Page 1

Catalog 865-5

Modular Self-Contained Air Conditioning Systems

Type SWT 023C—040C

20 to 45 Tons

Engineered for flexibility and performance™

Page 2

Continued Leadership in Floor-By-Floor,

Self-Contained System Designs . . . . . . . . . . . . . . 3

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Agency Listed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System Performance Providing Tenant Comfort

and Operating Economy . . . . . . . . . . . . . . . . . . . . 4

McQuay Self-Contained VAV Systems . . . . . . . . . 4

Cabinet, Casing and Frame . . . . . . . . . . . . . . . . . 5

Modular Design . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Condensing Section . . . . . . . . . . . . . . . . . . . . . . . 5

Design Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cooling Coil Section . . . . . . . . . . . . . . . . . . . . . . . 6

Heating Section . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Supply Fan Section . . . . . . . . . . . . . . . . . . . . . . . . 6

Economizer Options . . . . . . . . . . . . . . . . . . . . . . . 7

Filter Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Auxiliary Control Options . . . . . . . . . . . . . . . . . . . 8

Selection/Application Flexibility . . . . . . . . . . . . . . . 9

Modular Construction . . . . . . . . . . . . . . . . . . . . . . 9

System Flexibility . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ultraviolet Lights . . . . . . . . . . . . . . . . . . . . . . . . . 10

Refrigerant R-407C . . . . . . . . . . . . . . . . . . . . . . . 10

®

MicroTech

III Unit Controller . . . . . . . . . . . . . . . 11

Open Choices Benefits for Easy Integration . . . . 11

Alarm Management and Control . . . . . . . . . . . . . 17

Application Considerations . . . . . . . . . . . . . . . . . 18

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Unit Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Acoustical Considerations . . . . . . . . . . . . . . . . . . 19

Recommended Clearances . . . . . . . . . . . . . . . . 19

Equipment Room . . . . . . . . . . . . . . . . . . . . . . . . 19

Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Vibration Isolation . . . . . . . . . . . . . . . . . . . . . . . . 20

Condenser Water Piping . . . . . . . . . . . . . . . . . . . 20

Head Pressure Control . . . . . . . . . . . . . . . . . . . . 20

Variable Air Volume . . . . . . . . . . . . . . . . . . . . . . 20

Variable Frequency Drives . . . . . . . . . . . . . . . . . 20

Duct Static Pressure Sensor Placement . . . . . . . 20

Zone Sensor Placement . . . . . . . . . . . . . . . . . . . 20

Filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

System Operating Limits . . . . . . . . . . . . . . . . . . . 21

Coil Freeze Protection . . . . . . . . . . . . . . . . . . . . 22

Air Density Correction . . . . . . . . . . . . . . . . . . . . . 22

Unit Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Application Considerations . . . . . . . . . . . . . . . . . 22

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . 23

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Unit Efficiency Ratings . . . . . . . . . . . . . . . . . . . . 26

Correction Multipliers . . . . . . . . . . . . . . . . . . . . . 26

DX Cooling Capacity Data . . . . . . . . . . . . . . . . . 26

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . 26

Waterside Economizer Capacity . . . . . . . . . . . . . 29

Heating Capacity Data . . . . . . . . . . . . . . . . . . . . 31

Component Pressure Drops . . . . . . . . . . . . . . . . 31

Fan Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . 37

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Supply Power Wiring . . . . . . . . . . . . . . . . . . . . . . 41

Unit Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Engineering Guide Specifications . . . . . . . . . . . . 43

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Safety Agency Listed . . . . . . . . . . . . . . . . . . . . . 43

Cabinet, Casing and Frame . . . . . . . . . . . . . . . . 43

Filter/Economizer Section . . . . . . . . . . . . . . . . . . 43

Fan Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

MicroTech III Unit Controller . . . . . . . . . . . . . . . . 46

Open Communications Protocol . . . . . . . . . . . . . 48

2 McQuay Catalog 865-5

Page 3

SWT - 040 - C

Self-contained

Water-cooled

Top mounted fan

Design

vintage

Nominal

capacity

Introduction

Continued Leadership in Floor-By-Floor,

Self-Contained System Designs

McQuay SWT self-contained air conditioning systems trace their

history to the late 1970s and the pioneering concepts of Blazer

Industries. Working closely with the consulting engineer to solve

special system and space challenges, Blazer Industries developed

and provided the first self-contained, variable air volume systems

with water side economizer cycle for the prestigious 499 Park

Avenue office building. Following the success of this project was

more than a decade of innovation and product leadership, with

thousands of systems provided for prominent building projects.

In 1991, McQuay acquired Blazer Industries. The result has been

a continuation of this tradition of innovation and leadership. The

comprehensive, updated modular McQuay SWT system offering

is now supplying quiet, efficient and flexible systems to meet

today’s diverse and demanding performance needs for new and

retrofit, commercial, industrial and institutional buildings worldwide.

Nomenclature

Agency Listed

McQuay and MicroTech are registered trademarks of McQuay International.

DesignFlow, Hi-F, Protocol Selectability, RoofPak, SelectTools, SpeedTrol, SuperMod, UltraSeal, and VaneTrol

Microsoft is a registered trademark of Microsoft Corporation.

Copyright © 2011 McQuay International. All rights reserved throughout the world.

are trademarks of McQuay International.

Windows is a trademark of Microsoft Corporation.

McQuay Catalog 865-5 3

Page 4

McQuay Self-Contained VAV Systems

System Performance Providing Tenant Comfort and Operating Economy

Since the introduction of self-contained systems in the late 1970s,

the industry has seen this concept grow into one of the most

widely specified systems for new office buildings, for retrofitting

existing structures, and for institutional, industrial, and other specialized applications. The reason is simple: system performance.

Designed specifically to satisfy growing system retrofit needs,

McQuay SWT self-contained VAV systems provide the total performance advantage of:

• Modular construction

• Prime candidate for building renovation

• Special 34.5" maximum section width fits through a 3'

door frame

• Refrigerant lines always remain intact

• Requires minimum floor area when reassembled

• Retrofit alternative where existing chiller cannot be

accessed for replacement

• Tenant Comfort

• Tenants enjoy individual control over comfort conditions

and off-hour system operation

• Tenants benefit from their individual efforts to control

energy costs

• Routine service is located where it minimizes tenant

inconvenience

• Individual or dual systems per floor provide system

redundancy and standby

• First cost economics

• VAV system flexibility uses building diversity to reduce

system tonnage and first cost

• Factory packaged concept reduces field labor, installation

time and expense

• No expensive chilled water piping or chiller room

• Individually tested, factory designed systems reduce

start-up and installation expense

• Reduce penthouse and equipment room

requirements

• Centralize condenser water and condensate piping and

streamline system layout

• Energy-saving VAV system control

• Reduces fan kW and operating costs at part load conditions

• Savings maximized through use of variable speed fan

control

• Individual zone control without overcooling or use of

reheat

• Quiet system operation

• Provided by structural quality and specialized design

• Recognized for quiet operation by renowned U.S. acoustical consultants

• Energy saving economizer operation

• Water or air economizer capability for optimized energy

savings

• Economizer reduces compressor operating hours and

energy costs

• Year-round “free cooling” capability

• Energy saving building part load operation

• System energy efficiency comparable to central chilled

water systems

• Multiple systems and compressors versus a single, large

central plant

• Efficient system for partial occupancy and after hours

operation

• Operate only the system(s) on the floor(s) requiring after

hours use

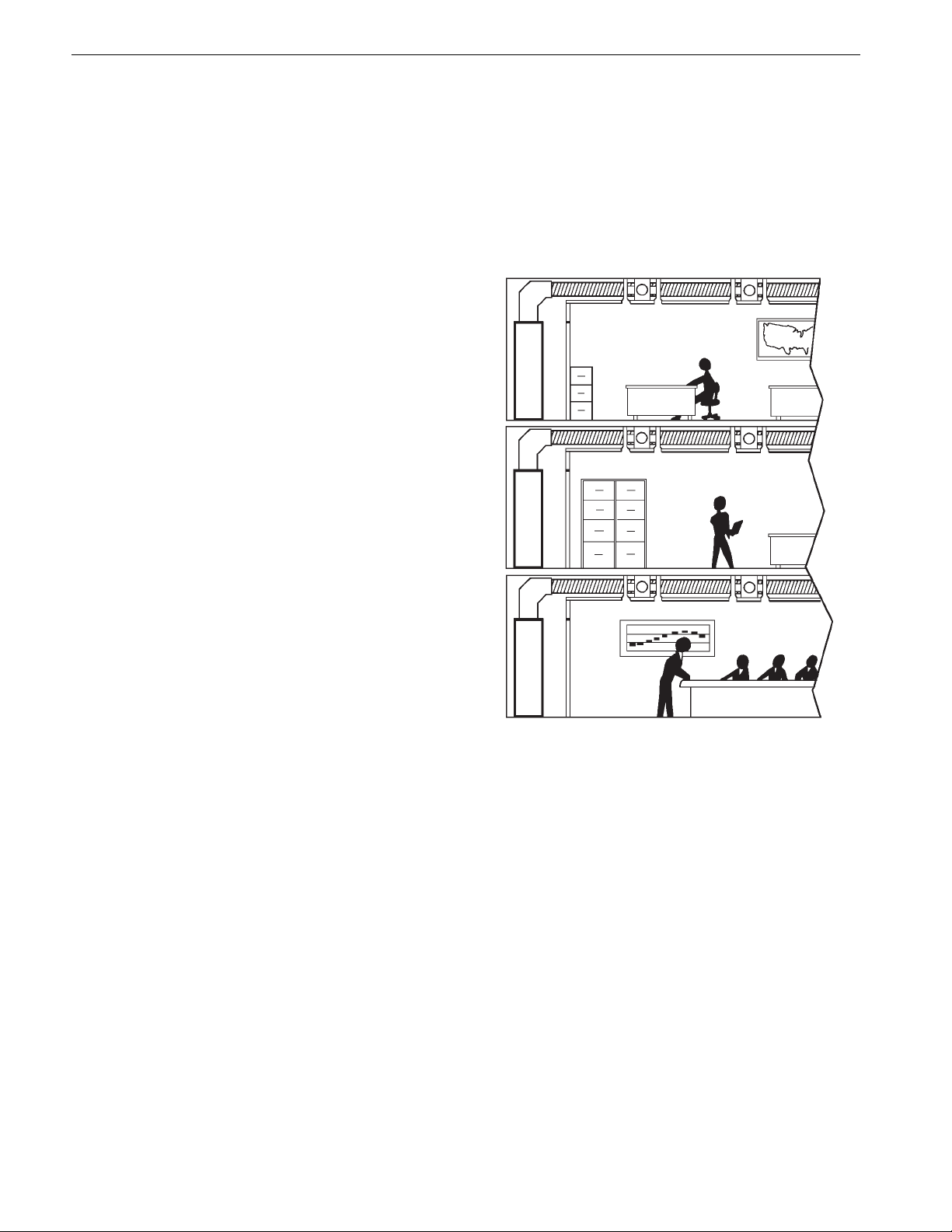

Figure 1. McQuay Self-Contained VAV Systems

• System savings of advanced MicroTech III™ DDC

control system

• Monitoring and diagnostics reduce the potential for

expensive field repairs

• Industry leading Protocol Selectability™ feature provides

effective BAS selection flexibility

• Reduced system maintenance and service costs

• No complicated central chiller plant to maintain

• Service and maintenance are performed out of the occupied space

• Control and product reliability functions designed by the

equipment manufacturer for single source responsibility

and improved reliability

4 McQuay Catalog 865-5

Page 5

Fan Section

Filter / Waterside

Economizer Section

Main Heating /

Cooling Section

Design Features

Cabinet, Casing and Frame

For vibration control and rigging strength, the SWT unit base is

constructed of welded structural steel channel and 10- gauge galvanized steel panels. Heavy-duty lifting brackets are strategically

placed for balanced cable or chain hook lifting.

For long equipment life, unit exterior panels are constructed of

heavy gauge, pre-painted, galvanized steel. The complete cabinet,

frame and access panels are insulated with 1 inch thick, 1.5 lb.

dual density insulation. Double wall construction is available to

enhance performance and satisfy IAQ requirements.

For maintenance and service ease, system components are strategically located for ease of inspection and maintenance. Refrigeration components are positioned out of the airstream so

adjustments and readings can be made without disrupting system

operation. Service friendly access is made through heavy-duty,

conveniently removable panels. Access panels are set on neoprene

gaskets to prevent air leakage.

Modular Design

The SWT unit is easily disassembled into three compact sections;

main cooling/heating, filter/waterside economizer and fan. See

“Modular Construction” under “System Flexibility” on page 9.

Figure 2. SWT Cabinet

Condensing Section

Multiple compressors are featured in all SWT systems for efficient system part load control, quiet operation and system redundancy. Compressors are quiet, reliable hermetic scroll type

complete with sightglass, anti-slug protection, and motor overload

protection. Suction and discharge service valves, with gauge

ports, are available on each compressor. Individual branch circuit

fusing protects each compressor. The unit’s MicroTech III™ control system incorporates timing functions to prevent compressor

short cycling. All compressors are resiliently mounted to minimize any noise transmission. The condensing section is insulated

and segregated from the air handling section of the unit to avoid

transmission of noise to the circulated air stream.

Figure 3. Copeland SpecterTM scroll compressor

Each compressor is on an independent refrigerant circuit complete

with filter-drier, liquid moisture indicator/sightglass, thermal

expansion valve capable of modulation from 100-25% of its rated

capacity, liquid line shutoff valve with charging port, high pressure relief device and high and low pressure cutouts. If any compressor is made inoperable, the remaining compressors are still

allowed to operate.

The unit’s MicroTech III controller senses entering condenser

water temperature and prevents mechanical cooling when the temperature falls below an adjustable setpoint value, minimum 55°F.

For systems which will see entering condenser water temperatures

below 55°F, a waterside economizer or head pressure activated

control valve is available.

SWT water cooled condensers feature a mechanically cleanable,

all copper design using the same high performance enhanced tubing found in modern centrifugal chillers. Liquid refrigerant subcooling is provided as standard. Each condenser is part of an

independent refrigerant circuit and comes complete with a spring

loaded high pressure relief valve. All condensers are independently leak tested. All completed units are leak tested, evacuated

and shipped with a full operating charge of R-22 and oil. R-407C

is also available as an alternate selection.

The condenser assembly and all factory water piping is rated for a

waterside working pressure of 400 psig and is factory leak tested

before shipment. Condenser water channels are mechanically

cleanable by removing brass service plugs that are sealed with

McQuay Catalog 865-5 5

Page 6

Refrig. Flow Ckt 1

Refrig. Flow Ckt 2

Ckt 2

Ckt 1

Ckt 1

Ckt 1

Ckt 1

Ckt 1

Ckt 1

Ckt 1

Ckt 1

Ckt 2

Ckt 2

Ckt 2

Ckt 2

Ckt 2

Ckt 2

Ckt 2

Airflow

a02

Design Features

reusable o-ring gaskets. Main interconnecting condenser water

headers include vent and drain plugs and a large cleanout plug for

removing debris dislodged during cleaning. Condensers are factory piped for a single condenser water supply and a single condenser water return connection.

Both right-hand and left-hand piping locations are available.

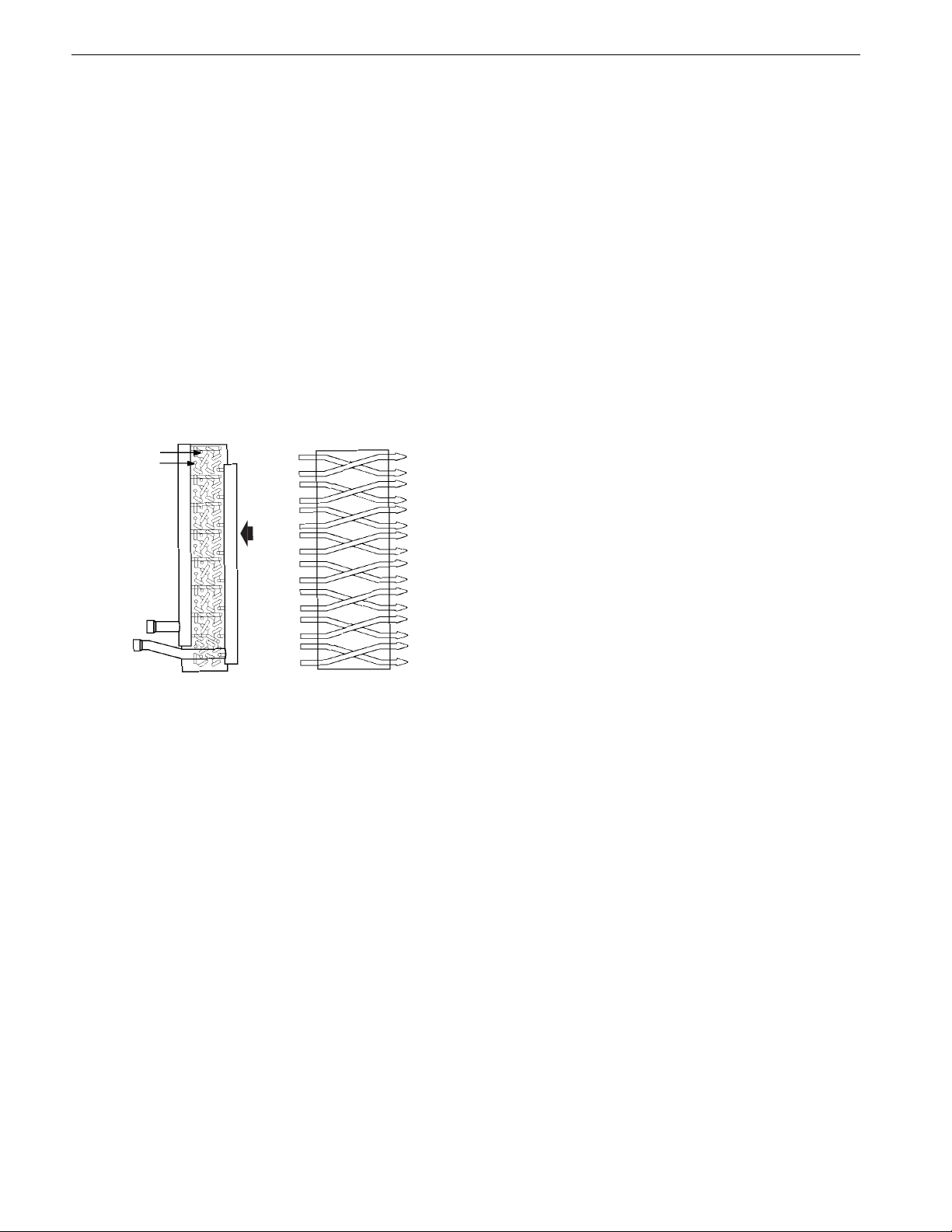

Cooling Coil Section

SWT evaporator coils incorporate a high efficiency ripple corrugated fin design. SWT system design maximizes coil face area

without developing uneven, performance robbing di sr upt ions in

airflow patterns. The result is high coil performance and reduced

static pressure losses. Coils are 4 or 6 row configurations.

The evaporator coil is mounted in a stainless steel double sloped

drain pan. The condensate drain line is trapped internal to the unit,

eliminating the expense and inconsistency of field installed traps.

Figure 4. Evaporator Coil Circuiting

Hot Water Heat

Hot water coils have 1 or 2 rows with high efficiency ripple corrugated fin design and 1/2 inch O.D. seamless copper tubes. Coils

are available complete with a factory mounted, piped and wired 2way or modulating valve controlled by the unit’s MicroTech III

controller. A factory mounted freezestat is provided to help protect against coil freeze-up.

Supply Fan Section

Figure 5. Supply Fan

The supply fan section uses one or two double width, double inlet

medium pressure forward curved fans and housings. Each fan is

statically and dynamically balanced. The fan assembly is constructed of high strength structural steel and welded for maximum

strength. The entire fan assembly is mounted on spring isolators

for excellent isolation effectiveness. Seismic control restrained

spring isolators are available. A vibration dampening flex connection is installed at the fan discharge. The entire fan, motor and

drive assembly is dynamically balanced at the factory for quiet

operation.

All evaporator coils are interlaced circuiting, keeping the full face

of the coil active to eliminate air temperature stratification. For

optimum part load performance, all three and four circuit evaporator coils are circuited for both interlaced and row control. Compressor staging is sequenced to take maximum advantage of

available coil surface.

Each evaporator coil circuit is furnished with a wide range thermostatic expansion valve with an adjustable superheat setting and

external equalizer.

Supply fans are configured with a gradual expansion, aerodynamic duct within the cabinet. This unique gradual expansion feature contributes to the high performance of the SWT by lowering

brake horsepower and sound power levels.

All fans are mounted on solid steel shafts rotating in 200,000 hour

pillow block ball bearings with grease fittings. Multiple belt,

fixed pitch sheaves are matched to the specific cfm, static pressure and horsepower requirements of the system. Drives rated for

a minimum of 150% of fan design are available. Drive components and fan bearings are easily accessed for periodic mainte-

Heating Section

SWT units are available as cooling only systems or with factory

installed electric or hot water heat for morning warm-up, constant

volume and specialty heating requirements.

Electric Heat

nance.

Fan motors are three phase, NEMA design B, rated at 40°C.

Motor availability includes high efficiency open drip-proof and

totally enclosed, EPACT compliant, NEMA T-frame selections

and premium efficiency selections. Motors are 1800 RPM with

grease lubricated ball bearings.

The factory assembled electric heating coils are constructed of

low watt density nickel-chromium elements for long lasting durability. Electric heaters are protected by automatic reset high limit

controls and line break protection. Heater branch circuits are individually protected by branch circuit fusing. The MicroTech III

control system sequences the electric heating elements for operating economy.

6 McQuay Catalog 865-5

Page 7

Design Features

Energy saving advanced technology variable frequency drive

(VFD) fan speed control is available with the convenience and

cost savings of factory mounting and testing. All VFD selections

are plenum rated. A manually activated bypass contactor is available to allow system operation even in the event of drive service.

MicroTech III controls provide advanced duct static pressure control. Static pressure can be controlled by either a single or two

duct static pressure sensors. All VAV systems include an adjustable duct high-limit switch to protect duct work from excessive

pressure.

Economizer Options

Waterside Economizer

An energy saving, waterside economizer package is available on

all units. The complete economizer system is factory mounted

including a 4-row mechanically cleanable coil, control valves and

factory piping complete with cleanouts. The complete economizer

package is rated for up to 400 psig waterside working pressure

and the entire coil and piping assembly is factory leak tested.

Economizer operation is controlled by the SWT’s MicroTech III

controller to maximize free cooling potential. Economizer operation is enabled whenever the available cooling tower water temperature is less than the unit entering air temperature by a field

adjustable value, generally 5-7°F. The economizer control valve

modulates in response to the cooling load. Control valve operation

can be selected to (1) maintain full flow through the unit at all

times or (2) isolate the unit from the condenser water loop when

there is no call for cooling to save energy with a variable pumping

system. (Economizer control valves do not eliminate the need to

provide unit isolation valves.) To extend free cooling savings,

mechanical cooling is enabled during economizer operation. Only

when the economizer valve is driven 90% open and the cooling

load is not satisfied, will compressors be staged to maintain cooling setpoint. Economizer control will maintain full free cooling

capability until disabled by the economizer changeover setpoint.

A factory mounted freezestat is provided to help protect against

coil freeze-up.

Condenser Head Pressure Control

For applications where a waterside economizer package is not

being used and entering condenser water temperatures can be less

than 55°F, condenser head pressure control is required. To satisfy

these applications, a factory installed 2-way, head pressure activated control valve is available to maintain unit operation with

entering condenser water temperatures as low as 40°F.

Figure 6. Mechanically Cleanable Waterside

Economizer Coil

Figure 7. Economizer Piping

Airside Economizer

An airside economizer control package is available for controlling

field installed mixing dampers capable of 100% outside airflow.

Economizer operation will be controlled by the SWT's MicroTech

III controller to maximize free cooling potential. Economizer

operation is enabled whenever an outside air (or comparative)

enthalpy sensor or outside air temperature sensor indicates that

outside air is suitable for free cooling. The economizer damper

control actuator shall modulate in response to the cooling load.

The outside air damper will be positioned to maintain minimum

ventilation requirements when economizer is disabled.

To extend free cooling savings, mechanical cooling is enabled

during economizer operation. Only when the economizer damper

is driven 90% open and the cooling load is not satisfied, will compressors be staged to maintain cooling setpoint. Economizer control will maintain full free cooling capability until disabled by the

economizer changeover setpoint. Factory supplied mixing boxes

are available for airside economizer use using the McQuay

Vision™ air handling unit platform.

McQuay Catalog 865-5 7

Filter Section

All SWT units are provided, as standard, with 4" deep extended

media 30% efficient filters. For higher filtration requirements,

65% and 85% AmericanAirFilter

with an optional pre-filter rack. Filters are removable from the

rear of the unit or through hinged and latched side access doors on

the filter box.

TM

Varicel® filters are available

Page 8

Design Features

Electrical

Each unit is completely wired and tested at the factory prior to

shipment. Wiring complies with NEC requirements and conforms

to all applicable UL standards for reliability and safety. All electrical components are labeled according to the electrical diagram

and are UL recognized whenever applicable. Line voltage components and wiring are physically separated from the low voltage

control system.

The supply fan motor, compressor motors and electric heat all

have individual branch circuit fuse protection. Control circuit

power is supplied through a factory installed, low voltage transformer. The supply fan motor circuit includes a three phase contactor and ambient compensated overload protection with manual

reset. Each refrigerant circuit includes both a high and low pressure cutout switch and a coil frost protection thermostat.

A terminal block is provided for the single, main power connection and a terminal board is provided for low voltage control wiring. A factory mounted, non-fused main circuit interrupter is

available for disconnecting the main electrical power to the unit.

The switch is visible, located at the front of the unit, and is accessible without unit penetration. Dual power blocks or disconnect

switches are available to accommodate requirements for standby,

emergency power supplies.

Controls

Phase Failure/Undervoltage Protection – Factory installed

phase failure/under voltage protection is available to protect three

phase motors from damage due to single phasing, phase reversal

and low voltage conditions.

Individual Unit Factory T est – All SWT units are provided completely factory assembled, piped, wired, tested, and shipped in one

piece. Each unit undergoes a factory test that includes:

• Dynamic trim balance of the completed fan assembly

• Run check of all electrical components, alarms and shutdowns,

including proper control sequencing

• Pressure test, at rated pressure, of refrigerant coils, water coils

and condensers prior to assembly

• Final leak check of the completed refrigerant circuits

• Final leak check of the completed water circuit

• Compressor run check

Verification of factory run test is available at time of unit shipment.

Figure 8. Test Stand

MicroTech III Unit Controls

All SWT units feature advanced MicroTech III DDC controls to

provide all temperature and static pressure control, product reliability control functions, system time clock and all monitoring

and diagnostics. Each MicroTech III control system features a

human interface with a 4-line, 20 character English language display for fast system diagnostics and adjustments. The complete

control system is factory installed and commissioned prior to

shipment.

Protocol Selectability™ Feature

All MicroTech III control systems have McQuay's exclusive Protocol Selectability feature. MicroTech III control systems can be

factory configured for standalone operation or for incorporation

into an independent building automation system using either the

BACnet

MS/TP, BACnet/IP or LonTalk protocols.

Auxiliary Control Options

Condenser Water Flow Switch –A factory installed, flow switch

is available to verify water flow status at each unit. Compressor

operation is disabled and an alarm signal provided if condenser

water flow is lost. Unit operation is restored when water flow has

again been sensed. Water flow status is displayed at the MicroTech III control’s plain language screen.

Freezestat – A nonaveraging type freezestat is available factory

installed on the entering face of the economizer coil. Upon sensing a potential freeze condition, the unit supply air fan is shut

down, the economizer (and heating) valve drives to the full open

position and an alarm signal is provided. Unit operation is

restored following the manual reset of the freezestat.

8 McQuay Catalog 865-5

Page 9

Fan Section

Main Heating /

Cooling Section

Optional Hot

Water Coil

Connections

Condensate

Drain

Filter /

Waterside

Economizer

Section

Water In

Water Out

System Flexibility

Along with providing high quality and state-of-the-art innovation,

SWT self-contained systems emphasize system flexibility, flexibility not even considered by the competition. McQuay SWT systems offer customized flexibility to satisfy a wide range of diverse

applications.

Selection/Application Flexibility

Nominal cooling capacities range from 15 to 45 tons and all units

feature a 6 row evaporator coil. In addition, all units offer multiple

compressor selections to meet exacting system requirements.

Many standard compressor/coil capacity selections are available.

The flexibility to optimize the self-contained system to fit the

application is a McQuay SWT advantage. Available system applications include:

• VAV discharge air temperature control with static

pressure control

• Discharge air temperature control with constant air

volume

• Constant volume, zone temperature control

• 100% outside air control

• Dehumidification control, with or without reheat control

In addition to compressor/coil flexibility, SWT systems offer double width, double inlet, forward curved fans with factory mounted

variable frequency drives for maximizing VAV system fan performance. High efficiency fan capability coupled with extensive

compressor flexibility can provide the right system selection for

the application.

pressure, a 20% reduction in supply air CFM can reduce the

fan BHP requirements by 25% or more.

• Reduced supply air CFM provides reduced fan sound power

generation and a quieter room environment.

• Reduced supply air CFM can often reduce the equipment room

size due to the use of a physically smaller unit size.

Figure 9. Modular Construction

Modular Construction

The SWT unit has been designed with the flexibility to be easily

disassembled into three compact sections. The three sections are

the main cooling/heating, filter/waterside economizer and fan sections. Whereas most competitive products require removal of the

door frame, each SWT section has a maximum width of 34.5",

including fastener heads, and can fit through standard 3' steel door

frames.

The system installer is able to break the unit down into its three

main sections without breaking any refrigerant lines. All SWT

refrigerant lines remain intact, contained in the main cooling/heating section. This SWT feature can add up to substantial savings

by avoiding the field expense to braze, evacuate and charge each

refrigerant circuit.

Optimal Discharge Air Temperature:

More and more system engineers are designing optimal discharge

air temperature systems to improve system performance and system first cost, and the McQuay SWT provides the flexibility to do

it successfully. Optimal discharge air temperature systems are

designed to provide unit leaving air temperature selections of 5253°F versus more conventional systems that supply air at temperatures closer to 58°F. This five to six °F reduction in air temperature to the room diffusers can subsequently reduce the required

supply air volume to the room by 20-25%.

The benefits of optimal discharge air temperature systems become

quite apparent with a look at the advantages offered with reduced airflow:

• Reduced supply air CFM reduces first cost and installation

cost by allowing smaller duct sizes and a smaller air distribution system.

• Reduced supply air CFM reduces fan BHP requirements.

Depending on changes in duct size and the resulting total static

Arrangement Flexibility

All SWT systems offer the flexibility of right-hand and left-hand

piping arrangements and front and rear fan discharge orientations.

Piping and fan arrangement flexibility can simplify mechanical

equipment room arrangement, improve installed cost and improve

total system performance.

Filtration Flexibility

SWT systems are offered with 4 inch, 30% efficient pleated filters

as standard. 4 inch, 65% efficient pleated filters and 4 inch, 85%

efficient filters with pre-filters are also available.

Energy Saving Economizer Flexibility

To improve system operating performance, all SWT s ystems of fer

complete factory mounted and controlled waterside economizer

capability. Each waterside economizer system includes a 4 row,

mechanically cleanable coil with dual, two-way control valves to

allow use in either a constant or variable volume pumping system.

In addition, units can be applied with air economizer cycles with

integrated factory control.

Heating Flexibility

A variety of heating media is offered with each SWT system. Hot

water coils with modulating valve and actuator are available along

with staged electric heat to provide heating control in a variety of

applications.

McQuay Catalog 865-5 9

Page 10

System Flexibility

Controllers

MicroTech III DDC control systems provide constant volume,

variable air volume, 100% outside air, and/or dehumidification

control flexibility. Each MicroTech III control system comes with

a control screen conveniently mounted on the front of the unit to

allow easy adjustment and monitoring of control functions. And

with its easy to follow and read English language menus and data

displays, it simply encourages and invites the operator to take

advantage of its many capabilities.

Figure 10. MicroTech III Controller

Protocol Selectability Feature

All MicroTech III control systems have McQuay's exclusive Protocol

Selectability feature. MicroTech III control systems can be factory

configured for standalone operation or for incorporation into an independent building automation system using either the BACnet

MS/TP, BACnet/IP or LonTalk protocols.

Summary of Available Options:

• Multiple compressor/coil capacity selections

• Multiple control op ti on s: VAV, C V, 100% OA,

dehumidification

• Non-fused main power disconnect switch

• Dual non-fused main disconnect switches

• Non-averaging freezestat for hot water, or waterside econo-

mizer coil protection

• Unit phase failure/under voltage protection

• Premium efficiency fan motors

• TEFC fan motors

• Condenser water flow switch

• 4-row waterside economizer system

• Air cycle economizer system

• Modulating hot water heat

• Staged electric heat

• Factory mounted and controlled variable

frequency drives

• High efficiency filtration options

• Right- and left-hand piping selections

• Front and back fan discharge arrangements

• Head pressure control valve

• Special coil coatings

• Double wall cabinet construction

• Seismic fan isolation

• R407C refrigerant

• UV lights

Ultraviolet Lights

Factory-installed ultraviolet lights are available on the downstream side of all cooling coils and above the unit drain pan.

All ultraviolet lights are pre-engineered and factory installed for

ease of use and proper placement for maximum effectiveness. The

ultraviolet lamps irradiate the coil and drain pan surfaces with

light in the 245 nanometer wavelength of the light spectrum (UVC). UV-C light has proven effective in killing most bacteria,

molds, and viruses in both laboratory and practical application.

This complete package of equipment and ultraviolet lights

includes Intertek Services Inc. (ETL) safety agency certification.

Figure 11: Ultraviolet light

Features

• High-output, hot cathode lamps produce ultraviolet germicidal

irradiation (UVGI) for 254 nm that constantly irradiates the

coil and drain pan surfaces.

• Fixture design and stainless steel construction make the ultra-

violet light device suitable for saturated air conditions.

• Automatic disconnects are standard on all doors (or panels)

with line-of-sight access to the lamps to help prevent eye contact with the UV-C ultraviolet light.

• Special ultraviolet filtering glass windows block ultraviolet

light, allowing the coil, drain pan, and lights to be inspected

while in use from outside the unit.

Benefits

• For pennies a day, UVGI can improve IAQ by destroying

mold, fungi, and bacteria on coil and drain pan surfaces.

• Clean coil surfaces maintain peak heat tra nsfer for “ near new”

performance and lower energy costs.

• Reduced coil and drain pan maintenance requirements and

costs.

• Satisfies GSA federal facilities standard requirements for

UVGI lights to be incorporated downstream of all cooling

coils and above all drain pans to control airborne and surface

microbial growth and transfer.

Refrigerant R-407C

McQuay SWP units with independent refrigerant circuits are

available with non-ozone depleting R-407C refrigerant.

Features

• HFC-407C refrigerant is environmentally friendly with zero

ozone depleting allowance (ODP).

• ASHRAE Standard 34, Designation and Safety Classification

of Refrigerants, classifies HFC-407C as an A1 (lower toxicity—no flame propagation) refrigerant.

• Units are factory engineered for proper cooling performance

using R-407C.

• Units are factory charged with R-407C and synthetic oil (such

as POE), and they include components and controls specifically tailored to R-407C.

• Units are factory tested prior to shipment.

Benefits

• HFC-407C allows you to provide your tenants with a comfort-

able building environment in an environmentally friendly way.

• With no phase out date for production of HFC-407C, a reliable

supply should be available for the life of your equipment.

10 McQuay Catalog 865-5

Page 11

MicroTech® III Unit Controller

McQuay SWP systems continue to provide industry leading

performance, equipped with a complete MicroTech III

control system. In addition to providing stable, efficient

temperature, and static pressure control, the controller is

capable of providing comprehensive diagnostics, alarm

monitoring, and alarm specific component shutdown if

critical equipment conditions occur. The unit controllers are

factory mounted and configured for stand-alone operation or

integration with a building automation system (BAS)

through an optional communication module with our Open

Choices feature.

Open Choices Benefits for Easy Integration

Easy, low cost integration into most building automation

systems without costly gateway panels.

• Flexibility to select either BACnet® or L

communication. Units are LonMark® 3.4 certified with

the appropriate communications module for L

networks.

• Comprehensive unit control and status information is

available at the BAS regardless of communication

protocol.

• Long-term choices for equipment adds or replacements,

and for service support.

• Flexible alarm notification and prioritization with Intrinsic

Alarm Management (BACnet).

• Simplified BAS integration with the ability to set network

parameters at the unit controller, reducing installation time

and costs.

• Easy monitoring and troubleshooting of communication

status from the unit controller to the BAS.

Components

Each SWP self-contained system is equipped with a

complete MicroTech III unit control system that is preengineered, preprogrammed, and factory tested prior to

shipment. Each of the MicroTech III unit control systems is

composed of several components that are individually

replaceable for ease of service.

ONWORKS®

ONWORKS

These components include:

• Unit controller with user interface display and navigation wheel

• Optional expansion modules

• Communication module (optional)

• Pressure transducers

• Unit-mounted temperature sensors

• Zone temperature sensor packages

• Humidity sensor

Main Control Board (MCB)

The main control board (MCB) contains a microprocessor

that is preprogrammed with the software necessary to

control the unit. This provides that schedules, set points and

parameters are not lost, even during a long-term power

outage. The microprocessor board processes system input

data and then determines and controls output responses. An

RS-232 communication port is provided as standard to allow

for direct or modem access with a PC-based service tool.

Expansion Modules

These boards are used to expand the input and output

capability of the unit controller. Each board communicates

via serial data communications. These microprocessor based

boards provide independent operation and alarm response

even if communication is lost with the unit controller.

Communication Module

An optional communication module provides the means to

factory or field configure MicroTech III unit controls for

interoperability with an independent BAS. Communication

modules are available to support industry recognized

communication protocols including BACnet MS/TP,

BACnet/ IP and L

Keypad/Display

All MicroTech III unit controllers include a push/pull

navigation wheel and display. The display is a supertwist

nematic type with highly visible black characters on a

yellow background. The 5-line by 22-character format

allows for easy to understand plain English display

messages. All operating conditions, system alarms, control

parameters and schedules can be monitored from the

keypad/display. If the correct password has been entered,

any adjustable parameter or schedule can be modified from

the keypad.

ONWORKS.

Figure 12. MicroTech III Keypad/DisplayMicroTech III Unit Controls

McQuay Catalog 865-5 11

Page 12

MicroTech® III Unit Controller

Temperature and Humidity Sensors

With the exception of the zone, outside air and return air

sensors, all temperature sensors are factory installed and

tested. Zone sensor packages are available to suit any

application. A humidity sensor is available for field

installation.

Static Pressure Transducers

All pressure transducers are factory installed and tested.

Connection and routing of field-supplied sampling tubes is

done at time of unit installation.

Zone Temperature Sensors

Two optional zone temperature sensors are available:

• Zone sensor with tenant override switch

• Zone sensor with tenant override switch and remote set

point adjustment

Timed tenant override is a standard MicroTech III

control feature.

Zone sensors are required for the controller’s purge cycle,

space reset of supply air set point, and night setback or setup

features. All zone sensors are field installed with field

wiring terminated at a separate, clearly marked terminal

strip.

Stand-alone Controller Features

MicroT ech III applied rooftop unit controls include all of the

essential features required to make them capable of

completely independent, stand-alone operation.

Internal Time Clock

An internal, battery-backed time clock is included in the

MicroTech III unit controller. Current date and time can be

quickly and easily set at the user interface keypad.

Internal Schedule

Seven daily schedules and one holiday schedule can be

entered at the keypad of all unit controllers. For each of

these eight schedules, one start and one stop time can be

entered. Up to 10 holiday periods, of any duration, can be

designated. The unit will automatically run according to the

holiday schedule on the holiday dates. To handle special

occasions, an additional ‘one event’ schedule can also be

used.

In lieu of its internal schedule, the unit can be operated

according to a network schedule from a BAS.

External Time Clock or Tenant Override Input

An input is supplied that can be used to accept a field wired

start/stop signal from a remote source. An external time

clock, a tenant override switch, or both may be connected.

Whenever the external circuit is closed, the controller

overrides the internal schedule (if activated) and places the

unit into the occupied mode.

If the internal schedule or a BAS network schedule is used,

field wiring is not required.

Timed Tenant Override

Off-hour operation flexibility is a must in today’s office

environments and even stand-alone MicroTech III controls

handle it with ease. When unit operation is desired during

unoccupied hours, initiate timed tenant override by pressing

the tenant override button on either of the optional zone

sensor packages. The unit then starts and runs in the

occupied mode for a keypad-adjustable length of time (up to

five hours). If the button is pressed again while the unit is

operating, the timer resets to the full time allowance without

interrupting unit operation. Tenant override operation also

can be initiated by a BAS.

Three Remote Set Point Adjustment Options

1 Remote user interface option (RUI).

2 Building automation system (BAS). See “Open Choices

Benefits for Easy Integration” on page 11.

3 All constant air volume-zone temperature control

(CAV-ZTC) unit controllers include an input that can

be used to remotely adjust the zone cooling and

heating set points. To use this feature, wire the optional

zone sensor package with set point adjustment to the

controller. The remote set point adjustment feature can

be enabled or disabled from the keypad at any time.

When enabled, remote set point adjustment is

available even if the return temperature is selected to

be the Control Temperature.

Auto/Manual Operation Selection

Automatic or manual operation can be controlled either

remotely or at the keypad.

All controllers include three inputs that can be used to

enable or disable cooling, heating, and fan operation from

remote switches. With the “heat enable” and “cool enable”

terminals, the operator can enable cooling, heating, or both

as desired. Using the system “off” terminals, the operator

can disable the fans, and thus the entire unit.

12 McQuay Catalog 865-5

Page 13

MicroTech® III Unit Controller

From the keypad, there are a variety of occupancy and auto!

manual control mode selections available to the operator:

• Occupancy modes

– Auto

– Occupied

– Unoccupied

– Bypass (tenant override)

• Control modes

– Off manual

– Auto

– Heat/cool

– Cool only

– Heat only

– Fan only

Compressor Lead-lag Selection

All unit controllers are capable of automatic compressor,

lead-lag control.

Waterside Economizer Changeover

On units equipped with a waterside economizer package, the

MicroTech III unit controller includes an internal

changeover strategy that compares entering cooling tower

water temperature to the unit’s mixed air temperature. If the

entering water temperature is less than the mixed air

temperature by a field-adjustable differential (typically 5°F

to 7ºF), the economizer control valve modulates in response

to the cooling load.

warm-up or cool-down periods or when the outdoor air

temperature is mild.

Night Setback and Setup Control

When one of the zone temperature sensors is connected to

the unit controller, night setback heating and night setup

cooling control are available. Separate, keypad

programmable night heating and cooling set points are used

to start the unit when necessary. After the unit starts, night

setback and setup control is similar to normal occupied

control except that the minimum outside air damper position

is set to zero. If the outside air is suitable for free cooling, it

is used during night setup operation.

Airside Economizer Changeover Selection

On units equipped with an economizer, there are three

methods of determining whether the outdoor air is suitable

for free cooling: two methods sense enthalpy (dry bulb

temperature and humidity) and one senses outdoor air dry

bulb temperature.

The two enthalpy changeover methods use external, factory

installed controls. One compares the outdoor ambient

enthalpy to a set point; the other is a solid state device that

compares the outdoor ambient enthalpy to the return air

enthalpy. This comparative enthalpy control can improve

total economizer performance.

All unit controls include an internal dry bulb changeover

strategy that can be selected at the keypad. When this

method is selected, the controller compares the outdoor air

dry-bulb temperature to a keypad programmable set point.

The external enthalpy control input is then ignored.

Cooling and Heating Lockout Control

All unit controls include separate keypad programmable set

points for locking out mechanical cooling and heating.

Mechanical cooling is locked out when the outdoor

temperature is below the cooling lockout set point; heating is

locked out when the outdoor temperature is above the

heating lockout set point. This feature can save energy cost

by eliminating unnecessary heating and cooling during

McQuay Catalog 865-5 13

Page 14

MicroTech® III Unit Controller

Except for 100% outside air applications, night setback

control is available even if the unit is not equipped with any

heating equipment. When the space temperature falls to the

night setback set point, the fans simply start and run until the

temperature rises above the differential. This feature might

be useful for applications that use, for example, ductmounted reheat coils.

Morning Warm-up Control

If the Control Temperature (space or return) is below set

point when the unit enters the occupied mode, the morning

warm-up control function will keep the outside air dampers

closed while heat is supplied to satisfy set point. The outside

air damper will remain closed until either the space

temperature rises to the

heating set point or the keypad adjustable morning warm-up

timer expires (default is 90 minutes). The morning warm-up

timer supplies the minimum required amount of outdoor air

after a certain time regardless of the space temperature.

Morning warm-up control is automatically included on all

except 100% outside air units. It is available even if the unit

is not equipped with any heating equipment, for applications

that utilize, for example, duct-mounted reheat coils.

Condenser Head Pressure Control (units without

waterside economizer only)

Mechanical cooling is allowed whenever the entering

cooling tower water temperature is 55ºF or warmer, without

the use of head pressure control. When the entering water

temperature is below 55ºF, a factory-installed and factorycontrolled two-way modulating head pressure control valve

can be utilized. The regulating valve is controlled by the

MicroTech III controller to maintain refrigerant head

pressure.

During the purge time window, the unit starts and runs

whenever these three requirements are met:

• The space temperature must be warm enough to enable

occupied cooling.

• The outside air enthalpy must be low enough to enable

the economizer.

• The outside air temperature must be at least 3°F less

than the space temperature.

When any one of these conditions is no longer true, the unit

shuts down. As conditions allow, purge cycles the unit in

this manner until it enters the occupied mode.

Proportional Integral (PI) Control

The Proportional Integral (PI) control algorithm controls

modulating actuators to maintain a measured variable

(temperature or pressure) at or near its set point. For

example, it controls economizer dampers to maintain the

discharge cooling set point and it controls the supply fan

variable frequency drives to maintain the duct static pressure

set point. The integral control feature effectively eliminates

“proportional droop” (load dependent offset) resulting in the

tightest possible control.

For each PI loop, four keypad adjustable parameters allow

the control loop to be properly tuned for any application:

•Period

• Dead band

• Proportional band

• Integral time

Appropriate default values for these parameters are loaded

into each controller. These default values will provide proper

control for most applications; therefore, field tuning is

usually not required and thus start-up time is reduced.

Outdoor Air Purge Control (units with airside

economizer only)

Purge control is designed to take advantage of cool early

morning outside air conditions. It starts the fans and

modulates the economizer dampers to maintain occupied

cooling requirements during unoccupied periods, if

conditions are appropriate. This provides the opportunity to

flush the space with fresh outdoor air prior to occupancy.

Purge operation is possible only during a keypad-adjustable

time window prior to occupancy (0 to 240 minutes). When

the purge-cycle is active, mechanical cooling is disabled. To

use the purge feature, connect one of the zone temperature

sensors to the unit controller. Below is a description of purge

control operation.

14 McQuay Catalog 865-5

Change Algorithm

The PI function is also used to adjust set points instead of

controlling variable speed drives or actuators directly. For

example, in zone control applications, the PI loop

automatically “changes” the discharge temperature set point

(cooling or heating) as the Control Temperature deviates

from the zone set point. Another PI loop then controls the

economizer actuator or heating valve actuator using the

current discharge temperature set point. Unlike a typical

“mastersubmaster” reset strategy, this “cascade control”

continuously adjusts the discharge set point, even if the

Control Temperature’s deviation from set point remains

constant. This means that the unit’s cooling or heating

output is set according to the actual load, not just the current

zone temperature. The tightest possible zone temperature

control results because “proportional droop” (load

dependent offset) is eliminated.

Calibrat

When initiated at the keypad by an operator, the Calibrate

function automatically calibrates all actuator position

feedback inputs and all pressure transducer inputs. It does

e

Page 15

MicroTech® III Unit Controller

this by shutting the unit down and then driving all actuators

to the full closed and full open positions. The controller

records the input voltage values that correspond to these

positions. The pressure transducer input voltages, which are

assumed for 0.00-in. W.C., are also recorded. When

Calibrate is finished, enter an operator command at the

keypad to start the unit.

Field Output Signals

All MicroTech III controls include two solid-state relay

outputs that are available for field connection to any

suitable device: the remote alarm output and the occupied

output. These two outputs are used to signal field equipment

of unit status.

Remote Alarm Output: The remote alarm output can

be used to operate a 24 volt relay to provide a remote

alarm signal to a light, audible alarm, or other device

when an alarm condition exists at the unit.

Fan Operation Output: The fan operation output is

used to operate a 24 volt relay to control field equipment that depends on fan operation; for instance, to

open field installed isolation dampers or VAV boxes. T o

allow actuators enough time to stroke, the fan operation

output is energized three minutes before the fans start. It

then remains energized until thirty seconds after the uni t

airflow switch senses no airflow. The fan operation output is on whenever the unit airflow switch senses airflow.

Outside Air Damper output: Use to signal an outside

air damper actuator to open whenever the unit is in an

occupied cooling or heating condition.

Standard Control Options

SWP Self-Contained systems are available for most any

constant or variable air volume application. MicroTech III

controls offer three basic control configurations that use

sophisticated state change control logic to provide stable,

reliable and efficient control:

• Variable air volume with discharge temperature control

(DAC)

• Constant air volume with zone temperature control (S

CC)

• Constant air volume with discharge temperature control (DAC)

When combined with MicroTech III’s many available

control capabilities, both factory-installed and keypadprogrammable, these three basic configurations can be

customized to meet the requirements of the most demanding

applications.

Constant Air Volume with Zone Temperature

Control (SCC)

SCC units are available in either cooling only or cooling

with modulating heat configurations. Either of these

configurations is available for 100% recirculated, mixed, or

100% outdoor air applications.

Constant Air Volume with Discharge Temperature

Control (DTC)

DTC units are available in cooling only, cooling with singlestage “morning warm-up” heat, or cooling with modulating

heat configurations. This unit configuration can be used for

applications that have zone controlled terminal heating coils

or for constant volume, 100% outdoor air applications. The

discharge temperature control strategies used with the hybrid

DTC unit are identical to those used with the DTC unit.

Discharge Temperature Control

MicroTech III VAV-DTC and CAV-DTC controls provide

sophisticated and flexible discharge air temperature control

that is only possible with DDC systems. Separate discharge

air temperature set points are used for cooling and

modulating heating control. At the keypad, the operator can

either enter the desired set points or select separate reset

methods and parameters for each set point.

Control Temperature

The Control Temperature make s the heat/cool changeover

decision. It determines whether cooling or heating is

enabled; the discharge temperature then determines whether

cooling or heating is actually supplied. At the keypad, the

operator can choose the source of the Control Temperature

from among the following selections.

• Space temperature sensor

• Return temperature sensor

• Outside air temperature sensor (modulating heat only)

• Network communication

The operator enters separate cool and heat enable set points

and deadbands that the Control Temperature is compared

with (see <CrossReference>Figure 13). When the Control

Temperature is greater than or equal to the cooling set point

plus DB/2, cooling is enabled. When the Control

Temperature is less than or equal to the heat set point minus

DB/2, heating is enabled. If desired, these set points and

differentials can be set so that there is a dead band in which

both cooling and heating are disabled. The controller’s

software prevents simultaneous cooling and heating.

Variable Air Volume with Discharge Temperature

Control (DTC)

All VAV units provide true discharge temperature control in

addition to duct static pressure control. Cooling only,

cooling with single-stage “morning warm-up” heat, and

cooling with modulating heat configurations are available.

McQuay Catalog 865-5 15

Page 16

MicroTech® III Unit Controller

Figure 13: Control Temperature Logic

Proportional Integral Modulation

When operating in economizer free cooling or unit heating,

the previously described PI algorithm maintains discharge

temperature control. It provides precise control of the

economizer dampers, modulating gas heat, steam or hot

water valves.

Compressor Staging

Two staging algorithms are available to control a unit’s

multiple steps of capacity control, Degree-Time (also known

as “average”) and Nearest. These control algorithms provide

reliable discharge temperature control while managing

compressor cycling rates. Constraints on compressor staging

are essential for preventing short cycling, which can reduce

compressor life by causing improper oil return and excessive

heat buildup in the motor windings.

The Degree-Time Compressor staging algorithm keeps track

of the discharge temperature and stages cooling up or down

to maintain an average temperature that is equal to the

discharge cooling set point. A stage change can occur only

(1) after the keypad adjustable inter-stage timer has expired

(five minute default setting) and (2) if the discharge

temperature is outside a keypad programmed dead band.

After these two conditions have been met, staging occurs as

the controller attempts to equalize two running totals:

degree-time above set point and degree-time below set point.

The result is that the average discharge temperature is

maintained at the cooling set point.

The Nearest Compressor staging algorithm keeps track of

the discharge temperature and stages cooling up or down to

maintain the discharge temperature as close as possible to

set point. A stage change can occur only (1) after the keypad

adjustable inter-stage timer has expired (five minute default

setting) and (2) if the control logic calculates that a stage

change will result in a discharge temperature closer to set

point than the existing condition. The controller logic

continually calculates the expected effect of a stage change

and uses this information before making a change. A change

is made only if it will bring the discharge temperature closer

to set point, resulting in a more consistent discharge

temperature, reduced compressor cycling and more stable

control VA V box control.

Supply Air Reset

By automatically varying the discharge air temperature to

suit a building’s cooling or heating needs, supply air

temperature reset can increase the energy efficiency of VAV

and CAV-DTC systems. MicroTech III controllers offer a

variety of different reset strategies that can be selected at the

keypad. Because they are keypad programmable, reset

strategies can be changed or eliminated as desired. Separate

strategies can be selected for both cooling and modulating

heat. If reset is not desired, a fixed discharge cooling or

heating set point can be entered.

The following reset methods are available:

• Space temperature

• Return temperature

• Outdoor air temperature

• Supply airflow (VAV, cooling set point only)

• External 0–10 VDC or 0–20 mA signal

• Network communication

For all temperature reset methods, the minimum and

maximum cooling and heating set points are keypad

programmable along with the corresponding minimum and

maximum space, return or outdoor air temperature

parameters. For the supply airflow method, the discharge set

point will be reset as the supply fan modulates between 30%

adjustable and 100% adjustable. For the external method,

the discharge set point will be reset as the voltage or current

signal varies over its entire range. For units in a BAS

network, the discharge set points are reset via the

communication signal.

Zone Temperature Control

MicroTech III CAV-ZTC controls provide the sophisticated

and flexible zone temperature control that is only possible

with DDC systems. Zone temperature sensors are available

with or without a remote set point adjustment. With the

remote adjustment model, the space set point can be set at

the keypad or at the zone sensor package. Even if a zone

sensor is connected, remote set point adjustment can be

enabled or disabled as desired at the keypad.

Control Temperature

The Control Temperature is the representative zone

temperature. When compared with the zone set points, the

Control Temperature determines whether the unit supplies

heating, cooling, or neither. It also determines the amount of

cooling or heating required to satisfy the load. Its source can

be selected at the keypad from among the following

selections:

• Zone temperature sensor

• Return temperature sensor

16 McQuay Catalog 865-5

Page 17

MicroTech® III Unit Controller

Because it is the representative zone temperature, the

Control Temperature is the primary input to the MicroTech

III zone temperature control algorithms. Control

Temperature parameters are described below. The

controller’s software will prevent cooling and heating from

being inadvertently enabled at the same time.

Change and Proportional Integral Mo du la tio n

When economizer “free” cooling or unit heating is required,

the two MicroTech III PI loops combine for cascade-type

control, providing the tightest possible zone temperature

control. By controlling the discharge temperature along with

the zone temperature, these functions eliminate temperature

variations near the diffusers that could otherwise occur as a

result of traditional zone control’s inherent lag effect.

Change: If the Control Temperature is above or below

the set point by more than the dead band, the Change PI

loop periodically adjusts the cooling or heating discharge air temperature set point either up or down as

necessary . The amount of this set point change corresponds to the Control Temperature’s position in the

modulation range. The farther the Control Temperature

is from the set point, the greater the discharge set point

change will be. The Change-adjusted discharge cooling

and heating set points are limited to ranges defined by

keypad programmable maximum and minimum values.

PI: Using the Change function’s current discharge set

point, the PI function maintains precise discharge temperature control by modulating the economizer dampers

and gas heat, steam or hot water heating valves.

Compressor Staging

Compressor staging is controlled directly by the Control

T emperature. When the Control Temperature is warmer than

the zone cooling set point, cooling is staged up; when the

Control Temperature is cooler than the zone cooling set

point, cooling is staged down. However, a stage change can

only occur when the Control Temperature is outside the dead

band (see <CrossReference>Figure 14). Staging is

constrained by an inter-stage delay timer (five minute

default setting) and minimum and maximum discharge air

temperature limits (all keypad programmable). These

constraints protect the compressors from short cycling while

eliminating temperature variations near the diffusers.

Figure 14: Compressorized Logic

Project Ahead Algorithm

Because the inherent lag effect in zone temperature control

applications can cause overshoot during warm-up or cooldown periods, MicroTech III features a “Project Ahead”

control algorithm. Project Ahead calculates the rate at which

the Control Temperature is changing and reduces the unit’s

cooling or heating output as the zone temperature nears its

set point, essentially eliminating overshoot.

Duct Static Pressure Control

On all VAV-DTC units, duct static pressure control is

maintained by the PI algorithm, which provides precise

control of the supply fan variable speed drive. The keypad

programmable set point can be set between 0.20-in. W.C.

and 4.00-in. W.C.

On larger buildings with multiple floors, multiple trunk runs

or large shifts in load due to solar effects (east/west building

orientation), an optional second duct static sensor is offered.

The MicroTech III controller automatically selects and uses

the lower of the two sensed pressures to control fan volume

to provide adequate static pressure to the most demanding

space at all times.

Operating States

Operating states define the current overall status of the selfcontained system. At the user interface, the operator can

display the current operating state and thereby quickly

assess the unit’s operating condition.

Alarm Management and Control

MicroTech III unit controllers are capable of sophisticated

alarm management and controlled response functions. Each

alarm is prioritized, indicated, and responded to with the

appropriate action. The active alarm (up to 10 alarms,

arranged by alarm priority) and previous alarm (up to 25

alarms, arrange by date/time cleared), each with a time and

date stamp, can be displayed at the user interface. Generally

speaking, whenever a current alarm is cleared, it is logged as

a previous alarm and the oldest previous alarm is removed.

Alarm Priority

The various alarms that can occur are prioritized according

to the severity of the problem. See

<CrossReference>Table 1. Three alarm categories are used:

faults, problems, and warnings.

1 Faults are the highest priority alarms. If a fault

condition occurs, the complete unit shuts down until

the alarm condition is gone and the fault is manually

cleared at the keypad. A fault example is Fan Fail

alarm.

McQuay Catalog 865-5 17

Page 18

MicroTech® III Unit Controller

2 Problems are the next lower priority to alarms. If a

problem occurs, the complete unit does not shut down,

but its operation is modified to compensate for the

alarm condition. A problem automatically clears when

the alarm condition that caused it is gone. Compressor

Fail is an example of a problem where only the

affected compressor is shut down.

3 Warnings are the lowest priority alarms. No control

action is taken when a warning occurs; it is indicated

to alert the operator that the alarm condition needs

attention. T o make su re that they are read, the operator

must manually clear all warnings. Dirty Filter

indication is an example of a warning.

Generally, a specific alarm condition generates an alarm that

falls into only one of these categories. Under different sets

of circumstances, however, the freezestat and most of the

sensor failure alarm conditions can generate alarms that fall

into multiple categories.

Adjustable Alarm Limits

Four alarm indications have adjustable limits that are used to

trigger the alarm. The high return temperature alarm and the

high and low supply temperature alarms are adjusted at the

user interface. The dirty filter alarm(s) is adjusted at the

sensing device.

Table 1: MicroTech III Alarm Summary

Alarm Name Fault Problem Warning

Freeze X X

Smoke X

Temperature Sensor

Failure

Duct High Limit X

High Return Temperature X

High Discharge

Temperature

Low Discharge

Temperature

Fan Failure X

Fan Retry X

Discharge Air Capacity

Feedback

Economizer Stuck X X

Auxillary Control Board

Enabled

Low Airflow X

Circuit 1–8

High Pressure

Circuit 1–8

Low Pressure/Frost

Compressor 1–8 Motor

Protection

Compressor 1–8 Failure X

Airflow Switch

(False Airflow)

Dirty Filter X

XX

X

X

X

X

X

X

X

X

18 McQuay Catalog 865-5

Page 19

Application Considerations

The following section contains basic application and installation

guidelines which must be considered as part of the detailed analysis of any specific project.

General

Units are intended for use in normal heating, ventilating and air

conditioning applications. Consult your local McQuay sales representative for applications involving operation at high entering

condenser water temperatures, high altitudes, non-cataloged voltages and for applications requiring modified or special control

sequences. Consult your local McQuay sales representative for

job specific unit selections that fall outside of the range of the catalog tables, such as 100% outside air applications.

For proper operation, rig units in accordance with instructions

stated in IM 709.

Factory check, test and start procedures must be explicitly followed to achieve satisfactory start-up and operation

(see IM 709).

Many self-contained system applications take advantage of the

significant energy savings provided by the use of economizer

operation. When a water economizer system is used, mechanical

refrigeration is typically not required below an entering condenser

water temperature of 55°F. Standard McQuay self-contained systems are designed to operate with entering water temperatures

down to 50°F when a water economizer is used and 55°F with no

water economizer. For applications where a water economizer

system cannot be used, a modulating head pressure control system

is available to permit operation at entering condenser water temperatures below 55°F.

Unit Location

Make sure that the floor is structurally strong enough to support

the unit with minimum deflection (See “Unit and Component

Weights in lbs.” on page 42). Provide proper structural support to

minimize sound and vibration transmission. A concrete floor

should be considered. Extra caution is required when installing on

a wooden structure. Units must be installed level from front-toback and over their length.

Unit fresh air intakes must be located away from building flue

stacks, exhaust ventilators and areas containing automotive or

other exhaust to prevent the possible introduction of contaminated

air to the system. Consult code requirements for minimum fresh

air volumes.

Allow sufficient space around the unit for service and maintenance clearance. Refer to Figure 15 for recommended service/maintenance clearances. See also “Recommended

Clearances” on page 19“. Locate equipment room access doors in

a manner that can assist in service access if needed (i.e., coil

removal). Contact your local McQuay sales representative if

reduced service/maintenance clearances are required.

Where code considerations, such as the NEC, require extended

clearances, they take precedence over minimum service/maintenance clearances.

Acoustical Considerations

Good acoustical design is a critical part of any successful installation and should start at the earliest stages in the design process.

Each of the four common sound paths must be addressed. These

are: (1) radiated sound through the casing of the unit, (2) structure

borne vibration, (3) airborne sound through the supply air duct

and (4) airborne sound through the return air duct.

Some basic guidelines for good acoustic performance include:

1. Always provide proper structural support under the unit.

2. Provide adequate mass in the floor structure, especially

when located over an occupied space where good acoustics are essential.

3. Seal all supply and return air duct penetrations once the

duct is installed.

4. Don't overlook the return air path. Always include some

duct work (acoustically lined tee) at the return inlet.

5. Minimize system static pressure losses to reduce fan

sound generation.

6. Select the appropriate unit/fan for the application. Fans

should be selected as close as possible to their peak

static efficiency. To assist you, peak static efficiency is

identified by the first system curve to the right of the

shaded "Do not select" region on each fan curve.

7. Design duct systems to minimize turbulence.

8. Account for low frequency duct breakout noise in system design. Route the first 20' of rectangular duct over

non-sensitive areas and avoid large duct aspect ratios.

Consider round or oval duct to reduce breakout.

Recommended Clearances

For good installation, service and maintenance access, follow recommended clearances. Minimum clearances required by local,

state or federal codes, such as the NEC, take precedence over

those listed below. Clearance is required to allow room for side

filter access, mechanical cleaning of condenser tubes and economizer coil access to expansion valves and other control components and to allow for possible fan shaft or compressor removal.

Unit Front 42 inch

Unit Rear 24 inch

Motor Location Side 36 inch

Piping Location Side 36 inch