Page 1

CSS-VC1

Embracing Challenge

Gas Conditioning Unit series CSS®

Version CSS-VC1 for max. 1 x 250Nl/h gas ow rate,

Version CSS-VC2 for max. 2 x 150Nl/h gas ow rate,

for 19”- or wall mounting or portable in transport case

Special Features

Compact high-performance construc-

tion with compressor cooler

Individually congurable, also beyond

the scope listed here

Completely pre-installed

Multi functional expandable control unit

TCU with warning and fault indicator in

plain text

One or two gas streams

19”- or wall mounting housing or port-

able in transport case

Low maintenance and self-monitoring

Outlet dew point adjustable from +2 °C

to +7 °C

Dew point stability ± 0,1°C

Operational in 10 minutes

Light weight

Optimum reliability

Operating hours counter

Resettable service interval

History memory

Application

The units CSS-VC.. provide a complete preinstalled compact high-performance sample

gas conditioning for continuous use. Due to

the multi functional expandable control unit

TCU and a big variety of additional options

the gas conditioning units excellently can be

adapted to the most diverse requirements of

gas analysis technique and therefore assume

tasks of complete anlayse systems.

Its compact construction only takes up little

space. The CSS-VC units are ready for use in

a few minutes. This makes time-consumingprocurement of individual components and

assembly superfluous. Also a portable version

in transport case is possible.

Description

All components of the gas conditioning unit

are mounted in a robust compact sheet steel

case for wall- or 19»-rack mounting. The ventilation grids in the sidewalls ensure that the

equipment is sufficiently ventilated.

Filter, flowmeter and peristaltic pump are

placed into the front panel and thus assure a

very easy maintenance. Due to a removable

lid and a foldable front plate also quick and

easy inspection and maintenance of all other

built-in components, especially easy change

of heat exchangers is possible.

The compressor gas cooler is equipped with

one or two heat exchangers of Duran glass,

stainless steel SS316Ti or PVDF.

Peristaltic pumps type SR25.2 are used for

contiuous condensate removal or also used

as dosing pump.

The current cooler temperature is displayed

at the front panel mounted multi functional

control unit TCU. Via keys the set temperature

of the cooler can be adjusted. In case of warnings or faults in plain text are displayed and

additionally via LED’s indicated ( cooler within

set temperature range - green LED, flow alarm

(option) - yellow LED, temperature +-3°C from

set point and liquid alarm (option) - red LED.

The fine filter downstream cooler (different

filter executions possible) ensures the necessary solid separation. The condition of the

filter element is visible from outside.

For protection of downstream analysers

against liquid breakthrough and for increase

of operating safety of the whole system

depending on the chosen type of filter a

suitable liquid alarm is possible or already

integrated in the filter.

A collective alarm message or on request

single alarm message inclusive mA outlet

for cooler temperature connected to output

terminals is available. Alarm message and

switching off the sample pump if present

happens via potential free contacts for collective alarm resp. single alarms (cooler temperature, flow, liquid in the system).

The downstream installed sample gas pump

N3/5/9 KPE is available with 3 pump capacities.

The flow meter FM40 with corresponding

measuring range installed in the sample gas

outlet can be equipped with a flow alarm

sensor FA-20mo and the adequate electronic.

Additionally for each sample outlet a second

sample outlet resp. bypass, also with flowmeter and flowalarm as option can be set up.

In case of aerosol problems a liquid particle

filter can be installed downstream the flowmeter in the sample gas outlet.

Via extension modules for control unit TCU

two more temperature controllers e.g. for

control of heated sample lines or gas sample

probes are available. Also external sample

gas pumps can be switched and gas sample

probes individually be purged back.

Technical specications and illustrations are without

obligation, subject to modications. 04.12/06.13

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

14.1a

Page 2

1

2

5

3

6

4

8

7

1

2

5

6

4

8

7

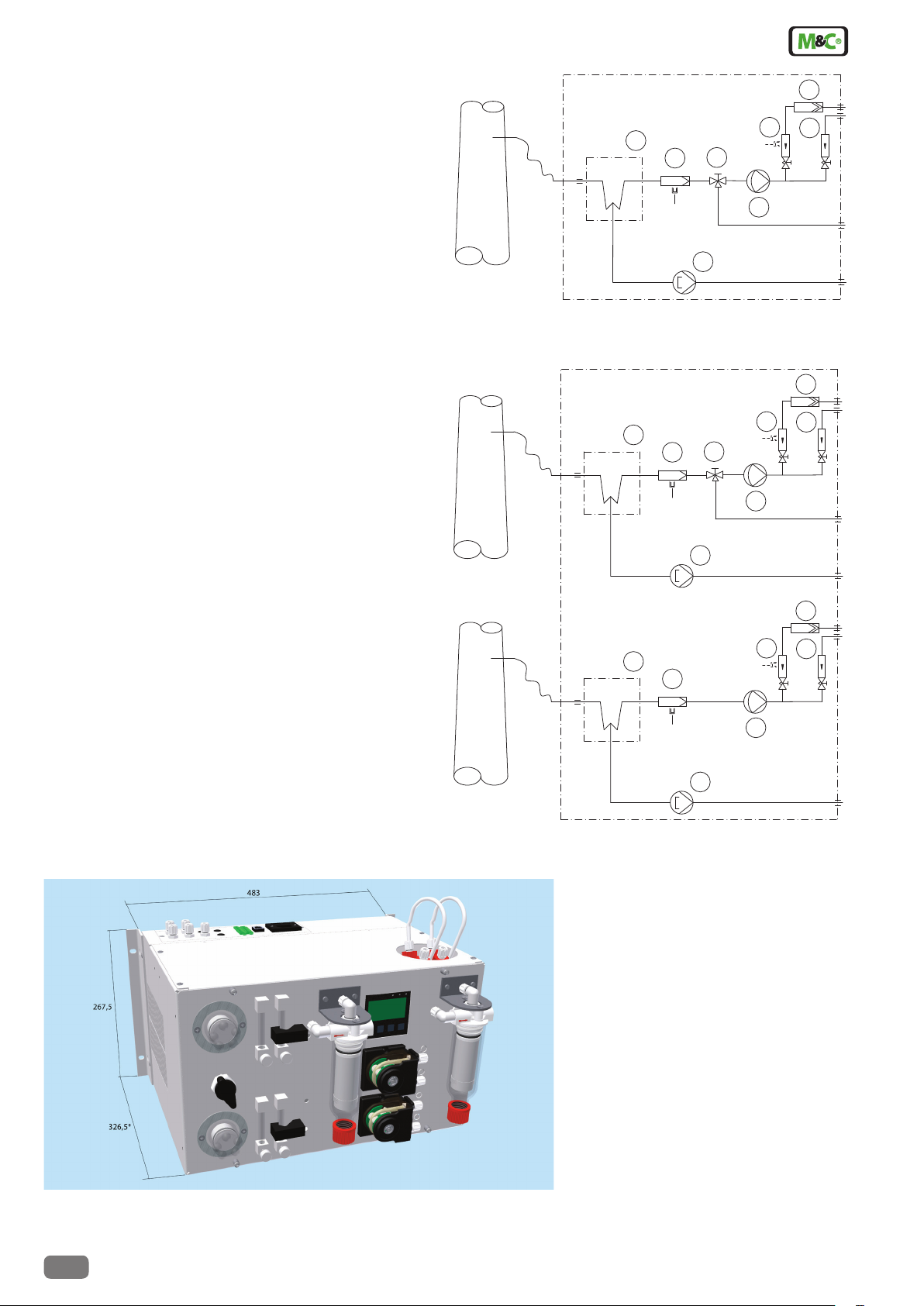

Example configuration CSS-VC1

1 Gas cooler series ECM-1

2 Option universal lter or front panel lter FPF-0,1GF, 0,1µm,

optional with liquid alarm LA or front panel lter

FPF+, optional with integrated liquid alarm

3 Option 3 or 5-way-ball valve 3L/PV or 5L/PV

4 Option sample gas pump N3/5/9KPE

5 Option peristaltic pump SR25.2

6 Option ow meter FM40 with ow alarm

7 Option ow meter FM40

8 Option liquid particle llter CLF-5/W or CLF-T(SS)

Example configuration CSS-VC2

1 Gas cooler series ECM-2

2 Option universal lter or front panel lter FPF-0,1GF, 0,1µm,

optional with liquid alarm LA or front panel lter

FPF-2-0,3GF, 0,3µm, with integrated liquid alarm

3 Option 3 or 5-way-ball valve 3L/PV or 5L/PV

4 Option sample gas pump N3/5/9KPE

5 Option peristaltic pump SR25.2

6 Option ow meter FM40 with ow alarm

7 Option ow meter FM40

8 Option liquid particle llter CLF-5/W or CLF-T(SS)

8

6

1

3

2

4

5

7

Dimensions CSS-VC..

Dimensions in mm

* 301,5 without wall mounting brackets

14.1a

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 04.12/06.13

Page 3

Technical Data

Gas Conditioning Unit series CSS® Version CSS-VC1 Version CSS-VC2

Part No. 230V 50Hz 01G6050 01G6055

Part No. 115V/50-60Hz 01G6050a 01G6055a

Sample outlet dew point range of adjustment: +2 °C ..... +7 °C, factory setting: +5 °C

Dew point stability at constant conditions < ±0,1 °C

Sample inlet temperature **max. 180 °C

Sample inlet dew point **max.+80 °C

Gas flow rate **max. 250 Nl/hr **max. 2 x 150 Nl/hr

Ambient temperature **+5 °C up to +40 °C

Storage temperature -25 °C up to +65 °C

Pressure 0,7 bar up to 1,4 bar abs.

Total cooling capacity ** max. 144 kJ/hr

Number of gas inlets 1 2

Number of gas outlets 1 2

Condensate outlet 1 2

Medium connections tube connection 4/6 mm

Material of sample contacting parts Heat exchanger : glass, PVDF or stainless steel 1.4571

Tubing and fittings : PTFE, PVDF

Universal filter FP-2T-D : PVDF, FPM, glass, PTFE

Front panel filter FPF-0,1GF : PVDF, glass, FPM

Front panel filter FPF+ : PVDF, glass, FPM

Peristaltic pump SR25.2 : PVDF, Novoprene

Liquid particle filter CLF-5/W : PVDF, glass, FPM, PTFE

Sample gas pumps N3/5/9 : PVDF, PTFE, FPM

Flowmeter FM40 : PVDF, glass, FPM, Hastelloy C4

Ball valve 3L/PV and 5L/PV : PVDF, FPM

Ready for operation approx. 10 min.

Power supply 230V 50-60Hz ±10% resp. 115V 50-60Hz ±10%***

Power consumption max. 220VA + max. 300VA for the sample gas pumpfür die Messgaspumpen

Fuse protection 4A t, 5x 20 mm

Electrical connection Cold appliance plug with 2 m of cable

Case protection IP20 EN 60529

Housing protection sheet steel case for 19“- or wall mounting, lacquered RAL 7032

Equipment dimensions (H x W x D) 267,5 mm x 483 mm x 301,5 mm

(portable version : 355 mm x 515 mm x 395 mm)

Electrical equipment standard EN61010

Weight approx. 22 kg

PVDF = Polyvinylidenuoride

PVC = Polyvinylchloride

FPM = Fluor caoutchouc = Viton

PPH = Polypropylene hard

PTFE = Polytetraourethylene

** Technische Daten mit Max.-Angaben sind unter Berücksichtigung der Gesamtkühlleistung bei 25 °C und einem Ausgangstaupunkt von 5 °C zu bewerten.

*** 115V/50Hz sample gas pump as feature artticle possible

®

®

Options

Description Part No.

Heat exchangers and housing version

Extra charge for gas connections directly at one heat exchanger

Extra charge for heat exchanger ECM-1 out of glass for CSS-VC1, sample gas connections at the heat exchanger 93K0140

Extra charge for heat exchanger ECM-1 out of stainless steel SS316Ti for CSS-VC1, sample gas connections at the heat exchanger 93K0160

Extra charge for heat exchanger ECM-1 out of PVDF for CSS-VC1, sample gas connections at the heat exchanger 93K0170

Extra charge for gas connections directly at two heat exchangers 01G6063

Extra charge for heat exchanger ECM-2 out of glass for CSS-VC2, sample gas connections at the heat exchanger 97K0100

Extra charge for heat exchanger ECM-2 out of stainless steel SS316Ti for CSS-VC2, sample gas connections at the heat exchanger 97K0115

Extra charge for heat exchanger ECM-2 out of PVDF for CSS-VC2, sample gas connections at the heat exchanger 97K0110

Extra charge for gas connections of one heat exchanger in the joint plate for e.g. 19“ mounting 01G6060

Extra charge for heat exchanger ECM-1 90° out of glass for CSS-VC1, sample gas connections in the joint plate for e.g. 19“ mounting 93K0150

Extra charge for heat exchanger ECM-1 out of PVDF for CSS-VC1, sample gas connections in the joint plate for e.g. 19“ mounting 93K0170

Extra charge for gas connections of two heat exchangers in the joint plate for e.g. 19“ mounting 01G6061

Extra charge for heat exchanger ECM-2 90° out of glass for CSS-VC1, sample gas connections in the joint plate for e.g. 19“ mounting 97K0150

Extra charge for heat exchanger ECM-2 out of PVDF for CSS-VC1, sample gas connections in the joint plate for e.g. 19“ mounting 97K0110

Peristaltic pumps for condensate removal (max. 2 pcs.)

Extra charge for mounting a peristaltic pump SR25.2 for condensate removal, completely flexible tubed (one per gas path necessary) 01G6140

Filters (max. 2 pcs. front panel filters and 2 pcs. universal filters resp. aerosol filters) and liquid alarm

Extra charge for mounting of front panel filter FPF-0,1GF 04F1000

Technical specications and illustrations are without

obligation, subject to modications. 04.12/06.13

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

01G6062

14.1a

Page 4

Options

Description Part No.

Extra charge for liquid alarm with flow chamber LS/LA2 at front panel filter FPF-0,1GF 03E3010

Extra charge for mounting a font panel filter FPF+ 04F2100

Extra charge for a filter element for FPF+ (depending on filter element) to choice

Extra charge for liquid alarm sensor LA3 integrated in FPF+ 03E1300

Extra charge for universal filter / aerosol filter CLF.. (depending on filter) to choice

Extra charge for mounting an universal filter / aerosol filter CLF on front plate (max. 2 pcs.) 01G6075

Extra charge for liquid alarm LA1S for universal filter F.-..-D 03E3001

Ball valves for test gas feeding (max. 1 pc.)

Extra charge for mounting a 3-way ball valve 3L/PV 01G9046

Extra charge for mounting a 5-way ball valve 5L/PV 01G9045

Sample gas pumps (max. 2 pcs.) (only with electronic controller 01G6175)

Extra charge for mounting sample gas pumps N..KPE 01G6070

Extra charge for mounting the sample gas pump N3KPE 01G6125

Extra charge for mounting the sample gas pump N5KPE 01G6130

Extra charge for mounting the sample gas pump N9KPE 01G6135

Flowmeter (max. 4 pcs. in total) and flow alarm (max. 2 pcs.)

Extra charge for mounting a flowmeter FM40 7-70Nl/hr in sample gas outlet 09F4000

Extra charge for mounting a fowmeter FM40 15-150Nl/hr in sample gas outlet 09F4005

Extra charge for mounting a fowmeter FM40 25-250Nl/hr in sample gas outlet 09F4010

Extra charge for mounting a fowmeter FM40 50-500Nl/hr in sample gas outlet 09F4015

Extra charge for flow alarm with forked light barrier FA-20mo 02E3500

Extra charge for second sample gas outlet resp. bypass with flow meter FM40 7-70Nl/hr 01G6200

Extra charge for second sample gas outlet resp. bypass with flow meter FM40 15-150Nl/hr 01G6210

Extra charge for second sample gas outlet resp. bypass with flow meter FM40 25-250Nl/hr 01G6220

Extra charge for second sample gas outlet resp. bypass with flow meter FM40 50-500Nl/hr 01G6230

Electronic controllers

Extra charge for electronic controller with collective status alarm 01G6170

Extra charge for single alarm messages (temperature, flow, liquid in the system) inclusive mA-outlet (4-20mA, or 0-20mA on request) for

cooler temperature for external temperature display

External additional modules (only with electronic controller 01G6175)

Extra charge for communication module (only necessary once for all extension modules of the TCU) 01B8620

Extra charge for temperature controller module (2 additional temperature controllers in TCU with 4 relays for excess resp. low temperature

monitoring) for control of solid state relays

For controller parameterization please specify with order which M&C devices should be controlled (type of gas sample probe(s) resp. type and length

of heated sample line(s)).

Extra charge for status module for collective alarm message via 1 changeover contact relay and 1 solid state relay for switching of external

sample gas pumps

Extra charge for blow back module for programmed control of solenoid valves for blow back of gas sample probes with status monitoring

(measuring/blow back), monitoring of the blow back pressure and control of the sample gas pumps (on/off)

Extra charge for M&C-bus for external modules 01G6180

Carrying case (only for 19“-version)

Extra charge for aluminium carrying case for portable gas conditioning 01G6250

Temperature controller for heated sample line (only with electronic controller 01G6175)

Extra charge for temperature controller for max. 10m heated sample line, 230V with PT100, with solid state relais and 7-pole plug 01G6190

Bending protection adapter for portable gas conditioning

Extra charge for bending protection for heated sample line DN4/6 01G9060

Extra charge for bending protection for heated sample line DN6/8 01G9061

01G6175

01B8640

01B8630

01B8650

Order example:

1x 01G6050 + 1 x 01G6060 + 1 x + 1x 93K0150 + 1 x 01G6140 + 1x 04F2100 + 1 x 90F0002 + 1 x 03E1300 + 1 x 03F3005 + 1 x 01G6075 + 1 x 01G6070 + 1 x

01G6130 + 1 x 09F4005 + 1 x 02E3500 + 1 x 01G6210 + 1 x 01G6175 + 1 x 01G9160 =

CSS-VC1, 230V, with heat exchanger out of glass, sample gas connections in the joint plate, built in peristaltic pump SR25.2, built in front panel filter FPF+2T

with integrated liquid alarm sensor LA3, aerosol filter CLF-5/W mounted on front panel, built-in sample gas pump N5KPE, flowmeter FM40 15-150Nl/hr and flow

alarm sensor FA-20mo in the sample outlet, flowmeter FM40 15-150Nl/hr in the bypass, single alarm messages and mA-outlet for external cooling temperature

indication, temperature controller module TCU.

14.1a

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 04.12/06.13

Page 5

CSS-VC in aluminium carrying case

The CSS-VC can be delivered in a robust aluminium carrying case with 2 ergonomic handles, removable perspex front and termination technique easily accessible

from outside. Dimensions : 355 mm x 515 mm x 395 mm (H x W x D)

Application example

Technical specications and illustrations are without

obligation, subject to modications. 04.12/06.13

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

14.1a

Loading...

Loading...