Page 1

Bulletin No. IM 127

Rev.

November 1973

INSTALLATION AND

MAINTENANCE DATA

WHC

CENTRIFUGAL WATER CHILLER

145 THRU 362 TONS

l

McQUAY-PERFEX

INC. l 13600 INDUSTRIAL PARK BLVD., P.O. BOX 1551

MINNEAPOLIS, MINNESOTA 55440

l PHONE: (612) 545-2892

Page 2

TABLE OF CONTENTS

Controls

...............................................

Sequence of Operation...................................1 5

Set Points

Wiring Diagram

Charging

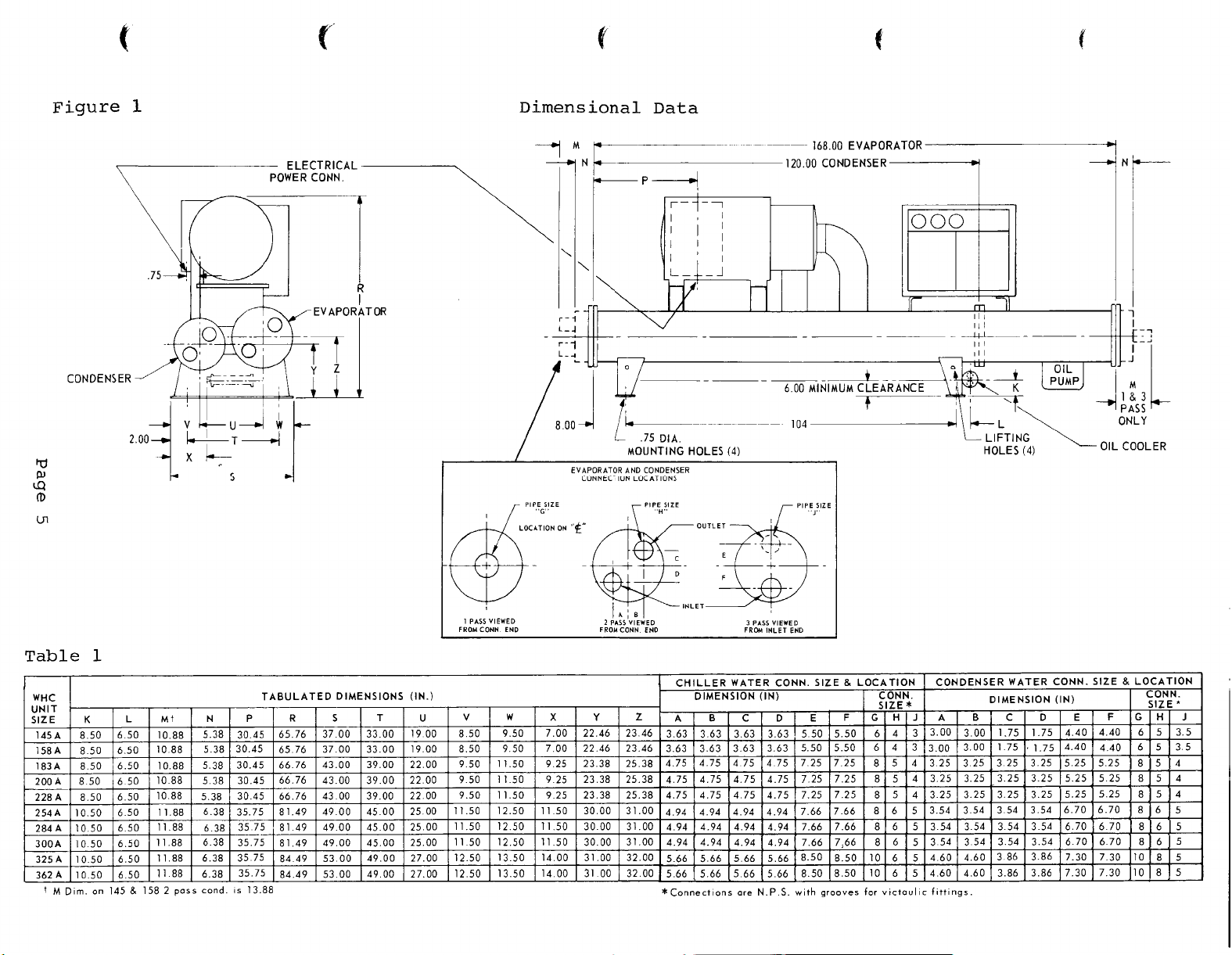

Dimensional Data

Electrical

Auxiliary Interlocks

Motor Data

Power Wiring

Electronic Control

Operation

Calibration

Evacuation

Leak Tests

Liquid Flow Control

Location

Motor Cooling

Moving and Mounting

Oil System

Physical Data

Pre-Installation

Pre-Startup

Pressure Drop-Evaporator

Pressure Drop-Condenser

Shutdown

Startup

................................................

Trouble Shooting

Vane Control

Warranty Information

Water Piping

Chilled Water

Condenser Water

Oil Cooler

System Schematic

...........................................

......................................

.................................................

.........................................

.............................................

..............................

..13.14

...........................................

.........................................

.......................................

............................................

............................................

................................

.._............3 6

..............................................

......................................

.................................................

..........................................

......................................

.............................................

..........................................

...................................

..ti

............................................

...............................

................................

...............................................

.........................................

..........................................

.....................................

.............................................

..........................................

........................................

............................................

.......................................

..12

..l

6

26,27

37

5

..ll

..4 5

..ll

34

..3 4

40

.3

6

32

3

..3

4

4

..2 4

..4 6

3

...

..19

..4 3

..4 4

..3 7

..2 3

48

...2 9

47

6

9

.lO

7

9

01972

McQuay

Division,

“McQUAY”

Nominal Capacity (Tons)

McQuay -

and “SEASONPAK”

Perfex Inc.

WHC _ 228A _ A t

are registered

NOMENCLATURE

trademarks of

- 6 k

- c k

- D t

Page 2

McQuay Division, Minneapolis, Minnesota.

R.H. CONDENSER, R H. EVAPORATOR

R.H. CONDENSER, L.H. EVAPORATOR

L.H. CONDENSER, R.H. EVAPORATOR

L.H. CONDENSER, L.H. EVAPORATOR

Page 3

INTRODUCTION

McQuay WHC Seasonpak centrifugal water chillers are completely

independent,

water.

The WHC Seasonpak centrifugal chillers are factory

assembled as a complete packaged unit, piped, wired,

automatic refrigeration systems, designed to chill

evacuated,

charged with refrigerant and oil, and performance tested, ready

for installation.

shell and water thru-tube condenser:

Each unit consists of: a flooded refrigerant

a single stage gear driven

centrifugal compressor with a liquid cooled hermetic motor,

and an independent oil pump with reservoir system.

Also

included are manual liquid line shut-off valves, liquid line

trimming valve,

liquid line orifice and discharge line check

valve.

The 115 volt control center supplies power to the oil pump, oil

heaters,

automatic operation of the centrifugal chiller.

and all safety and operating controls for complete

Terminals are

provided for all necessary field interlock wiring between

control panel and unit starter, condenser pump relay, chiller

pump starter,

flow switch and oil cooler solenoid.

PRE-INSTALLATION

I.

GENERAL

installation by qualified personnel only.

Equipment such as this is intended for

As a condition

of the warranty,the equipment start up must be performed

under the supervison of a McQuay Service Representative.

Failure to do so voids the warranty.

INSPECTION

II.

Upon receipt of equipment all items should

be carefully checked against the Bill of Lading to be sure

all crates and cartons have been received.

All units

should be carefully inspected for damage when received.

Shipping damage may cause loss of refrigerant charge and

contamination of system.

If any damage is found it

should be reported to the carrier immediately and a claim

filed for damage.

McQuay,

will not be responsible for

any damage incurred in shipment.

LOCATION

This unit is designed for indoor application and must be

A.

1

located in an area where the surrounding ambient

temperature is 40 F. or above.

A good rule of thumb is

to place units where ambients are at least 5 degrees

above the leaving water temperature.

Page 3

Page 4

LOCATION

Because of the electric control devices, the units should

B.

not be exposed to the weather.

(CONTINUED)

A plastic cover over the

control box is supplied as temporary protection during

transit.

An adequately strong foundation or base must be provided

C.

for mounting the concentrated load of the unit. If

necessary,

additional structural members should be provided

to transfer the weight of the unit to the nearest beams.

Surfaces must be reasonably level.

Adequate free area must be provided around the installed

D.

unit for connections and service.

Allow 14 feet for tube

removal and at least 3 feet around the remainder of the

unit for servicing compressor, oil pump, and controls.

MOVING AND MOUNTING UNIT

MOVING THE UNIT

I.

A.

B.

C.

D.

The McQuay Seasonpak centrifugal chiller is mounted on

heavy wooden skids to protect the unit from accidental

damage and to permit easy handling and moving.

Fig.

1 for physical and mounting information.

See

It is recommended that all moving and handling be

performed with the skids under the unit and that the

skids not be removed until the unit is in the final

location.

When moving the unit,

used under the skids.

dollies or simple rollers can be

In moving always apply pressure

to the base on skids only and not to the piping or

shells.

A long bar helps move the unit easily.

Always avoid dropping the unit.

When rigging the unit attach slings thru holes

provided in the base and always use spreader bars to

protect the control panel,

piping and insulation from

damage.

Do not attach slings to piping or equipment.

in the upright horizontal position at all times.

Move unit

Let

unit down gently when lowering from the trucks or

rollers.

Page 4

Page 5

Page 6

II.

HANDLING

Every model WHC Seasonpak centrifugal chiller is

A.

supplied with a full refrigerant charge.

shipment,

and is isolated by the manual condenser liquid line

valves and discharge line check valve.

Should the unit be damaged allowing the refrigerant

B.

to escape,

equipment area since the refrigerant will displace

the air.

Care should be taken to avoid rough handling or shock

due to dropping the unit.

UNIT FROM ANYTHING OTHER THAN THE BASE.

the charge is contained in the condenser

there may be danger of suffocation in the

Avoid exposing an open flame to refrigerant.

NEVER LIFT,

For

PUSH OR PULL

III.

MOUNTING THE UNIT

A.

The negligible vibration normally encountered with

the Seasonpak centrifugal chiller makes this unit

particularily

installations where the

to the floor if desired.

should be

building structure,

into the structure.

Mount the unit on the rubber

B.

for use under each corner of

level installations or areas

transmission is an important

rubber-in-shear or spring-type isolators are

recommended for maximum vibration isolation from the

building structure.

level unit.

desirable for basement or ground floor

unit

can be bolted directly

The floor construction

such

that the unit will not affect the

or transmit noise and vibration

isolation pads provided

the base.

in which vibration

consideration, optional

Use steel shims if necessary to

WATER PIPING

On a.11 upper

I.

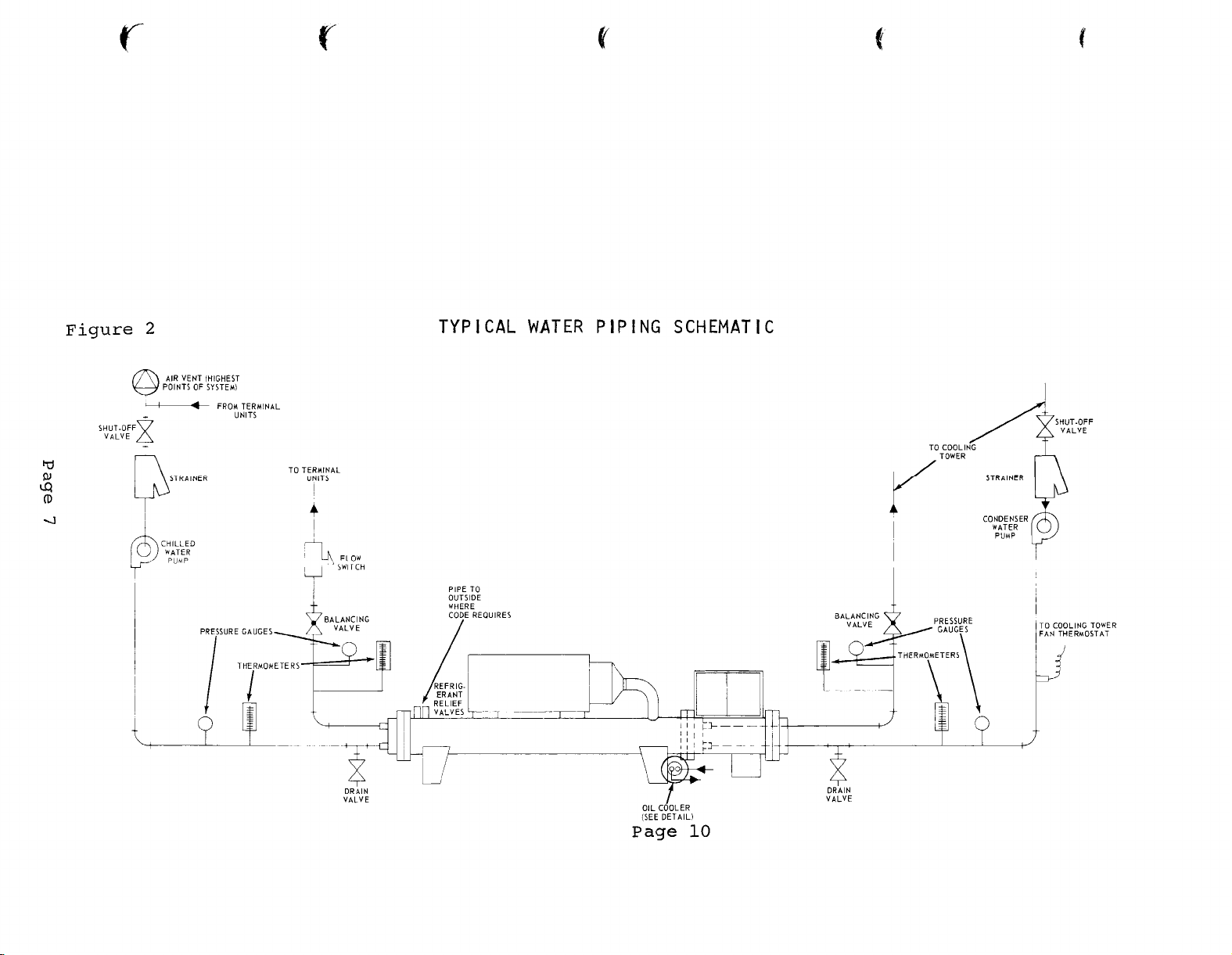

GENERAL CHILLER AND CONDENSER PIPING (See Fig. 2)

When installing water piping follow established practices

A.

and comply with local building and safety codes.

Shut-off valves should be provided at the unit so that

B.

normal servicing of the unit can be accomplished without draining the entire system.

Page 6

Page 7

Page 8

WATER PIPING (CONTINUED) GENERAL

All piping should be installed and supported to

C.

prevent the unit connections from bearing any strain

or weight of the system piping.

Vibration eliminators in all water piping connected to

D.

the unit are recommended to avoid straining the piping

and transmitting pump noise

building structure.

It is recommended that temperature and pressure

E.

indicators be installed within 3 feet of the inlet

and outlet of the shells to aid in the normal checking

and servicing of the unit.

A cleanable-type wire mesh strainer is recommended at

F.

the condenser pump suction and must be provided at

the evaporator pump suction to protect the pump and

shell from foreign matter.

foreign matter is allowed to block evaporator tubes.

and vibration to the

Freeze up can result if

Design the water piping so that it has a minimum

G.

number of changes in elevation.

Include manual or

automatic vent valves at the high points of the water

so

piping,

circuit.

that air can be vented from the water

System pressures can be maintained by using

an expansion tank or a combination pressure relief

and reducing valve.

A preliminary leak check of the water piping should be

H.

made before filling the system.

The water connections are of the grooved Victaulic

I.

type for use with Victaulic couplings.

Matched fittings

must be field provided for the inlet and outlet

connections.

The water inlet is the bottom connection

and the water outlet the top connection on both

evaporator and condenser for all 2 and 3 pass units.

See Table I for chiller and condenser connection sizes.

If the shells must be drained for winter shut-down it

J.

is recommended that an anti-freeze solution be circulated

and drained for positive freeze protection.

All supply and return water boxes for the evaporator

K.

and condenser are provided with two pipe plugs which

can be removed for venting and draining the shells.

Page 8

Page 9

II.

CHILLED WATER PIPING

A.

All chilled water piping should be insulated to

prevent condensation on the lines. If insulation is

not of the self-contained vapor barrier type, it

should be covered with a vapor seal.

not be insulated until completely leak tested. Vent

and drain connections must extend beyond proposed

insulation thickness for accessability.

Piping should

B.

C.

The system cycling thermostat, TC(W) and electronic

vane control EVC are mounted inside the control

console with the sensors mounted in the evaporator

leaving water connection. The low water temp safety

TS(LW),

sheet.

charged capillary tubing when working around the

unit.

before running the unit to be sure that it is firmly

anchored and not rubbing on the frame or any other

component.

The evaporator water boxes can be interchanged end

for end so that the water connections

either end of the unit.

sensors discussed above must be moved to sense the

leaving water temperature from the unit.

gaskets must be used if a change is made.

must be trimmed to conform to block-off baffle

arrangements in the water boxes which vary with the

number of passes in the shell.

sensing bulb is located in the chiller tube

Care should be taken not to kink or break the

It is also advisable to check the cap tube

can be

If this is done the 3

New head

made at

Gaskets

III.

CONDENSER

A.

Water cooled condensers may be piped for well water

applications,

cooling tower.

include a small amount of waste circulating water

and adequate water treatment provided to prevent

build-up of contaminants and scale in condenser tubes

and tower basin.

The condenser water boxes can be interchanged end

B.

for end so that the water connections can be made at

either end of the unit.

trimmed and used if a change is made.

C.

The minimum entering water temperature to the

condenser is 65 F.

cooling tower or condenser bypass or by thermostatic

control of the cooling tower fans,

-

WATER PIPING

or for use in conjunction with a

Cooling tower applications should

New head gaskets must be

This can be accomplished by a

Page 9

Page 10

CONDENSER WATER PIPING

A condenser flow switch is not required and cannot

D.

be wired directly into the interlock circuit. If

used,

a normally closed timer must be used to bypass

the condenser flow switch on start up.

(CONTINUED)

IV.

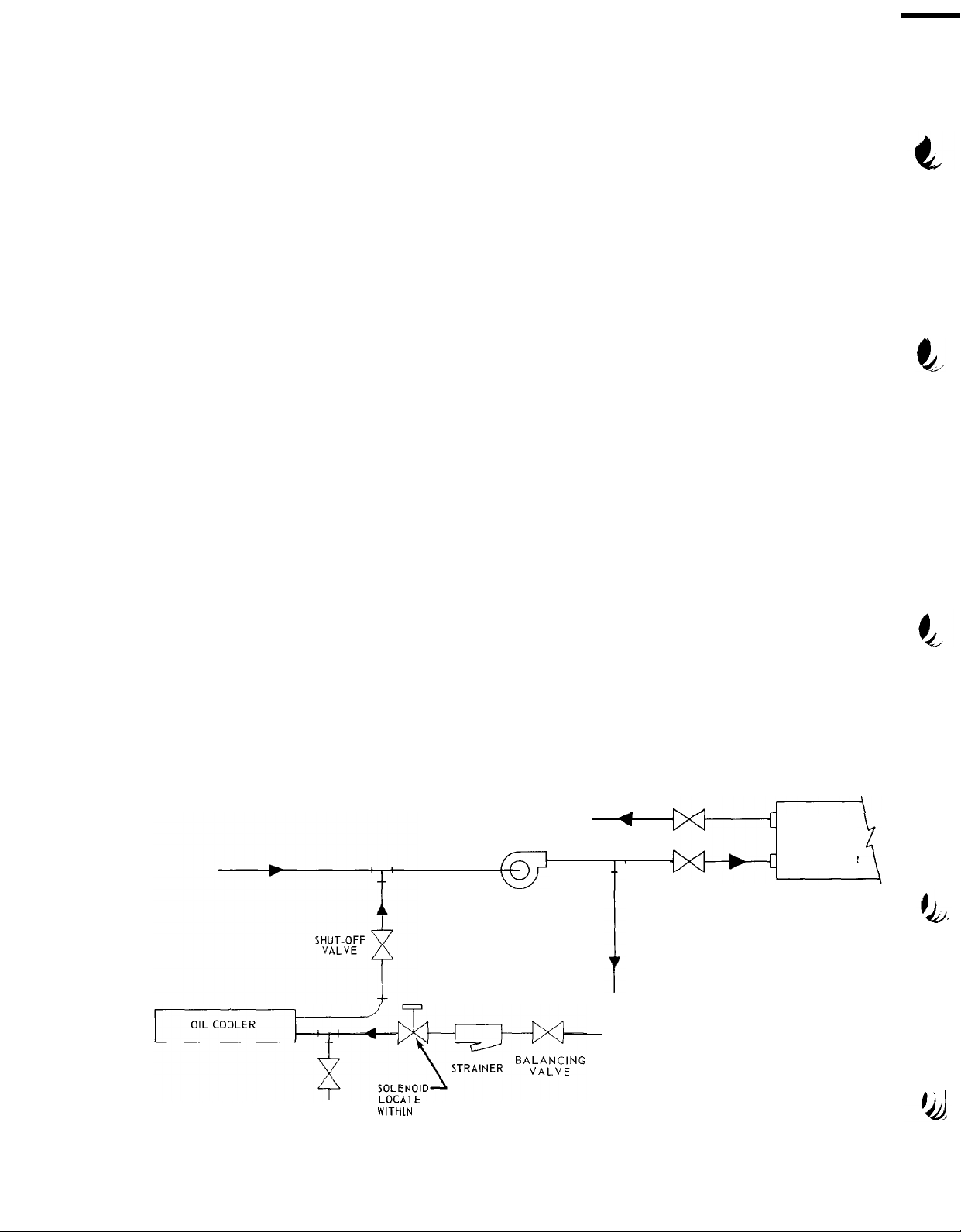

OIL COOLER WATER PIPING

A minimum of 8 GPM of water at 85 F. or lower

A.

temperature must be provided to the oil cooler to

maintain the oil temperature leaving the cooler at

NPT connection is

a maximum of

110 F.

the inlet and the top

If condensing water is used it is imperative that the

B.

The bottom

NPT connection is the outlet.

1""

1""

water temperature be kept within design limits to keep

oil temperature supply below 110 F.

There is also a

potential problem due to fouling which reduces

effectiveness.

This problem must be recognized and

frequent tube cleaning may be required.

When chilled water is used as the source of water for

C.

the oil cooler it should be piped across the chiller

pump directly to assure full pump pressure across the

oil cooler.

See Figure below.

DRAIN

VALVE

Preferred Oil Cooler Piping

A

A

t’

WITHLN

3FT OF

COOLER

CHILLED WATER

PUMP

EVAPORATOR

Page

10

Page 11

D.

If it is necessary to connect the oil cooler in

parallel with either shell, it is essential that

the

pressure

drop in the line be kept down to assure

adequate flow to the oil cooler. The oil cooler

water pressure drop is 3.5 feet of water at 8 GPM.

E.

City water can also be used as the source of supply.

A flow balance valve should be provided and the

drain line should be trapped to prevent the oil

cooler from draining on the off cycle.

F.

In a.11 cases a strainer with a maximum

l/4"

should be provided at the oil cooler inlet and a

normally closed

must be

provided and wired as shown on the unit

115V.

solenoid valve (water duty)

wiring diagram.

REFRIGERANT VENT PIPING

Both the evaporator and the condenser shells have

A.

pressure relief valves to vent out refrigerant gas

if an unsafe pressure should build up in the shell.

It is recommended that these valves be vented to

the outside to meet local codes.

piping procedure follow ASA

B9-Sec.

For proper vent

12, ASME and

local codes.

ELECTRICAL

mesh

I.

POWER

WIRING

The WHC Seasonpak centrifugal chiller is designed to be

used in conjunction with a separately supplied starter of

the across-the-line,star-delta or auto-transformer type.

The starter and overloads are specifically selected for

application with a specific size Seasonpak centrifugal

chiller.

A.

All field wiring must comply with local, state and

Standard NEMA motor starters are not acceptable.

National Electrical Codes.

All fuses and wiring between disconnect, starter, and

B.

motor must be in accordance with the National Electrical

Code.

The compressor motor is supplied with 6 terminals for

c.

use with across the line, star-delta, or auto-transformer

starters.

When across-the-line or auto-transformer

starters are used terminals l-6, 2-4 and 3-5 must be

jumpered together with terminal straps.

Page 11

Page 12

ELECTRICAL POWER WIRING (CONTINUED)

CARE must be used in wiring leads to compressor motor

D.

terminals to assure that proper phase relationship is

carried through starter to motor.

CONNECTIONS TO THE COMPRESSOR ARE NOT TO BE MADE UNTIL

POWER WIRING HAS BEEN CHECKED AND APPROVED AY AN

AUTHORIZED McQUAY FIELD SERVICE REPRESENTATIVE.

CAUTION: DO NOT TURN MOTOR TERMINAL STUDS WHEN MAKING

POWER CONNECTIONS.

THIS COULD LOOSEN STUD NUTS AND

CAUSE REFRIGERANT LEAKAGE.

The power wiring to the compressor must be in the

E.

proper phase sequence

for correct motor rotation.

With phase sequence of l-2-3 and

Tl-T6,

L2 connected to T2-T4 and L3 connected to T3-T5

the motor will rotate in the proper direction (clockwise when checking in motor sight glass).

and L3 lines at compressor motor junction box.

L2,

F.

EXTENSIVE DAMAGE CAN RESULT IF MACHINE IS ALLOWED TO

RUN IN WRONG DIRECTION.

McQUAY IS NOT RESPONSIBLE

FOR MACHINE DAMAGE CAUSED BY REVERSAL OF POWER PHASE

BY POWER COMPANIES,

ELECTRICIANS OR OTHERS.

NOTE:

Ll

connected to

FINAL

Label

Ll,

II.

CONTROL WIRING

60

A separate source of 115 volt,

cycle power is required

for the Seasonpak centrifugal chiller control circuit.

This circuit is to be fused at 15 amps to protect the

control circuit from overload.

A.B.IMPORTANT

THE DISCONNECT TO THIS CIRCUIT MUST REMAIN

ON AT ALL TIMES TO MAINTAIN PROPER OIL TEMPERATURE IN

THE SEASONPAK CENTRIFUGAL CHILLER TO PREVENT

REFRIGERANT FROM ACCUMULATING IN THE OIL.

ATTACH A LABEL WITH THE ABOVE NOTE TO THE CONTROL

CIRCUIT DISCONNECT SWITCH.

The source of power for the control circuit can be

transformer, if provided, in the unit starter.

The

transformer must be rated at 3 KVA with an inrush

rating of 18 KVA.

If the transformer is used as a

source of power the unit disconnect should also be

marked with the label shown above in Paragraph A.

a

Page 12

Page 13

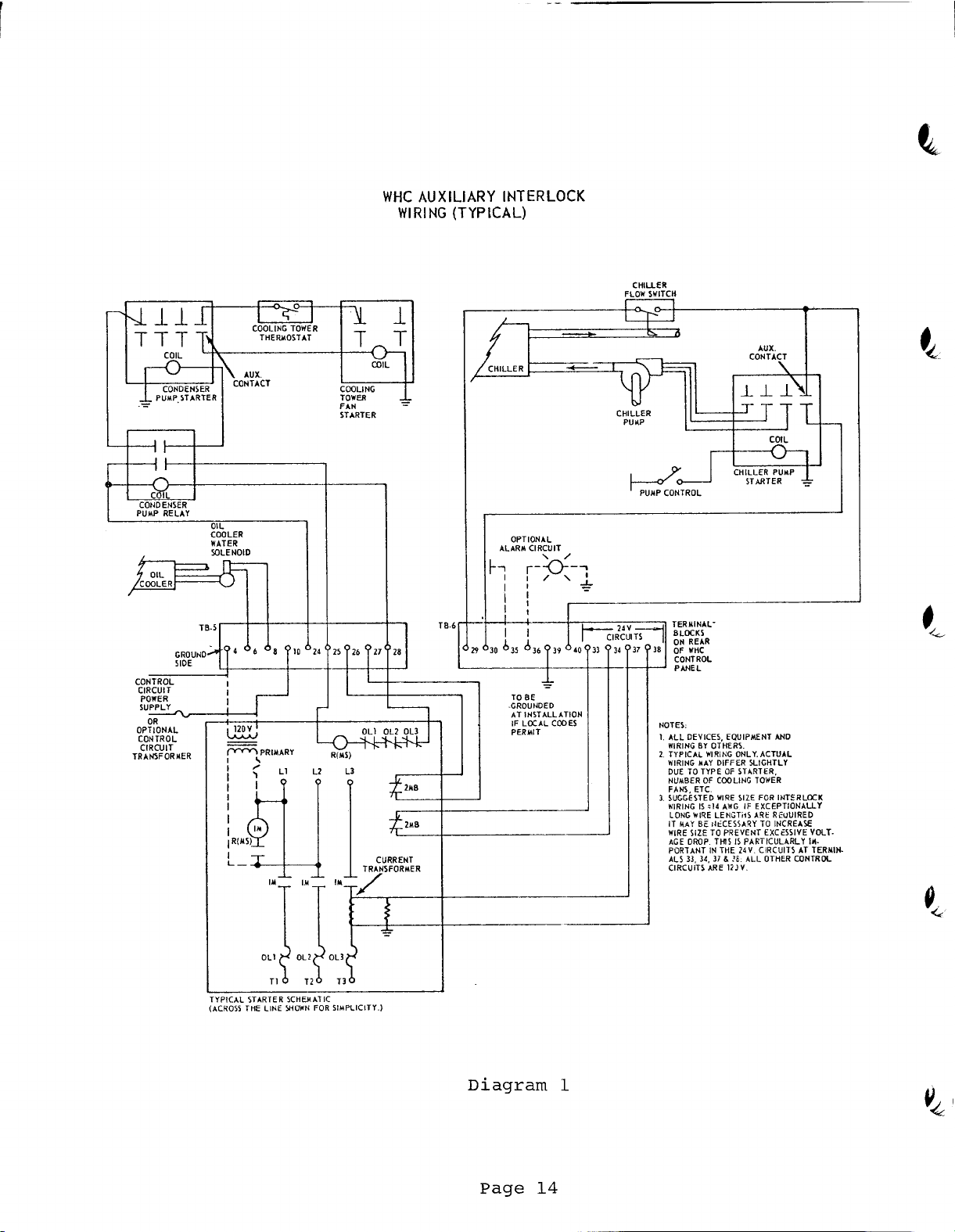

III.

AUXILIARY WIRING

In addition to the power wiring supplied to the unit

control center,

additional interlock wiring is required

and is to be wired directly to terminals provided in

the control center.

size for the amp capacity of the circuit.

Wire Gauge #14 THW is of sufficient

Consult the

auxiliary interlock wiring diagram (Diagram 1) for

detailed wiring information.

A.

Wire the two sets of normally closed contacts (in

unit starter) to terminals 26, 27, and 33, 34 in the

control center.

B.

Add wires from the current transformer provided in,

the unit starter to terminals 37, 38 in the control

center.

C.

Provide a chiller pump interlock to prevent the

compressor from starting until chiller water flow has

been established.

A set of normally open contacts

on the chiller pump starter is required in

conjunction with a flow switch to be wired to

terminals 29, 40, and 30.

D.

Provide a condenser pump relay with 2 sets of

normally open contacts (115 v. coil max. 100 VA

rating),

to start the condenser water pump at the

time the compressor is ready to start and cycle the

condenser pump with the compressor.

control center terminals 24,

28 with a set of normally

Wire coil to

open contacts wired to terminals 24, 25 and the

second set of normally open contacts to start the

condenser water pump.

E.

Wire in the leads from the

oil cooler water solenoid

(115 V. coil) to terminals 8 and 6 in the control

center.

F.

Add interlock wiring between the control center

terminals 25 and 28 and the m&r starter relay in

the unit starter.

G.

Terminals 35 and 36 in the control center can be

wired into a customer supplied and powered alarm

circuit if desired.

H.

Terminal 39 is a ground terminal for the control

panel and should be wired to a suitable ground if

local codes permit.

Page 13

Page 14

Page 15

The necessary operational and safety controls for the McQuay

Seasonpak centrifugal chiller are mounted in the control center

or incorporated in the system.

between the starter, pumps, and unit:

With the interlock wiring

the control circuit is complete

and the system will operate automatically.

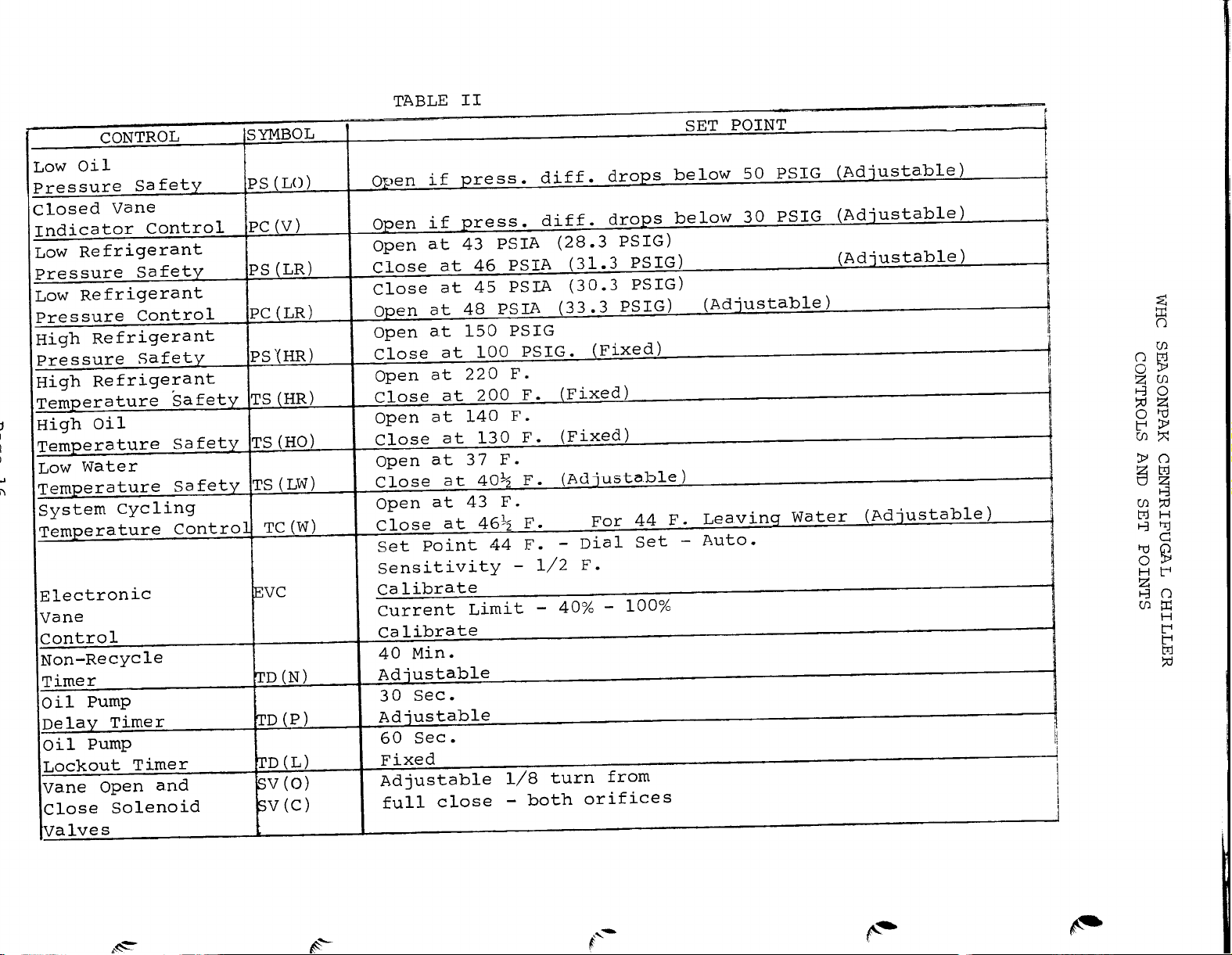

A description of the controls,

control function and set point is

shown in Table II.

A schematic wiring diagram incorporating wire numbers is shown on

P 26

27. The numbers on the left of the

diagram designate

the

&

line numbers as an aid in following the sequence of operation.

With 115 V. power to the control circuit, the system switch

"Off"

and the unit calling for cooling the following sequence

Sl

of operation applies.

I SEQUENCE OF OPERATION (Note: A simplified Sequence Appears

in Catalog 920)

A.

Power is fed thru the normally closed contacts of TD(P) and

energizes the oil sump heater and compressor heater (L. 65).

B.

Power is also fed to transformer,

Tl,

(L.85) energizing the

24V. circuit controlling the vanes and energizing the D.C. motor

relay (L. 82) closing R (T) contacts

C.

Providing all safeties

PS(L0)

and R(T) are made,

PS(HR), PS(LR), TS(HR), TS(HO), TS(LW);

reset switches 2-8 can be pushed energizing

relays R4-R10 and de-energizing lights

l-2(L.52).

LTl-LT7.

D.

With the l-3 contacts of R4-R9 closed,

R3 is energized closing

its contacts 4-6 in the compressor starter circuit (L.25).

E.

If 40 minutes have elapsed since the machine has last started,

Rll

will be de-energized and Rll contacts 1-2 closed (L-21).

F.

By switching Sl to the "on" position, power is now fed thru

TD(L) normally closed-timed open contacts if all interlocks are

closed and above conditions have been met.

G.

The

TD(P)

closed

motor,

H.

-

providing oil pump overload, OL is closed (L.13).

All Ml contacts of the oil pump starter close, starting the

clutch coil is energized closing TD(P) normally

timed open contacts which energizes Ml contactor and

oil pump and energizing the field wired oil cooler solenoid.

Closed vane indicator control, PC(V), will close at 30 PSIG oil

pressure differential (only if vanes are closed).

TD(P)

Page 15

Page 16

Page 17

As the oil pressure builds up the closed vane indicator control,

I.

PC(V),

vanes are closed).

suction pressure,

wired condenser pump relay, R(CP) (L-27).

J.

energized along with the TD(N) motor and

closed-timed open contact of

the machine from starting again for 40 minutes by keeping Rll

energized and

will close at 30 PSIG oil pressure differential (only if

As the oil pressure builds up to 60 PSIG above

PS(L0)

With the closing of Rl contacts 4-6

Rll

contact 1-2 open.

contacts close energizing Rl and the field

TD(N).

(L.59)

Rll

This

non recycle timer prevents

the TD(N) clutch is

thru the normally

When R(CP) is energized,

K-

the motor starter relay, R(MS) (L.27).

L.

The R(MS) normally open contact in the starter energizes the circuit

to the starter,

compressor will now start.

M.

The unit will have started on low load with the vanes closed since

normally closed starter interlock (Terminals 33, 34) will have

energized fast close solenoid

now opens permitting the EVC to control the vanes.

N. Compressor starter normally closed interlock (Terminals 26, 27)

(L.17)

opening the circuit.

up pressure in 60 seconds,TD(L) will open up the compressor circuit

and stop the oil pump.

0.

located in the chiller leaving water to control the compressor

inlet guide vanes. On temperature increase

causing the vanes to open and on temp.decrease

slowly closing the vanes and thereby limiting the volume of gas the

compressor handles.

also opens de-energizing TD(L) and preventing TD(L) from

The electronic vane control (EVC) utilizes an electronic sensor

providing power to the compressor motor. The

If for some reason the oil pump does not build

R(CP) contacts close energizing R2 and

SV(FC).

The normally closed interlock

SV(0)

is energized,

SV(C)

is energized

P.

The electronic vane control (EVC) also receives a signal from a

current transformer, CT,

current reaches 100% of the control set point, the current control

circuit in the EVC overides the temperature control circuit and

prevents the vanes from opening further.

to increase to 105% of the set point the current control energizes

SV(FC)and SV(C).These solenoids direct oil flow to swiftly close

the vanes and thereby limit the unit power.

The low refrigerant pressure vane control

Q.

also override the EVC and put the vanes in fast close as above if

the suction pressure drops to an undesirable low point.

located in the unit starter.

If motor current continues

PC(LR),

Page 17

If the

(L.78) can

Page 18

R.

The above control sequence described in 0, P, and Q will keep

the machine on the line and provide automatic operation down to a

10% load.

of TC(W)

and stop the compressor.

which starts the timing of the

to run for 30 seconds however until

S. The compressor can also be stopped similar to R above by any one

of the six safety controls:

or

PS(L0).

If leaving water temperature drops below the set point

(L.25),

it will open

The

,

de-energize the circuit to

TD(P)

clutch will also be de-energized

TD(P)

motor.

TD(P)

contacts time open.

The oil pump will continue

R(MS)

PS(HR), PS(LR), TS(HR), TS(H0) TS(LW),

If for example,

contacts R4,

light

1-2.

LTl,

de-energes R3 opens R3 contacts 4-6 and closes R3 contact

The R3,

supplied alarm bell if used.

upon pressure reduction,

energizing R4 and consequently R3.

PS(HR)

l-3 and 4-6 and closing R4, 4-5.

opens R4 (L.35) is de-energized opening

This lights warning

1-2 contacts will energize a circuit to a field

Although

PS(HR)

automatically resets

R4 cannot be energized until S2 is reset,

Operation of other safety controls

is similar.

T.

If the oil pressure drops below 50 PSIG differential during

operation,

de-energizing R-10 and lighting LT7.

resets to energize

PS(L0)

contacts (L.25) open stopping the compressor,

S8 must be reset after PS

R10

(L.55). On unit shut down or on

(LO)

operation of safeties in 2 above R2 normally closed contacts 1-2

keep

RlO

energized after PS(LO)opens and reset of S8 is not required.

For detailed control operation see control operation and calibration

P.

As described above,

the machine and the light will indicate the malfunction.

16

.)

an opening of a system safety control will stop

Before

resetting the corresponding reset button the cause of tie malfunction must be located and corrected.

Failure to do so will cause

repeated malfunction and machine damage.

Repeated tripping of a safety should be reported to the McQuay

Service Department and immediately investigated by a qualified

refrigeration service engineer.

PRECHECK FOR INITIAL START UP

After all of the piping and interlock wiring to the unit has been

completed,

up check is to be made per Items A

and all auxiliary components installed a pre-start

-

K below.

See

Appendix B

for

list of instruments and tools suggested for unit check out and

operation. At this point the McQuay Seasonpak Centrifugal Pre-Start

Check List (Form 240284A) must be completed and returned to the

McQuay Service Dept.

Page 18

Page 19

NOTE:

The completed form must be received by the McQuay Service

Department at least two weeks before a McQuay Service Representative

will be sent to the job site for start up.

c

'NOTE:

OF AN AUTHORIZED

I

A.

contactor to make sure it operates freely.

and clamps must be removed from relays and

operate relays,

freely.

compatibility of materials, dirt,

necessary.

at 105% of compressor FLA.

THE INITIAL UNIT START UP MUST BE PERFORMED IN THE PRESENCE

McQUAY

SERVICE REPRESENTATIVE TO VALIDATE WARRANTY.

PRE-START UP

With main disconnect open manually close and open main starter

All shipping wedges

contactors.

Manually

contacts and interlocks to see that they work

Check current carrying contacts and terminals for

and rust and change or clean if

Check the 3 overload relays to make sure they are rated

Check dashpot and piston assemblies

for cleanness and add dashpot fluid per manufactures overload

instructions.

B.

Check all electrical connections in control panel and starter

to be sure they are tight ardprovide qood electrical contact.

Although connections are tightened at the factory they may have

loosened enough in shipment to cause a malfunction.

*

C.

Check and inspect all water piping. Make sure flow direction

is correct and piping is made to correct connection on evaporator,

condenser and oil cooler.

D.

Open all water flow valves to the condenser and evaporator.

E.

Flush the cooling tower and system piping.

pump and manually start condenser pump and cooling tower.

all

piping for leaks.

and

condenser water circuit as well as from the entire water system.

F.

Check pressure drop across evaporator, condenser, oil cooler

and

see that water flow is correct per the design flow rates.

G.

Check the actual line voltage to the unit to make sure it is

the

same as called for on the compressor nameplate within

and

that phase voltage unbalance does not exceed

adequate power supply and capacity is

H.

Make sure all wiring and fuses are of the proper size.

Vent the air from the evaporator

available

Start evaporator

Check

210%

2%.

Verify that

to handle load.

Also

make sure all interlock wiring is completed per McQuay diagrams.

I.

Verify that all mechanical and electrical inspections by code

authorities have been completed.

Make sure all auxiliary load and control equipment is operative

J.

and that an adequate cooling load is available for initial start up.

Page 19

Page 20

K.

Arrange to have qualified maintenance personnel (who will be

in charge of operation of equipment) present at initial start up

for operating instructions.

Upon completion of the above checks, return the Pre-Start check

list (Form

After the above checks have been completed, the unit is ready for

leak testing and control circuit checking before actual start up.

THESE TESTS MUST BE DONE IN THE PRESENCE OF AN AUTHORIZED

SERVICE REPRESENTATIVE.

II

LEAK TESTING

Although the unit underwent two extensive refrigerant leak tests

at the factory and was free of leaks when shipped, leaks could

develop if damaged or mishandled in shipping.

be performed by the start up contractor under supervision of a

McQuay Service Representative.

testing.

240284A)

to the McQuay Service Dept.

See Appendix

A

McQUAY

A leak test must

for details on leak

III

Upon completion of above pre-start up check the control panel must

be checked.

factory before being shipped,

shipping and field interlock wiring circuits, if incorrect,

cause system malfunction.

NOTE:

open.

of oil pump and close the right hand pump return valve

turns from full back-seat position to allow oil drainage from vane

systems.

oil level is in top

The oil pump can be run during control circuit test for a short

period of a time, but the compressor must not be started.

T THIS TIME.

With the control circuit only energized and the unit disconnect

open,

motor starter relay in the unit starter.

CONTROL CIRCUIT CHECKS

Although the unit was completely checked at the McQuay

control settings may change during

could

Before control circuit is energized oil pump valves must be

Open fully all three shut off valves

Open oil shut off valve

l/4

of sight glass).

correct unit operation can be determined by observing the

(#6)

at oil filter.

(#3,

4, and 5) on top

(#4)

(Check that

1

l/2

For initial

terminals W and R on oil pump and tape individually to prevent

possible dead shorting.

Add (2)- 115V lights in parallel with oil cooler solenoid and

to observe simulated oil pump and compressor operation.

part

of test,

temporarily remove 2 wires from

Page

20

R (MS)

Page 21

Clamp ampmeter across heater circuits to check their operation.

A.

With system switch Sl "off"

lights 1-7 and alarm will be

energized when 115 V. power is applied to

-

Reset all safeties

alarm should stay on until last light is

reset.

B.

Warm bulb of

C.

Switch Sl to "on".

D.

TD(P)

clutch should start, closing

should start timing.

E.

TD(P)

motor should start. Ml contactor should pull in and the

TC(W)

above 45 deg.

TD(P)

Heaters should de-energize.

oil cooler solenoid should energize.

F.

Temporarily jumper

PS(L0)

G.

and

Rl

and R(CP) should then energize, close contact

Ll,

Ml on PC(V).

Ll,

Ml and L2, M2 on oil pressure control

and start the condenser pump.

H.

R2 and

R(MS)

should then energize and

the control

contacts.

TD(L)

should quit timing.

circuit.

TD(L)

R (CP)

On star-delta starters there will be approximately an 8 second

delay between starting and running

I.

TD(N)

TD(N)

should time for 40 minutes.

should continue to time independent of status of rest of

contactors.

After initially starting

circuit.

J.

Warm electronic sensor bulb.

EVC should simulate vane opening

by lighting load light on EVC.

K.

Cool electronic sensor bulb.

by lighting unload light on

L.

Drop pressure to suction control line by closing service

(#l)

valve

on top of evaporator and slowly relieving pressure

EVC.

from control line by loosening flare nut.

EVC should simulate vane closing

At 30.3 PSIG,

PC(LR)

contact should close and simulate vane fast closing by lighting

unload light on EVC.

M.

Drop suction

PS(LR)

R(MS)

should open,

and

R(CP).

control line pressure further.

drop out

LT5 should light,

R5

and R3 and de-energize relays

along with the alarm circuit.

At 28.3 PSIG

The oil cooler solenoid and oil pump contactor should remain

energized for 30 sec.

(#l)

and valve

and open valve slowly to raise line pressure.

Retighten flare nut on suction control line

Page 21

Page 22

At 31.3 PSIG

reset

PS(LR)

with S3.

and R(CP).

N.

Raise suction control line pressure to 33.3 PSIG and

should open.

0.

Operate EVC on manual switches and verify operation is correct.

PS(LR)

control should reset.

LT2 should energize, and pull in

It is now possible to

R(MS)

PC(LR)

P.

Check additional controls similar to Item L.

put sensor in ice water.

39%

36 F. and close at

For control circuit check of

Q.

F.

TS(LW)

should open on temp. drop at

PS(HR), TS(HR), TS(H0)

To check

temporarily remove lead from control and reconnect.

and R(T)

Corresponding

TS(LW)

light should light and reset switch should function as in Item L.

R.

Remove jumpers from

PS(L0).

LT7 should light and

R(MS)

should

drop out. Ml contactor and oil cooler solenoid should remain energized

for 30 seconds.

S.

Shut off chiller water pump.

R(MS).

to

NOTE:

IMPORTANT After all above tests have been

This should open the starter circuit

completed

satisfactorily,turn off power and remove all jumper wires used

for above test and re-wire oil pump to correct terminals. Leave

115 V. lights connected for oil pump operational check.

IV OIL PUMP OPERATIONAL CHECK

A.

Make sure all oil pump valves are open - See P.

20

.

B.

With system switch "off"

and/or compressor power disconnect "off",

compressor motor leads disconnected,

energize the unit control

circuit to provide power to heaters in oil pump and compressor.

NOTE:

HEATERS MUST BE ENERGIZED 24 HOURS BEFORE OIL PUMP IS

STARTED TO ASSURE ALL REFRIGERANT HAS BEEN DRIVEN FROM THE OIL.

OIL SHOULD BE HOT (APPROXIMATELY 130 F.) BEFORE TESTING AND

C. Reset safeties as necessary.

D.

Switch control circuit switch

Sl,

to "on"

(TD(W)

bulb must

be in an ambient temperature above set point).

E.

Oil pump should start per sequence of operation and build

llO#

up pressure to

on pump if necessary

F.

PC(V) switch should close at 30 PSI above suction pressure.

above suction.

-

clockwise raises pressure).

(Adjust relief valve

(#12)

Page 22

Page 23

G.

PS(L0)

Unload light should be on until

H.

Set EVC to

I.

Set EVC to unload

J.

K.

Switch Sl to "off"

switch should close at 50 PSI above suction pressure.

PS(L0)

and PC(V) are made.

"load" vanes should open (load light on).

-

vanes should close.

-

oil pump should run for 30 seconds before

(Unload light on)..

TD(P) turns it off.

V INITIAL UNIT START

After the above steps have been completed continue with the

following:

A.

Establish correct water flow to evaporator.

B.

Open up suction,

line valves.

(#l,

discharge and oil pressure

2 and 6).

gauge and control

C. Open up refrigerant liquid line valve

(#7)

for compressor

motor cooling.

D.

Open all liquid line valves (#8-10) between evaporator and

condenser.

E.

Check that all oil line valves

(#3,

4, 5 and 6) are open, and

that an adequate supply of hot oil is available.

F.

Check all auxiliary equipment (cooling tower cooling-load,

pumps,

G.

H.

I.

diagram in cover.

J.

oil pressure to build up oil and start compressor.

"Off"

Rotation must be clockwise from motor end.

change phase wiring if rotation is incorrect.

fans and air handlers) to be sure it is operative.

Set EVC at"unload"

for assured closed vane start.

Open oil cooler water valves.

Connect up power leads at compressor motor junction box per

JOG MACHINE

BE SURE PHASE IS CORRECT.

-

momentarily switch Sl to "on" long enough for

SEE P. 12

Switch

and check compressor rotation thru bulls eyes in compressor.

Turn off power and

Repeat if

necessary.

.

Sl

to

Page 23

Page 24

K.

After correct rotation has been established and the TD(N)

control has timed thru its 40 minute cycle the machine can

Sl

be restarted by switching

to "on".

CAUTION:

VI .

INITIAL UNIT OPERATION

Manually shut down unit if any malfunction is noted.

When initial start is satisfactory observe the following during

the

first few minutes of operation.

Adequate oil pressure

A.

B.

Liquid refrigerant to motor for cooling.

-

110 PSI above suction.

Sense temperature

drop across motor cooling orifice plate.

Water flow to oil cooler is sufficient and oil temp. to

C.

oil

bearings remains below 110 F. at outlet of

D.

Oil level

E.

No unusual noise or vibration.

F.

With EVC current control set at 100% set manual switch at

"Auto

fast,

"

and observe loading of machine. If vanes open too

adjust vane speed needle valve (See Control Operation and

Calibration (P.

-

top

40 ).

l/2

of sight glass.

cooler.

G. When machine is fully loaded check to be sure the temperatures

entering and leaving the evaporator and condenser are within

design limits,and that amperage and voltage are correct per load.

H.

Adjust EVC as needed per procedure outlined in Control Operation

and Calibration (P. 40

After the machine has been jogged and correct rotation determined,

I.

).

the motor terminals and exposed bare wire must be thermally insulated

with insulating tape provided with the unit.

This is necessary to

prevent moisture from condensing on the terminals during operation

which could cause current leakage and in severe cases a direct short.

IT IS EXTREMELY IMPORTANT THAT TERMINALS ARE PROPERLY INSULATED BEFORE

THE UNIT IS PUT INTO OPERATION.

SYSTEM OPERATION

I

OIL SYSTEM

The oil system for this unit is designed with a dual function; to

provide lubrication to the compressor bearings and provide oil

for the hydraulic vane control system. Figure 3 shows the complete

oil system with figures 4A and 4B and 5 showing in detail the

vane control system.

Page 24

Page 25

Page 26

Page 27

Page 28

A.

LUBRICATION SYSTEM

1.

Oil Pump

The major component of the oil system is an oil pump and

motor assembly operating at 115 V.

oil pump located in the oil reservoir also drives a centrifugal

oil separator which removes the refrigerant vapor from the oil

and returns it thru a service valve

The oil differential pressure, above suction, can be controlled

by adjusting the relief valve

assembly.

be adjusted upward by clockwise rotation.

operation pressure should be 110 PSIG above suction.

heater located in the bottom of the oil reservoir is energized

during the compressor off cycle and is used to provide warm

F)

(135

must be

the oil.

2.

refrigerant free oil on unit start up. The oil heater

enegized

Oil Cooler

and

Reservoir Assembly.

By using a

24 hours before start up to adequately heat

The direct coupled

(#5)

to the compressor.

(#12)

on top of the oil pump

l/4"

Allen head wrench the pressure can

During normal

An oil

The oil is pumped thru a service valve

to a water cooled oil cooler located on the unit.

oil temperature is lowered sufficiently to provide oil of

the proper temperature (90

3.

Oil Filter

The oil is then pumped to the oil filter which is an integral

part of the compressor housing.

micron cartridge that should be changed when the difference

between oil pressure and suction pressure (oil gauge reading)

drops to 60 PSIG.

To change the oil filter,

on the oil reservoir cover and close the

(#6)

on the oil filter.

before removing cover and replacing core.

filter outlet prevents losing pressure from compressor.)

After assembly vent air from oil lines before restarting

machine.

From the oil filter,

oil reservoir as well as the 2 low speed and 3 high speed

bearings thru internally drilled passages in the compressor

housing.

supplies adequate lubrication for 3 times the spindown time

during normal operation and in the event of oil pressure loss

due to power failure,

The spring loaded piston in the spindown reservoir

oil is supplied to the safety spindown

oil pump overload or oil pump failure.

-

110 F) to the bearings.

The filter contains a 10

front seat the outlet valve

Purge the oil supply lines

(#3)

in the oil pump

Here the

l/4"

shut off valve

(A check valve on

(#3)

slowly

Page 28

Page 29

4.

5.

Gear Lubrication

The oil drains from the bearings

into the gear housing and is returned to the oil pump

thru a full flow return line.

is in this line,

#3

valves

and 5 permit complete isolation of the oil

pump and reservoir.

at the oil pump reservoir and with

When the high pressure oil drains

A shut off valve

(#4)

from the bearings into the low pressure gear cavity it

immediately flashes into a fine oil mist, and releases

any refrigerant which may have been entrained in the

oil.

the gears.

This fine oil mist provides the lubrication for

A gear case heater is provided in the

compressor housing to prevent refrigerant collection

in the oil on the off cycle.

Oil Charging

The oil level during operation should always be visible

in the sight glass (normally at

l/2

level).

If necessary

to add oil use only McQuay oil

No.

921-238031X (Suniso

charging pump at valve

4G

S) and charge with an oil

(#13)

on the bottom of the oil

reservoir.

IS

0 OTHER OIL

NOTE:

Fill only to top

SUITABLE/

l/4

of sight glass on

Over charging can cause oil loss to the refrigerant system.

B.

VANE

CONTROL SYSTEM

The capacity of the unit is controlled by inlet guide vanes

located at the impellor eye.

The vanes are positioned by a

piston (Figures 4A and 4B) which moves to open or close the

vanes,

oil is supplied.

depending on which side of the vane control piston

The oil flow to the piston is controlled by

the operation of a 4-way normally open solenoid valve (coils

SV(S)

coil

and

SV(0))

SV(FC).

and a 2-way normally closed solenoid valve,

When a coil in the 4-way solenoid valve is energized, the flow

is from the port,

outlet.

inlet,

When a coil is de-energized the flow is from the

thru the solenoid valve and thru the port.

thru the adjustable orifice and to the

(See Fig. 4A and 4B).

Page 29

Page 30

Page 31

Page 32

When the electronic controls call for vane opening and

increased capacity the oil flow is as shown in Figure 4A

(with

SV(O)

energized

SV(S)

and

SV(FC)

de-energized). When

the electronic controls call for vane closing and reduced

capacity the oil flow is as shown in Fig. 4B (with

energized and

SV(0)

and

SV(FC)

de-energized).

SV(C)

When the electronic sensor indicates leaving chilled water

temperature has reached design conditions, all solenoids

will be de-energized,

full oil pressure is supplied to both

sides of the piston and the vanes will hold.

If the control circuit calls for fast vane closing as described

in the sequence of operation SV(C) and

SV(0)

Fig. 5.

will be de-energized and oil flow will be as shown in

Under this condition the metering valves A and B are

SV(FC)

will be energized,

by-passed speeding the oil flow and closing the vanes in

approximately 15 seconds.

When the vanes are completely closed, the vane closed switch

port is uncovered and with positive oil pressure the PC(V)

differential switch closes.

This assures a vane closed start.

The speed of the vanes is controlled during normal opening

and closing by two needle metering valves (adjustable orifices

B)

A and

in the oil drain line (See Figs. 4A and 4B).

needle valves are factory set to provide a minimum of

from full closed to full open vanes.

Closing the needle valves slightly slows the vanes down.

The correct speed should be slow enough to prevent hunting

and over controlling.

These needle metering valves are not

in the system during fast close and do not affect the fast

cbse

speed.

II

LIQUID FLOW CONTROL

The sub-cooled liquid refrigerant leaving the condenser is

expanded thru a liquid line orifice and equalizer system

and enters the distributor in the evaporator.

The

distributor assures uniform refrigerant distribution thru

out the full length of the evaporator.

The correct

refrigerant flow to the evaporator is maintained under all

conditions of operation by an automatic trimming valve

The automatic trimming valve is factory preset

to maintain

the correct level of refrigerant in the evaporator and does

not require field adjustment.

These

1

minute

(#ll).

Page 32

Page 33

Page 34

Shut off valves (#8-10) are provided in the liquid line to enable

isolation of condenser for pumpdown of the unit.

III

MOTOR COOLING SYSTEM

The hermetic motor is cooled by liquid refrigerant from the

condenser outlet. The sub-cooled liquid passed thru a shut off

valve

(#7),

check valve,and filter drier up to an orifice plate

mounted on the compressor housing.

Upon flashing into the motor housing,

rotor and

stator.

The gas and excess liquid is drained back

the refrigerant cools the

into the evaporator thru separate drains in compressor housing.

IV ELECTRONIC CONTROL OPERATION

A solid state combination electronic temperature control and motor

load control (EVC) is used to regulate the cooler leaving water

temperature and control the current draw of the motor.

A.

ELECTRONIC TEMPERATURE CONTROL

An electronic sensor located in the leaving chilled water changes

resistance with water temperature and sends a signal to a bridge

circuit in the electronic

temperature

control.

This signal is

amplified by the control module and is used to actuate the solid

state switches.

The solid state switches operate the coils of

the 4 way oil solenoid to open and close the vanes as described

under Vane Control.

The electronic temperature control contains a selector switch which

permits manual operation of the inlet guide vanes and overrides

the signal circuit.

"Auto".

To manually close vanes switch to "unload" (lower

and to manually open vanes switch to "load"

There is also a

position.

This switch should be set at "Auto" except when used

"hold" position which holds vanes in existing

During normal operation switch should be in

load)

(higher load).

to manually control vanes when servicing unit.

The electronic temperature control utilizes integral action to

provide a very precise control of leaving chilled water

temperature.

It eliminates the throttling range and feedback circuits usually

needed with this type of control.

With integral action the "on"

time of the load or unload switch is dependent upon the difference

between the set point and the leaving chilled water temperature.

As the difference between the set point and the control point

decreases,

the on time (either load or unload) becomes shorter.

The load status is shown by a red indicator light and the unload

status by a green indicator light for ease of service.

Page 34

Page 35

The solid state electronic temperature control is calibrated

at the factory but it should be checked for recalibration.

See Appendix C for calibration and adjustment.

B.

MOTOR LOAD CONTROL

The function of the motor load control circuit in the EVC is to

prevent the machine from operating at a higher amp rating than

design.

system for the compressor motor which limits the current to the

motor at any selected valve from 40% to 100% of full load.

A window type current transformer (CT) is located on one of the

motor leads in the starter and gives a secondary current which

varies with load.

transformer secondary to produce a voltage signal proportional

to load,

the voltage signal should be between

This voltage signal is used to activate solid state switches

in the EVC.

the vanes in a "hold" position.

to increase to

will go into fast close to prevent a further power increase.

If either the 100% or 105% switch is activated a "current control"

light is energized to indicate that the override control is in

operation.

The motor load control is a two stage override protection

A resistance load is added to the current

which operates the motor load control. At full load

.45

and

When the motor current reaches 100% a switch puts

If the motor current continues

105%,

another switch will close and the vanes

.55

volts.

The motor load control remains in control of the machine only

as long as the compressor attempts to deliver more than 100%

of full load.

under any condition when needed.

the position of the vane selector

"Load", etc.

The motor load control contains a

with

power input of the machine at any point between 40 and

thus limiting demand charges.

If, for example,

load amp (FLA) rating is 265 amps, the unit will go into "hold"

at 159 amps

(.60

To calibrate the motor load control see Appendix C.

a range of 40% to 100%.

x 1.05 x 265).

It will override the electronic temperature control

It operates independently of

This permits setting the maximum

this switch is set at 60% and the chiller full

(.60

x 1.0 x 265) and "fast

switch,

percent current limit switch

whether,

close"

at 167 amps

"Auto", "Hold",

lOO%,

Page 35

Page 36

I.

LEAK TESTING

APPENDIX A

The unit

A.

start up, to

should be completely leak tested before initial

check for leaks which may have resulted from

shipping damage. The presence of refrigerant oil on or

near the unit may indicate a leak and adjacent areas should

be carefully checked.

B.

The refrigerant charge shipped with the unit will provide

a positive pressure for this test.

is isolated in the condenser.

Crack one condenser shut off

During shipment the charge

valve and allow enough. refrigerant to enter the evaporator

to build up pressure to approximately 60 psig. and immediately

close valve.As a general rule of thumb this pressure should

be approximately 10 PSIG below the corresponding saturation

pressure at ambient temperature.

C.

With an electronic leak detector carefully check all

brazed joints,pipe connections,

"Victaulic" connections and

control line flare connections for leaks.

D.

If leaks are found they must be repaired.

Leaks in the

evaporator circuit, liquid lines, control lines, etc., can

be easily repaired without removing charge since the unit

is shipped pumped down with charge isolated in the condenser.

II.

E.

After any leak is repaired retest by building up pressure

in the circuit by bleeding a slight amount of refrigerant

from the condenser as in Item B above.

If no leaks are found

on recheck,unit is ready for evacuation.

EVACUATION

To evacuate evaporator circuit keep valves at condenser

(#7,

8 and 9) and oil pump

at evaporator

and condenser

(#l0)

and gauge line valves on top of evaporator

(#l

and 2) should be open.

(#3,

4, and 5) closed.

Valve

Remove existing cores in filter drier in liquid line and

install new cores.

Evacuate by attaching one or more lines from vacuum pump to

valves on bottom of evaporator and to

evaporator liquid line valve

(#l0).

l/4"

fittings on

Page 36

Page 37

Continue evacuation until a reading of 1000 microns (1 millimeter)

or less is obtained and maintained for a minimum of 15 minutes

after the vacuum line is closed.

An electronic or micron gauge

should be connected at the unit to accurately determine the

correct unit vacuum.

If the vacuum pump is incapable of pulling down to 1 millimeter,

a triple evacuation can be used.

inches of mercury vacuum,

add a small amount of refrigerant 12

Pull down to approximately 29

vapor to build up to a positive pressure and pull down to 29

inches.

Repeat 3 times.

Charging

After evacuation, refrigerant

liquid line,

shut off valves at condenser

-

12 charge is to be added. Open up

and allow pressure to

equalize in evaporator and condenser.

If some charge has been lost due to a leak it will

be necessary

to trim charge with unit running.

Note

This additional charge should not be added at this time.

before charging can

preliminary pre-start up checks (P

continue.

)

Complete

After machine has been initially jogged and started per sequence

outlined and additional charge can be added.

THE UNIT MUST BE

OPERATING NORMALLY WITH OIL PUMP RUNNING, WATER FLOW TO CHILLER

AND CONDENSER, AMPS AND VOLTS NORMAL, AND LEAVING CHILLED WATER

TEMPERATURE AND SUCTION PRESSURE ABOVE

FREEZING

.

CAUTION

DO

NOT

LIQUID CHARGE OR RUN UNIT (UNDER ANY

CONDITION)IF

SYSTEM

PRESSURE IS LOWER THAN 30 PSIG.

Connect the refrigerant charging line to the service valve on

bottom of evaporator and charge with R-12 vapor.

The unit is

adequately charged when suction superheat is 2-4 degrees at

full load operation.

UNIT SHUTDOWN

During winter or extended shutdown special precaution should be

taken to prevent possible unit damage.

Page 37

Page 38

A.

water in the chiller,

If the machine will be exposed to freezing conditions all

condenser and oil cooler circuits must be

drained.

This can best be done by disconnecting Victaulic

connection at water boxes and opening vent and drain connection

on water boxes.

-

CAUTION

tubes,

since it is possible that water could hang up in the

the only sure way of removing all water and avoiding

freeze up is to circulate anti-freeze solution thru the tubes,

as well as oil cooler.

Leave drains and vents open until system is refilled.

B.

To prevent accidental start-up of unit during shutdown

cycle open compressor disconnect

and remove fuses from disconnect.

NOTE:

starter,

heaters.

prevent absorption of refrigerant by the oil.

prevent accidental start up,

If control circuit power is provided by transformer in

the disconnect must be left on to provide power to oil

It is important to keep the oil heater energized to

In this case, to

position system switch

Sl

to "off"

and remove R-3 relay.

PUMPDOWN

It is possible to make repairs or replacements on compressors,

controls,

liquid lines, etc.

if necessary without losing the

refrigerant charge by pumping the unit down and isolating the

charge in the condenser.

If it is necessary to pump the system

down use extreme caution to prevent freeze up of the chiller.

CAUTION:

chiller while unit is in pumpdown cycle.

Be sure that full water flow is maintained thru the

Use the following

procedure to pumpdown:

1.

Close liquid line valves at condenser

(#7,

8 and 9).

2.

Jumper

from

3.

PC(LR).

With water flow thru the chiller and condenser, start

PS(LR)

control and temporarily disconnect wire #150

compressor.

4.

Operate unit until suction pressure stabilizes at

approximately 20-25 PSIG.

5.

Operate unit at this point for approximately 2 minutes and

then turn off.

Page 38

Page 39

The discharge line check valve along with the condenser liquid

line valves will isolate the major portion of the charge in the

condenser. Purge remaining gas pressure from evaporator circuit

before working on system.

Approximately 40-60 lbs. of refrigerant

12 will be lost depending on the completeness of the pumpdown.

APPENDIX B

TOOLS AND EQUIPMENT

The following tools,

equipment and instruments are useful in

servicing and checking the unit.

1.

Electronic leak detector (preferred) or halide torch.

2.

Portable high vacuum pump (capacity at least 3 CFM recommended).

3.

Refrigerant charging lines and equipment (gauges, scale,

-

Refrigerant

4.

Refrigeration servicemans hand tools (wrenches, screwdriver,

etc.).

5.

Volt- ohmeter (voltage scale

Vacuum tube voltmeter (VTVM).

6.

7.

Clamp on ammeter (up to 750 amp scale).

Thermometers (4

8.

Water pressure gauges or manometer.

9.

12 etc.).

-

minimum of 2) (2 deg. increments).

to 480 volts).

10.

11.

Oil charging pump suitable to pump against 70 psi pressure.

Phase sequence meter.

Page 39

Page 40

APPENDIX C

I.

SOLID STATE COMBINATION ELECTRONIC TEMPERATURE AND MOTOR

LOAD CONTROL CALIBRATION

The following procedure applies to the Honeywell Centrifugal

Chiller Control

A.

GENERAL

While the basic function of the Centrigual Chiller Control is

to maintain the temperature of the chilled water at the

control point setting by modulating the compressor vanes,

its protective function of limiting excessive current draw

by the compressor drive motor is very important.

current calibration must be done first to provide protection

during temperature calibration or other testings.

W901A

only.

(EVC).

Therefore,

CAUTION:

made while the machine is running.

Set control switches as shown in the startup column of

Table 1.

Adjustment and Calibration of the control must be

I

Manual Position Switch

% Current Control

Control Point

Current Calibration

Temperature Calibration

STARTUP

Close (Unload)

100%

Center of Travel Desired Chilled

(Vertical)

Full Clockwise

Center of Rotation

NORMAL

RUNNING POSITION

Auto

Desired

(100% or less)

Water Temperature

Leave at Position

Determined at

Start-Up

Leave at Position

Determined at

Calibration

Percentage

Page 40

Page 41

B.

CALIBRATE FOR CURRENT

This calibration procedure adjusts the current control section

of the control to the current input signal at terminals A-B.

This signal must be

.50 2 .20

VAC when motor load is 100% of

rated current.

When the above signal has been provided, adjust the CURRENT

CALIBRATION control ccw until current control light just comes

on.

NOTE:

Calibration at 100% automatically calibrates for current

control action at 105%.

CURRENT INPUT SIGNAL TO TERMINALS A-B

(MOTOR

LOAD

AT 100% OF

RATED CURRENT.)

This signal comes from a current transformer and shunt resistor

normally supplied as part of the compressor motor starter.

The

transformer and resistor must be sized, along with a specified

size and length of two-wire lead,

to provide a nominal

0.5 volts

rms to terminals A-B of the control.

CAUTION:

5 volts ac.

GROUNDING NOTE:

Maximum allowable voltage to terminals A-B is

Ground at current transformer only, NOT at

terminals A-B.

CURRENT CONTROL SYSTEM OPERATES AS FOLLOWS:

a.

When the compressor drive motor current rises to 100%

of its rated value,the current control system prevents

further opening of the vanes.

If compressor motor current reaches 105%

b.

(+O, -2)

the

vanes drive toward the closed position until the current

drops to 100%

+l.

(The vanes can still be driven closed

by the temperature control.)

When the compressor current falls to 95%

C.

its full value,

the device returns to full temperature

(+2,

-0) of

control.

Check the preceeding by using the manual position switch to

change compressor load,

After checking,

return the selector switch to AUTO.

then look for proper vane action.

The

device is now calibrated for current.

Page 41

Page 42

C. CALIBRATE FOR TEMPERATURE

Set the manual switch in the AUTO position.

1.

Operate the system until the chilled water temperature

2.

reaches 45 deg. F. For accurate control calibration

the temperature sensing bulb must be maintained at a

constant temperature which can be accurately measured.

Set the control point to mid position (pointer vertical).

3.

Adjust the temperature calibration potentiometer to

4.

achieve a null condition (no vane

Because of the "pecking"

control section, (integral action control) the device is

in a null condition only after a minimum of 45 seconds

with no signal to either load or unload.

The device is now calibrated for 45 deg.

5.

water temperature.

movement)

.

action of the temperature

F. +

1 deg. F.

NOTE:

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

APPENDIX E

PHYSICAL DATA

WHC

UNIT

SIZE

145A

158~

183A

200A

228A

254111

284A

300A

325A

362~

OIL

CHARGE

GALLONS)

(

4

4

4

4

4

7

7

7

7

7

-r

COOLER

AREA TO

I

3E INSULATE1

(FT2)

66

66

83

83

83

92

92

92

109

109

COND.*PUMP

DOWN CAP.

(LBS.-R-12)

396

396

548

522

492

926

886

866

827

769

RELIEF VALVE

SETTING

(PSI)

VAP.

150

150

150

150

150

150

150

150

150

150

COND

180

180

180

180

180

180

180

180

180

180

*Based on 80% of condenser volume and liquid R-12 at 100 F.

WARRANTY RETURN

.

Material may not be returned except by permission of authorized

factory service personnel of McQUAY Division McQUAY-PERFEX INC.

at Minneapolis, Minnesota. A "Return Goods"

to be included with the returned material.

tag will be sent

Enter the

information as called for on the tag in order to expedite

handling at our factories and prompt issuance of credits.

All parts shall be returned to the McQUAY factory, designated

on the

"Return Goods" tag,

transportation charges prepaid.

The return of the part does not constitute an order for

replacement.

through your nearest McQUAY Representative.

include part number,

Therefore,

model number and serial number of the

a purchase order must be entered

The order should

unit involved.

Following our personal inspection of the returned part and if it

is

determined that the failure is due

workmanship,

credit will be issued on

to

faulty material or

customer's purchase order.

REPLACEMENT PARTS

When writing to McQUAY for service

the model number and serial number Of

serial plate,

required,

attached to the unit.

mention the date of installation of the unit and date

replacement parts, refer to

Or

the unit as stamped on the

If replacement parts are

of failure,along with an explanation of the malfunctions and a

description of the replacement parts required.

Page 47

Page 48

APPENDIX F

TROUBLE SHOOTING

As an aid to servicing your WHC Seasonpak centrifugal chiller

several trouble shooting charts have been prepared.

The trouble

shooting should only be performed by a qualified refrigeration

service man.

If additional information is required, call your

McQuay Service Representative.

The following steps should be taken prior to attempting any service

on the control center:

Check wiring diagram so that you understand the operation of

1.

the Seasonpak,

Before investigating trouble in the control center, check for

2.

centrifugal chiller.

burned out light bulbs by testing across the appropriate ter-

minals.

even though the system switch is off.

Caution

-

the panel is always partially energized

If it is necessary to

de-energize the complete panel,including crankcase heaters,

pull main disconnect.

3.

Check lights and compare with the trouble chart. The possible

of

trouble area

the panel can then be easily isolated.

This chart is merely a quick indication of possible major trouble

spots in the panel or unit.

By comparing the indicator lights

with the unit wiring diagram,additional comparisons can be made.

It is important to have a qualified control panel electrician

service this panel. Unqualified tampering with the controls can

cause serious damage to equipment and void the warranty.

WARNING

Warranty is voided if wiring is not in accordance with specifica-

tions.

or overload

A blown fuse or tripped protector indicates a short ground

-

before replacing a fuse or re-starting compressor,

the trouble must be found and corrected.

Page 48

Page 49

Page 50

Page 51

Page 52

Loading...

Loading...