8100 01K8140 01K8120

Material of heat exchanger Duran glass® PVDF SS 316Ti

Gas pressure max.-bar abs. 2) with GL adapter 2 / 32) 3 10**

Sample gas connection for ø 6 mm o.d. tube G1/4"i

Condensate connection for ø 12 mm o.d. tube G3/8"i

∆P at 500 Nl/hr flow rate 5 mbar

Stagnant space per heat exchanger approximately 70 ml

Gas stream / Gas flow rate 1x max. 500 Nl/hr *

Ambient temperature +5 to +45 °C

Storage temperature -20 to +60°C

Sample outlet dew point range of adjustment: +2 °C ..... +15 °C, factory setting: +5 °C

Dew point stability at constant conditions < ± 0,1 °C

Sample inlet temperature max. 180 °C*

Sample inlet dew point max. 80 °C*

Total cooling capacity at +25 °C ambient 80 kJ/h

Main power connection / Power consumption 230V 50Hz or 115V 60Hz switchable, 250VA

Ready for working <20 min.

Electrical connection terminals 2,5 mm2, 2x PG11 cable gland

Status alarm 1 changeover contact, potential free contact rating 250V, 2A, 500VA, 50W alarm point: ∆ ±3 °C to T

Case protection / Electrical standard IP54 EN60529 / EN61010

Method of mounting / Case colour wall mounting / case colour black

Dimension / Weight 210x385x 226 mm / 12,5 kg

* Maximum values in technical datas must be rated in consideration of total cooling capacity at 25 °C ambient temperature and an outlet dew point of 5 °C.

** Other versions on request.

GL-adapter and tube ttings for the connection of dierent tube diameters at the heat exchanger see chapter 11, data sheet 11.5 and 11.6.

®

ECP 20-2

SOLL

Technical specications and illustrations are without

obligation, subject to modications. 05.97/06.06

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

6.2

Loading...

Loading...