Page 1

Operating Manual

Electric gas cooler series EC

®

Version EC-EX (from model nos. 9904417)

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 2

2

This Operating Manual does not claim completeness and may be

subject to technical modifications.

© 09/1999 M&C TechGroup Germany GmbH. Reproduction of this

document or its content is not allowed without permission from M&C.

EC® is a registered trade mark.

4th Edition: 09/2004

Dear customer,

we have made up this operating manual in such a way that all necessary information about the

product can be found and understood quickly and easily.

Should you still have any question, please do not hesitate to contact M&C directly or go through your

appointed dealer. Respective contact addresses are to be found in the annexe to this operating

manual.

Please also contact our homepage www.mc-techgroup.com for further information about our

products. There, you can read or download the data sheets and operating manuals of all M&C

products as well as further information in German, English and French.

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 3

3

List of Contents

1 General information ...................................................................................................................... 4

2 Declaration of conformity ............................................................................................................ 4

3 Electrical standards ...................................................................................................................... 5

4 Safety instructions ....................................................................................................................... 5

5 Information and safety instructions for using the cooler in hazardous areas ........................ 6

6 Warranty ........................................................................................................................................ 6

7 Used terms and signal indications ............................................................................................. 7

8 Introduction ................................................................................................................................... 8

9 Application .................................................................................................................................... 8

10 Technical data ............................................................................................................................... 9

11 Description .................................................................................................................................. 10

12 Function ....................................................................................................................................... 12

13 Reception and storage ............................................................................................................... 13

14 Installation instructions ............................................................................................................. 13

15 Supply connections .................................................................................................................... 14

15.1 Hose connections ............................................................................................................... 14

15.2 Electrical connections ........................................................................................................ 15

16 Start-up ........................................................................................................................................ 16

16.1 Function sequence and LED function display .................................................................... 17

17 Closing down .............................................................................................................................. 18

18 Maintenance ................................................................................................................................ 18

18.1 Adding and replacing the heat exchangers ........................................................................ 19

19 Trouble shooting ........................................................................................................................ 20

20 EC automatic control board ....................................................................................................... 22

20.1 Temperature setting for the EC/ECS cooler ....................................................................... 23

21 Checking the temperature sensor ............................................................................................. 24

22 Spare parts list ............................................................................................................................ 25

23 Appendix ..................................................................................................................................... 26

List of Illustrations

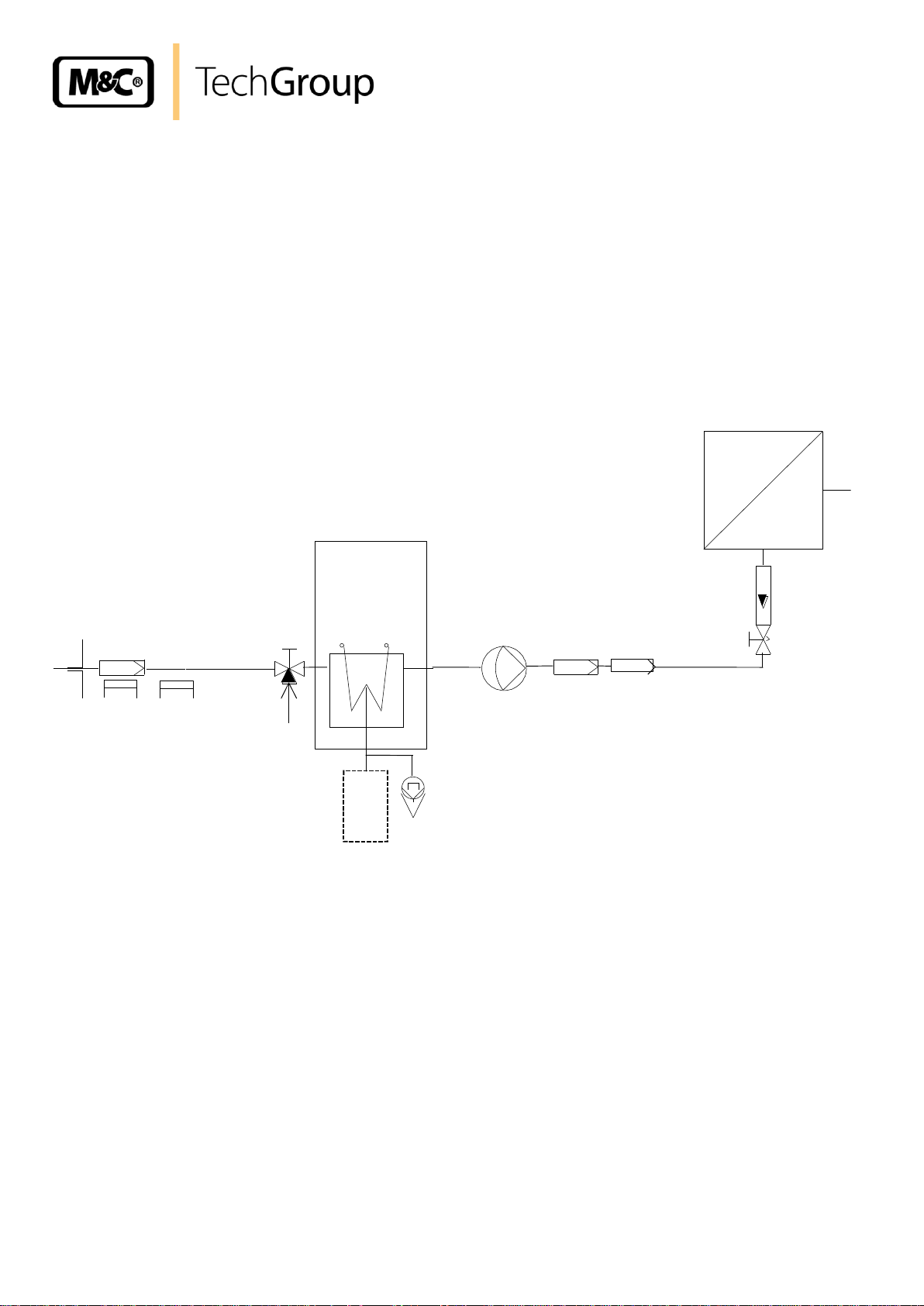

Figure 1 Example of application of EC-EX ........................................................................................ 8

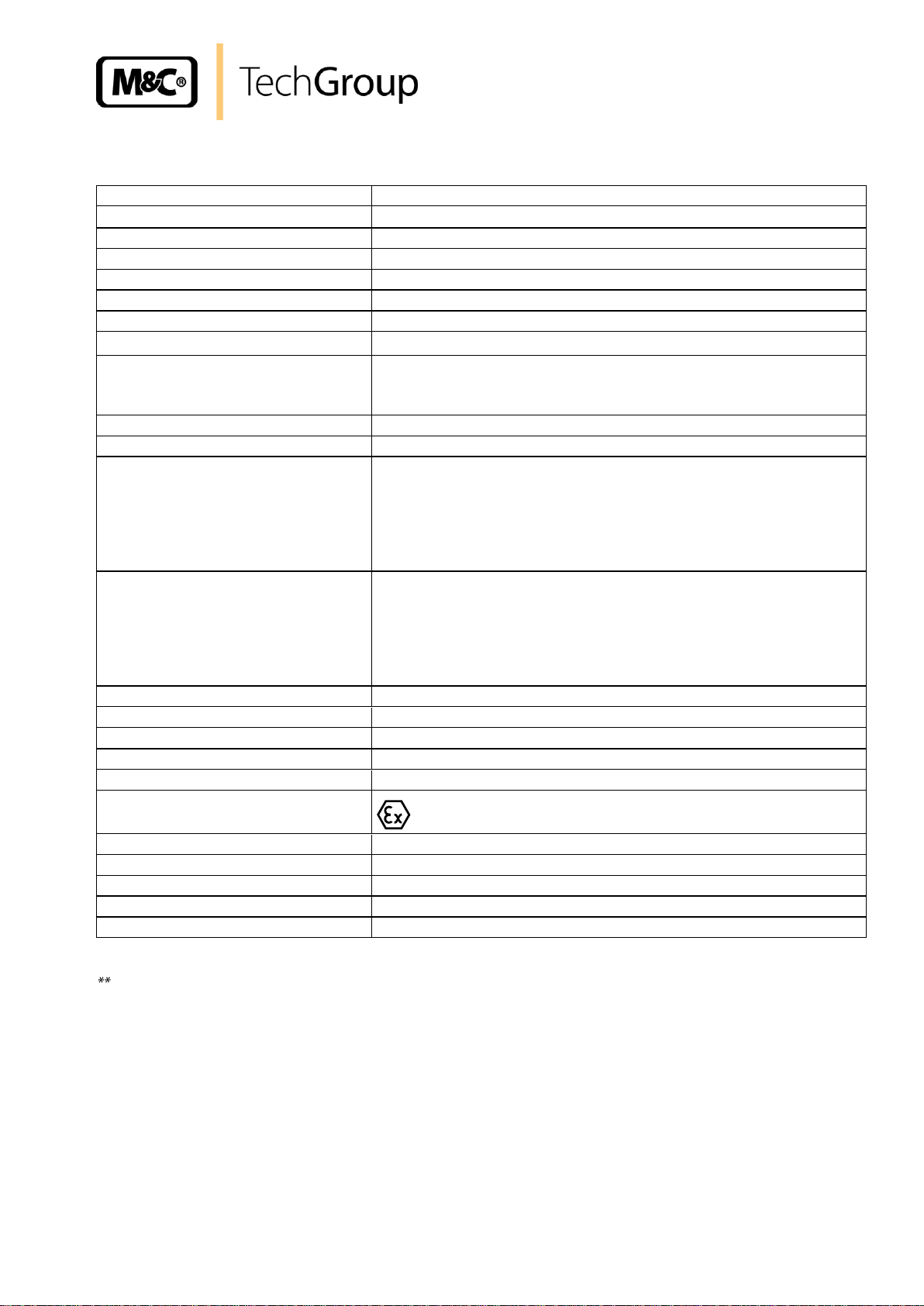

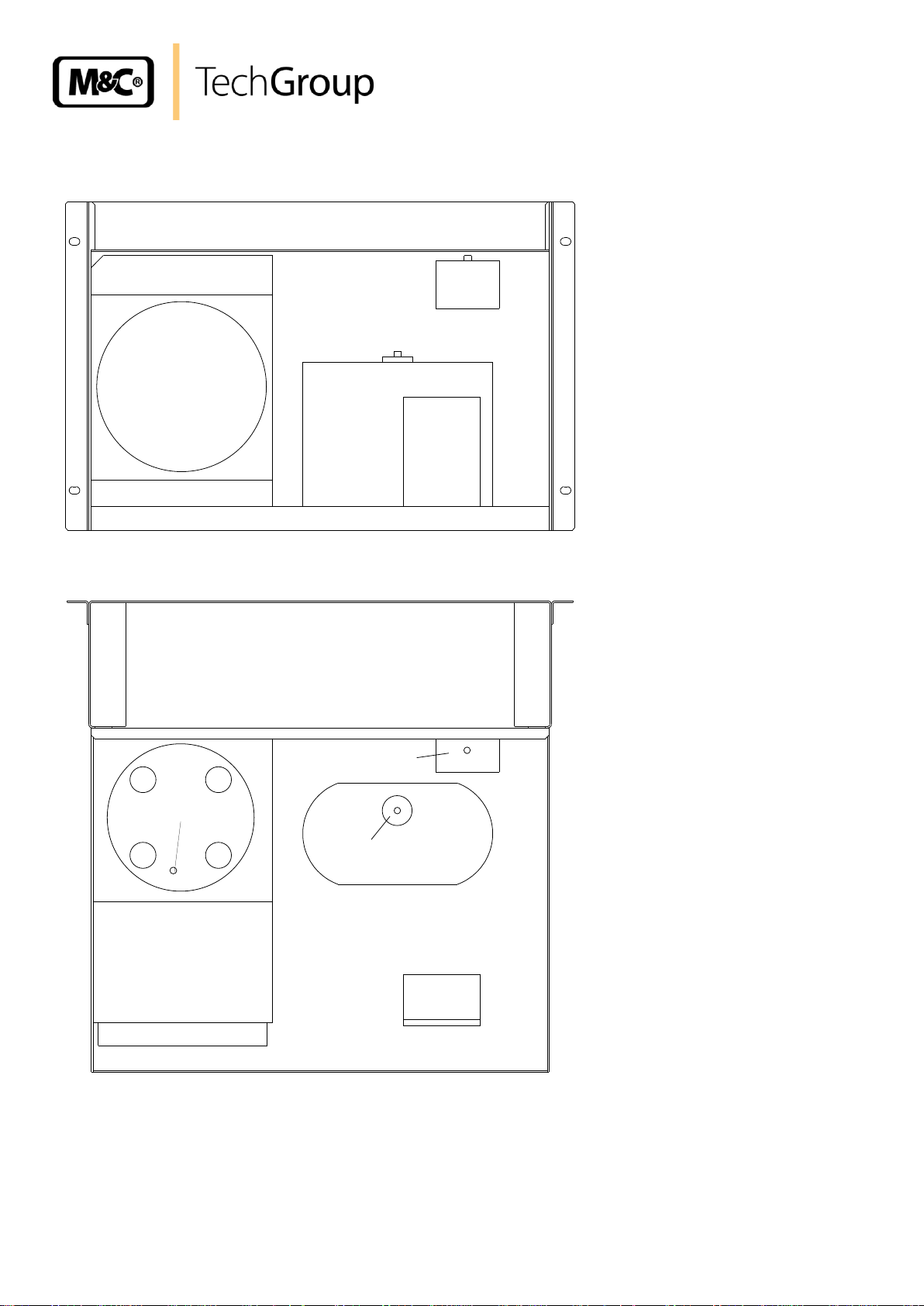

Figure 2 EC-EX cooler .................................................................................................................... 10

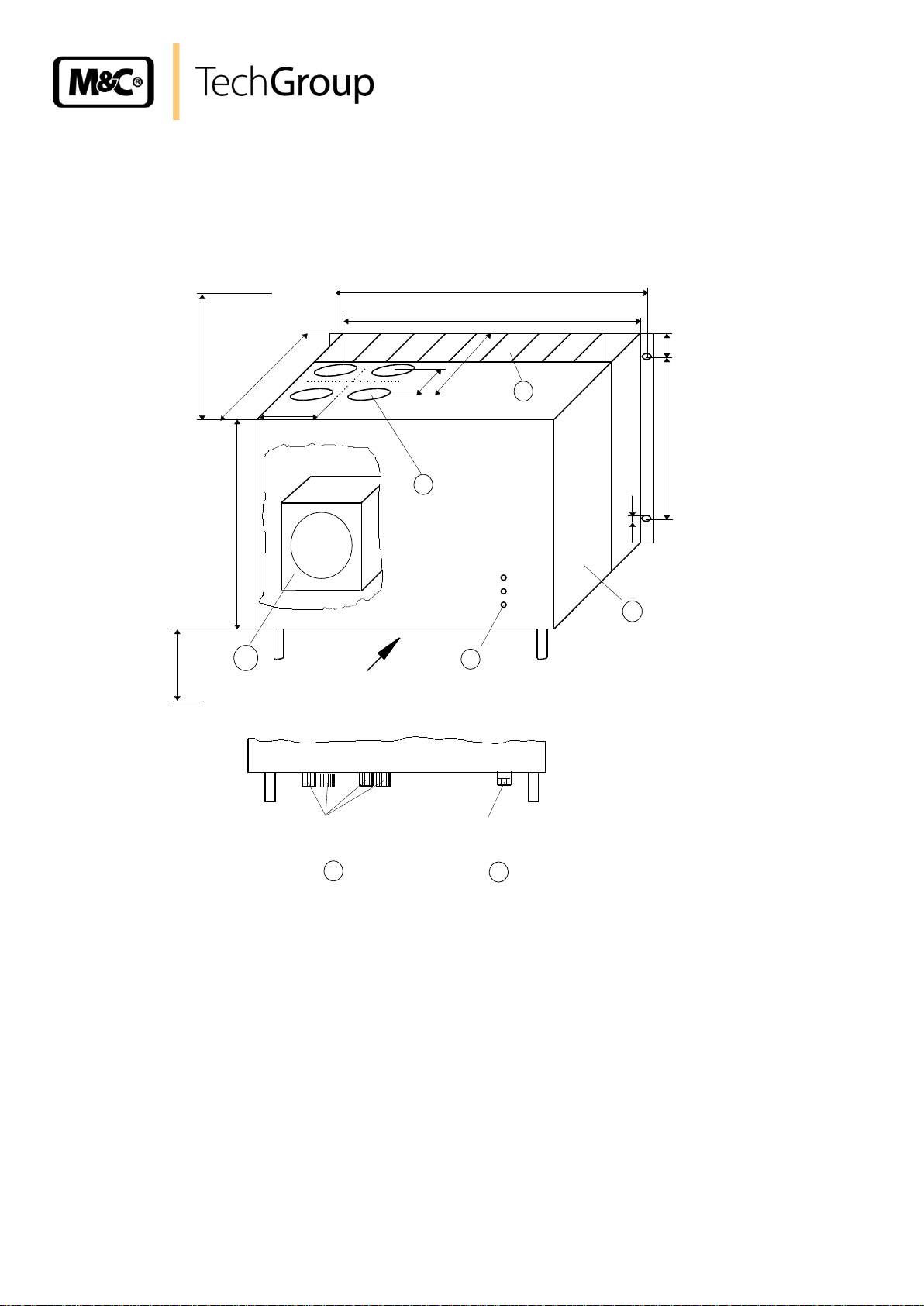

Figure 3 Functioning of heat exchanger .......................................................................................... 12

Figure 4 Electrical sockets .............................................................................................................. 15

Figure 5 EC-EX automatic control board ......................................................................................... 22

Figure 6 Temperature setting .......................................................................................................... 23

Figure 7 Temperature sensor resistance ........................................................................................ 24

Figure 8 Sample outlet dew point .................................................................................................... 27

Figure 9 Schematic drawing ............................................................................................................ 28

Figure 11 Circuit diagram EC-EX 230V/50Hz ................................................................................... 29

Figure 12 Circuit diagram EC-EX 115V/50-60Hz .............................................................................. 30

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 4

4

Head Office

M&C TechGroup Germany GmbH Rehhecke 79 40885 Ratingen Germany

Telephone: 02102 / 935 - 0

Fax: 02102 / 935 - 111

E - mail: info@mc-techgroup.com

www.mc-techgroup.com

1 GENERAL INFORMATION

The product described in this operating manual has been examined before delivery and left our works

in perfect condition related to safety regulations. In order to keep this condition and to guarantee a

safe operation, it is important to heed the notes and prescriptions made in this operating manual.

Furthermore, attention must be paid to appropriate transportation, correct storage, as well as

professional installation and maintenance work.

All necessary information a skilled staff will need for appropriate use of this product are given in this

operating manual.

2 DECLARATION OF CONFORMITY

CE - Certification

The product described in this operating manual complies with the following EC directives:

ATEX-Directive

The product described in this manual is produced in accordance with the EC directive for devices and

protection systems for appropriate use in hazardous areas 94/9/EG appendix II.

EMV-Instruction

The requirements of the EC directive 2004/108/EC “Electromagnetic compatibility“ are met.

Low Voltage Directive

The requirement of the EC directive 2006/95/EC “Low Voltage Directive“ are met.

The compliance with this EC directive has been examined according to DIN EN 61010.

Declaration of conformity

The EU Declaration of conformity can be downloaded from the M&C homepage or directly requested

from M&C.

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 5

5

3 ELECTRICAL STANDARDS

The electrical standard of electrical equipment corresponds to the safety regulations concerning the

EN61010, EN 50014 A1 to A5, EN 50016 A1, EN 50017 A1, EN 50018 A1 to A3, EN 50019 A1 to A3

and EN 50020 A1 to A2, for operating in hazardous areas Group II Category 2G. Attention must be

paid to the certificate of conformity KEMA 03ATEX2113 (see appendix).

4 SAFETY INSTRUCTIONS

Please note the following basic safety procedures when using this equipment:

Read these operating instructions carefully before start-up and use of the equipment! The

information and warnings given in these operating instructions must be heeded.

Attention must be paid to the requirements of the certificate of conformity (see appendix): 03

ATEX 2113.

Work on electrical equipment is only to be carried out by trained specialists as per the

regulations currently in force.

Attention must be paid to the requirements of VDE 0100 when setting high-power electrical

units with nominal voltages of up to 1000V, together with the associated standards and

stipulations.

For use in hazardous area observe the relevant national and international instructions and

regulations.

Check the details on the type plate to ensure that the equipment is connected up to the correct

mains voltage.

Protection against touching dangerously high electrical voltages. Before opening the

equipment, it must be switched and hold no voltages. This also applies to any external control

circuits that are connected.

The equipment is only to be set within the permitted range of temperatures and pressures.

Check that the location is weather-protected. It should not be subjected to either direct rain or

moisture.

Installation, maintenance, monitoring and any repairs may only be done by authorised

personnel with respect to the relevant stipulations.

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 6

6

5 INFORMATION AND SAFETY INSTRUCTIONS FOR USING THE COOLER IN

HAZARDOUS AREAS

The compressor cooler EC-Ex is suitable for using in hazardous area category 2G.

The explosion proof protection is:

230V / 115 : II 2 G EEx pedq [ib] IIC T4 (appr.-no.: 03 ATEX 2113)

The certification of the cooler was done by the Kema the authorized institute of electrical equipment in

the Netherlands. For detailed information and a copy of the certificate see appendix.

Installation and operating of the cooler has to be done corresponding to the conditions fixed in the Excertificate (see appendix). Only in this case the reliability of the operation in the hazardous area can

be guaranteed.

All changes of the standard configuration with parts which are not specified or approved by M&C as

well as repair and service with not specified parts means a loss of the Excertificate.

In case of doubt please turn directly to M&C respectively to your M&C franchised dealer.

6 WARRANTY

If the equipment fails, please contact M&C directly or else go through your M&C authorised dealer.

We offer a one year warranty as of the day of delivery as per our normal terms and conditions of sale,

and assuming technically correct operation of the unit. Consumables are hereby excluded. The terms

of the warranty cover repair at the factory at no cost or the replacement at no cost of the equipment

free ex user location. Reshipments must be send in a sufficient and proper protective packaging.

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 7

7

DANGER!

This means that death, severe physical injuries and/or important

material damages will occur in case the respective safety measures

are not fulfilled.

WARN I N G!

This means that death, severe physical injuries and/or important

material damages may occur in case the respective safety

measures are not fulfilled.

CARE!

This means that minor physical injuries may occur in case the

respective safety measures are not fulfilled.

CARE!

Without the warning triangle means that a material damage may

occur in case the respective safety measures are not met.

ATT E NT I ON!

This means that an unintentional situation or an unintentional status

may occur in case the respective note is not respected.

NOTE!

These are important information about the product or parts of the

operating manual which require user’s attention.

SKILLED STAFF

These are persons with necessary qualification who are familiar with

installation, use and maintenance of the product.

NOTE!

These are important information about the product or parts of the

instruction manual referring to operating in hazardous areas.

7 USED TERMS AND SIGNAL INDICATIONS

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 8

8

Sample gas

in

+5°C

EC-EX

Collecting vessel

Checkgas in

8 INTRODUCTION

The M&C EC-EX gas cooler unit is always to be installed in situations where there is interference from

moisture in the gas to be measured and if the point of installation is declared as hazardous area (see

appendix).

Reduction of the gas temperature inside the cooler to a stable and very low dew point effects a

condensing-out of the sample gas.

9 APPLICATION

Figure 1 shows a typical example of an application for installation of an EC-EX gas cooler unit.

Filter sample probe SP2000-H/Ex 3-way ball valve Super-fine filter FP...

Heated sample line Ex-version Peristaltic pump SR25.1/Ex Aerosol filter CLF

EC-EX cooler Membrane pump MP47/Ex Flow meter FM 10

Figure 1 Example of application of EC-EX

The gas to be measured is taken from the EC-EX gas cooler by a gas sample probe and cooled

down to a dew point of +5°C. The super-fine filter located afterwards removes solid particles. For

increased operating safety of the entire system we recommend installing a super-fine filter with a

liquid alarm sensor (for example LA1 with electronic controller type ER 142 Exi). If required an aerosol

filter can be installed in front of the flow meter . The gas thus treated can now be passed into the

analyser .

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Analyser PMA50 Ex

Page 9

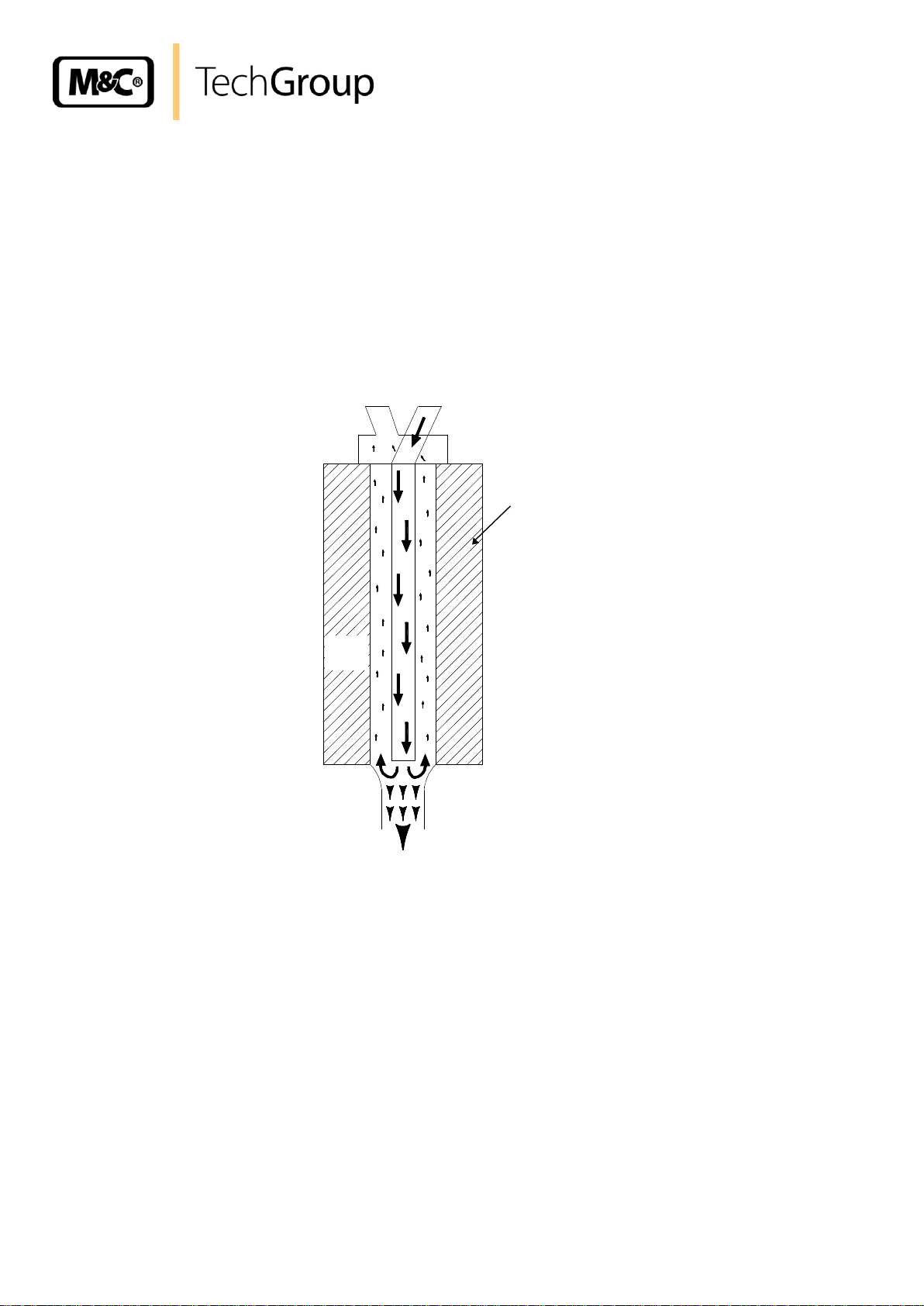

10 TECHNICAL DATA

Sample outlet dew point

range of adjustment: +2 °C ..... +7 °C, factory setting: +5 °C

Dew point stability

at constant conditions 0,25°C

Sample inlet temperature

**Max. + 180°C

Sample inlet dew point

**Max. +80°C

Gas flow rate per heat exchanger

**Max. 250l/h

Number of heat exchangers

1*, installation of max. 4 heat exchangers possible

Material of heat exchangers

Borosilicate glass or PVDF or stainless steel 316

Ambient temperature

**+0 to +45°C

Admissible gas pressure

with glass and PVDF: max. 3 bar

with stainless steel : 10 bar*

with option EC-FD : 1,2 bar

Total cooling power

Max. 520 KJ/h at +25°C

Dead volume per heat exchanger

70 ml

Sample gas connection glass:

PVDF:

stainless steel:

For tube 6mm*,

option: 8mm, 10mm or hose connector

G 1/4“i,

option: hose connector

G 1/4“i*,

option: NPT or hose connector

Condensate connection glass:

PVDF:

stainless steel:

For tube 12mm*,

option: 8mm, 10mm or hose connector

G 3/8“i,

option: hose connector

G 3/8“i*,

option: NPT or hose connector

Ready for operation

< 30 minutes

Power consumption

280VA, start up current at 230V = 8,1A at 115V= 17A

Mains power supply

230V 50Hz +/- 10% *, or 115V 50-60Hz +/- 10%

Electrical connections

Terminal 2,5 mm²

Status alarm

1 changeover contact, max. 230V 2A AC/DC 100VA, 50W

Ex-Protection

II 2G EEx p e d q [ib] IIC T4

Casing colour

RAL 9003

Method of mounting

19“ rack or wall mounting

Casing dimensions

84 TE x 7 HE x 450mm, 40 kg

Refrigerant

R134A 100% CFC free

Electrical equipment standard

EN 61010

9

* standard

Maximum values in technical datas must be rated in consideration of total cooling capacity at 25 °C

ambient temperature and an outlet dew point of 5 °C.

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 10

11 DESCRIPTION

°C>

ON

°C<

A

235

310

435

1

2

4

3

37,5

6,2

* necessary locating distance

240

70

85

88 * 2HE

100 *

7 HE

465

84 TE

View A

2 X cable glands

PG 13,5

max. 4 X condensate out

6

7

450

5

Figure 2 shows the EC-EX cooler unit .

10

Figure 2 EC-EX cooler

The EC-EX is equally suitable for wall installation or mounting in a 19“ rack.

The versions differ in the positioning of the LED function display . While for wall installation the LED

function display can be fitted into the corresponding cut-outs in the EC-EX front panel, for 19” rack

mounting this is done using the cut-outs in the back panel of the casing. This positioning can be done

at the factory by when stating the type of installation of the EC-EX gas cooler. It is relatively simple to

subsequently reconfigure it on site at the user location. The location for installation of the LED function

display will be marked correspondingly.

The casing depth of the EC-EX cooler is 450mm. Additional installations within the casing aren’t

possible.

The electrical parts of the cooler EC-EX are explosion protected. The EC-EX control board and the

protective motor switch are mounted in a flameproof enclosure EEx-d .

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 11

11

NOTE!

The manual Reset for the pressure alarm is cancelled since September 2004.

The cooler is switched off continuously in case of a leaking cooling system!

The EC-EX cooling compressor has a special junction box and one surface area temperature alarm

contact with manual reset button. The refrigeration circulation suction side of the EC-EX compressor

has a pressure alarm unit with manual reset button.

This alarms are connected into the Ex-i-circuit and to switch off the voltage of the compressor during

compressor temperature alarm or pressure alarm.

The EC-EX cooler in 230V-version has two EEx-q compressor start capacitors, the EC-EX cooler in

115V-version three.

The electrical connectors for mains power supply and the alarm contact output are located in the

EEx-e terminal box.

On the upper side of the cooler casing you will see the cut-outs for maximum 4 heat exchangers.

Sample gas enters and leaves the heat exchangers by the correspondingly connections on the upper

part of the heat exchangers.

At the rear part of the casing the condenser to remove heat given off in the compressor can be

seen.

On the underside of the casing the following connections are provided as standard:

Standard condensate outlets from the heat exchangers respectively,

Cable glands PG 13,5;

As standard, the condensate is removed externally with collecting vessels, peristaltic pumps

SR25.1/Ex, or by “over-pressure operation”, with automatic drawing-off of condensate, as e.g. type

AD-... .

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 12

12

+5°C

Sample gas

out

Sample gas

in

Condensate out

Coolingblock

12 FUNCTION

The M&C EC-EX gas cooler is a compressor cooler with status alarm capability. This ensures 100%

availability of the cooler.

Up to 4 Jet-stream heat exchangers made of Borosilicate glass, PVDF or stainless steel are located in

a heat-insulated cooling block. All the heat exchangers are easily accessible and are arranged in such

a way that they can be removed very simply.

Figure 3 shows a schematic diagram of the functioning of the heat exchanger..

Figure 3 Functioning of heat exchanger

The compressor cooler system has a heat-insulated cooling block at a constant temperature of +5°C.

The novel construction of the heat exchanger guarantees a very good pre-separation of condensate

and for that reason an optimal drying of sample gas.

Alarm warnings for over- and under-temperature are given as a collective status alarm via a relay

output with two potential-free changeover contacts. Alarm will be released if the current temperature is

out of a range of 3°C referring to the set-temperature (+5°C).

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 13

13

NOTE!

The cooler must be stored in a weatherproof frost-free area!

NOTE!

During transport and when in storage, the cooler must always be stood up

with the transport feet positioned underneath so that the oil in the closed

compressor circuit cannot run out of this compressor case. If the cooler is

transported on its back by mistake, it must stood in the operating position

for approx. 24 hours before it is switched on!

NOTE!

The compressor cooler EC-Ex is suitable for using in hazardous Group II

Category 2G. Attention must be paid to the certificate of conformity KEMA

03ATEX2113 (see appendix).

NOTE!

Please state the desired type of mounting when ordering so that the LED

function display can be positioned to match at the factory!

NOTE!

The operating position for this cooler is exclusively vertical. This is the

only way to ensure proper separation and removal of condensate in the

heat exchangers. During transport and installation, the cooler must

always be stood up with the transport feet positioned underneath so that

the oil in the closed compressor circuit cannot run out of the compressor

case.

The cooler should be kept away from sources of heat and well ventilated

when installed, so that condensation from warmth will not occur and

interfere with operation.

The minimum installation dimensions (fig. 2) must be followed without

fail. If the unit is installed in the open, the cooler must be installed in a

housing that is frost-free in winter and adequately ventilated In summer.

avoid locating the unit in direct sunlight.

Unheated gas sample lines must be provided with slope up to the cooler.

In that case pre-separation of the condensate is not required.

Connect the heated sample line with sufficient thermal decoupling to the

cooler!

13 RECEPTION AND STORAGE

The EC-EX gas cooler is a complete pre-installed unit.

Carefully inspect the cooler and any special accessories included with it immediately on arrival by

removing them from the packing and checking for missing articles against the packing list!

Check the items for any damage in transit and, if required, inform the shipping insurance company

immediately of the damage found!

14 INSTALLATION INSTRUCTIONS

The EC-EX cooler is equally suitable for wall mounting or for installation in a 19" rack.

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 14

14

NOTE!

Do not mix up the hose connections; the inlet and outlet connections of the

heat exchangers are marked with arrows;

Ensure that the connections are sealed adequately;

To ensure free removal of the condensate, ensure that the listed diameters

for the condensate removal lines are not reduced!

NOTE!

When fixing the connectors in the PVDF heat exchanger hold up with a

wrench at the pane of the bolt head!

NOTE!

NOTE!

Stainless steel heat exchangers with G 3/8“ thread joint can be directly fitted

up with the float-type condensate trap AD-SS by means of a thread adapter

part number FF 11000 (1/2“ NPT to G 3/8“i). By this wall mounting of the AD-

SS unit isn’t necessary!

15 SUPPLY CONNECTIONS

15.1 HOSE CONNECTIONS

The hoses for the heat exchangers are laid out as per Figure 3.

The connection for sample gas inlet and outlet happens on the upper part of the heat exchangers. For

possible connectors see technical data (10.).

Correspondingly tube or hose connectors are optional available by M&C.

Ensure that the connections are sealed adequately by noting the following:

Borosilicate glass heat exchangers with connections GL 18-6 respectively GL 25-12

Before assembly, check the GL coupling rings to see if the PTFE/silicon locking rings have been

damaged.

The sealing rings should be installed with the PTFE side facing the medium.

To grant a functional and unproblematic mounting we recommend to use union pieces with taper

pipe thread type R according to DIN 2999/1 in connection with suitable sealing tape.

PVDF respectively stainless steel heat exchangers with G 1/4“i respectively G 3/8“i

The correspondingly dimensioned tube respectively hose couplings with threaded connections

have to be screwed in with PTFE thread sealing tape.

Option: stainless steel heat exchanger with NPT

The heat exchangers with NPT threaded connectors are marked with circulated notches.

The NPT thread must be screwed in with sealant or fixed with adhesive.

In the standard configuration, the tubes for removal of condensate are connected directly to the heat

exchangers. These protrude with the GL 25-12 tube connectors* (Borosilicate glass heat exchanger)

respectively with G 3/8“* thread joint (PVDF or stainless steel heat exchanger) above the base plate of

the cooler casing (Fig.2) (* standard).

Condensate removal is done by customer according to the type of operation with:

- Automatic float-type condensate traps AD-... only for over-pressure operation;

- Condensate collector container that is emptied manually;

- External peristaltic pump SR 25.1/Ex.

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 15

15.2 ELECTRICAL CONNECTIONS

WARN I N G!

When connecting the equipment, please ensure that the supply

voltage is identical with the information provided on the model type

plate.

NOTE!

Attention must be paid to the requirements of IEC 364 (DIN VDE

0100) when setting high-power electrical units with nominal

voltages of up to 1000 V, together with the associated standards

and stipulations.

Check the details on the type plate to ensure that the equipment is

connected up to the correct mains voltage.

The main circuit must be equipped with a fuse of 10AT for the 230V

version and 16AT for the 115V version (automatic cut-out); for

electrical details see technical data.

Power supply : 230V/50Hz oder 115V/50-60Hz (see type plate)

Status alarm : one changeover contact

Contact rating : 230V AC, 2A, 100VA or

230V DC, 2A, 50W

Power

supply

2 N

3 PE

4

230V 50Hz

5

6

7

8

11 NC

12 Com

13 NO

Alarm

contact

230V 100VA

15

Figure 4 shows the electrical connections at the plastic housing behind the front panel of the EC-EX

casing (Fig. 2).

Figure 4 Electrical sockets

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 16

16

Terminal

1 2 3

EC-EX Terminal box

Connection

L N PE

Terminal

11

12

13

EC-EX Terminal box

Connection

NC

COM

NO

NOTE!

If you want to connection this alarm contact, please remove the certified

stopping plug and install the enclosed certified cable gland. Certified cable

gland PTB-Nr. EX-90.C.1004 EEX eII must be used only, to maintain the EEx-e

class of protection.

NOTE!

Before starting up the gas cooler, it must be placed in its operating position

for at least two hours. The liquid inside the system may have been

redistributed, and this could cause problems in operating!

NOTE!

The status contacts must be connected to the external sample gas pump or

to a valve in the sample gas line to protect the entire analysis system by

immediately cutting off the gas supply in the event of error messages from

the cooler!

The power connection is in the terminal box inside the cooler housing

The potential-free contact of the status collector alarm is located as well in the terminal box inside the

EC-EX cooler housing.

Two PG 13.5 cable glands are provided for the cable bushings through the base plate of the cooler

casing.

The volt free contact output of the status group alarm is located on the same EEx-e terminal box.

16 START-UP

The automatic control electronics of the EC-EX permit automatic start-up of the cooler. The error

diagnostics guarantee full monitoring and reporting of possible sources of error.

The following description is valid for start-up of the gas cooler for an ambient temperature > 8°C.

The following steps should be carried out before initial start-up:

Connect the cooler unit to the mains power supply;

Check that the equipment is connected to the correct mains voltage, 115V or 230V, as shown on

the type plate!

Lead the status contacts for reporting of under- and over-temperature to the measuring station;

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 17

17

°C >

ON

°C <

red

pink

green

°C >

ON

°C <

pink

green

16.1 FUNCTION SEQUENCE AND LED FUNCTION DISPLAY

Three function display LED's are provided to give a visualization of the function sequence during startup of the cooler. According to the type of installation, they are located either on the front panel or the

back panel of the cooler (Fig. 2). The top LED (red) indicates that the temperature set by the EC

automatic control electronics has been exceeded or has not been reached. The two-colour

(pink/green) LED in the middle shows that the cooler compressor is operating. The bottom red function

display LED gives an alarm if the temperature falls too low.

Switching the cooler on

As soon as there is a mains voltage, the top red LED lights up. This

indicates that the temperature of the cooler is above +8°C. The twocoloured LED in the middle lights up as pink once the cooler

compressor is in operation.

Normal operation

After around 30 minutes the cooler has been cooled down to a

temperature below +8°C. The top red LED goes out.

The status collector alarm contacts are deactivated and control the

automatic external release for gas measurement.

The cooler compressor is switched of as soon as the cooler stage

reaches the controlled temperature of +5°C. The middle LED lights up

as green.

The cooler compressor will be alternately switched on and off by the EC automatic control electronics

in a load-dependent cycle. The middle LED will alternately light up as pink and green (normal

operating functions).

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 18

18

NOTE!

The location for the cooler must remain frost-free, even when the

unit has been switched off!

WARN I N G!

Aggressive condensate is possible.

Wear protective glasses and proper pretective clothing!

WARN I N G!

It is necessary to take the cooler off the mains before any

assembly, maintenance or repair work is carried out!

17 CLOSING DOWN

If the cooler unit is putting out of action for a short time no particular measures need to be taken.

We recommend sweeping the cooler with inert gas or ambient air while the unit is putting out of action

for a longer time.

18 MAINTENANCE

The safety instructions specific to the plant and process are to be consulted prior to any maintenance

work!

The EC-EX cooler unit does not require any special maintenance intervals.

Depending on the quality of the ambient air the cooling fin block should be blown out with compressed

air from time to time.

When using automatic condensate removal by means of peristaltic pumps, the hoses of the peristaltic

pumps must be checked every three or six months, depending on the operating conditions, and

replaced if necessary. The procedure for changing the hoses is given in the corresponding operating

instruction SR25.1/Ex (Appendix).

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 19

19

NOTE!

Do not mix up the hose connections; gas outlet and gas inlet are marked

with arrows!

18.1 ADDING AND REPLACING THE HEAT EXCHANGERS

Removal of the heat exchangers may be necessary to carry out maintenance or repair work.

We recommend the following procedures and in this order for replacement of the heat exchangers:

Release the upper gas connections and lower condensate connections;

Pull the heat exchangers upwards with rotation out of the cooling block;

Replace the heat exchangers as follows:

Dry and clean the push-in opening in the aluminium cooling block with a cloth;

Smear the heat exchangers with a thin and equal layer over the whole surface with thermal

conductivity paste (part no. 90K0115) to ensure good conduction of heat. It is best to close off the

condensate removal of the heat exchangers tube with adhesive tape to prevent any of the thermal

conductivity paste from getting into the heat exchanger;

Lightly push the heat exchangers with rotation back into the push-in opening of the cooling block

and press to the upper block;

Remove the adhesive tape and any surplus thermal conductivity paste;

Reconnect the hoses.

Mounting the Borosilicate glass heat exchangers please notice:

Check the PTFE/Silicon locking rings for damage. in assembly, the locking rings must have the

PTFE side facing the medium, otherwise the required degree of sealing cannot be guaranteed!

Do up the red GL coupling rings hand-tight by turning them to the right;

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 20

20

LED display

Function error

and status

alarm

Probable cause

Checking / Correction

°C >

ON

°C <

Equipment

does not cool;

No mains power;

Fuse F1

defective;

Check for main supply voltage 230V (115V)

at terminals X1.1 (L1) and X1.2 (N)

If O.K.:

check main supply voltage after fuse F1 on

control board in EEX-d box, if necessary

replace fuse. If O.K.: replace faulty control

board.

°C >

ON

°C <

red

pink

(red LED

V18 on

control board

is out)

Equipment does

not cool or

cooling is

insufficient;

Cooling

compressor is

not running;

Protective motor

switch M1.1

Compression

senor alarm S2

Temperature

sensor-alarm S1

First check the correct fit of the plugs in the

EEx-d box ( power supply for compressor )

If o.k.:

Check voltage in EEx-d box at terminals X2.7

(L) and X2.6 (N) (230V/115V) for compressor:

If 0 Volt on X2.6 and X2.7:

Either the protective motor switch M1.1 has

released and will switch on again after 3 min.

(this state can alternate; a possible reason is

that the ambient temperature or the needed

cooling power is to high) or the internal alarm

relays K1 has cut off because of temperatureor low pressure alarm:

1. Check compression sensor alarm S2.

Bridge over terminal X3.3 and X3.4. If

compressor runs, remove bridge and reset with

S2. (Possible reasons: very low ambient

temperature while starting the compressor or

empty cooling circuit).

Since September 2004 the pressure sensor

works without a reset switch. If the pressure

sensor releases the cooling aggregate is

potentially empty; please change the

aggregate

2. Check temperature sensor alarm S1.

Bridge over Terminal X3.5 and X3.6. If

compressor runs, remove bridge. After 10 min.

reset with S1. Otherwise renew defect EC-EX

control board.

19 TROUBLE SHOOTING

Troubleshooting is made much easier by the LED function display.

The following table shows possible reasons for error and how to correct them (not applicable for the

running-up phase of the cooler).

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 21

21

LED display

Function error

and status

alarm

Probable cause

Checking / Correction

°C >

ON

°C <

red

pink

(red LED V18

on control

board is on)

Equipment does

not cool or

cooling is

insufficient;

see above

Cooling

compressor is

not running;

Cooling

compressor is

running; Cooler

is overstressed

1. Check voltage in the EEx-d box at terminals

X2.9 and X2.6 (N) (drive of the compressor

starting coil). In case of 230V (115V) renew the

EC-EX control board.

There is no voltage at terminals X2.9 and X2.6

(N):

2. Check the starting coil;

The red LED V18 must be light up. Check the

voltage at clamps X2.12 and X2.6. In case of

voltage change the control board or renew the

capacitors.

Note: If the compressor is stuck the described

stage (red LED V18 on) can alternate with the

above described stage (red LED V18 out),

because the protective motor switch will release

and switch on again after 3 min.

Check:

-Is gas flow 4 x 250 l/h maximum?

-Is ambient temp. +45°C maximum?

-Cooling fins are dirty?

Release EC-EX temperature sensor R51

at terminals X3.1+ X3.2 and measure

resistance.

It should be > 1.7 k at 20°C ambient temp.

If O.K.:

Replace complete EC-EX compressor unit

°C >

ON

°C <

green

red

or

°C >

ON

°C <

green

red

Equipment does

not cool;

Cooling

compressor

stopped;

Release EC-EX temperature sensor R51 at

X3.1 and X3.2 and measure resistance.

It should be >1.7 k at 20°C ambient temp.

If faulty:

fit new EC-EX temperature sensor to cooling

block using heat sink paste.

If o.k.:

Replace faulty EC-EX control board.

°C >

ON

°C <

red

pink

Cooler has been

over-cooled

(temp. < 2°C);

Cooling

compressor runs

to long or

continuously;

Release EC-EX temperature sensor R51 at

X3.1 and X3.2 and measure resistance.

Should be >1.7 k at 20°C ambient temp.

If faulty:

fit new EC-EX temperature sensor to cooling

block using heat sink paste.

If o.k.:

Replace faulty EC-EX control board

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 22

22

20 EC AUTOMATIC CONTROL BOARD

Figure 5 shows the arrangement of the EC-EX automatic control board (wiring scheme in Appendix).

Figure 5 EC-EX automatic control board

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 23

23

NOTE!

Do not adjust the temperature below +2°C or above +7°C.

Freezing-up of the heat exchanger can happen below +2°C.

Above +7°C the cooling unit will not work sufficiently!

20.1 TEMPERATURE SETTING FOR THE EC/ECS COOLER

The EC-EX gas cooler is set at the factory to a regulated temperature of +5°C.

Setting of the regulated temperature is done by trimming potentiometer P1, on the EC-EX automatic

control board of the cooler. The setting range covers from 0°C to 20°C. Turning it to the left sets a

lower temperature, and turning it to the right sets a higher temperature.

Figure 6 Temperature setting

Connecting an external temperature measuring device into the cooling block out of aluminium the real

temperature can be taken and controlled.

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 24

24

21 CHECKING THE TEMPERATURE SENSOR

The temperature sensor of the EC-EX cooler is a KTY-semiconductor.

Figure 7 Temperature sensor resistance

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 25

25

Electric gas cooler EC-EX

(C) consumable parts and (R) recommended spare parts

recommended quantity

EC-EX being in

operation [years]

Part number

Description

C/R 1 2

3

02 K 9105

EC-G jet stream heat exchanger

material: Borosilicate glass

R 1 1

1

02 K 9150

EC-G-90° jet stream heat exchanger

material: Borosilicate glass

R 1 1

1

02 K 9200

EC-SS jet stream heat exchanger

material: stainless steel

R 1 1

1

02 K 9250

EC-SS/NPT jet stream heat exchanger

material: stainless steel

Connections: sample gas in and out 1/4“i NPT

condensate out 3/8“i NPT

R 1 1

1

02 K 9300

EC-PV jet stream heat exchanger

material: PVDF

R 1 1

1

90 K 0115

EC thermal conductivity paste 50 g (-40°C to

140°C)

R 1 1

2

90 K 5010

EC-EX temperature sensor R51

E - -

1

90 K 5015

EC-EX Temperature contact S1

E - -

1

90 K 1010

EC-EX LED-display unit with connecting cable

E - -

1

90 K 5035

EC-EX cooling unit complete with compressor

vaporizer and condenser. Supply 230V, 50Hz

E - -

-

90 K 5040

EC-EX cooling unit complete with compressor

vaporizer and condenser. Supply 115 V, 50-60 Hz

E - -

-

90 K 5021

EC-EX control board complete with EEx-d box,

230V/50Hz

E - -

-

22 SPARE PARTS LIST

Wear, tear and replacement part requirements depend on specific operating conditions.

The recommended quantities are based on experience and are not binding.

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 26

26

23 APPENDIX

Sample output dew point (ambient temperature 20°C) depending on gas flow rate

Circuit diagram EC-EX automatic control board 230V,

drawing number : 2392 - 5.04.0;

Circuit diagram EC-EX automatic control board 115V,

drawing number : 2392 - 5.05.0;

Certificate KEMA 03ATEX2113

More product documentation is available on our Internet catalogue:

www.mc-techgroup.com.

Instruction manual peristaltic pump SR 25.1,

Document : 3-7.1-MD;

Condensate vessel TG, TK

Document : 3-6.3.1

GL-connectors

Document : 3-5.1.1

Automatic liquid drain AD-SS

Document : 3-6.2.3

Automatic liquid drain AD-P

Document : 3-6.2.1

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 27

27

Gasausgangs-Taupunkt

Sample outlet dewpoint

EC-G

10

5

187,5

125

250

°C

N l/h

Messgas-Durchfluss

Gas flow rate

Gasausgangs-Taupunkt

Sample outlet dewpoint

EC-SS

10

5

°C

N l/h

Messgas-Durchfluss

Gas flow rate

Gasausgangs-Taupunkt

Sample outlet dewpoint

EC-PV

10

5

°C

N l/h

Messgas-Durchfluss

Gas flow rate

62,5

187,5

125

250

62,5

187,5

125

250

62,5

60°C

40°C

Sample outlet dew point (ambient temperature 20°C) depending on gas flow rate

Sample input dew point

Figure 8 Sample outlet dew point

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 28

28

Temperature sensor

Temperature contact

Compression contact

Schematic description of the EC-EX cooler including installation position of sensors

Figure 9 Schematic drawing

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 29

29

Figure 10 Circuit diagram EC-EX 230V/50Hz

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 30

30

Figure 11 Circuit diagram EC-EX 115V/50-60Hz

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 31

31

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 32

32

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Page 33

33

Gas sampling and gas conditioning technology 3-4.1ME EC-EX 9904

Loading...

Loading...