Page 1

Page 2

Page 3

INTRODUCTION

This manual covers only the mechanical aspects of WHR chillers equipped with the

trol. All of the operating, safety control and installation requirements of the

MicroTech

MicroTech

reciprocating chiller con-

control are coveted in the separate

Installation and Maintenance Bulletin 493, which must be consulted before startup and operation is attempted.

GENERAL

McQuay Type WHR SEASONPAK water chillers are designed for indoor installations and are compatible with either

air or water as a condensing medium. Each unit is completely assembled and factory wired before evacuation, charging

and testing. Each unit consists of multiple accessible hermetic

compressors, replaceable tube dual circuit shell-and-tube

evaporator, water cooled condenser, and complete or partial

refrigerant piping depending on the condensing medium.

Liquid line components that are included are manual liquid

line shutoff valves, charging valves, filter-driers, liquid line

solenoid valves,

sightglass/moisture indicators, and balance

DESCRIPTION

port type thermal expansion valves. Other features include

compressor crankcase heaters, recycling

pumpdown

“on” or “off” seasons, compressor lead-lag switch to alternate the compressor starting sequence, and sequenced starting of compressors.

The electrical control center includes. all safety and operat-

ing controls necessary for dependable automatic operation.

Compressors are not fused, but may be protected by optional circuit breakers, or may rely on the field installed

fused disconnect for protection.

NOMENCLATURE

W HR

- 040

D W

-

Nominal Capacity (Tons)

Basic Unit with Single Water Cooled

H

-

Basic Unit with Dual Water Cooled Condensers per Refrigerant Circuit

Condenser per Refrigerant Circuit

INSPECTION

When the equipment is received, all items should be careful-

ly checked against the bill of lading to insure a complete

ship-

ment. All units should be carefully inspected for damage upon

arrival. All shipping damage should be reported to the

car-

rier and a claim should be filed. The unit serial plate should

be checked before unloading the unit to be sure that it agrees

with the power supply available. Physical damage to unit after

acceptance is not the responsibility of McQuay.

NOTE: Unit shipping and operating weights are available

in the physical data table (pages 21 through 23).

during

INSTALLATION

NOTE: Installation and maintenance are to be performed only by qualified personnel who are familiar with local codes

and regulations, and experienced with this type of equipment. CAUTION: Sharp edges are a potential injury hazard.

Avoid contact.

HANDLING

Every model WHR SEASONPAK water chiller with water

cooled condensers (Arrangements W and H) is supplied with

a full refrigerant charge. A holding charge is supplied in

condenserless models (Arrangement A). For shipment the charge

is contained in the condenser and is isolated by the manual

condenser liquid valve and the compressor discharge service valve.

MOVING

The McQuay SEASONPAK water chiller is mounted on heavy

wooden skids to protect the unit from accidental damage and

to permit easy handling and moving.

It is recommended that all moving and handling be performed with the skids under the unit when possible and that

the skids not be removed until the unit is in the final location.

When moving the unit, dollies or simple rollers can be

used under the skids.

Never put the weight of the unit against the control box.

In moving, always apply pressure to the base on skids only and not to the piping or shells. A long bar helps move the

unit easily. Avoid dropping the unit at the end of the roll.

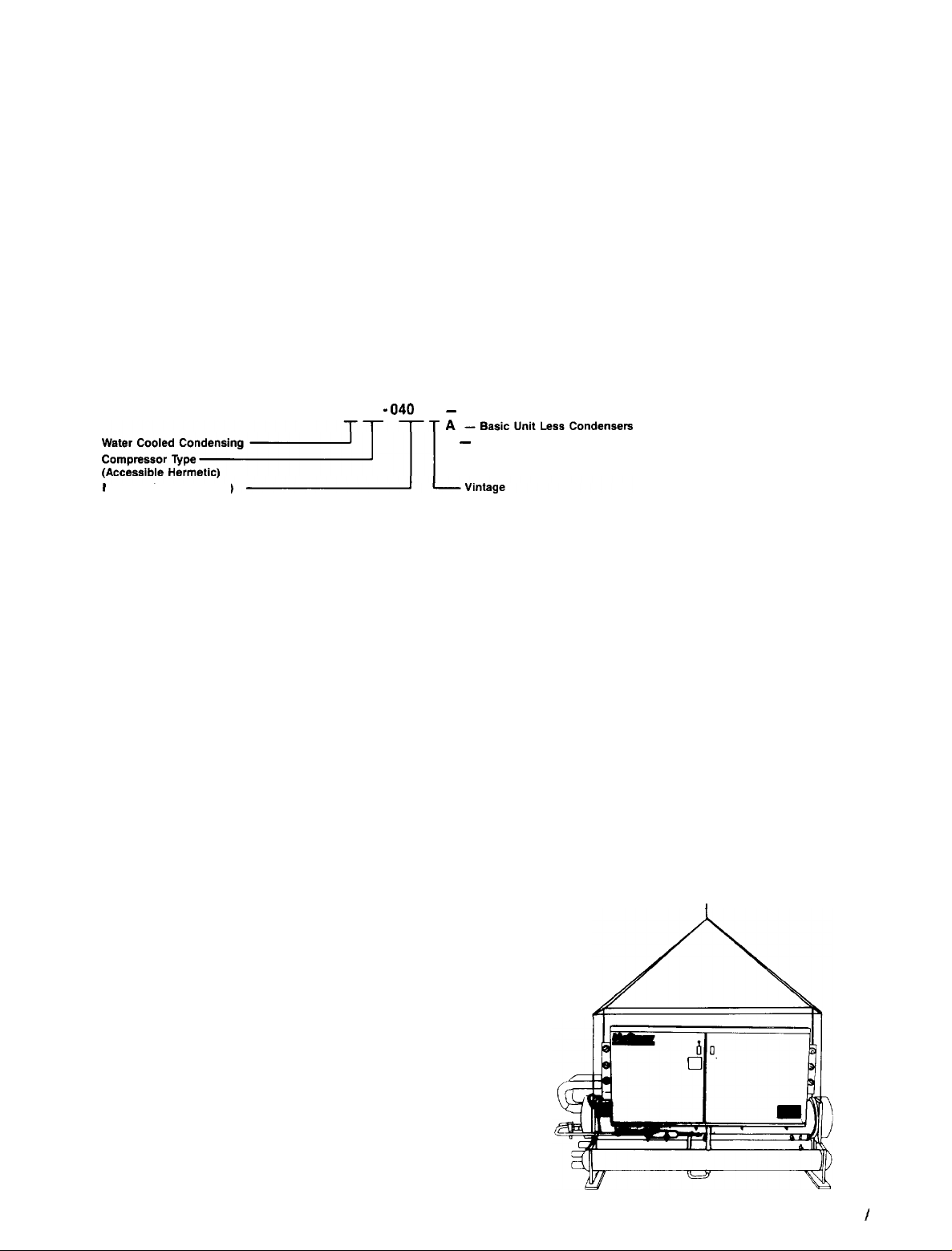

If the unit must be hoisted, it is necessary to lift the unit

by attaching cables or chains at the lifting holes in the

evaporator tube sheets. Spreader bars must be used to protect the control cabinet and other areas of the chiller (see

Figure 1).

Should the unit be damaged, allowing the refrigerant to

escape, there may be danger of suffocation in the equipment

area since the refrigerant will displace the air. Avoid exposing an open flame to refrigerant. Care should be taken to avoid

rough handling or shock due to dropping the unit. NEVER

LIFT, PUSH OR PULL UNIT FROM ANYTHING OTHER

THAN THE BASE.

THE UNIT

Figure 1.

I

IM 508 / Page 3

Page 4

Do not attach slings to piping or equipment. Move unit in

the upright horizontal position at all times. Set unit down gently

when lowering from the trucks or rollers.

240D,

NOTE: On unit sizes 120 through

ordered with the

LOCATION

Unit is designed for indoor application and must be located

in an area where the surrounding ambient temperatures are

40°F or above. A good rule of thumb is to place units where

ambients are at least 5 degrees above the leaving water

temperature.

Because of the electrical control devices, the units should

not be exposed to the weather. A plastic cover over the

con-

optional acoustical enclosure, there will be extension brackets

attached to the evaporator tube sheets. These brackets will

be used for hoisting the unit and should be removed when

unit is in place.

trol box is supplied as temporary protection during transfer.

A reasonably level and sufficiently strong floor is all that

is required for the SEASONPAK water chiller. If necessary,

additional structural members should be provided to transfer

the weight of the unit to the nearest beams.

NOTE: Unit shipping and operating weights are available

in the physical data table, pages 21 through 23.

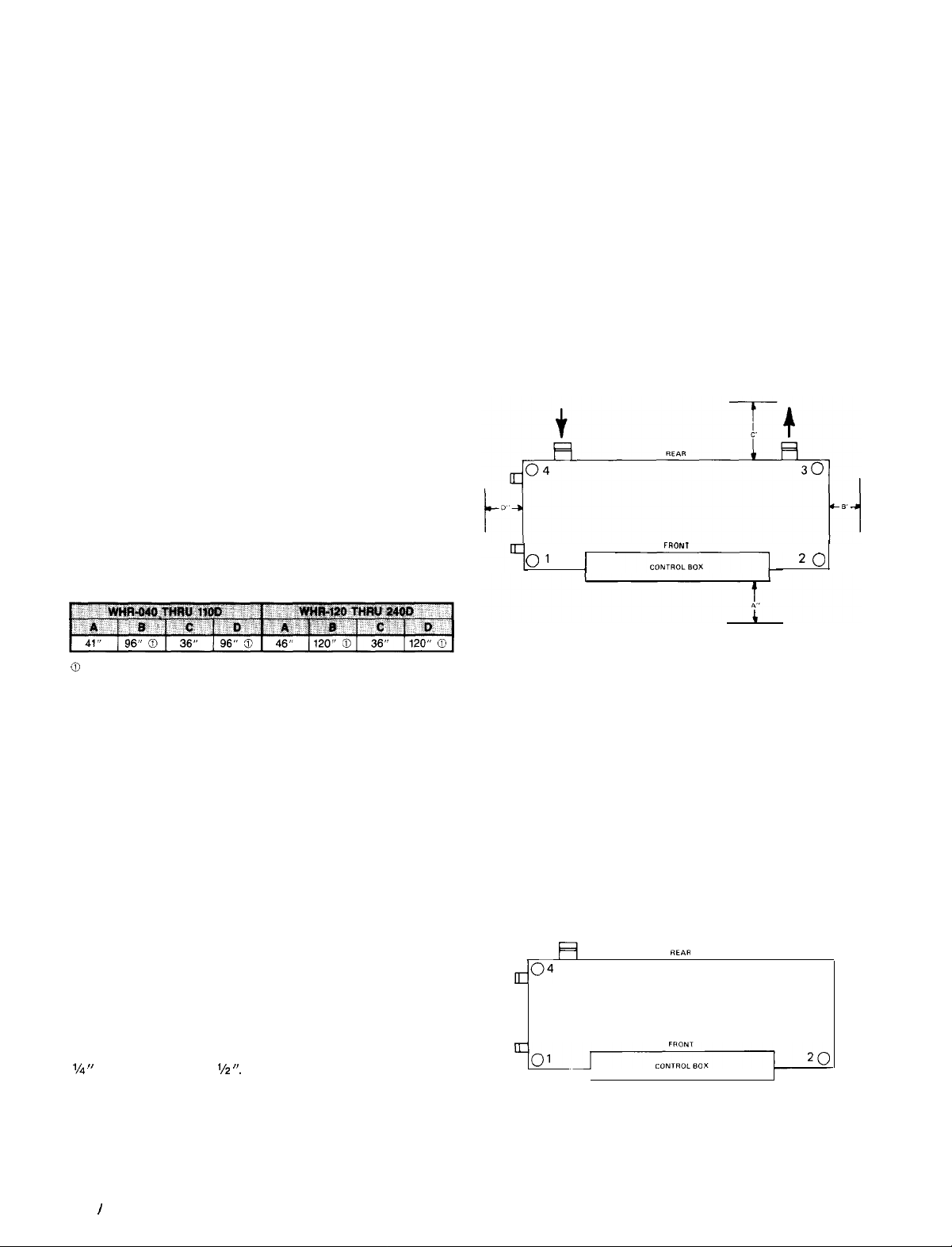

SPACE REQUIREMENTS FOR

The chilled water piping for all units enters and leaves the

cooler from the rear, with the control box side being the front

side of the unit. A clearance of 3 to 4 feet should be provided for this piping and for replacing the filter-driers, for servicing the solenoid valves, or for changing the compressors,

should it ever become necessary.

The condenser water piping enters and leaves the shell

from the ends. Work space must be provided in case water

regulating valves are being used and for general servicing.

Clearance should be provided for cleaning condenser tubes

or for removing cooler tubes on one end of the unit as

specified in Table 1. It is also necessary to leave a work area

on the end opposite that used for replacement of a cooler tube.

Table 1. Minimum recommended clearance requirements

0

Minimum clearance required for removal and replacement of cooler tubes

(either end).

PLACING THE UNIT

The small amount of vibration normally encountered with the

SEASONPAK water chiller makes this unit particularly desirable for basement or ground floor installations where the unit

can be bolted directly to the floor. The floor construction

should be such that the unit will not affect the building

struc-

ture, or transmit noise and vibration into the structure. See

CONNECTIONS AND SERVICING

Figure 2. Clearance requirements

FRONT

0'

I

20

vibration isolator section for additional mounting information.

240D,

NOTE: On the WHR 120D thru

shipping bolts are

used to secure the compressor rails to the evaporator

brackets. Remove these and discard after unit is mounted and

before unit is started.

Rubber-in-shear or spring isolators can be furnished and field

placed under each corner of the package. It is recommended that a rubber-in-shear pad be used as the minimum

isolation on all upper level installations or areas in which

tion transmission is a consideration.

Transfer the unit as indicated under “Moving the Unit.” In

all cases, set the unit in place and level with a spirit level.

When spring type isolators are required, install springs running under the main unit supports. Adjust spring type mountings so that upper housing clears lower housing by at least

l/4 ”

and not more than

l/z “.

A rubber anti-skid pad should be

used under isolators if hold-down bolts are not used.

Vibration eliminators in all water piping connected to the

SEASONPAK water chiller are recommended to avoid straining the piping and transmitting vibration and noise.

I

Page 4

IM 508

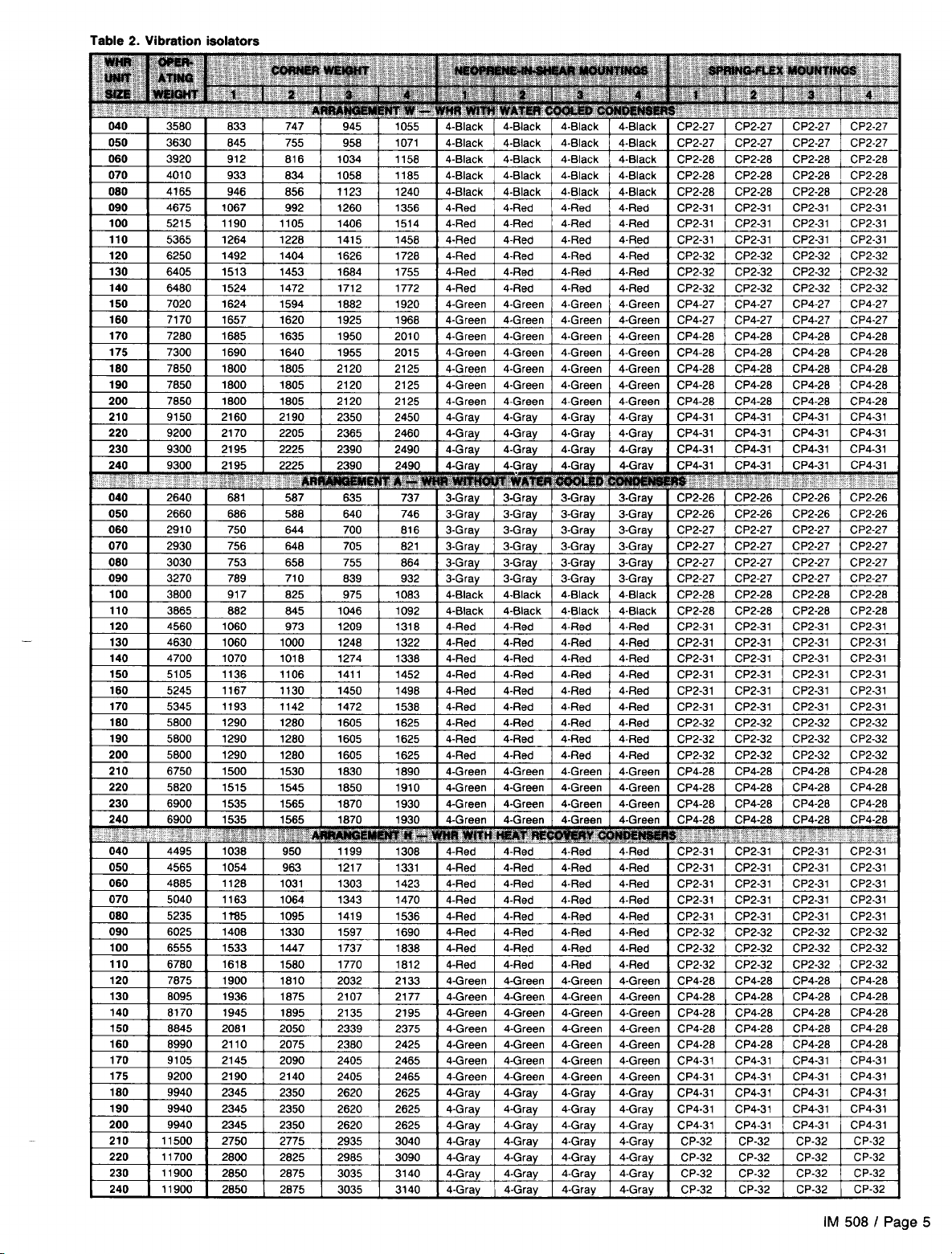

VIBRATION ISOLATORS

Figure 3. Isolator Locations

vibra-

;04

REPlR

a

30

Page 5

Page 6

Table 3. Spring Flex Isolators

Figure 4. Spring Flex Mountings

POSITIONING PIN

ADJUST MOUNTING SO UPPER

HOUSING CLEAR3 LOWER HOUSING

SY

‘/2”

DIA

AT LEAST %S 8 NOT

ACOUSTICAL NON-SKID

NEOPRENEPAD

WATER PIPING

GENERAL

Since regional piping practices vary considerably, local ordinances and practices will govern the selection and installation of piping. In all cases local building and safety codes and

ordinances should be studied and complied with.

All piping should be installed and supported to prevent the

unit connections from bearing any strain or weight of the

system piping.

Vibration eliminators in all water piping connected to the

unit are recommended to avoid straining the piping and

transmitting pump noise and vibration to the building

structure.

It is recommended that temperature and pressure indicators

be installed within 3 feet of the inlet and outlet of the shells

to aid in the normal checking and servicing of the unit.

A strainer or some means of removing foreign matter from

Figure 5. Single Neoprene-in-Shear

Mounting

“S” DIA

POSITIONING PIN

“D” D,A

the water before it enters the unit or the pump is recommended. It should be placed far enough upstream to prevent

cavitation at the pump inlet (consult pump manufacturer for

recommendations). The use of a strainer will prolong pump

life and thus keep system performance up.

A preliminary leak check of the water piping should be

made before filling the system.

Shutoff valves should be provided at the unit so that normal servicing can be accomplished without draining the

system.

A WATER FLOW SWITCH OR PRESSURE DIFFERENTIAL

SWITCH MUST BE MOUNTED IN THE WATER LINES TO

THE EVAPORATOR TO ASSURE WATER FLOW BEFORE

STARTING THE UNIT

CHILLED WATER PIPING

The water flow entering the cooler must always be on the end

nearest the expansion valves and cooler refrigerant connec-

tions to assure proper expansion valve operation and unit

capacity (see pages 16 thru 20).

Design the piping so that it has a minimum number of

changes in elevation. Include manual or automatic vent valves

at the high points of the chilled water piping, so that air can

be vented from the water circuit. System pressures can be

Page 6

I

IM 508

maintained by using an expansion tank or a combination

pressure relief and reducing valve.

All chilled water piping should be insulated to prevent condensation on the lines. If insulation is not of the self-contained

vapor barrier type, it should be covered with a vapor seal.

Piping should not be insulated until completely leak tested.

Vent and drain connections must extend beyond proposed insulation thickness for accessibility.

Page 7

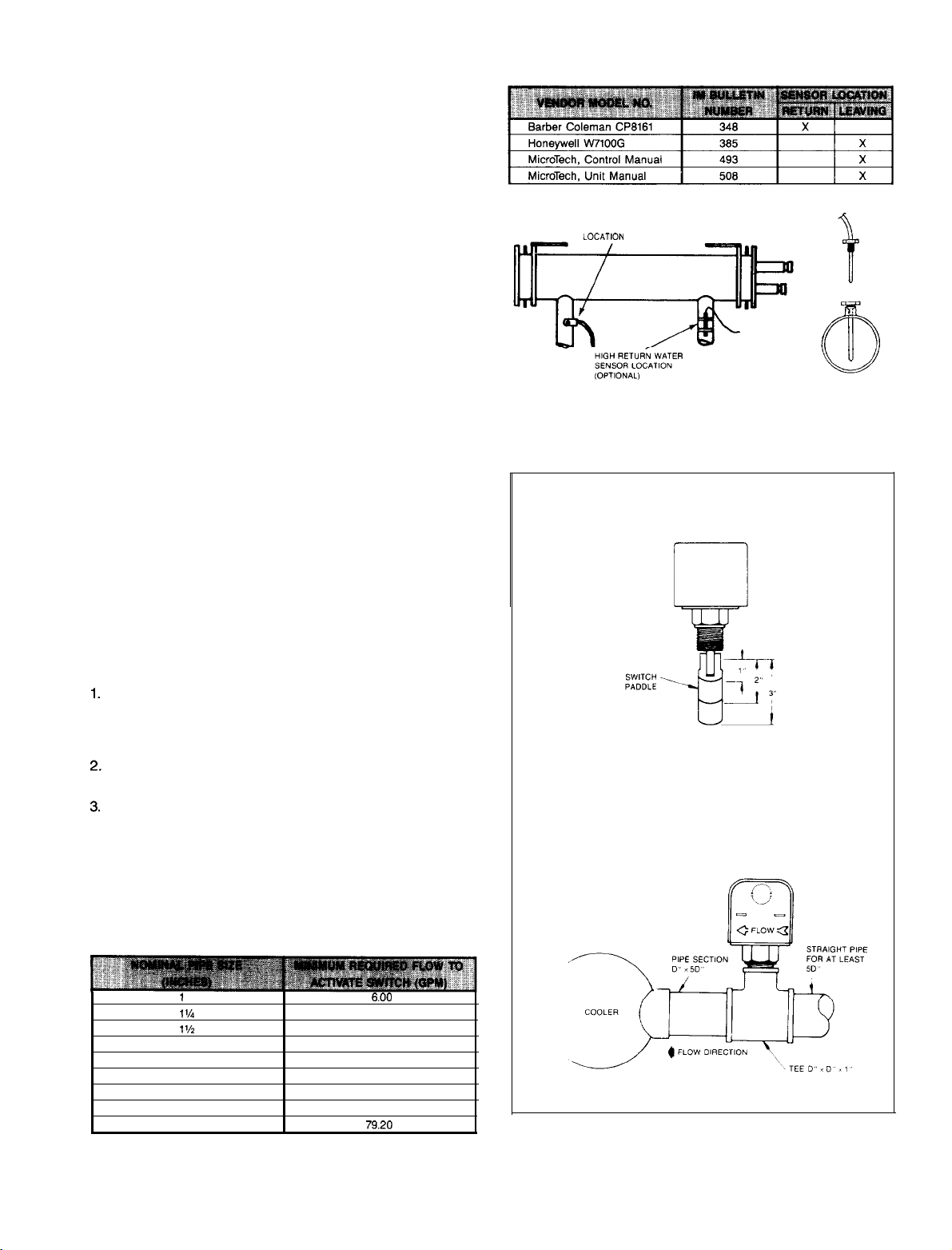

CHILLED WATER SENSOR

On units WHR-040D thru

240D.

the chilled water sensor is

factory installed in the leaving water connection on the

evaporator. For detailed specifications regarding the chilled

water sensor or any other sensors/transducers, refer to IM 493.

Care should be taken not to damage the sensor cable or leadwires when working around the unit. It is also advisable to

check the leadwire before running the unit to be sure that it

is firmly anchored and not rubbing on the frame or any other

component. Should the sensor ever be removed from the well

for servicing, care should be taken as not to wipe off the heat

conducting compound supplied in the well.

NOTE: See IM 493 for additional thermostat information.

CAUTION: The thermostat bulb should not be exposed to

water temperatures above 125°F since this will damage the

control.

FLOW

A WATER FLOW SWITCH MUST SE MOUNTED in either the

entering or leaving water line to insure that there will be ade-

quate water flow and cooling load to the evaporator before

the unit can start. This will safeguard against slugging the

compressors on startup. It also serves to shut down the unit

in the event that water flow is interrupted to guard against

evaporator freeze-up.

A flow switch is available from under ordering number

1750338-00. It is a “paddle” type switch and adaptable to any

pipe size from

1”

to 6” nominal. Certain minimum flow rates

are required to close the switch and are listed in Table 6. Installation should be as shown in Figure 7. The flow switch

should be wired per actual unit wiring diagram found on the

inside of the unit control panel door or refer to IM 493.

Apply pipe sealing compound to only the threads of the

switch and screw unit into

Figure

7).

The flow arrow must be pointed in the correct

D”x D”x 1”

reducing tee (see

direction.

Piping should provide a straight length before and after

the flow switch of at least five times the pipe diameter.

Trim flow switch paddle if needed to fit the pipe diameter.

Make sure paddle does not hang up in pipe.

CAUTION: Make sure the arrow on the side of the switch is

pointed in the proper direction of flow. The flow switch is

designed to handle the control voltage and should be connected according to the wiring diagram (see wiring diagram

inside control box door).

Table

Figure 6.

SWITCH

Fioure 7.

5.

Thermostat Well Installation

TEMPERATURE SENSOR

LOCATICJN

FLOW SWITCH

VIEW FROM END OF COOLER

Table 6. Flow Switch Minimum Flow Rates

1

1%

l'h 12.70

2 18.80

2%

3

4

5

24.30

30.00

39.70

58.70

6.00

9.80

IM 508 I Page 7

Page 8

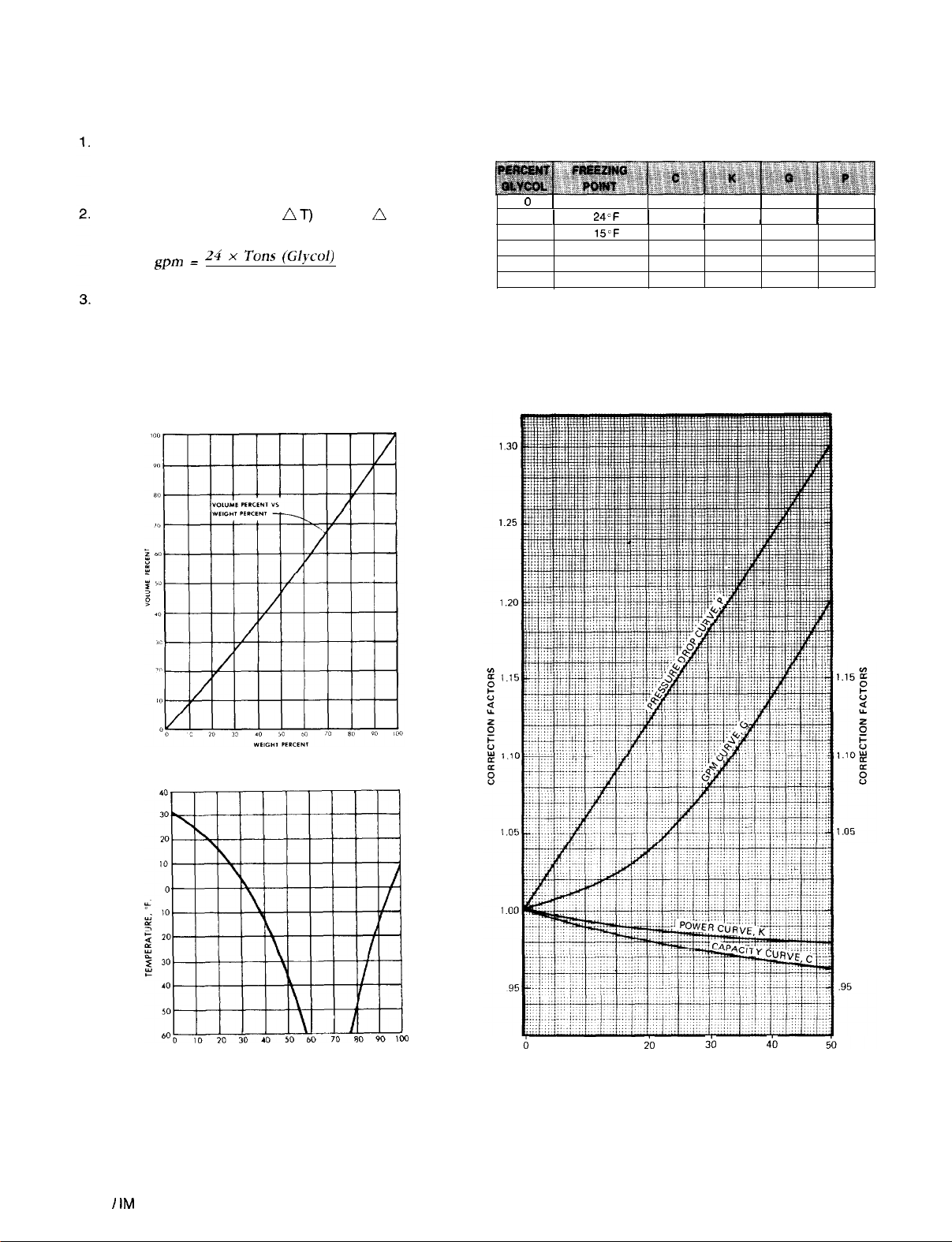

GLYCOL SOLUTIONS

The system glycol capacity, glycol solution flow rate in gpm,

and pressure drop through the cooler may be calculated

us-

ing the following formulas and table.

-

CAPACITY

Capacity is reduced from that with plain

water. To find the reduced value multiply the chiller’s water

system tonnage by the capacity correction factor C to find

the chiller’s capacity in the glycol system.

/I T)

GPM -To determine gpm (or

knowing n T (or gpm)

and tons:

Glvcol gp:pm = 24 x Tons (WW

,

AT

x G (from table)

PRESSURE DROP -To determine glycol pressure drop

through the cooler, enter the water pressure drop graph

on page 9 at the glycol gpm. Multiply the water pressure

drop found there by P to obtain corrected glycol pressure

drop.

Test coolant with a clean accurate glycol solution hydrometer

(similar to that found in service stations) to determine freezing point. Then obtain percent glycol from the freezing point

table below.

0

1

10

1

20

30

40

50

CONDENSER

j

1.000

1

32°F

24'F

15'F

-12°F 0.968

-33°F 0.964

-

1

1.000

/

1

0.990

0.981

4°F 0.974

0.994

'

0.988

0.984

0.981 1.13

0.980

The use of a glycol solution in the heat

1.00

1

1.01

1.04

1.08

1.20

1.00

1

1.06

1

1.12

1.18

1.24

1.30

recovery condensers will not affect heat recovery capacity.

1.30

1.25

PERCENT BY VOLUME

lb

% ETHYLENE GLYCOL BY WEIGHT

i0

3b

1.20

100

4-o

Page 8 I IM 508

Page 9

Page 10

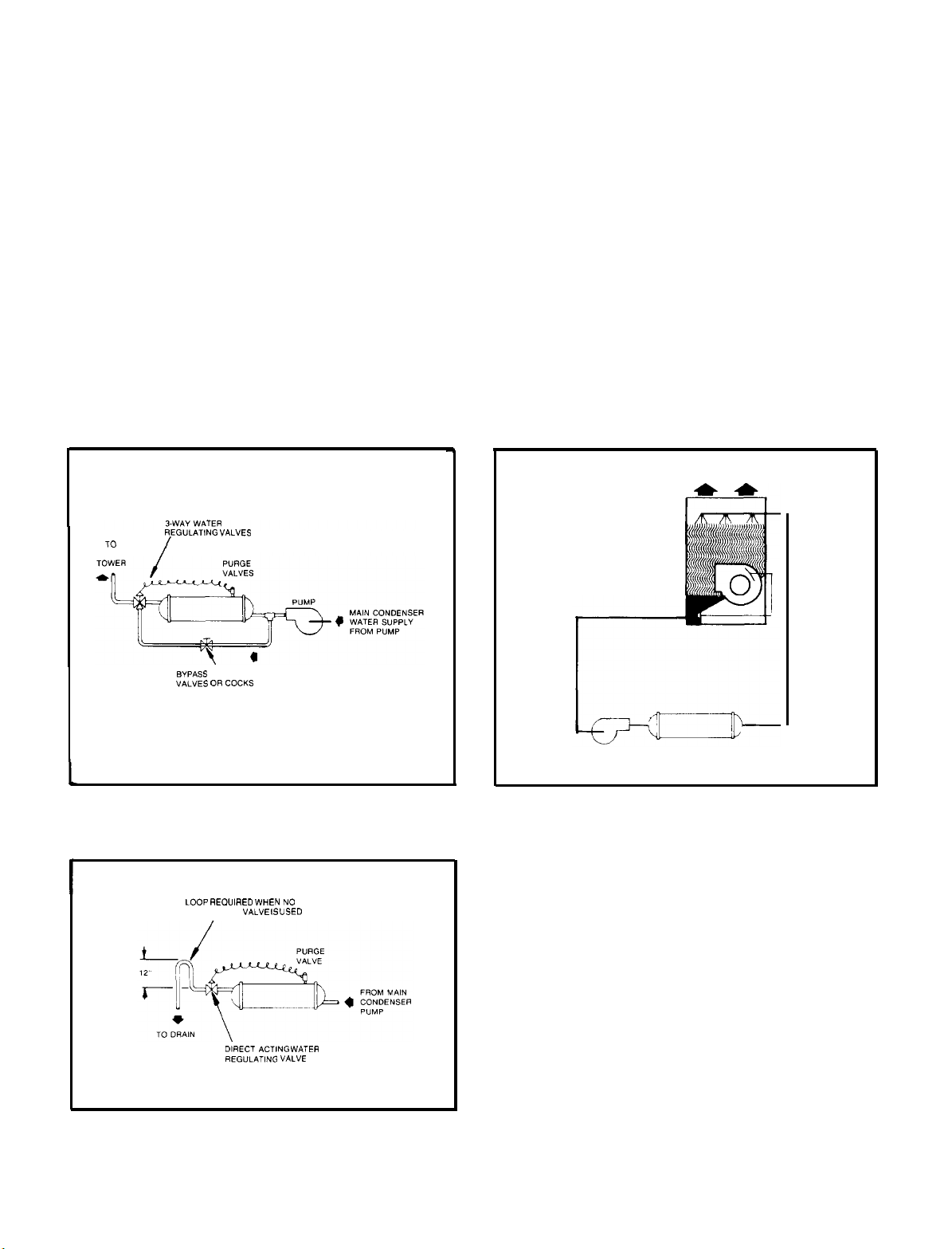

CONDENSER

WATER PIPING

GENERAL - For proper performance, the condenser water

must enter the bottom connection of the condenser. Water

cooled condensers may be piped for use with cooling towers,

well water or heat recovery applications. Cooling tower applications should be made with consideration to freeze protection and scaling problems. For specific applications, contact cooling tower manufacturer for equipment characteristics

and limitations.

HEAD PRESSURE CONTROL, TOWER SYSTEM

-

Some

means of controlling operating head pressure must be provided. Minimum condensing temperature allowed is 80°F.

Minimum entering tower condenser water temperature is

70°F. Typical systems are shown in Figures 8 and 9. In Figure

8, a three-way pressure actuator water regulating valve is

used for cooling applications, In Figure 9 the capacity of the

cooling tower is controlled through damper and/or fan

COOLING TOWER SYSTEMS-HEAD PRESSURE CONTROL

Figure 8. 3-Way Water Valve

TO

COOLING

REGULATING VALVES

modulation. These typical systems, depending on the specific

application, must maintain a constant condensing pressure,

regardless of temperature conditions and must assure

enough head pressure for proper thermal expansion valve

operation. Note also that both systems assure full water flow

to the tower.

HEAD PRESSURE CONTROL, WELL WATER SYSTEM

-

Where well water is used for condensing refrigerant, a direct

acting water regulating valve is recommended (see Figure

10). The valve is normally installed at the outlet of the con-

denser. On shutdown, the valve will close and, in this way,

prevent water siphoning out of the condenser. Siphoning

causes drying of the waterside of the condenser and rapid

build-up of fouling. When no valve is used, a loop at the outlet

end is recommended (See Figure 10).

Figure

9. Fan

Modulation

COOLING TOWER

BYPASS

BALANCING

VALVES OR COCKS

Figure 10. Well Water Cooling System

I

LOOP REOUIAED WHEN

REGULATING VALVE IS USED

DIRECT

REGULATING VALVE

NO

ACTlNG

WATER

Page 10 I IM 508

Page 11

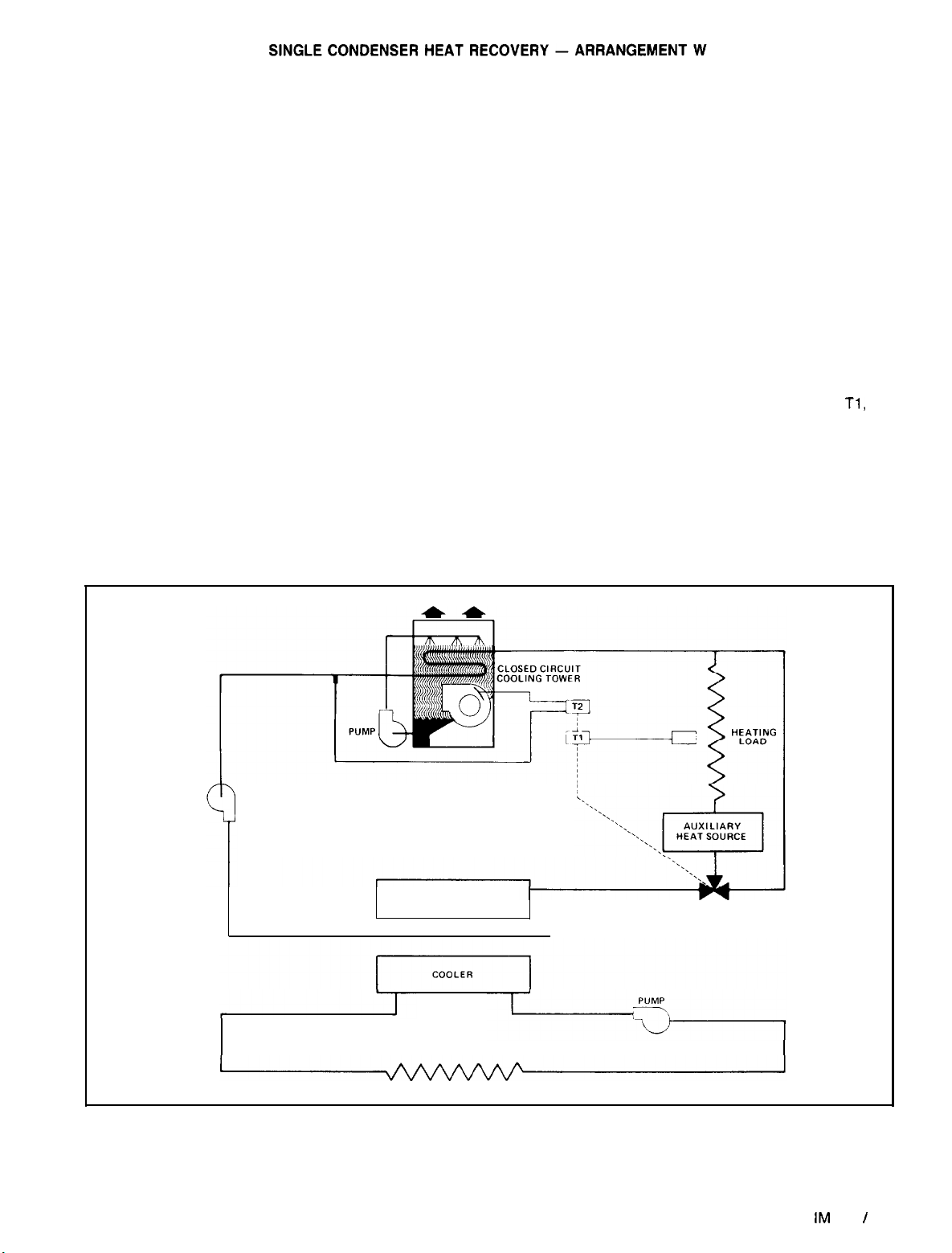

Single circuit heat recovery employs a standard water

cooled chiller equipped with heavier electrical components

and a 380 psig high pressure limit switch. These modifica-

tions allow leaving condenser water temperatures up to 135°F

for building or process heating applications.

A typical heat recovery arrangement will include a closed

circuit cooling tower used to reject unwanted condenser heat

to the outdoor ambient air. The cooling tower should be

sized to reject all the condenser heat during summer design

operation. This insures proper operation in the

nonheatrecovery mode. Use of a closed circuit tower is normally required in order to prevent fouling of heating coils in the heat

recovery loop. Condenser water remains free of contamination from minerals and impurities normally contained in makeup water in an open cooling tower.

If a closed circuit cooling tower is to be located in an ambient temperature below freezing, protection against coil and

sump freeze-up must be provided. Coil freeze protection can

be provided by using a glycol solution or by maintaining a

heat load on the coil

at all times and maintaining water flow

through the coil. Sump water freeze protection can be provided by locating the spray water circulating pump and sump

tank inside a heated space or by placing heating coils in the

sump. Head pressure and water temperature are normally

controlled by the tower capacity control. Adequate capacity

control is usually obtained by fan cycling and regulating

dampers located in the fan discharge. This will maintain a

constant tower water temperature. Consult the closed circuit

manufacturer for information on specific applications.

An auxiliary heat

source is necessary if the available con-

denser heat is not sufficient to satisfy all of the heat load.

The auxiliary heat source must be located between the condenser and the heat load and the control should be inter-

locked with the closed circuit tower to prevent auxiliary

heating while rejecting heat to the ambient.

When the heating load is satisfied, a two-position, three-

way valve is set to divert condenser water around the heat

load and the auxiliary heat source. Whether operating in summer or winter, the chiller is always controlled by the cooling

load and not the heating load.

-

TYPICAL OPERATION

On a call for cooling, the chiller

starts and hot condenser water flows through the diverting

valve to the closed circuit cooling tower rejecting heat to the

outdoors. The tower dampers modulate to maintain a pro-

per entering condenser water temperature which will give ef-

ficient operation by means of the proportional controller T2

located in the outlet fluid line of the tower.

When a heating load is sensed by mode switch

Tl,

the

three-way valve is switched to allow condenser water to flow

through the heating circuit. The proportional controller T2 is

also reset upwards to give the desired water temperature for

heat recovery. The unused condenser heat will be rejected

out through the closed circuit tower. If the condenser heat

of rejection cannot satisfy the heating load after an appropriate delay, the auxiliary heat source will be activated.

Figure

11. Typical Single Condenser (Per Refrigerant Circuit) Heat Recovery

PUMP

HEATRECOVERY

CONDENSER

TWO POSITION

DIVERTING VALVE

COOLING LOAD

NOTE: The schematic shows one refrigerant circuit. Models with two refrigerant circuits have two condensers

IM

508 I Page 11

Page 12

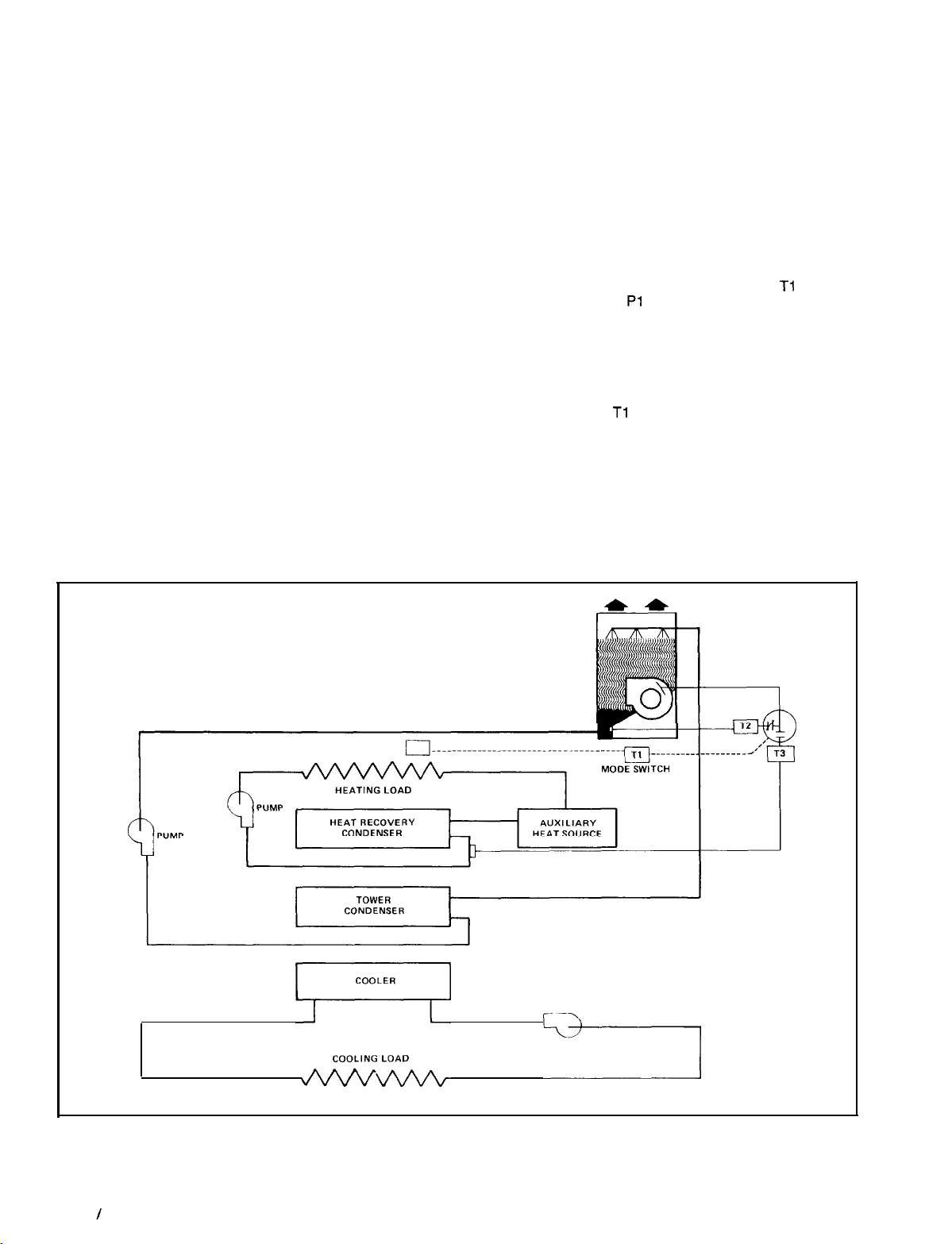

DUAL CONDENSER HEAT RECOVERY - ARRANGEMENT H

Dual condenser heat recovery chiller models have two water

cooled condensers per refrigerant circuit. The upper condenser is the heat recovery condenser and is piped into the

building’s hot water system. The lower condenser is the tower

condenser and is piped to an open cooling tower. Condensing is done in either the tower condenser or heat recovery

condenser, or partial condensing is done in each. The tower

and heat recovery water circuits are independent and do not

intermix. This use of an open tower and the closed heat

recovery loop prevents fouling of the building’s heating

system.

A subcooling circuit is provided in the tower condenser to

provide optimum cooling efficiency. When the unit is

operating on maximum heat recovery, the cooling tower will

be modulated down to its minimum capacity, usually about

5% of full capacity. This provides subcooling for the system

during heat recovery operation. Water can be heated up to

135°F in the heat recovery condensers to satisfy a heating

load. If all of the condenser heat of rejection cannot be

used, the remainder is rejected out through the cooling tower.

The cooling tower should be sized to reject all of the condenser heat during summer operation. Freeze protection for

the cooling tower must be provided if it is to operate in below

freezing temperatures, Adequate capacity control must be

provided to maintain a constant water temperature leaving

the cooling tower. Head pressure and water temperature are

controlled by the tower capacity control. Fan cycling and

modulating fan discharge dampers should be used. Consult

the cooling tower manufacturer for information on specific

applications.

If the available condenser heat cannot satisfy all of the heat

load, an auxiliary heat source must be provided. The auxiliary heat source should be located between the heat

recovery condenser and the heat load and interlocked with

the cooling tower so that auxiliary heat is not being supplied

unless the cooling tower is modulated down all the way. The

chiller operation is always controlled by the building’s cooling load and not the heating load.

TYPICAL OPERATION

-

On a call for cooling the chiller

starts. If a heating load is sensed by mode switch Tl , the heat

recovery water pump Pl will start and the cooling tower

dampers will modulate to control the heat recovery condenser

by means of proportional temperature controller T3. If maximum heat recovery is required, the tower dampers close and

only

the fans shut off. The tower will then provide

subcool-

ing. If more heat is required than the heat recovery condensers can provide, the auxiliary heat source is activated.

When mode switch Tl senses that a heating load no longer

exists, the heat recovery pump shuts off and the cooling tower

modulates to control the entering tower condenser water

temperature by means of proportional controller T2 and a sensor located in the tower sump. Proportional controller T2 is

set at a temperature lower than T3 to provide optimum

efficiency.

Figure

12. Typical Dual Condenser (Per Circuit) Heat Recovery

COOLING TOWER

COOLER

PUMP

Page 12

‘&k’

NOTE: The schematic shows one refrigerant circuit. Heat recovery WHR models with two refrigerant circuits

/

IM 508

have two heat recovery condensers and two tower condensers.

------j

Page 13

REFRIGERANT PIPING

UNIT WITH REMOTE CONDENSER-ARRANGEMENT A

General

cooled condenser, the chillers are shipped containing a

Refrigerant 22 holding charge. It is important that the unit be

kept tightly closed until the remote condenser is installed,

piped to the unit and the high side evacuated.

sized and installed according to the latest

book. It is important that the piping be properly suported with

sound and vibration isolation between tubing and hanger and

that the discharge lines be looped at the condenser and

trapped at the compressor to prevent refrigerant and oil from

draining into the compressor discharge manifold. Looping the

discharge line also provides greater line flexibility.

drier(s), moisture indicator(s), and thermostatic expansion

valve(s) are all provided as standard equipment with the

SEASONPAK water chiller.

condenserless units (Arrangement A) between the liquid line

filter-drier and remote condenser.

charged with Refrigerant 22, then run at design load condi-

tions, adding charge until the liquid line sightglass is clear,

with no bubbles flowing to the expansion valve. Total operating

charge will depend on the air cooled condenser used and

the length of external piping, but generally will be similar to

the water cooled charge shown in Tables 16, 17, and 18, pages

21 through 23.

densers), the installer is required to record the refrigerant

charge by stamping the total charge and the charge per circuit on the serial plate in the appropriate blocks provided for

this purpose.

piping to a remote condenser of some type. The design of

refrigerant piping when using air cooled condensers involves

a number of considerations not commonly associated with

other types of condensing equipment. The following discussion is intended for use as a general guide to sound,

economical and trouble-free piping of air cooled condensers.

and to protect the compressor from damage that may result

from condensing liquid refrigerant in the line during shutdown.

Total friction loss for discharge lines of 3 to 6 psi is considered

good design. Careful consideration must be given for sizing

each section of piping to insure that gas velocities are sufficient at all operating conditions to carry oil. If the velocity in

a vertical discharge riser is too low, considerable oil may col-

lect in the riser and the horizontal header, causing the com-

pressor to lose its oil and result in damage due to lack of

lubrication. When the compressor load is increased, the oil

that had collected during reduced loads may be carried as

a slug through the system and back to the compressor, where

a sudden increase of oil concentration may cause liquid slugging and damage to the compressor.

away from the compressor approximately l/4” per foot or more.

This is necessary to move by gravity any oil lying in the header.

Oil pockets must be avoided as oil needed in the compressor

would collect at such points and the compressor crankcase

may become starved.

horizontal discharge header rise above the center line of the

-

For remote condenser application such as an air

Refrigerant piping, to and from the remote unit, should be

The discharge gas valve(s), liquid line solenoid(s), filter-

A liquid line shutoff valve must be added in the field on

After the equipment is properly installed, the unit may be

NOTE: On the Arrangement A units (units with remote con-

SEASONPAK water chillers without condensers require field

Discharge lines must be designed to handle oil properly

Any horizontal run of discharge piping should be pitched

It is recommended that any discharge lines coming into a

ASHRAE

Hand-

discharge header. This is necessary to prevent any oil or condensed liquid from draining to the top heads when the compressor is not running.

In designing liquid lines it is important that the liquid reach

the expansion valve with no presence of flash gas since this

gas will reduce the capacity of the valve. Because “flashing”

can be caused by a pressure drop in the liquid lines, the

pressure losses due to friction and changes in static head

should be kept to a minimum.

A check valve must be installed in the liquid line in all applications where the ambient temperature can get below the

equipment room temperature. This prevents liquid migration

to the condenser, helps maintain a supply of refrigerant in the

liquid line for initial startup and keeps liquid line pressure high

enough on “off” cycle to keep the expansion valve closed.

On systems as described above, a relief valve or relief type

check valve must be used in the liquid line as shown in piping systems (Figure 14) to relieve dangerous hydraulic

pressures that could be created as cool liquid refrigerant in

the line between the check valve and expansion or shutoff

valve warms up. A relief device is also recommended in the

hot gas piping at the condenser coil as shown in Figures 14

through 16.

Typical Arrangements

ing arrangement involving a remote air cooled condenser

located at a higher elevation than the compressor and

receiver. This arrangement is commonly encountered when

the air cooled condenser is on a roof and the compressor and

receiver are on grade level or in a basement equipment room.

In this case, the design of the discharge line is very critical.

If properly sized for full load condition, the gas velocity might

be too low at reduced loads to carry oil up through the

discharge line and condenser coil. Reducing the discharge

line size would increase the gas velocity sufficiently at reduced load conditions; however, when operating at full load,

the line might be greatly undersized and thereby create an

excessive refrigerant pressure drop. If this condition occurs,

it can be overcome in one of the two following ways:

1. The discharge line may be properly sized for the desired

pressure drop at full load condition and an oil separator

installed at the bottom of the trap on the discharge line

from the compressor.

2. A double riser discharge line may be used as shown in

Figure 15, page 15. Line ‘A” should be sized to carry the

oil at a minimum load condition and line

sized so that at the full load condition, both lines would

carry oil properly.

Notice in all illustrations that the hot gas line is looped at

the bottom and top of the vertical run. This is done to prevent oil and condensed refrigerant from flowing back into the

compressor and causing damage. The highest point in the

discharge line should always be above the highest point in

the condenser coil; it is advisable to include a purging vent

at this point to release noncondensables from the system.

Figure 16 illustrates another very common application

where the air cooled condenser is located on essentially the

same level as the compressor and receiver. The discharge

line piping in this case is not too critical. The principal problem encountered with this arrangement is that there is frequently insufficient vertical distance to allow free drainage of

liquid refrigerant from the condenser coil to the receiver.

Figure 14 illustrates a typical pip-

-

“B”

should be

IM 508

/ Page 13

Page 14

UNIT WITH FACTORY MOUNTED CONDENSER(S)

Units with factory mounted condensers are provided with

complete refrigerant piping and full operating refrigerant

charge at the factory.

There is a remote possibility on Arrangement W units utilizing low temperature pond or river water as a condensing

medium, and if the water valves leak, that the condenser and

liquid line refrigerant temperature could get below the equipment room temperature on the off cycle. This could open the

expansion valve and cause recycling pumpdown. This

prob-

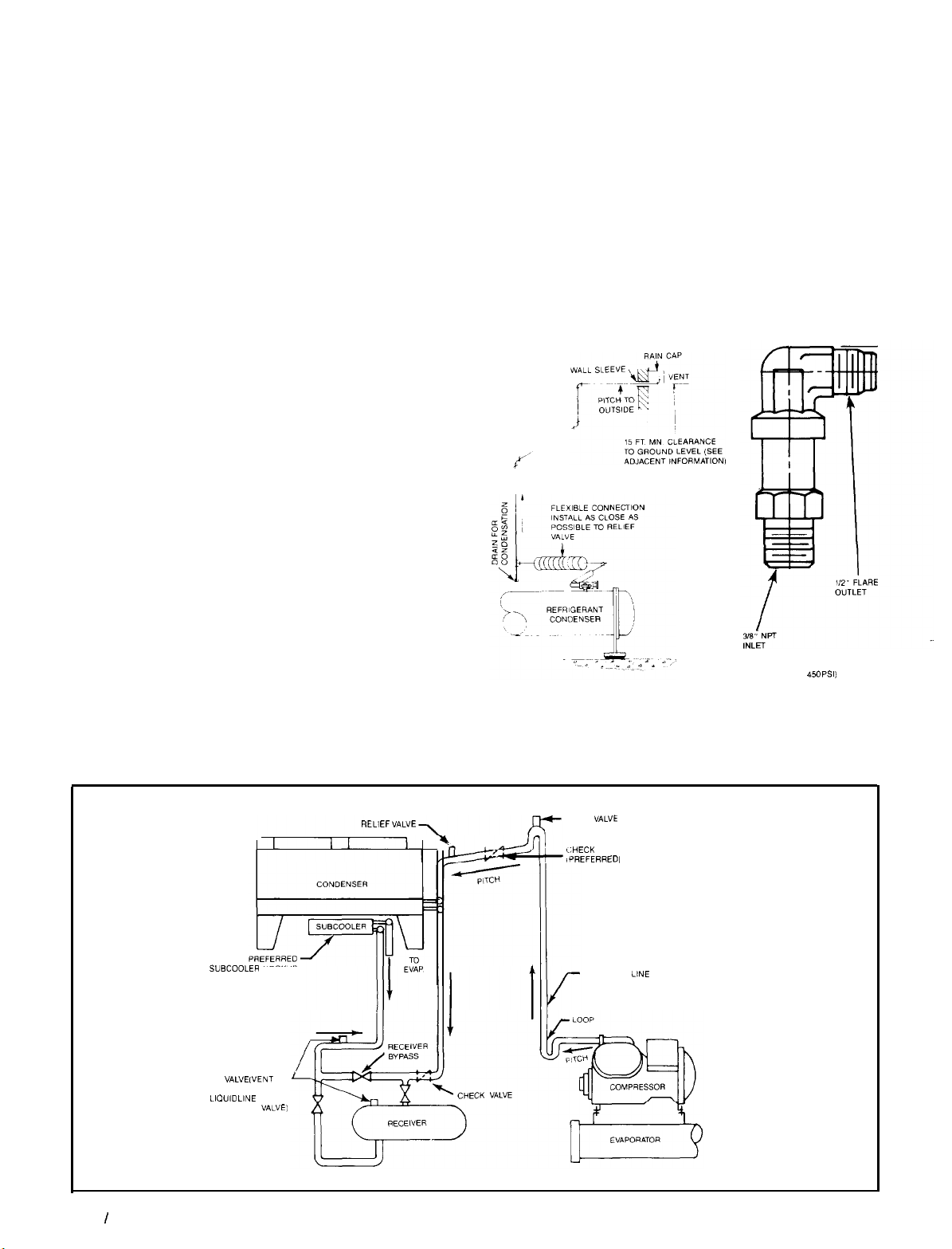

RELIEF VALVE PIPING

The ANSMASHRAE Standard 15-1978 specifies that pressure

relief valves on vessels containing Group 1 refrigerants (R-12,

R-22 and R-500) “shall discharge to the atmosphere at a location not less than 15 feet above the adjoining ground level

and not less than 20 feet from any window, ventilation open-

ing or exit in any building.” The piping must be provided with

a rain cap at the outside terminating point and a drain at the

low point on the vent piping to prevent water buildup on the

atmospheric side of the relief valve. In addition, a flexible pipe

section should be installed in the line to eliminate any piping

stress on the relief valve(s).

The size of the discharge pipe from the pressure relief valve

shall not be less than the size of the pressure relief outlet.

When two or more vessels are piped together, the common

header and piping to the atmosphere shall not be less than

the sum of the area of the relief valve outlets connected to

the header. Fittings should be provided to permit vent piping to be easily disconnected for inspection or replacement

of the relief valve.

only arises during periods when cold water continues to

lem

circulate through the condenser and the unit remains off due

to satisfied cooling load.

If this condition occurs:

1.2.Cycle the condenser pump off with the unit.

Check the liquid line solenoid valve for proper operation.

If these valves are closing liquid tight as designed, no

recycling of

Figure

13. Relief Valve Piping

pumpdown

should occur.

NOTE: Provide adequate fittings in piping to permit repair

or replacement of relief valve.

REFRIGERANT PIPING

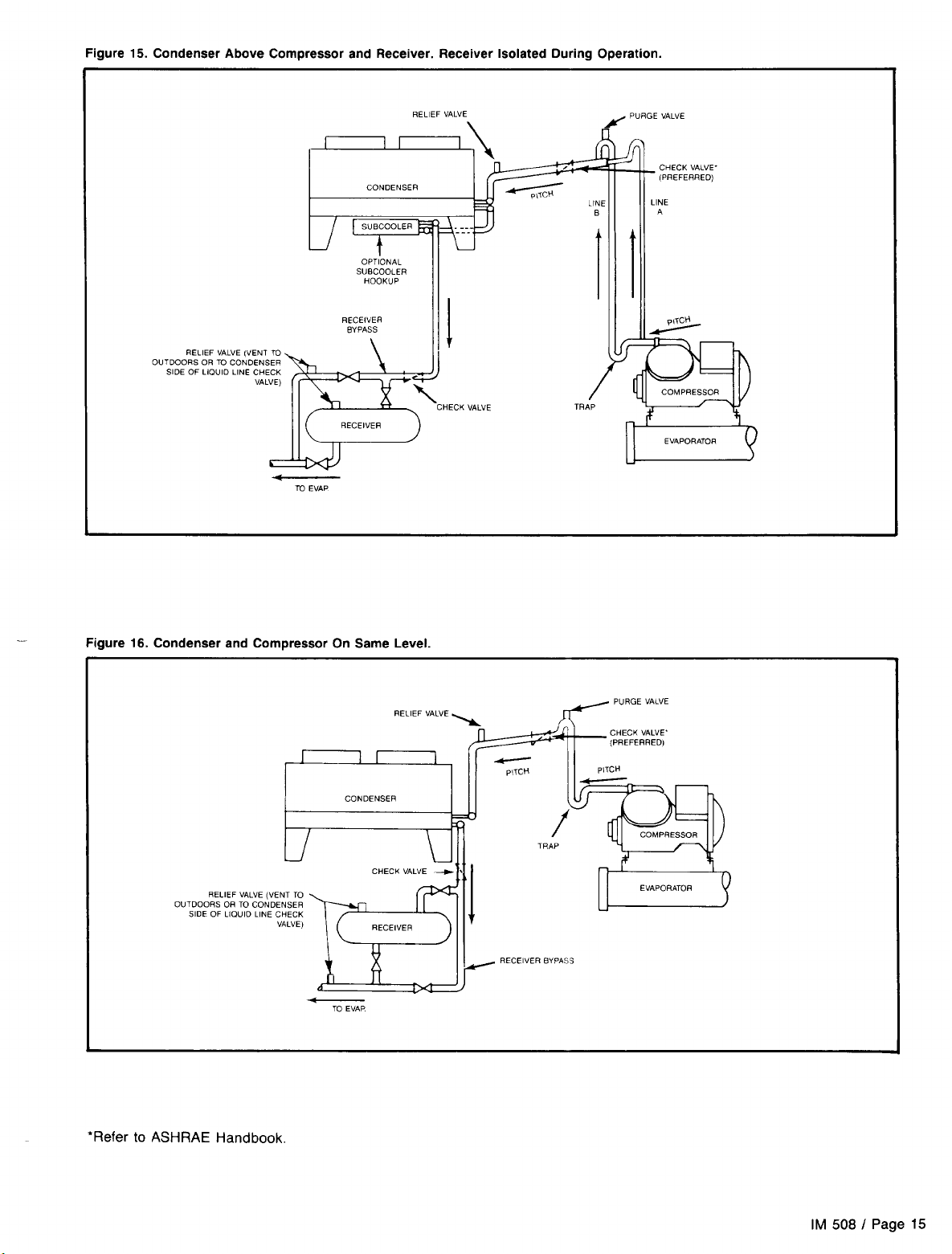

Figure 14. Condenser Above Compressor and Receiver

REM3 VALVE

SUBCOOLER HOOKUP

RELIEF

VALVE

OUTDOORS OR TO CONDENSER

SIDE OF IIOUID LINE CHECK

(VENT TO

VALVE)

PURGE

VALVE

GHECK VALVE’

iPREFERRED,

DISCHARGE LINE

RELIEF VALVE

(SET AT 4%

PSI1

Page 14 I IM 508

Page 15

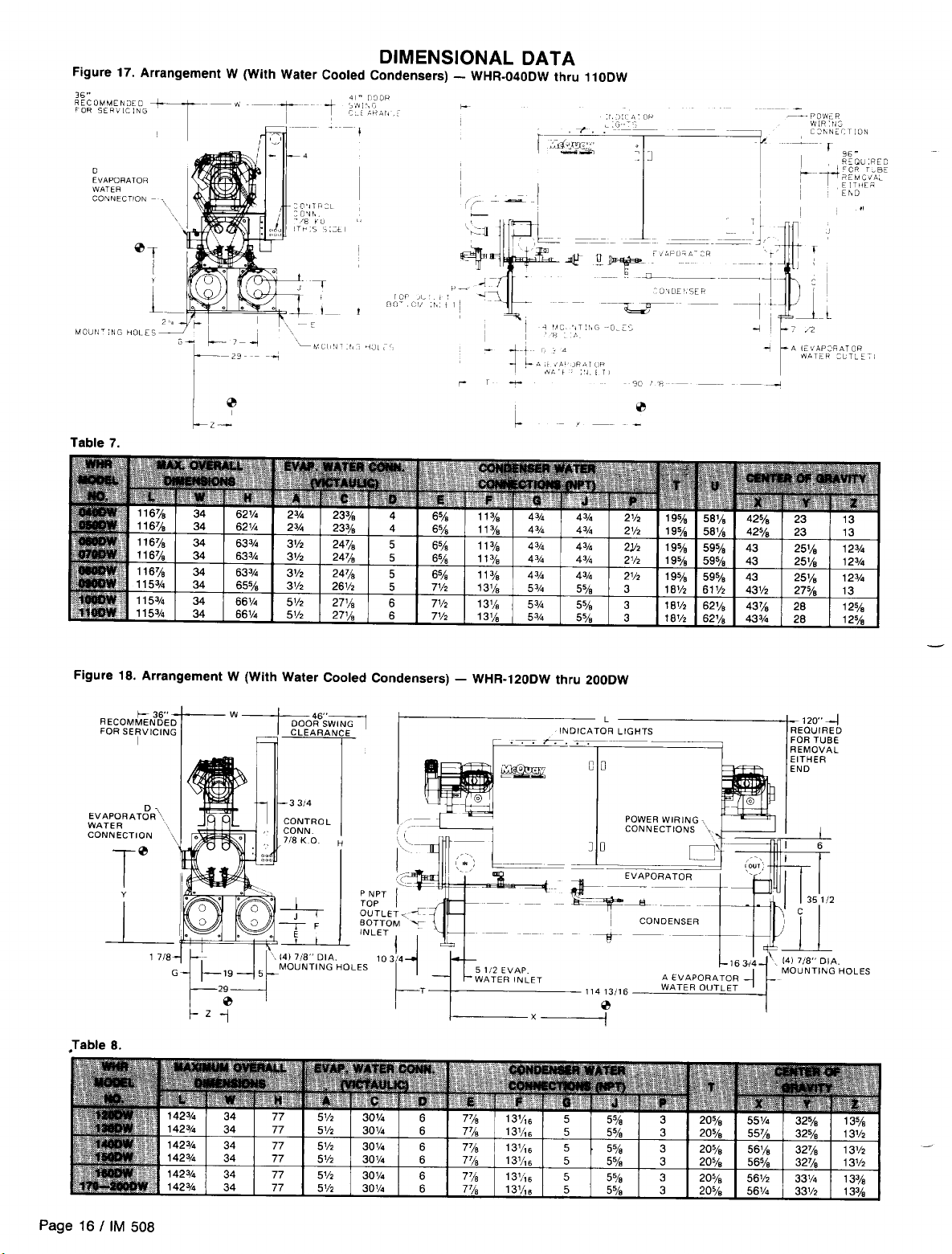

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

CONTROL CENTER

All electrical controls are enclosed in a control center with

locking, hinged access door(s). A partition separates the ad-

justable safety controls from the starting and operating

con-

trots. A “deadfront” panel covers all starting and operating

controls so that no electrical contacts or terminals are

posed. The deadfront panel is hinged for servicing. The

ex-

ad-

POWER PANEL LAYOUT

Figure 27. WHR-040D thru

Right Side, High Voltage Control Section

1

1lOD

0 0

justable controls are covered and can be adjusted without fear

of contacting line voltage.

IM

Please refer to

493 for control section layout, all low

voltage field wiring and normal sequence of operation for units

equipped with

Figure 28. WHR12OD thru 240D

MicroTech

Right Side, High Voltage Power Section

control.

pq”

&,

WIRING

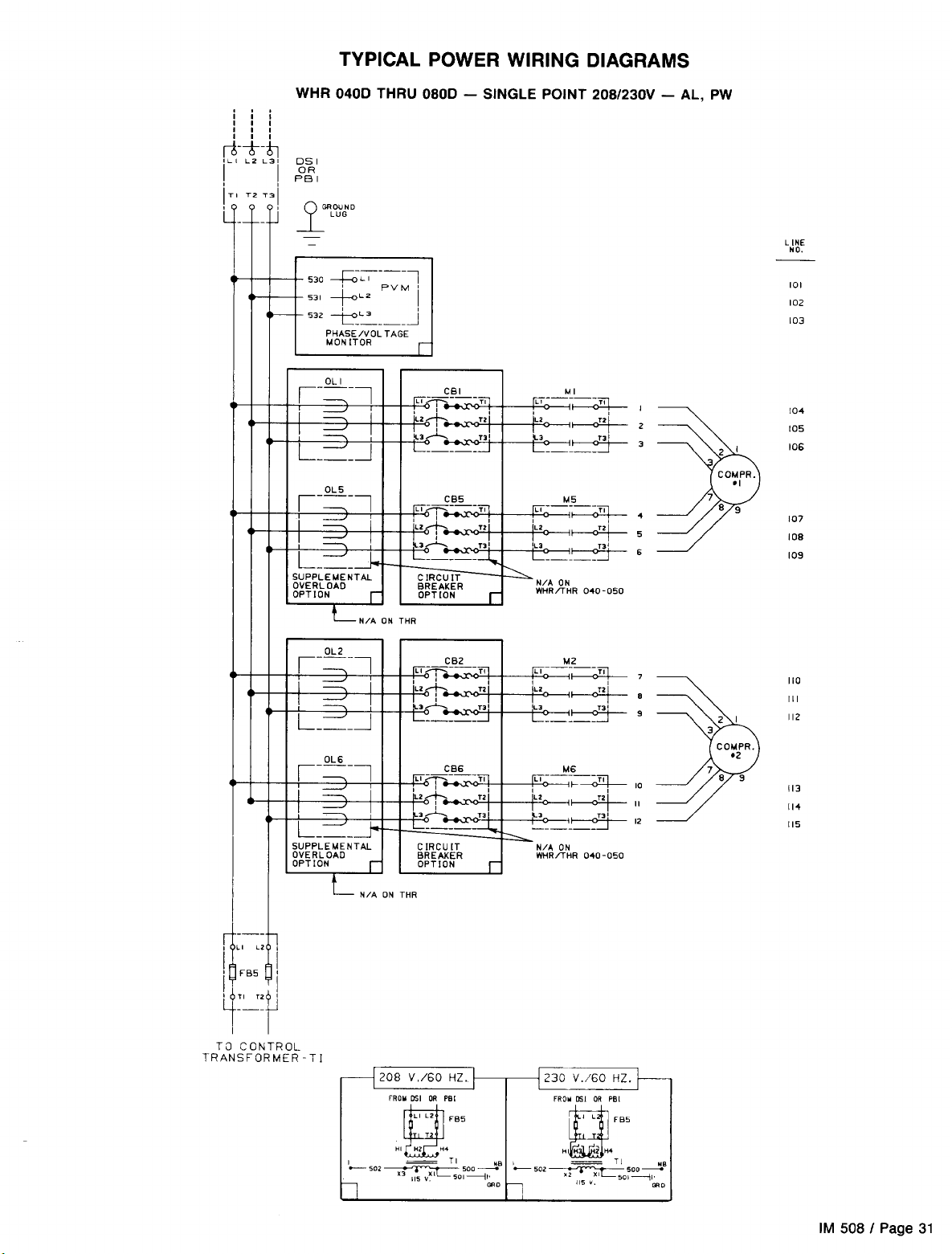

FIELD WIRING, POWER

The WHR

pressor contactors and power terminal block, designed for

single power supply to unit. Optional power connections include a nonfused disconnect switch mounted in the control

box or multi-point power connection.

A factory installed control circuit transformer is available

as an option with single power supply or disconnect switch;

it is not available with multi-point option.

On water cooled units only, optional compressor overloads

are available, allowing reduced unit ampacity ratings and

smaller field wiring.

Optional circuit breakers are available for backup com-

pressor short circuit protection on 040D thru

are standard on all four (4) compressor units 120D thru 240D.

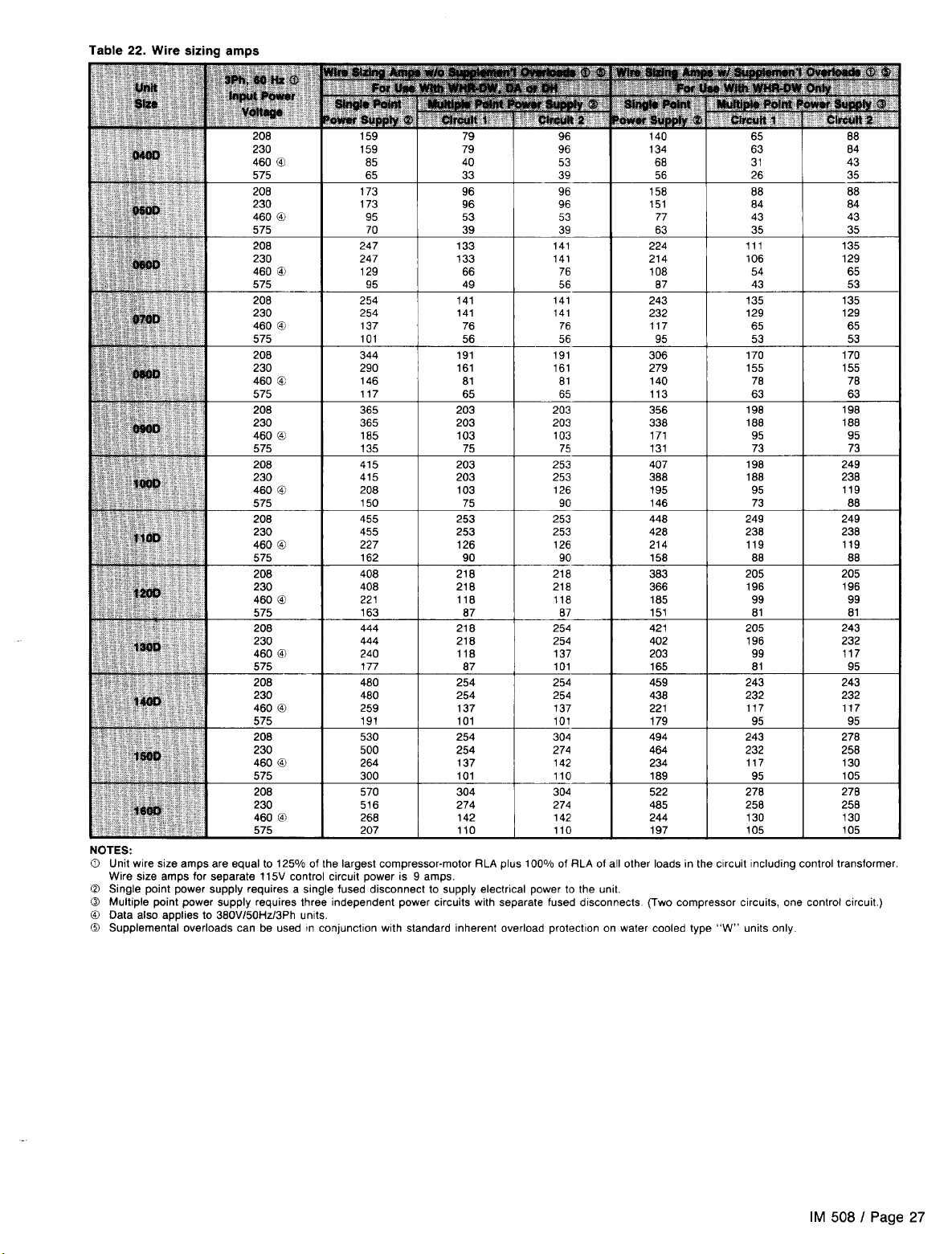

Wiring and conduit selections must comply with the Na-

“D”

vintage chillers are built standard with com-

110D

units and

NOTES:

1. PBl and

2.

Pf32

Circuit breakers and overloads are provided as an option. The power panel

could contain one, both, or neither of these options.

are used with multiple point power wiring.

tional Electrical Code and/or local requirements.

An open fuse indicates a short, ground, or overload. Before

replacing a fuse or restarting a compressor or fan motor, the

trouble must be found and corrected. Tables in the Electrical

Data section give specific information on recommended wire

sizes.

Unit power inlet wiring must enter the top of the control box

(right side) through a patch plate provided for field terminating

conduit. (Refer to control panel layout drawings for general

location of power inlet and components.)

WARNING: Use only copper conductors in main terminal

block. If the power input conductors are aluminum, use a compression splice to change to copper before terminating in

block.

TYPICAL CONTROL AND SAFETY WIRING DIAGRAMS

Refer to IM 493 for typical control and safety wiring or actual unit wiring diagrams.

CURRENT TRANSFORMER

The typical power wiring diagrams shown on pages 19 thru 35 include the current transformer

(CTI)

wiring shown in Figure 29. CT1 provides a O-4 vdc signal to the

MicroTech

panel which

is then converted to XXX% RLA.

IM 508 I Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

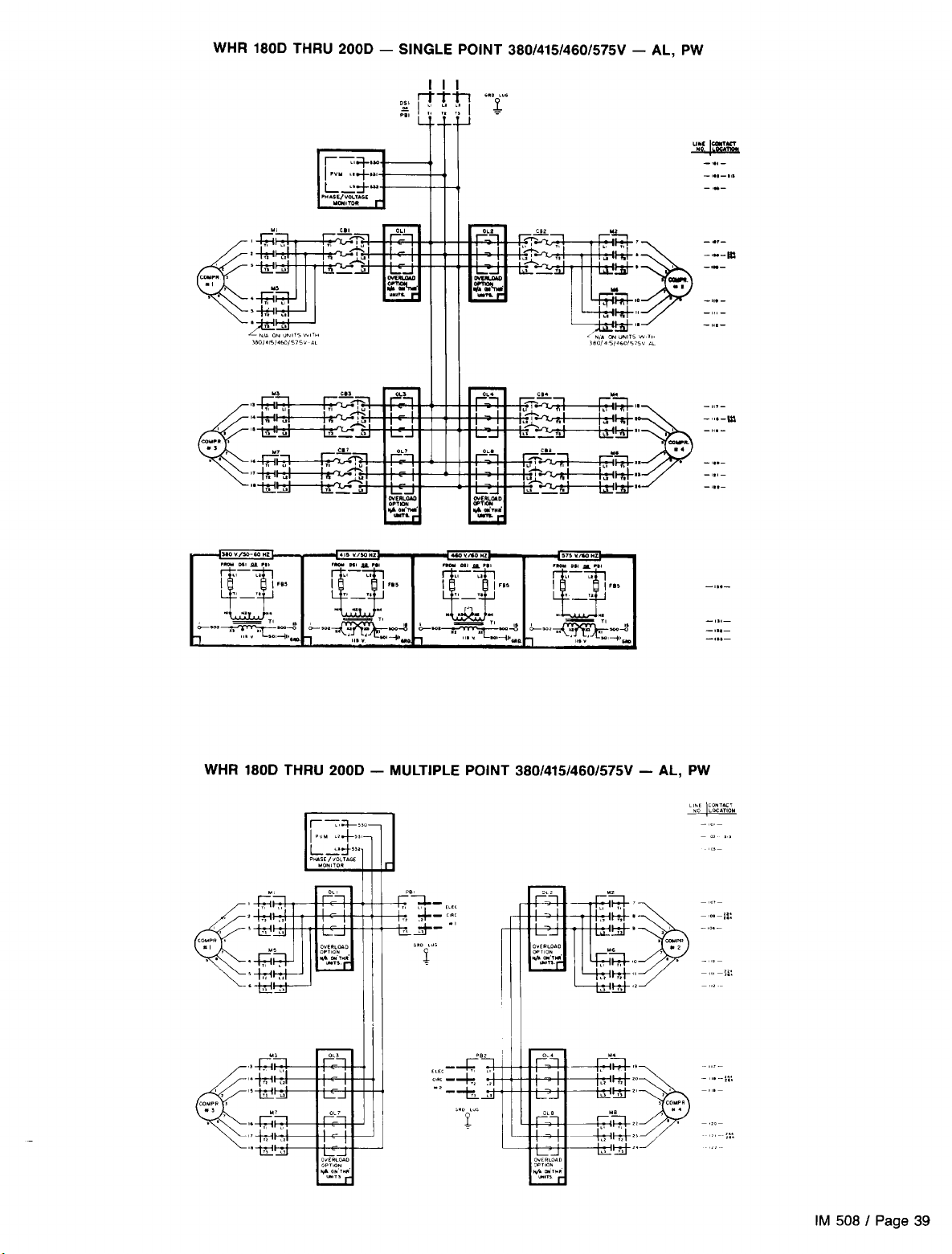

Page 39

Page 40

Page 41

Page 42

STARTUP AND SHUTDOWN

This manual covers only the mechanical aspects of WHR chillers equipped with the

trol. All of the operating, safety control and installation requirements of the

Installation and Maintenance Bulletin 493, which must be consulted before startup and operation is attempted.

PRE STARTUP

1.

With main disconnect open, check all electrical connections in control panel and starter to be sure they are tight

and provide good electrical contact. Although connections are tightened at the factory, they may have

loosened enough in shipment to cause a malfunction.

2.

Check and inspect all water piping. Make sure flow direction is correct and piping is made to correct connection

on evaporator and condenser.

3.

Open all water flow valves to the condenser and

evaporator.

4.

Flush the cooling tower and system piping to be sure the

system is clean. Start evaporator pump and manually

start condenser pump and cooling tower. Check all pip-

ing for leaks. Vent the air from the evaporator and condenser water circuit as well as from the entire water

system. The cooler circuits should contain clean, noncorrosive water.

If water regulating valves are provided, connect their

5.

capillary to the manual valves provided on the condensers and open the manual valves.

Check to see that the water temperature thermostat sen-

6.

sor is installed in the entering water line to the chiller.

7.

Making sure control stop switch

Sl

is open (off) and

pumpdown

down,” throw the main power and control disconnect switches to “on.” This will energize crankcase heaters. Wait

a minimum of 12 hours before starting up unit.

Check compressor oil level. Prior to startup, the oil level

8.

should cover at least one-third of the oil sightglass.

Check pressure drop across evaporator and condenser,

9.

and see that water flow is correct per the design flow rates

and data on page 9.

Check the actual line voltage to the unit to make sure

10.

it is the same as called for on the compressor nameplate

within

exceed 2%. Verify that adequate power supply and

capacity is available to handle load.

Make sure all wiring and fuses are of the proper size. Also

11.

make sure all interlock wiring is completed per McQuay

diagrams.

Verify that all mechanical and electrical inspections by

12.

code authorities have been completed.

Make sure all auxiliary load and control equipment is

13.

operative and that an adequate cooling load is available

for initial startup.

MicroTech

rtlO% and that phase voltage unbalance does not

MicroTech

control are covered in the separate

switches PSl and PS2 are on “manual

reciprocating chiller con-

pump-

STARTUP

1.

Open the compressor suction and discharge shutoff valves

until

backseated. Always replace valve seal caps.

2.

Open the manual liquid line shutoff valve.

3.

Verify

crankcase heaters have operated for at least 12 hours

prior

to startup. Crankcase should be warm.

4.

After

running the unit for a short time, check the oil level

n each compressor crankcase, rotation of condenser fans

(if

any), and check for flashing in the refrigerant sight-

glass.

At this point it will be necessary to complete

1. Move the Circuit 1 and Circuit 2 switches to the “Pumpdown and Stop” position, causing each circuit to pump

down and stop. In this condition, the compressors will

main off and no additional

evaporator pressure rises above the low pressure control

cut-in setpoint.

Close the remote stop switch to enable the chiller. Move the the unit will stage as required. If the controller is not calling

Circuit

1

controller is calling for cooling, the compressors will start and there is a call for cooling.

and Circuit 2 switches to the Auto position. If the for cooling the compressors may pump down and stop until

pumpdown

STARTUP AFTER TEMPORARY SHUTDOWN

MicroTech

TEMPORARY SHUTDOWN

re-

will occur even if

pre-start checkout found in IM 493 before system operation is attempted. After

startup is complete be sure to complete the following

mechanical startup requirements.

5. After system performance has stabilized, it is necessary

that the “Compressorized Equipment Warranty Form”

(Form No. 206036A) be completed to obtain full warranty

benefits. Be sure to list the pressure drop across both

vessels. This form is shipped with the unit and after completion should be returned to the McQuayService Depart-

ment through your sales representative.

2. After both circuits have pumped down, open the remote

stop switch and the controller will stop the chilled water

pump.

MicroTech

pre-start checkout and

Page 42

I

IM 508

Page 43

EXTENDED SHUTDOWN

1.

Move the Circuit 1 and Circuit 2 switches to the “Pumpdown and Stop” position. After the compressors have shut

off, open the remote stop switch and the controller will stop

the chilled water pump.

2.

Move the system switch to the “Emergency Stop”

tion and turn off main power to the chiller and the chilled

water pumps.

STARTUP AFTER EXTENDED SHUTDOWN

1.

Inspect all equipment to see that it is in satisfactory At this point is will be necessary to complete

operating condition.

2.

Remove all debris that has collected on the surface of the

condenser coils (remote condenser models).

3.

Open the compressor suction and discharge valves until

backseated. Always replace valve seal caps.

4.

Open the manual liquid line shutoff valves.

5.

Allow the crankcase heaters to operate for at least 12 hours

prior to startup.

posi-

3. Close the manual liquid line shutoff valves.

4. Close the compressor suction and discharge service valves

and oil equalization valves on four compressor units.

5. Tag all opened electrical disconnect switches to warn

against startup before opening the compressor

discharge and liquid line service valves.

pre-start checkout found in

iion is attempted. After

startup is complete be sure to complete the following

mechanical startup requirements.

8

After running the unit for a short time, check the oil level

in each copressor crankcase and for flashing in the

refrigerant sightglass (see Maintenance section).

IM

493 before system

MicroTech

pre-start checkout and

sucton,

MicroTech

opera-

SYSTEM MAINTENANCE

GENERAL

To assure smooth operation at peak capacity and to avoid

damage to package components, a program of periodic inspections should be set up and followed. The following items

are intended as a guide to be used during inspection and must

be combined with sound refrigeration and electrical practices

to assure trouble-free performance.

The liquid line sightglass/moisture indicator on all circuits

must be checked to be sure the glass is full and clear and

the moisture indicator indicates a dry condition. If the indicator

shows that a wet condition exists or if bubbles show in the

glass, even with a full refrigerant charge, the filter-drier element must be changed.

Water supplies in some areas may tend to foul the water

cooled condenser to the point where cleaning is necessary.

The fouled condenser will be indicated by an abnormally high

condensing pressure and may result in nuisance tripouts. To

clean the condenser, a chemical descaling solution should

be used according to the manufacturer’s directions.

Systems with remote air cooled condensers require periodic

cleaning of the finned surface of the condenser coil. Cleaning

CONTROL CENTER ELECTRICAL SERVICE

The electrical control center is relativelv easv to service since

indicator lights are provided to show unit status. Determine

that the problem is actually in the control panel before

proceeding.

By referring to the schematic wiring diagrams, the trouble

can be isolated to a particular section of the panel.

WARNING: Warranty is voided if wiring is not in accordance

with specifications. A blown fuse or tripped protector indicates

a short ground or overload. Before replacing fuse or restarting compressor, the trouble must be found and corrected.

It is important to have a qualified control panel electrician service this panel. Unqualified tampering with the controls can

cause serious damage to equipment and void the warranty.

The following steps should be taken prior to attempting any

ing may be accomplished by using a cold water spray,

brushing, vacuuming, or high pressure air. No tools should

be used that could damage the coil tubes or fins.

A lead-lag switch is provided on all multiple compressor

models to permit even distribution of wear on the compressors. This switch should be turned on on an annual basis.

The compressor oil level must be checked periodically to

be sure the level is at the center of the oil sightglass. Low

oil level may cause inadequate lubrication and oil failure

switch tripout. If the oil level is low and oil must be added,

use oils referred to in “Compressor Oil Level” section below.

A pressure tap has been provided on the liquid line

downstream of the filter-drier and solenoid valve but before

the expansion valve. An accurate subcooled liquid pressure

and temperature can be taken here. The pressure read here

could also provide an indication of excessive pressure drop

through the filter-drier and solenoid valve due to a clogging

filter-drier.

NOTE: A normal pressure drop through the solenoid valve

is approximately 3 psig at full load conditions.

service on the control center:

1.

Study the wiring diagram so that you understand the operation of the SEASONPAK water chiller.

2.

Before investigating trouble in the control center, check for

burned out light bulbs by testing across the appropriate

terminals.

CAUTION: The panel is always energized to ground

even though the system switch is off. If it is necessary to

de-energize the complete panel including crankcase

heaters, pull main disconnect.

If motor or compressor damage is suspected, do not restart

until a qualified serviceman has checked the unit.

IM 508 I Page 43

Page 44

ELECTRICAL TERMINALS

CAUTION: Electric shock hazard. Turn off all power before continuing with following service.

All power electrical terminals should be retightened every six months, as they tend to loosen

in service due to normal heating and cooling of the wire.

OPERATING LIMITS

0 Maximum allowable condenser water pressure is 250 psig.

0 Maximum allowable cooler water pressure is 225 psig.

0 Maximum leaving condenser water temperature is

135” F.

0 Minimum leaving water temperature from the cooler with-

This corresponds to 340 to 350 psig head pressure.

0 Maximum allowable water temperature to cooler in a

operating cycle is 105°F. Maximum entering water

temper-

non-

0

COMPRESSOR OIL LEVEL

The oil level should be watched carefully upon initial startup

than keeping the oil clean and dry.

and for sometime thereafter.

At the present time, Suniso No.

3GS,

Calumet

R015,

and

Texaco WF32 oils are approved by Copeland for use in these

compressors. The oil level should be maintained at about

onethird of the sightglass on the compressor body but is acceptable at any height on the sightglass.

Oil may be added to the

Copeland

compressor through the

oil fill hole in the crankcase. To add oil, isolate the crankcase

and pour or pump in the necessary oil. If the system contains

no refrigerant, no special precautions are necessary other

tion valve and reduce crankcase pressure to 1 to 2 psig. Stop

the compressor and close the discharge valve.

pressor is exposed to the atmosphere, the refrigerant will

generate a vapor pressure, retarding the entrance of contaminants. Before resealing the compressor, purge the crankcase by opening the suction valve slightly for 1 or 2 seconds.

Close the oil port, open the compressor valves and restore

the system to operation.

ature for operating cycle is 90°F (during system

change-

over from heating to cooling cycle).

out freeze protection is 42°F.

Minimum entering tower condenser water temperature is

70°F.

If the system contains a refrigerant charge, close the suc-

Add the required amount of oil. During the period the com-

OIL EQUALIZATION

Some larger models with four compressors (WHR-180 thru

240D) come equipped with oil equalization lines connecting

the crankcase of both compressors in each refrigerant circuit.

This allows the oil to move from one compressor crankcase

to the other during normal operation, and balance between

the two when the compressors are off. This method of equali-

zation prohibits the oil level from dropping below the bottom

level of the sightglass. Some difference in crankcase oil levels

will still exist during unit operation due to compressor internal

REFRIGERANT SIGHTGLASS AND MOISTURE INDICATOR

The refrigerant sightglasses should be observed period-

ically. (A monthly observation should be adequate.) A clear

glass of liquid indicates that there is adequate refrigerant

charge in the system to insure proper feed through the

pansion

valve. Bubbling refrigerant in the sightglass indicates

ex-

that the system is short of refrigerant charge. Refrigerant gas

flashing in the sightglass could also indicate an excessive

CRANKCASE HEATERS

The compressors are equipped with crankcase heaters. The

20 HP and larger model compressors have heaters inserted

into the crankcase. The function of the heater is to keep the

temperature in the crankcase high enough to prevent refrig-

erant from migrating to the crankcase and condensing in the

oil during off-cycle.

When a system is to be started up initially in cold ambient,

the power to the heaters should be turned on for some time

pressures.

The oil equalization line contains a manual shutoff valve

for isolating a compressor during service work. The ball valves

are shipped in the closed position with a tag attached stating

“Notice, Valve Shipped In Closed Position. Can Be Open For

Normal Operation.” When valves are closed for compressor

service, make sure they are opened again for unit operation.

For water cooled units, operation with oil equalization lines

closed should be satisfactory for most jobs.

pressure drop in the line, possibly due to a clogged filter-drier

or a restriction elsewhere in the system. An element inside

the sightglass indicates what moisture condition corresponds

to a given element color. If the sightglass does not indicate

a dry condition after about 12 hours of operation, the unit

should be pumped down and the filter-driers changed.

(at least 12 hours) before the compressor is started. The

crankcase should be up to about 80°F before the system is

started up, to minimize lubrication problems on liquid slugging of compressor on startup.

If the crankcase is cool (below 80°F) and the oil level in

the sightglass is FULL to top, allow more time for oil to warm

before starting the compressor.

Page 44

I

IM 508

Page 45

SYSTEM SERVICE

NOTE: Service on this equipment is to be performed by qualified refrigeration personnel. Causes for repeated tripping of safety

controls must be investigated and corrected. CAUTION: Disconnect all power before doing any service inside the unit.

FILTER-DRIERS

To change the filter-drier, pump each refrigerant circuit down

by closing the manual liquid line shutoff valve while a com-

pressor is running. After both refrigerant circuits are pumped

down, move the system switch to the “Emergency Stop” posi-

tion. This will remove all liquid refrigerant from the evaporator

and section of liquid line up to the shutoff valve. Only a small

amount of vapor will remain in the liquid line/filter-drier section. Front seat the compressor suction valve(s), Remove and

replace the filter-drier(s). Evacuate the lines through the liquid line manual shutoff valves to remove non-condensables

that may have entered during filter replacement. A leak check

is recommended before returning the unit to operation.

LIQUID LINE SOLENOID VALVE

The liquid line solenoid valves, which are responsible for

automatic

pumpdown

during normal unit operation, do not

normally require any maintenance. However, in the event of

failure they may require replacement of the solenoid coil or

of the entire valve assembly.

The solenoid coil may be removed from the valve body

without opening the refrigerant piping by moving Circuit 1 and

Circuit 2 switches to the “Pumpdown and Stop” position.

NOTE: On Arrangement A units, the filter-drier cores are shipped in the unit

control box and are to be Installed prior to evacuating and charging the unit.

The coil can then be removed from the valve body by simply

removing a nut or snap-ring located at the top of the coil. The

coil can then be slipped off its mounting stud for replacement.

Be sure to replace the coil on its mounting stud before

return-

ing the unit to operation.

To replace the entire solenoid valve, follow the steps involved when changing a filter-drier.

THERMOSTATIC EXPANSION VALVE

The expansion valve is responsible for allowing the proper

amount of refrigerant to enter the evaporator regardless of

cooling load. It does this by maintaining a constant superheat.

(Superheat is the difference between refrigerant temperature

as it leaves the evaporator and the saturation temperature corresponding to the evaporator pressure.) All WHR chillers are

factory set for between

8°F

and

12°F

superheat at full load.

If it is necessary to increase the superheat setting of the valve,

remove the cap at the bottom of the valve to expose the ad-

justment screw. Turn the screw clockwise (when viewed from

the adjustment screw end) to increase the superheat and

counterclockwise to reduce superheat. Allow time for system

rebalance after each superheat adjustment.

The expansion valve, like the solenoid valve, should not normally require replacement, but if it does, the unit must be

pumped down by following the steps involved when changing a filter-drier.

If the problem can be traced to the power element only,

it can be unscrewed from the valve body without removing

the valve, but only after pumping the unit down.

WARNING: Adjustment of expansion valve should only be

performed by a qualified service technician.

EVAPORATOR

The evaporator is of the direct expansion, shell-and-tube type

with refrigerant flowing through the tubes and water flowing

through the shell over the tubes. The tubes are internally

finned to provide extended surface as well as turbulent flow

of refrigerant through the tubes. Normally no service work is

required on the evaporator. There may be instances where

a tube will leak refrigerant into the water side of the system.

In the cases where only one or two tubes leak, the problem

can best be solved by plugging the tube at both ends. When

the tube must be replaced, the old tube can be removed and

replaced.

To remove a tube, the unit should be temporarily pumped

Figure

30.

,.._.,

Inlet

WIII

NOTE: Superheat

imately as follows- between 6°F and 12°F at full load; between 6°F and 10°F

at part load.

vary with compressor unloading, but should be approx-

Power Element

(Contains Diaphragm)

Adjustment Screw

down. Follow the steps involved when changing a filter-drier.

These steps will insure a minimum amount of refrigerant loss

when the evaporator is opened up. The tubes are mechanical-

ly expanded into the tube sheets (see Figure 31) at each end

of the cooler. In order to remove the tubes, it is necessary

to break this bond by collapsing the tube. After doing this at

both ends of the shell, the tube can be removed for replacement. The new tube can then be inserted and re-expanded

into the tube sheet.

NOTE: The bond produced by expansion must be refrig-

erant tight. This bond must be produced by applying Locktite

(red) to the

fube

and rolling it into the

fube

sheet.

IM 508 I Page 45

Page 46

After re-assembling the evaporator, a small amount of

refrigerant should be introduced by momentarily opening the

manual liquid line valve. A leak check should then be

per-

formed on the evaporator.

Tube removal can only take place after the leaking tube is

located. One method that would work would be to subject each

tube to

air pressure by plugging each end and, with a pressure

Figure

31. Top View of Typical Dual Circuit Shell-and-Tube Evaporator

Liquid Connections

Suction Connections

WATER COOLED CONDENSER

The condenser is of the shell-and-tube type with water

flow-

gauge attached to one of the end plugs, observing if there

is a loss of air pressure over a period of a minute or two.

Another method is to place a cork plug in each tube on both

ends of the cooler and applying pressure to the shell of the

cooler. After a period of time, the pressure will leak from the

shell into the leaking tube or tubes and pop out the cork plug.

Water Baffles

L

Refrigerant Tubes

Shell

Water Nozzles

ment W units. Heat recovery units have integral subcoolers

ing through the tubes and refrigerant in the shell. External in the tower condensers. All condensers are equipped with

finned copper tubes are rolled into steel tube sheets. Integral 450 psig relief valves. Heat recovery condensers are freesubcoolers are incorporated on 40 ton and larger Arrange- draining to the lower (tower) condensers and do not subcool.

HOT GAS BYPASS (OPTIONAL)

This option allows passage of discharge gas to the evaporator

permitting operation at lower loads than available with compressor unloading. It also keeps the velocity of refrigerant gas

high enough for proper oil return at light load conditions. A

solenoid valve in the hot gas bypass line is wired in parallel

with the compressor unloader

Ul.

Thus, the hot gas solenoid

cannot open unless the compressor is operating in an unloaded mode. If only one hot gas valve is specified for the

unit, the hot gas bypass is wired in the first refrigerant circuit

and the lead-lag switches are therefore eliminated. The hot

gas bypass option is also available for the second refrigerant

circuit whereby the lead-lag switches remain.

The pressure regulating valve is factory set to begin open-

ing at 58 psig (32°F for R-22). This setting can be changed

Figure 32.

Hot Gas Bypass Piping Diagram

f

I

I

b,

TL”

by changing the pressure of the air charge in the adjustable

bulb. To raise the pressure setting, remove the cap on the

bulb and turn the adjustment screw clockwise. To lower the

setting, turn the screw counterclockwise. Do not force the adjustment beyond the range it is designed for, as this will

damage the adjustment assembly.

The regulating valve opening point can be determined by

slowly reducing the system load while observing the suction

pressure. When the bypass valve starts to open, the refrigerant

line on the evaporator side of the valve will begin to feel warm

to the touch.

CAUTION: The hot gas line may become hot enough to

cause injury in a very short time; care should be taken during valve checkout.

Figure 33. Hot Gas Bypass Adjustment Range

Page 46 I IM 508

30

40

50

TEMPERATURE

60

70

(“F)

80

AT BULB LOCATION

90

100

110

Page 47

IN-WARRANTY RETURN MATERIAL PROCEDURE

COMPRESSOR

Copeland

who maintain a stock of replacement compressors and service parts to serve refrigeration contractors and servicemen.

sales representative, or Warranty Claims Department at the

address on the cover of this bulletin. You will be authorized

to exchange the defective compressor at a Copeland wholesaler, or an advance replacement can be obtained. A credit

is issued you by the wholesaler for the returned compressor

after Copeland factory inspection of the inoperative compressor. If that compressor is out of Copeland’s warranty, a

salvage credit only is allowed. Provide full details; i.e., unit

Material may not be returned except by permission of authoriz-

ed factory service personnel at Minneapolis, Minnesota. A

“return goods” tag will be sent to be included with the returned

material. Enter the information as called for on the tag in order

to expedite handling at our factories and prompt issuance of

credits.

replacement. Therefore, a purchase order must be entered

through your nearest McQuay representative. The order

Refrigeration Corporation has stocking wholesalers

When a compressor fails in warranty, contact your local

COMPONENTS OTHER THAN COMPRESSORS

The return of the part does not constitute an order for

model and unit serial numbers. Include the invoice and the

salvage value credit memo copies and we will reimburse the

difference. In this transaction, be certain that the compressor

is definitely defective. If a compressor is received from the

field that tests satisfactorily, a service charge plus a transportation charge will be charged against its original credit value.

On all out-of-warranty compressor failures,

the same field facilities for service and/or replacement as

described above. The credit issued by Copeland on the returned compressor will be determined by the repair charge

established for that particular unit.

should include part name, part number, model number and

serial number of the unit involved.

Following our personal inspection of the returned part, and

if it is determined that the failure is due to faulty material or

workmanship, and in warranty, credit will be issued on

customer’s purchase order.

All parts shall be returned to the pre-designated factory,

transportation charges prepaid.

Copeland

offers

IM 508

I

Page 47

Page 48

TROUBLESHOOTING CHART

Compressor Will

Not Run

Compressor Noisy

or Vibrating

High Discharge

Pressure

Low Discharge

Pressure

High Suction

Pressure

Low Suction

Pressure

Little or No Oil

Pressure

Compressor

Loses

Oil

Motor Overload

Relays or Circuit

Breakers Open

Compressor Thermal

Protector Switch Open

Freeze Protection

Opens

1.

Main switch, circuit breakers open.

2.

Fuse blown.

3.

Thermal overloads tripped or fuses blown

4.

Defective contactor or coil.

5.

System shut down by safety devices.

6.

No cooling requrred.

7.

Liquid line solenoid will not open.

6.

Motor electrical trouble.

9.

Loose

wmng.

1. Flooding of refrigerant into crankcase.

2. Improper piping support on suction or liquid line.

3. Worn compressor.

1. Condenser water insufficient or temperature too high

2. Fouled condenser tubes (water cooled condenser). Clogged spray

nozzles (evaporative condenser). Dirty tube and fin surface (air

cooled condenser).

3. Noncondensables in system.

‘4. System overcharged with refrigerant.

5. Discharge shutoff valve partially closed.

‘6. Condenser undersized.

‘7. High ambient conditions.

1.

Fault condenser temperature regulation.

2. Suction shutoff valve partially closed.

3. Insufficient refrigerant in system.

4. Low suction pressure.

5. Compressor operating unloaded.

‘6. Condenser too large.

‘7. Low ambient conditions.

1. Excessive load.

2. Expansion valve overfeeding.

3. Compressor unloaders open.

1.

Lack of refrigerant.

2.

Evaporator dirty.

3.

Clogged liquid line filter-drier.

4.

Clogged suction line or compressor suction gas strainers.

5.

Expansion valve malfunctioning.

Gasket failure in evaporator head ring.

6.

7.

Condensing temperature too low.

Compressor will not unload.

0.

9. Insufficient water flow.

1.

Clogged suction oil strarner.

2. Excessive liquid in crankcase.

3. Oil pressure gauge defective.

4. Low oil pressure safety switch defective.

5. Worn oil pump.

6. Oil pump reversing gear stuck in wrong position

7. Low oil level.

6.

Loose fitting on oil lines.

9. Pump housing gasket leaks.

10. Flooding of refrigerant into crankcase.

1. Lack of refrigerant.

‘2. Velocity in risers too low.

‘3. Oil trapped in line.

4. Excessive compression ring blow-by.

1. Low voltage during high load conditions.

2. Defective or grounded wiring

3. Loose power wiring.

4. High condensing temperature.

5. Power line fault causing unbalanced voltage.

6. High ambient temperature around the overload relay.

7. Failure of second starter to pull in on part

start system.

1. Operating beyond design

2. Discharge valve partially shut.

3. Blown valve plate gasket.

1.

Thermostat set too low.

2. Low water flow.

3. Low suction oressure.

m

motor or power circuits.

conditrons.

windmg

1. Close switch.

2. Check electrical circuits and motor winding for shorts or grounds.

Investigate for

breakers after fault is corrected.

3. Overloads are auto reset. Check unit closely when unit comes

back on line.

4. Repair or replace.

5. Determine type and cause of shutdown and correct it before reset-

ting safety switch.

6. None. Wait until unit calls for cooling.

7. Repair or replace coil.

6. Check motor for opens, short circuit, or burnout.

9. Check all wire junctions. Tighten all terminal screws.

1.

Check superheat setting of expansion valve.

2. Relocate, add or remove hangers

3. Replace.

1.

Readjust temperature control or water regulating valve. Investigate

ways to increase water supply

2. Clean.

3. Purge the noncondensabies.

4. Remove excess refrigerant.

5. Open valve.

6. Check condenser rating tables against the operation.

7. Check condenser rating tables against the operation.

1. Check condenser control operation.

2. Open valve.

3. Check for leaks. Repair and add charge.

4. See corrective steps for low suction pressure below.

5. See corrective steps for failure of compressor to load.

6. Check condenser rating table against the operation.

7. Check condenser rating tables against the operation.

1. Reduce

2. Check remote bulb. Regulate superheat.

3. See corrective steps

1. Check for leaks. Reoarr and add charoe.

2. Clean chemically.

3.

Replace cartridge(s).

4. Clean strainers.

5. Check and reset for proper superheat. Replace if necessary.

6. Check

7. Check means for regulating condensing temperature.

6. See

9. Adjust gpm.

1. Clean.

2. Check crankcase heater. Reset expansion valve for higher

superheat. Check liquid line solenoid valve operation.

3. Repair or replace. Keep valve closed except when taking reading.

4. Replace.

5. Replace.

6. Reverse direction of compressor rotation by switching compressor

leads.

7. Add oil.

6. Check and tighten system.

9. Replace gasket.

10. Adjust thermal expansion valve.

TCheck

2. Check riser sizes.

3. Check pitch of lines and refrigerant velocities.

4. Replace compressor.

1. Check supply voltage for excessive line drop.

2. Replace compressor-motor.

3. Check all connections and tighten.

4. See corrective steps for high discharge pressure.

5. Check supply voltage. Notify power company. Do not start until

fault

6. Provide ventilation to reduce heat.

7. Repair or replace starter or time delay mechanism.

1. Add facilities so that conditions are

2. Open valve

3. Replace gasket.

1 Reset to

2. Adjust gpm.

3. See “Low Suction Pressure

posstble overloading. Replace fuse or reset

loador

add additional equipment.

foffailure

of compressor to load.

”

”

withrn allowable

Irmrts.

’

fIP

across evaporator.

corrrective steps for failure of compressor to unload.

for leaks and repair Add refrigerant.

IS corrected

42’F

or above.

Page 48 I IM 508

*

Remote Condenser Models.

NOTE: FOR TROUBLESHOOTING PROCEDURES ON MICROTECH CONTROL REFER TO IM 493.

Page 49

PRODUCT WARRANTY

SnyderGeneral Corporation, hereinafter referred to as the

“Company,” warrants that it will provide, at the Company’s

option, either free replacement parts or free repair of component parts in the event any product manufactured by the

Company and used

material or workmanship within twelve (12) months from initial startup or eighteen (18) months from the date shipped

by the Company, whichever comes first. For additional consideration, the Company warrants that for four (4) years following the initial warranty period it will provide, at the Company’s

option, free replacement parts for the motor-compressor, or,

free replacement for any integral component of the

compressor which proves defective in material or workmanship. For an additional consideration, the Company warrants

that for nine (9) years following the initial warranty period it

will provide free replacement of the heat exchanger in

fired or oil-fired furnaces which proves defective in material

and workmanship. (Extended warranties for motor-compressors and heat exchangers are not applicable unless separately

purchased.)

To obtain assistance under this parts warranty, extended

motor-compressor warranty, or extended heat exchanger warranty, simply contact the selling agency. To obtain informa-

tion or to gain factory help: For brandnames Arcoaire and/or

Comfortmaker contact SnyderGeneral Corporation, Warranty Department, 302 Nichols Drive, Hutchins, TX 75141,

telephone (214) 2257351. For McQuay, Climate Control, Barry

Blower and

Corporation, Warranty Claims Department,

Minneapolis, MN 55440, telephone (612)

THIS WARRANTY CONSTITUTES THE BUYER’S SOLE

REMEDY. IT IS GIVEN IN LIEU OF ALL OTHER WARRAN-

in the United States proves defective

JennFan

brandnames, contact SnyderGeneral

553-5330.

motor-

P.

0. Box 1551,

in

gas-

TIES. THERE IS NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

IN NO EVENT AND UNDER NO CIRCUMSTANCES SHALL

THE COMPANY BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, WHETHER THE THEORY BE

BREACH OF THIS OR ANY OTHER WARRANTY, NEGLIGENCE OR STRICT TORT.

This parts warranty and the optional extended warranties

extend only to the original user. Of course, abuse, misuse,

or alteration of the product in any manner voids the Company’s warranty obligation. Neither the parts or extended war-

ranty obligates the Company to pay any labor or service costs

for removing or replacing parts, or any shipping charges.

Refrigerants, fluids, oils, and expendable items such as filters