Page 1

Operating Manual

19 Inch Rack Mounting Gas Conditioning Unit

series CSS

®

(incl. the new temperature controller type 70304)

Gas sampling and gas conditioning technology 4-1.1-ME

Page 2

2

List of contents

1 General information ................................................................................................................... 5

2 Declaration of conformity .......................................................................................................... 5

3 Safety instructions ..................................................................................................................... 6

4 Warranty ...................................................................................................................................... 6

5 Used terms and signal indications ........................................................................................... 7

6 Introduction ................................................................................................................................. 8

6.1 Serial number ........................................................................................................................... 8

6.2 Power supply ............................................................................................................................ 8

7 Technical Data ............................................................................................................................ 9

8 Description ................................................................................................................................ 10

9 Function .................................................................................................................................... 16

10 Electrical Connections ............................................................................................................. 18

10.1 Electrical junction box X1 ....................................................................................................... 18

10.2 Sub-D-plug X2 ........................................................................................................................ 19

10.2.1 Status contacts ................................................................................................................. 19

10.2.2 Local control ..................................................................................................................... 20

10.2.3 External Control ................................................................................................................ 21

10.3 Liquid- and flow alarm card LFC-2 ......................................................................................... 22

11 Description of the optional temperature controller 70304 for heated sample lines ........... 24

12 Operating principle of the controller 70304 ........................................................................... 24

12.1 Parameter of the user level with factory setting ...................................................................... 24

13 Change of parameters .............................................................................................................. 25

13.1 Removing and activating the level inhibit ............................................................................... 25

13.2 Menue structure...................................................................................................................... 26

13.3 Time Out ................................................................................................................................. 26

14 Receipt Of Goods and storage ................................................................................................ 27

15 Installation instructions ........................................................................................................... 27

16 Supply connections ................................................................................................................. 28

16.1 Hose connection ..................................................................................................................... 28

16.2 Electrical connections ............................................................................................................. 28

17 Starting ...................................................................................................................................... 29

17.1 Measure.................................................................................................................................. 29

17.2 Check/Calibration ................................................................................................................... 30

17.3 Self-optimising (PID-Function) of the controlled system ......................................................... 31

18 Closing down ............................................................................................................................ 31

19 Maintenance .............................................................................................................................. 32

20 Dismounting the flow components sub panel ....................................................................... 32

21 Alarms and elimination ............................................................................................................ 33

21.1 Voltage loss ............................................................................................................................ 33

21.2 Cooler alarm/temperature controller alarm ............................................................................. 34

21.3 Flow alarm .............................................................................................................................. 34

21.4 Liquid alarm ............................................................................................................................ 35

22 Spare part lists .......................................................................................................................... 36

23 Appendix ................................................................................................................................... 38

Gas sampling and gas conditioning technology 4-1.1-ME

Page 3

3

List of illustrations

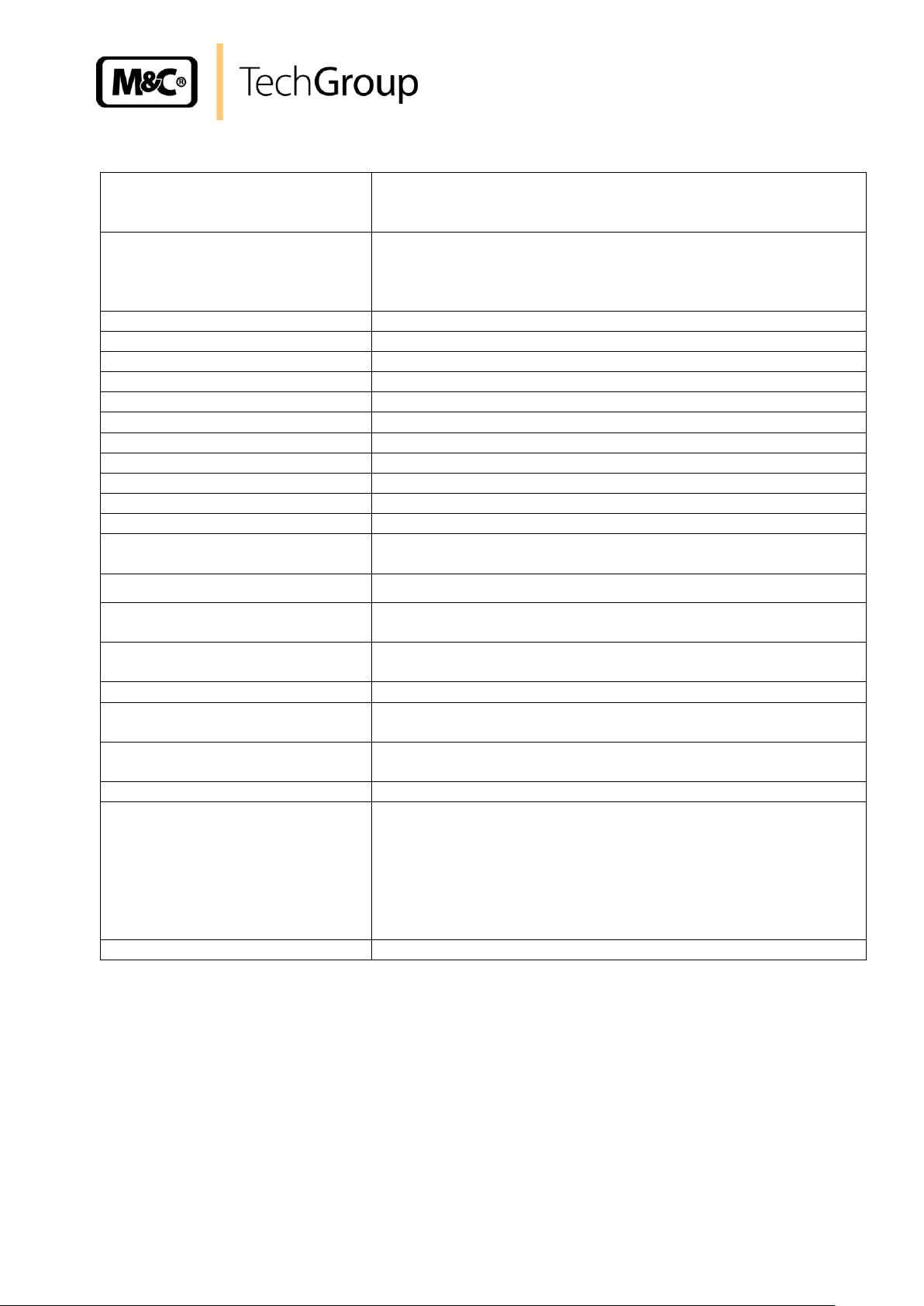

Figure 1 Front view of the CSS ...................................................................................................... 10

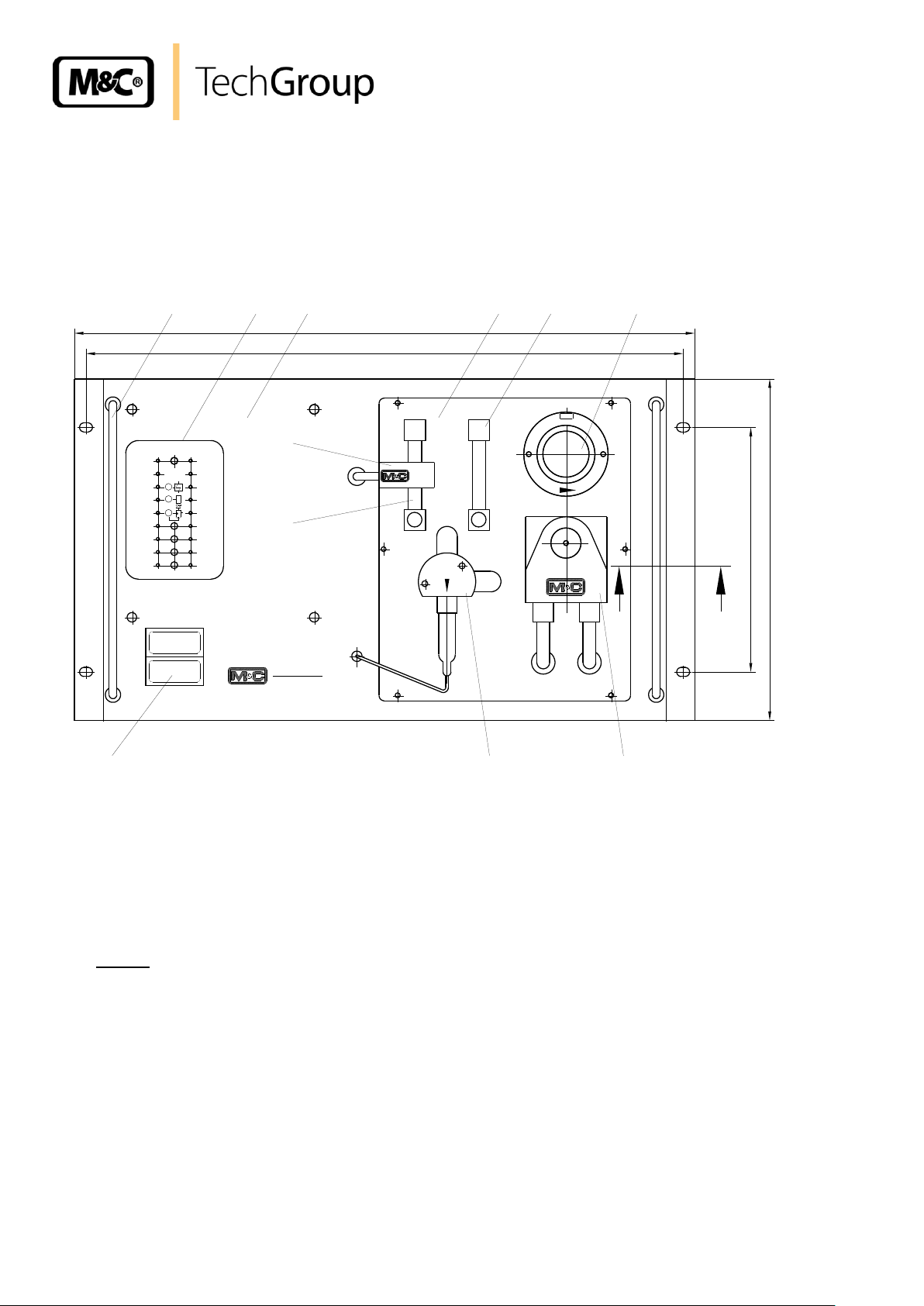

Figure 2 Operation and control board............................................................................................. 11

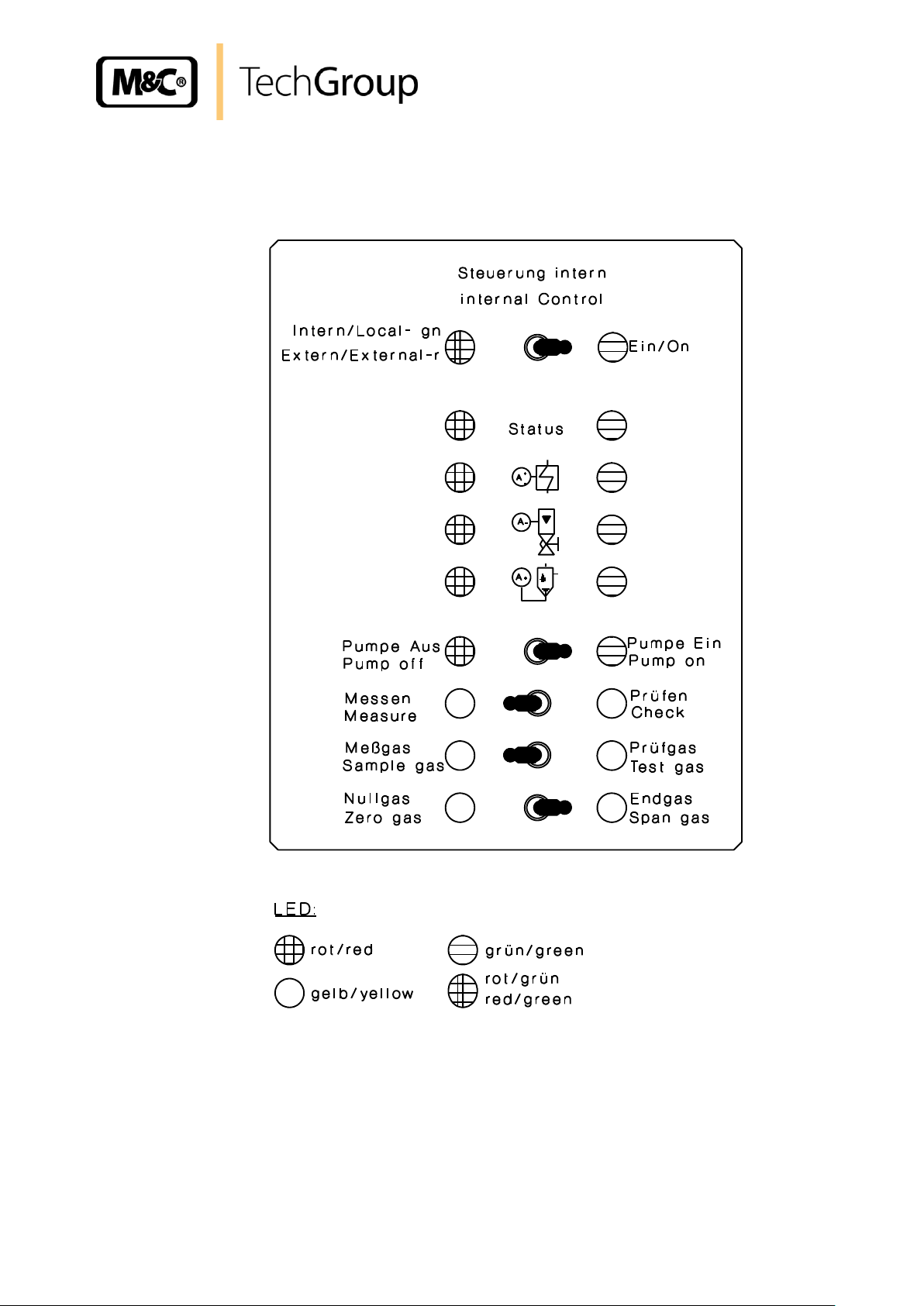

Figure 3 Plan view of the components mounted on the Flow components sub panel .................... 13

Figure 4 Components mounted in the 19“ rack housing ................................................................. 14

Figure 5 Back-panel of the 19" rack housing .................................................................................. 15

Figure 6 Gas flow schematic .......................................................................................................... 16

Figure 7 Electrical junction box X1 (B) ........................................................................................... 18

Figure 8 Status contacts ................................................................................................................. 19

Figure 9 Plan of terminal connections in the Sub-D-Plug X2 (A) for local control of the

CSS... and CSS.../C ......................................................................................................... 20

Figure 10 Plan of terminal connections in the Sub-D-Plug X2 (A) for external control of

the CSS... and CSS.../C ................................................................................................... 21

Figure 11 Circuit diagram LFC-2 ...................................................................................................... 23

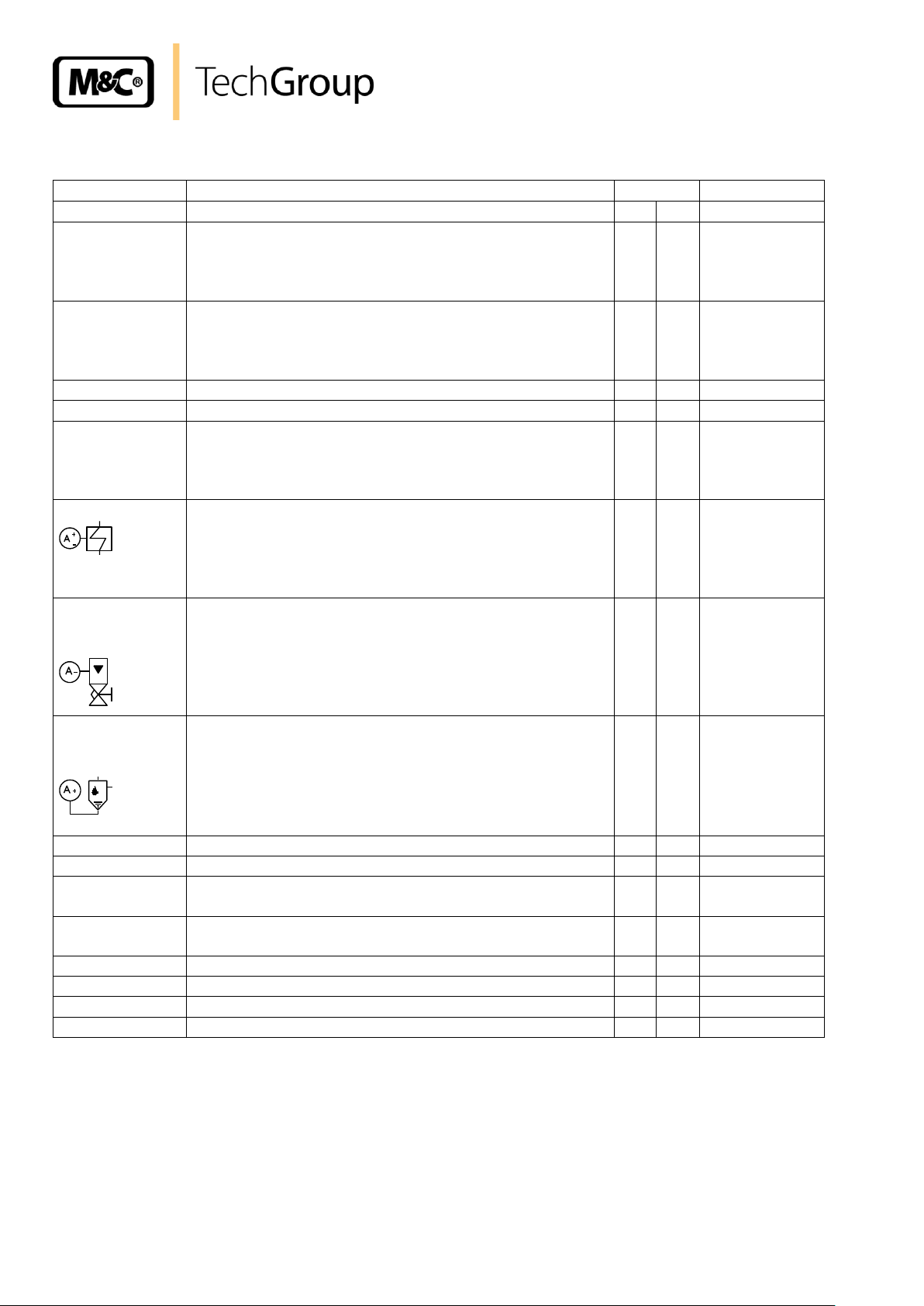

Figure 12 Display/control elements .................................................................................................. 24

Figure 13 Menue structure ............................................................................................................... 26

Figure 14 Pin assignment for external drive of the CSS ................................................................... 39

Figure 15 Circuit diagram gas conditioning CSS .............................................................................. 40

Figure 16 CSS with 4 x span solenoid valves .................................................................................. 41

Gas sampling and gas conditioning technology 4-1.1-ME

Page 4

4

This Operating Manual does not claim completeness and may be subject to technical modifications.

© 10/1996 M&C TechGroup Germany GmbH. Reproduction of this

document or its content is not allowed without permission from M&C.

CSS® is a registered trade mark.

4th Edition: 02/2008

Dear customer,

we have made up this operating manual in such a way that all necessary information about the product can be found and understood quickly and easily.

Should you still have any question, please do not hesitate to contact M&C directly or go through your

appointed dealer. Respective contact addresses are to be found in the annexe to this operating manual.

Please also contact our homepage www.mc-techgroup.com for further information about our products. There, you can read or download the data sheets and operating manuals of all M&C products as

well as further information in German, English and French.

Gas sampling and gas conditioning technology 4-1.1-ME

Page 5

5

Head Office

M&C TechGroup GmbH Rehhecke 79 40885 Ratingen Germany

Telephone: 02102 / 935 - 0

Fax: 02102 / 935 - 111

E - mail: info@mc-techgroup.com

www.mc-techgroup.com

1 GENERAL INFORMATION

The product described in this operating manual has been examined before delivery and left our works

in perfect condition related to safety regulations. In order to keep this condition and to guarantee a

safe operation, it is important to heed the notes and prescriptions made in this operating manual. Furthermore, attention must be paid to appropriate transportation, correct storage, as well as professional

installation and maintenance work.

All necessary information a skilled staff will need for appropriate use of this product are given in this

operating manual.

2 DECLARATION OF CONFORMITY

CE - Certification

The product described in this operating manual complies with the following EC directives:

EMV-Instruction

The requirements of the EC directive 2004/108/EC “Electromagnetic compatibility“ are met.

Low Voltage Directive

The requirement of the EC directive 2006/95/EC “Low Voltage Directive“ are met.

The compliance with this EC directive has been examined according to DIN EN 61010.

Declaration of conformity

The EU Declaration of conformity can be downloaded from the M&C homepage or directly requested

from M&C.

Gas sampling and gas conditioning technology 4-1.1-ME

Page 6

6

3 SAFETY INSTRUCTIONS

Please take care of the following basic safety procedures when mounting, starting up or operating this equipment:

Read this operating manual before starting up and use of the equipment. The information and warnings given in this operating manual must be heeded.

Any work on electrical equipment is only to be carried out by trained specialists as per the regulations

currently in force.

Attention must be paid to the requirements of VDE 0100 (IEC 364) when setting high-power electrical

units with nominal voltages of up to 1000 V, together with the associated standards and stipulations.

Check the details on the type plate to ensure that the equipment is connected to the correct mains

voltage.

Protection against touching dangerously high electrical voltages:

Before opening the equipment, it must be switched off and hold no voltages. This also applies to any

external control circuits that are connected.

The device is only to be used within the permitted range of temperatures and pressures.

Check that the location is weather-protected. It should not be subject to either direct rain or moisture.

The device must not be used in hazardous areas.

Installation, maintenance, monitoring and any repairs may only be done by authorized personnel with

respect to the relevant stipulations.

4 WARRANTY

If the equipment fails, please contact M&C directly or else go through your M&C authorised dealer.

We offer a one year warranty as of the day of delivery as per our normal terms and conditions of sale,

and assuming technically correct operation of the unit. Consumables are hereby excluded. The terms

of the warranty cover repair at the factory at no cost or the replacement at no cost of the equipment

free ex user location. Reshipments must be send in a sufficient and proper protective packaging.

Gas sampling and gas conditioning technology 4-1.1-ME

Page 7

7

DANGER!

This means that death, severe physical injuries and/or important

material damages will occur in case the respective safety measures are not fulfilled.

W ARNIN G!

This means that death, severe physical injuries and/or important

material damages may occur in case the respective safety measures are not fulfilled.

CARE!

This means that minor physical injuries may occur in case the

respective safety measures are not fulfilled.

CARE!

Without the warning triangle means that a material damage may

occur in case the respective safety measures are not met.

AT TE NTION !

This means that an unintentional situation or an unintentional

status may occur in case the respective note is not respected.

NOTE!

These are important information about the product or parts of the

operating manual which require user’s attention.

SKILLED STAFF

These are persons with necessary qualification who are familiar

with installation, use and maintenance of the product.

5 USED TERMS AND SIGNAL INDICATIONS

Gas sampling and gas conditioning technology 4-1.1-ME

Page 8

8

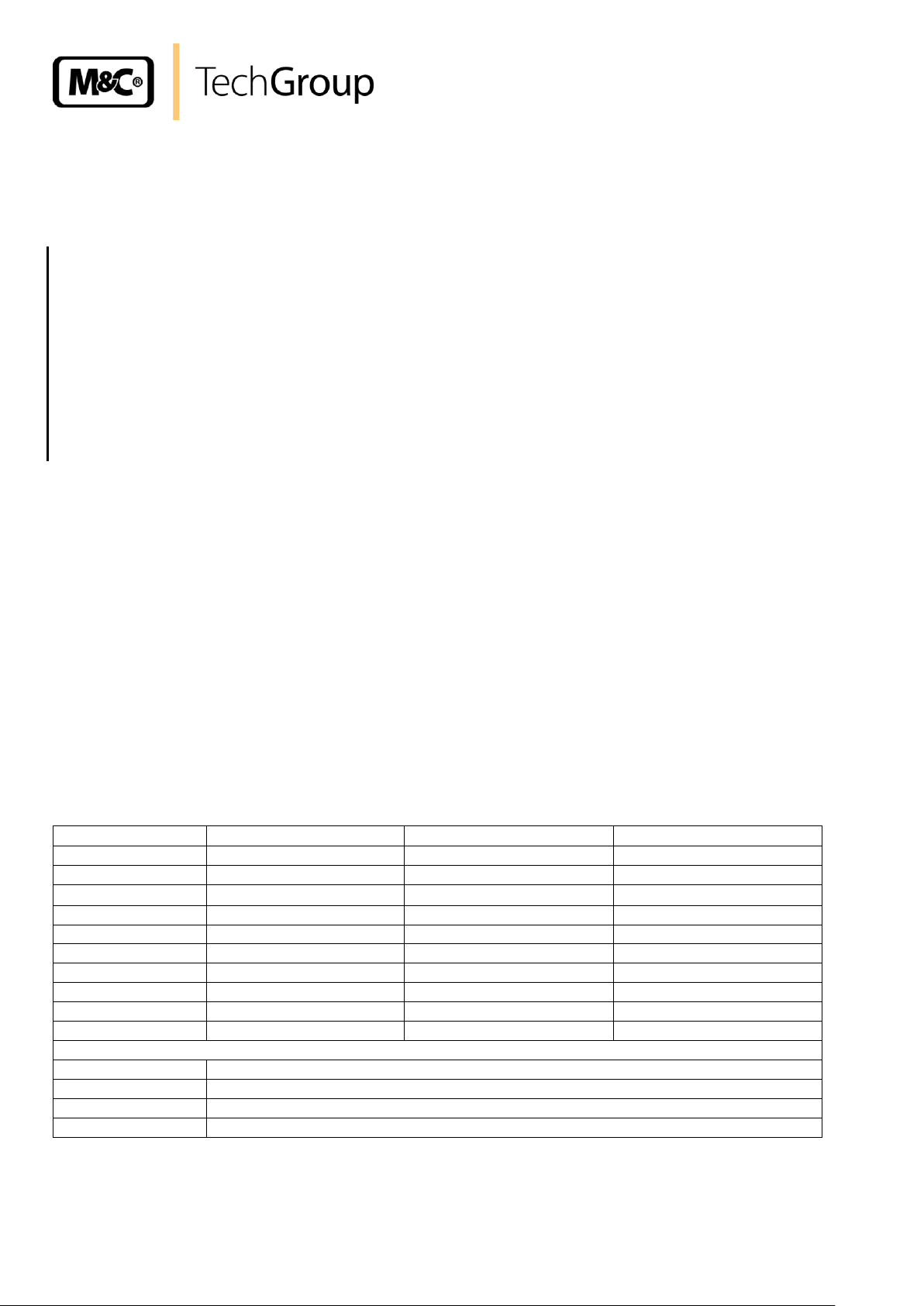

Part number

Type

Cooler - gas flow [l/h]

Power supply

03 G 1000

CSS 230V

ECP 1000 - 140l/h

230V 50/60Hz

03 G 1000a

CSS 115V

ECP 1000 - 140l/h

115V 60Hz

03 G 1100

CSS/C* 230V

ECP 1000 - 140l/h

230V 50/60Hz

03 G 1100a

CSS/C* 115V

ECP 1000 - 140l/h

115V 60Hz

03 G 2000

CSS-2 230V

ECP 2000 - 2 x 140l/h

230V 50/60Hz

03 G 2000a

CSS-2 115V

ECP 2000 - 2 x 140l/h

115V 60Hz

03 G 3000

CSS-3 230V

ECP 3000 - 350l/h

230V 50/60Hz

03 G 3000a

CSS-3 115V

ECP 3000 - 350l/h

115V 60Hz

03 G 3100

CSS-3/C* 230V

ECP 3000 - 350l/h

230V 50/60Hz

03 G 3100a

CSS-3/C* 115V

ECP 3000 - 350l/h

115V 60Hz

Options

03 G 9000

Extra charge for CSS... with integr. temp. controller 70304 f. heated sample line

03 G 9020(a)

Extra charge for CSS... with altogether 3 check valves

03 G 9025(a)

Extra charge for CSS... with altogether 4 check valves

03 G 9030(a)

Extra charge for CSS... with altogether 5 check valves

6 INTRODUCTION

This M&C unit provides completely pre-installed sample gas conditioning for continuous use and can

be excellently integrated within analysis systems. It is equipped with:

1 sample gas inlet;

Electric gas cooler;

Sample gas pump;

Condensation pump;

Micro fine filter with glass-fibre element (0,1µm);

External or manual switching for testing with zero or span gas by 3-way and 2-way

solenoid valves;

Status alarm with display for cooler temperature, flow alarm and liquid alarm;

2 sample gas outlets with flow meters incl. needle valve (70 l/h or rather 250 l/h);

PTFE hosing;

Optional: electronic temperature controller for heated sample lines.

Its compact construction means that it takes up little space. The CSS unit is ready for use within a

matter of a few minutes. This at last makes the usual time consuming procurement of individual components and assembly superfluous.

6.1 SERIAL NUMBER

The type plates bearing the serial number are located on the back panel of the 19“-rack-housing.

Always quote the device’s serial number when making inquiries and ordering spare parts.

6.2 POWER SUPPLY

Depending on the version, the CSS is operated with 115 or 230 V AC.

Precise details can be found on the device's type plate.

In dependence of the cooler type, the power supply and the version .../C -test gas to the probe- the

following types of the CSS can be distinguished:

* Version CSS.../C: test gas to sample probe

(a) : 115V-Version

Gas sampling and gas conditioning technology 4-1.1-ME

Page 9

7 TECHNICAL DATA

Gas flow rate**

CSS(/C) : max. 140l/h

CSS-2 : max. 2 x 140l/h

CSS-3(/C) : max. 350l/h

Flow meter

CSS(/C), CSS-2: 2 x with needle valve, adjustable to 70l/h,

flow meter FM1 with flow alarm sensor

CSS-3(/C) : 2 x with needle valve, adjustable to 250l/h,

flow meter FM1 with flow alarm sensor

Gas pressure

0,7bar to 1,4bar abs.

Sample inlet temperature**

max. 150°C

Sample inlet dew point**

max. 80°C

Sample outlet dew point

range of adjustment: +2 °C ..... +15 °C, factory setting: +5 °C

Dew point stability

at constant conditions < ± 0,1 °C

Gas filter F-0,1GF50

Glass fiber, retention rate 99,99% for particles > 0,1µm

Ambient temperature**

+5°C to +45°C

Storage temperature

-25°C to +65°C

Relative humidity

< 80%

Housing

19"-rack housing mounting 6 U, depth 350mm

Degree of protection

IP20, DIN40050

Weight

CSS(/C) : approx. 15kg

CSS-2, CSS-3(/C): approx. 16,5kg

Connections

G 1/4 i* - DIN ISO 228/1

Power supply

230V 50/60Hz or 115V 60Hz, CSS : 150VA

CSS-2/3: 250VA

Electrical connection

Power terminals max. 4 mm2 (4 x PG 13,5)

Alarm-/Control signal 15 pin Sub-D-Connector

Warm up time

approx. 10 min.

Material of sample contacting

parts

PVDF, glass, Viton, Novoprene, PTFE

Status signal for

Measure/Check, cooler temperature, liquid alarm, flow alarm:

potential free change over contact, max. 24V/1A

Test gas inlet - 2 x

solenoid valve actuated by manual or external switch

Option:

Electronic PID temperature controller for heated sample lines

front panel mounting

control range : 0°C to 200°C

sensor inlet : PT 100 and Fe-CuNi

controlling outlet : 10A solid state relay #

status alarm : integrated into the status signal

parameter : free adjustable

Electrical equipment standard

EN 60204-1 (DIN VDE 0113 Teil 1/02.86)

9

* other connections on request

** Maximum values in technical datas must be rated in consideration of total cooling capacity at 25 °C ambient temperature and an outlet dew

point of 5 °C.

#

standard for max. 20m heated sample line at 110W/m

Gas sampling and gas conditioning technology 4-1.1-ME

Page 10

10

Pumpe EinPumpe Aus

Sampling-Sy stem

Temp. controller

Nullgas

Zero gas

Meßgas

Sample gas

Messen

Measure

Pump off

Temp. Regler

CSS

Pump on

Prüfen

Check

Prüfgas

Test gas

Endgas

Span gas

LS/LA

Steuerung Intern

Extern-rt

Intern-gn

A-

A-

A±

Status

control intern

Ein

2

1

FA-1,bi

Sensor

Open

Auf

FPF-0,1

M&C

190,5

266

465

483

(1.4) 1 (1.2)

optional tempreature controller

(1.3)

1.2.1

1.2.4

1.2.5

1.2.3 1.2.2

1.2.6

A

A

(1.1)

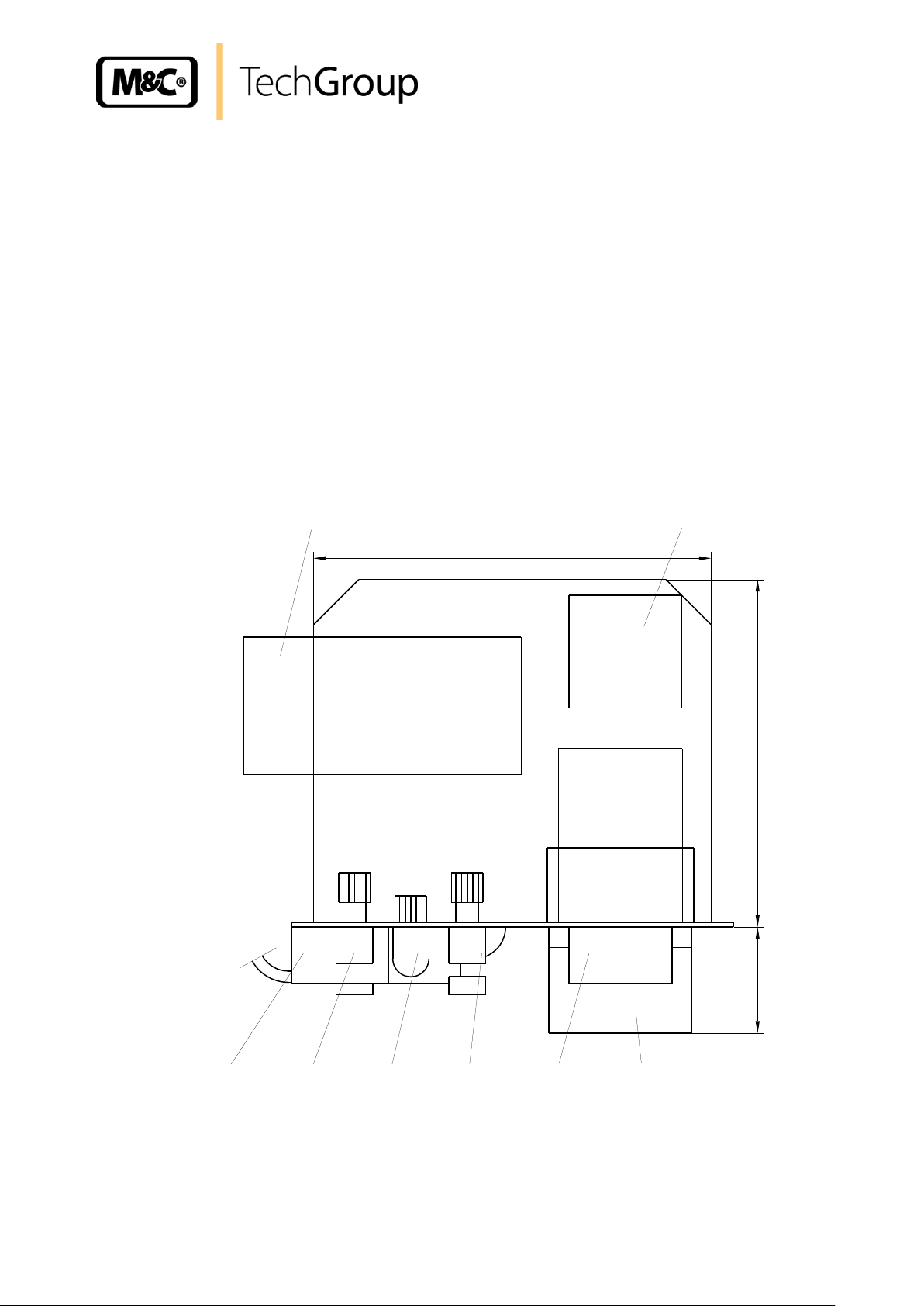

8 DESCRIPTION

The components of the M&C gas conditioning sampling system type CSS are mounted in a 19" rack

housing. The CSS may also be configured with an optional wall-mounting-bracket (Part-No.

03G9005).

Figure 1 Front view of the CSS

The front plate (1) displays the following components:

(1.1) operation and control board;

(1.2) flow components sub panel;

(1.3) option*- temperature controller for heated sample line (Part No. 03G9000);

(1.4) handles.

*

If the temperature controller option is not chosen a plastic plate will cover the opening.

Gas sampling and gas conditioning technology 4-1.1-ME

Page 11

11

Figure 2 shows the operation and control board (1.1). The different functions are selected by toggle

switches and indicated with LED’s. The internal or external function is configured through the wiring in

the Sub-D-Plug (see 4.1) and indicated by a dual coloured LED on the operation and control board.

Figure 2 Operation and control board

Gas sampling and gas conditioning technology 4-1.1-ME

Page 12

12

Function

Description

Switch

LED

l

r

Local Control

(intern)

control of the CSS with operation and control board;

link between pin 1 and 9 (connector X2, s. 10.2.2);

control power supply;

(dual col-

oured)

green

External Control

(extern)

external control with Sub-D-Plug X2 (s. 10.2.3),

switches of the operation and control board out of

function; control power supply after switching the CSS

on ;

(dual col-

oured)

red

On

internal control activated;

X green*

Off

switches CSS off

X no LED

Status

no alarm: CSS ready for operation;

alarm : cooler-/temperature-controller alarm;

flow alarm;

liquid alarm.

green*

red*

Cooler- Alarm

no alarm: CSS ready for operation;

alarm : CSS not ready for operation,

temperature of cooler <2°C or >8°C,

or optional temperature-controller:

controller not in range

green*

red*

FlowAlarm

no alarm: CSS in operation;

alarm : no gas flow (i.e. inlet or outlet

is blocked),

sample gas pump not in operation,

liquid alarm,

cooler-/temperature-controller alarm;

green*

red*

LiquidAlarm

no alarm: CSS ready for operation

alarm : condensate alarm;

green*

red*

Pump Off

sample gas pump off;

X red

Pump On

sample gas pump on;

X green*

Measure

CSS in sample mode,

signal contact available;

X yellow*

Check

CSS in test mode,

signal contact available;

X yellow*

Sample Gas

3-way solenoid valve open for sample mode;

X yellow*

Test Gas

3-way solenoid valve open for test mode;

X yellow*

Zero Gas

2-way solenoid valve open for Zero Gas;

X yellow*

Span Gas

2-way solenoid valve open for Span Gas;

X yellow*

The following chart describes the functions of the operation and control board.

* LED display also for external control

Gas sampling and gas conditioning technology 4-1.1-ME

Page 13

13

175

1.2.7 1.2.8

152

48

1.2.1 1.2.21.2.61.2.31.2.41.2.5

All of the maintenance components are mounted on the flow components sub panel (1.2) (s. Fig. 1

and 3) and are easily accessed by removing front panel mounting screws. These are:

(1.2.1) Gas-Filter FPF-0,1GF;

(1.2.2) Peristaltic pump SR25.1;

(1.2.3) Liquid-Alarm-Sensor LA1 with Flow-Chamber LS;

(1.2.4) Flow-Meter 1 FM40, measuring range 7-70l or 25-250l**

(1.2.5) Optical bi stable Flow-Alarm-Sensor FA-1,bi;

(1.2.6) Flow-Meter 2 FM40, measuring range 7-70l or 25-250l**;

(1.2.7) Gas Pump N3 KPE or N9 KPE**;

(1.2.8) Terminal X8

(** with version CSS-3... and CSS-3/C...)

Figure 3 Plan view of the components mounted on the Flow components sub panel

For maintenance it is possible to pull out the rack housing (1.2), without dismounting the complete

unit.

Gas sampling and gas conditioning technology 4-1.1-ME

Page 14

14

265

6

23

5

9

8

14

10 13

2120

Schnitt A-A

16

17

15 1924

1.2

Cooler

max. flow rate [l/h]

ECP 1000

140

ECP 2000

2 x 140

ECP 3000

350

NOTE!

The PSS must be stored in a weather-protected frost-free area ! Allows ade-

quate ventilation around the chassis !

Figure 4 Components mounted in the 19“ rack housing

The gas cooler (10) is fixed on the back panel of the 19“ rack housing. With respect to the maximum

flow rate required, the following versions are available:

Ambient air enters the chassis through the slots in the bottom (8) and top plate (9) of the 19“ rack

housing. This allows ventilation and cooling of the internal components including the gas cooler.

The cooler fan exhausts air out of the cut out in the side wall (6) of the 19“ rack housing.

The 3-way solenoid valve (14), for switching of the sample and test gas, is mounted in a special holder

(13) on the back panel (5).

Sectional view A-A in illustration 4 shows the two 2-way solenoid valves (16) and (17), for zero and

span gas. They are mounted with valve block (15) below the valve (14) on the back panel of the 19"

rack housing. Additional 3 span gas valves are possible as option (see page 8). The span gas valves

are preselected by snap switch 1.5 (Fig. 1).

The combined card for flow- and liquid alarm LFC-2 (20) is connected on the main circuit board (21).

The CSS is protected by fuse (F1= 2A, see wiring diagram in appendix).

Gas sampling and gas conditioning technology 4-1.1-ME

Page 15

15

10

7

435

258

X 1

Status X2

465

190,5

A

C G B

F

D

E I J

M

Power

connection

A1

L K H

N

All the electrical and tube-/hose connections are located on the back panel of the 19" rack housing.

These are:

(A) Sub-D-Plug X2 (see 10.2):

device status

- external status inquiry

measuring/test mode

internal ( the link between pin 1 and 9 is factory installed and

- control functions must exist for the local control to function)

external (with potential free contacts)

(A1) Reserve

(B) electrical junction box X1 (see 10.1):

- power supply

- option: connection heated sample line and temperature-sensor

(C)* sample gas inlet

(D) sample and test gas outlet 1 with Flow-Alarm

(E) sample and test gas outlet 2

(F) zero gas inlet

(G) span gas inlet

(H) condensate outlet

(I) test gas to the probe**

(J) ventilation**

(K) option: span gas 2 inlet, condensate outlet 2***

(L) option: span gas 3 inlet, sample gas outlet 3***

(M) sample gas inlet 2***

(N) option: span gas 4 inlet

Figure 5 Back-panel of the 19" rack housing

* (C) - (M) are PVDF G 1/4“ i fittings

** only version CSS.../C, test gas to probe

*** only version CSS-2

Gas sampling and gas conditioning technology 4-1.1-ME

Page 16

16

13

12

11

10

9

7

4

5 8 6

3 2 1

F G H

D

E

C

FM1

FM2

A

B

B2

FI1

M1

B1

E1

Y1

Y2

Y3

M1

CSS; CSS-3

Zero

gas

Span

gas

9

7

4

C

B1

E1

Y1

M K L

CSS-2

9 FUNCTION

The gas flow schematic of the CSS is shown in the following illustration.

Figure 6 Gas flow schematic

Principally, there are two main ways for gas to enter and flow through the CSS:

- sample gas flow (C, 4, 7, 9, 10, 12 and 13, D and E);

(version CSS-2 additional: M, 7, K);

- test gas flow (F or G, 5 or 6, 4, 7, 9, 10, 11, 12 and 13, D or E)

(Version CSS.../C: F or G, 5 or 6, I, 2, C, 4, ... see above).

The gas sample pump (10) transports the sample gas via the gas sample probe, consisting of a sample tube (1) and a filter (2), to the CSS. The heated sample line (3) is connected at the sample gas

inlet (C). In order to prevent early condensation of the sample gas, components (2) and (3) are

heated.

In the measuring mode, the 3-way solenoid valve (4) allows the flow to the gas cooler (7).

The dew point of the gas is maintained at a stable value of +5°C +/- 0,1 °C (for further specifications

see appendix).

Gas sampling and gas conditioning technology 4-1.1-ME

Page 17

17

The peristaltic pump (8) draws and removes the condensate via the condensation outlet (H) on back

panel.

The liquid alarm sensor (9) which located after the gas cooler protects the gas analysers in the event

of faulty gas drying. In the event of an alarm in the condensate removal, cooling or heating functions,

the 3-way solenoid valve is automatically closed. Also the measuring pump is switched off so that no

wet gases can reach the gas outlets (D) and (E). The alarm is shown on the operation and control

board of the CSS and is available on Sub-D-Plug X2 (A) as a status contact outlet (see 10.2.2 and

10.2.3).

After the sample gas pump (10) is a gas filter (11) for precipitation of the finest particles.

After the filter, the sample gas flows through both flow meters: the flow meters FM1 (12) and FM2 (13),

and the measuring outlets (D) and (E). Both flow meters are individually adjustable by a needle valve.

In order to keep the gas outlet dew point of 5°C, the total flow rate should not exceed the specified

maximum value (see 7.).

The minimum flow rate is determined by the sample gas pump (see 17.1). If the flow rate remains under the minimum value the pump membrane can be premature destroyed by over pressure.

The flow rate is controlled via needle valve on the flow meter FM1 and the optical bi stable flow sensor. The flow sensor can be moved on the flow meter glass and adjusted to an alarm value of your

choice. The flow is below the alarm value, this effects a flow alarm which is shown on the operation

and control board of the CSS and which is also available on Sub-D-Plug X2 (A) as a status contact

(see 10.2).

In the test mode, the 3-way solenoid valve (4) is switched to allow zero or span gas to enter the system. The inlets (F) and (G) are then available and the 2-way valves (5) or (6) open respectively.

Additional 3 span gas valves (K, L, N) are possible as option (see page 8). The span gas valves are

preselected by snap switch 1.5 (Fig. 1).

The versions CSS.../C are configured in such a way that the test gases first flow via the sample gas

probe and then via the sample gas inlet (C) to the gas cooler. Therefore, the CSS.../C is equipped with

the additional inlet fittings (I) and (J). The test gas outlet (I) is connected with the test gas inlet of the

sample gas probe.

In Version CSS-2 the gas cooler ECP2000 with two heat exchangers is mounted. Thus it is possible to

operate with a second independent sample gas flow. The sample gas line for the second independent

sample gas flow has to be connected to the inlet (M) and outlet (K) by customer. Condensate removal

happens via the condensate outlet (L). Sample gas pump, condensate pump, gas filter and alarm sensors have to be installed extern by customer.

In case of alarm, the 3-way solenoid valve opens automatically the gas way (4) - (J) and closes the

way (4) - (C). This guarantees that no sample gas or test gas can enter the system.

Zero and span gas both flow through the heat exchanger of the gas cooler. This configuration guarantees the same conditions during measuring and calibration.

The CSS gets its respective voltage via an electrical junction box X1 (B). Here, you can also find the

connections for the option "heated sample line with temperature controller" (specification see 10.1).

Gas sampling and gas conditioning technology 4-1.1-ME

Page 18

18

Electrical junction box X1

Power In 230V 50Hz, 150VA for CSS

Option controller 70304 for heated sample line

Power In 150V 60Hz, 1100VA for heated sample line

Power In 150V 60Hz, 1100VA for heated sample line

Connection for the temperature sensor of the heated sample line

PT100 / thermocouple +

PT100 / thermocouple -

PT100 (3-wire)

screening

10 ELECTRICAL CONNECTIONS

The electrical connections are located on the back panel of the 19“ rack housing (see fig.5)

10.1 ELECTRICAL JUNCTION BOX X1

Figure 7 shows the possible connections of the electrical junction box X1 (B).

For devices from 12/2001 to 01/2008 with controller 703: thermocouple + at terminal 11, thermocouple –

at terminal 12

Figure 7 Electrical junction box X1 (B)

The CSS is protected by fuse (F1= 2A, see wiring diagram in appendix). The fuse is located on the

main circuit board (see fig.4).

Gas sampling and gas conditioning technology 4-1.1-ME

Page 19

19

NOTE!

To guarantee the function of the CSS, the SUB-D-Plug must be mounted!

NOTE!

Breaking capacity : maximum 24V 1A!

10.2 SUB-D-PLUG X2

10.2.1 STATUS CONTACTS

Two potential free switches operating in ‘Safety-First’ function and guarantee an adequate signal for

CSS being in test mode, alarm mode or loosen voltage.

For one of the above mentioned situations the circuit is closed by the contacts MC (master contact, 5

and 15) ) and NC (normal closed, 7 and 14). In case that the CSS is ready for operation the contacts

MC and NO (normal open, 6 and 13) are switched.

Figure 8 Status contacts

The kind of alarm is displayed on the operation and control board (see fig.2).

Gas sampling and gas conditioning technology 4-1.1-ME

Page 20

20

NOTE!

For local control, the link between PIN 1 and 9 in the SUB-D-Plug is neces-

sary!

10.2.2 LOCAL CONTROL

For local control all functions of the CSS are effected by the operation and control board (functions

see 8.).

The way for gas to enter the CSS is chosen by operating the adequate switch on the operation and

control board (see 8.). All other possible gas ways will be automatically closed. This avoids measuring

inaccuracy by simultaneous feeding the CSS with different gases.

For version CSS.../C -test gas to sample gas probe (see 9.)- pin 1 and 4 in the Sub-D-Plug are

shorted-out.

Figure 9 Plan of terminal connections in the Sub-D-Plug X2 (A) for local control of the CSS... and CSS.../C

Gas sampling and gas conditioning technology 4-1.1-ME

Page 21

21

NOTE!

For external control, the link between PIN 1 and 9 in the D-SUB-Plug must

be removed!

Operating error by feeding the CSS simultaneous with sample- and test gas

must be excluded by customer!

10.2.3 EXTERNAL CONTROL

The external control off the CSS has to be realised by customer by means of potential free switches.

The selector switch functions of the control board (s. 8.) are out of operation.

Figure 10 Plan of terminal connections in the D-Sub-Plug X2 (A) for external control of the CSS... and

CSS.../C

For version CSS.../C -test gas to sample gas probe a link between pin 1 and 4 in the D-Sub-Plug is

mounted.

Gas sampling and gas conditioning technology 4-1.1-ME

Page 22

22

Terminal

Path

Connections

Terminal

Path

Connections

d2

power 230/115V

L

d32

alarm contact 2

NC

z2

power 230/115V

N

d12

FA sensor

brown

z4

power 230/115V

PE

d16

FA sensor

green

d4

supply

+15V up to +24V DC

d14

FA sensor

white

z4

supply

0V DC

z16

FA sensor

yellow

d8

LA sensor

shielding

z22

alarm contact 1

MC

z8

LA sensor

white

d22

alarm contact 1

NO

z28

alarm contact 1

MC

z24

alarm contact 1

NC

d28

alarm contact 1

NO

d24

alarm contact 2

MC

z30

alarm contact 1

NC

z26

alarm contact 2

NO

d30

alarm contact 2

MC

d26

alarm contact 2

NC

z32

alarm contact 2

NO

+

+

+

LM1830

IC2

5

10

11

+

9

47nF

12

1

7

14

+

3,9nF

gn

rtgnrt

gn

K1

K1

100nF

100nF

B5-bi

mono=offen

bi=geschlossen

B4+B5

B4-bi

open at mono

120-200mV

120-200mV

1µF

+

+

22µF

&

1412

7

3

4

&

65IC3 4093

br=brown/braun

gn=green/grün

rt=red/rot

ws=white/weiß

ge=yellow/gelb

V2-V5 Transistoren BC 239C

D3;D8-D12;D14 Dioden 1N4148

Relais K1;K2 max. 250V DC/AC 90W,250VA,1A

LFC-2 01E1385 T1=3,5VA Frontplatte 6TE

LFC-2CSS 03E2026 T1=7VA ohne Frontplatte

P5 = switch-off-hysterysis 3-13 sec.

P5 = Alarmfreigabeverzögerung 3-13 sek.

P6 = Alarmfreigabeverzögerung 3-13 sek.

P6 = switch-off-hysterysis 3-13 sec.

10-100k

K2

K2

X1

(DC +15V-24V)

d2

B2 115V

B1 230V

B3 115V

d4

z2

L 230V/115V

N 230V/115V

z4

(PE/DC 0V)

LA-Sensor

d8

LA-Sensor ws

z8

LA 1MC

z28

LA 1NO

d28

LA 1NC

z30

LA 2NC

LA 2NO

LA 2MC

d32

z32

d30

d12

FA-Sensor gn

d16

FA-Sensor ge

z16

FA-Sensor ws

d14

FA 2MC

FA 2NO

FA 2NC

d24

z26

d26

FA 1NC

FA 1MC

FA 1NO

z24

z22

d22

Steckerleiste DIN 41612 F-d/z

2x115V/2x15 3,5VA

T1

1N4007

D1

1N4007

D2

230V

B1 geschlossen/close

B2;B3 offen/open

115V

B2;B3 geschlossen/close

B1 offen/open

FA-Sensor br

470µF

C1

35V

IC1

7812

1µFC235VC335V

47µF

C4

35VC535V

D5

R2

470

D3

K1

D6

D7

ZPD 5,6

D41kR3

3k3

R24

BC239C

V1

D16

D15

3k3

R21

1k

R22

K2

D14

R1

39k

V4

V5

R17

47k

R18

220k

R19

47k

R20

220k

C8

35V

C9

16V

D13

ZPD9.1

R23

470k

R16

100k

R15

100k

P6

1M

P5

1M

R14

10k

R12

15k

R10

10k

P2

200k

R13

1k5

R11

56k

D9

D10

D11

D12

R8

10kR615k

C7

35V

C6

35V

V3

V2

R9

56kR756k

D8

P1

200kR5330

10.3 LIQUID- AND FLOW ALARM CARD LFC-2

The LFC-2 is a combined electronic card operating the flow alarm sensor FA1bi and the liquid alarm

sensor LA1.

Pulsating gas flow can release a unintentional flow alarm. To avoid this the LFC-2 is equipped with

slow operation -time lag to eliminate the alarm- and slow release -alarm with time lag. Times in between 3 and 13 seconds (3 seconds are factory-aligned) are continuously adjustable by the potentiometers P5 and P6 (see Fig. 11, wiring diagram LFC-2). For more specific information about the liquid

alarm sensor LA1 and the flow alarm sensor FA1bi please see the data sheets 5-6.10.1 and 5-5.1.1.

The plan of terminal connections is displayed in the following chart.

Gas sampling and gas conditioning technology 4-1.1-ME

Page 23

23

From Version 03.2000

Figure 11 Circuit diagram LFC-2

Gas sampling and gas conditioning technology 4-1.1-ME

Page 24

24

(1)

Actual value display

red, 10mm high, 4 digits

(4)

PGM-key in order to select parameters

in order to change values

in order to change values

Exit-key in order to leave the levels

(2)

Active Setpoint

Factory setting SP1

(5)

Indication

yellow for

- Switch status of binaryoutputs 1 – 6

(display lights up = on)

- ramp/programm function is active

- manual operation is active

(3)

Setpoint

Four digit, green; decimal place is configurable;

Also used for operator prompting (display of

parameter and level symbols)

(6)

16-segment display for the unit °C / °F

factory setting °C

11 DESCRIPTION OF THE OPTIONAL TEMPERATURE CONTROLLER 70304 FOR

HEATED SAMPLE LINES

Figure 12 Display/control elements

12 OPERATING PRINCIPLE OF THE CONTROLLER 70304

Operating and programming of the controller takes place on two levels. On the first level for normal

operation, alarms can be resetted or in case of startup a control circuit, self-optimising is activated.

Underneath there is the user level. All important adjustments of the controller are combined on the

user level and can be changed after removing the level inhibit.

12.1 PARAMETER OF THE USER LEVEL WITH FACTORY SETTING

Setpoint SP, factory setting = 180°C

Max. low temperature difference to the setpoint Lo-t, factory setting = 10°C. In case of falling

Gas sampling and gas conditioning technology 4-1.1-ME

below, an alarm signal takes place

Page 25

25

W AR NIN G!

Observe the maximum temperature of the device to be controlled

to avoid damaging the same.

Function of the controller Fnct, factory setting = 0 : fixed-setpoint controller. Other values are

not adequate for the operation of M&C products.

Sensor type SenS, factory setting = 2: Resistance thermometer in 2-wire circuit

1: Resistance thermometer in 3-wire circuit

2: Resistance thermometer in 2-wire circuit

4: Thermocouple

Linearization Lin, factory setting = 1, Pt100

1: Pt100

9: Fe-CuNi J

11: Fe-CuNi L

12: NiCr-Ni K

Further information is in the separate manual 2-5.1.1ME of the controller 70304. The manual is available for download on the M&C-website www.mc-techgroup.com.

13 CHANGE OF PARAMETERS

To change parameters the level inhibit on the user level has to be removed.

13.1 REMOVING AND ACTIVATING THE LEVEL INHIBIT

To remove the level inhibit, act as follows:

Standard display (below setpoint, up actual value ) has to be visible

Press key PGM and simultaneously for 5sec.,

display = Code 3 (all levels are locked)

Press PGM

Change value from 3 to 2 with key

The value is blinking after 2sec. and the change is taken over

The user level is unlocked now

Press EXIT

To activate the level inhibit, act as follows:

Standard display (below setpoint, up actual value ) has to be visible

Press key PGM and simultaneously for 5sec.,

display = Code 2 (all levels are locked)

Press PGM

Change value from 2 to 3 with key

The value is blinking after 2sec. and the change is taken over

The user level is locked now

Press EXIT

Gas sampling and gas conditioning technology 4-1.1-ME

Page 26

13.2 MENUE STRUCTURE

Lin

Exit

Time out >2 min

290 .0

300 .0

PGM

User

SP

ALSE

Lo-t

PGM

LFun

Fnct

rASL

SenS

PGM

Standard display

PGM

PGM

PGM

PGM

PGM

PGM

PGM

Exit

Changing parameters with or

Takeover of changed values after 2 sec.

Exit

SP = Setpoint

(ALSE = Excess temperature with

lock)

Lo-t = Low temperature alarm

(LFun = Limit comparator function)

Fnct = Function of controller

(rASL = Ramp slope)

SenS = Sensor type

Lin = Linearization

Parameter in brackets do not apply!

Generally:

Changing to the user level with PGM-key (display = User)

To choose the first parameter press PGM-key again (display = SP)

Changing to the next parameter with -key

Back to the standard display press EXIT-key (2x)

Figure 13 Menue structure

13.3 TIME OUT

If no operation takes place, the controller automatically returns to the standard display after about 2

minutes using any changed parameters.

Gas sampling and gas conditioning technology 4-1.1-ME

26

Page 27

27

NOTE!

The CSS must be stored in a weather-protected frost-free area!

NOTE!

The equipment is to be used in a vertical position only. The perfect

functioning of the seperation and drainage procedures will only be

guaranteed if the equipment is used in a vertical position.

The gas conditioning system should be installed in an area well away

from any heat emitting sources in order to prevent demage caused by

an accumulation of heat.

Pay attention to a non critical installation for individuals.

The compact gas conditioning system is preferably designed for

mounting in a cabinet. When the cabinet is installed outside, ample protection against the effects of direct sunlight and dampness must be

provided. In winter, the equipment must only be used in frost-free areas; pay attention to the protection class of the device.

In order to guarantee the operational safety of the gas conditioning system and the additionally connected analysers, and to avoid false

alarms, the gas conditioning system should not be used at temperatures other than those specified.

It is of great importance that the analysers which have been additionally connected be used at temperatures well above the specified gas

outlet dew point of +5°C. This prevents the gas in the connector lines

from condensing completely.

In the event of the unheated sample gas lines being connected to the

gas conditioning system on a slope, it is not necessary to carry out a

preliminary condensate removal.

14 RECEIPT OF GOODS AND STORAGE

The CSS is completely pre-installed and normally delivered in one packaging unit.

Please take the gas conditioning system and possible special accessories carefully out of the pack-

aging material immediately after arrival, and compare the goods with the items listed on the delivery

note;

Check the goods for any damage caused during delivery and, if necessary, notify your transport

insurance company without delay of any damage discovered.

15 INSTALLATION INSTRUCTIONS

The compact construction of the CSS means that it takes up little space and that the 19“ unit can be

excellently integrated within analysis systems.

Gas sampling and gas conditioning technology 4-1.1-ME

Page 28

28

NOTE!

The CSS is equipped with G1/4“i connections.

Do not mix up the hose connections: they are clearly marked. After all the hoses have been connected, the tightness of such leads

should be checked.

NOTE!

The tightness of the connections can only be guaranteed if the

connecting hose has a straight rim (hose cutter).

W AR NIN G!

Aggressive condensate is possible. Wear protective glasses and

proper protective clothing!

W AR NIN G!

False supply voltage can demage the equipment. When connecting the equipment, please ensure that the supply voltage is identical with the information provided on the model type plate!

16 SUPPLY CONNECTIONS

16.1 HOSE CONNECTION

Connection hoses with dimensions DN 4/6mm are utilised for all models.

The following lines have to be connected (Fig. 5):

sample gas line to connection (C) respectively to connection (M), operating with version CSS-2

(second independent gas flow);

zero gas line to connection (F);

span gas line to connection (G);

line -test gas to sample gas probe (CSS.../C)- to connection (I);

analyser(s) to outlets (D) and (E); maximum two sample gas outlets are available; with version

CSS-2 an additional sample gas outlet (K) is available;

connect the condensate hose to the outlet (H) respectively to the outlet (L), operating with version

CSS-2 ( second independent gas flow); the hose must be laid with slope to a ventilated sewer or

reservoir; it is absolutely necessary to install the ventilation outside the analysers cabinet and analysers house;

16.2 ELECTRICAL CONNECTIONS

Gas sampling and gas conditioning technology 4-1.1-ME

Page 29

29

NOTE!

For the erection of power installations with rated voltages up to 1000V, the

requirements of VDE 0100 and relevant standards and specifications must

be observed!

The main circuit must be equipped with a fuse corresponding to the nominal current (over current protection); for electrical details see technical

data.

Connect power supply (optional heated sample line with temperature sensor) to the correspond-

ing terminals of the electrical junction box X1 (Fig.7); intend for a main switch and a corresponding fuse protection; the dual coloured LED for local control shines green if the CSS is alive.

17 STARTING

Before starting the gas conditioning system please pay attention to the site-oriented and processoriented precautions.

The following description is valid for starting the device at ambient temperatures > +8°C.

The following steps should be carried out before initial start-up:

The function of the CSS is only guaranteed when the sub-D-plug X2 is mounted;

For internal control of the CSS a bridge between contact 1 and 9 in the sub-D-plug is necessary;

For external control of the CSS operating errors caused by feeding test- and sample gas simultaneous

have to be prevented by customer.

17.1 MEASURE

Turn switch to ‘On’ (see fig.2, LED green); for external control the dual coloured LED shines red;

Switching the CSS into operation displays the following alarms:

Cooler alarm (LED red):

after the cooler is ready for operation (cooler temperature >2°C and <8°C) the alarm is eliminated

(LED green). The 3-way solenoid (4) (see fig.6) opens automatically for sample gas and the sample

gas pump (10) (see fig.6) is ready for operation.

Flow alarm (LED red):

up to now there is no gas flow. Even when the ball of the flow meter passes the alarm value the alarm

is eliminated (LED green).

Turn switch to ‘Measure’ (LED yellow); available as contact outlet (see Fig.9);

If the cooler alarm is eliminated:

turn switch to ‘Pump on’ (LED green);

adjust flow meter with needle valve to the demanded value;

Gas sampling and gas conditioning technology 4-1.1-ME

Page 30

30

NOTE!

Adjust the flow meter FM1 to a flow rate above the demanded alarm value.

Because of breaking the outlet dew point (5°C) the total flow rate should not

pass the specified maximum value (see 2.).

The minimum flow rate is determined by the sample gas pump. This requires the following minimum values:

N3 KPE: approx. 60l/h;

N9 KPE: approx. 200l/h;

If the flow rate remains under the minimum value the pump membrane can

be premature destroyed by over pressure !

17.2 CHECK/CALIBRATION

turn switch to ‘Check’ (LED yellow); is available as contact outlet;

turn switch to ‘Test gas’ (LED yellow);

turn switch to ‘Zero gas’ (LED yellow);

After this calibration or checking the measuring range with zero gas can happen.

turn switch to ‘Span gas’ (LED yellow);

Now calibration or checking the measuring range with span gas can be started.

For returning to the measuring mode:

turn switch to ‘Sample gas’ (LED yellow);

If the analyser has reached the measuring range:

turn switch to ‘Measure’ (LED yellow).

Gas sampling and gas conditioning technology 4-1.1-ME

Page 31

31

NOTE!

For self-optimising of the control circuit, the heating of the heated

sample line must be connected to the appropriate terminals of the

CSS (s. 10.1).

W ARNIN G!

Before connecting the heated sample line, isolate the unit from

the supply!

NOTE!

Before stopping the CSS, sample gas should be expelled with

inert gas (Nitrogen or air).

The area in which the equipment is situated when not in use must

be kept free of frost at all times.

17.3 SELF-OPTIMISING (PID-FUNCTION) OF THE CONTROLLED SYSTEM

The controller type 70304 has the possibility of a self-optimisation-function if it operates as a PIDcontroller. In all M&C components this function is pre-adjusted. This means that a self-optimisation is

necessary starting up the component.

The self-optimising function can be activated as follows:

After cable connection (Figure 7), switch on the supply.

When the actual value (top display, red indicator)

reaches the setpoint value (bottom display, green indicator), press + keys simultaneously

for longer than 2 seconds. The word ”tUnE” now flashes in the setpoint value display and the

self-optimising function is activated.

Self-optimization has finished when the display changes to the standard display. The time of

self-optimizing depends on the control circuit.

To cancel the self-optimization press the keys + simultaneously.

The heated sample line now works in optimized operation.

18 CLOSING DOWN

For stopping the CSS carry out the following steps:

turn switch to ‘Pump off’ (LED red ); is not displayed on the control board in case of external control.

switch the CSS off; for local control turn the switch ‘On’ left (LED extinguishes)

Gas sampling and gas conditioning technology 4-1.1-ME

Page 32

32

W ARNIN G!

Dangerous voltage. It is necessary to take the equipment off the

mains before any assembly, maintenance or repair work is carried

out.

In order to do this the mains plug has to be removed from the

mains plug socket!

NOTE!

In order to protect the analysers which have been additionally

connected, it is recommended that in the event of a condensation

irruption the moist filter elements be replaced.

19 MAINTENANCE

Before the maintenance work is carried out, it is necessary that the specific safety procedures pertaining to the system and operational process be observed!

The frequency of the maintenance work depends on the operational process and can therefore only be

determined in each individual case. Maintenance instructions pertaining to individual components can

be found in the instruction manual for individual components.

All parts which require maintenance work are housed in the gas conditioning system in such a way so

that they are easily accessible. These are:

The filter element of the preliminary filter FPF-0,1GF.

The preliminary filter for the peristaltic pump PF2. If the condensate contains particle residue, the

preliminary filter should be replaced at regular intervals. The ‘one-way’ filter is situated in the suction side of the pump hose and can be easily replaced;

Hoses of the Condensate pump SR25.1. These should be checked every six months and, if neces-

sary, replaced;

Diaphragm of the sample gas pump N3KPE or N9KPE.. These should be checked every six

months and, if necessary, replaced;

20 DISMOUNTING THE FLOW COMPONENTS SUB PANEL

The dismounting of the flow components sub panel is carried out stepwise as follows:

check if the CSS is disconnected from all power supplies;

loosen the fastening screw from the flow alarm sensor;

remove the sensor from the flow meter glass;

turn the union nut of the liquid alarm sensor left by hand (fix the sensor while loosen the nut);

pull out the sensor of the flow chamber;

unscrew the hose connections of the condensate pump;

Gas sampling and gas conditioning technology 4-1.1-ME

Page 33

33

W ARNIN G!

Aggressive condensate is possible. Wear protective glasses and

proper protective clothing!

NOTE!

The flow components sub panel is not rail mounted!

release the fastening screws from the flow components sub panel;

pull out half the sub panel and lower so that the backside tube connections are accessible;

release the tube connections at the top of the flow meters FM1 and FM2;

disconnect the tube ‘flow chamber/heat exchanger’ on the side of the chamber;

pull out the hoses of the condensate pump through the guides in the sub panel;

pull out the plug in connection from the connector block X8 (see fig.3).

Now the sub panel can be completely taken out of the 19“ housing.

Mounting the sub panel happens in opposite order. Please pay attention to the following instructions:

mounting the plug in connection look out for the sequence of numbers;

after the implementation of the condensate hoses pay attention of possible folds;

tighten the union nut of the liquid alarm sensor by hand;

position the flow alarm sensor and tighten the fastening screw by hand.

21 ALARMS AND ELIMINATION

The alarms are displayed on the operation and control board (see fig.2) by LED’s. The alarms are

available as a status contact in the Sub-D-Plug (s. 10.2.2 u. 10.2.3).

21.1 VOLTAGE LOSS

At a voltage loss the operation and control board of the CSS is out of function and the LED’s are extinguished (see 8.). A signal is available at the alarm status contact in the Sub-D-Plug (s. 10.2.1).

Carry out the following controlling steps:

check the position of the main switch;

check the external fuse; if necessary exchange the fuse;

check the fine fuse (F1=2A, see circuit diagram in the appendix) on the main board of the CSS; if

necessary exchange the fuse.

Gas sampling and gas conditioning technology 4-1.1-ME

Page 34

34

21.2 COOLER ALARM/TEMPERATURE CONTROLLER ALARM

Cooler alarm is released if the cooler temperature is <2°C or >8°C, also

in the period till the CSS is ready for operation. As well cooler alarm is

released if the temperature controller (option) of the heated sample line

is out of range. The operative cooler/temperature controller opens the 3way solenoid valve and makes the function ‘Pump On’ possible.

For alarm elimination please check:

the function of the cooler; see separate manual 3-1.1-MD;

ambient temperature > 2°C ?

the function of the temperature controller; see separate manual 2-5.1.2-MD.

21.3 FLOW ALARM

The gas flow is adjusted by the flow meter FM1 and observed by an optical bi stable flow alarm sensor. The sensor can be moved on the flow

meter glass and adjusted to any alarm value. The sensor recognises the

variation in direction of the ball in the flow meter. If the ball passes the

alarm limit in the direction of increasing flow rates the alarm is eliminated. In opposite direction alarm is released.

Possible reasons for flow alarm are:

period till the CSS is ready for operation;

sample gas pump is out of order;

the flow rate is adjusted below the alarm limit;

cooler alarm/temperature controller alarm; the 3-way solenoid valve is automatically closed and the

sample gas pump is switched out of order;

liquid alarm; the 3-way solenoid valve is automatically closed and the sample gas pump is switched

out of order;

the tubes are blocked so gas flow isn’t possible;

The following steps are possible to eliminate the flow alarm:

check if the adjusted flow rate is above the alarm limit;

check if the sample pump is switched on (see fig.2, LED green);

check if there is no other alarm; correction see 21.2 and 21.4

check if the gas can passes the gas tubes.

If the alarm can not be eliminated in spite of the above mentioned steps the electronic card LFC-2 has

to be checked.

Gas sampling and gas conditioning technology 4-1.1-ME

Page 35

35

21.4 LIQUID ALARM

The M&C liquid sensor alarm unit LA1 is useful whenever liquid can

damage a gas analyser system. This may occur if a gas dryer unit or a

drain system fails.

The M&C LA1 liquid sensor is constructed in the following way that any

droplets of liquid in the sample gas are attracted under gravity to the

sensor surface and even the smallest liquid droplets trigger a sure and

rapid alarm.

In the event of an alarm the liquid alarm sensor switches the sample gas

pump off and closes the 3-way solenoid valve for sample gas.

To eliminate the alarm carry out the following steps:

switch the CSS off;

disconnect the line to the analyser;

open the sample gas inlet;

check the hoses of the condensate pump SR25.1; if they are defective change hoses;

switch power supply on and check the condensate pump if it works;

let the condensate pump work, until no more condensate is conveyed;

dismount the LA sensor;

dry the sensor;

remove the filter element from the gas filter FPF-0,1GF;

before starting the CSS with sample gas the gas ways must be dry. For this the CSS must be

sweeping about 1 hour with ambient air. The filter element remains dismounted and the sample gas

inlet and outlets remain open, disconnected from the system.

install dry or new filter element.

If the elimination of the alarm is not possible in spite of the above mentioned steps you should check

the following components:

gas cooler;

electronic card LFC-2.

Gas sampling and gas conditioning technology 4-1.1-ME

Page 36

36

19“ GAS CONDITIONING UNIT TYPE CSS...

(C) consumable parts, (R) recommended spare parts, (S) spare parts

recommended quantity

in operation [years]

Artikel-Nr.

Bezeichnung

C/R/S

1 2 3

Cooler ECP-1000/ECP-2000, ECP-3000: 10 (s. Fig.4)

93 K 1030

Jet-Stream heat exchanger ECP-1000/2000G 90°

R 0 1

1

93 K 0150

Jet-Stream heat exchanger ECP-3000G 90°

R 0 1

1

90 K 0115

Thermal conductivity paste, 50g

R 1 1

2

93 K 0020

Power supply board compl. for ECP1000-3000

R - 1

1

93 K 0530

ECP-1000 Netzteilplatine kompl.

R - -

1

93 K 0030

Fine fuse 0,8AT 5x20 ECP-1000

R 2 4

4

93 K 0540

Fuse 5 X 20, 1,6 AT for ECP-2000/3000

R 2 4

4

93 K 0010

ECP-1000 fan 12V DC

C - -

1

93 K 0036

Diode ECP-1000

R - -

1

90 K 2010

Rectifier for cooler type ECP1000-3000

R - -

1

90 K 2020

Power transistor BUZ11 for ECP1000-3000

R - -

1

93 K 0040

PT-100 temperature sensor

R - -

1

93 K 0045

ECP-1000 peltier element 4/4

R - -

1

93 K 0520

ECP-2000/3000 peltier element 6/6

R - -

1

90 K 0145

ECP-alarm relay DSP1

R - -

1

Peristaltic pump SR25: 1.2.2 (s. Fig.3)

90 P 1007

SR25 pump hose with PVDF tube connectors DN

4/6mm

C 1 2

4

90 P 1020

Driver complete for peristaltic pump SR25.1

S - 1

1

90 P 1010

Set contact spring for SR25.1 (4 pcs.)

R 1 2

2

90 P 1045

Contact pulley(1 pc.) for (2 pcs./pump required)

S 2 4

4

90 P 1050

Conveying belt for SR25

S - 1

2

90 P 1025

S-bolt S - - 1

01 P 1000

Peristaltic pump complete, 230/115V 50/60Hz

R - -

1

3-Way solenoid valve: 14 (s. Fig.4)

90 K 6040

3-Way solenoid valve, 230V f. CSS(/C)/CSS-3(/C)

S - -

1

90 K 6041

3-Way solenoid valve, 115V f. CSS(/C)/CSS-3(/C)

S - -

1

2-Way solenoid valve: 16 (s. Fig.4)

90 G 3000

2/2-way solenoid valve 6011 for CSS 230V 50Hz

for CSS(/C) and CSS-3(/C)

S - -

1

90 G 3005

2/2-way solenoid valve 6011 for CSS, 115V

for CSS(/C) and CSS-3(/C)

S - -

1

Universal filter FPF-0,1: 1.2.1 (s. Fig.3)

90 F 0009

Filter element type F-0,1GF50 0,1µm

R 4 8

12

90 F 0118

Filter glass F-45

R 1 2

2

90 F 0044

Viton-O-ring, 35 for FPF-0,1

R 1 2

2

90 F 0095

PVDF filter ement clamp FPF-GF

S - 1

1

22 SPARE PART LISTS

Wear, tear and replacement part requirements depend on specific operating conditions.

The recommended quantities are based on experience and are not binding.

Gas sampling and gas conditioning technology 4-1.1-ME

Page 37

37

19“ GAS CONDITIONING UNIT TYPE CSS...

(C) consumable parts, (R) recommended spare parts, (S) spare parts

recommended quantity

in operation [years]

C/R/S

1 2 3

Flowmeter FM40: 1.2.4 (s. Abb.3)

90 A 0015

Flow meter glass for FM40 range 7-70 l/h air

for version CSS... and CSS.../C

S - 1

1

94 F 0015

Flow meter glass for FM40 range 25-250 l/h

air for version CSS... and CSS.../C

S - 1

1

90 A 0018

Viton O-ring 9 für flow meter glass

R 2 4

6

09 F 4000

Flow meter FM40 7-70l/h (compl.),

for versions CSS... und CSS.../C

S - -

1

09 F 4010

Flow meter FM40 25-250l/h (compl.),

for versions CSS... und CSS.../C

S - -

1

Liquid sensor LA1S: 1.2.3 (s. Abb.3)

90 E 1000

O-ring, Viton - 14, LA1

R 1 2

3

90 E 1010

Ring, PVDF - 16, LA1

R 1 2

3

Fine-wire fuse CSS:

90 G 3010

Fuse 5 X 20mm, 2 AT for CSS

R 2 4

4

Internal tubing:

05 V 6600

Ferrule 4/6 PV

R

10

15

15

05 V 6605

Union nut M10-4/6 PV

R

10

15

15

02 B 1000

PTFE- tube NW 4/6, quantity per meter

S 2 4

6

10 T 1000

Hose cutter

S 1 1

1

Diaphragm pump type N3 KPE/KP18; N5 KPE/KP18

90 P 2100

Square cap type D3 for N3-N5 KPE, PVDF,

1/8"i

S - -

1

90 P 2120

Membrane type S3, Viton/PTFE for N3N5KPE

C 1 2

3

90 P 2115

O-Ring type O3, for N3-N5 KPE, 1pc., Viton,

(2 pcs./pump)

C 2 4

6

90 P 2110

Valve reed type V3, for N3-N5 KPE, 1 pc,

material: Viton

C 2 4

6

90 P 2105

Spacer type Z3, for N3-N5 KPE, material:

PVDF

S - -

1

Diaphragm pump type N9 KPE/KP18

90 P 2200

Square cap type D9 for N9 KPE, PVDF, 1/8"i

S - -

1

90 P 2220

Diaphragm type S9, for N9 KPE, material:

Viton/PTFE

C 1 2

3

90 P 2211

Valve plate with seal for N9 KPE, 1 pc., material: Viton. (2 pcs./pump)

C 2 4

6

90 P 2205

Spacer type Z9, for N9 KPE, material: PVDF

S - -

1

Gas sampling and gas conditioning technology 4-1.1-ME

Page 38

38

23 APPENDIX

Pin assignment for external drive of the CSS

Circuit diagram gas conditioning CSS,

drawing number : 2443-5.01.5;

CSS wit 4 x span solenoid valves,

drawing number : 2443-5.03.0;

For further product documentation, please see our internet catalogue:

www.mc-techgroup.com

Instruction manual electric gas cooler ECP 1000/2000/3000,

document : 3.1.1-ME

Instruction manual peristaltic pump SR25.1, SR25.1-G,

document : 3-7.1-ME

Instruction manual diaphragm pump series N

document : 6-1.2.1-ME

Instruction manual Universal-Filter FPF-0,1,

document : 5-0.1-ME

Flowmeter FM 40,

document : 5-6.1.10

Optical bi-stable flow alarm sensor FA-1, bi,

document : 5-6.10.1

Liquid alarm sensor LA1...,

document : 5-5.1.1

Temperature controller 70304,

document : 2-5.1.3-ME

Gas sampling and gas conditioning technology 4-1.1-ME

Page 39

39

12345678910111213

25 24 23 22 21 20 19 18 17 16 15 14

Endgas 4 EIN

Span gas 4 ON

Span gas 2 ON

Endgas 2 EIN

Span gas 1 ON

Endgas 1 EIN

Span gas 3 ON

Endgas 3 EIN

Prüfen NO

Check NC

Prüfen NC

Check NO

Status MC

Status MC

Status-Kontaktausgänge

Status-contacts

Schaltleistung 24V 1A

contact rating 24V 1A

Check MC

Prüfen MC

Status NC

Status NC

Meßgas EIN

Zero gas ON

Nullgas EIN

Sample ON

Prüfgas über Sonde nur bei Option CSS-C

Cal. gas to the probe only by option CSS-C

+15V

+15V

Pump ON

Pumpe EIN

Steuerung extern

Controll extern

Status NO

Status NO

CSS Ansteuerung von Extern

CSS controlling external

Achtung! Bei Steuerung intern ist die Brücke

1-14 im Dsub-Stecker unbedingt erforderlich. *

pin1 and 14 in the Dsub-plug is necessary. *

Attention! For function intern the link between

*

intern extern

Figure 14 Pin assignment for external drive of the CSS

Gas sampling and gas conditioning technology 4-1.1-ME

Page 40

40

Figure 15 Circuit diagram gas conditioning CSS

Gas sampling and gas conditioning technology 4-1.1-ME

Page 41

41

Figure 16 CSS with 4 x span solenoid valves

Gas sampling and gas conditioning technology 4-1.1-ME

Loading...

Loading...