Page 1

DIL-U/A(N)

Embracing Challenge

Sample dilution system version DIL-U

consisting of dilution probe SP2000H/DIL-U/P

and dilution pump unit DIL-U/A (N)

Special Features

Lowest dilution ratio 1:1

Ambient air as dilution gas possible

Low dilution gas consumption

No inuence of barometric pressure

Compact design

Gas sample probe SP2000H/...

Incorporated pre heater for dilution gas

Test gas connection at the probe inlet

Completely heated up to 180°C

1

varying process pressure must be taken into

consideration

1

Application

The electrically heated M&C dilution system

DIL-U is applicable for such processes, where

the measuring procedure or the handling of

the process gas requires the dilution of the

sample respectively the component to be

measured in a range of 100:1 up to 1:1.

Typical applications:

• toxic gases above TLV value

• explosive gas mixture above LEL

• adapting the concentration of the sample components to the measuring range

of the analyser

• measuring possibility at low sample flow

rates from 1Nl/hr

• moisture measurement in flue gas with

IR-analyser

The M&C dilution probe (part of this system)

is based on the well tested modular designed

M&C gas sample probe SP2000H. This enables

the user to adapt the probe to nearly every

application, using for example special filter

techniques or special materials.

For test procedure with zero and span gas a

3 way ball valve and a flowmeter is installed.

Version DIL-U/A is suitable for ambient air as

a dilution gas and version DIL-U/N for bottle

gas. Bottle gas requires a pressure regulator,

a pressure gauge and a flowmeter which can

be installed optional in the pump unit.

If the dew point of the diluted sample is

higher then ambient temperature an optional integrated M&C cooler, ECP1000G/SR25,

reduces it to +5 °C.

High dilution ratios cause a very low sample flow. Therefore it is necessary to use an

additional sample bypass 2 to reduce the

response time. This will be done with the

option DIL-U/B with an additional pump and

flowmeter and the cooler as an option.

The heated M&C sample line(s) 3/4-N/M/H

between the probe and the pump unit can

be controlled via an temperature controller

703, built into the pump unit.

The design of the dilution system DIL-U guarantees easy maintenance.

Technical specications and illustrations are without

obligation, subject to modications. 12.99/06.06

Description

The M&C dilution system DIL-U consists of the

dilution probe SP2000H/DIL-U/P and the dilution pump unit DIL-U (A/N).

The dilution unit, including the critical orifices, is integrated in the sample probe outlet,

heated up with the probe to a stable temperature. The incorporated pre heater heats

up the dilution gas to the probe temperature.

Both steps avoid that the temperature of

sample gas decreases under the dew point.

The test gases for the system calibration enter

the sample probe via an integrated valve.

A vacuum pump integrated in the pump unit

DIL-U sucks the required vacuum, which is

necessary for the function of the critical orifices. A pressure gauge indicates the function of

the dilution system. The flowmeters indicate

the analyser and bypass flow 1. A flow alarm

is available as well.

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

5.3

Page 2

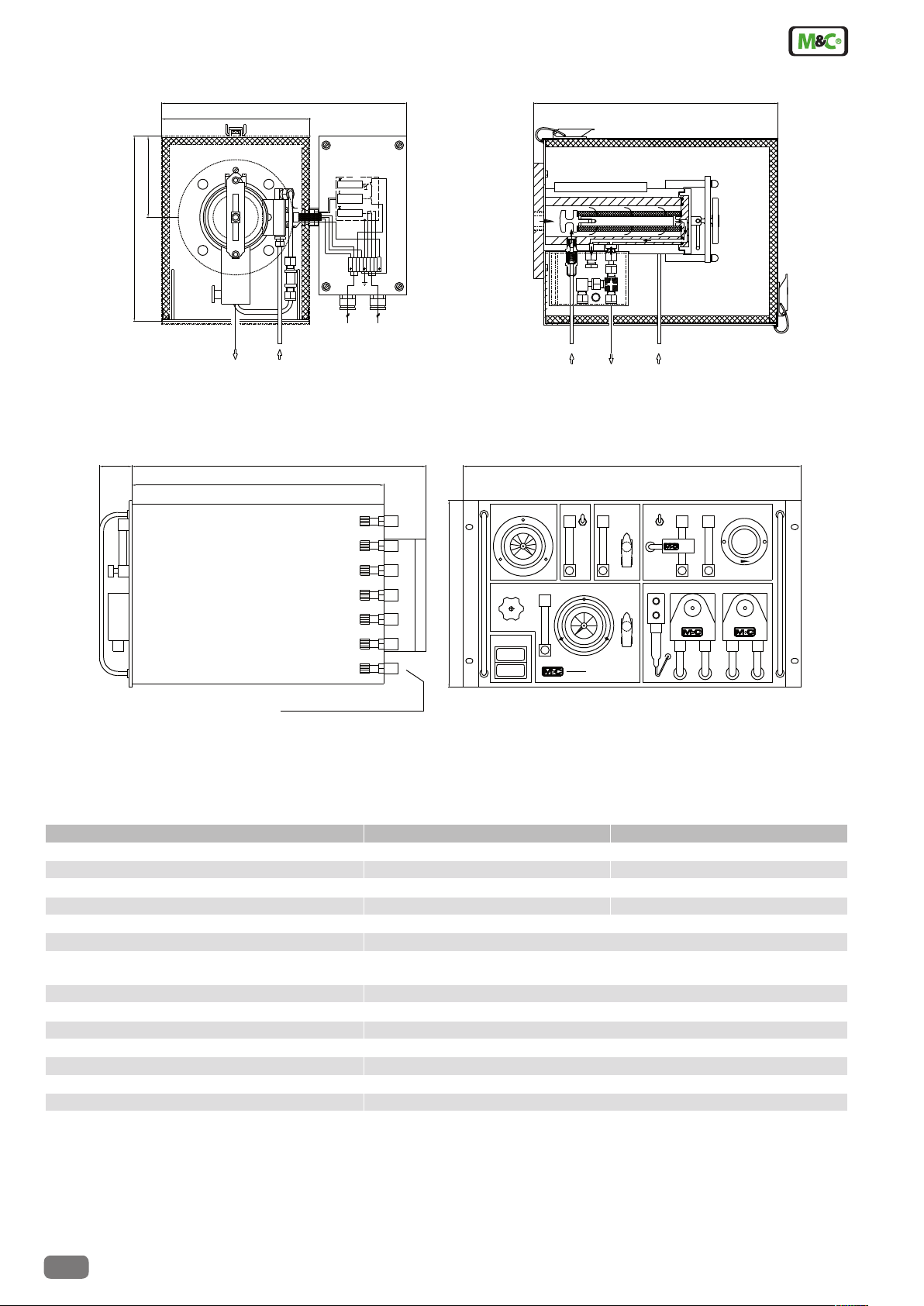

Dimensions

110

260

345

207

340

Sample

89L45

'76NL

231

Sample

Gas connections DN4/6

Tsoll

Tu <-30 C

0-180 C

To >+30 C

Test gas

Dilution gas

Low temp. alarm

Power

230V, 50Hz

(115V, 60Hz)

Dilution gas

6HE

45 84TE

360

420

M&C

FPF-0,1

Filter

FM2

Messgas

Sample

FM1

S1

Vakuum Ein

Vacuum On

Bypass1

FM1

On

S2

Test gas

Testgas

Bypass2 Pump

Vakuum

Vacuum

Endgas

Span

Open

Fi1

FM2

Auf

Kondensat/Messgas

Condensate/Sample

P1

Sensor

FA-1,bi

FM1

Kondensat/Bypass1

Condensate/Bypass1

Y1

LA1

P2

Y2

Auf

Zu

Closed

FM4

-0,2

M1

Durchuss

Flow rate

Verdünnungsgasdruck

Dilution gas pressure

FM5

3,0

4,0

5,0

6,0

M2

Zu/Closed

2,0

1,0

0,0

FM3

-0,8

-1,0

Pressure set

Druckeinstellung

PR1

Beh.Leitung

0,0

DIL-U

Dilution unit

Open

Span

Endgas

Dilution gas

Verdünnungsgas

-0,4

-0,6

Gas connections G1/4"-i

Dimensions in mm

Technical Data

Gas sample dilution system version DIL-U Part-No. Type

Dilution gas sample probe SP2000H/DIL-U/P Part No. SP2000H/DIL-U/P 20S4950(a) *see to dilution ratio

Dilution pump unit, standard DIL-U/A Part No. DIL-U/A 20S4955(a)

Dilution pump unit, standard DIL-U/A Part No. DIL-U/N 20S4960(a)

Option: Gas cooler ECP1000G/SR25 Part No. ECP1000G/SR25 20S4965(a)

Option: bypass DIL-U/B Part No. DIL-U/B 20S4970(a)

Insitu sample tube or prefilter optional available, see data sheet 2-1.1b; 2-1.5.1; 2-1.6.1/2; 2-1.9.5

Dilution ratio 1:1 up to 100:1; adjustable via corresponding orifices

* please specify the required dilution ratio with the order

Sample flow rate from approx. 1 Nl/hr up to 50 Nl/hr

Dilution gas flow rate from approx. 30 Nl/hr up to 100 Nl/hr

Dilution gas pressure at DIL-U/N >3 bar g

Material of sample contacting parts stainless steel 316Ti, 1.4404, glass, FPM, PTFE

Dimensions from dilution pump unit DIL-U 19"-rack, 6U, 84HP, depth = 460 mm

Gas connections thread G1/4" i

Power supply 230V 50Hz optional 115V 60Hz (a)

Weight dilution gas sample probe SP2000H/DIL-U/P: 15 kg, dilution pump unit DIL-U: 15 kg

Further technical data see data sheet SP2000, 2-1.1b and 2-1.1.7.

5.3

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 12.99/06.06

Loading...

Loading...