Page 1

BA-C

Embracing Challenge

Air clean up supply series BA

Version BA-C

Special Features

High degree of purity:

Cn Hm < 0,1ppm,

H2O dew point < -100 °F

CO2 < 2ppm

Long service life

Minimum operating costs

Status self-monitoring

Compact, easy-to-use and easy-to-

service 19 inch plug-in or wall mounting

housing

Safe handling and easy servicing

Application

Dilution extractive technology requires a constant low dew point clean air supply that

removes the concentrations well below the

lower detection limits (LDL) of the analyzers

used. This translates to low ppb concentrations in some cases.

With ever decreasing concentrations of measured pollutants, an increased purity specification is required to maintain system repeatability since simply changing dilution ratios

can cause serious complications

The air clean up supply BA-C has been developed in order to achieve proper dilution air

for gas sample dilution probes (see data sheet

2-1.1.7), independent of gas cylinders.

The BA-C unit can also be used as a zero gas

generator when calibrating I.R.-analysers for

immission monitoring and for hydrocarbon

free burner air when measuring hydrocarbons

with a FID, FTIR and gas Chromatography also

need an ultra-pure reference as well as carrier

air supplies.

Description

The M&C-air clean up supply version BA-C has

been designed as compact, easy-to-use and

easy-to-service 19 inch and wall mounting

module.

With version BA-C compressed air is taken via

the rear-mounted air filter and is directed to

particle and condensate separation by means

of a high-performance filter (0.01 micron of

filter fineness) with an integrated, floating

condensate drainer.

There upon the compressed air is cleaned as

a result of low power catalytic oxidation by

means of a platinum/palladium catalyst of

hydrocarbon traces

(CnHm -> CO2 + 2H2O).

Drying the condensate-free compressed air

to <-100 °F dew point and removing NOx and

CO2 takes place in two mol sieve columns.

Technical specications and illustrations are without

obligation, subject to modications. 09.96/01.07

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

12.2

Page 2

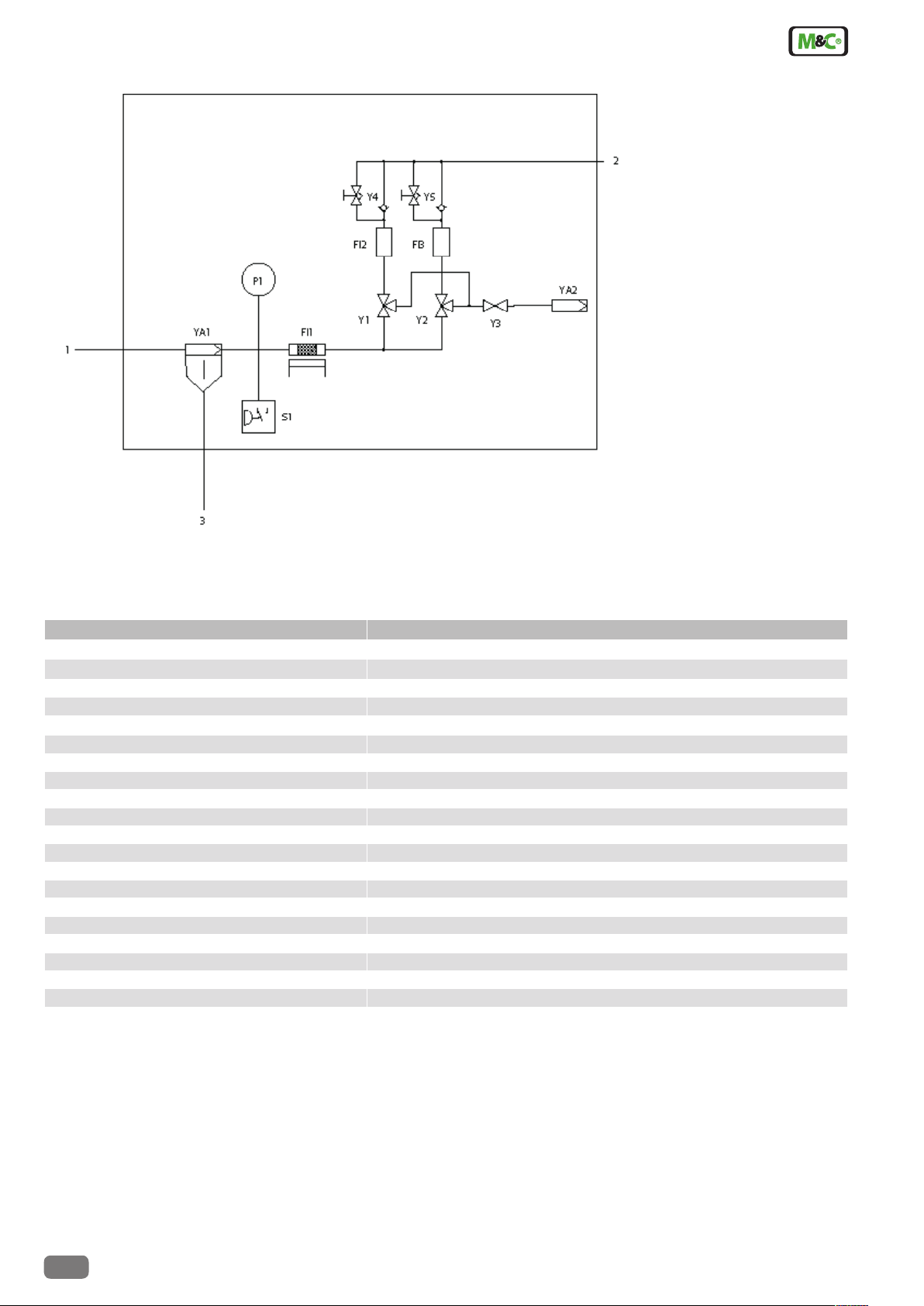

Functional diagram BA-C

1 Air inlet

2 Zero air outlet

3 Condensate outlet

FI1 Oxidizer

FI2 Mol sieve column

FI3 Mol sieve column

P1 Pressure gauge

S1 Pressure switch

Y1 Solenoid valve

Y2 Solenoid valve

Y3 Solenoid valve

Y4 Check/Needle valve

Y5 Check/Needle valve

YA1 Air filter with

condensate drainer

YA2 Sound absorber

Technical data

Air clean up supply series BA version BA-C

Part No. 60A3000A

Flow (lpm) max. 12

Instrument air inlet pressure (psig) 70 - 145

Ambient temperature +41 °F to +104 °F

Start up time approx. 5 min.

Air purity Total hydrocarbon content < 0,1 ppm Cn H

CO2 - concentration < 2 ppm

Dewpoint < -100 °F

Catalyst poisons Halogens, silicon, lead, materials containing phosphorous

Storage temperature -13 °F to +149 °F

Relative humidity <75 %, avoid condensation

Inlet gas connection compressed air in G1/4"i

Outlet gas connections G 1/4”i

Condensate connection G1/4” i

Power supply 115V 60Hz 150W

Status signal contact for pressure and temperature 1 contact - potential free, contact rating 24V, 1A

Case protection IP 20 EN60529

Wall mounting or 19”- housing dimensions (in) 6” x 19” x 10” (H x W x D)

Weight (lbs) approx. 46

Electrical equipment standard EN 61010

Notes:

1) Exceeds 40 CFR 72.2, 40 CFR 75 Appendix H and the Acid Rain Program CEMS Field Audit Program Manual zero grade air material requirements.

2) Custom conguration and higher purity specication are available on request.

m

12.2

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 09.96/01.07

Loading...

Loading...