Page 1

EC-30/FD

Embracing Challenge

Ultra Low Gas Cooler Series EC®

Version EC-30 dew-point -30 °C,

250 Nl/hr sample ow rate

Special Features

Jet-Stream heat exchangers

Dew Point -30 °C

250 Nl/hr sample gas ow rate

Continuous operation

Low maintenance

Self-monitoring incl. status alarm

Optimum reliability

19” Rack- or wall mounting housing

Application

The patented M&C Ultra-Low Cooler EC-30

finds its applications in the analytical field

for reducing the dew point of humid sample

gases, providing a stable and very low dew

point and reducing aerosol formation in the

analyser. By mounting the cooler EC-30 near

to the sample point, costly energy consuming heated sample lines can be avoided.

An extremely stable and low gas dew point

avoids water vapour cross-sensitivity and volumetric errors.

Description

The patented M&C gas cooler EC-30 is a

two stage combination of compressor and

Peltier cooler with status alarm and automatic

defrosting of the dual deep freezer unit for

100% sample availability.

The pre-cooler “3“ of the gas cooler EC- is fitted with a “Jet-Stream“ heat exchanger EC-G

which is cooled by a compressor cooling

unit with electronic control at a constant

temperature of +2 °C. Optimum cooling of

sample gases and pre-elemination of a larger

part of the condensate from the gas is reliably

achieved.

No external pre-draining is normally needed.

The deep freezer “1“ and “2“ is cooled with two

modified “Jet-Stream“ heat exchangers EC-30

fitted between two automatic cooling units

for a minimum temperature of -30 °C.

The special design of the Jet-Stream heat

exchanger guarantees optimum dew point

reduction to a low, stable value and secures

condensate separation.

The gas outlets of the heat exchangers are

connected to a 3/2 way solenoid valve. An

electronic control system EC-30 switches

the solenoid valve for simultaneous changeover and automatic defrosting of the heat

exchangers EC-30.

In order to guarantee the necessary and

minimum operation of the gas cooler EC-30,

we provide this unit with an accessory module EC-F containing two fans for forced air

ventilation and cooling of the compressor

unit. Alternative we deliver an the cooler with

the module EC-FD containing additionally

three peristaltic pumps SR-25.1 for automatic

removal of condensate.

Technical specications and illustrations are without

obligation, subject to modications. 09.96/06.06

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

6.7

Page 2

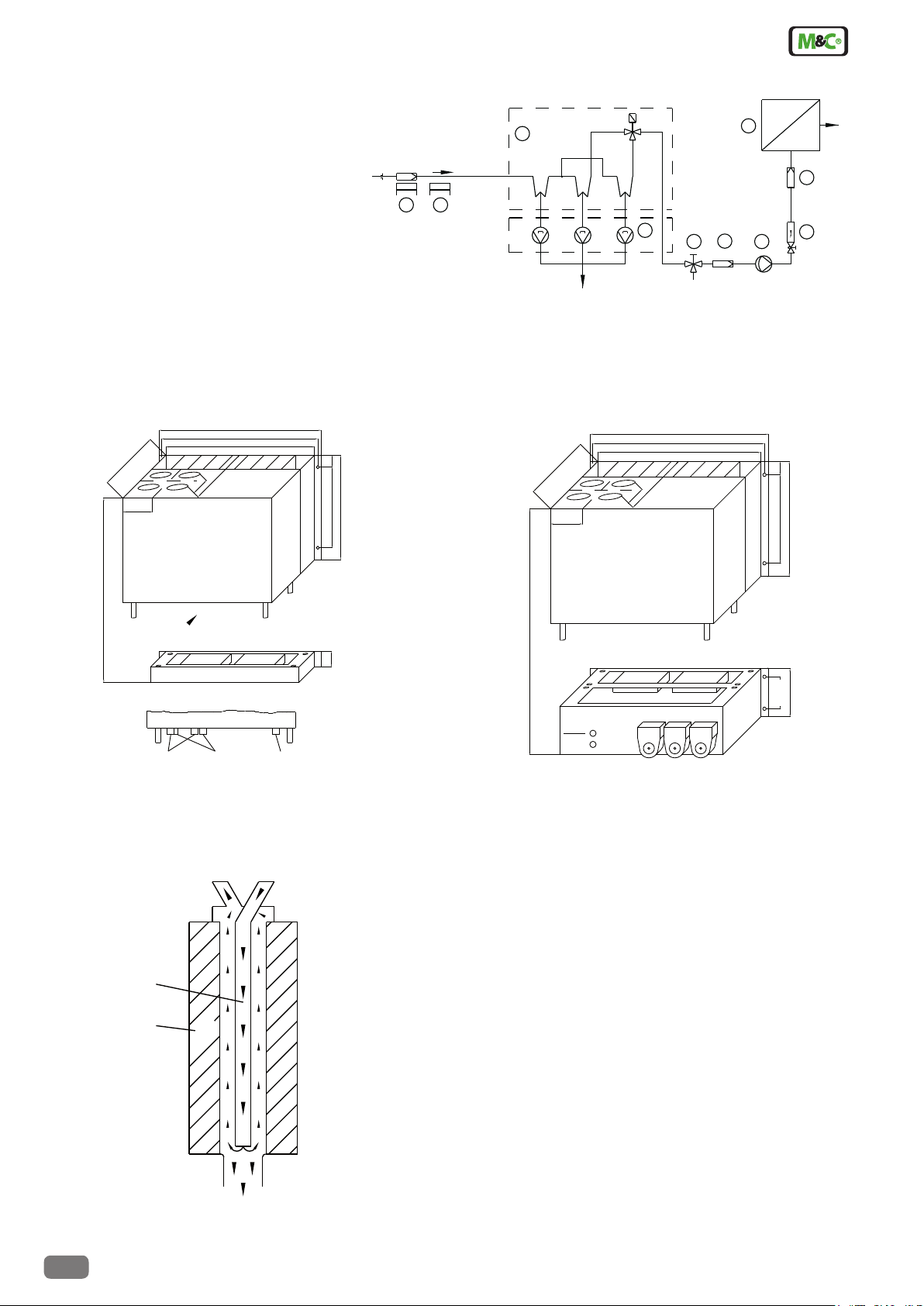

Example application for EC-30/FD

1 Heated filter sample probe SP2000-H

2 Heated sample line 4M4/6

3 Ultra low cooler EC-30

4 Universal unit EC-FD with 3 peristaltic pumps SR25.1

5 3-way ball valves 3L/PV-1

6 Fine filter FP-2T-D with liquid alarm LA1

7 Diaphragm pump MP47

8 Flow meter FM10, 25-250Nl/hr

9 Aerosol filter CLF-5/W optional according to application

10 Analyser, f.e. PMA100

Dimensions

1 2

Sample gas IN

EC-30

3

Condensate OUT

213

-30 °C-30 °C+2 °C

4

EC-FD

5

Test gas

IN

10

9

6

8

7

EC-30 basic version with unit EC-F

483 (84HP)

465

355

360

435

1

2

85

view A

240

70

3

A

Standard unit EC-F

EC-30 with unit EC-F

3x Condensate Out2x cable gland

GL25/12PG 13,5

Sample gas out

DN 4/6

37,5

235

310 (7U)

45(1U)

Dimensions in mm

Functioning diagram of M&C heat-exchanger

EC-30 basic version with unit EC-FD

483 (84HP)

465

435

360

443

85

Universal unit

EC-FD

1

2

Sample gas out

Condensate out

3

Option: unit EC-FD

70

240

SR 25 SR 25

SR 25

37,5

235

57

310 (7U)

133 (3U)

6.7

Sample gas - OUT

Sample gas - IN

M&C Jet-Stream

heat exchanger

Cooling block

+2°C

-30°C

Condensate - OUT

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 09.96/06.06

Page 3

Technical Data

Cooler series EC

Part No.: 02K6000 (a)** 02K6010 (a)**

With integrated universal unit: EC-F to force the ventilation EC-FD ventilation and condensate removal

Gas connection tube connector DN 4/6 i./o. d. mm

Condensate connections 3x tube connector GL25-12 mm 1x tube connector DN 4/6 i./o. d. mm

Material of sample contacting parts Duran Glass, PTFE, PVDF Duran Glass, PTFE, PVDF, Novoprene

Single stream, gas flow rate 90 Nl/hr-250 Nl/hr*

Gas pressure max. 3 bar abs.

Ambient temperature +5 to +45 °C

Storage temperature -20 to +60°C

Sample outlet dew point -30 °C

Sample inlet temperature max. 180 °C*

Sample inlet dew point max. 80 °C*

Cooling capacity at 25 °C ambient max. 860 kJ/hr*

Main power connection / Power consumption 230V 50Hz 380VA or **Part No. ...-a = 115V 60Hz, 380VA

Start up time < 60 min.

Stagnant space approx. 160 ml

∆P at 250 Nl/hr flow rate 5 mbar

Electrical connection 2.5 mm2 terminals, 2x PG13,5 cable glands

Status alarm 2 changeover contacts, potential free contact rating 250V, 3A, 500VA, 50W

Case protection / Electrical equipment standard IP20 EN 60529 / EN 61010

Method of mounting / Case colour 19" rack or wall / case colour RAL 9003

Dimension / Weight 84 HP x 8U x 360 mm / 37 kg 84HP x 10U x 360 mm / 42 kg

* Maximum values in technical data must be rated in consideration of total cooling capacity at 25 °C ambient temperature.

®

version EC-30 version EC-30/FD

Option

Aerosol-Filter CLF-5

External mounting in the outlet of an ultra low gas cooler EC-30 when sample tends to form aerosols. Part Number 03F3000

Technical data see data sheet 5-1.10.7 Fluid particle filter CLF-5

Technical specications and illustrations are without

obligation, subject to modications. 09.96/06.06

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

6.7

Loading...

Loading...