Page 1

Operating Manual

Gas conditioning unit Series CSS

®

Version CSS-M portable

Gas sampling and gas conditioning technology 4-2.1.3-ME

Page 2

List of Contents

1 General information ....................................................................................................................... 4

2 Declaration of conformity .............................................................................................................. 4

3 Safety instructions ......................................................................................................................... 5

4 Warranty .......................................................................................................................................... 5

5 Used terms and signal indications ............................................................................................... 6

6 Introduction .................................................................................................................................... 7

7 Application ...................................................................................................................................... 7

8 Technical Data ................................................................................................................................ 8

9 Description ..................................................................................................................................... 9

10 Receipt of marchendise and storage ...................................................................................... 10

11 Installation instructions .......................................................................................................... 10

12 Supply connections ................................................................................................................. 11

12.1 Hose connections ................................................................................................................... 11

12.2 Electrical connections ............................................................................................................. 12

13 Starting ...................................................................................................................................... 12

13.1 Cooler regulation ..................................................................................................................... 13

13.2 New pump switch since 06/2007 ............................................................................................ 13

14 Closing down ............................................................................................................................ 14

15 Maintenance .............................................................................................................................. 15

15.1 Replacement of the filter element and the O-Ring .................................................................. 15

15.2 Dismountage of the sample gas pump for examination or maintenance ................................ 16

15.3 Maintenance of the integrated peristaltic pump type SR 25.2 ................................................ 16

16 Operating of the integrated electronic temperature regulator ............................................. 19

16.1 Changing the set value ........................................................................................................... 20

17 Trouble shooting ...................................................................................................................... 21

18 Spare part list ............................................................................................................................ 23

19 Appendix ................................................................................................................................... 24

List of Illustrations

Figure 1 Scheme of gas flow .............................................................................................................. 7

Figure 2 Dimensions CSS-M .............................................................................................................. 9

Figure 3 Hose connections CSS-M portable .................................................................................... 11

Figure 4 Electronic board CSS-M.. ................................................................................................... 14

Figure 5 Replacement of the filter element and the O-ring ............................................................... 16

Figure 6 Replacement of the pump hose ......................................................................................... 17

Figure 7 Disassembly of pump head and driver ............................................................................... 18

Figure 8 Check of axes and rolls ...................................................................................................... 18

Figure 9 Front view of the temperature regulator ............................................................................. 20

Figure 10 Circuit diagram CSS-M ....................................................................................................... 25

2 Gas sampling and gas conditioning technology 4-2.1.3-ME

Page 3

This Operating Manual does not claim completeness and may be

subject to technical modifications.

© 05/2004 M&C TechGroup Germany GmbH. Reproduction of this

document or its content is not allowed without permission from M&C.

CSS® is a registered trade mark.

3rd Edition: 05/2013

Dear customer,

we have made up this operating manual in such a way that all necessary information about the

product can be found and understood quickly and easily.

Should you still have any question, please do not hesitate to contact M&C directly or go through your

appointed dealer. Respective contact addresses are to be found in the annexe to this operating

manual.

Please also contact our homepage www.mc-techgroup.com for further information about our

products. There, you can read or download the data sheets and operating manuals of all M&C

products as well as further information in German, English and French.

4-2.1.3-ME Gas sampling and gas conditioning technology 3

Page 4

Head Office

M&C TechGroup Germany GmbH Rehhecke 79 40885 Ratingen Germany

Telephone: 02102 / 935 - 0

Fax: 02102 / 935 - 111

E - mail: info@mc-techgroup.com

www.mc-techgroup.com

1 GENERAL INFORMATION

The product described in this operating manual has been examined before delivery and left our works

in perfect condition related to safety regulations. In order to keep this condition and to guarantee a

safe operation, it is important to heed the notes and prescriptions made in this operating manual.

Furthermore, attention must be paid to appropriate transportation, correct storage, as well as

professional installation and maintenance work.

All necessary information a skilled staff will need for appropriate use of this product are given in this

operating manual.

2 DECLARATION OF CONFORMITY

CE - Certification

The product described in this operating manual complies with the following EC directives:

EMV-Instruction

The requirements of the EC directive 2004/108/EC “Electromagnetic compatibility“ are met.

Low Voltage Directive

The requirement of the EC directive 2006/95/EC “Low Voltage Directive“ are met.

The compliance with this EC directive has been examined according to DIN EN 61010.

Declaration of conformity

The EU Declaration of conformity can be downloaded from the M&C homepage or directly requested

from M&C.

4 Gas sampling and gas conditioning technology 4-2.1.3-ME

Page 5

3 SAFETY INSTRUCTIONS

Please take care of the following basic safety procedures when mounting, starting up or

operating this equipment:

Read this operating manual before starting up and use of the equipment. The information and

warnings given in this operating manual must be heeded.

Any work on electrical equipment is only to be carried out by trained specialists as per the regulations

currently in force.

Attention must be paid to the requirements of VDE 0100 (IEC 364) when setting high-power electrical

units with nominal voltages of up to 1000 V, together with the associated standards and stipulations.

Check the details on the type plate to ensure that the equipment is connected to the correct mains

voltage.

Protection against touching dangerously high electrical voltages:

Before opening the equipment, it must be switched off and hold no voltages. This also applies to any

external control circuits that are connected.

The device is only to be used within the permitted range of temperatures and pressures.

Check that the location is weather-protected. It should not be subject to either direct rain or moisture.

The gas conditioning unit CSS-M.. must not be used in hazardous areas.

Installation, maintenance, monitoring and any repairs may only be done by authorized personnel with

respect to the relevant stipulations.

4 WARRANTY

If the equipment fails, please contact M&C directly or else go through your M&C authorised dealer.

We offer a one year warranty as of the day of delivery as per our normal terms and conditions of sale,

and assuming technically correct operation of the unit. Consumables are hereby excluded. The terms

of the warranty cover repair at the factory at no cost or the replacement at no cost of the equipment

free ex user location. Reshipments must be send in a sufficient and proper protective packaging.

4-2.1.3-ME Gas sampling and gas conditioning technology 5

Page 6

DANGER!

This means that death, severe physical injuries and/or important

material damages will occur in case the respective safety measures

are not fulfilled.

W ARNING !

This means that death, severe physical injuries and/or important

material damages may occur in case the respective safety

measures are not fulfilled.

CARE!

This means that minor physical injuries may occur in case the

respective safety measures are not fulfilled.

CARE!

Without the warning triangle means that a material damage may

occur in case the respective safety measures are not met.

ATTENT I O N !

This means that an unintentional situation or an unintentional status

may occur in case the respective note is not respected.

NOTE!

These are important information about the product or parts of the

operating manual which require user’s attention.

SKILLED STAFF

These are persons with necessary qualification who are familiar with

installation, use and maintenance of the product.

5 USED TERMS AND SIGNAL INDICATIONS

6 Gas sampling and gas conditioning technology 4-2.1.3-ME

Page 7

6 INTRODUCTION

The portable unit CSS-M has been especially designed so that precise gas analyses can be carried

out in any place.

The entire gas conditioning unit is housed in a compact and robust steel plate case which ensures that

the gas analyses can be carried out quickly, safely and with a minimum amount of maintenance.

The portable gas conditioning unit CSS-M may not be used for sampling of explosive gas/air or

gas/oxygen mixtures, for sampling of combustible gases which may result in an explosive mixture in

combination with air or oxygen nor in explosive atmospheres and hazardous areas.

7 APPLICATION

The portable gas conditioning unit CSS-M is ideally suited for both intermittent and continuous

operation.

The components of the system CSS-M are intended for "standard use."

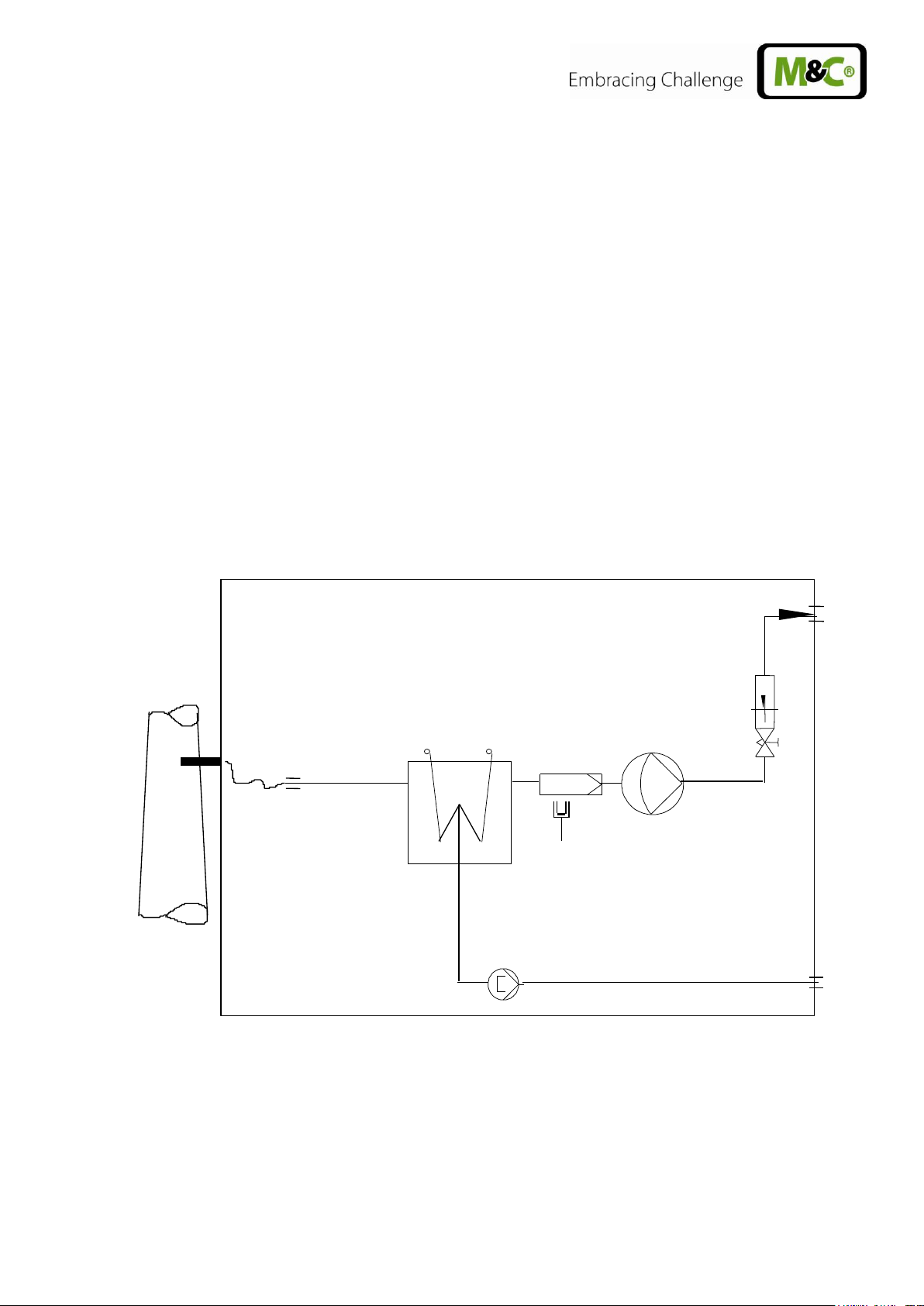

Figure 1 Scheme of gas flow

Gas cooler ECP

Front panel filter FPF-2-0,3GF, 0,3µm porosity with integrated liquid alarm

Sample gas pump N3 KPE

Flowmeter FM40

Peristaltic pump SR25.2 for continuous automatic condensate removal

4-2.1.3-ME Gas sampling and gas conditioning technology 7

Page 8

Portable Gas Conditioning Unit

Type

CSS-M

Sample outlet dew point

range of adjustment: +2 °C ..... +15 °C, factory setting: +5 °C

Dew point stability

at constant conditions < ± 0,1 °C

Sample inlet temperature

**max. 80°C**

Gas inlet water vapour saturation

**max. +50°C

Gas flow rate

**max. 70l/h

Ambient temperature

**+10°C to +45°C

Air humidity

75% year’s average, rare and slight dewing of 95% on 30

days per year admissible

Storage temperature

-25°C to +65°C

Pressure

0,7bar to 1,4bar abs.*

Total cooling capacity

max. 40kJ/h

Number of gas inlets

1

Number of gas outlets

1*

Sample gas connections

Hose connection 4/6 mm

Material medium-touched parts

Glass, PVDF, PVC, Novoprene®, FPM, PPH

Ready for operation

Approx. 10 min.

Mains power supply

230V 50Hz ± 10% or 115V 60Hz ± 10%

Power consumption

max. 240VA

Fuse protection

4A, time-lag, 5x20mm

Electrical mains supply

Cold appliance plug with 2m cable

Case protection

IP20 (EN 60529)

Housing version

Sheet steel case

Case dimensions (H x W x D)

177mm x 220mm x 300mm

Weight

Approx. 11kg

8 TECHNICAL DATA

PVDF=Polyvinylidenefluoride

PVC=Polyvinyl chloride

FPM=Fluor caoutchouc

PPH=Polypropylene hard

Specifications for components see appendix

* Standard

Maximum values in technical datas must be rated in consideration of total cooling capacity at 25 °C

ambient temperature and an outlet dew point of 5 °C.

8 Gas sampling and gas conditioning technology 4-2.1.3-ME

Page 9

220

17

300

47,5

9 DESCRIPTION

Figure 2 shows the dimensions and construction of the portable case.

Figure 2 Dimensions CSS-M

Fine filter FPF-2-0,3GF

Electronic controller

Flow meter FM40 with sample gas outlet

Peristaltic pump SR25.2 with condensate outlet

Pump switch

LED indication condensate alarm red

Sample gas inlet

All components of the gas conditioning unit are mounted in a portable sheet steel case. Filter and

peristaltic pump are placed into the front panel and thus assure a very easy maintenance.

The minimum debit is determined by the gas sampling pump (see also chapter 13). Premature

damage can be caused to the pump membrane if less than the minimal total amount of flow is

extracted as a result of excess pressure.

The gas cooler is equipped with a heat exchanger of Duran glass.

The fine filter FPF-2-0,3GF (0,3µm filter fineness) installed in front of the sample gas pump

N3 KPE ensures the necessary removal of solid particles.

The instrument contains a temperature alarm contact that is activated in case the temperature differs

more than +/-3 °C from the set value (+ 5°C) adjusted at the factory.

The temperature alarm contact of the cooler (+8°C or +2°C) controls automatically the switching on

and off of the sample gas pump provided the switch “Pump on” has been actuated (beaming green).

The condensate occurred is removed continuously via the peristaltic pump type SR25.2.

The DN4/6mm hose connections fort he condensate and sample gas outlet are located on the front

panel, the DN4/6mm sample gas inlet is located on the back side on the case.

The ventilation grids in the sidewalls ensure that the equipment is sufficiently ventilated.

A liquid alarm sensor is integrated in the filter FPF-2-0,3GF to protect the downward analysers against

liquid irruptions and to increase the operating safety of the whole system. In case of liquid inrush, the

internal electronic of the sample gas pump is automatically switched off.

4-2.1.3-ME Gas sampling and gas conditioning technology 9

Page 10

NOTE!

The portable gas conditioning system should be stored in a protected frost-

free area !

NOTE!

In order to ensure that the case is safe and stable when being used, it should

be laced on a horizontal surface free from vibrations. Only then, the perfect

functioning of the separation and drainage procedures of the condensate

inside the heat exchanger of the cooler will only be guaranteed.

The gas conditioning system should be kept away from heat sources and be

freely ventilated in order to prevent an accumulation of heat.

When the equipment is being used outside, ample protection against the

effects of direct sunlight and dampness must be provided. In winter, the

equipment must only be used in frost-free areas; pay attention to the type of

the equipment protection.

Please avoid temperature variations, strong airflow as well as aggressive

atmospheres at the instalment location.

In order to guarantee the operational safety of the gas conditioning system

and the downstream analysers, and to avoid false alarms, the gas

conditioning unit should not be used at temperatures other than those

specified. Furthermore, it must be protected against dust deposits and

penetrating dust.

It is of great importance that the analysers connected downstream are used

at temperatures well above the specified gas outlet dew point of +5°C. This

prevents the gas in the connector lines to the analysers from subsequent

condensing.

Unheated gas sample lines must be installed with slope up to the cooler. In

this case, a preliminary condensate separation is not required.

10 RECEIPT OF MARCHENDISE AND STORAGE

The portable gas sampling system CSS-M is a completely pre-installed unit. The scope of delivery

includes furthermore:

25 Filter elements (1 pckg.)

1 Connection cable

1 Operating Manual

Please take the CSS-M and possible special accessories carefully out of the packaging material

immediately after arrival, and compare the goods with the items listed on the delivery note;

Check the goods for any damage caused during delivery and, if necessary, notify your transport

insurance company without delay of any damage discovered.

11 INSTALLATION INSTRUCTIONS

10 Gas sampling and gas conditioning technology 4-2.1.3-ME

Page 11

220

177

Sample gas outlet

Condensate outlet

0

Sample gas inlet

NOTE!

Do not mix up the hose connections; the connections are marked

accordingly in figure 3.

After having connected all lines, please check the seals.

NOTE!

The tightness of the connections can only be guaranteed if the connecting

hose has a straight edge (use a hose cutter).

12 SUPPLY CONNECTIONS

12.1 HOSE CONNECTIONS

Figure 3 Hose connections CSS-M portable

All hose connections are DN4/6mm sealing ring threaded hose couplings out of PVDF/PPH as

standard. They are suitable for gas inlet temperatures of maximum 80°C (see chapter 8).

The mounting of the sample gas hoses and the condensate hoses is to be executed as follows:

Remove the union nut from the sealing ring couplings by turning it anti-clockwise. The nut should

be removed from the thread with great care so as to ensure that the loose sealing ring in the nut is

not lost.

Place the union nut over the connecting hose.

Push the sealing ring over the connecting hose with the thicker bead towards the nut.

Place the hose over the nipple on the thread.

The union nut is to be screwed tight by hand.

The hose will no longer be able to slip off, and is now compression-proof.

The hoses are to be removed in the reverse order.

4-2.1.3-ME Gas sampling and gas conditioning technology 11

Page 12

W ARNING !

Aggressive condensate is possible.

Wear protective glasses and proper protective clothing!

W ARNING !

False supply voltage can damage the equipment. When connecting

the equipment, please ensure that the supply voltage is identical

with the information provided on the model type plate!

NOTE!

For the assembly of power installations with rated voltages up to

1000V, the requirements of VDE 0100 and relevant standards and

specifications must be observed!

The main circuit is equipped with a fuse corresponding to the

nominal current (over current protection); for electrical details see

technical data.

NOTE!

Before connecting the equipment to the mains voltage, the main

switch must be in position “0“.

12.2 ELECTRICAL CONNECTIONS

The portable gas conditioning unit CSS-M is available with either 230V/50 Hz or 15V/60Hz (for circuit

diagram see Appendix). A 4A fuse is used on all models as fuse protection. The fuse is located on the

electronic board inside the steel sheet case.

The electrical connection is carried out by means of a cold appliance plug and 2m of cable located on

the back side of the case. The appliance plug socket is equipped with a two-pole main switch (see

also figure 3).

13 STARTING

Before starting the gas conditioning system, pay attention to the site-oriented and process-oriented

precautions. Please check once again that the operating voltage (see type plate) corresponds to the

supply voltage!

The following steps have to be done before starting up for the first time:

Place the cold appliance plug, which is delivered with the mains supply cable, into the cold

appliance plug socket;

Connect the mains plug to the mains;

Turn the main switch to the position ‘I’.

12 Gas sampling and gas conditioning technology 4-2.1.3-ME

Page 13

NOTE!

The request for a maximum pressure load of the sample gas pump N3

KPE of 1,4 bar abs. results in the following minimal gas flow rate:

N 3 KPE min. 30l/h air,

Premature damage can be caused to the pump membrane due to excess

pressure if less than the minimal total amount of flow is extracted.

In case of long-term measurements with a high level of dust, it is

necessary to utilise a suitable sample gas probe in order to protect the

sample leads from clogging-up.

Indication

LED K1

LED K2

After starting up

> 8°C

(Ambient temp.)

Off (Status alarm and pump

off)

Beaming permanently

yellow

(cooling)

After approx. 10

min.

7,5°C

Beaming yellow.

In case no condensate alarm

is given and the pump switch

is activated (beaming green),

the pump will be switched on.

Sample gas is lifted.

Beaming permanently

yellow

(cooling)

Normal operation

5°C

Beaming yellow

Beaming yellow

(Regulation of the

cooler)

After the starting time (LED K1 on the controller is beaming), the portable gas conditioning system is

ready for use, and the sample gas pump is switched on provided the key is activated (shines green).

The sample gas must not be fed before the starting time of the sample gas cooler is finished, i.e. if the

sample gas outlet temperature does not exceed the limits adjusted at works (LED K1 on the controller

is beaming).

13.1 COOLER REGULATION

13.2 NEW PUMP SWITCH SINCE 06/2007

In the past time, it happened repeatedly that the pump switch of the gas conditioning system CSS-M

failed. For that reason, we changed the switch in 06/2007 into a key button. The effect is that the

switch status of the pump in case of a voltage loss does not exist any more.

In order to keep the switch status, there is a jumper JP1 on the board by which you can determine

whether the pump shall restart automatically after a voltage loss or not.

With the bridge 2-3 (on), the pump restarts automatically.

With the bridge 1-2 (off), the pump does not restart again.

When delivered, the bridge is made between 1-2 (off), i.e. the pump does not restart after a voltage

loss.

4-2.1.3-ME Gas sampling and gas conditioning technology 13

Page 14

NOTE!

The location for the portable gas conditioning unit must remain

frost-free, even if the unit has been switched off.

W ARNING !

Aggressive condensate possible.

Wear protective glasses and proper protective clothing!

Figure 4 Electronic board CSS-M..

14 CLOSING DOWN

There are no special regulations to be observed if the portable gas conditioning unit CSS-M is to be

closed down for a short period of time.

In case of a long-term closing down, for example after a series of measurements has been completed,

it is recommended to purge the gas conditioning system with ambient air or inert gas. Under normal

conditions, the equipment needs only to be washed for 3 to 5 minutes. Condensate residues should

also be removed from the system.

14 Gas sampling and gas conditioning technology 4-2.1.3-ME

Page 15

W ARNING !

Dangerous voltage. Before any maintenance work is carried out on

the portable gas conditioning system, put the main switch of the

instrument into position “0” and tear the mains plug off!

NOTE!

In order to protect downstream analysers in case of a irruption of

condensate, always replace the humid filter element.

NOTE!

In any case you open the filter, the filter element must be changed.

15 MAINTENANCE

Before carrying out any maintenance work, the specific safety instructions referring to the instalment

and the process must be observed!

The frequency of the maintenance work depends on the operational process and can therefore only be

determined in each individual case.

All parts which require maintenance work are easily accessible and are installed on the front side of

the gas conditioning unit CSS-M. Only for any work on the gas sample pump, the case has to be

opened:

Replace the filter element of the fine filter FPF-2-0,3 GF in case the flow rate is to low or after

visible control.

The hose of the condensate pump SR25.2 should be checked every six months and, if necessary,

replaced (see chapter 15.3.1);

The diaphragm of the sample gas pump N3 KPE should be checked every six months and, if

necessary, replaced.

15.1 REPLACEMENT OF THE FILTER ELEMENT AND THE O-RING

For changing the filter element and the O-ring:

Disconnect the mains voltage;

Unscrew the filter housing cover;

Exchange the filter element and/or O-ring. Pay attention to the correct insertion of the filter

element and the O-ring (the structural surface of the filter element must show to the front!).

Screw down the filter housing cover again.

4-2.1.3-ME Gas sampling and gas conditioning technology 15

Page 16

O-ring

Filter element

W ARNING !

Aggressive sample residues possible.

Wear protective glasses and proper protective clothing during

dismountage, repair or cleaning of the peristaltic pump!

NOTE!

In case you send the peristaltic pump to the M&C Service

Department, please indicate what medium has been lifted.

Before returning the pump to M&C, it must be cleaned from

dangerous or highly aggressive contaminations.

Figure 5 Replacement of the filter element and the O-ring

15.2 DISMOUNTAGE OF THE SAMPLE GAS PUMP FOR EXAMINATION OR

MAINTENANCE

For dismounting the sample gas pump N3 KPE:

Disconnect the portable gas conditioning system from the mains voltage;

Unscrew the front panel and put it beside without detaching the piping and the wiring;

Loosen the 4 fastening screws of the mounting angle on which the pump is mounted;

Pull out the pump with mounting angle;

Examination and maintenance of the pump N3 KPE;

After examination and maintenance screw down the mounting angle again and mount the front

panel.

15.3 MAINTENANCE OF THE INTEGRATED PERISTALTIC PUMP TYPE SR 25.2

Pump hose, moving strap, pressure roller and springs are the only wearing parts of the pump. They

are easily to exchange.

15.3.1 REPLACEMENT OF THE PUMP HOSE

16 Gas sampling and gas conditioning technology 4-2.1.3-ME

Page 17

NOTE!

Only when using the original spare pump hose, the perfect function is

guaranteed.

Never grease the pump hose.

Before assembling the peristaltic pump, examine all parts for

contaminations and if necessary clean them.

Figure 6 Replacement of the pump hose

Disconnect the portable gas conditioning system from the mains voltage;

Loosen the hose connections on the pump;

Press the moving strap on the recessed grips and turn the S-bar clockwise as far as the

limit stop;

Take out the moving strap and pull the old pump hose on the hose nozzles out of the

guides;

Press the pressure rollers and check whether there is any tension on the springs, if not,

exchange the pressure springs (see chapter 15.3.2);

Place the new pump hose with the hose nozzles into the guides of the moving strap ;

Put he moving strap with the new hose completely into the dovetail guide of the pump

body; press the moving strap on the recessed grips and turn at the same time the S-bar

anticlockwise as far as it locks into place;

Turn the pump on.

15.3.2 CHANGE OF CONTACT PULLEYS AND SPRINGS

Switch off the mains;

Unscrew nuts of the pump head (wrench size 5,5) and remove snap ring from motor

shaft;

4-2.1.3-ME Gas sampling and gas conditioning technology 17

Page 18

NOTE!

The springs may occur in different coulerings. This does not constitute a

quality defect. But make sure that the right spring strength is used. This

can be identified by the spring wire diameter. The „standard version for

Novoprene pump hoses“ (part no. 90P1010) has a diameter of 1,1mm and

the strengthened version for FPM-, Acidflex- or Masterflex-hoses“ (part

no. 90P1015) has a diameter of 1,2mm.

NOTE!

At first delivery two different types of springs are mounted in the driver

(right and left springs). When spare springs are ordered, for simplified

storage only one type will be delivered (right spring) that can be replaced

without any problems and guarantees full functionality when all four

springs are replaced.

The dent prevents

rotation of the axis

new

worn out

Figure 7 Disassembly of pump head and driver

Draw the pump head out of the motor shaft

Take driver out of the pump head

The removal of the springs (4 pcs.) away from the driver is easily possible without the aid of

any tools. For this take spring out of the groove near to the shaft bore.

Dismount roller axes and change contact pulleys. Take care that axes are not worn out by the

springs and have damaged the dent at the axes front end. In case of abrasion the axes have to

be changed (see Fehler! Verweisquelle konnte nicht gefunden werden.).

Figure 8 Check of axes and rolls

18 Gas sampling and gas conditioning technology 4-2.1.3-ME

Page 19

NOTE!

While mounting pay attention to the fit of ‘rotational axisdriver’ and

check that the plunged boss at the shaft bore points to the front of the

pump head.

Use genuine spare parts only !

W ARNING !

Aggressive medium residues possible.

During dismountage, rapair or cleaning of the pump, wear

protective glasses and proper protective clothing!

Make sure that contact pulleys roll easily on the axis. After remounting the axis with contact

pulley into the driver the spring has to be mounted as shown in Figure 8. Please pay attention

to the alignment of the dent.

Remounting happens in reverse order.

15.3.3 CLEANING OF THE PUMP HEAD

We recommend to clean the single parts with a dry cloth. Principally, you should not use any

solvents for cleaning because they could affect the synthetic material. In case there is oil-free

compressed air available, the parts can be blown through.

16 OPERATING OF THE INTEGRATED ELECTRONIC TEMPERATURE REGULATOR

During normal operation, the display of the temperature regulator shows the actual cooling

temperature.

Figure 8 shows the front view of the temperature regulator.

4-2.1.3-ME Gas sampling and gas conditioning technology 19

Page 20

Figure 9 Front view of the temperature regulator

16.1 CHANGING THE SET VALUE

For changing the set value, you must press the P-button < 2s. The set value adjusted at the factory at

5°C is shown. With both arrow keys, the set value can be set upwards or downwards. However, this

value should not be adjusted below +1°C, otherwise you must expect a freezing up of the heat

exchanger. If you set the value above the ambient temperature, the cooler will not work.

20 Gas sampling and gas conditioning technology 4-2.1.3-ME

Page 21

Display

Fault

Possible cause

Examination/Correction

None

No supply voltage;

Check the supply voltage according to the type

plate;

ok?

Control whether the mains plug is put in correctly or

whether the main switch is in position „1“;

ok?

Examine the fine fuses F1, F2 on the internal

board;

ok?

LED K1 is

beaming

permanently

and temp. >

8°C

Cooler alarm „Excess

temperature“; cooler

switches the sample

gas pump

automatically off;

Ventilator does not

function

Ambient temperature too high;

ok?

Free convection inside the gas conditioning unit

upset internal temperature too high;

ok?

Sample flow or dew point too high? Reduce flow.

ok?

Return the instrument for repair to M&C.

Temp.

>2°C and

< 7,5°C

Cooler runs,

sample flow is

interrupted;

Alarm-LED in

front panel is

beaming red

(see 4)

Pump

defective

Diaphragm pump

does not work;

Pump is not switched

on

Liquid alarm sensor:

Sensor turns sample

gas pump

automatically off;

Switch in position „on“ (is beaming green)

Ok?

LED Liquid alarm is beaming red.

Liquid in the filter (Dry filter and liquid alarm sensor

and check peristaltic pump, see below.)

ok?

Check the hoses for condensate draining;

ok?

Check pump hose (see 15.3.1);

ok?

Check pump SR25.2 (see 15.3);

ok?

Return instrument for repair to M&C.

Pump works,

but sample

gas flow is

interrupted;

Flow meter :

Needle valve is shut.

Sample probe or

sample hose clogged

or line squeezed;

Set the desired flow rate on the needle valve.

Loosen the sample hose from the sample gas inlet

of the gas conditioning unit (see 12.1);

Gas flow?

Clean the clogged line or replace it;

17 TROUBLE SHOOTING

The following table shows possible sources of errors and how to remove them (not applicable for the

starting-up phase).

4-2.1.3-ME Gas sampling and gas conditioning technology 21

Page 22

Sample line to the

analyser clogged or

squeezed;

Pollution of the

diaphragm pump;

No gas flow?

Loosen the outlet hose on the analyser side and

check on the threaded hose coupling whether

sample gas flows;

Sample gas does not flow?

Clean the clogged line or replace it;

Sample gas flows?

ok?

Loosen the piping on the pump head and examine

it (see 15.2);

ok?

If necessary, clean the pump;

Ok?

Temp.

<2°C

Cooler switches the

sample gas pump

automatically off;

Cooler defective;

Ambient temperature too low;

ok?

Return the instrument for repair to M&C.

22 Gas sampling and gas conditioning technology 4-2.1.3-ME

Page 23

Portable Gas Conditioning Unit Version CSS-M

(V) Consumables, (E) Recommended Spare Parts and (T) Spare Parts

Recommended quantity after

operation of [years]

Part No.

Description

V/E/T 1 2

3

Fine filter FPF-2-0,3GF

90 F 0160

Filter element type F-2-0,3GF. Material:

glass fiber, porosity: 0,3µ 25 pcs./pack.

V 1 2

3

90 F 0167

O-ring FPF-2/54. Material: Viton.

E 1 1

1

Peristaltic pump SR25.1:

90 P 1007

SR25 pump hose with threaded hose

coupling of PVDF, DN 4/6mm

V 1 2

4

Diaphragm pump type N3 KPE

90P2100

Square cap type D3, 1/8“i for

N3/N5 KPE/KP18. Material: PVDF

T - -

1

90P2120

Diaphragm type S3, for

N3/N5 KPE/KP18,

Material: Viton, PTFE coated

V 1 2

3

90P2115

O-ring type O3, for N3/N5 KPE/KP18,

1 pc., Material: Viton (2 pcs. Required)

V 2 4

6

90P2110

Valve plate type V3, for N3/N5 KPE/KP18,

1 pc., Material: Viton (2 pcs. Required)

V 2 4

6

90P2105

Intermediate plate type Z3, for

N3/N5 KPE/KP18, Material: PVDF

T - -

1

Flow meter FM40:

90 A 0015

Flow meter glass for FM40

Measuring range 7-70 l/hr air

T - 1

1

90 A 0018

Viton O-ring 9 for FM40 glass

E 2 4

6

Miscellaneous:

90 K 6030

Fine fuse 4A T, 5x20mm for CSS...

E 5 5

5

Hose and threaded hose couplings:

05 V 3215

Bulkhead union SV-PVDF DN 4/6

E 2 2

2

05 V 6600

Ferrule 4/6 PVDF s.a.

E 5 10

10

05 V 6605

Union nut M10-4/6 PVDF s.a.

E 5 10

10

01 T 1000

Viton tube NW 4/6 (m)

T 1 2

3

10 T 1000

Hose cutter

T 1 1

1

18 SPARE PART LIST

Wear, tear and replacement part requirements depend on specific operating conditions.

The recommended quantities are based on experience and are not binding.

4-2.1.3-ME Gas sampling and gas conditioning technology 23

Page 24

19 APPENDIX

Circuit diagram CSS-M

For further product documentation, please see our internet catalogue:

www.mc-techgroup.com

Instruction manual peristaltic pump SR25.1, SR25.1-G,

document : 3-7.1-ME

Instruction manual diaphragm pump series N

document : 6-1.2.1-ME

Flowmeter FM 40,

document : 5-6.1.10

Liquid alarm sensor LA1...,

document : 5-5.1.1

24 Gas sampling and gas conditioning technology 4-2.1.3-ME

Page 25

Figure 10 Circuit diagram CSS-M

4-2.1.3-ME Gas sampling and gas conditioning technology 25

Loading...

Loading...