Page 1

AD-T

Embracing Challenge

Automatic liquid drainer

Version AD-P; AD-T; AD-So

Separator

including automatic liquid drainer

Version ADS-P; ADS-T; ADS-So

Special Features

Save condensate removal and sepera-

tion

Optical function control

Dierent materials possible

Simple and immediate cleaning

Application

In gas sample conditioning systems and

especially in gas coolers, the M&C-automatic

liquid drainers AD-.. are used for continuous

draining of condensate.

The ADS-.. drainer has a modified upper part

with additional seperating function in order

to seperate and drain condensate from wet

gas sample flow.

The drainer only works in over-pressure systems.

Description

The AD-.. and ADS-.. drainer work by the

buoyancy principal.

In the unscrewable lower part, a buoyant

float close with its needle the valve seat as

long as its weight will be neutralized from the

bouyancy of the condensate level. Then the

float lifts up, opens the valve seat, condensate

drains off till the condensate level will be so

low, that buoyancy is lower than float weight.

The 3 different drainer versions differ in

the material. Type AD-P, AD-T, ADS-P and

ADS-T have got a float housing made of glass,

type AD-So and ADS-So have got a complete

stainless-steel housing.

Cleaning is very simple and immediatly done

because all parts are remowable. With type

AD-P, AD-T, ADS-P and ADS-T, draining function is visable from outside through the glass

housing.

Technical specications and illustrations are without

obligation, subject to modications. 04.95/06.06

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

6.12

Page 2

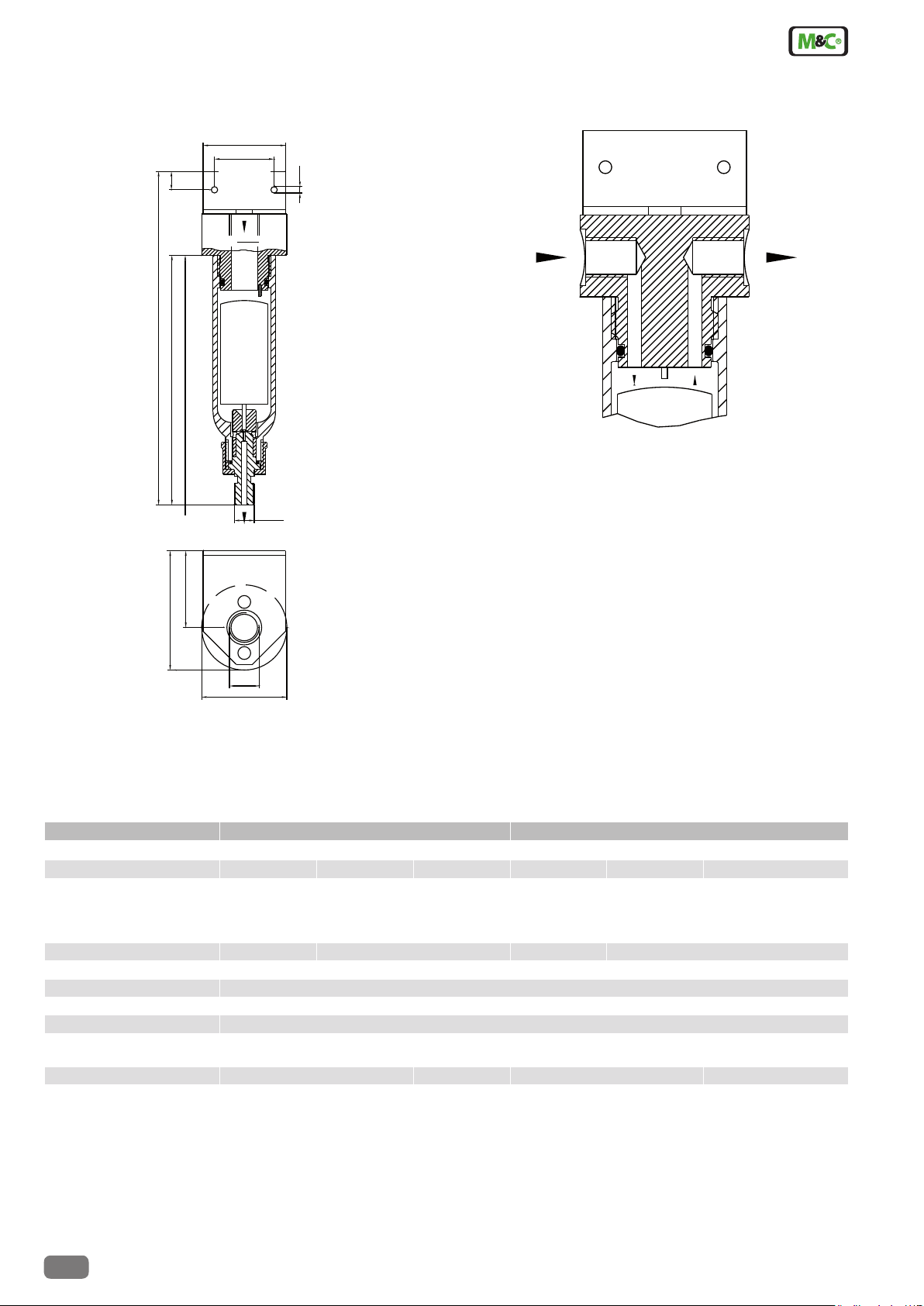

Dimensions

Liquid drainer AD-P/T/So

Condensate

13

176

235

Condensate OUT

58

42

IN

G1/2''i

G1/4"a

ø 5

Separator and liquid drainer ADS-P/T/So

Sample in

G1/4"i

Sample out

G1/4"i

84

54

G1/2"i

ø 60

Dimensions in mm

Technical Data

Liquid drainer Separator and drainer

AD-P AD-T AD-So ADS-P ADS-T ADS-So

Part No. 09K1000 09K2000 09K2500 09K6000 09K7000 09K7500

Material:

Housing

Float

Valve seat, O-rings

Operating temperature 60 °C 90 °C 60 °C 90 °C

Operating pressure 1-2 bar abs.

Function down to min. density 0,7 kg/dm3, at 1 bar

Drain capacity max. 2 l/hr H2O, at 1 bar and 20 °C

Mounting position vertical

Connections Condensate in: G1/2" i DIN ISO 228T1

Weight 0,35 kg 1,5 kg 0,35 kg 1,5 kg

PP, Glass

PP

PTFE, FPM

PTFE, Glass

PVDF

PTFE, FEP

Condensate out: G1/4" a DIN ISO 228T1

SS 316Ti

PVDF

PTFE, FPM

PP, Glass

PP

PTFE, FPM

PTFE, Glass

PVDF

PTFE, FEP

Sample in / out: G1/4"i DIN ISO 228T1

Condensate out: G1/4"a DIN ISO 228T1

SS 316Ti

PVDF

PTFE, FPM

6.12

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

info@mc-techgroup.com • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

Technical specications and illustrations are without

obligation, subject to modications. 04.95/06.06

Loading...

Loading...