Page 1

Operating Manual

Electric gas cooler series EC

®

Version EC-L

Gas sampling and gas conditioning technology 3-3.1-ME

Page 2

2

This Operating Manual does not claim completeness and may be

subject to technical modifications.

© 03/2010 M&C TechGroup Germany GmbH. Reproduction of this

document or its content is not allowed without permission from M&C.

1st Edition: 03/2010

Dear customer,

we have made up this operating manual in such a way that all necessary information about the

product can be found and understood quickly and easily.

Should you still have any question, please do not hesitate to contact M&C directly or go through your

appointed dealer. Respective contact addresses are to be found in the annexe to this operating

manual.

Please also contact our homepage www.mc-techgroup.com for further information about our

products. There, you can read or download the data sheets and operating manuals of all M&C

products as well as further information in German, English and French.

Gas sampling and gas conditioning technology 3-3.1-ME

Page 3

3

Content

1 General information ................................................................................................................... 4

2 Declaration of conformity ......................................................................................................... 4

3 Safety instructions ..................................................................................................................... 5

4 Warranty ..................................................................................................................................... 5

5 Used terms and signal indications ........................................................................................... 6

6 Introduction ................................................................................................................................ 7

6.1 Serial number ........................................................................................................................... 7

7 Application ................................................................................................................................. 7

8 Technical Data ............................................................................................................................ 8

8.1 For basic cooler EC-L without heat exchanger ......................................................................... 8

8.2 Options for basic cooler EC-L ................................................................................................... 8

9 Description ................................................................................................................................. 9

10 Function .................................................................................................................................... 10

11 Reception and storage ............................................................................................................ 10

12 Installation instructions .......................................................................................................... 11

13 Supply connections ................................................................................................................. 11

13.1 Hose connections ................................................................................................................... 11

13.2 Electrical connections ............................................................................................................. 12

14 Start-up ..................................................................................................................................... 14

15 Closing down ........................................................................................................................... 14

16 Maintenance ............................................................................................................................. 14

16.1 Adding and replacing the heat exchangers ............................................................................ 15

16.2 Cleaning the fins of the condenser ......................................................................................... 15

16.3 Maintenance of the optional mounted peristaltic pump(s), type SR25.2 ................................ 16

16.3.1 Change of the pump tube ................................................................................................ 16

16.3.2 Change of contact pulleys and springs ............................................................................ 17

16.3.3 Cleaning the pump head ................................................................................................. 17

17 Operating of the built-in electronic temperature controller ................................................. 18

17.1 Changing the set value ........................................................................................................... 18

17.2 Changing the temperature alarm window ............................................................................... 18

18 Trouble shooting ...................................................................................................................... 19

19 Spare parts list ......................................................................................................................... 20

20 Appendix ................................................................................................................................... 21

List of illustrations

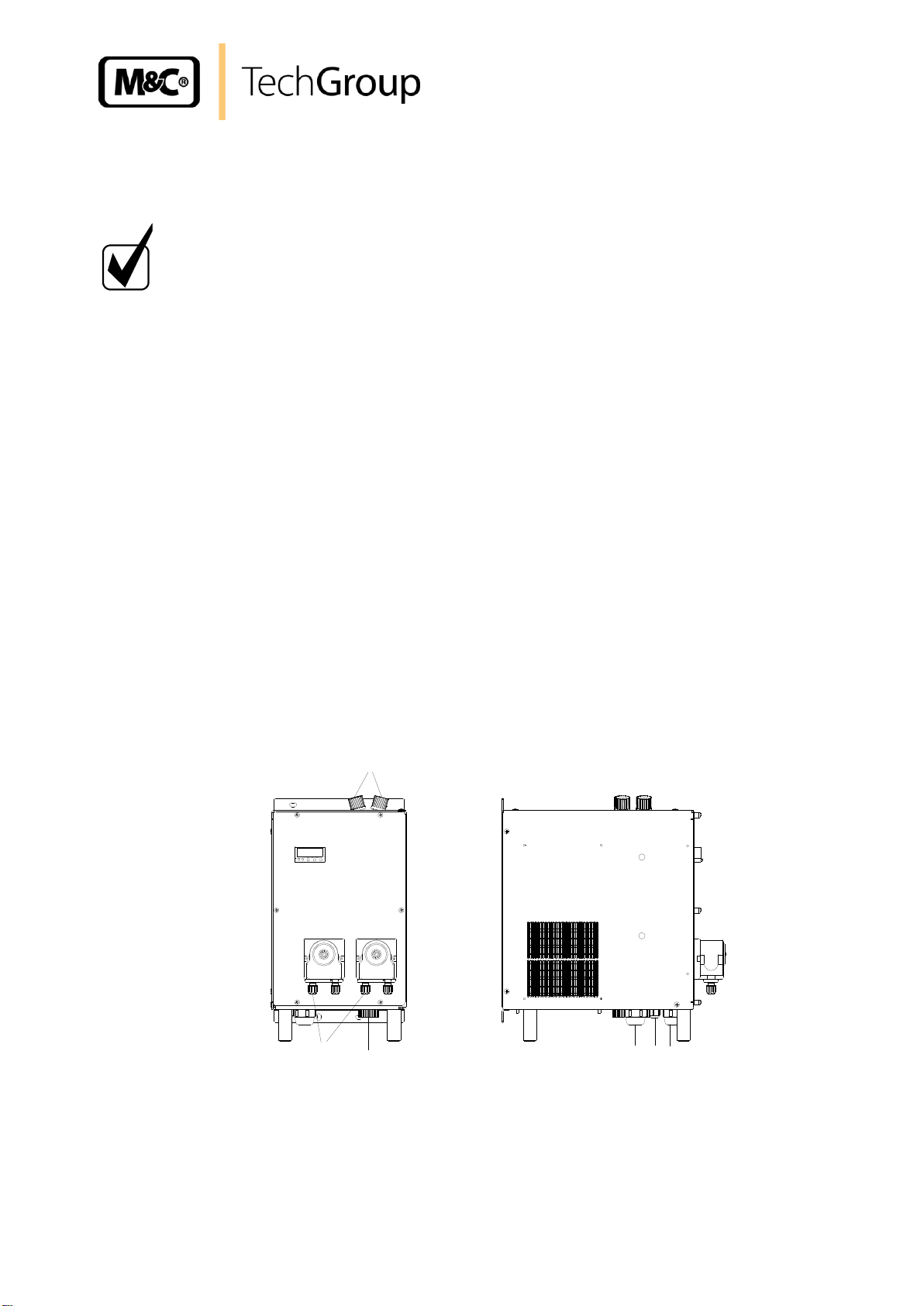

Figure 1 Application example of the EC-L ....................................................................................... 7

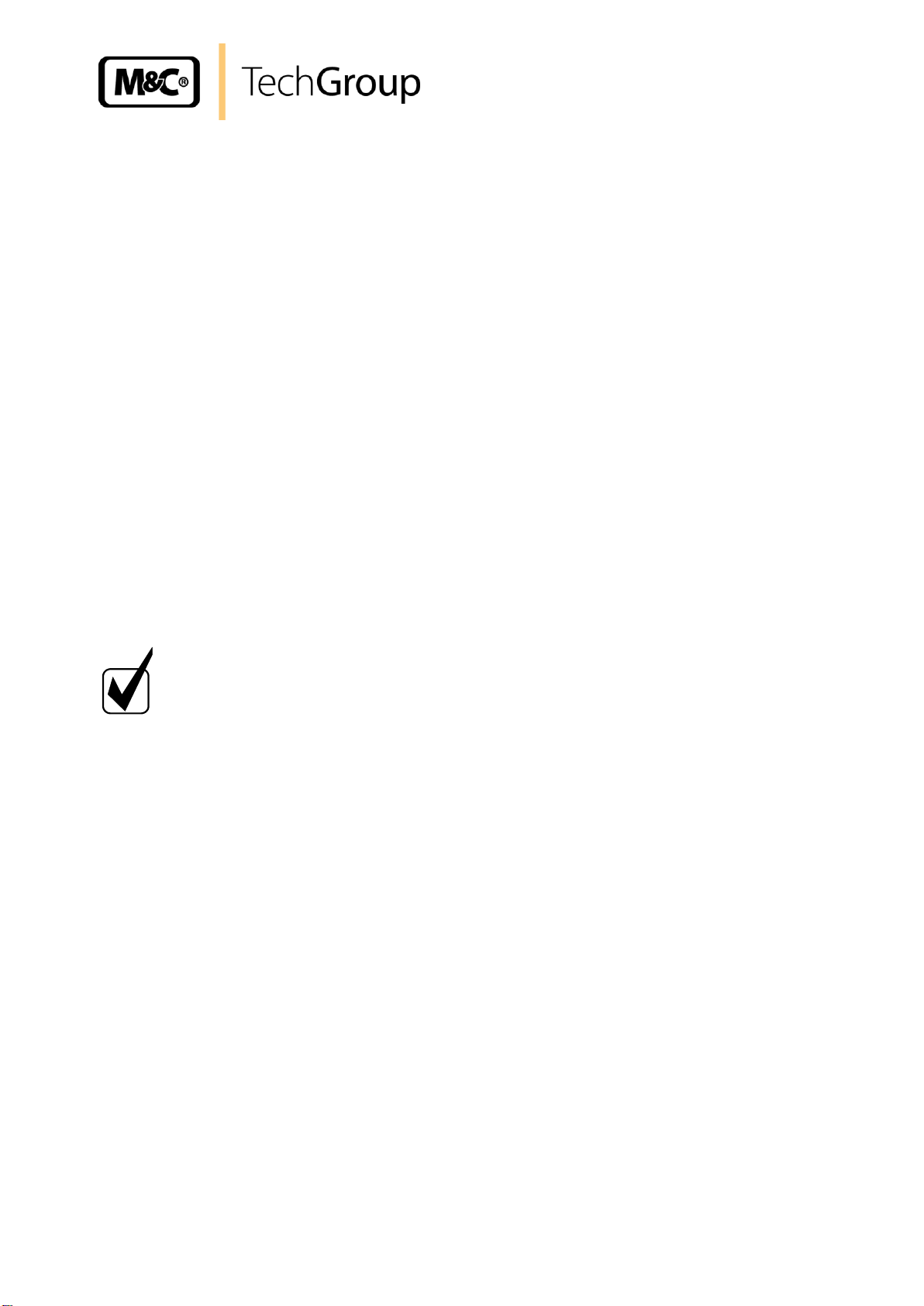

Figure 2 EC-L .................................................................................................................................. 9

Figure 3 Schematic diagram of the heat exchanger function ........................................................ 10

Figure 4 Position of the gas and condensate connections and the cable glands .......................... 11

Figure 5 Electrical connections ...................................................................................................... 13

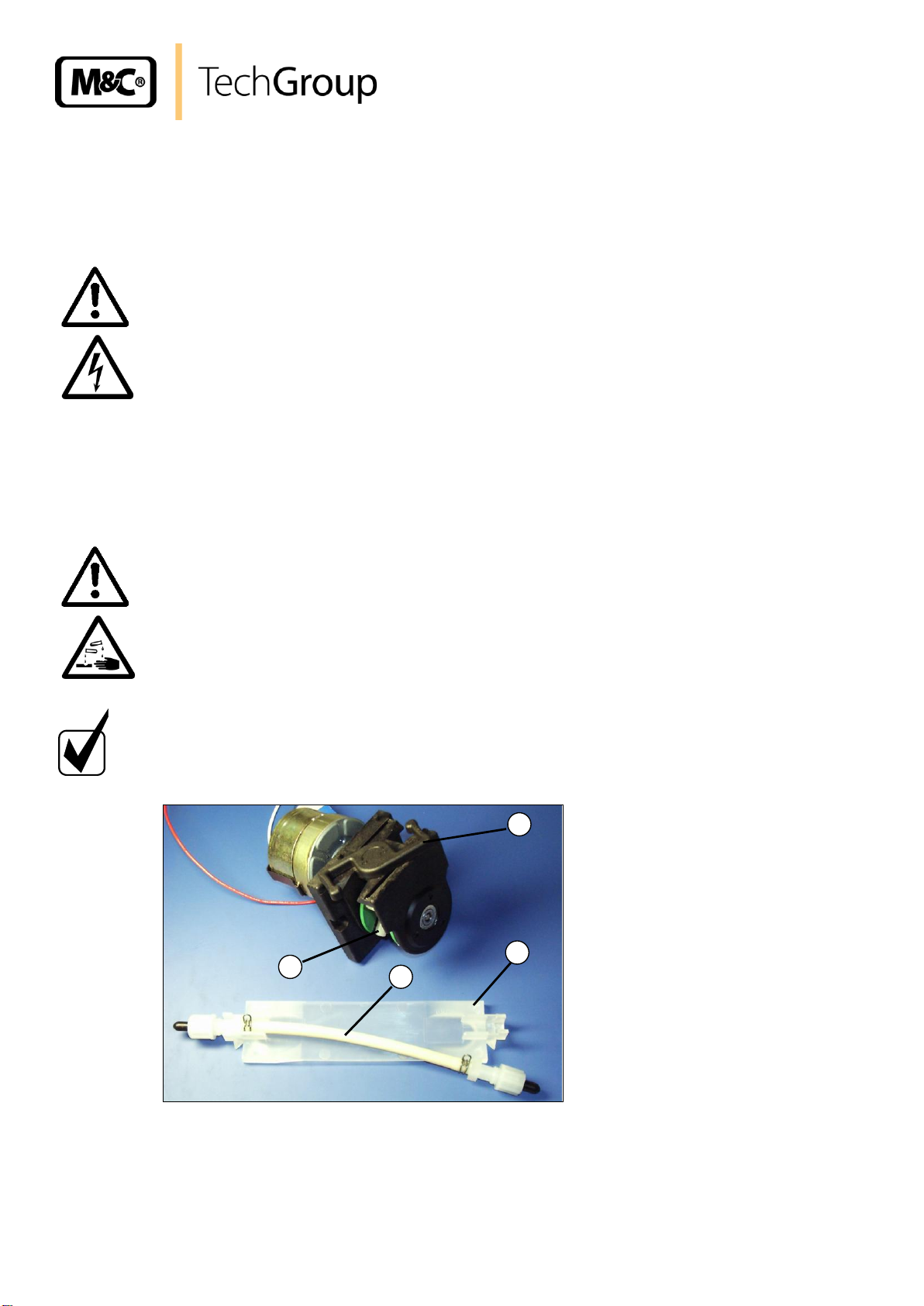

Figure 6 Change of the pump tube ................................................................................................ 16

Figure 7 Front view of the temperature controller .......................................................................... 18

Figure 8 Sample outlet dew point depending on gas flow rate and sample inlet dew points

of 80°C ............................................................................................................................. 21

Gas sampling and gas conditioning technology 3-3.1-ME

Page 4

4

Head Office

M&C TechGroup Germany GmbH Rehhecke 79 40885 Ratingen Germany

Telephone: 02102 / 935 - 0

Fax: 02102 / 935 - 111

E - mail: info@mc-techgroup.com

www.mc-techgroup.com

1 GENERAL INFORMATION

The product described in this operating manual has been examined before delivery and left our works

in perfect condition related to safety regulations. In order to keep this condition and to guarantee a

safe operation, it is important to heed the notes and prescriptions made in this operating manual.

Furthermore, attention must be paid to appropriate transportation, correct storage, as well as

professional installation and maintenance work.

All necessary information a skilled staff will need for appropriate use of this product are given in this

operating manual.

2 DECLARATION OF CONFORMITY

CE - Certification

The product described in this operating manual complies with the following EC directives:

EMV-Instruction

The requirements of the EC directive 2004/108/EC “Electromagnetic compatibility“ are met.

Low Voltage Directive

The requirement of the EC directive 2006/95/EC “Low Voltage Directive“ are met.

The compliance with this EC directive has been examined according to DIN EN 61010.

Declaration of conformity

The EU Declaration of conformity can be downloaded from the M&C homepage or directly requested

from M&C.

Gas sampling and gas conditioning technology 3-3.1-ME

Page 5

5

3 SAFETY INSTRUCTIONS

Please take care of the following basic safety procedures when mounting, starting up or

operating this equipment:

Read this operating manual before starting up and use of the equipment. The information and

warnings given in this operating manual must be heeded.

Any work on electrical equipment is only to be carried out by trained specialists as per the regulations

currently in force.

Attention must be paid to the requirements of VDE 0100 (IEC 364) when setting high-power electrical

units with nominal voltages of up to 1000 V, together with the associated standards and stipulations.

Check the details on the type plate to ensure that the equipment is connected to the correct mains

voltage.

Protection against touching dangerously high electrical voltages:

Before opening the equipment, it must be switched off and hold no voltages. This also applies to any

external control circuits that are connected.

The device is only to be used within the permitted range of temperatures and pressures.

Check that the location is weather-protected. It should not be subject to either direct rain or moisture.

The gas cooler EC-L must not be used in hazardous areas.

Installation, maintenance, monitoring and any repairs may only be done by authorized personnel with

respect to the relevant stipulations.

4 WARRANTY

If the equipment fails, please contact M&C directly or else go through your M&C authorised dealer.

We offer a one year warranty as of the day of delivery as per our normal terms and conditions of sale,

and assuming technically correct operation of the unit. Consumables are hereby excluded. The terms

of the warranty cover repair at the factory at no cost or the replacement at no cost of the equipment

free ex user location. Reshipments must be send in a sufficient and proper protective packaging.

Gas sampling and gas conditioning technology 3-3.1-ME

Page 6

6

DANGER!

This means that death, severe physical injuries and/or important

material damages will occur in case the respective safety measures

are not fulfilled.

W AR N IN G !

This means that death, severe physical injuries and/or important

material damages may occur in case the respective safety

measures are not fulfilled.

CARE!

This means that minor physical injuries may occur in case the

respective safety measures are not fulfilled.

CAR E!

Without the warning triangle means that a material damage may

occur in case the respective safety measures are not met.

ATT ENT ION !

This means that an unintentional situation or an unintentional status

may occur in case the respective note is not respected.

NOTE!

These are important information about the product or parts of the

operating manual which require user’s attention.

SKILLED STAFF

These are persons with necessary qualification who are familiar with

installation, use and maintenance of the product.

5 USED TERMS AND SIGNAL INDICATIONS

Gas sampling and gas conditioning technology 3-3.1-ME

Page 7

7

6 INTRODUCTION

The patented M&C EC-L gas cooler unit is always to be installed in situations where there is

interference from moisture in the gas to be measured.

Reduction of the gas temperature inside the cooler to a stable and very low dew point effects a

condensing-out of the sample gas.

6.1 SERIAL NUMBER

The type plate with the serial number is located at the side panel of the cooler housing. Whenever you

call M&C regarding questions or orders for the spares please give us the serial number of your EC-L.

7 APPLICATION

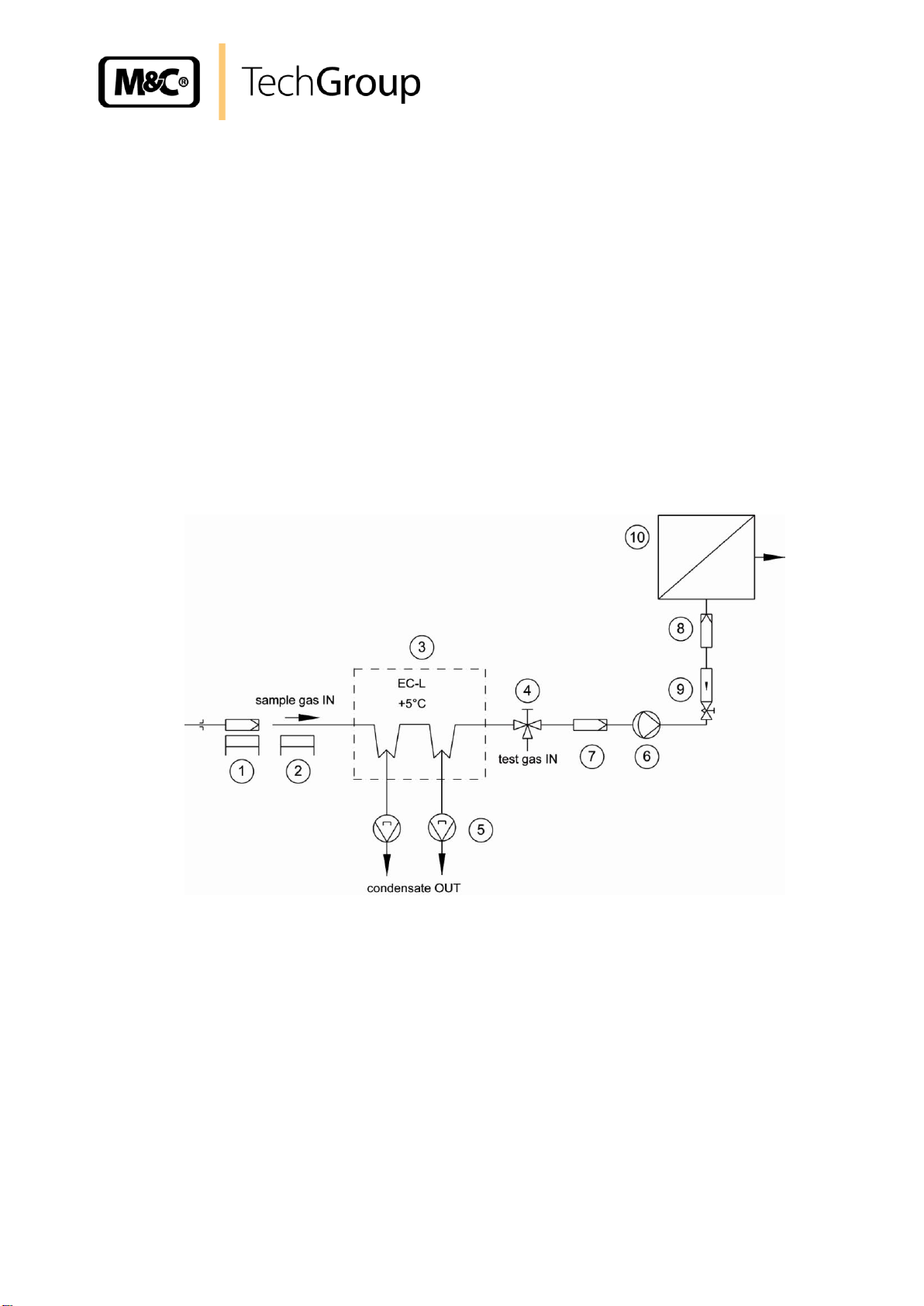

Figure 1 shows a typical example of an application for installation of an EC-L gas cooler unit.

Figure 1 Application example of the EC-L

1 : Filter sample probe SP ...

2 : Heating sample line

3 : EC-L cooler

4 : 3-way ball valve

5 : Peristaltic pump (option)

6 : Membrane pump

7 : Super fine filter FP ...

8 : Aerosol filter CLF-5

9 : Flow meter FM10

10 : Analyser

The gas to be measured is taken from the EC-L gas cooler by a gas sample probe via a heated

sample line and cooled down to a dew point of +5°C. The super-fine filter located afterwards

removes solid particles. For increased operating safety of the entire system we recommend installing a

super-fine filter with a liquid alarm sensor. If required an aerosol filter can be installed

downstream the flow meter . The gas thus treated can now be passed into the analyser .

Gas sampling and gas conditioning technology 3-3.1-ME

Page 8

8

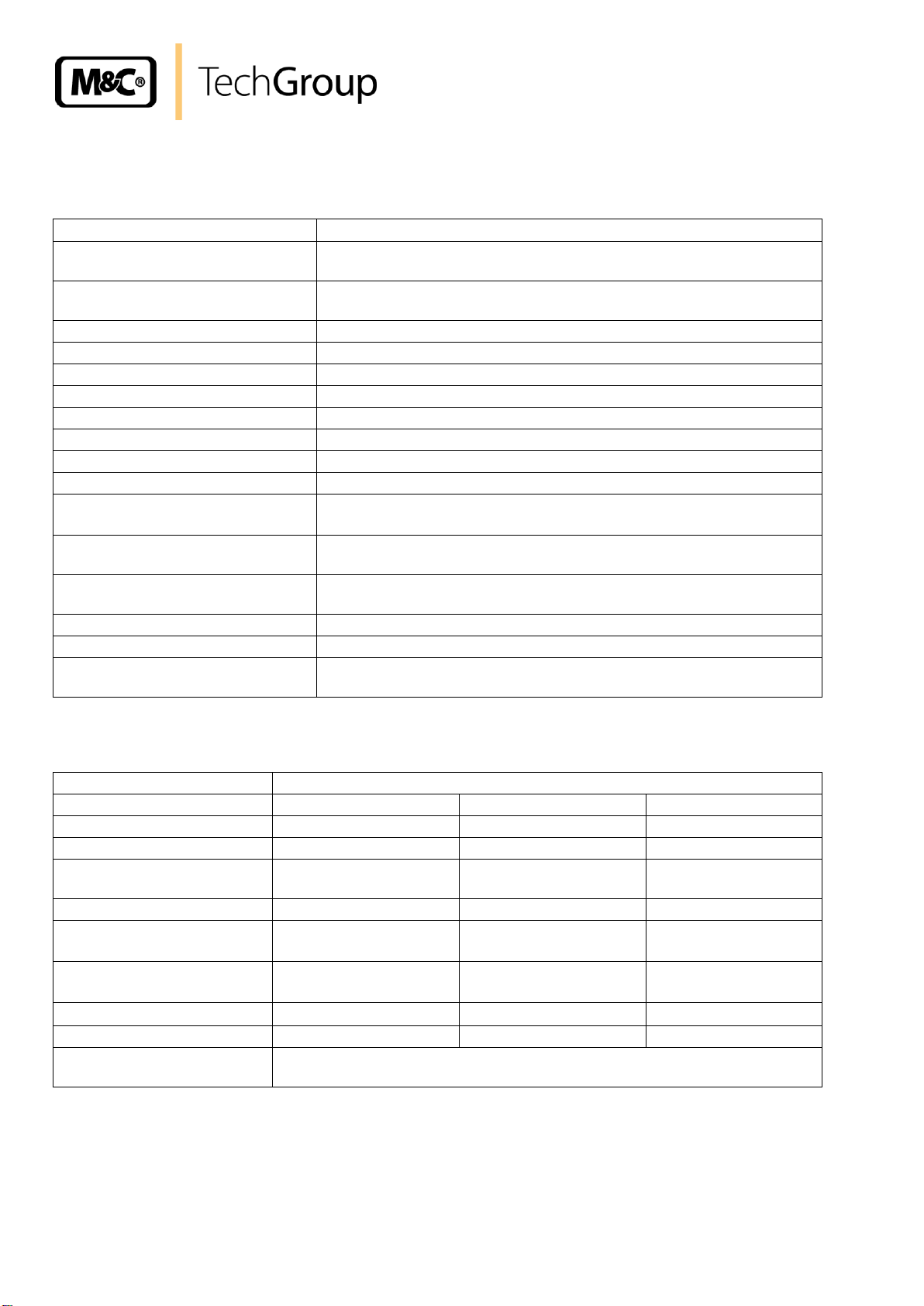

Gas cooler series EC

version EC-L

Part No. for basis cooler without

heat exchanger, 230V 50Hz

02K4000X (a)**

Part No. for basis cooler without

heat exchanger, 115V 50-60Hz

prepared for 1 stream

Number of heat exchangers

2

Ambient temperature

+10 up to +45 °C

Sample outlet dew point

range of adjustment: +2 °C ..... +7 °C, factory setting: +5 °C

Dew point stability

at constant conditions < ±0,1 °C

Sample inlet temperature

*** max. 180 °C

Sample inlet dew point

*** max. 80 °C

Total cooling capacity

144 KJ/h at +10 up +45 °C ambient

Ready for operation

< 15 min

Main power connection / power

consumption

230V AC* or 115V AC**(a) -15%/+10%, 50/60 Hz, max. 200VA

start up current: 230V 50Hz = 2,5A / 115V 60Hz = 4,5A

Electrical connection

terminals 2,5mm2, 2x PG11 cable gland (with FM-approval conduit-hub

1/2” NPT)

Status alarm

2 contacts, potential free contact rating 250VAC, 2A, 500VA, 50W,

alarm point <+2 °C and >+8 °C*

Case protection / Electrical standard

IP20 EN60529 / EN 61010

Method of mounting / Case colour

wall mounting / case colour grey, RAL 9003

Dimension / Weight

210x311,5x300 mm (w x h x d) / 17,6 kg (with 2 SR25.2 and 2 glass

heat exchangers)

Options for basic cooler

EC-L

Heat exchanger type

ECL-G

ECL-PV

ECL-SS

Part No

97K0605

97K0610

97K0600

Material of heat exchanger

Duran glass

PVDF

st. steel 316Ti

Max. gas flow rate per heat

exchanger

250Nl/h

250Nl/h

250Nl/h

Gas press. max. bar abs.

3)

2 / 3

2)

3

10*

Sample gas connection

GL18

for Ø6mm a.d. tube*

Tube ø 6 mm*

Tube ø 6 mm

Condensate connection

GL25 for Ø12mm tube*

Ø8mm or Ø10mm**

G3/8’’i

G3/8’’i or

3/8 NPT**

P at max. flow rate

1mbar

1mbar

1mbar

Stagnant space approx.

50ml

ml

ml

Peristaltic pump SR25.2

1 pc. incorporated in the cooler, compl. installed, Part No.: 01P9125 cooler

weight plus 0,6 kg per pump

8 TECHNICAL DATA

8.1 FOR BASIC COOLER EC-L WITHOUT HEAT EXCHANGER

8.2 OPTIONS FOR BASIC COOLER EC-L

* Standard, other version on request.

** Option

*** Maximum values in technical data’s must be rated in consideration of total cooling capacity at 25 °C ambient temperature..

2) With GL-Connecting adapter.

3) With SR25.2 max. 2 bar abs.

Gas sampling and gas conditioning technology 3-3.1-ME

Page 9

9 DESCRIPTION

210

350

143

63

332

300

349

380

Figure 2 shows the EC-L cooler unit.

9

Figure 2 Dimensions EC-L

The cooler EC-L is suitable for wall installation. The depth of the housing of the cooler is 300mm

(349mm with optional mounted peristaltic pumps ).

On the upper side of the cooler casing you will see the cutout for 2 heat exchangers. Sample gas

enters and leaves the heat exchangers by the correspondingly connections on the upper part of the

heat exchangers (see 8. technical data).

The main power connector and the contact output for the status alarm can be connected at terminals

X1 respectively X3 located behind the hinged front panel of the EC-L housing.

At the bottom of the housing the following connections are provided as standard:

standard condensate outlets from the heat exchangers,

cable bushings 2 x M20 x 1,5 clamp range 6-12mm;

cable bushing 1 x M12 x 1,5 clamp range 4-8mm

With low- respectively ambient pressure the condensate removal happens via the peristaltic pumps

SR25.2 optionally implemented in the cooler housing or externally with collecting vessels type

TG.../TK... . With over-pressure an automatic liquid drainer type AD-... is suitable.

The cooler has an integrated electronic for the liquid alarm sensor LA1S and a relay contact for pump

control. In case of liquid alarm the pump will be switched off via the relay. Both connections are on the

electronic board behind the front plate. The necessary plugs for electrical connection are in the range

of delivery.

Gas sampling and gas conditioning technology 3-3.1-ME

Page 10

10

+5°C

Sample

OUT

Sample

IN

Condensate OUT

Cooling

block

NOTE!

The cooler must be stored in a weather protected frost-free area!

During transport and when in storage, the cooler must always be stood up

with the transport feet positioned underneath so that the oil in the closed

compressor circuit cannot run out of this compressor case.

If the cooler is transported on its back by mistake, it must stood in the

operating position for approx. 24 hours before it is switched on!

10 FUNCTION

The M&C gas cooler type EC-L is a compressor cooler with status alarm capability. This ensures

100% availability of the cooler.

Two Jet-stream heat exchangers made of Borosilicate glass, PVDF or stainless steel are located in a

heat-insulated cooling block. All the heat exchangers are easily accessible and are arranged in such a

way that they can be removed very simply.

Figure 3 shows a schematic diagram of the functioning of the heat exchanger: The compressor cooler

system has a heat-insulated cooling block at a constant temperature of +5°C. The novel construction

of the heat exchanger guarantees a very good pre-separation of condensate and for that reason an

optimal drying of sample gas.

Figure 3 Schematic diagram of the heat exchanger function

11 RECEPTION AND STORAGE

The EC-L gas cooler is a complete pre-installed unit.

Carefully inspect the EC-L and any special accessories included with it immediately on arrival

by removing them from the packing and checking for missing articles against the packing list !

Check the items for any damage in transit and, if required, inform the shipping insurance

company immediately of the damage found!

Gas sampling and gas conditioning technology 3-3.1-ME

Page 11

11

NOTE!

The operating position for this cooler is exclusively vertical. This is the

only way to ensure proper separation and removal of condensate in the

heat exchangers. During transport and installation, the cooler must

always be stood up with the transport feet positioned underneath so that

the oil in the closed compressor circuit cannot run out of the compressor

case.

The cooler should be kept away from sources of heat and well ventilated

when installed, so that condensation from warmth will not occur and

interfere with operation.

The minimum installation dimensions (fig. 2) must be followed without

fail. If the unit is installed in the open, the cooler must be installed in a

housing that is frost-free in winter and adequately ventilated in summer.

Avoid locating the unit in direct sunlight.

Unheated gas sample lines must be provided with slope up to the cooler.

In that case pre-separation of the condensate is not required. Connect the

heated sample line with sufficient thermal decoupling of min. 20cm to the

cooler!

45

1

2

3

4

1 Gas in- and outlet

2 Condensate outlet

3 Condensate outlet with incorporated peristaltic pumps

4 Cable glands M20 x 1,5

5 Cable gland M12 x 1,5

12 INSTALLATION INSTRUCTIONS

The EC-L cooler is suitable for wall mounting.

13 SUPPLY CONNECTIONS

13.1 HOSE CONNECTIONS

The connection for sample gas inlet and outlet happens on the upper part of the heat exchangers. For

possible connectors see technical data (8.).

Figure 4 Position of the gas and condensate connections and the cable glands

Gas sampling and gas conditioning technology 3-3.1-ME

Page 12

12

NOTE!

Do not mix up the hose connections; the inlet and outlet connections of

the heat exchangers are marked with arrows;

Ensure that the connections are sealed adequately;

To ensure free removal of the condensate, ensure that the listed

diameters for the condensate removal lines are not reduced!

NOTE!

When fixing the connectors in the PVDF respectively stainless steel heat

exchanger hold up with a wrench at the pane of the bolt head!

CARE!

When connecting the equipment, please ensure that the supply

voltage is identical with the information provided on the model type

plate!

Correspondingly tube and hose connectors are optional available by M&C.

Ensure that the connections are sealed adequately by noting the following:

Borosilicate glass heat exchangers with connections GL18-6 respectively GL25-12 (standard)

Before assembly, check the GL coupling rings to see if the PTFE/silicon locking rings have

been damaged.

The sealing rings should be installed with the PTFE side facing the medium.

PVDF- resp. stainless steel heat exchangers with 6mm tube resp. G3/8“I

For sample gas in- and outlet use a corresponding tube/hose connector (e.g. D6-DN4/6, part

no. 05V3115).

The correspondingly dimensioned tube respectively hose couplings for condensate outlet with

threaded connections G3/8” have to be screwed in with PTFE thread sealing tape.

To grant a functional and unproblematic mounting we recommend to use union pieces with

taper pipe thread type R according to DIN 2999/1 in connection with suitable sealing tape.

Option: stainless steel heat exchanger with NPTi thread at the condensate outlet

The heat exchangers with NPT threaded connectors are marked with circulated notches at the

condensate outlet.

The NPT thread must be screwed in with sealant or fixed with adhesive.

In the standard configuration, the tubes for removal of condensate are connected directly to the heat

exchangers. These protrude with the GL25-12 tube connectors (standard, Borosilicate glass heat

exchanger) respectively with G3/8” (standard) thread joint PVDF or stainless steel heat exchanger

above the base plate of the cooler casing (fig.2). Condensate removal is done by customer according

to the type of operation with:

peristaltic pump(s) type SR25.2 implemented optionally in the cooler housing,

external mounted condensate vessel(s) with manually emptying respectively,

automatic float-type condensate traps type AD-... (only for excess pressure operation).

13.2 ELECTRICAL CONNECTIONS

Gas sampling and gas conditioning technology 3-3.1-ME

Page 13

13

NOTE!

Attention must be paid to the requirements of IEC 364 (DIN VDE

0100) when setting high-power electrical units with nominal

voltages of up to 1000V, together with the associated standards

and stipulations.

An external main switch must be provided.

The main circuit must be equipped with a fuse of 10AT (over

current protection); for electrical details see technical data (8.).

W AR N IN G !

Cooler versions with 115V resp. 120V have a built-in transformer

to generate an internal current of 230V. That means, device internal

live parts have a current of 230V not 115V/120V.

Figure 5 shows the electrical connections behind the front panel of the EC-L housing (fig. 2).

Alarms for excess- and low-temperature and liquid alarm (if connected) are given as a collective status

alarm via a relay output with a potential-free changeover contact. Alarm will be released if the current

temperature is out of a range of ±3°C referring to the set-temperature (+5°C) or if the liquid sensor

gets wet. A sample pump connected to terminal X4 will be switched off via an internal relay in case of

liquid alarm.

Figure 5 Electrical connections

The connection of the mains respectively , liquid alarm sensor, pump and status alarm signals

happens as follows:

release the captive screws (6 pcs.) at the cooler front and then swing open the front plate;

put the cables (6-12mm) through the cable glands M20 and connect them with the provided

plugs according to above mentioned wiring plan;

if a liquid alarm should be connected put the cable of the liquid alarm sensor through the cable

gland M12 and connect it with the provided plug according to above mentioned wiring plan;

the re-installation happens in the opposite way.

Gas sampling and gas conditioning technology 3-3.1-ME

Page 14

14

NOTE!

Before starting up the gas cooler, it must be placed in its operating

position for at least two hours. The liquid inside the system may have

been redistributed, and this could cause problems in operation.

NOTE!

The status contacts must be connected to the external sample gas pump

or to a valve in the sample gas line to protect the entire analysis system

by immediately cutting off the gas supply in the event of error messages

from the cooler!

NOTE!

The location for the cooler must remain frost-free, even when the unit has

been switched off!

If the cooler unit is put out of action for a short time no particular

measures need to be taken.

We recommend sweeping the cooler with inert gas or ambient air while

the unit is put out of action for a longer time.

CARE!

Aggressive condensate is possible.

Wear protective glasses and proper protective clothing!

DANGER!

Dangerous voltage!

It is necessary to take the gas cooler off the mains before any

assembly, maintenance and repair work is carried out!

14 START-UP

The thermo-hydraulic controlled cooling system of the EC-L permit automatic start-up of the cooler.

The following description is valid for start-up of the gas cooler for an ambient temperature > 8°C.

The following steps should be carried out before initial start-up:

Connect the cooler unit to the mains power supply; Check that the equipment is connected to

the correct mains voltage, 115V or 230V, as shown on the type plate.

Lead the status contact for status alarm to the measuring station;

15 CLOSING DOWN

16 MAINTENANCE

The safety instructions specific to the plant and process are to be consulted prior to any maintenance

work!

Gas sampling and gas conditioning technology 3-3.1-ME

Page 15

15

NOTE!

Do not mix up the hose connections; gas outlet and gas inlet are

marked with arrows!

The EC-L cooler does not require any special maintenance intervals. The cooler is to be cleaned with

compressed air according to the contamination level of the ambient air (see 16.2).

16.1 ADDING AND REPLACING THE HEAT EXCHANGERS

Removal of the heat exchangers may be necessary to carry out maintenance or repair work.

We recommend the following procedures and in this order for replacement of the heat exchangers:

Release the upper gas connections and lower condensate connections;

Pull the heat exchangers upwards with rotation out of the cooling block;

Replace the heat exchangers as follows:

Dry and clean the push-in opening in the aluminium cooling block with a cloth;

Smear the push-in opening with a thin and equal layer of thermal conductivity paste (part no.

90K0115);

Smear the heat exchangers with a thin and equal layer over the whole surface with thermal

conductivity paste (part no. 90K0115) to ensure good conduction of heat. It is best to close off

the condensate removal of the heat exchangers tube with adhesive tape to prevent any of the

thermal conductivity paste from getting into the heat exchanger;

Lightly push the heat exchangers with rotation back into the push-in opening of the cooling

block and press to the upper block;

Remove the adhesive tape and any surplus thermal conductivity paste;

Reconnect the hoses.

Mounting the Borosilicate glass heat exchangers please notice:

Check the PTFE/Silicon locking rings for damage. In assembly, the locking rings must have the

PTFE side facing the medium, otherwise the required degree of sealing cannot be guaranteed!

Remount the red GL coupling rings hand-tight by turning them to the right;

To ensure a safe connection of the sample gas respectively condensate tubes to the Borosilicate glass

heat exchanger(s) we recommend the use of GL-couplings.

We would like to advise you.

16.2 CLEANING THE FINS OF THE CONDENSER

Dust on the fins of the condenser reduces the cooling capacity. Therefore it is necessary to clean the

fins from time to time. The following steps are recommended:

Shut off the gasflow;

Take off the cooler of the mains;

release the captive screws (6 pcs.) at the cooler front and then swing open the front plate;

Clean the fins through the ventilation slots on the left side carefully with compressed air;

Re-install the front plate;

Connect the tubing for gas in- and outlet.

Gas sampling and gas conditioning technology 3-3.1-ME

Page 16

16

DANGER

Dangerous voltage !

It is necessary to take the pump off the mains before any assembly,

maintenance and repair work is carried out !

CARE!

Aggressive condensate is possible !

Wear protective glasses and proper protective clothing !

NOTE!

If you send back the peristaltic pump to the M&C service for repair,

please let us know what kind of condensate has been pumped.

Before sending the pump back clean all parts from dangerous or highly

aggressive contaminants.

1

2

3

4

16.3 MAINTENANCE OF THE OPTIONAL MOUNTED PERISTALTIC PUMPS, TYPE

SR25.2

Before the maintenance work is carried out, it is necessary that the specific safety procedures

pertaining to the system and operational process are observed !

Flexible tube, conveying belt, contact pulleys and contact springs are the only parts of the pump

subject to wear. They are simple to change.

16.3.1 CHANGE OF THE PUMP TUBE

Figure 6 Change of the pump tube

Take off the cooler of the mains;

Open hose connectors at the pump;

Press conveying belt at the recessed grips and turn S-bolt 2 clockwise up to limit stop;

Gas sampling and gas conditioning technology 3-3.1-ME

Page 17

17

NOTE!

Only the usage of the original hose set guarantees a perfect function.

Never lubricate the hose.

Before mounting the pump check all parts for impurity and clean if

necessary.

NOTE!

While mounting pay attention to the fit of ‘rotational axisdriver’.

Use genuine spare parts only!

CARE!

Aggressive sample is possible!

Wear protective glasses and proper protective clothing

during disassembly, repair or cleaning!

Take away conveying belt and remove the old hose set from the guides by the hose

connectors;

Press the two contact pulleys and check whether the spring pressure is still sufficient, if not,

the contact springs have to be changed;

Put the new hose set with the hose connectors into the guides of the conveying belt ;

Put the conveying belt with the new hose into the dovetail guide of the pump body;

Press conveying belt at the recessed grips and simultaneously turn the S-bolt anticlockwise

until it snaps;

Switch on pump.

16.3.2 CHANGE OF CONTACT PULLEYS AND SPRINGS

Take off the cooler of the mains;

Unscrew the nut of the pump head (span of the jaw 5,5);

Draw the pump head out of the motor shaft;

Now the driver can picked out of the pump head and is ready for maintenance.

The removal of the springs (4 pcs.) away from the driver is possible without the aid of any

tools. Therefore press together the spring and take it out of the groove in the driver respectively

out of the boring in the axle. Now the roller bearing axle can be dismounted and the contact

pullets are ready for change.

Remounting happens in the opposite way.

16.3.3 CLEANING THE PUMP HEAD

When changing flexible tube or other parts, inspect all parts for dirt before assembling the

pump head and clean them if necessary.

As far as possible clean the parts with a dry cloth. Solvents should not be used as they can

attack the plastics and synthetic rubber parts. If a compressed air line is available, blow the

parts out with it.

Gas sampling and gas conditioning technology 3-3.1-ME

Page 18

18

17 OPERATING OF THE BUILT-IN ELECTRONIC TEMPERATURE CONTROLLER

In normal operation the display of the temperature controller shows the actual cooling temperature.

Figure 7 shows the front view of the temperature controller.

Figure 7 Front view of the temperature controller

17.1 CHANGING THE SET VALUE

To change the set value the P-key has to be pushed < 2 sec. The company fixed value of 5°C

appears. With the two arrow keys the value can be changed. This value should not be adjusted lower

than +1°C, because otherwise the heat exchanger will freeze up. Is the value adjusted higher than the

ambient temperature the cooler will not work.

17.2 CHANGING THE TEMPERATURE ALARM WINDOW

The exact description of changing the temperature alarm window can be found in the manual of the

temperature controller.

Gas sampling and gas conditioning technology 3-3.1-ME

Page 19

19

Error

Possible reason

Check/Repair

Condensate in the gas outlet

Ambient temperature < 5C

Cooler overloaded

Peristaltic pump doesn’t work

Tube of the peristaltic pump

defective

Cooling capacity too low

(cooler is not overloaded)

Motor protection switch released

Heat up the components downstream;

Keep the operational data (8.);

Change peristaltic pump;

Change the tubing (16.3.1);

Clean the fins of the condenser (16.2);

Check the vent;

Check the safety distance to other

heated components;

Secure sufficient ventilation;

Thermal load caused by the sample gas

resp. ambient is too high;

Clean the fins of the condenser;

Keep the operational data (8.);

Let the cooler cool down before restarting

it;

Gas flow blocks up reading

Contamination of the sample gas

way

Optimize the dust pre-separation

upstream the cooler;

Clean the gas ways and the cooling

system;

Wrong temperature

Temperature sensor defective

Temperature controller defective

Circuit of cooling agent leaky

Check the PT100-sensor;

Check the temperature controller;

Send the cooler for repair;

Cooler break-down

Power supply interrupted

Check the power supply and reconnect;

Pay attention to the relevant

safety instructions!

Compressor does not work

Compressor defective;

Motor protection switch defective

Send the cooler for repair;

18 TROUBLE SHOOTING

The following table should give an overview of possible errors and an instruction to check and to repair

them (is not valid for the starting-up period of cooler).

Gas sampling and gas conditioning technology 3-3.1-ME

Page 20

20

Electric gas cooler EC-L

(C) Consumable parts

(R) Recommended spare parts

(S) Spare parts

Recommended quantity being in

operation [years]

Part No.

Indication

C/R/S

1 2 3

97 K 0605

ECL-G Jet-Stream heat exchanger

material: Borosilicate glass

connections gas: GL18-6mm

condensate: GL 25-12mm

R

1 1 1

97 K 0610

ECL-SS Jet-Stream heat exchanger

material: SS 316

connections gas: 6mm tube

condensat:e: G 3/8“i

R 1 1

1

97 K 0600

ECL- PV Jet-Stream heat exchanger

material: PVDF (Polyvinylidenfluorid)

connections gas: 6mm tube

condensate: G 3/8“i

R 1 1

1

90 K 0115

EC-thermal conductivity paste 50g (-40°C bis 140°C)

R 1 1

2

01 H 9005X

Fan EC-L 230V, 50Hz

C - -

1

93 K 0040X

PT-100 temperature sensor for EC-L

C - -

1

97 K 0010

ECM transformer 115V/230V, ... 230VA

R - -

-

01 B 8360

Electron. PID-temperature controller type with LED indication, in a

front mounting housing standard control ranges: PT100, 0-200°C,

Fe-CuNi 0-400/0-800°C controlling outlet: 12V DC to an external

solid state relais status signal outlet: 1 voltage free contact NO for

high and low alarm switch capacity 250VAC,3A power 230/115V

50/60 Hz.

T - -

1

Peristaltic pump SR25.2

(C) Consumable parts

(R) Recommended spare parts

(S) Spare parts

Recommended quantity being in

operation [years]

Part No.

Indication

C/R/S

1 2 3

90 P 1007

Hose set SR25

with PVDF-tube connectors 4/6mm, standard

C 1 2

4

90 P 1020

Driver SR25, complete

S - 1 1 90 P 1010

1 set (4 pcs) contact springs SR25 for driver

R 1 2 2 90 P 1045

Contact pulleys SR25 PVDF for driver

S 2 4

4

90 P 1050

Conveying belt SR25

S - 1

2

90 P 1025

S-bolt SR25

S - - 1 01 P 1300

Peristaltic pump SR25.2, complete 230V/115V, 50/60Hz

R - - 1 90 P 1030

Heat peristaltic pump SR25, complete without motor and gears

S - -

1

19 SPARE PARTS LIST

Wear, tear and replacement part requirements depend on specific operating conditions.

The recommended quantities are based on experience and they are not binding.

Gas sampling and gas conditioning technology 3-3.1-ME

Page 21

21

20 APPENDIX

Sample outlet dew point depending on gas flow rate at sample inlet dew points of 80C

Further product documentation can be seen and downloaded from our home page:

www.mc-techgroup.com

Threaded couplings for ”GL” glass connections

Document: 3-5.1.1

Instruction manual peristaltic pump SR25.1

Document: 3-7.1ME

Automatic liquid drain AD-SS

Document: 3-6.2.3

Automatic liquid drain AD-P

Document: 3-6.2.1

Condensate vessel TG, TK

Document: 3-6.3.1

Figure 8 Sample outlet dew point depending on gas flow rate and sample inlet dew points of 80°C

Gas sampling and gas conditioning technology 3-3.1-ME

Loading...

Loading...