Page 1

ECS-1G/EC-F, ECS-4G/EC-FD

Embracing Challenge

Gas Cooler Series EC®

Version ECS and EC-Ex

for 4x 250 Nl/h

Special Features

Jet Stream heat exchangers in 3 stand-

ard materials

Ambient temperature up to 50°C

Outlet dew point adjustable from +2 °C

to +7 °C

Dew point stability ± 0,25°C

Status alarm contact standard

Optimum reliability

Self-controlled

TA-Luft approved

Explosion proof version according to

ATEX and NEPSI for zone 1

100% CFC-free

Application

ECS and EC-Ex gas coolers are used in gas

analysis to lower the dew point of humid

to avoid condensation in the analyser. An

extremely stable gas dew point avoids water

vapour crosssensitivity and volumetric errors.

Description

The electronically controlled compressor

cooling system and the special design of the

jet stream heat exchanger guarantees optimum dew point reduction to a low, stabel

value and secures condensate formation. No

external pre-draining is needed.

Up to 4 peristaltic pumps can be installed in

the ECS to drain condensate. Otherwise the

condensate must be removed with traps or

collected in vessels.

A fan unit EC-F for ambient temperatures

>40°C or a peristaltic pump unit EC-D is available to fit the base of the ECS for condensate

drainage. The peristaltic pump unit is also

available as version EC-FD with additional fans

to force the airventilation.

The new design enables up to 4 heat exchangers to be incorporated either at the factory or

later, without any problem. They can be connected in series or parallel.

Heat exchangers are available in various materials depending on the application. LED indicate the operating conditions. A temperature

deviation of ±3 °C triggers an alarm. The gas

coolers are self controlling and maintenancefree in operation.

Technical specications and illustrations are without

obligation, subject to modications. 10.96/09.09

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

6.5

Page 2

435

85

360

205

465

483

50

235

310

Gas Inlet/outlet

Condensate

EC

Cooler

C <

C >

ON

Ø70

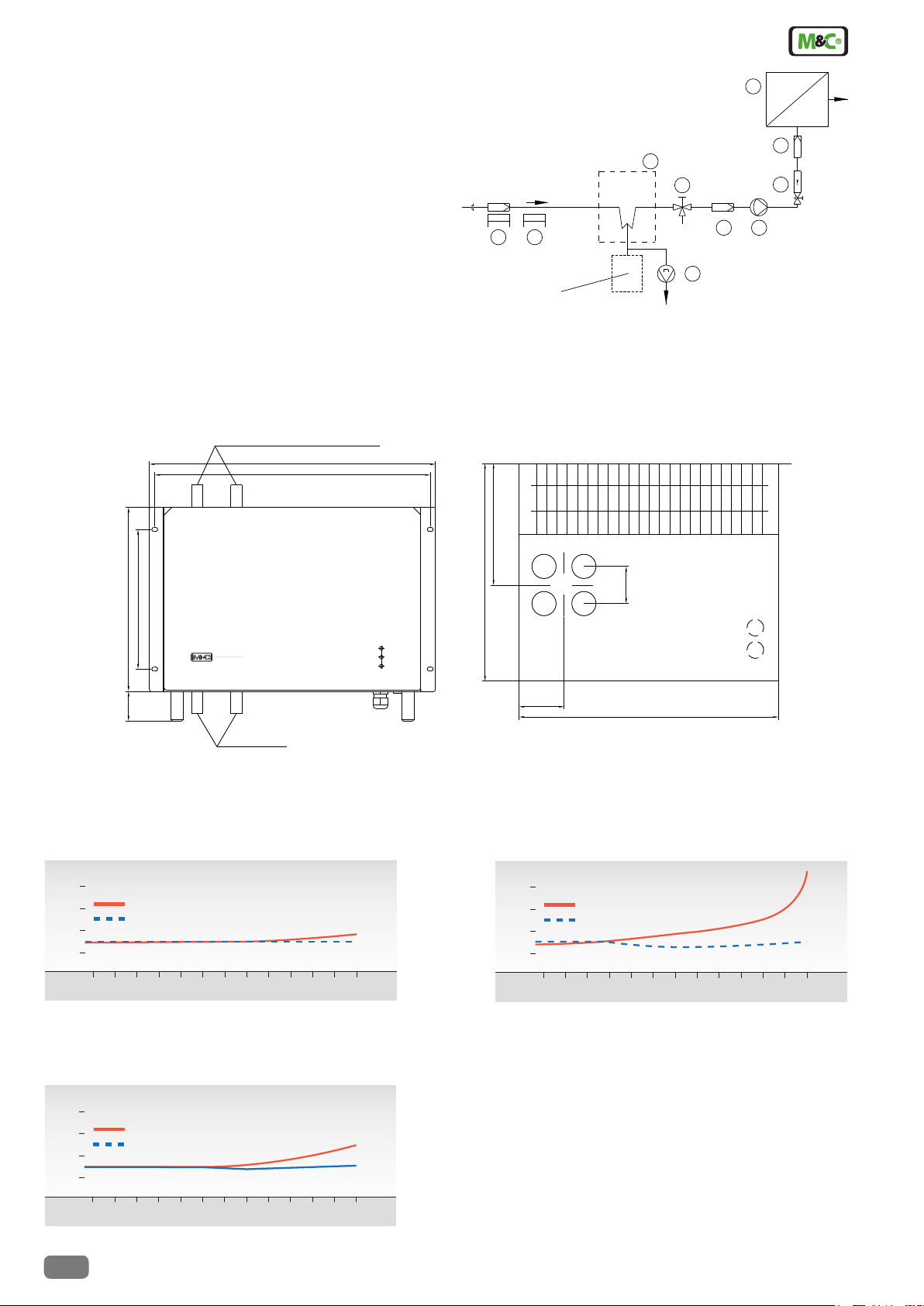

Application example for ECS

8

Alternative:

trap with float or condensate

5

+5°C

4

3

10

9

7

ECS

1 2

sample gas IN

test gas

IN

6

1 Heated lter sample probe SP210-H or SP2000-H

2 Heated sample line 4M4/6

3 Cooler ECS

4 3-way ball valve 3L/PV-1

5 Peristaltic pump SR25.2

6 Diaphragm pump MP47 or MP06/12 or N5KP

7 Fine lter FP-2T-D with liquid alarm LA1

8 Aerosol lter CLF-5 /W optional according to application

9 Flow meter FM10 or FM40, 25-250 Nl/hr

10 Analysers f. e. PMA100

Dimensions

Gas cooler ECS...

Dimensions in mm

Cooler type EC-G with heat exchanger out of

glass

°C

10

Sample inlet dew point

8

6

4

Sample outlet dew point

60 °C

40 °C

Ambient temp. 20 °C

10 30 50 70 90 110 130 150 170 190 210 230 250 Nl/h

Cooler type EC-SS with heat exchanger out

of SS316Ti

°C

10

8

6

4

Sample outlet dew point

6.5

Sample inlet dew point

60 °C

40 °C

10 30 50 70 90 110 130 150 170 190 210 230 250 Nl/h

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Ambient temp. 20 °C

Gas flow rate

Gas flow rate

Cooler type EC-PV with haet exchanger out

of PVDF

°C

10

Sample inlet dew point

8

6

4

Sample outlet dew point

60 °C

40 °C

Ambient temp. 20 °C

10 30 50 70 90 110 130 150 170 190 210 230 250 Nl/h

Gas flow rate

Technical specications and illustrations are without

obligation, subject to modications. 10.96/09.09

Page 3

Technical Data

Gas Cooler Series EC® ECS EC-Ex

Part number with glass heat exchanger 02 K 1500 (a) 02 K 5000 (a)

Part number with stainl. steel heat exchanger 02 K 2500 (a) 02 K 5010 (a)

Part number with PVDF heat exchanger 02 K 3500 (a) 02 K 5020 (a)

Number of heat exchanger 1 optional to 4

Gas flow rate per heat exchange 250 Nl/h**

Ambient temperature +5 to +45 °C, with option EC-F = +5 to +50 °C +5 to 45 °C

Storage temperature -20 to +60 °C

Sample outlet dew point range of adjustment: +2 °C ..... +7 °C, factory setting: +5 °C

Dew point stability at constant conditions ±0,25 °C

Sample inlet temperature max. 180 °C**

Sample inlet dew point max. 80 °C**

Total cooling power max. 520 KJ/h at 25° C ambient temperature

Power consumption 280VA, Start up current at 230V= 7,9A

Main connection 230V ±10%, 50Hz,

optional 115V ±10%, 60Hz

Ready for working < 30 min.

Electrical connection 2,5 mm2 terminals

Status alarm: ECS 2 changeover contacts Contact rating: 250V, 2A, 500VA, 50W, Alarm point: ∆T ±3 °C zu Tsoll

Status alarm: EC-Ex 1 changeover contact Contact rating: 220V, 2A, 100VA, 50W, Alarm point: ∆T ±3 °C zu Tsoll

Case protection IP 20; EN 60529

Electrical standard EN 61010

Case color RAL 9003

Method of mounting 19’’ rack- or wallmounting

Dimension / Weight 84HP x 7U x 360 mm / 31 kg 84HP x 7U x 450 mm / 40 kg

230V ±10%, 50Hz,

optional 115V ±10%, 50-60Hz

II2G EEx p, e, d, q, (ib) IIC T4

Options

Heat exchanger execution

Material of heat exchanger Borosilicate glass PVDF stainless steel 316Ti

Part number 02 K 9100 02 K 9300 02 K 9200

Admissible gas pressure bar g 3 2) / 2

3)

3 / 2

3)

10 bar

Sample gas connection GL18-6 ø6 mm 8 o. 10 mm* G 1/4’’ i G 1/4’’ i NPT*

Condensate connection GL25-12 ø12 mm 10 o. 8 mm* G 3/8’’ i G 3/8“ i NPT*

∆P per heat exchanger at 300 l/h 1 mbar

Dead volume per heat exchanger 70 ml

* Optional

** Maximum values in technical datas must be rated in consideration of total cooling capacity at 25 °C ambient temperature and an outlet dew point of 5 °C.

1) Others on request.

2) With GL-Anschlussadapter.

3) With SR25.1 max. 2 bar abs.

(a) Addition to part number for 115V execution

GL adapter and tube ttings for the connection of diererent tube diameters at the heat exchanger see chapter 11, data sheet 11.5 and 11.6.

Technical specications and illustrations are without

obligation, subject to modications. 10.96/09.09

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

6.5

Page 4

Gas cooler ECS...

483

Types P.N. Execution in wall mounting housing

1)

ECS 1-G 02 K 1500 Gas cooler with 1 heat exchanger out of Borosilicate glass, epth of housing 360 mm, 230V, 50Hz

ECS-1-SS 02 K 2500 Gas cooler with 1 heat exchanger out of stainless steel, depth of housing 360 mm, 230V, 50Hz

ECS-1-PV 02 K 3500 Gas cooler with 1 heat exchanger out of PVDF, depth of housing 360 mm, 230V, 50Hz

/115V 02 K ...A Power EC/ECS 115V 60Hz

EC-Ex-1G 02 K 5000 Gas cooler with 1 heat exchanger out of Borosilicate glass, depth of housing 450 mm, 230V, 50Hz, EEx execution

EC-Ex-1SS 02 K 5010 Gas cooler with 1 heat exchanger out of stainless steel, depth of housing 450 mm, 230V, 50Hz, EEx execution

EC-Ex-1PV 02 K 5020 Gas cooler with 1 heat exchanger out of PVDF, depth of housing 450 mm, 230V, 50Hz, EEx execution

/115V 02 K ...A Power EC-Ex 115V 60Hz

Another heat exchanger

EC-G 02 K 9100 Jet stream heat exchanger out of Borosilicate glass

EC-G-90° 02 K 9150 Jet stream heat exchanger out of Borosilicate glass with 90° bend at the gas connectors

EC-SS 02 K 9200 Jet stream heat exchanger out of stainless steel 316Ti

EC-PV 02 K 9300 Jet stream heat exchanger out of PVDF

Options

/PT 100 02 K 9500 PT 100 Sensor built in cooling block of EC / ECS for external temperature controlling

EC-F* 02 K 9530 Universal unit with 2 fans and dust filter for mounting under EC / ECS cooler,completely mounted, 230V 50Hz or 115V 60Hz,

not at EC-Ex

EC-FD* 02 K 9540 Universal unit for up to 4 peristaltic pumps with 2 fans and dust filter for mounting under EC / ECS cooler, incl. one peristaltic

pump, completely mounted, 230V 50Hz or 115V 60Hz, not at EC-Ex

EC-D* 02 K 9535 Universal unit for up to 4 peristaltic pumps for mounting under EC / ECS cooler, incl. one peristaltic pump,

completely mounted, 230V 50Hz or 115V 60Hz, not at EC-Ex

/115V 02K95..A Universal unit, power 115V 60Hz

/SR25.2 01P9140 Extra charge for 1 pc. peristaltic pump SR25.2 incorporated in the front plate of the cooler, compl. installed, cooler weight

plus 0,6 kg per pump

1) 19“- housing on request - please note on your order

* Universal units, peristaltic pumps, collecting vessels and ttings are presented in separate data sheets.

Order example:

1 gas cooler ECS-2G, power 115V 60Hz, with 2 heat exchangers out of glass and a universal unit EC-FD with 2 peristaltic pumps

P.N. 1x02K1500A + 1x02k9100 + 1x02K9540A + 1x01P1000 (peristaltic pump SR25.1) + 1x01P9100

Gas cooler ECS... with SR25.2 incorporated in the front plate of the cooler

360 44

310

50

235

Cooler

EC

465

°C>

ON

°C<

6.5

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 10.96/09.09

Loading...

Loading...