Page 1

Manual

Gas conditioning series CSS

®

Version CSS VC1 and CSS VC2

for 19"- or wall mounting

or portable version in carrying case

with software version 1.6

Gas sampling and gas conditioning technology 14.1a ME

Page 2

Contents

1 General information ..................................................................................................................... 5

2 Declaration of conformity ............................................................................................................ 5

3 Safety ............................................................................................................................................ 6

4 Warranty ........................................................................................................................................ 6

5 Terminology and symbols used ................................................................................................. 7

6 Introduction .................................................................................................................................. 8

7 Application .................................................................................................................................... 9

8 Technical specifications ............................................................................................................ 10

8.1 Technical specifications for the expansion modules .............................................................. 11

8.2 Options ................................................................................................................................... 12

9 Description ................................................................................................................................. 15

10 Goods receiving and storage .................................................................................................... 16

11 Installation instructions ............................................................................................................. 17

11.1 Conversion to wall mounted or 19" rack housing ................................................................... 17

12 Supply connections ................................................................................................................... 18

12.1 Hose connections ................................................................................................................... 19

12.2 Lay the connectors on the rear panel ..................................................................................... 19

12.3 Connection of the heated line with antikink adapter for portable version (Art. No. 01G9060

or 01G9061) ........................................................................................................................... 20

12.4 Electrical connections ............................................................................................................. 20

12.4.1 Group connection alarm (Art. No. 01G6170) .................................................................... 21

12.4.2 Connection of individual alarms, external pump control and external cooler

temperature display (Art. No. 01G6175) ........................................................................... 22

12.4.3 Connection of heated line for portable version (Art. No. 01G6190) .................................. 23

12.4.4 Connecting the optional expansion modules .................................................................... 24

13 Commissioning .......................................................................................................................... 24

13.1 Cooler controller ..................................................................................................................... 25

14 Decommissioning ...................................................................................................................... 26

15 The multifunctional control unit TCU ....................................................................................... 26

15.1 Basic functions of the TCU ..................................................................................................... 26

15.2 Properties of the TCU ............................................................................................................. 26

15.3 Enhancements to the TCU ..................................................................................................... 27

15.3.1 The communication module .............................................................................................. 27

15.3.2 The temperature control module ....................................................................................... 28

15.3.3 The status module ............................................................................................................ 29

15.3.4 The backflush module ................................................................ ....................................... 30

16 Operation of the multifunctional control unit TCU ................................................................. 31

16.1 Display of control temperatures or cooling temperature curve ............................................... 32

16.2 Configure the switching on and off of the sample pumps ....................................................... 33

16.3 Configure backflushing ........................................................................................................... 34

16.4 Display of events .................................................................................................................... 35

16.5 Operating data ........................................................................................................................ 36

16.6 Resetting service and operating time ..................................................................................... 36

16.7 Setting service interval, language, control temperatures and temperature sensor types ....... 37

17 Alarms and faults ....................................................................................................................... 39

17.1 Meaning of the LEDs .............................................................................................................. 39

17.2 Temperature alarms from cooler and temperature control module ........................................ 40

17.3 Flow disturbance and liquid alarms ........................................................................................ 40

17.4 Other fault and alarm messages ............................................................................................ 41

18 Maintenance ............................................................................................................................... 41

18.1 Change the filter elements and O rings .................................................................................. 42

18.2 Maintenance of the sample gas pump(s) ............................................................................... 42

2 Gas sampling and gas conditioning technology 14.1a-ME

Page 3

18.2.1 Remove pump head Type N 3/5/9 KPE ............................................................................ 44

18.2.2 Replacing the diaphragm Type N 3/5/9 KPE ................................................................... 44

18.2.3 Valve plate change Type N 3/5/9 KPE ............................................................................. 44

18.2.4 Mount pump head type N 3/5/9 KPE ................................................................................ 44

18.2.5 CleaningType N 3/5/9 KPE ............................................................................................... 45

18.3 Maintenance of the built-in peristaltic pump type SR 25.2 ..................................................... 45

18.3.1 Exchange the pump hose ................................................................................................. 46

18.3.2 Change of contact pulleys and springs ............................................................................. 47

18.3.3 Cleaning the pump head ................................................................................................... 49

18.4 Cleaning of the cooling fins of the compressor cooler ............................................................ 49

19 Spare parts lists ......................................................................................................................... 50

20 Appendix .................................................................................................................................... 52

List of figures

Figure 1 Example of a gas flow diagram CSS-VC1 ................................................................... 9

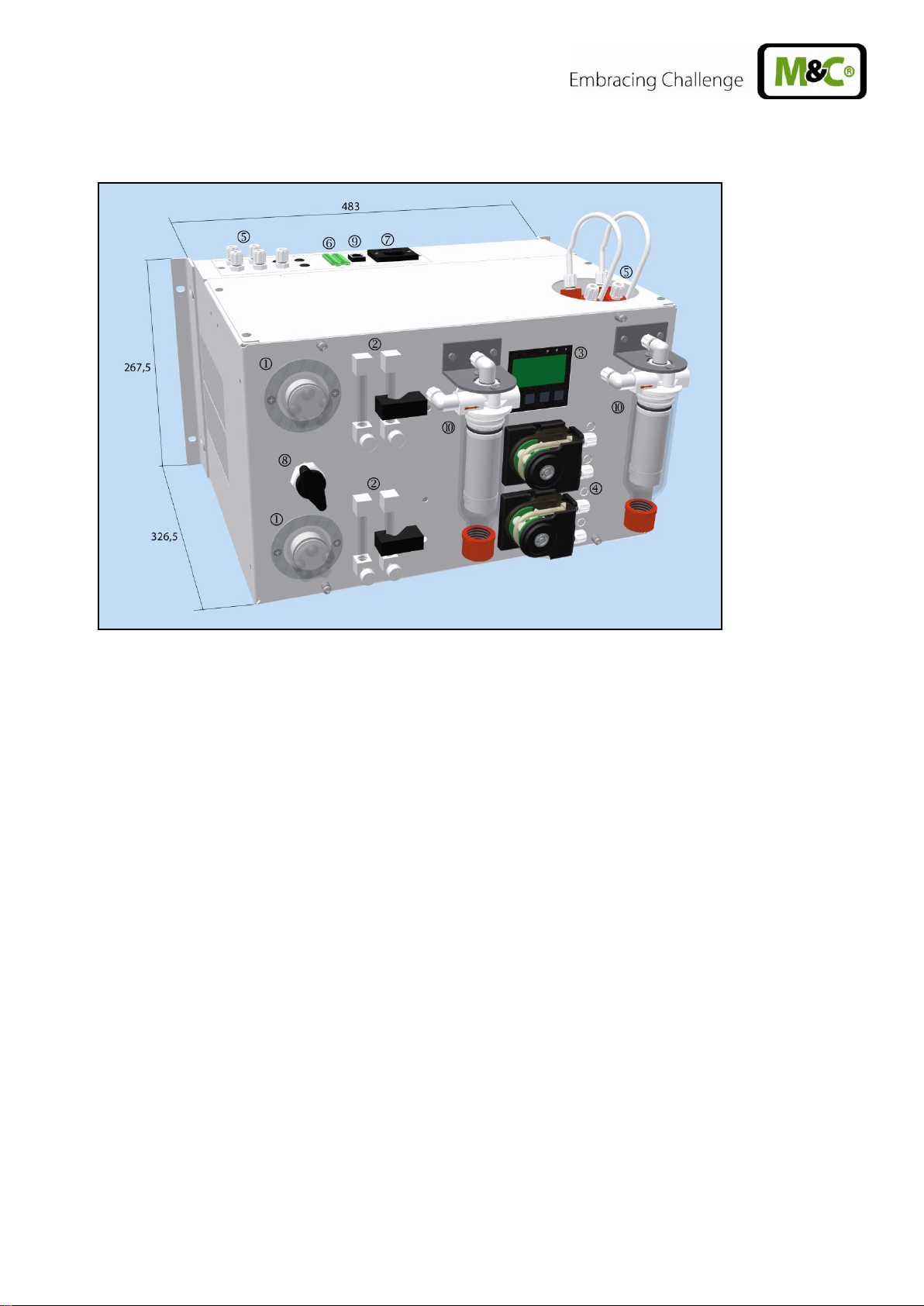

Figure 2 Dimensions and possible construction CSS-VC.. ...................................................... 15

Figure 3 Connections in the connection panel of the CSS-VC.. ............................................... 18

Figure 4 Connection group alarm ............................................................................................. 18

Figure 5 Connecting heated line DN4/6 with antikink adapter ................................................. 20

Figure 6 Plug assignment for the version with group alarm (Art. No. 01G6170) ...................... 21

Figure 7 Upper and lower channel of CSS-VC2 ....................................................................... 21

Figure 8 Plug assignment for design with individual alarms (Art. No. 01G6175) ..................... 22

Figure 9 Connection examples for alarm outputs ..................................................................... 23

Figure 10 Heated line connection for portable version to 10A ................................................... 24

Figure 11 Electrical connections communication module .......................................................... 27

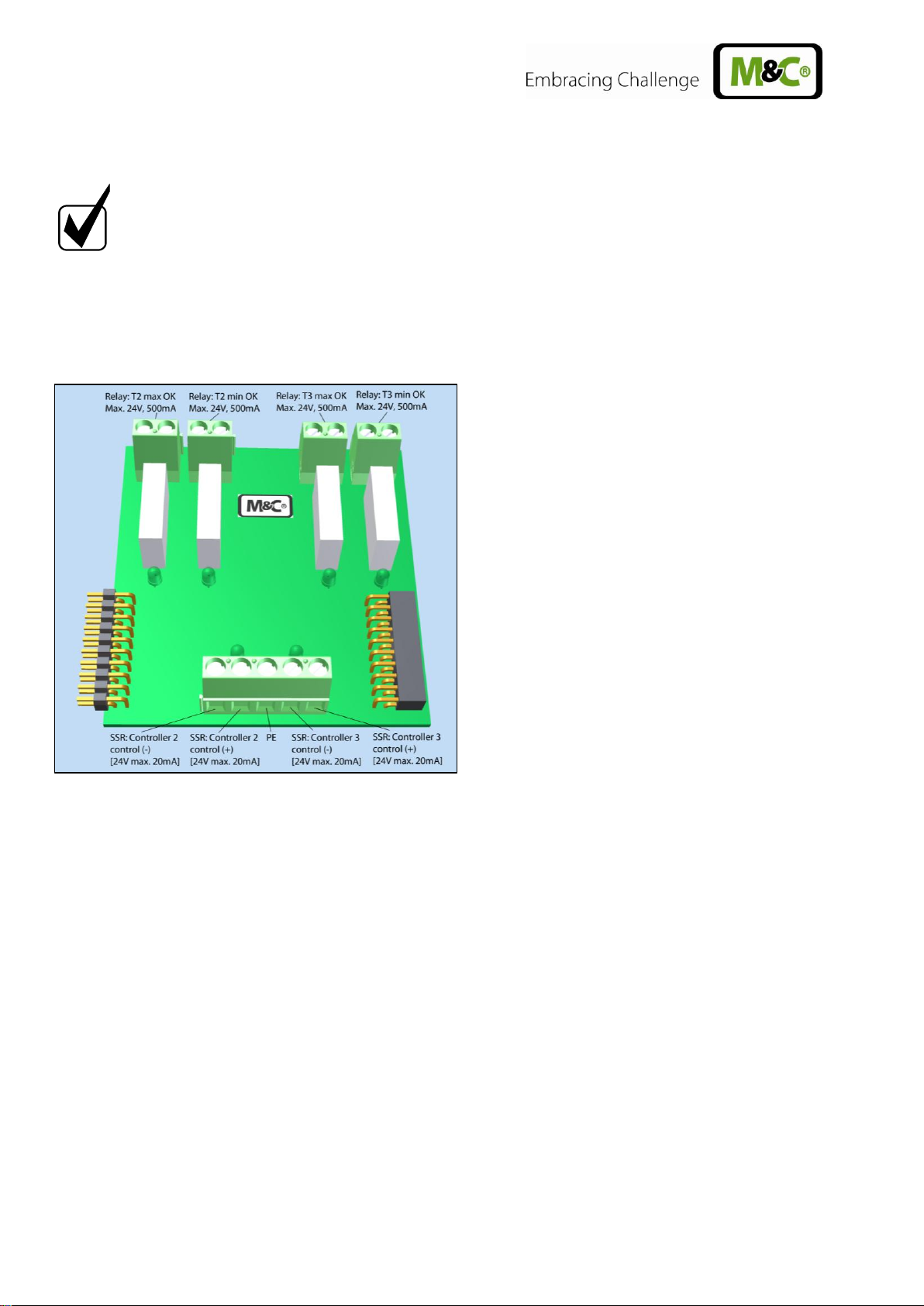

Figure 12 Electrical connections temperature control module ................................................... 28

Figure 13 Electrical connections status module ......................................................................... 29

Figure 14 Electrical connections backflush module ................................................................... 30

Figure 15 Front view of the TCU in normal operation without temperature control module ....... 31

Figure 16 Front view of the TCU in normal operation with temperature control module ............ 31

Figure 17 Maintenance of sample gas pump(s) ......................................................................... 43

Figure 18 Sectional drawing N3/5 KPE and N9 KPE ................................................................. 43

Figure 19 Components of the peristaltic pump SR25.2 .............................................................. 46

Figure 20 Replacing the pump hose .......................................................................................... 47

Figure 21 Disassembly of pump head and driver ....................................................................... 48

Figure 22 Check of axes and rolls .............................................................................................. 48

Figure 23 TCU menu .................................................................................................................. 56

14.1a ME Gas sampling and gas conditioning technology 3

Page 4

This manual does not purport to be complete and is subject to technical

changes.

© 09/2012 M&C TechGroup Germany GmbH. Reproduction of this

document or its content is not allowed without the express permission

of M&C.

CSS ® is a registered trademark.

4. Circulation: 06/2013

Dear Customer,

We have organised this manual to enable you to find and understand all the necessary information

about the product quickly and easily.

If nevertheless you should still have questions regarding the product or its use, do not hesitate to

contact us directly at M&C, or your local dealer. Contact addresses can be found in the appendix of

this manual.

Please also consult our homepage www.mc-techgroup.com for further information about our products.

There you will find the manuals and product data sheets for all M&C products and other information

in German, English and French for download.

4 Gas sampling and gas conditioning technology 14.1a-ME

Page 5

Headquarters

M&C TechGroup Germany GmbH Rehhecke 79 40885 Ratingen Germany

Tel: 02102 / 935 - 0

Fax: 02102 / 935 - 111

e-mail: info@mc-techgroup.com

www.mc-techgroup.com

1 GENERAL INFORMATION

The product described in this manual has been supplied in a safe and tested condition. For safe

operation and to maintain this condition, the information and instructions in this manual must be

followed. In addition, the appropriate transportation, proper storage and installation as well as careful

operation and maintenance are necessary.

For the proper use of this product, all information required for technical personnel is contained in this

manual.

2 DECLARATION OF CONFORMITY

CE Mark

The product described in this operating manual complies with the following EC Directives.

EMC Directive

The requirements of EC Directive 2004/108/EC "Electromagnetic compatibility" are met.

Low Voltage Directive

The requirements of EC - Directive 2006/95/EC "Low Voltage Directive" are met.

Compliance with this EC Directive has been verified according to DIN EN 61010.

Declaration of conformity

The EU declaration of conformity is available for download on the M&C homepage or can be

requested directly from M&C.

14.1a ME Gas sampling and gas conditioning technology 5

Page 6

3 SAFETY

Please note the following basic safety precautions when installing, commissioning and

operating the device:

Before operation and use of the equipment, read the operating manual. The instructions and warnings

listed in the operating manual must be followed.

Work on electrical equipment must only be performed by qualified personnel in accordance with the

regulations currently in force.

The requirements of VDE 0100 together with its associated standards and regulations must be

complied with for the creation of power installations with nominal voltages up to 1000V.

When connecting the device, ensure the correct mains voltage in accordance with the specifications

on the rating plate.

Protection against contact with dangerously high electrical voltages:

Before opening the equipment, it must be switched off. This also applies to any connected external

control circuits.

Only use the device in approved temperature and pressure ranges.

Ensure installation is weather-protected. Do not directly expose to dust, rain or liquids.

The device must not be operated in hazardous areas;

Installation, maintenance, monitoring and any repairs must be performed by authorised personnel in

compliance with the relevant provisions.

4 WARRANTY

If the device fails, please contact M&C directly, or your M&C authorised dealer.

Provided that the device is used correctly, we undertake to provide a 1 year warranty from the date of

delivery according to our terms of sale. Consumables are not covered by the warranty. The warranty

covers free repair at the factory or free replacement of the device sent free to the point of use. Returns

must be made in sufficient and proper protective packaging.

6 Gas sampling and gas conditioning technology 14.1a-ME

Page 7

DANGER!

means that death, serious personal injury and/or substantial property

damage will result if proper precautions are not taken.

WARNING!

indicates that death, serious personal injury and/or substantial

property damage might occur if proper precautions are not taken.

CAUTION!

means that minor personal injury may result if proper precautions

are not taken.

CA UTION!

without a warning triangle symbol, indicates that property damage

may result if proper measures are not taken.

AT TENTI ON

indicates that an undesirable result or an undesirable situation may

occur if the corresponding instructions are not followed.

NOTICE!

This is important information about the product or the appropriate

part of the manual to which particular attention should be paid.

SPECIALIST

PERSONNEL

These are persons who are familiar with the installation, use,

maintenance, and operation of the product and have the necessary

skills through training or instruction.

5 TERMINOLOGY AND SYMBOLS USED

14.1a ME Gas sampling and gas conditioning technology 7

Page 8

6 INTRODUCTION

The gas conditioning CSS-VC unit, either for 19 "- or wall mounting or as a portable unit in carrying

case, is a fully pre-assembled compact continuously-operating gas purification system, which,

depending on the design, can supply a sample gas volume of max. 1 x 250Nl/h (CSS VC1) or 2 x

150Nl/h (CSS-VC2). Sample gas conditioning units are suitable due to their equipment and additional

options for the wide-ranging requirements of continuous gas analysis.

The entire gas conditioning unit is housed in a compact, rugged steel housing so that gas analyses

can be performed rapidly without a great deal of effort, with low maintenance and reliability.

Gas conditioning unit CSS-VC must not be used to support gas/air or gas/oxygen mixtures that are

ignitable during operation, for the supply of combustible gases that can form an ignitable mixture in

combination with air or oxygen, or in potentially explosive atmospheres and in potentially explosive

locations.

8 Gas sampling and gas conditioning technology 14.1a-ME

Page 9

7 APPLICATION

With the CSS-VC, fully pre-installed gas conditioning systems are created for continuous use, which

can be integrated perfectly into analytical systems. The compact design makes few demands on

space. The gas conditioning systems are operational within minutes. This renders time-consuming and

expensive procurement of individual components and small parts and their assembly unnecessary. A

portable version is also available in a carrying case.

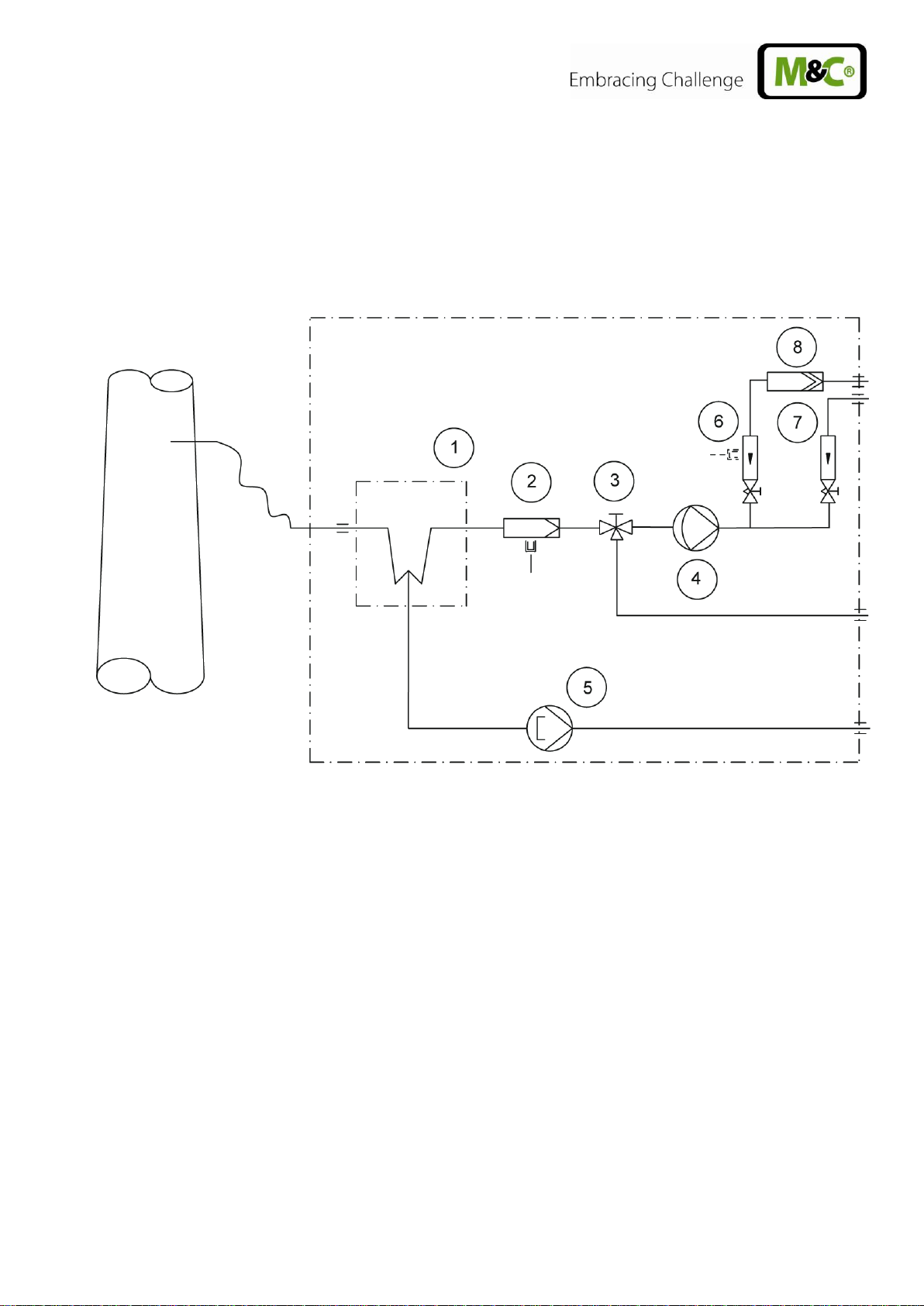

Figure 1 Example of a gas flow diagram CSS-VC1

Gas cooler series ECM-1

Option universal filter or front-installed filter FPF-0, 1GF, 0. 1μm, with optional liquid alarm LA

or front-installed filter FPF-2-0, 3GF, 0. 3μm, with integrated humidity alarm

Option 3 or 5-way ball valve 3L/PV or 5L/PV

Option sample gas pump N3/5/9KPE

Option peristaltic pump SR25.2

Option flow meter FM40 with flow alarm

Option flow meter FM40

Option liquid particulate filter CLF-5/W or CLF-T (SS)

In version CSS-VC2 there are 2 parallel gas lines in one gas conditioning unit.

14.1a ME Gas sampling and gas conditioning technology 9

Page 10

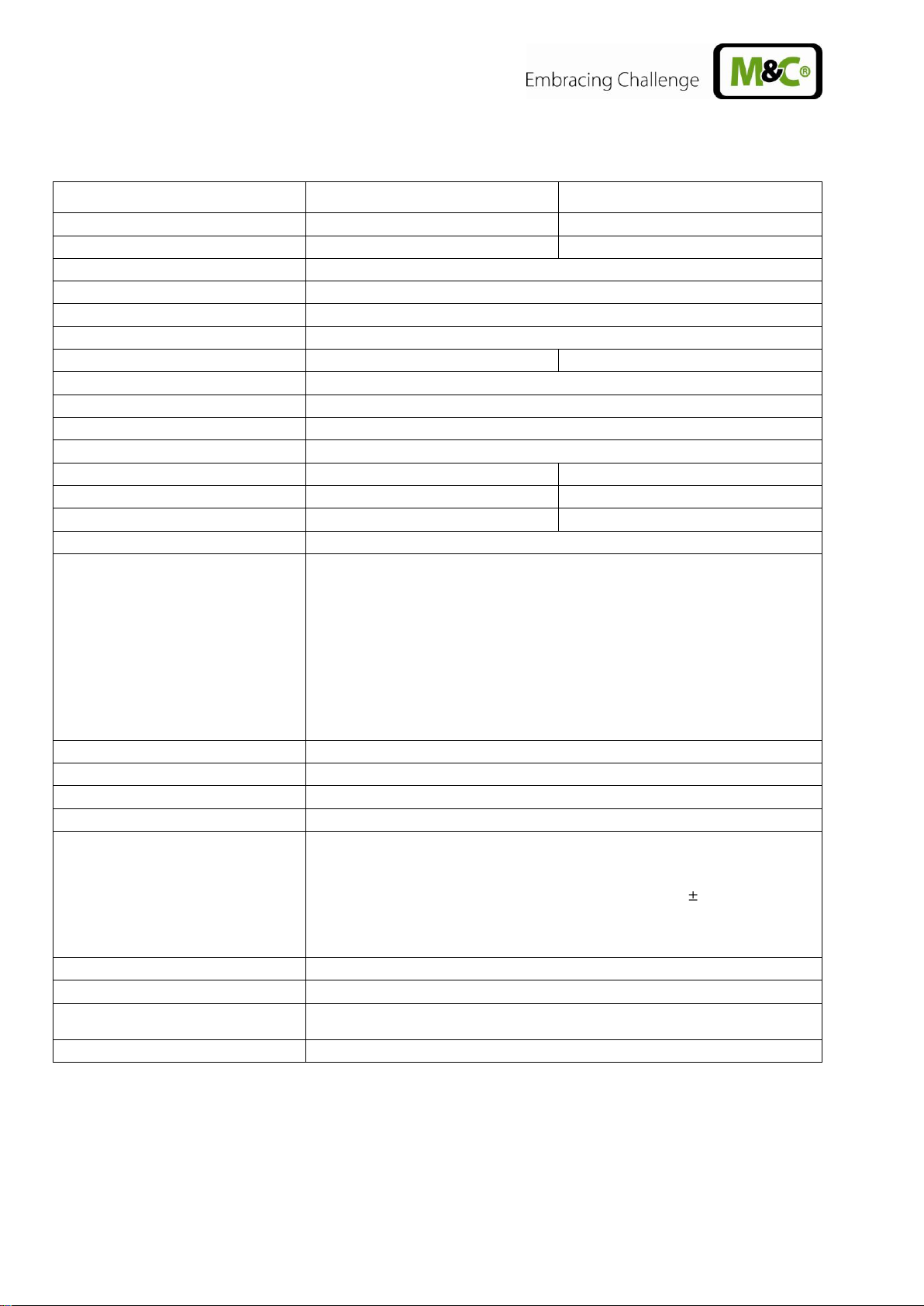

Gas conditioning series CSS ®

Version CSS-VC1

Version CSS-VC1

Article number 230V 50Hz

01G6050

01G6055

Article number 115V/50-60Hz

01G6050a

01G6055a

Gas outlet dew point

Setting range: + 2 ° C ..... + 7 ° C, factory setting: + 5 ° C

Dew point stability

under constant conditions < ± 0.1 ° C

Gas inlet temperature

**max. 180° C.

Gas inlet water-vapour saturation

**max. + 80 ° C

Gas flow

**max. 250 Nl/hr

**max. 2 x 150 l/h

Ambient temperature

** 10 ° C to + 40° C

Storage temperature

-25 ° C to + 65 ° C.

Pressure

0.7 bar to 1.4 bar abs.

Total cooling capacity **

max. 144 kJ/h

Number of gas inlets

1 2 Number of gas outlets

1 2 Condensate connection

1

2

Medium connections

Hose connection 4/6 mm

Material of parts in contact with

medium

Heat exchangers: Glass, PVDF or stainless steel 1.4571

Hoses/screwed connectors: PTFE/PVDF

Universal filter e.g. FP-2T-D: PVDF, FPM, glass, PTFE

Front-installed filter FPF-0.1GF: PVDF, glass, FPM

Front-installed filter FPF-2-0.3GF: PVC, FPM, PPH

Peristaltic pump SR25.2: PVDF, Novoprene ®

Liquid particle e.g. CLF-5/W: PVDF, glass, FPM, PTFE

Sample gas pumps N3/5/9: PVDF, PTFE, FPM

Flow meter FM40: PVDF, glass, FPM, Hastelloy C4

Ball valve 3L/PV and 5L/PV: PVDF, FPM

Operational

approx. 10 minutes.

Mains connection

230V 50-60Hz ± 10% or 115V 50-60Hz ± 10% ***

Power input

max. 220VA + max. 300VA for sample gas pumps

Device fuse

4A inert, 5x20 mm

Electrical connection

- Cold-device connector with 2 m cable

- Single alarm connections (11 & 12-pole) or status alarm(s)

(6-pole) : maximum capacity of the relays 24V 500mA

- mA-outlet : maximum load 500Ohm, accuracy 2% of

measuring range end value for display indication

- M&C Bus

- Heated sample line : maximum length 10m

Device protection class

IP20 to EN 60529

Housing design

Steel housing for 19"- or wall mounting, painted RAL 7035

Device dimensions (H x W x D)

267.5 mm x 483 mm x 301.5 mm

(Portable version: 355 mm x 515 mm x 395 mm)

Electrical device standard

EN 61010

8 TECHNICAL SPECIFICATIONS

FPM = Viton ®

PVDF = Polyvinylidene fluoride

PVC = Polyvinyl chloride

FPM = Fluorinated rubber

PPH = Hard polypropylene

PTFE = Polytetrafluoroethylene

**Technical specifications with maximum values must be rated in consideration of total cooling capacity at 25° C and an outlet dew point of 5 ° C.

*** 115V/50Hz sample gas pump available as a special item

10 Gas sampling and gas conditioning technology 14.1a-ME

Page 11

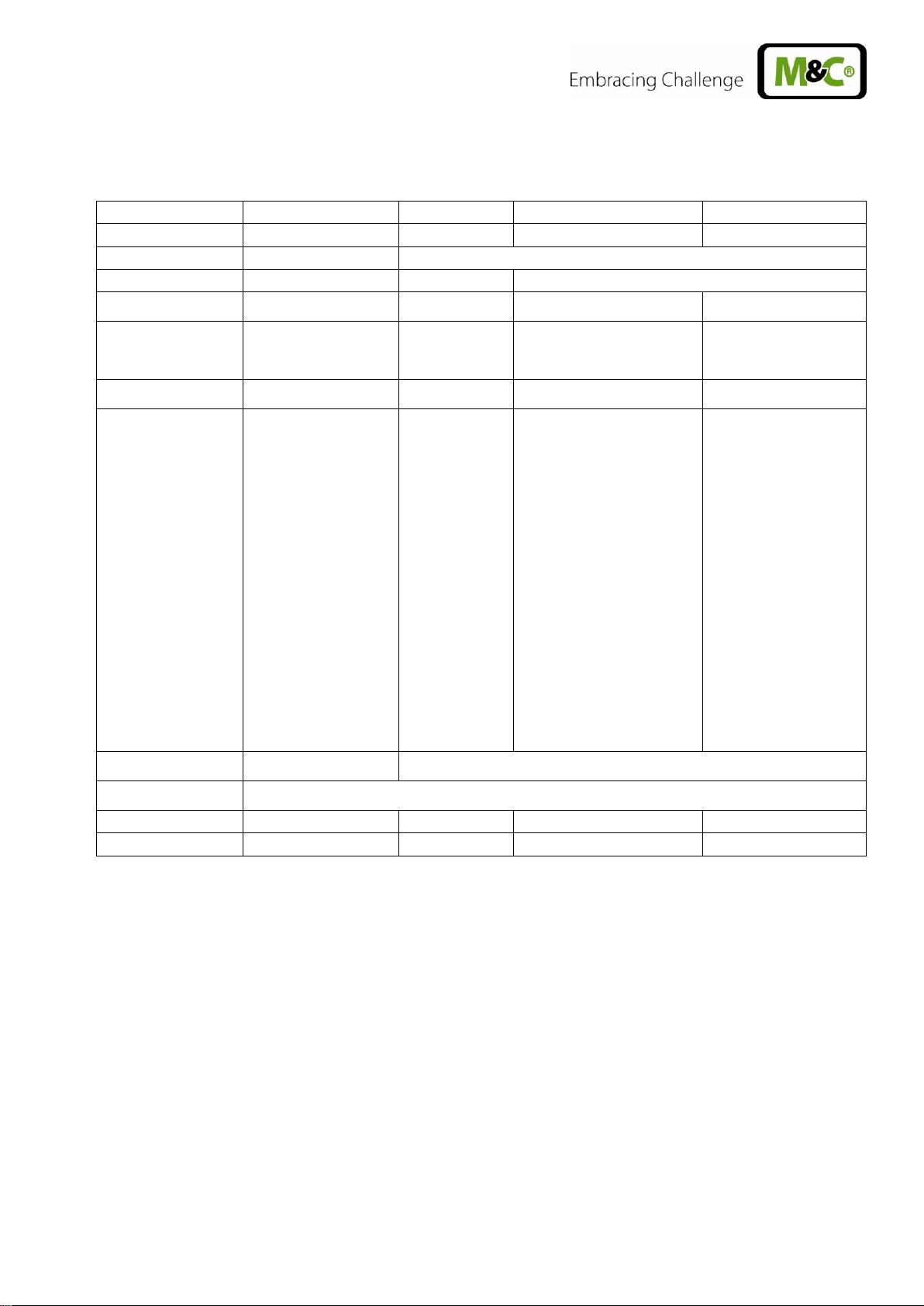

Module

Communication module

Status module

Temperature control module

Backflush module

Article No.

91 B 8620

91 B 8630

91 B 8640

91 B 8650

Power supply

24V DC + - 20%

internal

Earthing

L <3m

-

L <3m

Communication

M & C system (RJ-45) L

<3m

- - -

Inputs

2 x PT100 (2-wire)

L <30 m or

2 x thermocouples

L <30 m

-

-

Switching input

(Pressure switch)

Connection cable

length

see above

-

-

Max. 100 m

Outputs

-

Function: Status

1 potential-free

contact

(Changeover

switch 230VAC

1A)

(Can be used up

to 24V, 500mA!)

1 solid-state

output

230VAC 3A

Function: Pump1

1 solid state

output

230VAC 3A

Function: Pump 2

1 solid-state

output

230VAC 3A

2 x small signal digital output for

solid state relay control

24V max. 20mA

Function: High temperature

alarm

2 potential-free contacts

(N/O contact 230VAC 1A)

(can be used up to 24V

500mA!)

Function: Low temperature

alarm

2 potential-free contacts

(N/O contact 230VAC 1A)

(can be used up to 24V

500mA!)

Function: Measurement

1 potential-free contact

(Changeover switch

48VAC 1A)

(can be used up to 24V

500mA!)

Function: Backflush 1

1 solid-state output

230VAC 3A

Function: Control air

1 solid-state output

230VAC 3A

Function: Backflush 2

1 solid state output

230VAC 3A

Connection cable

length

-

Max. 100 m

Ambient temperature

max.

+ 60 ° C

Dimensions:

72 x 88 x 20mm

72 x 68 x 30mm

72 x 68 x 18mm

72 x 79 x 30mm

Weight

90 g

100 g

48 g

106 g

8.1 TECHNICAL SPECIFICATIONS FOR THE EXPANSION MODULES

The power consumption of all modules together is max. 140mA at 24V => 3.36 W.

14.1a ME Gas sampling and gas conditioning technology 11

Page 12

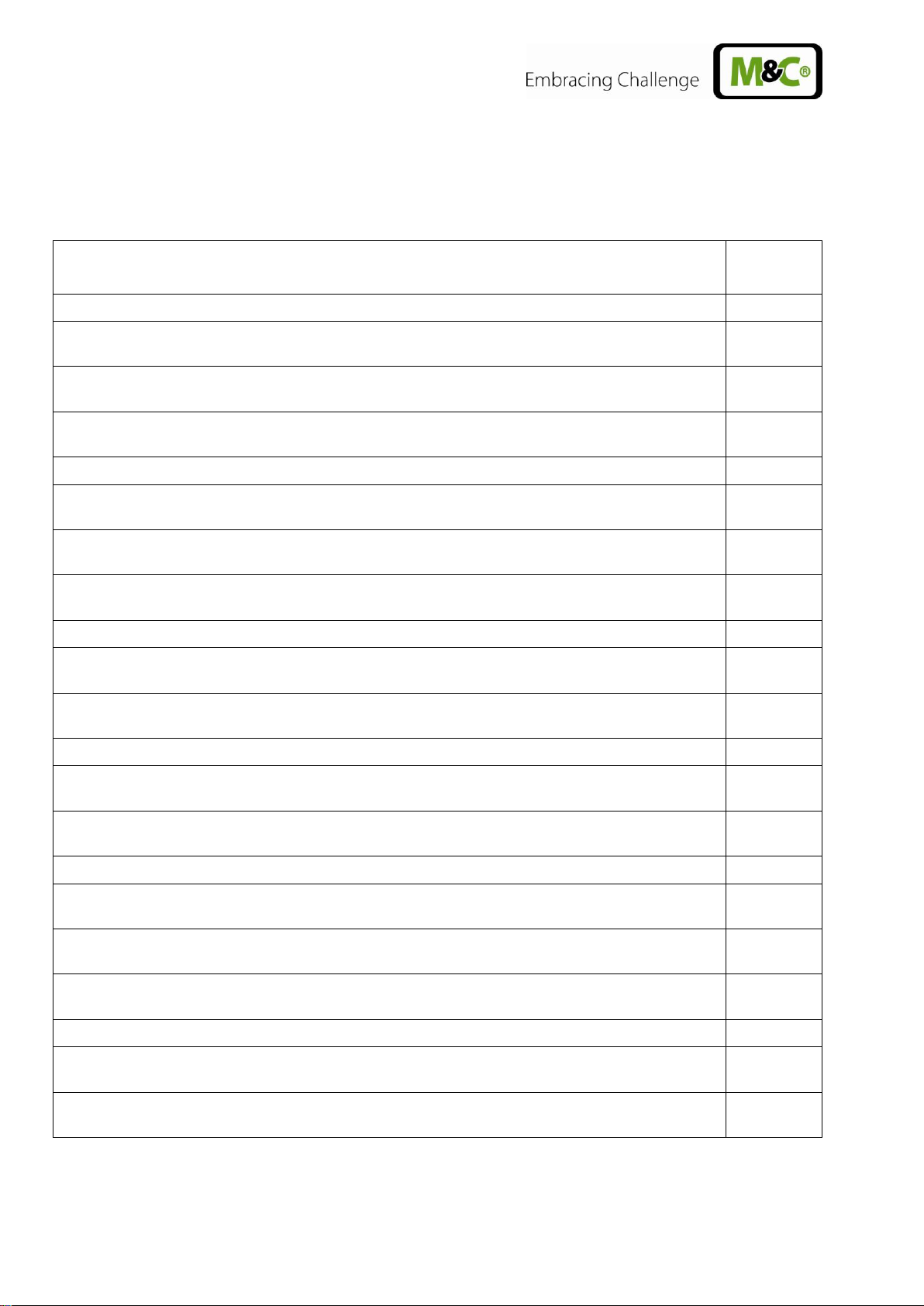

Description

Article No.

Extra charge for gas connections directly to a heat exchanger

01G6062

Extra charge for glass heat exchanger ECM-1 for

CSS-VC

1, sample gas connections on the

heat exchanger

93K0140

Extra charge for stainless steel heat exchanger ECM-1 for

CSS-VC

1, sample gas connections

on the heat exchanger

93K0160

Extra charge for PVDF heat exchanger ECM-1 for

CSS-VC

1, gas connections on the heat

exchanger

93K0170

Extra charge for gas connections directly to two heat exchangers

01G6063

Extra charge for glass heat exchanger ECM-2 for

CSS-VC

2, sample gas connections on the

heat exchangers

97K0100

Extra charge for stainless steel heat exchanger ECM-2 for

CSS-VC

2, sample gas connections

on the heat exchangers

97K0115

Extra charge for PVDF heat exchanger ECM-2 for

CSS-VC

1, sample gas connections on the

heat exchangers

97K0110

Extra charge for gas connections of a heat exchanger in the connection plate for e.g. 19" mount

01G6060

Extra charge for glass heat exchanger ECM-1 90 ° for

CSS-VC

1, sample gas connections in the

connection plate for e.g. 19" mount

93K0150

Extra charge for PVDF heat exchanger ECM-1 90° for

CSS-VC

1 sample gas connections in the

connection plate for e.g. 19" mount

93K0170

Extra charge for gas connections of 2 heat exchangers in the connection plate for e.g. 19" mount

01G6061

Extra charge for glass heat exchanger ECM-2 90° for

CSS-VC

2 sample gas connections in the

connection plate for e.g. 19" mount

97K0150

Extra charge for PVDF heat exchanger ECM-2 90° for

CSS-VC

2 sample gas connections in the

connection plate for e.g. 19" mount

97K0110

Extra charge for gas connections directly to a heat exchanger

01G6062

Extra charge for glass heat exchanger ECM-1 for

CSS-VC

1, sample gas connections on the

heat exchanger

93K0140

Extra charge for stainless steel heat exchanger ECM-1 for

CSS-VC

1, sample gas connections

on the heat exchanger

93K0160

Extra charge for PVDF heat exchanger ECM-1 for

CSS-VC

1, gas connections on the heat

exchanger

93K0170

Extra charge for gas connections directly to two heat exchangers

01G6063

Extra charge for glass heat exchanger ECM-2 for

CSS-VC

2, sample gas connections on the

heat exchangers

97K0100

Extra charge for glass heat exchanger ECM-2 for

CSS-VC

2, sample gas connections on the

heat exchangers

97K0100

8.2 OPTIONS

Beyond the standard scope of options of this for the CSS-VC, other customised options are possible

that cannot be listed in this manual.

12 Gas sampling and gas conditioning technology 14.1a-ME

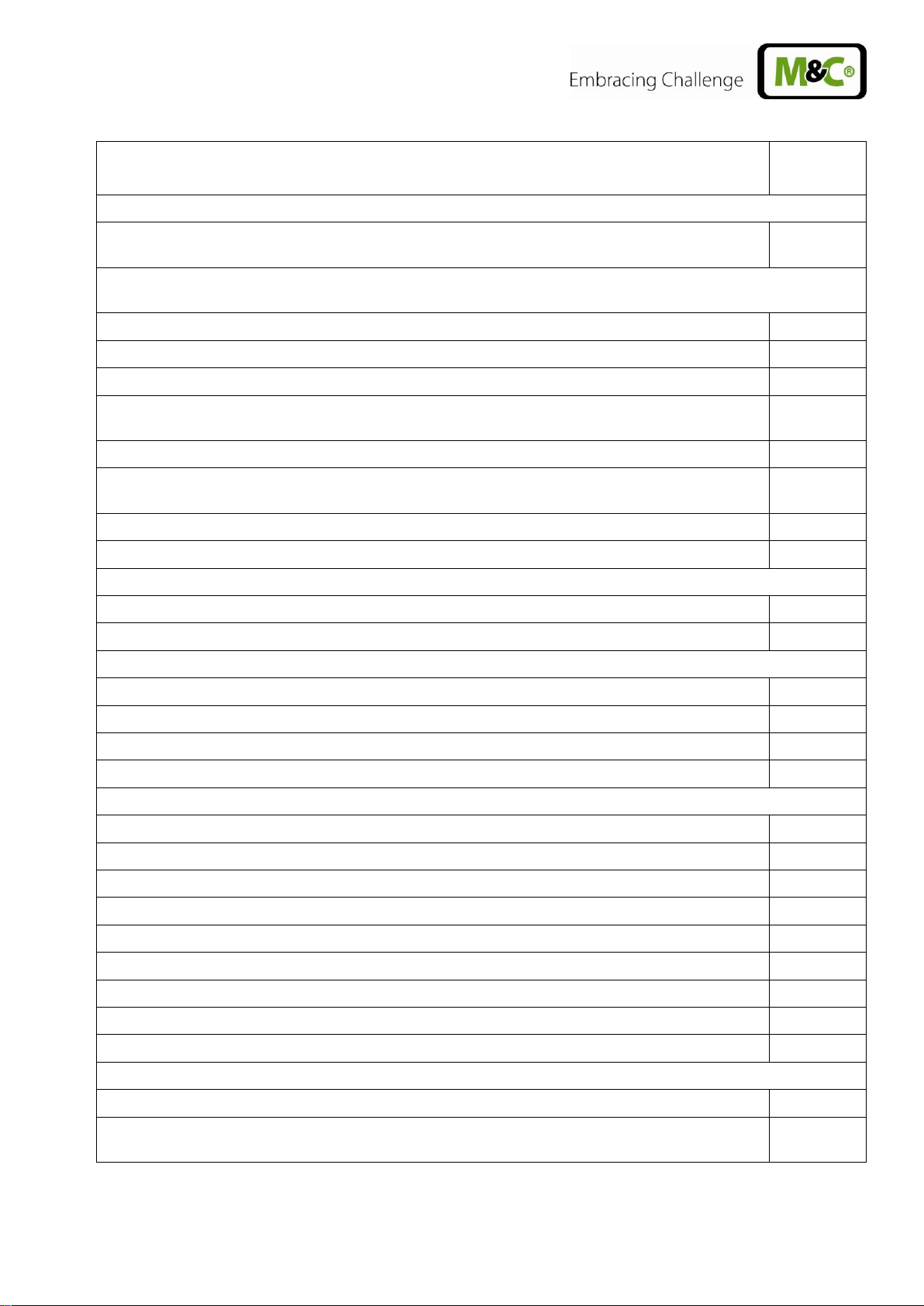

Page 13

Description

Article No.

Peristaltic pumps for condensate disposal (max. 2 pcs.)

Extra charge for mounting a peristaltic pump SR25.2 for condensate disposal, with hoses preinstalled (one required for each gas line)

01G6140

Filter (max. 2 pcs. Front-installed filters and 2 pcs. Universal or aerosol filters) and liquid alarm (max. 2

pcs.)

Extra charge for installation of a sample gas filter FPF-0, 1GF

04F1000

Extra charge for liquid alarm with flow chamber LS/LA2 with sample gas filter FPF-0, 1GF

03E3010

Extra charge for installation of a sample gas filter FPF+

04F2100

Extra charge for filter element for FPF+ (see datasheet 7.2a)

according

to choice

Extra charge for liquid sensor LA3 integrated into FPF+

03E1300

Extra charge for universal filter (see data sheet 7.1)/aerosol filter CLF... (see data sheet 7.7 and

7.8)

according

to choice

Extra charge for installation of universal filter/aerosol filter CLF on front plate (max 2 pcs.)

01G6075

Extra charge for liquid alarm LA1S with universal filter F. -..-D

03E1001

Ball valves for calibration gas feeding (max. 1 pc.)

Extra charge for installation of a 3-way ball valve 3L/PV

01G9045

Extra charge for installation of a 5-way ball valve 5L/PV

01G9046

Sample gas pumps (max. 2 pcs., only with evaluation electronic system 01G6175)

Extra charge for installing sample pumps N.. KPE

01G6070

Extra charge for sample gas pump N3KPE

01G6125

Extra charge for gas pump N5KPE

01G6130

Extra charge for gas pump N9KPE

01G6135

Flow meter (max. 4 pc. total) and flow alarm (max. 2 pcs.)

Extra charge for installation of a flow meter FM40 7-70N1/h/in the sample gas outlet

09F4000

Extra charge for installation of a flow meter FM40 15-150Nl h/in the sample gas outlet

09F4005

Extra charge for installation of a flow meter FM40 25-250Nl h/in the sample gas outlet

09F4010

Extra charge for installation of a flow meter FM40 50-500Nl/h in the sample gas outlet

09F4015

Extra charge for flow alarm with forked light barrier FA-20mo

02E3500

Extra charge for second sample gas output or bypass flow meter FM40 7-70Nl/h

01G6200

Extra charge for second sample gas output or bypass flow meter FM40 15-150Nl/h

01G6210

Extra charge for second sample gas output or bypass with flow meter FM40 25-250Nl/h

01G6220

Extra charge for second sample gas output or bypass flow meter FM40 50-500Nl/h

01G6230

Electronic evaluation system

Extra charge for electronic evaluation system with group status alarm

01G6170

Extra charge for electronic evaluation system with individual alarm (temperature, flow, liquid in

system) including MA output for cooler temperature for external temperature display

01G6175

14.1a ME Gas sampling and gas conditioning technology 13

Page 14

Description

Article No.

External expansion modules (only with electronic evaluation system 01G6175)

Extra charge for communication module (one-time necessity for all expansion modules of the

TCU)

01B8620

Extra charge for temperature control module (2 additional thermostats in TCU with 4 relays for

high or low temperature monitoring) for controlling solid-state relays

01B8640

Extra charge for status module for group alarm via 1 changeover relay and 1 solid-state relay for

switching external sample gas pumps

01B8630

Description

Article No.

Extra charge for backflush module for programmed control of solenoid valves for backflushing of

gas probes with status monitoring (measuring/backflush), monitoring of backflush pressure and

control of the sample pumps (on/off)

01B8650

Extra charge for

M&C

bus for external modules

01G6180

Transport case (19" version only)

Extra charge for carrying case for portable gas conditioning

01G6250

Temperature controller for portable version (only with electronic evaluation system 01G6175)

Extra charge for thermostat for maximum 10m heated line, 230V with PT100, with solid-state

relays and 7-pin connector

01G6190

Kink protection for portable gas conditioning

Extra charge for kink protection for heated line DN4/6

01G9060

Extra charge for kink protection for heated line DN6/8

01G9061

14 Gas sampling and gas conditioning technology 14.1a-ME

Page 15

9 DESCRIPTION

Figure 2 Dimensions and possible construction CSS-VC..

Fine filter FPF-0, 1GF

Flow meter FM40 with and without forked light barrier FA-20mo

Multifunctional expandable controller unit TCU

Peristaltic pumps SR25.2 with condensate output at the pump

Sample gas inputs and outputs DN4/6 in connection plate or sample gas inputs on the heat

exchanger

Connection of group alarms (temperature, flow, liquid penetration)

Cold-device socket

3 or 5-way ball valve for calibration gas feeding or 3L/PV or 5L/PV

M&C bus interface

Aerosol filter CLF..

All components of the gas conditioning systems are installed in a strong compact steel housing for wall

or 19" mount. The ventilation grilles in the side walls provide adequate forced ventilation.

Filter, flow meter and peristaltic pumps are located in the front panel and thus ensure very simple

maintenance. Due to a removable lid and a hinged front panel, quick and easy inspection and

maintenance of all other built-in components is possible, in particular the easy changing of heat

exchangers.

The compressor gas cooler can be equipped with one or two heat exchangers made of glass, stainless steel or PVDF.

Peristaltic pumps of type SR25.2 are used for continuous condensate removal or as a metering pump.

14.1a ME Gas sampling and gas conditioning technology 15

Page 16

NOTICE!

Storage of the gas conditioning unit should be in a sheltered frost-free

room!

The current cooler temperature is displayed on the multi-functional control unit TCU mounted on the

front panel. The setpoint temperature of the cooler can be set by pressing keys. In the event of

warnings or faults, plain text information appears on the display and is also indicated by LEDs (e.g.

cooler within the setpoint range and no other alarms - green LED, flow alarm (option) - yellow LED,

temperature ± 3° C from the setpoint and humidity alarm (option) - red LED).

The fine filter downstream of the cooler (different filter types available) provides for the necessary

separation of solids. The condition of the filter can be judged from the outside. To protect the

downstream analysers against liquid penetration and to increase the operating reliability of the whole

system, according to the selected filter type, a suitable liquid alarm is possible or already integrated

into the filter.

A group alarm or on request individual alarms including mA output for the cooler temperature at the

output terminals is available wired. Via potential-free contacts for the group alarm or the individual

alarms (cooler temperature, flow, fluid in the system), an alarm message and shutdown of the sample

gas pump, if present, occurs.

Integrated sample gas pumps are available in three performance levels to choose from N3/5/9 KPE.

The flow meter FM40 arranged in the sample gas outlet with a measuring range adapted to the pump

power can be supplied for flow monitoring with a flow sensor FA-20mo. In addition, each sample gas

line can be equipped with a second sample gas outlet or bypass flow meter and flow control.

In the event of an aerosol problem, a liquid particulate filter CLF can be added downstream of the flow

meter in the sample gas outlet.

Via expansion modules for the control unit TCU two further temperature controllers are available e.g.

to regulate heated lines or gas probes. Here too external sample gas pumps can be connected and

individual sample gas probes can be backflushed.

10 GOODS RECEIVING AND STORAGE

The gas conditioning unit CSS-VC.. is a fully pre-assembled unit. In addition there are included:

1 x connection cable

1 x 6-pin or 11 and 12-pin connector

Optional 2 - 4 expansion modules

Immediately after arrival carefully remove the CSS-VC.. and any special accessories from the

dispatch packaging and check the supplied items in accordance with the delivery note and the list;

Check the goods for shipping damage and, if necessary, inform your transport insurer immediately

of any damage.

16 Gas sampling and gas conditioning technology 14.1a-ME

Page 17

NOTICE!

So that the unit is safe and operates reliably, it should be mounted

horizontally and without vibration. Only then is proper separation and

drainage of the condensate in the heat exchanger of the cooler

ensured.

The mounting of the gas conditioning unit should take place away from

heat sources and be freely ventilated so that there can be no disruptive

accumulation of heat.

When installed outdoors, adequate protection against direct sunlight

and moisture needs to be ensured. In winter, the place of installation

must be frost-free; ensure correct protection for the device.

Temperature variations, strong air movement and aggressive

atmospheres at the place of installation are to be avoided.

To ensure safe operation of the gas conditioning unit and downstream

analysers and to avoid false alarms, the gas conditioning unit should

not be used outside the specified temperature range. It must also be

protected against the ingress and accumulation of dust.

Downstream analysers and lines must operate at temperatures

significantly above the specified gas outlet dew point of +5 ° C. This

will avoid subsequent condensation of the gas in the connecting lines

to the analysers.

Unheated gas sample lines must be laid on a slope to the cooler.

11 INSTALLATION INSTRUCTIONS

11.1 CONVERSION TO WALL MOUNTED OR 19" RACK HOUSING

Gas conditioning units CSS-VC.., if not in a carrying case, are delivered with wall-mounting or 19"

housing.

Depending on which housing is required, the gas conditioning unit can be converted very simply by

moving the mounting bracket:

Remove two screws per bracket

Align bracket to the mounting holes according to the desired housing forward or rearward

Secure the bracket flush with the housing panel (19" mounting) or with protrusion to the rear

(wall mounting) with the two fixing screws on the housing

14.1a ME Gas sampling and gas conditioning technology 17

Page 18

12 SUPPLY CONNECTIONS

Figure 3 Connections in the connection panel of the CSS-VC..

Depending on the version of the CSS-VC, instead of the 11 and 12-pin connector for single alarms,

mA output cooler temperature and external sample gas pump control, a 6-pin connector may also be

present for group alarm (see Figure 4 ). The sample gas inlet, depending on the version, may also lie

directly on the heat exchangers.

Figure 4 Connection group alarm

In the portable version of the CSS-VC.., the supply connectors shown above are located on the rear

panel of the housing. The RJ45 connector is not present here. With the temperature controller option

for the portable version (Art. No. 01G6190), a 7-pin connector (see section 0) is present at the position

of the RJ45 connector in Figure 3.

18 Gas sampling and gas conditioning technology 14.1a-ME

Page 19

NOTICE!

Do not confuse the hose connections. They are marked appropriately.

After connecting all the lines, they should be checked to ensure there

are no leaks.

NOTICE!

The tightness of the connection can only be guaranteed if the

hose has a straight end edge (using a hose cutter).

WA RNING !

Possible aggressive condensate.

Wear protective glasses and proper protective clothing!

12.1 HOSE CONNECTIONS

The connection of the sample gas input, depending on the connection type, is directly on the heat

exchanger or on the clamping plate.

The condensate connections are made directly to the hose pump.

All hose connections are standard DN4/6mm ferrule hose fittings made of PVDF, for gas inlet

temperatures up to 105° C (see section 8 ).

Installation of the sample gas hoses or the condensate hose must be carried out as follows:

Loosen the clamping ring screwed fitting counterclockwise; It is important to ensure that the nut is

carefully removed from the threaded joint, so that the loose clamping ring which is in the nut is not

lost;

Slide the nut over the hose connection;

Slide the clamping ring with the thicker bulge facing the nut, onto the connection hose;

Attach the hose to the nipple in the threaded support;

Hand-tighten the nut.

The hose is now mounted slip-proof and pressure-tight.

The dismantling of the hoses is carried out in the reverse order.

12.2 LAY THE CONNECTORS ON THE REAR PANEL

If, for example with the 19" mounting, mounting conditions require the connections to be moved up in

the connection panel onto the back of the device, this is quite possible:

Remove the connection-panel mounting screws (see Figure 3)

14.1a ME Gas sampling and gas conditioning technology 19

Remove the cover-bracket mounting screws on the rear panel

Page 20

Sample gas IN

bulkhead fitting

Pressure ring 6mm Øi

Pressure ring 10mm Øi

Clip ring 10mm Øi

Clip ring 6mm Øi

Support sleeve 4mm

Junction nut 10mm Øi

Heated sample line

Adapter

WA RNING !

Incorrect voltage can destroy the device. On connection, ensure

the correct mains voltage in accordance with the rating plate!

NOTICE!

For the erection of power installations with nominal voltages up

to 1000V the requirements of VDE 0100 and relevant standards

and regulations must be complied with!

Mount the connection plate with 2 mounting screws on the rear panel

Mount the cover bracket with 2 connection screws on the device cover

12.3 CONNECTION OF THE HEATED LINE WITH ANTIKINK ADAPTER FOR

PORTABLE VERSION (ART. NO. 01G9060 OR 01G9061)

Figure 5 Connecting heated line DN4/6 with antikink adapter

Place special adapters according to the above drawing on Teflon tubing;

Slide the support sleeve slide into the Teflon tubing;

Draw the Teflon tubing all the way into the bulkhead union 'Sample Gas ON' and hand-tighten

the adapter;

Tighten the adapter with wrench (SW 14) 1 1/4 turns; here hold the lock nut of the bulkhead

union with a wrench (SW 15);

Insert the 10mm pipe of the heating line all the way into the adapter and hand-tighten using the

nut;

Tighten nut with wrench (SW 19), 1 1/4 turns; here hold the adapter with wrench;

The union is now cut to be gas-tight and can be loosened as often as required.

12.4 ELECTRICAL CONNECTIONS

20 Gas sampling and gas conditioning technology 14.1a-ME

Page 21

1

2

3

4

5 6 Internal

External

Status Alarm

Contact load

Contact rating

24V AC/DC 0,5A

Plug/male connector type Phoenix MSTB

2,5/6-STF 5,08

Socket/Female X2

Upper Channel

Channel 2

Lower channel

Channel 1

The CSS-VC.. is to be supplied in voltages 230V/50Hz or 115V/50-60Hz (for the circuit diagram see

Appendix). Protection is provided as standard with two 4A fuses. These are located in the cold-device

socket.

The electrical connection is via the 2m long power cord with cold-device connector depending on the

mounting of the connection plate either at the back or in the lid of the housing (see Section 12.2).

12.4.1 GROUP CONNECTION ALARM (ART. NO. 01G6170)

The electrical connection of the general alarm (condenser, fluid and flow) is via a 6-pin connector,

depending on the mounting of the connection plate, either at the back or in the lid of the housing.

The corresponding 6-pin socket is included.

The connector is wired as follows:

Figure 6 Plug assignment for the version with group alarm (Art. No. 01G6170)

Figure 7 Upper and lower channel of CSS-VC2

14.1a ME Gas sampling and gas conditioning technology 21

Page 22

NOTICE!

For the alarm relays „safety first“ is valid, i.e. contacts are open

currentless and in case of alarm.

For external pump control potential free contacts have to be used!

Switch open => pump off

Switch closed => pump on

12.4.2 CONNECTION OF INDIVIDUAL ALARMS, EXTERNAL PUMP CONTROL AND

EXTERNAL COOLER TEMPERATURE DISPLAY (ART. NO. 01G6175)

The electrical connection of the individual alarms is via two connectors, depending on the mounting of

the connection plate, either on the back or in the lid of the housing.

The corresponding 11 and 12-pin connectors are included.

The connectors are assigned as follows:

Figure 8 Plug assignment for design with individual alarms (Art. No. 01G6175)

On X2 connector pin 10-12, external switches can be connected for controlling the sample gas pumps

(internal or external).

On X2 connector pin 7+8, an indicator can be connected that warning messages are present (yellow

LED lights up on the front of the TCU).

On X2 connector pin 7+9, an indicator can be connected that alarm messages are present (red LED

lights up on the front of TCU).

On X2 connector pin 1+6, an indicator can be connected that a cooler temperature alarm is present

(excess or low temperature alarm).

On connector X2 pin 1+2, 1+3, 1+4, 1+5, an indicator can be connected that excess or low

temperature alarms of the optional temperature controller module are present.

22 Gas sampling and gas conditioning technology 14.1a-ME

Page 23

NOTICE!

Route the indicator lines separately from the power supply lines.

On connector X2.1 pin 3+8, 3+9, 3+10, 3+11 respectively, an indicator can be connected that flow

alarm messages are present. Since this is a warning message, the yellow LED on the front of the TCU

lights up.

On X2.1 connector pin 3+4, 3+5, 3+6, 3+7 respectively, an indicator can be connected that liquid

alarm messages are present. Since this is an alarm message, the red LED on the front of the TCU

lights up.

On connector X2.1 pin 1+2, an indicator of cooler temperature can be connected (standard 4-20mA.

0-20mA if ordered).

Figure 9 Connection examples for alarm outputs

14.1a ME Gas sampling and gas conditioning technology 23

Page 24

3 Mains

probe

1 Mains L

2 Mains N

4 Mains

probe

6 PT100

5 PT100

NOTICE!

The RJ45 socket is only suitable for the connection of the

communication module. A network connection is not possible with it!

WA RNUNG!

Before comissioning exclude that for one channel as well

internal as external a PT100 is connected.

12.4.3 CONNECTION OF HEATED LINE FOR PORTABLE VERSION (ART. NO. 01G6190)

If, for the portable version in a carrying case, the option temperature controller for heated line (Art. No.

01G6190) is selected, on the rear of the housing of the CSS-VC.. there is a 7-pin connector for

connection of heated lines type PSP and PSP 4M and PSP 4M-W. These have at the point of

connection and termination a 7-pin connector and a 7-pin socket for connection to the portable gas

conditioning unit CSS-VC.. and the portable gas sampling probe type PSP4000H. This is the power

supply to the heated line and gas sampling probe using the CSS-VC...

Figure 10 Heated line connection for portable version to 10A

12.4.4 CONNECTING THE OPTIONAL EXPANSION MODULES

The connection of expansion modules to the CSS-VC.. is via the communication module with the

appropriate cable to the RJ-45 socket in the connection panel (see Figure 3).

The electrical connection of the individual expansion modules is described in Section 15.

13 COMMISSIONING

Before commissioning, the plant and process-specific safety measures must to be observed.

Before switching on the power supply, it should be checked again that the operating voltage (see

nameplate) and the power supply voltage correspond!

24 Gas sampling and gas conditioning technology 14.1a-ME

Page 25

NOTICE!

In the case of long-term measurements with high dust content in

the sample gas, a suitable gas sampling probe to protect the

sample line from clogging must be provided.

Display

LED red

LED yellow

LED green

Status message

After

commissioning

> 8° C (room

temperature)

ON (status

alarm)

Lights up in the

case of an existing

flow alarm

OFF

Hightemp.: 1

Pump-warn.: 1.2 (when

pump is connected and

configured accordingly,

see Section 16.2)

After about. 10

min.

5.5 ° C

OFF

OFF

ON (cooling)

OK

Normal operation

5 ° C

OFF

OFF

ON (cooling)

OK

NOTICE!

If a cooler temperature alarm is present, after default setting, the

gas sample pumps are switched off (if available) to prevent the

transport of wet sample gas into the analyser.

The following steps are to be carried out before initial commissioning:

Plug the cold-device connector of the supplied mains connection cable into the cold-device socket

for gas conditioning;

Connect power cord to the network;

Switch on power supply.

After the end of the lead time, the gas conditioning unit is ready for operation (green LED on the

controller lights up).

13.1 COOLER CONTROLLER

14.1a ME Gas sampling and gas conditioning technology 25

Page 26

NOTICE!

The location of the compact conditioning unit must remain frost-

free, even during periods when the unit is switched off.

WA RNING !

Possible aggressive condensate.

Wear protective glasses and proper protective clothing!

14 DECOMMISSIONING

On short-term decommissioning of the gas conditioning unit CSS-VC.. no special measures need to

be taken.

For long-term decommissioning, it is recommended to flush the gas conditioning unit with ambient air

or inert gas. A flushing time of 3 to 5 minutes is sufficient under normal conditions. Likewise,

condensate residue must be removed from the system.

15 THE MULTIFUNCTIONAL CONTROL UNIT TCU

The multifunctional control unit TCU in the front panel of the gas conditioning unit CSS-VC.. can

undertake a series of different tasks centrally and provide wide-ranging system information.

15.1 BASIC FUNCTIONS OF THE TCU

1 x temperature controller for the integrated sample gas cooler

Evaluation of max. 2 liquid alarm sensors

Evaluation of max. 2 flow monitoring sensors

An mA output for external cooler temperature display e.g. in the control room

Control (on/off) of 2 sample gas pumps depending on the cooler temperatures and liquid alarms or

permanent switching on or off. In addition, setting of external pump control yes/no

Optional 1 x temperature controller for max. 10m heated hose for portable version (Art. No.

01G6190)

With expansion modules backflush programme for gas sampling probes, 2 more temperature

controllers for heated line(s) and/or gas sampling probe(s) and the control of external sample

pumps are possible

15.2 PROPERTIES OF THE TCU

Menu navigation with 3 language selections (German, English, French)

Error history (32 messages)

Detailed status indicators: Group alarm or individual alarm (cooler temperature, liquid flow),

warnings, OK condition, control temperature, temperature gradient, total running time after

service, error-free time

Configuration options: Service interval, language, pump control, temperature control and

backflush programme

26 Gas sampling and gas conditioning technology 14.1a-ME

Page 27

WA RNUNG!

Before comissioning exclude that for one channel as well

internal as external a PT100 is connected.

15.3 ENHANCEMENTS TO THE TCU

The TCU can be expanded by up to 4 modules in the range of functions. The modules are plugged

together according to requirements and provided for rail mounting.

15.3.1 THE COMMUNICATION MODULE

Communication of the TCU with the expansion modules is always with the communication module via

the M&C bus. This is therefore the base module for all other modules.

The TCU or CSS-VC.. and communication module are connected via RJ45 sockets.

On the communication module there are the temperature sensor ports (PT100 or thermocouples E, J,

T, K, N) of the temperature controller module.

Figure 11 Electrical connections communication module

14.1a ME Gas sampling and gas conditioning technology 27

Page 28

NOTICE!

If the CSS-VC.. is purchased with an external thermostat module, it

must be specified at the time of ordering which devices should be

regulated (2 probes or 2 heated lines or 1 probe and 1 heated line) so

that the controller can be configured accordingly.

15.3.2 THE TEMPERATURE CONTROL MODULE

The temperature control module includes 2 additional thermostats e.g. for control of heated lines or

gas sampling probes. Control is by control of external solid-state relays. The module also includes 4

relays for high and low temperature monitoring. The connections for the temperature sensors are

located on the communication module.

Figure 12 Electrical connections temperature control module

28 Gas sampling and gas conditioning technology 14.1a-ME

Page 29

15.3.3 THE STATUS MODULE

On the status module, by the group alarm message of the TCU a changeover relay and a solid-state

relay are connected. These can be used for alarm indication. In addition, external sample gas pumps

can be switched off via two further solid-state relays e.g. in the event of an alarm and switched on

under good conditions. For external control of the pumps, see Section 12.4.2.

Figure 13 Electrical connections status module

14.1a ME Gas sampling and gas conditioning technology 29

Page 30

15.3.4 THE BACKFLUSH MODULE

With the backflush module, on the TCU a backflush programme can be set for gas sampling probes

(duration of a backflush pulse, number of backflush pulses, time between backflush pulses, timing of

backflush). The programme switches with time delay two solid-state relays with which in turn solenoid

valves can be switched, which accordingly release purging air to the gas sampling probe.

At start and end of a backflush programme, another solid-state relay is switched one second before

start and after the end of the programme, with which a solenoid valve can be controlled, which

releases control air to shut off and open the sample gas output of the gas sampling probe with

pneumatic valve.

In addition, at the start and end of a backflush programme, a changeover relay for status monitoring

(measuring/backflush) is switched. Here at the TCU dead time can be specified to ensure that, on the

"Measure" message, sample gas is currently flowing in the analyser. In addition, a connection is

present for pressure monitoring of the backflush gas. For this purpose, a pressure switch is connected

in the backflush line which closes the contact at upcoming pressure.

Figure 14 Electrical connections backflush module

30 Gas sampling and gas conditioning technology 14.1a-ME

Page 31

16 OPERATION OF THE MULTIFUNCTIONAL CONTROL UNIT TCU

In normal fault-free operation, the TCU display shows the current cooling temperature and the green

LED is lit constantly when the cooler temperature is within the alarm limits. The bottom line of the

display shows "status: OK" or current warning and error messages.

Figure 15 Front view of the TCU in normal operation without temperature control module

If the external temperature controller module has been purchased with the CSS-VC.., under error-free

normal operation, the temperature of the devices to be controlled (gas sampling probe (probe) and/or

heated sample gas line (B. line)) is indicated.

Figure 16 Front view of the TCU in normal operation with temperature control module

From any screen (except single temperature view and Service Reset) returns the TCU after 60s back

into the temperature overview without any key being pressed. If appropriate, altered and unapproved

settings jump back to the original state.

14.1a ME Gas sampling and gas conditioning technology 31

Page 32

16.1 DISPLAY OF CONTROL TEMPERATURES OR COOLING TEMPERATURE CURVE

By 1 x pressing of the arrow button, the following screen will appear on the CSS-VC.. without an

external temperature control module:

If the external temperature control module was purchased with the CSS-VC.., there is a choice as to

which display will appear here after the PRG key has been pressed once.

Selection is made with the arrow keys (flashing) and

confirmed by pressing the PRG key again .

The following displays are available to choose from, depending on the controller configuration:

Cooler temperature Probe temperature Temp. heated line Cooling temperature curve

32 Gas sampling and gas conditioning technology 14.1a-ME

Page 33

16.2 CONFIGURE THE SWITCHING ON AND OFF OF THE SAMPLE PUMPS

By 2 x pressing of the arrow key and then 1 x pressing of the PRG key, the following view

appears:

Here it is visible whether the pump is working or not. Using the arrow keys, the pump to be

configured can be selected. By pressing the PRG key again, the following view will appear:

Using the arrow keys, the parameters to be

changed can be selected. By pressing the PRG key,

the parameter can now be changed with the arrow keys

and then confirmed with the PRG key or

discarded with the ESC key .

Here you select the parameter to be taken into consideration for switching off the pump.

- = Not taken into consideration/= x is taken into consideration

T1 = Pump off with cooler temperature alarm (default setting x)

T2 + T3 = Pump off with temperature alarms from external temperature control module or

Temperature controller for heated line in portable version (Art. No.. 01G6190)

(Factory setting x)

Ext = external pump control (with closed switch on) (Default setting -)

LA = Pump 1 resp. 2 off with liquid alarm 1 resp. 2 (x factory setting) At activated reset

(see 16.7) R occurs behind – or x.

On = Pump is always on (overrides all other settings) (default setting -)

Off = Pump is always off (overrides all other settings) (default setting -)

RSp = Pump off during backflush programme (default setting x)

14.1a ME Gas sampling and gas conditioning technology 33

Page 34

16.3 CONFIGURE BACKFLUSHING

By 3 x pressing of the arrow key, then 1 x pressing of the PRG key, the following view

appears when the backflush module is connected:

Using the arrow keys, the parameters to be

changed can be selected. By pressing the PRG key,

the parameter can now be changed with the arrow keys

and then confirmed with the PRG key or

discarded with the ESC key .

Here the backflushing of gas sampling probes is determined:

Start in = specifies the time of the first backflushing.

Flushing time T1 = Duration of backflushing in a channel

Deadtime = Delay after the end of backflushing in channel 2 until the indication

shows "Measure" (changeover switch on the backflush module is switched)

Interval T2 = Period until the next backflush

On time T3 = Duration of a backflush pulse

Off time = Duration between backflush pulses

Pulse number i = Number of resulting backflush pulses (cannot be entered)

Activation = Backflush programme is to run (on) or not (off). When deactivating, "Start in" = 0

is set.

A programmed backflush runs always automatically after

a delay of T1 on two channels. Thus, for example 2 gas

sampling probes directly following one another or first the

internal probe (/ BB/F), and then the pre-filter (/ BB) are

backflushed. The dead time for channel 1 is therefore

always extended to T1.

If only one gas sampling probe is backflushed, T1 must

be added to the dead time or already represents sufficient

dead time, so that the value for the dead time can be set

to 0.

This menu appears only when the communication module is connected in conjunction with the

backflush module (automatic detection).

34 Gas sampling and gas conditioning technology 14.1a-ME

Page 35

Parameters:

Default setting

Info

Start in:

0d 0h 0m

Max.: 9T 23h 59m

Flushing time T1

30s

Max.: 99m 59s

Dead time

60s

0-120s

Interval T2

24h

On time T3

1s

Max.: 99s

Off time T4

5s

Max.: 99s

Pulse number

10

Is only calculated and cannot be <1

Activation

Off

16.4 DISPLAY OF EVENTS

By 4 x pressing (3 x without backflush module) of the arrow key and then 1 x pressing of the PRG

key, the event list appears in which the last 32 error messages and warnings are listed on 8

pages. The individual pages can be seen by using the arrow keys .

At the bottom of the list of events, furthermore, the error-free time and the total run time (operating

time counter) are displayed. The error-free time indicates how much time has passed since the last

error. The total running time indicates how long the device has been running since the last service.

If service reset is performed, the error messages are erased and the times reset.

During a power failure, the data remains stored.

14.1a ME Gas sampling and gas conditioning technology 35

Page 36

NOTICE!

A reset can only be carried out when no alarm is present!

16.5 OPERATING DATA

By 5 x pressing (4 x without backflush module) of the

arrow key (or 1 x pressing of the arrow key ) the

following view appears:

Here the actual device temperature, the period until the

next service warning, the service interval, the software

version and serial number are displayed.

By pressing the arrow key again, the display of the

control temperature reappears.

16.6 RESETTING SERVICE AND OPERATING TIME

Service and operating time can be reset as follows:

Press the ESC key and press both arrow keys at the same time. The following

screen appears:

Press the PRG key . Service life and operating time are reset and “Service OK” occurs.

With the ESC key resetting can be cancelled.

36 Gas sampling and gas conditioning technology 14.1a-ME

Page 37

16.7 SETTING SERVICE INTERVAL, LANGUAGE, CONTROL TEMPERATURES AND

TEMPERATURE SENSOR TYPES

To change service interval, language, control temperatures and temperature sensor types:

Disconnect the device from the mains.

Hold the PRG key down and switch the device back on until the message to release the

key is displayed. The following is displayed (2nd screen ):

Select the parameter to be changed using the arrow key and confirm using the PRG

key.

Use the arrow keys, the settings and values can be changed and confirmed with the

PRG key . Press and hold down the PRG key for 5 seconds to apply all changes.

To discard the changed settings, keep the ESC key pressed for 5 seconds

14.1a ME Gas sampling and gas conditioning technology 37

Page 38

After saving or discarding the settings, you will automatically return to the start screen.

If the unit is disconnected from the mains voltage while it is in user setup, all changes made are also

rejected.

The following values can be set:

Service interval = (0 (-----) - 365 days/default setting 180Tage/off). After the set

time has elapsed, the warning LED (yellow) LIGHTS UP and

the following appears in plain text: "Service required". In

addition, the pending warning is also reported via the individual

alarm connection (see Section 12.4.2).

Language = (German, English, French)

Cooler setpoint temperature = (0-7 ° C/default setting 5 ° C)

Temperature channel 2 = (temperature range dependent on sensor type (see below) /

default setting 180° C)

Temperature channel 3 = (temperature range dependent on sensor type (see below) /

default setting 180° C)

Thermocouple 2 = (T, N, K, J, E, ---/--- Default setting --- = PT100)

Thermocouple 3 = (T, N, K, J, E, ---/--- Default setting --- = PT100)

T : Cu/CuNi, -10 to +400°C

N : NiCrSi/NiSi, -50 to 800°C

K : NiCr/NiAl, -10 to +700°C

J : Fe/CuNi, 0 to +500°C

E : NiCr/CuNi, +10 to 400°C

--- : PT100, 0 to +240°C

LA-Reset = (x = reset necessary, ----- = no reset necessary)

38 Gas sampling and gas conditioning technology 14.1a-ME

Page 39

NOTICE!

A thermocouple type must be set only when the temperature control

module is connected in conjunction with equipment which do not use a

PT100 as a temperature sensor.

If a thermocouple type is set, on warming up, an internal check is made whether a heating rate of +

3°C/minute is being reached. If this is not the case, a cable break in the temperature sensor or a

thermocouple not connected are assumed. The heating is turned off and the display shows "Thermal

Error: 2 (and/or 3) ". The error can only be corrected by removing the cause and switching on again.

17 ALARMS AND FAULTS

In the event of warnings, or errors, plain text information appears on the screen and simultaneously via

the LEDs on the controller front, as well as alarms via the group alarm connection (Art. No. 01G6170)

or alarms and warnings via the individual alarm connector (Art. No. 01G6175) (see 12.4.1. and

12.4.2).

In front of the plaintext information, is the serial number of the error message and the total number of

messages is specified, e.g. 1/3 ... = Error message 1 of 3.

Depending on the alarm and TCU configuration, an alarm can result in further alarms and warnings:

E.g. the liquid alarm (LA-Alarm:1,2) can trigger the pump alarm (Pump-Warn:1,2) and that in turn can

trigger the flow alarm (FA-Warn.:1,2).

The comm. error (e.g. interrupted connection cable RJ45) causes temperature sensor range exceeded

(T> max.:2,3) and flushing pressure alarm (flushing pressure not present!) as temperature sensors

and pressure sensors are connected to the communication module. From this follows the temperature

alarm (Hightemp.:2.3), then the pump alarm (Pump-Warn:1, 2) (with the appropriate TCU configuration

and then as a result the flow alarm FA-Warn.:1,2).

17.1 MEANING OF THE LEDS

Green LED: Coolant temperature within the setpoint range, there are no faults

Yellow LED: Flow alarm, low temperature of temperature controller modules and/or service time

reached or exceeded. Also message via individual alarm connection (see Section

12.4.2). In addition, device temperature <1° C or > 50° C, flushing pressure absent or

internal error requiring the device to be returned.

Red LED: Temperature> 8 ° C or <2 ° C and/or humidity alarm and/or breakage of the cable of the

liquid sensor and/or high temperature alarm Temperature controller module at +10 ° C. to

Tset. Message also via group alarm connection (see Section 12.4.1), or via individual

alarm connection (see Section 12.4.2). In addition, short circuit and cable break of a

temperature sensor, and "Thermal Error" if during heating on channel 2 and/or 3, the

temperature does not increase

14.1a ME Gas sampling and gas conditioning technology 39

Page 40

Error message

Alarm

Warning

LED

Error

Lowtemp.: 1

x - red

Low temperature cooler

Hightemp: 1

x - red

High temperature cooler

T> Max: 1

x red

Temperature sensor range exceeded

=> sensor defective

T <min:1

x red

Temperature sensor measuring range

fallen below => sensor defective

Lowtemp.: 2, 3

- x yellow

Low temperature channel 2, 3

Hightemp.: 2, 3

x - red

High temperature channel 2, 3

T> Max.: 2, 3

x red

Temperature sensor range exceeded

=> sensor defective

T <Min:2, 3

x red

Temperature sensor measuring range

fallen below => sensor defective

Error message

Alarm

Warning

LED

Error

FA-Warn: 1, 2

- x yellow

Flow disturbance channels 1 and/or 2

LA-Alarm: 1, 2

x - red

Liquid alarm channel 1and/or 2

LA-Break: 1, 2

x - red

Cable break liquid sensor channel 1 and/or 2

17.2 TEMPERATURE ALARMS FROM COOLER AND TEMPERATURE CONTROL

MODULE

For channels 2 and 3 appears when the control temperature is fallen below (+10° C alarm hysteresis)

of the following screen:

This prevents the heated line or the heated probe from overheating due to a defect ! The triggered

alarm (red LED) must be acknowledged by pressing any key. If the error is not corrected, the error

screen comes back after 60s.

17.3 FLOW DISTURBANCE AND LIQUID ALARMS

In case of liquid alarm and activated LA-Reset (see 16.7) the following screen occurs :

40 Gas sampling and gas conditioning technology 14.1a-ME

Page 41

Error message

Alarm

Warning

LED

Error

Pump-Warn.: 1, 2

x x red

+

yello

w

Pump 1 and/or 2 off due to an alarm

(temperature, liquid)

Maintenance needed!

- x yello

w

Maintenance interval expired

Comm. Error

x - red

Error on connecting cable RJ45 between

CSS-VC.. and communication module

Flushing pressure not

present!

- x yello

w

Pressure for probe backflushing too low or

non-existent

Thermal Error: 2, 3

x - red

Thermocouple set and defective or not

connected or PT100 connected

WARNING!

Hazardous voltage. Pull the mains plug out before carrying out

work on the gas conditioning unit!

This prevents liquid pumped along to the analyser and thus damaging ! The triggered alarm (red LED)

must be acknowledged by pressing any key. If the error is not corrected, the error screen comes back

after 60s.

17.4 OTHER FAULT AND ALARM MESSAGES

18 MAINTENANCE

Before performing maintenance work, the system and process-specific safety measures must be

observed!

14.1a ME Gas sampling and gas conditioning technology 41

Page 42

NOTICE!

In order to protect downstream analysers, in the event of a

condensate breakthrough, the wet filter element must always be

changed.

WARNING!

Hazardous voltage. Pull the mains plug out before carrying out

work on the gas conditioning unit!

The maintenance intervals depend on the process conditions and therefore need to be determined for

specific applications.

All serviceable parts are mounted in an easily accessible location in the front of the compact gas

conditioning unit CSS-VC...

Change filter elements of the dust and aerosol filters (FPF-0,1GF/FPF+/universal filter/aerosol

filter) when there is too little flow or after visual inspection (see Section 18.1);

Check the condensate pump SR25.2 every six months and replace if necessary (see section

18.3.1)

Clean cooling fins on the compressor cooler of dust regularly using compressed air (see Section

18.4)

18.1 CHANGE THE FILTER ELEMENTS AND O RINGS

To change the filter elements and O-rings:

Unplug the gas conditioning unit from the mains

Unscrew filter glass

Unscrew filter element with filter holder

Exchange filter element and/or O-ring(s). Ensure correct seating of filter element and O-

ring(s).

Screw glass filter cap back

18.2 MAINTENANCE OF THE SAMPLE GAS PUMP(S)

Diaphragm and valve plates are the only pump parts subject to wear. They are easy to change. Wear

is indicated by a drop in pneumatic power.

Unplug the gas conditioning unit from the mains;

Loosen 4 screws (captive) on the front panel and, without removing the hoses and wiring, bring

slightly forward and pull up out of the housing support; the front panel can now be suspended

back in the housing holder by rotating it 90° (Figure 17).

42 Gas sampling and gas conditioning technology 14.1a-ME

Page 43

NOTICE!

Valve plates, diaphragms and seals should always be replaced at the

same time.

3

4 2 9

1

13

16

14

11

7

8

N9 KPE

N3/5 KPE

Figure 17 Maintenance of sample gas pump(s)

Loosen hoses on the pump head; mount [sic] any existing flow chamber(s) with mounting plate

from the stud bolts.

Figure 18 Sectional drawing N3/5 KPE and N9 KPE

14.1a ME Gas sampling and gas conditioning technology 43

Page 44

The changing of diaphragm(s), valve plates and sealing rings is to be carried out in the following

order:

Remove pump head

Change the diaphragm

Change valve plates and sealing rings

Mount pump head.

Proceed as follows:

18.2.1 REMOVE PUMP HEAD TYPE N 3/5/9 KPE

Mark head cover 3 (with metal frame with N3/5), intermediate plate 2 and housing 1 with a felt

pen (M). This rules out parts being mounted incorrectly during subsequent assembly.

Loosen the four head cap screws 4 and remove the head cover from the pump housing together

with the intermediate plate.

18.2.2 REPLACING THE DIAPHRAGM TYPE N 3/5/9 KPE

Move the structured diaphragm 9 by turning the fan wheel into the top dead centre position.

Lift the structured diaphragm on the opposite side edges, grip and unscrew counterclockwise.

Make sure that the adjusting washer(s) 11 do not fall from the threaded bolt of the structure

diaphragm into the housing.

Remove adjusting washer(s) 11 from the threaded bolt of the structure diaphragm and keep.

Inspect all parts for contamination and clean if necessary

Place the adjusting washer(s) onto the threaded bolts of the new structure diaphragm.

Move the connecting rod 13 into the top dead centre position.

Screw the new structure diaphragm with washer(s) onto the connecting rod (clockwise) and

hand-tighten.

18.2.3 VALVE PLATE CHANGE TYPE N 3/5/9 KPE

Separate head cover 3 (with metal frame with N3/5) from the intermediate plate 2.

Remove the valve plate 7 and the sealing rings 8 from the intermediate plate.

Check valve seat, intermediate plate and head cover for cleanliness; in the event of

unevennesses, scratches and corrosion, these parts are to be replaced.

Insert the new valve plate 7 into the valve seat of intermediate plate 2; the valve plates for

pressure and suction sides are identical; the same applies to upper and lower sides of the valve

plates.

By slight horizontal movement of the valve plates, ensure that these are not strained.

Insert sealing rings into the intermediate plate.

18.2.4 MOUNT PUMP HEAD TYPE N 3/5/9 KPE

Move structure diaphragm via fan wheel into top dead centre (dead point) position.

Place intermediate plate 2 on the housing with valve plates 7 and 8 as well as head cover 3 in

accordance with the marks (M).

Check its centering by slight lateral movement of the head cover.

Fit metal frame with N3/5.

Only slightly tighten 4 screws diagonally.

44 Gas sampling and gas conditioning technology 14.1a-ME

Page 45

WA RNING !

Aggressive media residues possible.

On dismantling, repairing or cleaning the pump, protective

glasses and protective clothing must be worn!

Check ease of movement of the pump by turning the fan wheel.

Move structure diaphragm via fan wheel into the top dead centre (dead point) position.

Now hand tighten the screws 4.

18.2.5 CLEANINGTYPE N 3/5/9 KPE

On changing valve plates and diaphragm, prior to assembly of the pump head, all parts should be

checked for contamination and cleaned if necessary.

Wipe the parts as dry as possible with a cloth. Solvents should not be used when cleaning

because they may damage the plastic parts. If oil-free compressed air is available, blow out the

parts.

18.3 MAINTENANCE OF THE BUILT-IN PERISTALTIC PUMP TYPE SR 25.2

Pump hose, belt, pressure rollers and springs are the only wear parts of the pump. They are easy to

change.

14.1a ME Gas sampling and gas conditioning technology 45

Page 46

WARNING!

Aggressive media residues possible.

On disassembly, repair or cleaning of the hose pump, wear

protective glasses and appropriate protective clothing!

WA RNING !

If you return the hose pump to M&C customer service for repair,

we will ask for information concerning the delivered liquid.

The pump should be cleaned of hazardous or highly aggressive

contaminants prior to return shipment.

Figure 19 Components of the peristaltic pump SR25.2

18.3.1 EXCHANGE THE PUMP HOSE