Page 1

Operating Manual

Gas Dilution Unit

Versions DIL-1, DIL-1/H

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 2

2

This Operating Manual does not claim completeness and may be subject to technical modifications.

© 11/2005 M&C TechGroup Germany GmbH. Reproduction of this

document or its content is not allowed without permission from M&C.

1st Edition: 11/2005

Dear customer,

we have made up this operating manual in such a way that all necessary information about the product can be found and understood quickly and easily.

Should you still have any question, please do not hesitate to contact M&C directly or go through your

appointed dealer. Respective contact addresses are to be found in the annexe to this operating manual.

Please also contact our homepage www.mc-techgroup.com for further information about our products. There, you can read or download the data sheets and operating manuals of all M&C products as

well as further information in German, English and French.

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 3

3

Contents

1 General information ...................................................................................................................... 5

2 declaration of conformity ............................................................................................................. 5

3 Safety instructions ....................................................................................................................... 6

4 Warranty ........................................................................................................................................ 6

5 Used terms and signal indications ............................................................................................. 7

6 Introduction ................................................................................................................................... 8

7 Application .................................................................................................................................... 8

7.1 Variations .............................................................................................................................. 10

8 Technical Data ............................................................................................................................ 13

9 Dilution principle ........................................................................................................................ 14

10 Dimensions ................................................................................................................................. 15

11 Receipt and storage ................................................................................................................... 18

12 Installation information .............................................................................................................. 18

13 Installation ................................................................................................................................... 18

13.1 Connection of the supply or sample lines .............................................................................. 18

13.2 Connection of sample gas and heated sample lines ............................................................. 19

13.3 Connection of dilution gas or bypass gas .............................................................................. 20

13.4 Connection of calibration gas ................................................................................................ 20

13.5 Electrical connection ............................................................................................................. 20

14 Initial starting .............................................................................................................................. 22

14.1 Calibration ............................................................................................................................. 24

15 Closing down .............................................................................................................................. 24

16 Maintenance ................................................................................................................................ 25

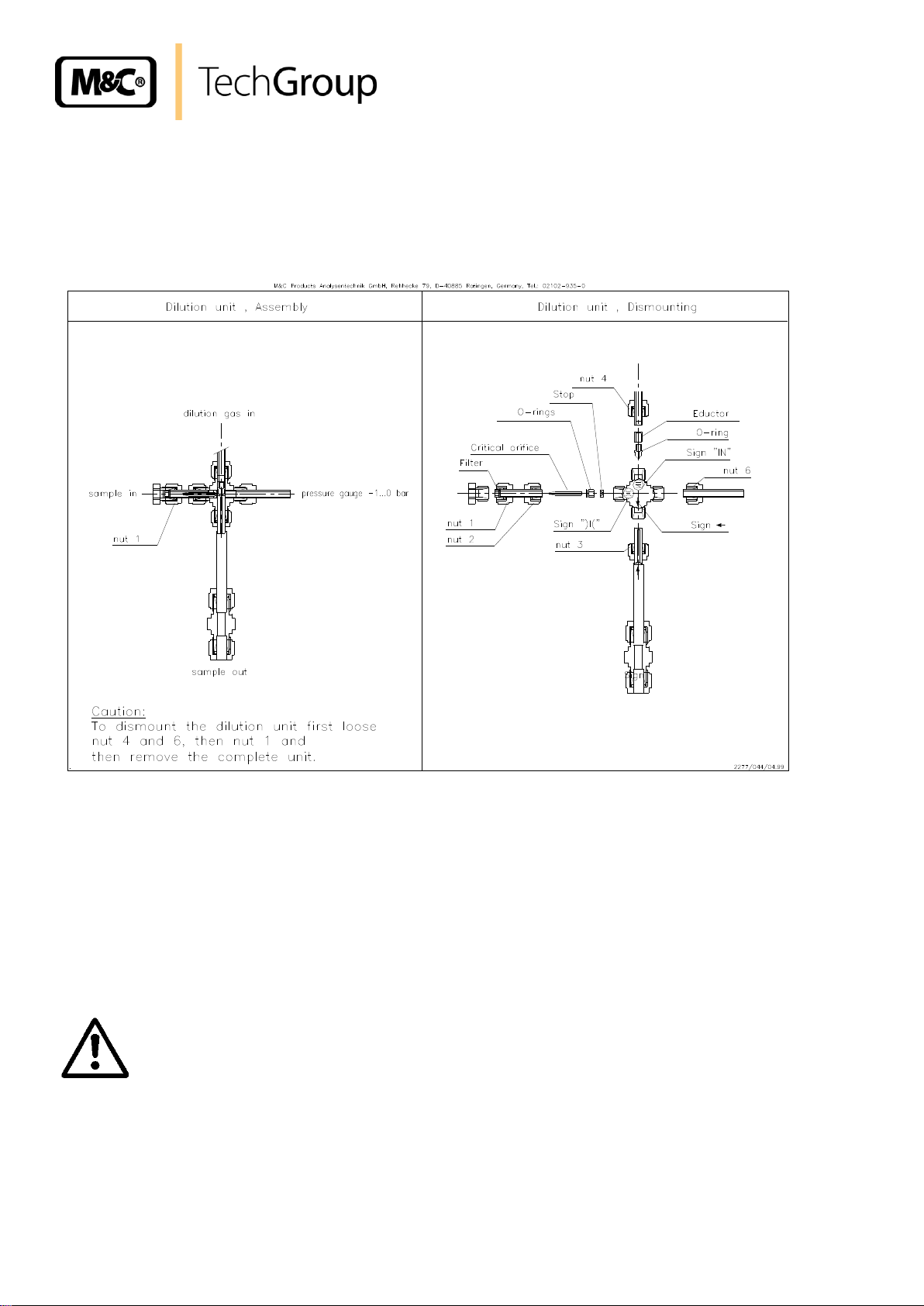

16.1 Disassembly of the crosspiece .............................................................................................. 26

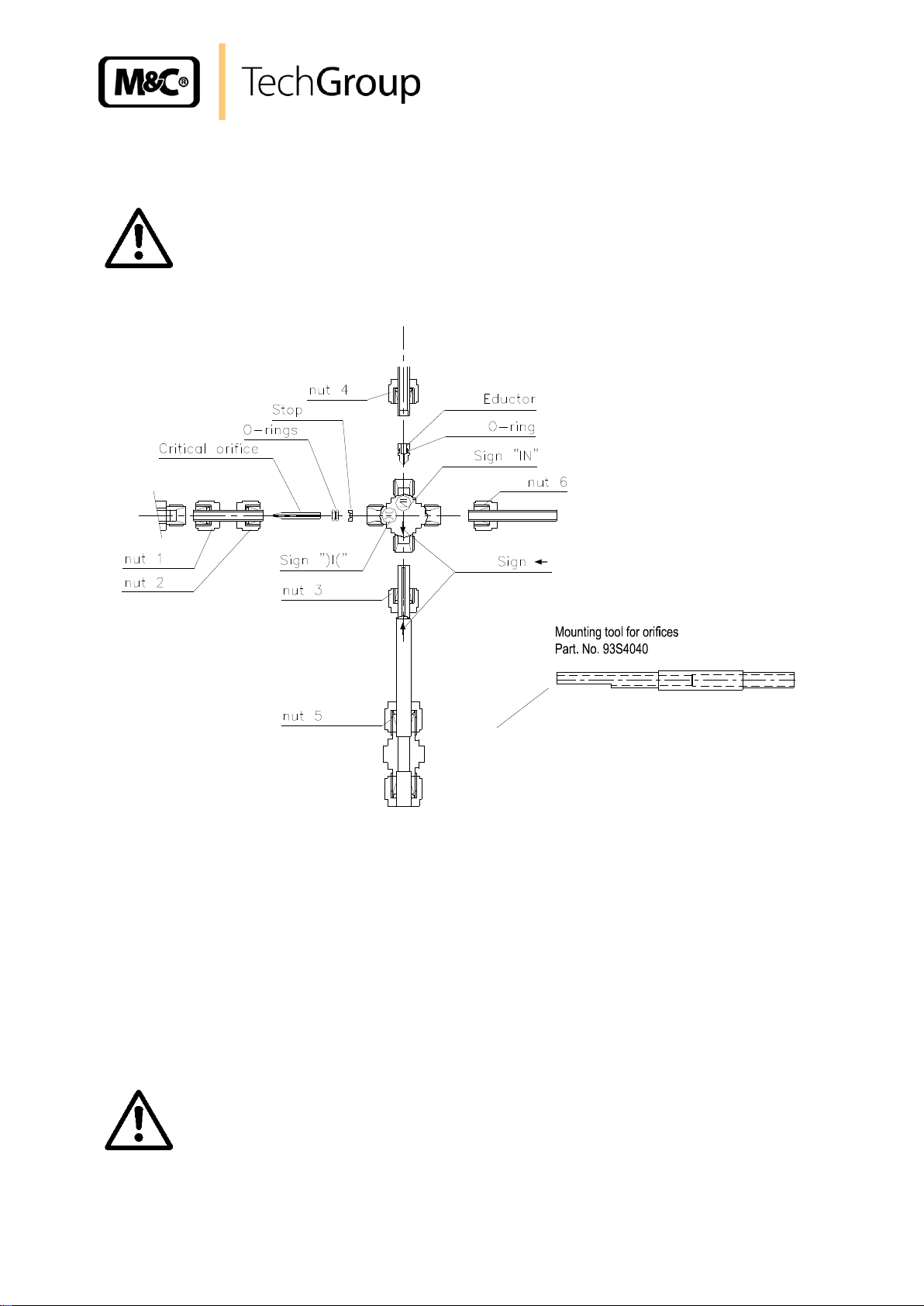

16.2 Cleaning of the critical orifice and check or change of the O-rings ....................................... 27

16.3 Change and cleaning of the injection nozzle ......................................................................... 28

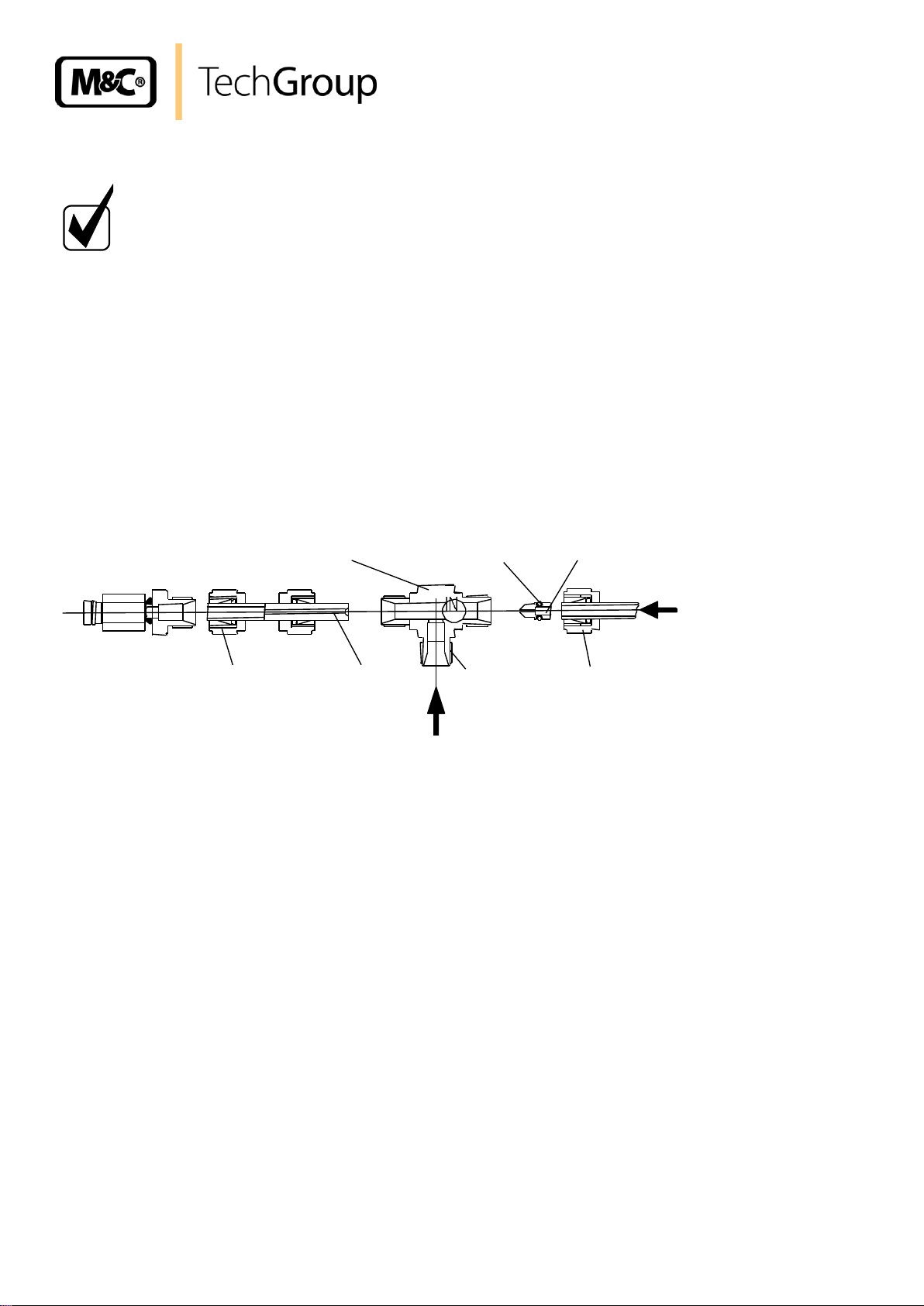

16.4 Removing the bypass T-piece ............................................................................................... 28

16.5 Change and cleaning of the bypass injection nozzle and control or change of the o-ring .... 28

17 Spare parts list ............................................................................................................................ 29

18 Appendix ..................................................................................................................................... 29

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 4

4

List of Illustrations

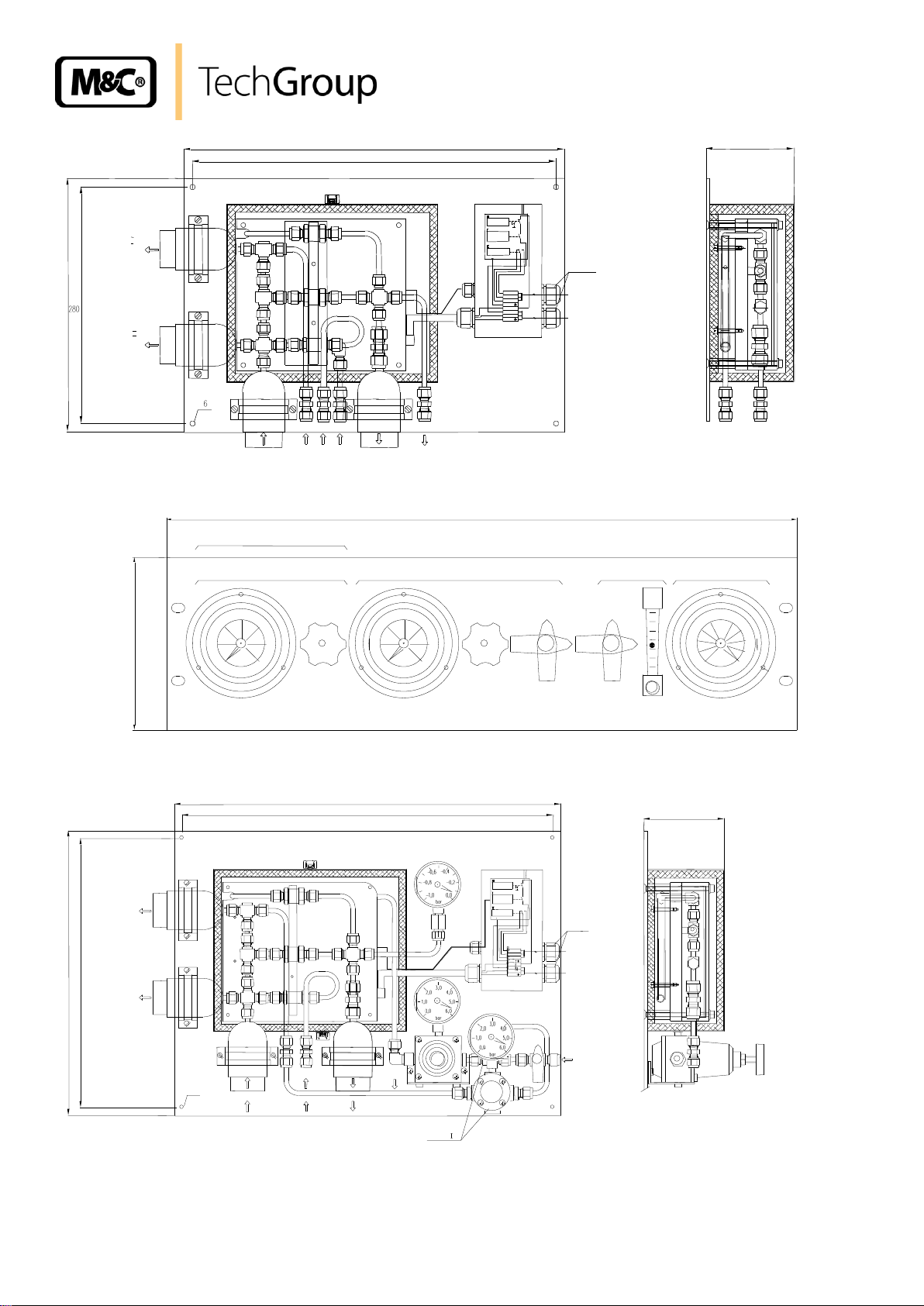

Figure 1 Dilution unit DIL-1 ............................................................................................................... 8

Figure 2 Dilution unit DIL-1/H ............................................................................................................ 9

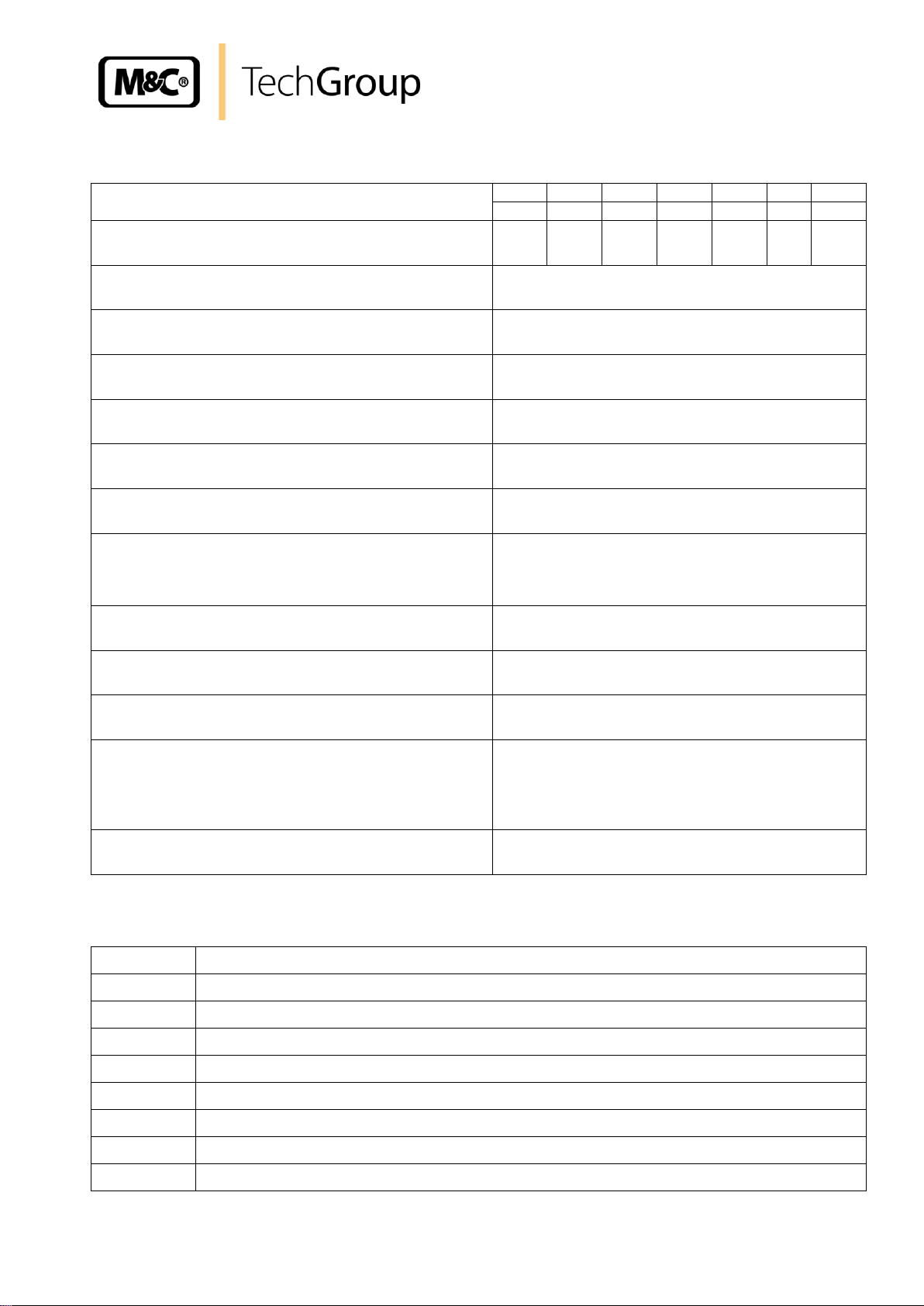

Figure 3 Gas flow scheme DIL-1 with possible options .................................................................. 11

Figure 4 Gas flow scheme DIL-1/H with possible options ............................................................... 11

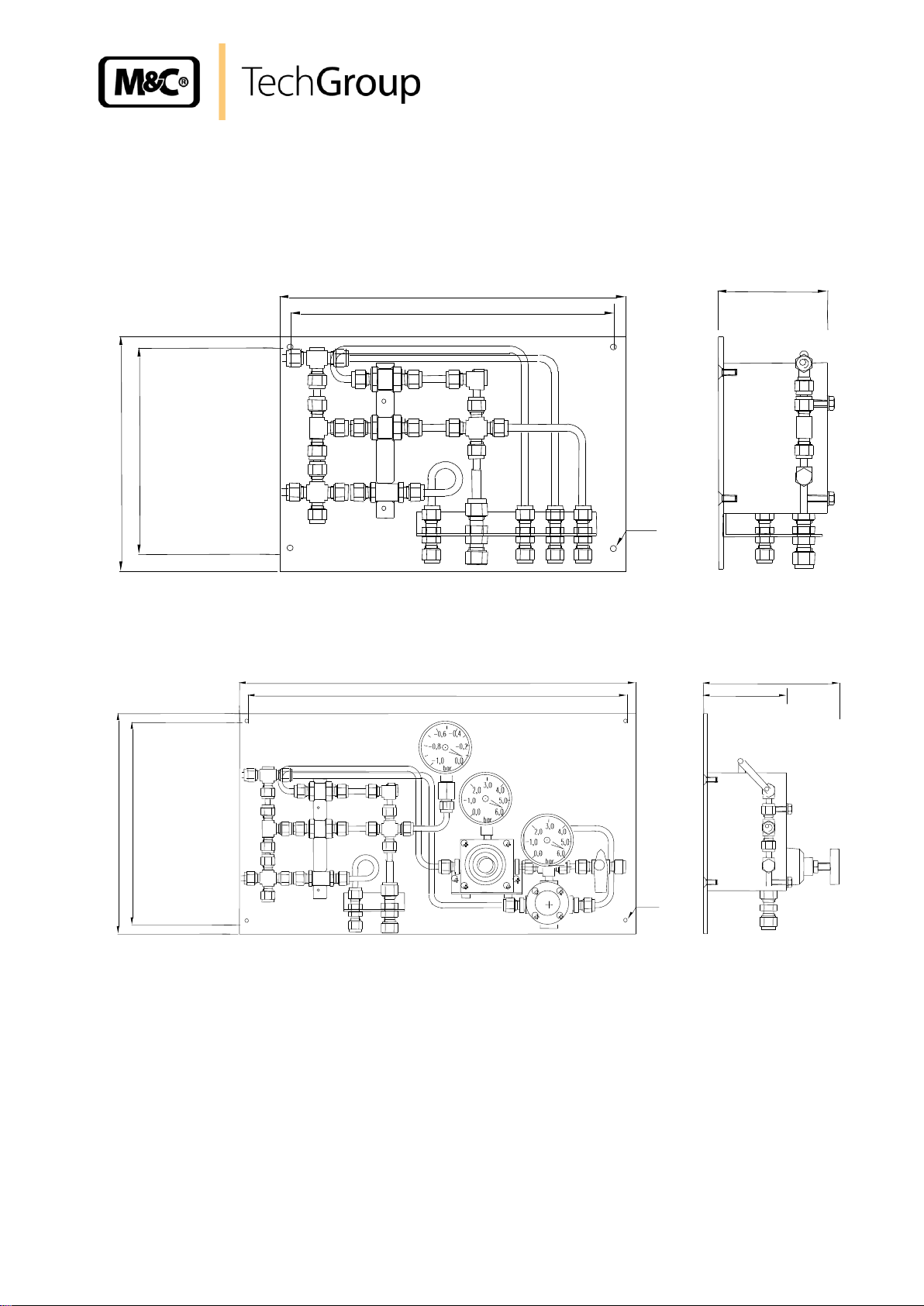

Figure 5 Dilution unit DIL-1/H with control panel –S or -S1 ............................................................. 12

Figure 6 Dilution unit DIL-1/H with set -A or -A1 ............................................................................. 12

Figure 7 Dilution principle ............................................................................................................... 14

Figure 8 Dimensions (mm) dilution units DIL–1.. and control panel –S or –S1 ............................... 17

Figure 9 DIL-1 with control panel -S1.............................................................................................. 17

Figure 10 Electrical connection for DIL-1/H.. .................................................................................... 21

Figure 11 Extract from the injector data sheet .................................................................................. 23

Figure 12 Suction flow at 0,9 or 1bar abs. in dependence on the bypass gas pressure .................. 23

Figure 13 Explosion drawing of the dilution crosspiece .................................................................... 26

Figure 14 Crosspiece with critical orifice and O-ring seals ............................................................... 27

Figure 15 Bypass T-piece with injection nozzle and o-ring ............................................................... 28

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 5

5

Head Office

M&C TechGroup Germany GmbH Rehhecke 79 40885 Ratingen Germany

Telephone: 02102 / 935 - 0

Fax: 02102 / 935 - 111

E - mail: info@mc-techgroup.com

www.mc-techgroup.com

1 GENERAL INFORMATION

The product described in this operating manual has been examined before delivery and left our works

in perfect condition related to safety regulations. In order to keep this condition and to guarantee a

safe operation, it is important to heed the notes and prescriptions made in this operating manual. Furthermore, attention must be paid to appropriate transportation, correct storage, as well as professional

installation and maintenance work.

All necessary information a skilled staff will need for appropriate use of this product are given in this

operating manual.

2 DECLARATION OF CONFORMITY

CE - Certification

The product described in this operating manual complies with the following EC directives:

EMV-Instruction

The requirements of the EC directive 2004/108/EC “Electromagnetic compatibility“ are met.

Low Voltage Directive

The requirement of the EC directive 2006/95/EC “Low Voltage Directive“ are met.

The compliance with this EC directive has been examined according to DIN EN 61010.

Declaration of conformity

The EU Declaration of conformity can be downloaded from the M&C homepage or directly requested

from M&C.

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 6

6

3 SAFETY INSTRUCTIONS

Please take care of the following basic safety procedures when mounting, starting up or operating this

equipment:

Read this operating manual before starting up and use of the equipment. The information and warnings given in this operating manual must be heeded.

Any work on electrical equipment is only to be carried out by trained specialists as per the regulations

currently in force.

Attention must be paid to the requirements of VDE 0100 (IEC 364) when setting high-power electrical

units with nominal voltages of up to 1000 V, together with the associated standards and stipulations.

Check the details on the type plate to ensure that the equipment is connected to the correct mains

voltage.

Protection against touching dangerously high electrical voltages:

Before opening the equipment, it must be switched off and hold no voltages. This also applies to any

external control circuits that are connected.

The device is only to be used within the permitted range of temperatures and pressures.

Check that the location is weather-protected. It should not be subject to either direct rain or moisture.

The device must not be used in hazardous areas.

Installation, maintenance, monitoring and any repairs may only be done by authorized personnel with

respect to the relevant stipulations.

4 WARRANTY

If the equipment fails, please contact M&C directly or else go through your M&C authorised dealer.

We offer a one year warranty as of the day of delivery as per our normal terms and conditions of sale,

and assuming technically correct operation of the unit. Consumables are hereby excluded. The terms

of the warranty cover repair at the factory at no cost or the replacement at no cost of the equipment

free ex user location. Reshipments must be send in a sufficient and proper protective packaging.

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 7

7

DANGER!

This means that death, severe physical injuries and/or important material damages will occur in case the respective safety measures

are not fulfilled.

WAR N ING !

This means that death, severe physical injuries and/or important material damages may occur in case the respective safety measures

are not fulfilled.

CARE!

This means that minor physical injuries may occur in case the respective safety measures are not fulfilled.

CAR E!

Without the warning triangle means that a material damage may occur in case the respective safety measures are not met.

ATT ENT I ON !

This means that an unintentional situation or an unintentional status

may occur in case the respective note is not respected.

NOTE!

These are important information about the product or parts of the

operating manual which require user’s attention.

SKILLED STAFF

These are persons with necessary qualification who are familiar with

installation, use and maintenance of the product.

5 USED TERMS AND SIGNAL INDICATIONS

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 8

8

Depression

manometer*

300

280

Sample gas in*

(non diluted)

Test gas*

in

Bypass gas

in*

Option I

Bypass out*

(diluted)

205

180

Ø6mm

95

Option II

Sample gas out*

(diluted)

Sample gas

out**

(non diluted)

Dilution gas

in*

* Tube connection 6mm ( 1/4“ on request)

** Tube connection 8mm ( 3/8“ on request)

6 INTRODUCTION

The non-heated or electrically heated M&C dilution unit DIL-1 /(H) is used in the analysis technique

whereever the measuring method or the handling of the process gas requires a dilution of the sample

gas or the components to be measured. Examples are the measurement of extremely toxic gases, the

determination of the gas moisture or emission measurement.

The M&C dilution unit is based on the functional dilution technique which is proved since years in the

M&C gas sample probe SP2000-H/DIL.

For further information or personal advice, we have pleasure to be at your disposal. Further you may

contact our internet pages with our complete product catalogue under:

www.mc-techgroup.com

7 APPLICATION

The following illustrations show versions DIL-1 and DIL-1/H.

Figure 1 Dilution unit DIL-1

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 9

450

430

300

280

** Connection tube 8x1mm

* Connection tube 6x1mm

Bypass-

gas in*

Sample in*

(non diluted)

Ø 6

Sample out**

(non diluted)

Dilution

gas in*

Testgas

in*

Depression-

manometer*

Option I

Bypass out*

(undiluted)

Alarm-Kontakt

230V,50Hz

(115V,60Hz)

Temp.-min

Netz

Tsoll

Tu<-30°C

0-180°C

To>+30°C

Reset

PG 13,5

104

Option II

Sample out*

(undiluted)

Figure 2 Dilution unit DIL-1/H

9

The M&C dilution units DIL-... are mounted on a plate for wall mounting. The operating temperature of

the non heated version DIL-1 is the ambient temperature. Version DIL-1/H is heated up to 180 °C and

is equipped with a heat insulated cover (Version for 320 °C on request).

The temperature is regulated by an integrated capillary thermostat, adjustable from 0-180 °C, including an excess temperature limiter and a low temperature alarm. (Optional: Temperature sensor PT100

or thermocouple “”K” for external temperature controller on request)

The connection of the heated lines is made without cold bridges into the heated part. Before the dilution gas enters the dilution unit, it is heated up to the operating temperature via a gas pre-heater. In

order to protect the dilution part against contaminations, internal protective filters are installed for the

sample gas and the dilution gas stream.

For calibration of the analyser, test gas can be feeded via the integrated test gas connection. A precision pressure controller with manometer is used for adjustment of the necessary dilution gas admission pressure. Via a vacuum pressure gauge, the function of the dilution injector is controlled. Both,

pressure controller and pressure gauge have to be ordered separately. Two versions are available:

Set -A (-A1) for direct mounting on the mounting plate and control panel type -S (-S1) for external 19"

rack mounting. A shut-off valve and a flowmeter for adjustment of the calibration gas are included in

the version –S (-S1).

The dilution unit can realize dilution ratios of 10:1 to 500:1. In case of high dilution ratios, a respective

small quantity of gas is sampled from the process. Optionally, a bypass injector –B (Option I) is available in order to shorten the response time in case of operation with atmospheric pressure. The bypass

injector is integrated right in front of the dilution unit.

The pressure regulator versions –A / -S include a pressure regulator with manometer for the dilution

gas as well as a manometer for control of the depression on the critical orifice. In case of option I, an

additional pressure controller with manometer is included in both mounting versions -A1 / -S1.

The construction of the dilution unit guarantees easy operation and maintenance being independent

from process temperature.

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 10

10

7.1 VARIATIONS

The two basic versions DIL-1 and DIL-1/H can be extended by several options.

Option I

Includes a bypass for dilution gas with bypass injector for a fast suction of sample gas in order to

shorten for example the response time in case of high dilution ratios.

Option II

Includes an additional sample gas outlet „non-diluted“.

Option –A

Includes a pressure regulator with manometer and a manometer for control of the low pressure on the

critical orifice. These are mounted directly onto the dilution unit. (see figure 6).

Option –A1

Includes in addition to option -A a pressure regulator with manometer for operating the bypass of option I. This option is also mounted directly onto the dilution unit (see figure 6).

Option –S

Includes the necessary pressure regulator with manometer, shut-off valves and flowmeter, incorpo-

rated externally in a 19“ control panel (see figure 5). The connection of the sampling or the supply

lines to the downstream analysis system have to be executed by the client. Connections which are

marked accordingly are available on the back side of the 19“ unit.

Option –S1

Includes in addition to option -S the pressure regulator with manometer for operating the bypass of option I, mounted externally into the 19“ control panel (see figure 5). The connection of the sampling or

supply lines to the downstream analyse system has be made by the client. Connections which are

marked accordingly are available on the back side of the 19” unit.

The following illustrations show the gas flow of the dilution units DIL-1 and DIL-1/H with all possible

options.

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 11

11

Bypass-out

Test gas

Sample

in

Sample out

Sample out

Undiluted (Option II )

diluted

Dilution gas

-1-0bar

0-6bar

Option I

Bypass

0-6bar

*

**

**

*

**

** Components for version/control panel -A or -S

* Additional components for -A or -S for version/control panel -A1 or -S1

Bypass out

180°C

Sample

in

Test gas

Sample out

undiluted (Option II )

Sample out

undiluted

Dilution gas

0-6bar

**

-1-0bar

0-6bar

*

Bypass

**

Option I

**

*

** Components for version/control panel -A or -S

* Additional components for -A or -S for version/control panel -A1 or -S1

Figure 3 Gas flow scheme DIL-1 with possible options

Figure 4 Gas flow scheme DIL-1/H with possible options

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 12

12

450

430

300

** Connection tube 8x1mm

* Connection tube 6x1mm

Bypass

gas IN*

Sample IN*

(undiluted)

Ø

Sample

OUT**

(undiluted)

Dilution gas

IN*

Testgas

IN*

Depression

manometer*

Option II

Sample out*

(undiluted)

(undiluted)

Bypass out*

Option I

104

Alarm-Kontakt

230V,50Hz

(115V,60Hz)

Temp.-min

3

2

1

L

N

8

6

7

4 5 L’

Netz

Tsoll

Tu<-30°C

0-180°C

To>+30°C

Reset

PG 13,5

open

482

132 (3HE)

Option: Bypass

1,0

0,0

6,0

5,0

Bypass-Injector

3,0

2,0

4,0

Steuer panel

Dilution gas

1,0

0,0

6,0

5,0

3,0

2,0

4,0

open

-0,4

0,0

Injector

Depression

-1,0

-0,8

Test gas

-0,6

-0,2

Option

500

480

370

350

Ø 6

Sample in*

(undiluted)

Test gas in*

Sample out**

(diluted)

Option I

Bypass out*

(undiluted)

Dilution gas

in*

104

PG 13,5

0-180°C

Tu<-20°C

To>+20°C

Tsoll

Reset

Power

230V 50Hz

115V 60Hz

Alarm contact

Temp.-min

Option II

Sample out*

(undiluted)

* Tube connection 6 x 1mm

** Tube connection 8 x 1mm

Figure 5 Dilution unit DIL-1/H with control panel –S or -S1

Figure 6 Dilution unit DIL-1/H with set -A or -A1

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 13

8 TECHNICAL DATA

Dilution ratios of the critical orifices „a“ to „g“

a b c d e f g

500

200

100

50

30*

20

10:1

Sample flow rate with critical orifices „a“ to „g“

1,4

2,7

5,5

11

19*

28

55l/h1)

Possibility to adapt the dilution factor

With dilution gas pressure adjustment -5% to +30%2)

Dilution gas flow rate with injector version I or II

I: 480 - 600 Nl/h, optional II: 1800 – 3000 Nl/h

Dilution gas pressure on inlet of pressure controller

Min. 4,5 bar, max. 16 bar

Bypass injector /B: pressure / Gas consumption / flow

rate

approx. 2 bar : injector gas approx. 300 l/h : sample

gas approx. 150 l/h

Process pressure

0,9 to 2 bar abs. at constant pressure

Fault caused by process temperature variations

No fault, operation independent of process temperature

Fault caused by process low or over pressure

Influence negligible at pressure changes ≤ 200mbar

and if test gas is given to the probe under process

conditions. Otherwise proportional to pressure

changes.

Fault caused by atmospheric pressure variations

< 1% with a variation of 50 mbar

Material in contact with the sample gas

Stainl. Steel 316Ti, quartz glass, FPM, graphite

Power supply for DIL-1/H

230V 50Hz, (optional 115V 60Hz), 800W

Temperature controller for DIL-1/H

Capillary thermostat adjustable 0-180 °C, with excess temperature limiter and low temperature alarm

as changeover contact, potentialfree alarm point T30

°C to T

Set

,

contact rating max. 250V 3A~ 0,25A =

Weight

approx. 8 kg

Type

M&C Dilution unit DIL-1/(H) with orifice „e“, dilution ratio 30:1, Standard

DIL-1

Dilution unit non heated

DIL-1/H(a)

Dilution unit electrically heated to 180°C, (a) = voltage 115V 60Hz

Option I

Bypass injector –B

Option II

Additional sample gas outlet undiluted

DIL-1/..-A

Option: mounting set for dilution unit, 1 pressure controller and 2 manometers

DIL-1/..-A1

Option: mounting set for dilution unit/Bypass injector, 2 pressure controllers and 3 manometers

DIL-1/..-S

Option: control panel with 1 pressure controller, 2 manometers, flowmeter, 2 shut-off valves

DIL-1/..-S1

Option: control panel with 2 pressure controller, 3 manometers, flowmeter, 2 shut-off valves

13

* Standard, others to be indicated along with order, intermediate values possible.

1)

approx at 3 bar dilution gas.

2)

-5%, however not possible with orifice „g“.

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 14

14

Orifice type

a b c d e f g

Dilution ratio*

500:1

200:1

100:1

50:1

30:1

20:1

10:1

Volume flow through the orifice [Nl/h]

1,4

2,7

5,5

11

19

28

55

9 DILUTION PRINCIPLE

The functional principle of the dilution unit is based on ultrasonic flow through a critical orifice (see Fig.

4). The flow through the orifice is constant when the differential pressure via the orifice is higher than

500 mbar. For the atmospheric inlet pressure (Pin = 1020 mbar), this means a pressure at the orifice

outlet (Pout) of less than 520 mbar absolute.

The necessary vacuum at the orifice outlet is produced by an injector operated with dilution gas.

Depending on the critical orifice selected, dilution rates can be between 10:1 and 500:1. The table below gives an overview of the dilution factor and sample gas volume using the injector I (480 – 600

Nl/h):

* with Injector II 50:1 to 2000:1

Figure 7 Dilution principle

How to check the dilution ratios and the exact adjustment of the pressure conditions are described in

chapter 14.1.

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 15

15

300

280

205

180

95

Ø 6

450

430

250

230

Ø6

155

95

10 DIMENSIONS

The following illustration shows the dimensions of the dilution units DIL-1 and DIL-1/H.

DIL-1:

DIL-1 with /A or /A1:

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 16

DIL-1/H:

450

430

300

280

Ø 6

Tsoll

Tu<-30°C

0-180°C

To>+30°C

Reset

PG 13,5

104

500

480

350

Ø 6

104

PG 13,5

0-180?C

Tu<-30°C

To>+30°C

Tsoll

Reset

16

DIL-1/H with /A or /A1 :

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 17

Option control panel –S or -S1:

Auf

Open

482 (84TE)

132 (3HE)

Option: Bypass

1,0

0,0

6,0

5,0

Bypass-Injector

Beipass-Injektor

3,0

2,0

4,0

Steuerpanel

Dilution gas

Verdünnungsgas

1,0

0,0

6,0

5,0

3,0

2,0

4,0

Auf

Open

-0,4

0,0

Injektor-Unterdruck

Injector-vacuum

-1,0

-0,8

Test gas

Prüfgas

-0,6

-0,2

Back pressure max. 1,2 bar abs.

Sample gas IN

17

Figure 8 Dimensions (mm) dilution units DIL–1.. and control panel –S or –S1

Figure 9 DIL-1 with control panel -S1

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 18

18

NOTE!

The dilution unit should be stored in a protected, frost-free room!

NOTE!

The dilution unit must be checked for its suitability for use with the available

operating parameters prior to installation (see type plate).

NOTE!

Increases of pressure due to use of long sample gas lines at the outlet may

have a great influence on the measuring result. For this reason, we recommend the following nominal widths and lengths for the sample lines in dependence on the type of injector:

Injector type I:

i

6mm max. 50m

i

8mm max. 150m

Injector type II:

i

8mm max. 15m

i

10mm max. 40m

i

12mm max. 80m

11 RECEIPT AND STORAGE

Carefully remove the dilution unit and any accessories from the transport packaging immediately af-

ter receipt and check the completeness of the delivery against the packing list.

Check the goods for possible transport damages and, if necessary, notify immediately your trans-

port insurer of any damage.

12 INSTALLATION INFORMATION

The safety rules and regulations for the prevention of accidents must be observed during installation

and also subsequent operation. The information in chapter 3 “Important Safety Information“ must be

observed.

The following also applies:

Select the optimal sampling point according to the generally applicable directives or coordinate

with the responsible departments.

13 INSTALLATION

The M&C dilution units DIL-1... are designed for stationary use. With correct selection of the sample

point and proper installation, they will work for many years with a minimum of maintenance required.

13.1 CONNECTION OF THE SUPPLY OR SAMPLE LINES

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 19

19

Connection

Dimension

Sample In (undiluted)

Tube 6 x 1mm

Testgas in

Tube 6 x 1mm

Dilution gas In

Tube 6 x 1mm

Low pressure manometer

Tube 6 x 1mm

Sample gas Out (diluted)

Tube 8 x 1mm

Option I:

Bypass gas In

Tube 6 x 1mm

Bypass gas Out (diluted)

Tube 6 x 1mm

Option II:

Sample gas Out (undiluted)

Tube 6 x 1mm

NOTE!

When connecting hose pipes to stainl. Steel fittings, a supporting sleeve

must always be used.

The connection must be checked for tightness.

The connections for the supply and sample lines are as follows:

13.2 CONNECTION OF SAMPLE GAS AND HEATED SAMPLE LINES

All connections for the sample gas or heated sample lines are tube connectors out of stainl. steel suitable for connection of stainl. steel tubes or hose pipes with dimension 6x1mm. Only the outlet of the

diluted sample gas is dimensioned for stainl. steel tube or flexible tube of 8x1mm.

The connection to the non heated versions DIL-1 is made directly to the respective fittings (see figure

1).

The connection of the heated sample lines to the heated versions DIL-1/H is shown in figure 2.

Remove the protective cover

Open the fastening clamp

Mount the hose pipe or tube to the respective fittings

Shut the fastening clamp again

Install the protective cover again.

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 20

20

WAR N ING !

The incorrect mains voltage can destroy the unit. Check the type

plate for the correct voltage prior to connection!

The dilution units must be mounted in such a way that touching the

live parts is excluded!

In any case, we recommend the use of temperature resistant cables!

The alarm contact for low temperature must be controlled!

In case of a low temperature alarm (failure of heating or sensor) the

dilution gas or bypass gas supply must be interrupted to avoid serious damage of the dilution unit. We recommend to switch the low

temperature alarm onto external solenoid valves that provide the

above mentioned function!

13.3 CONNECTION OF DILUTION GAS OR BYPASS GAS

For connection of the supply lines, tube connectors with dimension 6 x 1mm are available. mm zur

Verfügung. The connection fittings of the heated dilution units are located outside the cover and can

be connected without disassembly. Only when using the heated versions and option I, a heated “undiluted” sample line is connected to the bypass outlet. Please act as follows:

Remove protective cover

Open the fastening clamp

Mount the hose pipe or tube to the respective fitting

Shut the fastening clamp again

Install the protective cover again.

When using option –A (only dilution gas) or –A1 (dilution and bypass gas), the supply lines are connected to the connection fittings of the precision pressure regulator.

When using the 19“ control panels –S or –S1, corresponding connectors for the supply gases are pro-

vided at the rear of the unit.

13.4 CONNECTION OF CALIBRATION GAS

For all versions of DIL-1 and DIL-1/H, a tube connector 6 x 1 mm is available for connection of the

calibration gas (see figure 4).

13.5 ELECTRICAL CONNECTION

The temperature setting on the dilution unit DIL-1/H is made on the internal capillary thermostate.

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 21

21

NOTE!

For the erection of power installations with nominal voltages of up

to 1000V, the requirements of VDE 0100 and its associated standards and specifications must be observed.

A main switch must be provided externally.

The supply circuit of the unit must be equipped with a fuse with the

correct rating (over current protection); the electrical details see

technical data.

Mains 230V 50Hz

or 115V 60Hz

Alarm outlet

1

2

1

2

+30

-30

800 W

WAR N ING !

We recommend the use of temperature resistent cables!

Remove cover of the connection box.

Insert the mains cable (min. 3 x 1,5 mm2) through the cable gland and connect to the appropriate

terminals.

Insert the signal cable (low temperature alarm) through the cable gland and connect to the appro-

priate terminals (contact position Tu shows alarm event).

Screw cover back in place.

Figure 10 Electrical connection for DIL-1/H..

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 22

22

WAR N ING !

The supply of gas to the injectors is only allowed when the heated

dilution unit has reached its operating temperature (see technical

data).

Prior to initial use, make sure that the mains voltage corresponds

to the voltage indicated on the type plate!

Do not touch the surface of the heated dilution unit during operation. Due tp its high surface temperatures, it may cause burns. Protective gloves must be worn and the dilution unit must be protected

against unauthorised access!

NOTE!

If the set temperature on the capillary controller should be reduced

by more than 30°C in one step, the excess temperature cut-off on

the thermostat is activated (for re-starting press the reset button).

NOTE!

The total heating time is about 2 hours. After about 1 hour, the

lower threshold value ( 30°C below set value) is exceeded.

NOTE!

For safety reasons, the low pressure gauge must show a low pressure of >-0,6 bar. With a low pressure of < -0, 6 bar, the critical orifice will not function properly. If the necessary low pressure will

not be reached, the dilution gas supply pressure must be increased.

14 INITIAL STARTING

Prior to initial use, system and process-specific safety measures must be observed.

The relevant safety requirements and procedures for the medium to be sampled must be heeded.

The following step-by-step procedure is recommended:

If possible, separate the dilution unit from the sample point, eg. above the ball valve.

In case of heated versions, check the set temperature on the installed thermostat.

For heated versions, switch on the mains voltage.

Open the valve for the dilution gas (for heated version: wait until the complete dilution unit is

heated, approx. 2 h). Set the precision pressure reducer to the pressure specified on the enclosed

injector data sheet (see figure 9).

The following table shows an extract from the injector data sheet.

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 23

23

Injektortyp

I

Injektor-Nr.

689

Für Verdünnungssystem-Nr.

8652/222835

Typ

DIL-1/H-A1

Injector

type

Injector

No.

For dilution system

No.

Type

Betriebsdruck

Operating pres-

sure

[bar]

Durchfluss

Flow

[l/h]

Unterdruck ohne kritische Düse

Vacuum without critical orifice

[bar]

Unterdruck mit kritischer Düse

Vacuum with critical orifice 5,1l/h

[bar]

2,4

415

-0,62

-0,61

2,6

435

-0,65

-0,64

2,8

460

-0,68

-0,67

3,0

490

-0,80

-0,77

3,2

510

-0,79

-0,77

3,4

535

-0,79

-0,77

3,6

560

-0,78

-0,76

3,8

585

-0,77

-0,76

4,0

605

-0,77

-0,75

Überprüfung des Verdünnungsfaktors

Check of the dilution ratio

Messgasdruck atmosphärisch

Sample gas pressure atmospheric

Kritische Düse

Critical nozzle

Verd.gas

Dilution

gas

Verdünnungsgasdruck

Dilution gas pressure

Messgas

Sample

Verdünnung

Dilution

Messwert d. verd. Gases

Meas. value of the dil. gas

5,1 l/h

100% N2

3,2 bar

100% O2

100:1

1,0 % O2

NOTE!

The attached bypass injector table shows the suction flows at corresponding bypass gas pressures for two different process pressures, 1 bar and 0,9 bar absolute (see figure 12).

Bypassgas / Bypass gas

Prozessgas / Sample gas

Betriebsdruck

Operating pressure

[bar]

Durchfluss

Flow

[l/h]

Ansaugvolumenstrom bei 1bar abs.

Suction flow at 1bar abs.

[l/h]

Ansaugvolumenstrom bei 0,9bar

abs.

Suction flow at 0,9bar abs. [l/h]

0,5

110

45

-

1,0

155

115

-

1,5

190

200

65

2,0

235

250

135

2,5

270

300

200

3,0

310

350

250

3,5

355

370

270

4,0

395

390

305

4,5

430

425

350

WAR N ING !

In the event of low temperature (failure of the heating) the supply of

dilution gas must be interrupted!

Figure 11 Extract from the injector data sheet

For the operation of an installed bypass injector, the necessary pressure must be set on the pres-

sure regulator (see figure 12).

Figure 12 Suction flow at 0,9 or 1bar abs. in dependence on the bypass gas pressure

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 24

24

WAR N ING !

The gas pressure must be above 0,7 bar, because the pressure

control valve installed has an opening pressure of 0, 7 bar.

When using the control panel, the respective ball valve for the test

gas supply must be opened and the flow rate be set on the flow-

meter.

14.1 CALIBRATION

A calibration of the downstream analyser system or checking the dilution factor must always be effected under operation conditions.

Above the test gas valve, an appropriate test gas can be feeded.

The procedure for calibration or checking the dilution ratio is as follows:

Supply test gas of a concentration you know.

Check the dilution ratio on the downstream analyser and, if necessary, correct the pressure on the

pressure regulator of the dilution gas.

Test gas feeding without bypass injector

In order to assure that sufficient test gas is available, the test gas quantity should be at least threefold

of the flow quantity passing through the critical orifice (see injector data sheet).

Test gas feeding with bypass injector

The test gas quantity must be approximately 10% above the quantity of the volume flow passing

though the bypass (see figure 12) and the critical orifice (see figure 11).

15 CLOSING DOWN

Prior to closing down, the heated dilution unit should be purged with inert gas or air to prevent the

condensation of agressive components from the process gas.

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 25

25

WAR N ING !

Agressive condensate possible. Wear safety glasses and appropriate protective clothing!

Do not touch the surface of the dilution unit during operation as

this can cause burns due to the high surface temperatures. Wear

protective gloves. The dilution unit must be protected against unauthorized access!

Before carrying out maintenance work on electrical components,

the mains voltage must be disconnected in all poles. This also applies to any connected alarm and control circuits !

NOTE!

The dilution unit does not need to be removed for repair or maintenance.

16 MAINTENANCE

Prior to any maintenance of repairing works, system and process specific safety measures must be

observed.

No recommendation for maintenance intervals can be given. Maintenance intervals must be determined depending on the particular process conditions and specific application.

The maintenance of the dilution unit is limited mainly to the cleaning of the filter elements, inspection

of the seals and maintenance of the dilution systems.

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 26

26

WAR N ING !

Nut 2 must only be removed after having disassembled the dilution

cross. Disregard may lead to destruction of the critical orifice!

16.1 DISASSEMBLY OF THE CROSSPIECE

For disassembling of the crosspiece, the heating of the heated dilution unit should be switched off so

that the unit can cool down.

Figure 13 shows the explosion drawing of the dilution crosspiece.

Figure 13 Explosion drawing of the dilution crosspiece

We recommend to proceed according to the following steps:

Remove the insulation cover of the dilution unit, if applicable;

Remove all tube connectors on the dilution crosspiece. These are:

- Depression manometer nut 6

- Dilution gas inlet nut 4

- Sample gas outlet nut 5

- Removal of nut 1.

Now, the dilution crosspiece is accessible for further maintenance and repair work.

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 27

27

WAR N ING !

Do not clean the critical orifice mechanically.

Cleaning should be effected in an ultrasonic bath !

WAR N ING !

The Swagelok® fittings must be carefully tightened to avoid damage

of the internal components. Do not tighten the fittings too fast.

If a fitting is believed to be leaking, do not tighten further. Disassemble the fitting completely and tighten it again.

8

16.2 CLEANING OF THE CRITICAL ORIFICE AND CHECK OR CHANGE OF THE ORINGS

Figure 13 shows the position of the orifice in the crosspiece and the O-ring seals.

Figure 14 Crosspiece with critical orifice and O-ring seals

Please proceed as follows:

Loosen union nut 3 and remove the jet pipe;

Loosen nut 2 and remove the pipe piece with both nuts;

Push the injection nozzle out of the jet pipe side by using the mounting tools (item 8, figure 14);

Push the critical orifice with its nozzle seat and o-ring carefully from the back side of the cross-

piece by using the mounting tool (item 8, figure 14);

Check the o-rings and change them if necessary;

Push the new orifice or the cleaned old one into the o-rings until block.

Now, the dilution unit can be reassembled in reverse order.

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 28

28

NOTE!

For cleaning the injector, it is not necessary to remove the nozzle out of the

crosspiece. The nozzle can be cleaned together with the complete crosspiece in an ultrasonic bath.

Injection nozzle

O-ring

Bypass T-piece

Jet pipe

Nut 2

Nut 1

Nut 3

Sample gas

Dilution gas

16.3 CHANGE AND CLEANING OF THE INJECTION NOZZLE

For changing the injector nozzle, see figure 14:

Loosen nut 3 and remove jet pipe;

Push the injection nozzle out of the jet pipe side by using the mounting tools (item 8, figure 14);

Check the o-ring and change it if necessary;

Push the new nozzle with o-ring until blocking.

16.4 REMOVING THE BYPASS T-PIECE

For cleaning or changing the bypass injector, the bypass T-piece can be completely disassembled.

The following figure shows the bypass T-piece.

Figure 15 Bypass T-piece with injection nozzle and o-ring

Dismantle the T-piece as follows:

Romove insulation cover if applicable;

Remove all tube connectors on the bypass-T. These are: (see figure 15):

- Bypass inlet union nut 1

- Union nut 2 (jet pipe side)

- Union nut 3 (sample inlet).

The bypass-T is now ready for further maintenance and repair.

16.5 CHANGE AND CLEANING OF THE BYPASS INJECTION NOZZLE AND CONTROL OR CHANGE OF THE O-RING

Push the injection nozzle out of the jet pipe side by using the mounting tools (item 8, figure 14);

Check the o-ring and change if necessary;

Push in the new or cleaned old nozzle with o-ring until blocking.

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Page 29

29

NOTE!

For cleaning the injection nozzle, you need not necessarily pull the nozzle

out of the T-piece. The nozzle can be cleaned together with the complete Tpiece in an ultrasonic bath.

If you blow through the nozzle, this must be done from the jet pipe side.

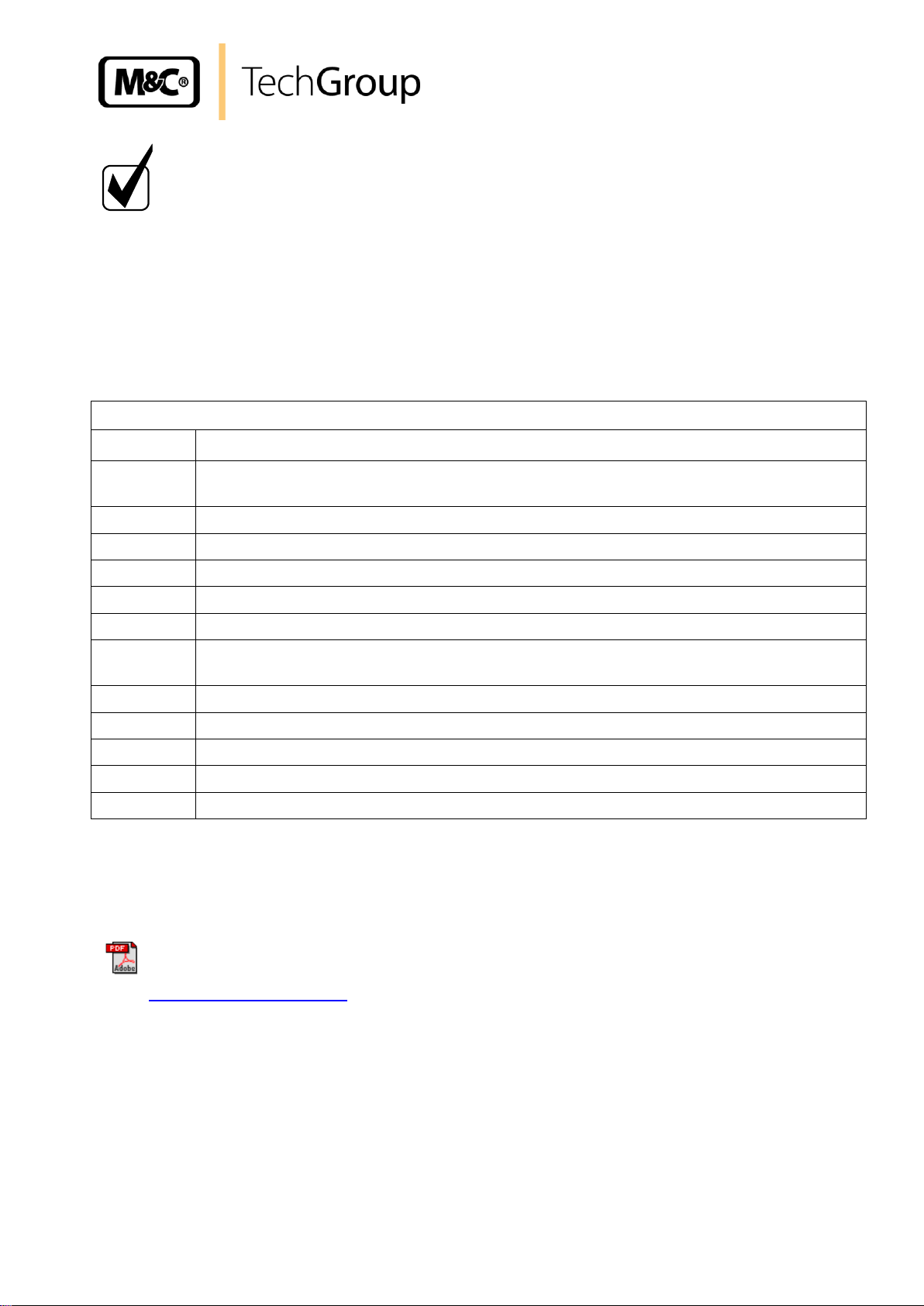

Recommended spare parts

Part No.

Description

20 S 4300

Complete set critical orifice incl. 2x o-rings. Material: glass # Please specify dilution ratio along with order. #

93 S 4000

Injection nozzle incl. o-ring (crosspiece)

93 S 4006

Dilution crosspiece empty, without any inserts, material: SS316

93 S 4016

Bypass T-piece empty, without any inserts, material: SS316

93 S 4020

Crosspiece complete. # Please specify dilution ration along with order #

93 S 4025

Bypass T-piece complete

90 S 4035

Suction tube for DIL 6x1mm with integrated filter sieve incl. Swagelok® nuts, silverplate cutting ring for dilution crosspiece, material SS316

93 S 0010

Spare thermostate 0-180°C

93 S 0015

Spare heating cartridge HLP, 230V 800W

93 S 0017

Spare heating cartridge HLP, 115V 800W

93 S 0018

Heat conductivity paste for insertion of heating cartridge

93 S 4015

Eductor incl. O-ring for bypass-T-piece

17 SPARE PARTS LIST

The wear, tear and spare part requirements depend on the specific operating conditions.

The following table shows an extract of the recommended spare parts for the diluiton units DIL-1 and

DIL-1/H :

18 APPENDIX

Further documentation of our products can be seen in our internet catalogue:

www.mc-techgroup.com

Gas sampling and gas conditioning technology 2-1.1.7.6-ME

Loading...

Loading...