Page 1

Self-Contained Air Conditioning Systems

Type SWP Vintage H

with R-410A Refrigerant

Capacity: 20 through 130 tons

Catalog 860-9

Engineered for flexibility and performance™

Page 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Continued Leadership in

Self-Contained Systems Design s . . . . . . . . . . . . . . .3

McQuay Self-Contained Systems . . . . . . . . . . . . . . . 4

SWP 012–130 Features and Options . . . . . . . . . . . . 4

Cabinet, Casing and Frame . . . . . . . . . . . . . . . . . 6

Compressor/ Condensing Section . . . . . . . . . . . . 7

Cooling Coil Section . . . . . . . . . . . . . . . . . . . . . . .8

Supply Fan Section . . . . . . . . . . . . . . . . . . . . . . . .8

Acoustical Discharge Plenum . . . . . . . . . . . . . . . 10

Variable Air Volume Control . . . . . . . . . . . . . . . . 10

Economizer Options . . . . . . . . . . . . . . . . . . . . . .10

Condenser Head Pressure Control . . . . . . . . . . .11

Filter Section . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Blank Sections . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Heating Section . . . . . . . . . . . . . . . . . . . . . . . . . .12

System Flexibility with Unit Options . . . . . . . . . . . . 13

Selection/Application Flexibility . . . . . . . . . . . . . .13

Arrangement Flexibility . . . . . . . . . . . . . . . . . . . .13

Optimal Discharge Air Temperature . . . . . . . . . .13

Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

R-410A Refrigerant . . . . . . . . . . . . . . . . . . . . . . . 14

MicroTech III Unit Controls . . . . . . . . . . . . . . . . . . . . 15

Open Choices Benefits for Easy Integration . . . . 15

Alarm Management and Control . . . . . . . . . . . . . 21

Application Considerations . . . . . . . . . . . . . . . . . . .23

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Unit Location . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Acoustical Considerations . . . . . . . . . . . . . . . . . .24

Equipment Room . . . . . . . . . . . . . . . . . . . . . . . .24

Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Condenser Water Piping . . . . . . . . . . . . . . . . . . . 25

Head Pressure Control . . . . . . . . . . . . . . . . . . . . 25

Variable Air Volume . . . . . . . . . . . . . . . . . . . . . . 25

Variable Frequency Drives . . . . . . . . . . . . . . . . .26

Duct Static Pressure Sensor Placement . . . . . . .26

Zone Sensor Placement . . . . . . . . . . . . . . . . . . .26

Filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

System Operating Limits . . . . . . . . . . . . . . . . . . .27

Airflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Fan Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Condenser Water Flow . . . . . . . . . . . . . . . . . . . . 27

Coil Freeze Protection . . . . . . . . . . . . . . . . . . . . 28

Air Density Correction . . . . . . . . . . . . . . . . . . . . . 28

Unit Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Terms of Sale . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 29

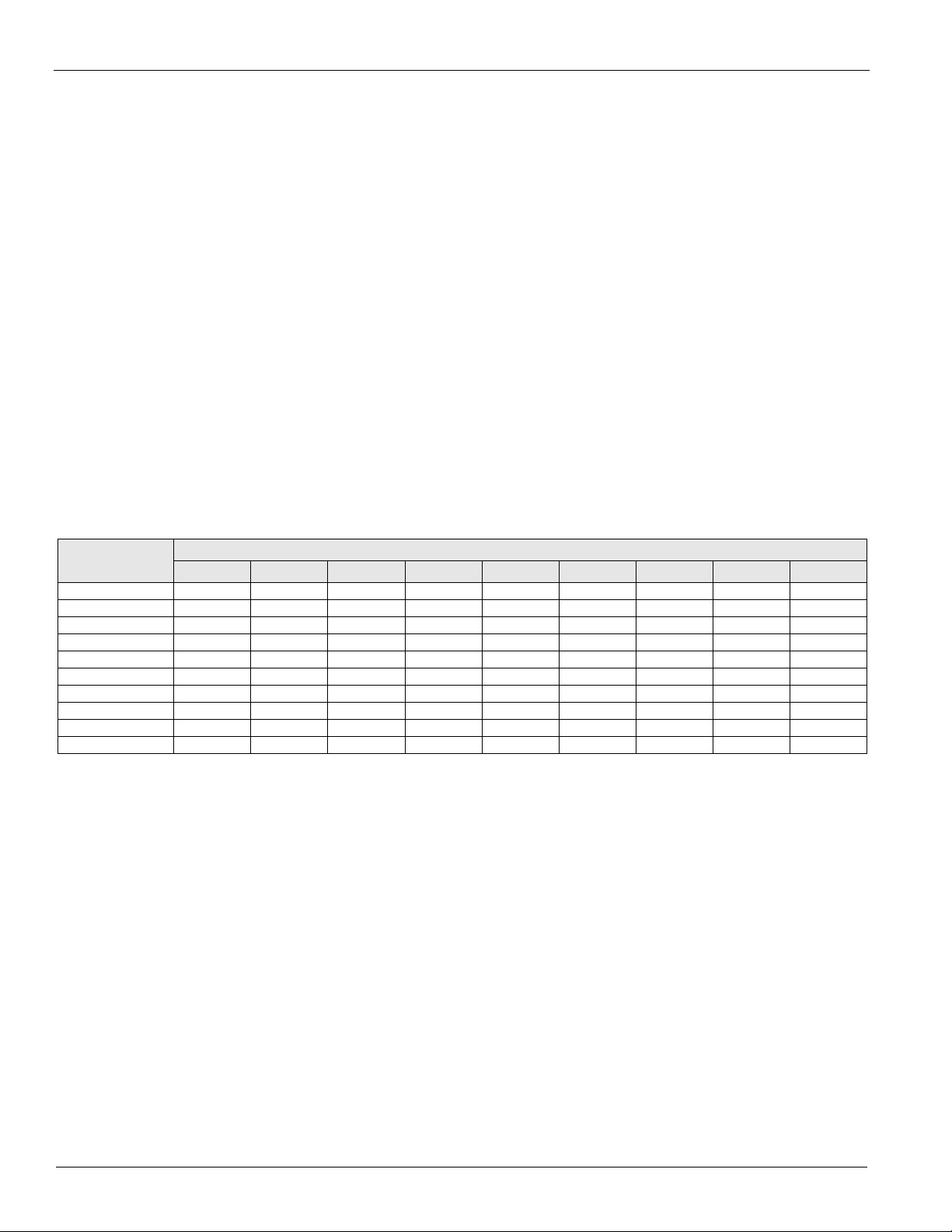

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

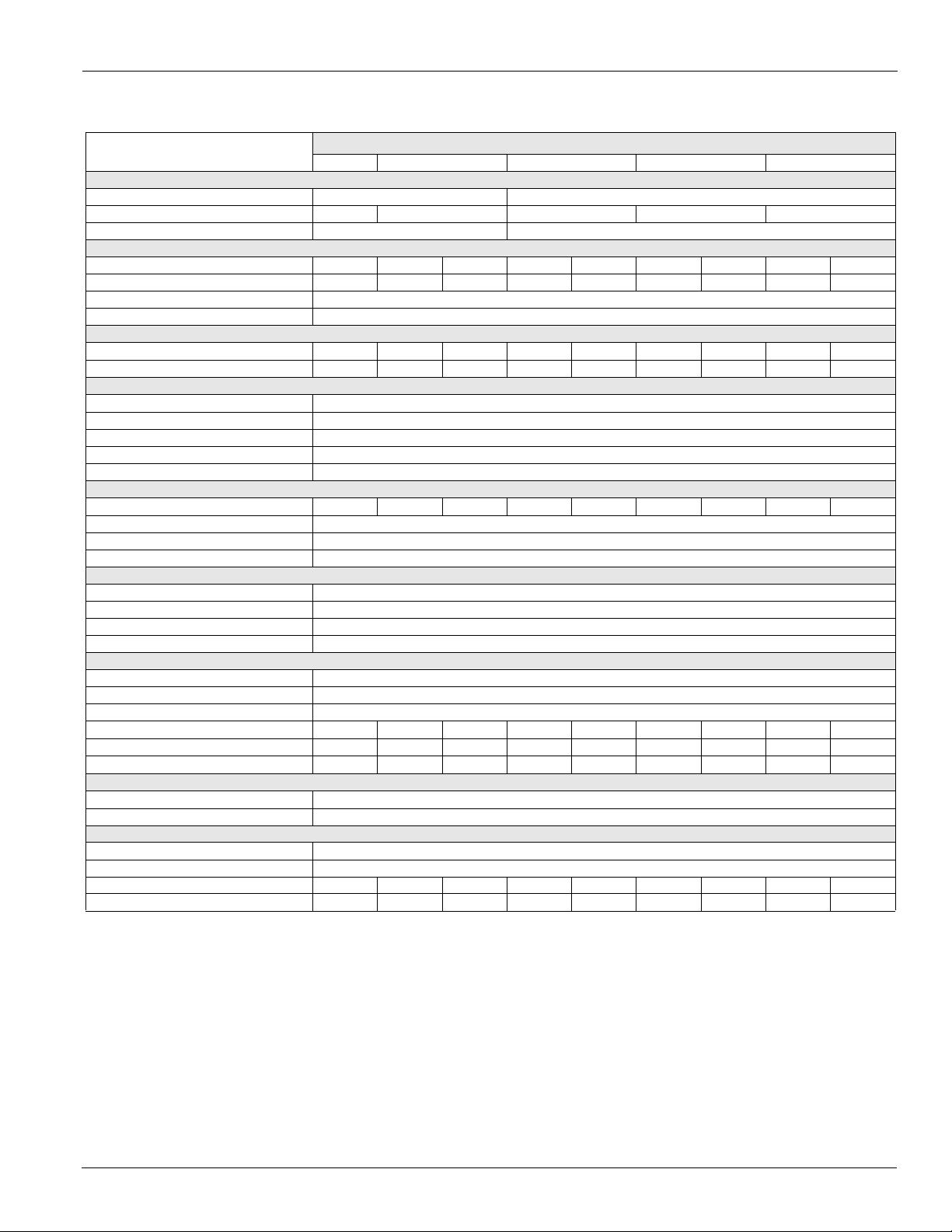

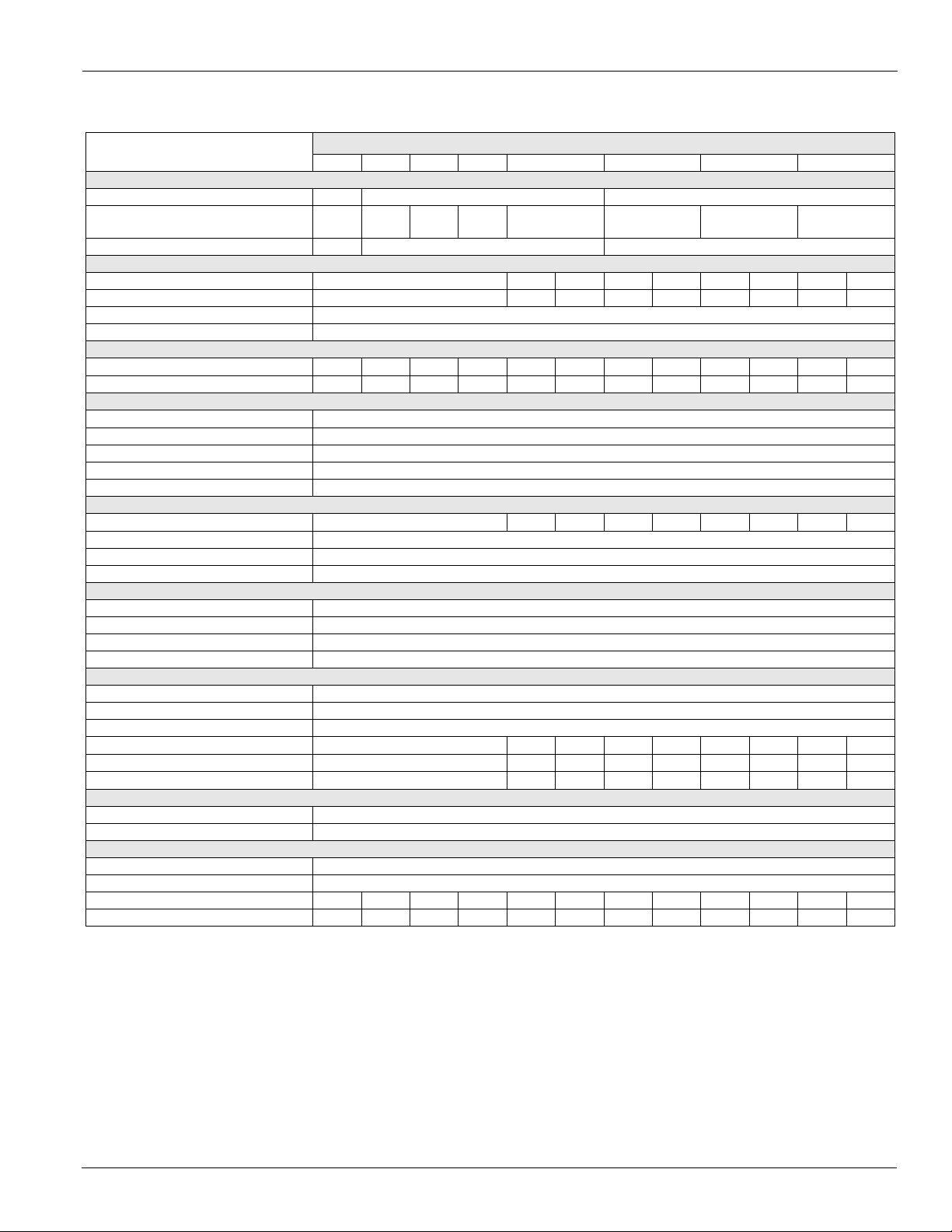

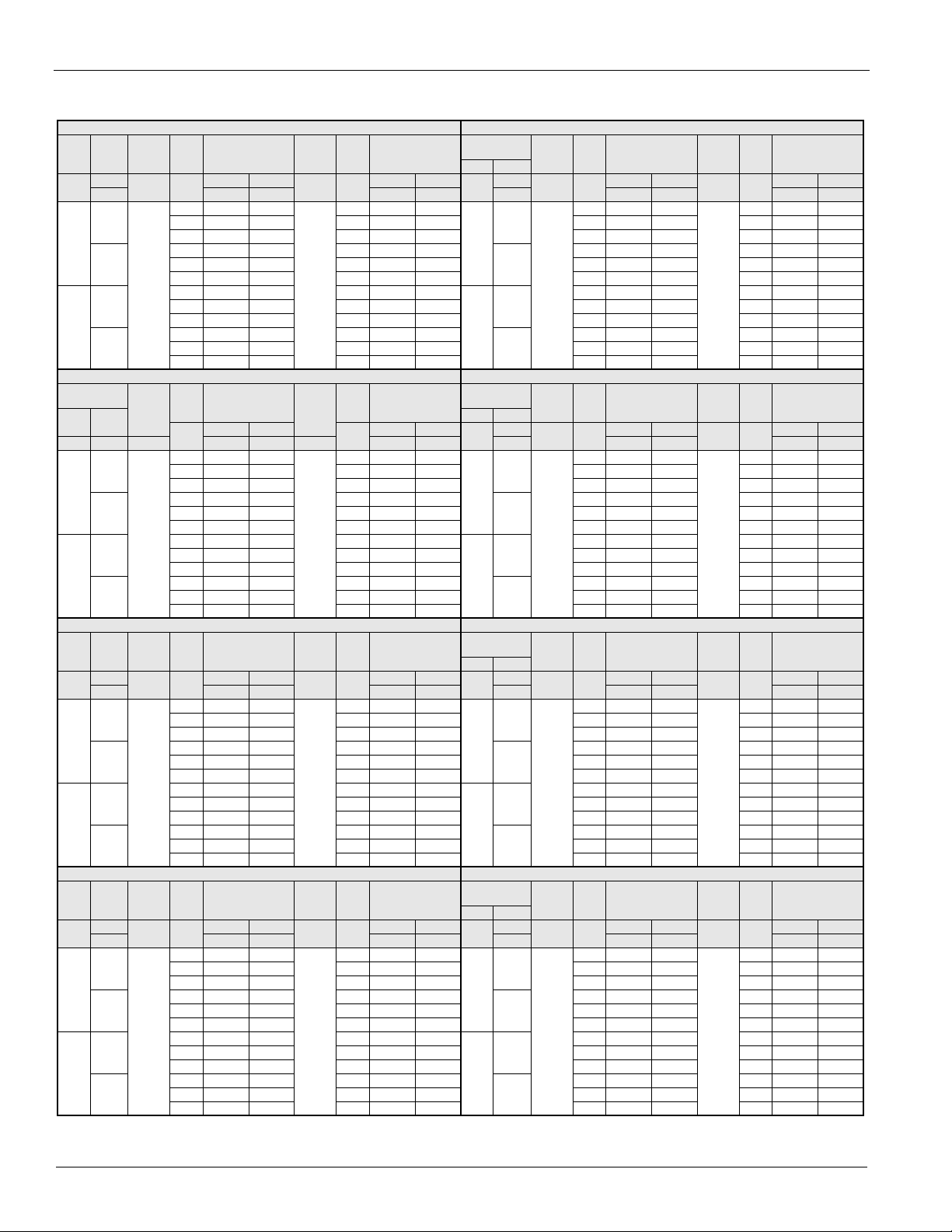

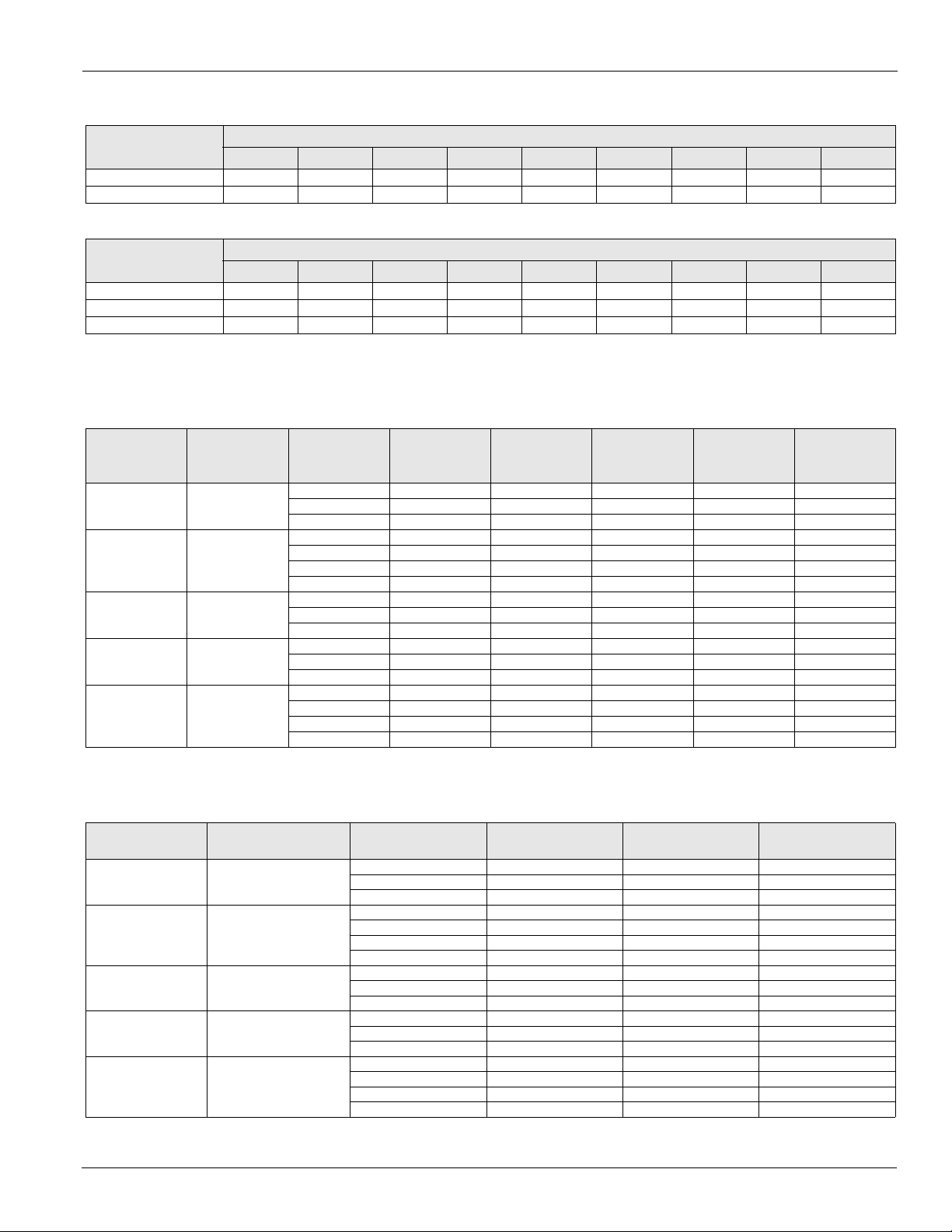

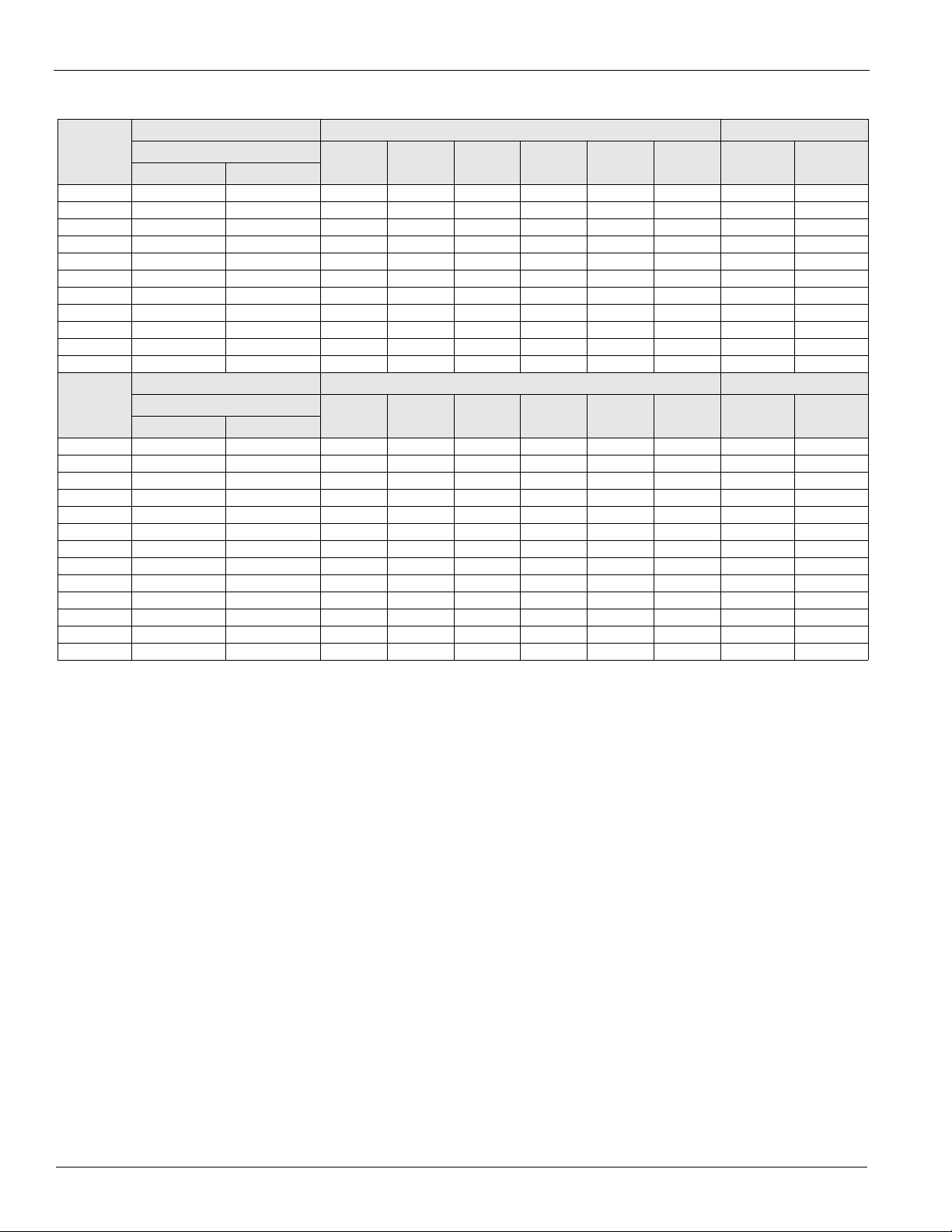

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

DX Cooling Capacity Data . . . . . . . . . . . . . . . . . 36

Waterside Economizer Capacity . . . . . . . . . . . . 44

Heating Capacity Data . . . . . . . . . . . . . . . . . . . . 45

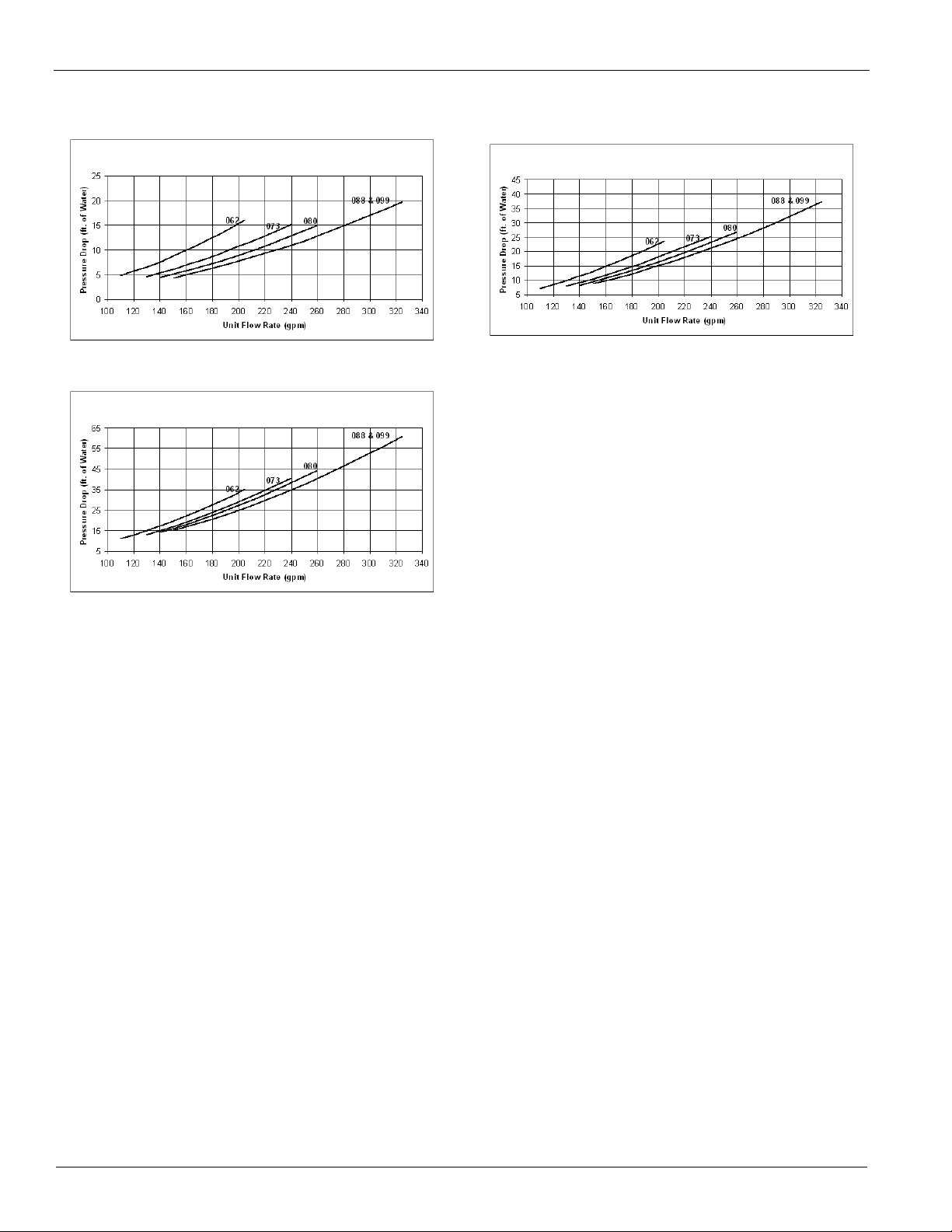

Component Pressure Drops . . . . . . . . . . . . . . . 46

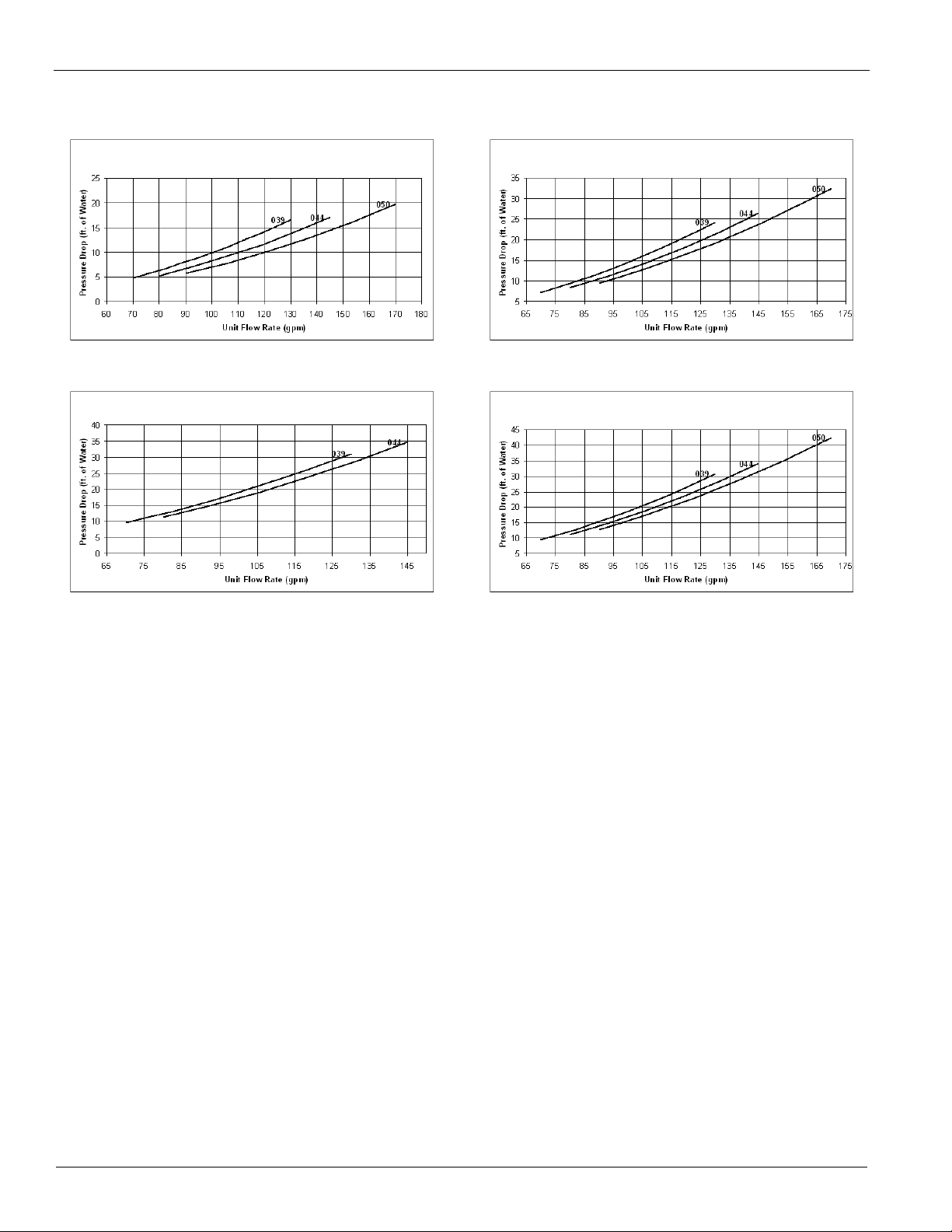

Total Unit Water Pressure Drop . . . . . . . . . . . . . 49

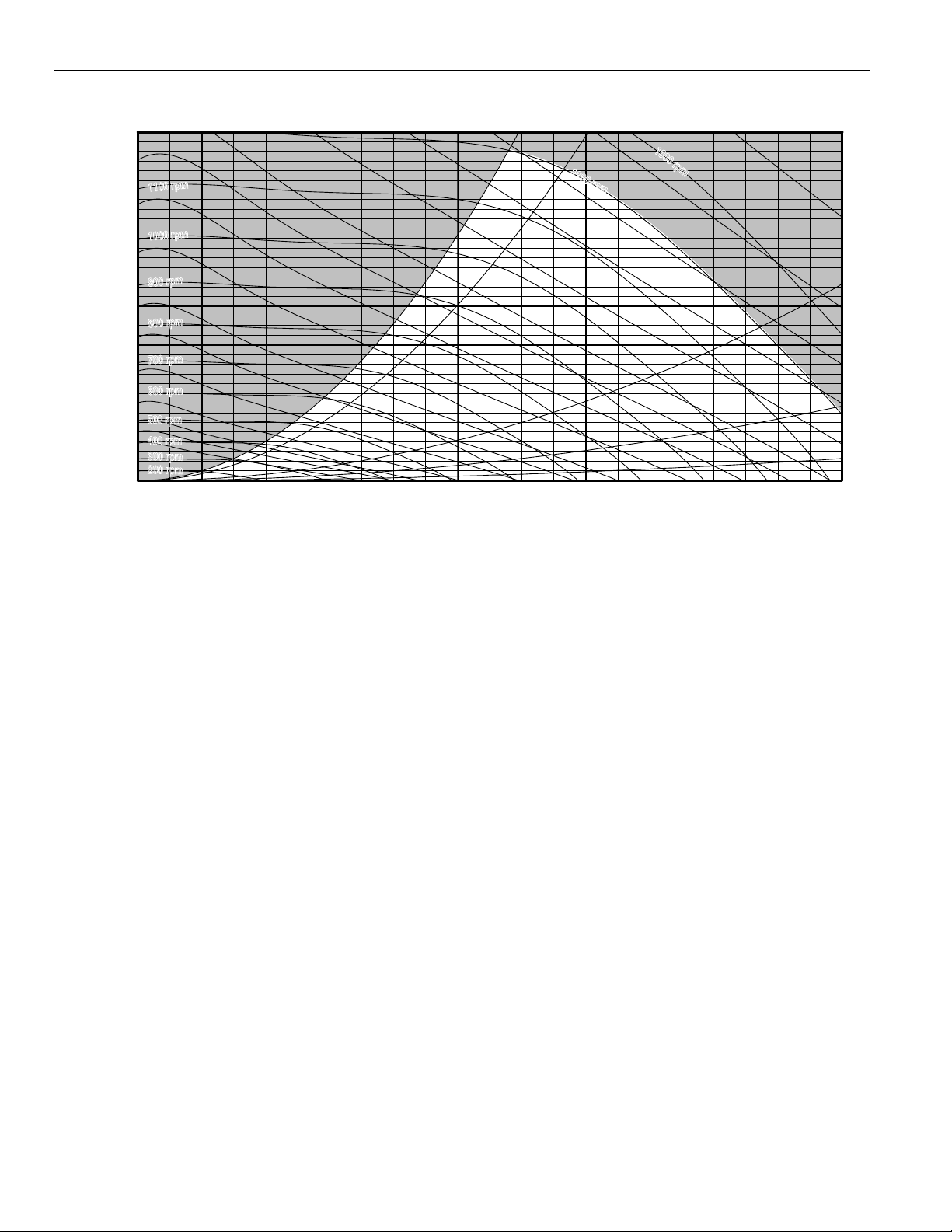

Fan Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Recommended Clearances . . . . . . . . . . . . . . . . 61

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Supply Power Wiring . . . . . . . . . . . . . . . . . . . . . 65

Unit Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

2 McQuay Catalog 860-9

Page 3

Introduction

Introduction

Continued Leadership in Self-Contained Systems Designs

McQuay SWP self contained air conditioning systems trace

their history to the late 1970s. The first self contained variable

air volume systems with waterside economizer cycle was

developed by us for the prestigious 499 Park Avenue office

building in New York City. McQuay SWP, with decades of

innovation, design flexibility, durable construction, low capitol

and operating cost, make us the leader of self contained system

market and the preferred HVAC solution for thousand of most

prominent building projects.

SWP water cooled self-contained air conditioner is an ideal

option for a job where energy efficiency, reliability, indoor air

quality and acoustic are top priorities. Along with providing

high quality and state-of-the-art technology, SWP selfcontained systems offer the following valuable features and

benefits to satisfy a wide range of diverse applications.

• Comfort and Redundancy

– Occupants enjoy individual control over comfort condi-

tions and off-hour system operation.

– Tenants benefit from their indivi dual efforts to control

energy costs.

– Routine service is located where it minimizes tenant

inconvenience.

– Individual or dual systems per floor provide system

redundancy and standby.

• Economical First Cost

– VAV system flexibility uses building diversity to reduce

system tonnage and first cost.

– Factory-packaged concept reduces field labor, installation

time and expense.

– No expensive chilled water piping or chiller room.

– Individually tested, factory-designed systems reduce

startup and installation expense.

– Reduced penthouse and equipment room requirements.

– Centralized condenser water and condensate piping and

streamlined system layout.

– Modular units design make renovation projects easier

since individual section designed for narrow hallways,

elevators and doorways.

– Optional acoustical discharge plenum is an available

option in any height to match your job needs and mini-

mizes supply duct transition losses.

• Energy Efficient System

– Reduces fan kW and operating costs at part load condi-

tions.

– Savings maximized through use of variable speed fan

control.

– Individual zone control.

• Improving Indoor Air Quality

For better filtration filter selection flexibility includes:

– MERV 7, 8, 11, 13, or 14 options with & without pre-fil-

ter. Microbial-resistant filter option is also an available

option.

– Featured Double-wall panel construction that eliminates

fibers in the supply air stream and is easy to clean.

– Provided with double-sloped, galvanized or stainless steel

drain pans eliminate stagnant water and minimizes bacterial growth.

• Quiet System Operation

– Provided by structural quality and specialized design.

– Recognized for quiet operation by renowned U.S. acous-

tical consultants.

– Provided with a SWSI airfoil plenum fan for excellent

acoustics and better efficiency

– Unit featured discharge plenum with sound baffles is an

available option for sound sensitive job

• Free Cooling

– Water or air economizer capability for optimized energy

savings.

– Economizer reduces compressor operating hours and

energy costs.

– Year-round “free cooling” capability.

• Efficient Part Load Operation

– System energy at part load operation is more efficient

than to central chilled water systems.

– Multiple systems and compressors versus a single, large

central plant.

– Efficient and reliable system for partial occupancy and

after hours operation.

– Operates only the system(s) on the floor(s) requiring after

hours use.

• Economical Integrated or Stand Alone DDC controls

– Monitoring and diagnostics reduce the potential for

expensive field repairs.

– Industry leading Protocol Selectability™ feature provides

effective BAS selection flexibility.

• Maintenance Costs Reduction

– No complicated central chiller plant to maintain.

– Service and maintenance are performed out of the occu-

pied space.

– Control and product reliability functions designed by the

equipment manufacturer for single source responsibility

and improved reliability.

• System Versatility

– Applicable to schools, offices, shopping centers, manu-

facturing facilities, etc.

– Prime candidate for floor by floor building renovation.

– Retrofit alternative where existing chiller cannot be

ed for replacement.

access

McQuay Catalog 860-9 3

Page 4

McQuay Self-Contained Systems

McQuay Self-Contained Systems

SWP 012–130 Features and Options

Airfoil Plenum Fans

• SWSI fans more energy efficient and quieter than forward

curved fans

• Premium high efficiency open, drip-proof standard

motors and TEFC motors, an available option

• Seismic control restrained spring isolators are available

• Aerodynamically designed fan also available with 12

blades for even lower sound levels

Coils

• High efficiency enhanced corrugated fin design

• High coil performance and reduced static

pressure losses

• Interlaced and/or row split circuiting to keep

full face of the coil active and to eliminate air

temperature stratification and optimum part

load performance

Durable Construction

• Pre-painted or G90 galvanized steel exterior

cabinet panels

• Standard foam injected panels with R-13

insulation provide superior rigid double wall

construction and minimizes air leakage

• For better acoustics, an additional 2", 1. 5# density

R-8 fiberglass insulation is an available option for

fan and plenum sections

• Double-sloped drain pans help eliminates

standing stagnant water

Blank Sections

• Available to mount air blenders, carbon or

charcoal filters, sound attenuators or other

specialty equipment

• Allow customization for maximum system

performance and efficiency

• Can reduce design and installation costs

Scroll Compressor(s)

• Durable and reliable multiple compressors

• Lower operating cost with High EERs

• Customize selections to match specific

application

• Mounted on resilient rubber isolation for

smooth and quiet operation

Access Panels and Doors

• All panels and access doors shall be sealed

with permanently applied bulb-type gasket

• Access doors are flush mounted to cabinetry,

with hinges, latch and handle assembly

4 McQuay Catalog 860-9

Page 5

Refrigerant Circuits

• Suction and discharge service valves, an available

option, to isolate each compressor

• Hot gas bypass, an available option, on units with

two refrigerant circuits

McQuay Self-Contained Systems

Shell and Tube Condensers

• Carbon steel Shell and Tube Condenser , non-

ferrous water channels and enhanced tubing for

high performance

• Integral sub-cooling circuit is provided as

standard to maximize efficiency

• Mechanically cleanable condenser and water

piping is rated for standard 300 psig waterside

working pressure & 450 psig is an available

option

• Two-way valve for head pressure control is

available for low condenser water temperatures

Multiple Filter Options

• 2" 30% (MERV7) and 75% (MERV13) filter s

• 4" 30% (MERV8), 65% (MERV1 1), 75% (MERV13)

and 85% (MER V14) longer lasting filters available

• 4" primary filters also available with 2" or 4" with

pre-filter

Economizer Options

• W aterside economizer effectively uses low cooling tower

water temperatures to offload compressor operation

• An airside economizer control package is available for

controlling field installed mixing dampers capable of 100%

outside airflow.

MicroTech® III Control System

• Factory-installed and tested to help minimize costly field

commissioning.

• Open Choices™ feature for easy integration into the BAS of

your choice using open, standard protocols such as BACnet®

or LONTALK®.

• Easily accessed for system diagnostics and adjustments via a

keypad/display on unit.

• Optionally add a remote keypad and display that is identical to

the unit mounted user interface.

Factory-Mounted Variable Frequency Drives

• Controlling fan motor speed can lower fan operating

costs and sound levels

• All VFD selections are plenum rated

• Manually activated bypass contactor is available to

allow system operation in the event of drive service

McQuay Catalog 860-9 5

Page 6

McQuay Self-Contained Systems

McQuay Self -Contained SWP systems are built to perform,

with features and options that provide for lower installed and

operating costs, good indoor air quality, quiet operation and

longevity.

Cabinet, Casing and Frame

• Unit base constructed of 15-gauge and 10-gauge galvanized

steel for vibration control and rigging strength.

• Heavy-duty lifting brackets strategically placed for balanced

cable or chain hook lifting.

Figure 1: Low Leak Gasketed Frame and Foam Panels

• Unit cabinet constructed with foam insulation standard and

heavy gauge [pre-painted] [galvanized steel] exterior panels

for long equipment life.

• All sections have galvanized steel internal lining.

• 2-inch thick panels and access doors are thermal broke

double wall assembly, with [R-13 foam] [R-8 fiberglass].

• System components strategically located for ease of

inspection, serviceability and maintenance.

• Refrigeration components positioned out of the airstream so

adjustments and readings can be made without disrupting

system operation.

• Access doors flush mounted to cabinetry, with hinges, latch

and handle assembly.

• Doors on positive pressure sections are provided with

secondary latches to relieve pressure and prevent injury

upon access.

Figure 2: Hinged Access Doors with double latches

• Low leak gasketed frame channels minimize air leakage and

eliminates metal-to-metal contact between paneling and

frame work. Air leakage is only 0.5 cfm/square foot at 5"

cabinet pressure.

6 McQuay Catalog 860-9

Page 7

McQuay Self-Contained Systems

Control Panel

Coil/Access

Section

Supply Fan

Section

Compressor/

Condenser

Section

Base Plates

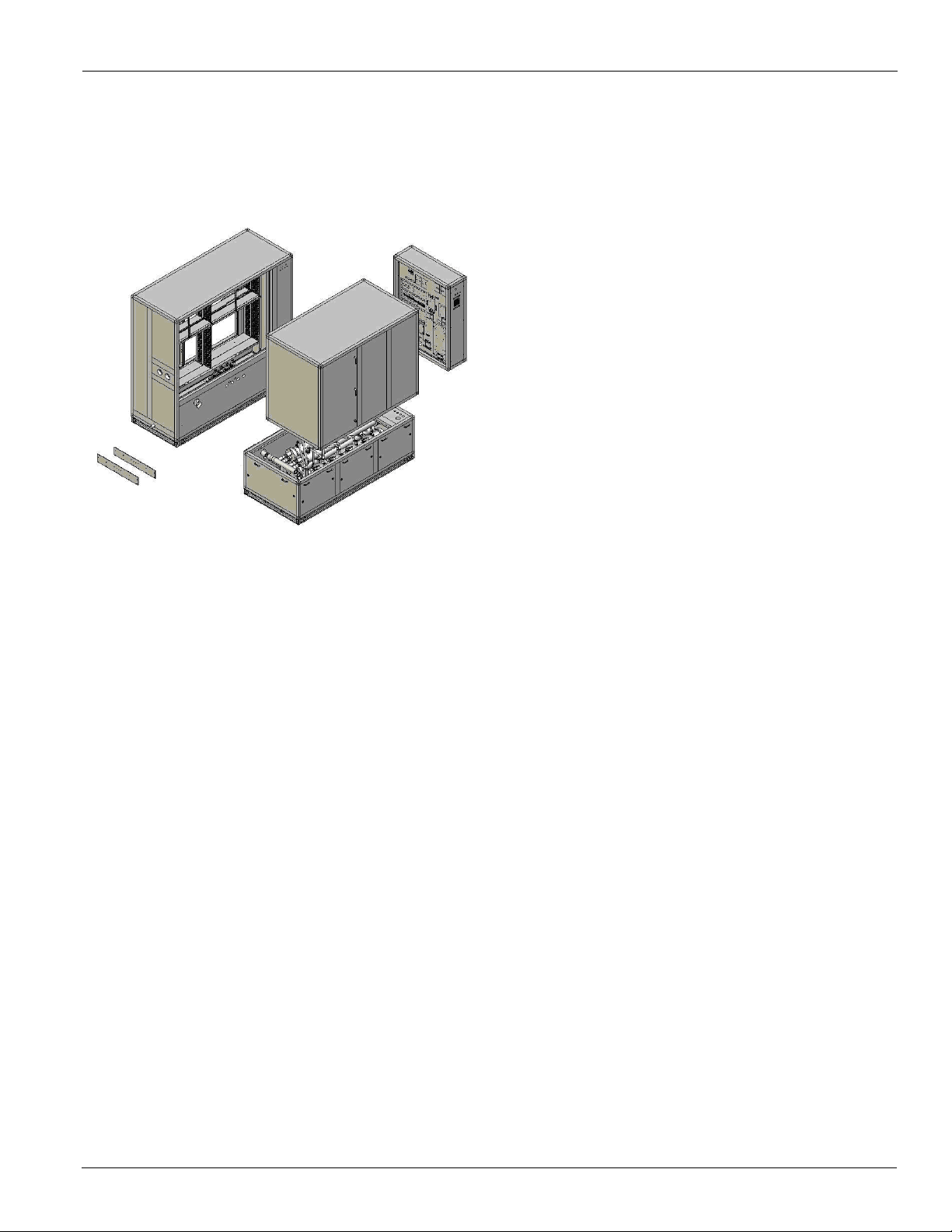

Modular Design

• Optional modular construction unit shipped with a nitrogen

holding charge.

• Four distinct sections; coil/access section, supply fan

section, compressor/condenser section and the control panel.

Figure 3: SWP Modular Sections

• Insulated and segregated condensing section from the air

handling section to avoid transmission of noise to the

circulated air stream.

• Each refrigerant circuit is furnished with filter-drier, liquid

moisture indicator/sight glass , th erm a l ex pansion valve,

liquid line shutoff valve with charging port, high pressure

relief device and high and low pressure cutouts.

• If any compressor is made inoperable, the remaining

compressors are still allowed to operate.

• Thermal expansion valve capable of modulation from 100-

25% of its rated capacity.

• Hot gas bypass also available on units with two refrigerant

circuits.

Condensers

• All units feature carbon steel mechanically cleanable shell

and tube condenser.

• Includes non-ferrous water channels and enhanced tubing

for high performance.

• Serves an independent refrigerant circuit and includes a

spring loaded high pressure relief valve

• Integral sub-cooling circuit provided as standard to

maximize efficiency.

Compressor/ Condensing Section

Compressors

• All units feature multiple reliable scroll compressors for

• Suction and discharge service valves and gauge ports,

• Individual branch circuit fusing protects each compressor.

• T o prevent compressor short cycling, MicroTech® III

• Compressors mounted on resilient rubber isolation for

Figure 4: Compresors

efficient system part load control, quiet operation and

system redundancy.

available option, on each compressor.

control system incorporates timing functions.

smooth and quiet operation.

Figure 5: Condensers

• All units are leak tested, evacuated and shipped with a [full

operating charge of R-410A] [for modular design nitrogen

holding charge] and POE oil.

• Condenser assembly and all factory water piping rated for a

waterside working pressure of 300 psig as standard [450

psig] tested before shipment.

• Provided with a single supply and return water connections

• Unit available in both right-hand and left-hand piping

locations.

• Optional two-way valve provides accurate head pressure

control for condenser entering water temperatures as low as

40ºF.

McQuay Catalog 860-9 7

Page 8

McQuay Self-Contained Systems

Refrig. Flow Ckt 1

Refrig. Flow Ckt 2

Ckt 2

Ckt 1

Ckt 1

Ckt 1

Ckt 1

Ckt 1

Ckt 1

Ckt 1

Ckt 1

Ckt 2

Ckt 2

Ckt 2

Ckt 2

Ckt 2

Ckt 2

Ckt 2

Airflow

Cooling Coils

Cooling Coil Section

• Large face area coils with high efficiency , enhanced copper

tubing and ripple corrugated aluminum fins.

• Features interlaced and/or row split circuiting to keep the

full face of the coil active and eliminate air temperature

stratification and optimum part load performance.

Figure 6: Evaporator Coil Circuiting

• 5 or 6 row evaporator coil with 12 fins/ inch spacing and

multiple face areas allows a custom match to specific design

loads.

• Provides low air pressure drop, high full and part load

operating efficiencies.

• Mounted in a [galvanized] [stainless steel ] cross broke and

double sloped drain pan with a full 2 inches of insulation.

• Compressor staging sequenced to take maximum advantage

of available coil surface.

• Each evaporator coil circuit furnished with a wide range

thermostatic expansion valve with an adjustable superheat

setting and external equalizer.

• An intermediate drain pan in the coil bank helps to provide

condensate removal without carryover.

Figure 7: Cooling Coil Section Shown

Supply Fan Section

• Single width, single inlet (SWSI) airfoil supply air fan

selections provide efficient, quiet operation at wide ranging

static pressure and air flow requirements.

• Each fan assembly is dynamically trim balanced at the

factory for quiet operation before shipment.

• All fan drives are factory sized according to job specific

airflow, static pressure, and power requirements.

• For seismic sensitive regions, spring fan isolators are

available with seismic restraints.

• 150% service factor drives extend service life of the fan

belts. Drive components and fan bearings are easily accessed

for periodic maintenance.

• Mounted on 2 inch deflection spring isolators for excellent

isolation effectiveness.

• Solid steel shafts rotating in 200,000 hour pillow block ball

bearings with grease fittings.

• Motor availability includes premium efficiency, open, drip-

proof, and totally enclosed selections; EPACT compliant

premium efficiency selections.

8 McQuay Catalog 860-9

Figure 8: Airfoil Fan

Page 9

McQuay Self-Contained Systems

McQuay Plenum Fan

Least turbulance

and best acoustics

* Ceiling heights restrict “h” and

increase the problem with housed fans

Competitive Housed Fan

Excessive turbulance

and mediocre acoustics

Competitive Housed Fan

Worst turbulance

and worst acoustics

h*

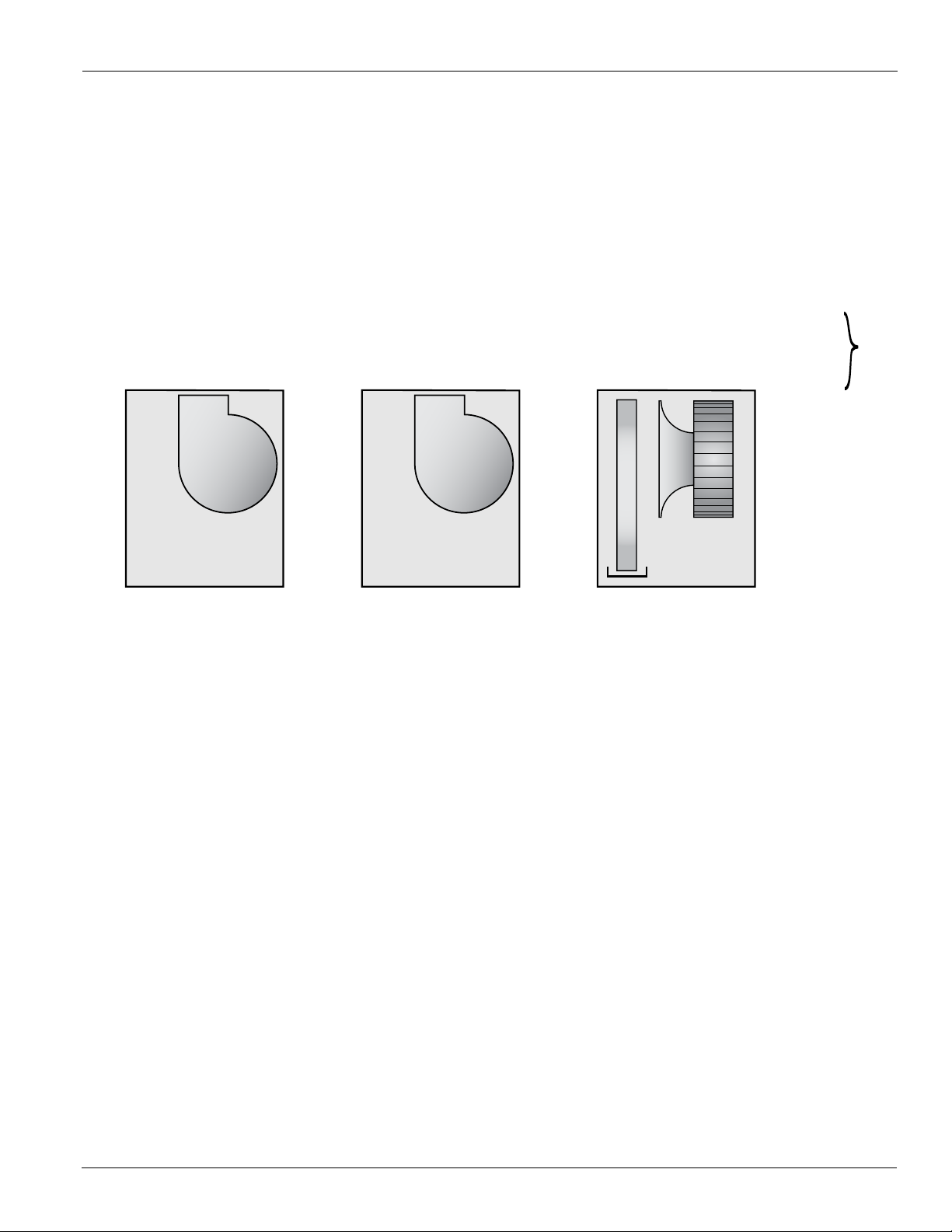

Acoustical Advantages

McQuay SWP Self-contained units are provided with a high

efficient, SWSI airfoil plenum fan and have several acousti cal

advantages:

• Airfoil fans are more efficient than forward curved fans

contributing to less noise.

• For specific unit sizes, several fan diameters are available,

fan selection provides optimal efficiency.

Figure 9: Supply Fan Comparison

• Competitive supply duct work normally involves

discharging air vertically into a ceiling, then routing it

horizontally, Figure 10. McQuay’s plenum fan discharge has

far less velocity pressure than competitive housed fan

discharge, resulting in:

• 90º duct elbows that generate far less turbulance.

• Air flow that can be routed in any direction.

McQuay Catalog 860-9 9

Page 10

McQuay Self-Contained Systems

McQuay Optional Plenum

“h” can be varied

to match ceiling height

h

Competition

Expansion Loss

90° Elbow Loss

Standard Exterior

Galvanized Surface

Standard Galvanized Liner

Standard Injected Foam Panel

Optional Fiberglass Insulation

Perforated Liner

Interior Optional

Acoustical Discharge Plenum

McQuay offers an optional acoustical discharge plenum,

Figure 10, that minimizes supply duct transition losses and

noise:

• Plenum fans pressurize the entire cabinet and have no

significant plenum air pressure drop (housed fans have

expansion, contraction and 90º elbow losses).

• Discharge plenums offered in any height to match ceiling

height.

• Custom size duct connections are available on any size

plenum.

Discharge Plenum with Foam Insulation and Sound

Baffles

Optional discharge plenum with foaminjected panels can be

provided with the additional sound attenuating baffle option

consisting of:

• Additional 2" of fiberglass insulation.

• Perforated liners, Figure 11.

Figure 10: Acoustical Discharge Plenum

Variable Air Volume Control

• Energy saving advanced technology variable frequency

drive (VFD), fan speed control is available with the

convenience and cost savings of factory mounting and

testing.

Figure 12: Variable Frequency Drive Controller

Figure 11: Foam Insulation and Sound Baffles

• All VFD selections are plenum rated and are conveniently

mounted within the control panel.

• MicroTech III controls provide advanced duct static pressure

control and controlled by either single or two-duct static

pressure sensors.

• A manually activated bypass contactor is available to allow

system operation even in the event of drive service.

• All VAV systems include an adjustable, duct high-limit

switch to protect duct work from excessive pressure.

Economizer Options

Waterside Economizer

• An energy saving, waterside economizer package, an

available option on all return air unit.

• Includes factory mounted 4-row [chemically cleanable coil]

[mechanically cleanable coil], control valves and piping.

• Rated for 300 psig as standard [450 psig] waterside working

pressure and the entire coil and piping assembly is factory

leak tested.

• Factory integrated MicroTech III controller to control

economizer operation and maximize free cooling potential.

• Unit enables economizer operation whenever cooling tower

water temperature is less than the unit entering air

temperature by a field adjustable value, generally 5-7°F.

10 McQuay Catalog 860-9

Page 11

McQuay Self-Contained Systems

Mechanically Cleanable

Economizer Coil

• To save energy with a variable pumping system control

valves operation can be selected to maintain full flow

through the unit at all times or to isolate the unit from the

condenser water loop when there is no call for cooling.

• To extend free cooling savings, economizer operation can be

enabled during mechanical cooling.

• Unit enables mechanical cooling only when the economizer

valve is driven 90% open and cooling load is not satisfied.

• Economizer control will maintain full free cooling capability

until disabled by the economizer changeover set point.

• T o help protect against coil freeze-up an optional factory

mounted freeze stat is available.

Figure 13: Mechanically Cleanable Waterside

Economizer Coil

• To extend free cooling savings, economizer operation can be

enabled during mechanical cooling.

• Unit enables mechanical cooling only when the economizer

damper is driven 90% open and cooling load is not satisfied.

• Economizer control will maintain full free cooling capability

until disabled by the economizer changeover set point.

Condenser Head Pressure Control

• Unit requires condenser head pressure control for

applications where a waterside economizer package is not

being used and entering condenser water temperatures can

be less than 55°F.

• Optional two-way valve provides accurate head pressure

control for condenser entering water temperatures as low as

40degree F

Filter Section

• Selection flexibility includes face loaded rack with non-

gasketed frames and filter clips.

• Unit features 2-inch filter option available in 30% (MERV 7)

& 75% (MERV 13) nominal efficiency

• Longer lasting 4-inch filters higher filtration option is

available in 30% (MERV 8) & 65% (MERV 11), 75%

(MER V 13) & 85% (MERV 14) nominal efficiency with and

without 2-inch or 4-inch 30% pre-filter.

Airside Economizer

• A mixing box containing outdoor air, return air and exhaust

air dampers are available using the McQuay Vision™ air

handling unit platform.

• Factory integrated MicroTech III controller controls

economizer operation and maximize free cooling potential.

• Airside economizer control package available to control

field installed mixing dampers capable of 100% outside

airflow.

• Unit enables economizer operation whenever outside air

enthalpy , comparative enthalpy or dry bulb temperature

changeover provides control flexibility to bring in most

amount of outside air for free cooling.

• Economizer damper control actuator modulates in response

to the cooling load.

• MicroTech III controller positions outside air damper to

maintain minimum ventilation requirements when

economizer is not in operation.

Figure 14: 4 Inch Filters

Blank Sections

• Available to mount air blenders, pre-heat coils, sound

attenuators or other specialty equipment using the McQuay

Vision™ air handling unit platform and shipped loose.

• Allow customization for maximum system performance and

efficiency and reduce design and installation costs.

McQuay Catalog 860-9 11

Page 12

McQuay Self-Contained Systems

Electrical

• Units are completely wired and tested at the factory prior

shipment.

• Wiring complies with NEC requirements and all applicable

UL standards.

• For ease of use, wiring and electrical components are

number coded and labeled according to the electrical

diagram whenever applicable.

• Supply air fan motors, compressor motors and electric heat

all branch circuits have individual short circuit protection.

• Control circuit power is supplied through a factory installed,

low voltage transformer.

• The supply fan motor circuit includes a three phase

contactor and ambient compensated overload protection

with manual reset.

• Each refrigerant circuit includes both a high and low

pressure cutout switch.

• A terminal block is provided for the single, main power

connection and a terminal board is provided for low voltage

control wiring.

• A factory mounted, non-fused main circuit interrupter is

available for disconnecting the main electrical power to the

unit.

• Dual power blocks or disconnect switches are available to

accommodate requirements for standby, emergency power

supplies.

Heating Section

Hot Water Heat

• Multiple coil selections offered to size heating output to

application needs.

• Hot water coils are 5/8-in. O.D. copper tube/ aluminum fin

design with patented HI-F5 fins.

• Rated in accordance with ARI Standard 430.

• Pre-heating control fully integrated into the unit’s

MicroTech III control system is available using the McQuay

Vision™ air handling unit platform.

• Available with factory-mounted freezestat.

Steam Heat

• Steam heating coils are 5/8-in. O.D. copper tube/aluminum

fin jet distributing type with patented HI-F5 fin design.

• Rated in accordance with ARI Standard 430.

• Multiple different steam coil selections offered to size

heating output to application needs.

• Pre-heating control fully integrated into the unit’s

MicroTech III control system is available using the McQuay

Vision™ air handling unit platform.

• Available with factory-mounted freezestat.

Electric Heat

• Factory assembled, installed and tested.

• Two stage capability for application flexibility.

• Durable low watt density nickel chromium elements for

longer life.

• Entire heat bank protected by a linear high limit control with

each heater element protected by an automatic reset high

limit control.

• Fuses provided in each branch circuit.

12 McQuay Catalog 860-9

Page 13

System Flexibility with Unit Options

Along with providing high quality and state-of-the-art

innovation, SWP self-contained systems offer customized

flexibility to satisfy a wide range of diverse applications.

System Flexibility with Unit Options

discharge orientations. Piping and fan arrangement flexibility

can simplify mechanical equipment room arrangement,

improve installation costs, and total system performance.

Selection/Application Flexibility

Nominal cooling capacities range from 12 to 130 tons. In

addition, all units offer multiple compressor selections to meet

exacting system requirements. The flexibility to optimize the

self-contained system to fit the application is a McQuay SWP

advantage. Available system applications include the

following:

• VAV dischar ge air temperature control with static pressure control.

• Discharge air temperature control with constant air volume.

• Constant volume, zone temperature control.

• 100% outside air control.

• Dehumidification control, with or without reheat control.

In addition to compressor/coil flexibility, SWP systems offer

single width, single inlet, air foil fans with factory-mounted

variable frequency drives for maximizing VAV system fan

performance. High efficiency fan capability coupled with

extensive compressor flexibility provide the right system

selection for the application.

Arrangement Flexibility

All SWP systems offer the flexibility of right-hand and lefthand piping and control panel arrangements and multiple fan

Optimal Discharge Air Temperature

More and more system engineers are designing optimal

discharge air temperature systems to improve system

performance and system first cost; the McQuay SWP provides

the flexibility to do it successfully. Optimal discharge air

temperature systems are designed to provide unit leaving air

temperature selections of 52°F to 53°F versus more

conventional systems that supply air at temperatures closer to

58°F . This five to six degree reduction in air temperature to the

room diffusers can subsequently reduce the required supply air

volume to the room by 20% to 25%.

The benefits of optimal discharge air temperature systems

become quite apparent with a look at the advantages offered

with reduced supply air cfm airflow:

• Reduced first cost and installation cost by allowing

smaller duct sizes and a smaller air distribution system.

• Reduced bhp requirements. Depending on changes in

duct size and the resulting total static pressure, a 20%

reduction in supply air cfm can reduce fan bhp requirements by 25% or more.

• Reduced fan sound power generation and a quieter room

environment.

• Reduced equipment room size may be possible due to

using a physically smaller unit size.

• Filtration Flexibility.

McQuay Catalog 860-9 13

Page 14

System Flexibility with Unit Options

Controllers

MicroTech III DDC control systems provide constant volume,

variable air volume, 100% outside air, and/or dehumidification

control flexibility . See “MicroTech III Unit Controller” section

for more information.

Summary of Available Options

• Multiple different compressor/coil capacity selections

• Mult ip le control options: VAV, CV, 100% O A, dehumidification

• Nonfused main power disconnect switch

• Dual nonfused main disconnect switches

• Nonaveraging freezestat for hot water or waterside economizer coil protection

• Unit phase failure/under voltage protection

• Premium efficiency fan motors

• TEFC fan motors

• Condenser water flow switch

• 4-row waterside economizer system

• Air cycle economizer system

• Modulating hot water heat control

• Staged electric heat

• Multi direction, acoustic discharge plenum

• Factory-mounted and factory-controlled variable frequency drives

• High efficiency filtration options

• Right-hand and left-hand piping se lections

• Multiple fan discharge arrangements

• Head pressure control valve

• Special coil coatings

• Double wall cabinet construction

• Seismic fan isolation

• Independent refrigerant circuit units offer the following

options:

• Five-row or six-row DX coils with enhanced heat transfer surfaces

• R-410A refrigerant

• Service and shut off valves on liquid and discharge

Figure 15: MicroTech III DDC Co ntroller

R-410A Refrigerant

McQuay SWP units with independent refrigerant circuits are

available with non-ozone depleting R-410A refrigerant.

Features

• R-410A refrigerant is environmentally friendly with zero

ozone depleting allowance (ODP). Customers have no

phase out and replacement concerns.

• Units are factory engineered for proper cooling performance using R-410A.

• R-410A efficiency is excellent. McQuay R-410A SWP

units are available with EERs that exceed ASHRAE 90.1-

2010.

• Units are factory charged with R-410A and synthetic oil

(such as POE), and they include components and controls

specifically tailored to R-410A.

• R-410A refrigerant is a blend, but the glide is negligible.

This is not true for R-407C. If R-407C leaks, the remaining charge may not have a proper mix of components. R410A does not have this problem so leaks are easier to

repair.

• Units are factory tested prior to shipment.

14 McQuay Catalog 860-9

Page 15

MicroTech III Unit Controls

McQuay SWP systems continue to provide industry leading

performance, equipped with a complete MicroTech III control

system. In addition to providing stable, efficient temperature,

and static pressure control, the controller is capable of

providing comprehensive diagnostics, alarm monitoring, and

alarm specific component shutdown if critical equipment

conditions occur. The unit controllers are factory mounted and

configured for stand-alone operation or integration with a

building automation system (BAS) through an optional

communication module with our Open Choices feature.

Open Choices Benefits for Easy Integration

Easy, low cost integration into most building automation

systems without costly gateway panels.

• Flexibility to select either BACnet® or L

communication. Units are LonMark® 3.4 certified with the

appropriate communications module for L

networks.

• Comprehensive unit control and status information is

available at the BAS regardless of communication protocol.

• Long-term choices for equipment adds or replacements, and

for service support.

• Flexible alarm notification and prioritization with Intrinsic

Alarm Management (BACnet).

• Simplified BAS integration with the ability to set network

parameters at the unit controller, reducing installation time

and costs.

• Easy monitoring and troubleshooting of communication

status from the unit controller to the BAS.

ONWORKS®

ONWORKS

MicroTech III Unit Controls

Components

Each SWP self-contained system is equipped with a complete

MicroTech III unit control system that is pre-engineered,

preprogrammed, and factory tested prior to shipment. Each of

the MicroTech III unit control systems is composed of several

components that are individually replaceable for ease of

service. These components include:

• Unit controller with user interface display and navigation

wheel

• Optional expansion modules

• Communication module (optional)

• Pressure transducers

• Unit-mounted temperature sensors

• Zone temperature sensor packages

• Humidity sensor

Main Control Board (MCB)

The main control board (MCB) contains a microprocessor that

is preprogrammed with the software necessary to control the

unit. This provides that schedules, set points and parameters

are not lost, even during a long-term power outage. The

microprocessor board processes system input data and then

determines and controls output responses. An RS-232

communication port is provided as standard to allow for direct

or modem access with a PC-based service tool.

Expansion Modules

These boards are used to expand the input and output

capability of the unit controller. Each board communicates via

serial data communications. These microprocessor based

boards provide independent operation and alarm response even

if communication is lost with the unit controller.

Communication Module

An optional communication module provides the means to

factory or field configure MicroTech III unit controls for

interoperability with an independent BAS. Communication

modules are available to support industry recognized

communication protocols including BACnet MS/TP, BACnet/

IP and L

Figure 16: MicroTech III Keypad Display

McQuay Catalog 860-9 15

ONWORKS.

Page 16

MicroTech III Unit Controls

Keypad/Display

All MicroTech III unit controllers include a push/pull

navigation wheel and display. The display is a supertwist

nematic type with highly visible black characters on a yellow

background. The 5-line by 22-character format allows for easy

to understand plain English display messages. All operating

conditions, system alarms, control parameters and schedules

can be monitored from the keypad/display. If the correct

password has been entered, any adjustable parameter or

schedule can be modified from the keypad.

Temperature and Humidity Sensors

With the exception of the zone, outside air and return air

sensors, all temperature sensors are factory installed and

tested. Zone sensor packages are available to suit any

application. A humidity sensor is available for field

installation.

Static Pressure Transducers

All pressure transducers are factory installed and tested.

Connection and routing of field-supplied sampling tubes is

done at time of unit installation.

Zone Temperature Sensors

Two optional zone temperature sensors are available:

• Zone sensor with tenant override switch

• Zone sensor with tenant override switch and remote set

point adjustment

Timed tenant override is a standard MicroTech III

control feature.

Zone sensors are required for the controller’s purge cycle,

space reset of supply air set point, and night setback or setup

features. All zone sensors are field installed with field wiring

terminated at a separate, clearly marked terminal strip.

Stand-alone Controller Features

MicroTech III applied rooftop unit controls includ e all of th e

essential features required to make them capable of completely

independent, stand-alone operation.

Internal Time Clock

An internal, battery-backed time clock is included in the

MicroTech III unit controller. Current date and time can be

quickly and easily set at the user interface keypad.

Internal Schedule

Seven daily schedules and one holiday schedule can be entered

at the keypad of all unit controllers. For each of these eight

schedules, one start and one stop time can be entered. Up to 10

holiday periods, of any duration, can be designated. The unit

will automatically run according to the holiday schedule on the

holiday dates. To handle special occasions, an additional ‘one

event’ schedule can also be used.

In lieu of its internal schedule, the unit can be operated

according to a network schedule from a BAS.

External Time Clock or Tenant Override Input

An input is supplied that can be used to accept a field wired

start/stop signal from a remote source. An external time clock,

a tenant override switch, or both may be connected. Whenever

the external circuit is closed, the controller overrides the

internal schedule (if activated) and places the unit into the

occupied mode.

If the internal schedule or a BAS network schedule is used,

field wiring is not required.

Timed Tenant Override

Off-hour operation flexibility is a must in today’s office

environments and even stand-alone MicroTech III controls

handle it with ease. When unit operation is desired during

unoccupied hours, initiate timed tenant override by pressing

the tenant override button on either of the optional zone sensor

packages. The unit then starts and runs in the occupied mode

for a keypad-adjustable length of time (up to five hours ). If th e

button is pressed again while the unit is operating, the timer

resets to the full time allowance without interrupting unit

operation. Tenant override operation also can be initiated by a

BAS.

Three Remote Set Point Adjustment Options

1 Remote user interface option (RUI).

2 Building automation system (BAS). See “Open Choices

Benefits for Easy Integration” on page 15.

3

All constant air volume-zone temperature control (CAVZTC) unit controllers include an input that can be used to

remotely adjust the zone cooling and heating set points.

To use this feature, wire the optional zone sensor

package with set point adjustment to the controller. The

remote set point adjustment feature can be enabled or

disabled from the keypad at any time. When enabled,

remote set point adjustment is available even if the return

temperature is selected to be the Control Temperature.

16 McQuay Catalog 860-9

Page 17

MicroTech III Unit Controls

Auto/Manual Operation Selection

Automatic or manual operation can be controlled either

remotely or at the keypad.

All controllers include three inputs that can be used to enable

or disable cooling, heating, and fan operation from remote

switches. With the “heat enable” and “cool enable” terminals,

the operator can enable cooling, heating, or both as desired.

Using the system “off” terminals, the operator can disable the

fans, and thus the entire unit.

From the keypad, there are a variety of occupancy and auto!

manual control mode selections available to the operator:

• Occupancy modes

– Auto

– Occupied

– Unoccupied

– Bypass (tenant override)

• Control modes

– Off manual

– Auto

– Heat/cool

– Cool only

– Heat only

– Fan only

Compressor Lead-lag Selection

All unit controllers are capable of automatic compressor, leadlag control.

Waterside Economizer Changeover

On units equipped with a waterside economizer package, the

MicroTech III unit controller includes an internal changeover

strategy that compares entering cooling tower water

temperature to the unit’s mixed air temperature. If the entering

water temperature is less than the mixed air temperature by a

field-adjustable differential (typically 5°F to 7ºF), the

economizer control valve modulates in response to the cooling

load.

Airside Economizer Changeover Selection

On units equipped with an economizer, there are three methods

of determining whether the outdoor air is suitable for free

cooling: two methods sense enthalpy (dry bulb temperature

and humidity) and one senses outdoor air dry bulb

temperature.

The two enthalpy changeover methods use external, factory

installed controls. One compares the outdoor ambient enthalpy

to a set point; the other is a solid state device that compares the

outdoor ambient enthalpy to the return air enthalpy. This

comparative enthalpy control can improve total economizer

performance.

All unit controls include an internal dry bulb changeover

strategy that can be selected at the keypad. When this method

is selected, the controller compares the outdoor air dry-bulb

temperature to a keypad programmable set point. The external

enthalpy control input is then ignored.

Cooling and Heating Lockout Control

All unit controls include separate keypad programmable set

points for locking out mechanical cooling and heating.

Mechanical cooling is locked out when the outdoor

temperature is below the cooling lockout set point; heating is

locked out when the outdoor temperature is above the heating

lockout set point. This feature can save energy cost by

eliminating unnecessary heating and cooling during warm-up

or cool-down periods or when the outdoor ai r tem perature is

mild.

Night Setback and Setup Control

When one of the zone temperature sensors is connected to the

unit controller, night setback heating and night setup cooling

control are available. Separate, keypad programmable night

heating and cooling set points are used to start the unit when

necessary. After the unit starts, night setback and setup control

is similar to normal occupied control except that the minimum

outside air damper position is set to zero. If the outside air is

suitable for free cooling, it is used during night setup

operation.

Except for 100% outside air applications, night setback control

is available even if the unit is not equipped with any heating

equipment. When the space temperature falls to the night

setback set point, the fans simply start and run until the

temperature rises above the differential. This feature might be

useful for applications that use, for example, duct-mounted

reheat coils.

Morning Warm-up Control

If the Control Temperature (space or return) is below set point

when the unit enters the occupied mode, the morning warm-up

control function will keep the outs

heat is supplied to satisfy set point. The outside air damper will

remain closed until either the space temperature rises to the

heating set point or the keypad adjustable morning warm-up

timer expires (default is 90 minutes). The morning warm-up

timer supplies the minimum required amount of outdoor air

after a certain time regardless of the space temperature.

Morning warm-up control is automatically included on all

except 100% outside air units. It is available even if the unit is

ide air dampers closed while

McQuay Catalog 860-9 17

Page 18

MicroTech III Unit Controls

Condenser Head Pressure Control (units without

waterside economizer only)

Mechanical cooling is allowed whenever the entering cooling

tower water temperature is 55ºF or warmer, without the use of

head pressure control. When the entering water temperature is

below 55ºF , a factory-installed and factory-controlled two-way

modulating head pressure control valve can be utilized. The

regulating valve is controlled by the MicroTech III controller

to maintain refrigerant head pressure.

Outdoor Air Purge Control (units with airside

economizer only)

Purge control is designed to take advantage of cool early

morning outside air conditions. It starts the fans and modulates

the economizer dampers to maintain occupied cooling

requirements during unoccupied periods, if conditions are

appropriate. This provides the opportunity to flush the space

with fresh outdoor air prior to occupancy. Purge operation is

possible only during a keypad-adjustable time window prior to

occupancy (0 to 240 minutes). When the purge-cycle is active,

mechanical cooling is disabled. To use the purge feature,

connect one of the zone temperature sensors to the unit

controller. Below is a description of purge control operation.

During the purge time window, the unit starts and runs

whenever these three requirements are met:

• The space temperature must be warm enough to enable

occupied cooling.

• The outside air enthalpy must be low enough to enable

the economizer.

• The outside air temperature must be at least 3°F less than

the space temperature.

When any one of these conditions is no longer true, the unit

shuts down. As conditions allow, purge cycles the unit in this

manner until it enters the occupied mode.

Proportional Integral (PI) Control

The Proportional Integral (PI) control algorithm controls

modulating actuators to maintain a measured variable

(temperature or pressure) at or near its set point. For example,

it controls economizer dampers to maintain the discharge

cooling set point and it controls the supply fan variable

frequency drives to maintain the duct static pressure set point.

The integral control feature effectively eliminates

“proportional droop” (load dependent offset) resulting in the

tightest possible control.

For each PI loop, four keypad adjustable parameters allow the

control loop to be properly tuned for any application:

•Period

• Dead band

• Proportional band

• Integral time

Appropriate default values for these parameters are loaded into

each controller. These default values will provide proper

control for most applications; therefore, field tuning is usually

not required and thus start-up time is reduced.

Change Algorithm

The PI function is also used to adjust set points instead of

controlling variable speed drives or actuators directly. For

example, in zone control applications, the PI loop

automatically “changes” the discharge temperature set point

(cooling or heating) as the Control Temperature deviates from

the zone set point. Another PI loop then controls the

economizer actuator or heating valve actuator using the current

discharge temperature set point. Unlike a typical

“mastersubmaster” reset strategy, this “cascade control”

continuously adjusts the discharge set point, even if the

Control Temperature’s deviation from set point remains

constant. This means that the unit’s cooling or heating output

is set according to the actual load, not just the current zone

temperature. The tightest possible zone temperature control

results because “proportional droop” (load dependent offset) is

eliminated.

Calibrate

When initiated at the keypad by an operator, the Calibrate

function automatically calibrates all actuator position feedback

inputs and all pressure transducer inputs. It does this by

shutting the unit down and then driving all actuators to the full

closed and full open positions. The controller records the input

voltage values that correspond to these positions. The pressure

transducer input voltages, which are assumed for 0.00-in.

W.C., are also recorded. When Calibrate is finished, enter an

operator command at the keypad to start the unit.

Field Output Signals

All MicroTech III controls include two solid-state relay

outputs that are available for field connection to any

suitable device: the remote alarm output and the occupied

output. These two outputs are used to signal field equipment of

unit status.

Remote Alarm Output: The remote alarm output can be

used to operate a 24 volt relay to provide a remote alarm

signal to a light, audible alarm,

alarm condition exists at the unit.

Fan Operation Output: The fan operation output is used

to operate a 24 volt relay to control field equipment that

depends on fan operation; for instance, to open field

installed isolation dampers or VAV boxes. To allow actuators enough time to stroke, the fan operation output is

energized three minutes before the fans start. It then

remains energized until thirty seconds after the unit airflow switch senses no airflow. The fan operation output is

on whenever the unit airflow switch senses airflow.

Outside Air Damper output: Use to signal an outside air

damper actuator to open whenever the unit is in an occupied cooling or heating condition.

or other device when an

18 McQuay Catalog 860-9

Page 19

MicroTech III Unit Controls

Standard Control Options

SWP Self-Contained systems are available for most any

constant or variable air volume application. MicroTech III

controls offer three basic control configurations that use

sophisticated state change control logic to provide stable,

reliable and efficient control:

• Variable air volume with discharge temperature control

(DAC)

• Constant air volume with zone temperature control (S

CC)

• Constant air volume with discharge temperature control

(DAC)

When combined with MicroTech III’s many available control

capabilities, both factory-installed and keypad-programmable,

these three basic configurations can be customized to meet the

requirements of the most demanding applications.

Variable Air Volume with Discharge Temperature

Control (DTC)

All VAV units provide true discharge temperature control in

addition to duct static pressure control. Cooling only, cooling

with single-stage “morning warm-up” heat, and cooling with

modulating heat configurations are available.

Control Temperature

The Control Temperature make s the heat/cool changeover

decision. It determines whether cooling or heating is enabled;

the discharge temperature then determines whether cooling or

heating is actually supplied. At the keypad, the operator can

choose the source of the Control Temperature from among the

following selections.

• Space temperature sensor

• Return temperature sensor

• Outside air temperature sensor (modulating heat only)

• Network communication

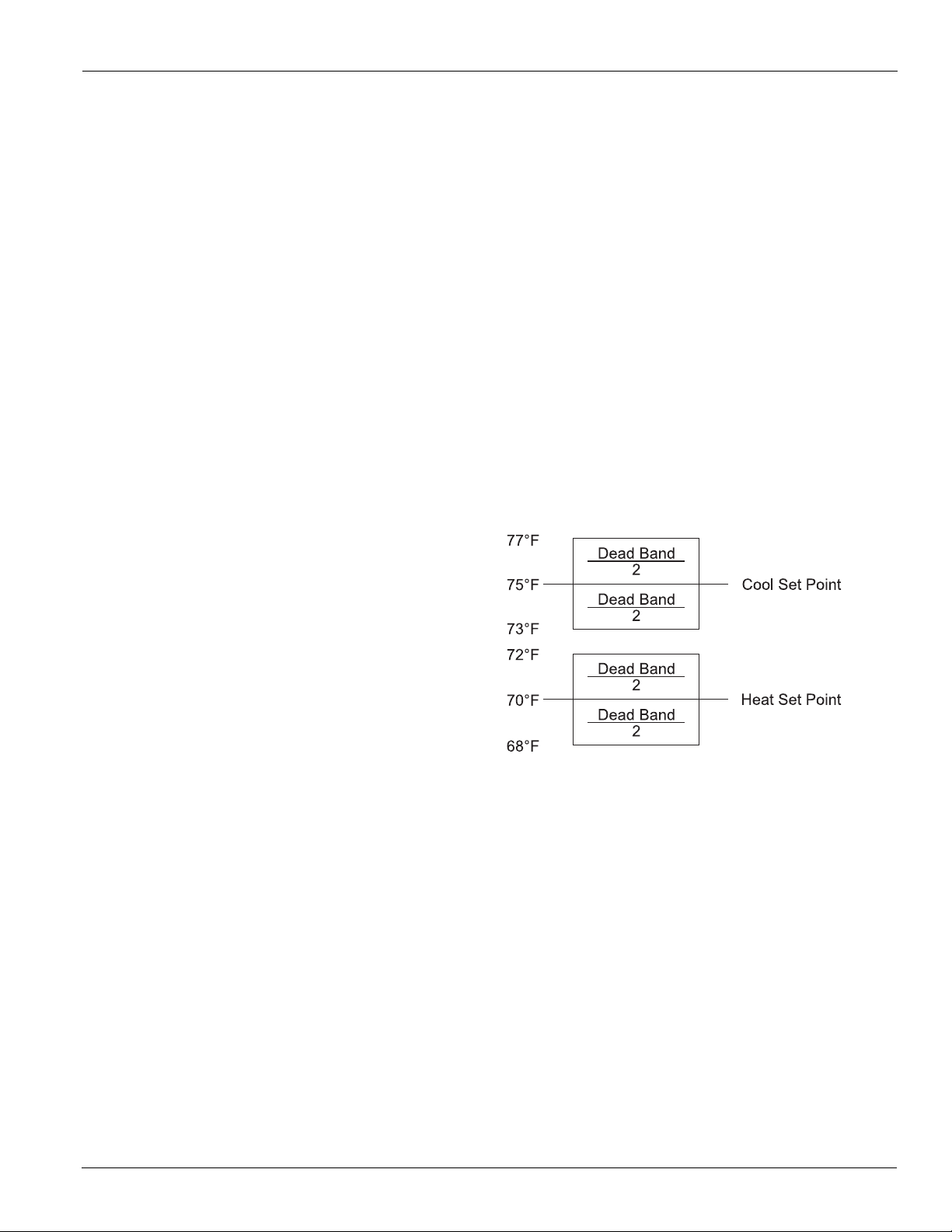

The operator enters separate cool and heat enable set points

and deadbands that the Control Te mperature is compared with

(see Figure 17). When the Control Temperature is greater than

or equal to the cooling set point plus DB/2, cooling is enabled.

When the Control Temperature is less than or equal to the heat

set point minus DB/2, heating is enabled. If desired, these set

points and differentials can be set so that there is a dead band

in which both cooling and heating are disabled. The

controller’s software prevents simultaneous cooling and

heating.

Figure 17: Control Temper a ture Logi c

Constant Air Volume with Zone Temperature Control

(SCC)

SCC units are available in either cooling only or cooling with

modulating heat configurations. Either of these configurations

is available for 100% recirculated, mixed, or 100% outdoor air

applications.

Constant Air Volume with Discharge Temperature

Control (DTC)

DTC units are available in cooling only, cooling with singlestage “morning warm-up” heat, or cooling with modulating

heat configurations. This unit configuration can be used for

applications that have zone controlled terminal heating coils or

for constant volume, 100% outdoor air applications. The

discharge temperature control strategies used with the hybrid

DTC unit are identical to those used with the DTC unit.

Discharge Temperature Control

MicroTech III VAV-DTC and CAV-DTC controls provide

sophisticated and flexible discharge air temperature control

that is only possible with DDC systems. Separate discharge air

temperature set points are used for cooling and modulating

heating control. At the keypad, the operator can either enter the

desired set points or select separate reset methods and

parameters for each set point.

Proportional Integral Modulation

When operating in economizer free cooling or unit heating, the

previously described PI algorithm maintains discharge

temperature control. It provides precise control of the

economizer dampers, modulating gas heat, steam or hot water

valves.

Compressor Staging

Two staging algorithms are available to control a unit’s

multiple steps of capacity control, Degree-Time (also known

as “average”) and Nearest. These control algorithms provide

reliable discharge temperature control while managing

compressor cycling rates. Constraints on compressor staging

are essential for preventing short cycling, which can reduce

compressor life by causing improper oil return and excessive

heat buildup in the motor windings.

The Degree-Time Compressor staging algorithm keeps track

of the discharge temperature and stages cooling up or down to

maintain an average temperature that is equal to the discharge

McQuay Catalog 860-9 19

Page 20

MicroTech III Unit Controls

cooling set point. A stage change can occur only (1) after the

keypad adjustable inter-stage timer has expired (f ive minute

default setting) and (2) if the discharge temperature is outside a

keypad programmed dead band. After these two conditions

have been met, staging occurs as the controller attempts to

equalize two running totals: degree-time above set point and

degree-time below set point. The result is that the average

discharge temperature is maintained at the cooling set point.

The Nearest Compressor staging algorithm keeps track of the

discharge temperature and stages cooling up or down to

maintain the discharge temperature as close as possible to set

point. A stage change can occur only (1) after the keypad

adjustable inter-stage timer has expired (five minute default

setting) and (2) if the control logic calculates that a stage

change will result in a discharge temperature closer to set point

than the existing condition. The controller logic continually

calculates the expected effect of a stage change and uses this

information before making a change. A change is made only if

it will bring the discharge temperature closer to set point,

resulting in a more consistent discharge temperature, reduced

compressor cycling and more stable control VAV box control.

Supply Air Reset

By automatically varying the discharge air temperature to suit

a building’s cooling or heating needs, supply air temperature

reset can increase the energy efficiency of VAV and CA V-DTC

systems. MicroTech III controllers offer a variety of different

reset strategies that can be selected at the keypad. Because

they are keypad programmable, reset strategies can be changed

or eliminated as desired. Separate strategies can be selected for

both cooling and modulating heat. If reset is not desired, a

fixed discharge cooling or heating set point can be entered.

The following reset methods are available:

• Space temperature

• Return temperature

• Outdoor air temperature

• Supply airflow (VAV, cooling set point only)

• External 0–10 VDC or 0–20 mA signal

• Network communication

For all temperature reset methods, the mini mum and maximum

cooling and heating set points are keypad programmable along

with the corresponding minimum and maximum space, return

or outdoor air temperature parameters. For the supply airflow

method, the discharge set point will be reset as the supply fan

modulates between 30% adjustable and 100% adjustable. For

the external method, the discharge set point will be reset as the

voltage or current signal varies over its entire range. For units

in a BAS network, the discharge set points are reset via the

communication signal.

Zone Temperature Control

MicroTech III CAV-ZTC controls provide the sophisticated

and flexible zone temperature control that is only possible with

DDC systems. Zone temperature sensors are available with or

without a remote set point adjustment. With the remote

adjustment model, the space set point can be set at the keypad

or at the zone sensor package. Even if a zone sensor is

connected, remote set point adjustment can be enabled or

disabled as desired at the keypad.

Control Temperature

The Control Temperature is the representative zone

temperature. When compared with the zone set points, the

Control Temperature determines whether the unit supplies

heating, cooling, or neither. It also determines the amount of

cooling or heating required to satisfy the load. Its source can

be selected at the keypad from among the following selections:

• Zone temperature sensor

• Return temperature sensor

Because it is the representative zone temperature, the Control

Temperature is the primary input to the MicroTech III zone

temperature control algorithms. Control Temperature

parameters are described below. The controller’s software will

prevent cooling and heating from being inadvertently enabled

at the same time.

Change and Proportional Integral Modulation

When economizer “free” cooling or unit heating is required,

the two MicroTech III PI loops combine for cascade-type

control, providing the tightest possible zone temperature

control. By controlling the discharge temperature along with

the zone temperature, these functions eliminate temperature

variations near the diffusers that could otherwise occur as a

result of traditional zone control’s inherent lag effect.

Change: If the Control Temperatur e is above or below the

set point by more than the dead band, the Change PI loop

periodically adjusts the cooling

temperature set point either up or down as necessary. The

amount of this set point change corresponds to the Control

Temperature’s position in the modulation range. The farther the Control Temperature is from the set point, the

greater the discharge set point change will be. The

Change-adjusted discharge cooling and heating set points

are limited to ranges defined by keypad programmable

maximum and minimum values.

PI: Using the Change function’s current discharge set

point, the PI function maintains precise discharge temper-

or heating discharge air

20 McQuay Catalog 860-9

Page 21

MicroTech III Unit Controls

Compressor Staging

Compressor staging is controlled directly by the Control

Temperature. When the Control Temperature is warmer than

the zone cooling set point, cooling is staged up; when the

Control Temperature is cooler than the zone cooling set point,

cooling is staged down. However, a stage change can only

occur when the Control Temperature is outside the dead band

(see Figure 18). Staging is constrained by an inter-stage delay

timer (five minute default setting) and minimum and

maximum discharge air temperature limits (all keypad

programmable). These constraints protect the compressors

from short cycling while eliminating temperature variations

near the diffusers.

Figure 18: Compressorized Logic

Project Ahead Algorithm

Because the inherent lag effect in zone temperature control

applications can cause overshoot during warm-up or cooldown periods, MicroTech III features a “Project Ahead”

control algorithm. Project Ahead calculates the rate at which

the Control Temperature is changing and reduces the unit’s

cooling or heating output as the zone temperature nears its set

point, essentially eliminating overshoot.

Duct Static Pressure Control

On all VAV-DTC units, duct static pressure control is

maintained by the PI algorithm, which provides precise control

of the supply fan variable speed drive. The keypad

programmable set point can be set between 0.20-in. W.C. and

4.00-in. W.C.

On larger buildings with multiple floors, multiple trunk runs or

large shifts in load due to solar effects (east/west building

orientation), an optional second duct static sensor is offered.

The MicroT ech III controller automatically selects and uses the

lower of the two sensed pressures to control fan volume to

provide adequate static pressure to the most demanding space

at all times.

Operating States

Operating states define the current overall status of the selfcontained system. At the user interface, the operator can

display the current operating state and thereby quickly assess

the unit’s operating condition.

Alarm Management and Control

MicroTech III unit controllers are capable of sophisticated

alarm management and controlled response functions. Each

alarm is prioritized, indicated, and responded to with the

appropriate action. The active alarm (up to 10 alarms, arranged

by alarm priority) and previous alarm (up to 25 alarms, arrange

by date/time cleared), each with a time and date stamp, can be

displayed at the user interface. Generally speaking, whenever a

current alarm is cleared, it is logged as a previous alarm and

the oldest previous alarm is removed.

Alarm Priority

The various alarms that can occur are prioritized according to

the severity of the problem. See Table 1. Three alarm

categories are used: faults, problems, and warnings.

1 Faults are the highest priority alarms. If a fault condition

occurs, the complete unit shuts down until the alarm

condition is gone and the fault is manually cleared at the

keypad. A fault example is Fan Fail alarm.

2 Problems are the next lower priority to alarms. If a

problem occurs, the complete unit does not shut down,

but its operation is modified to compensate for the alarm

condition. A problem automatically clears when the

alarm condition that caused it is gone. Compressor Fail is

an example of a problem where only the affected

compressor is shut down.

3 Warnings are the lowest priority alarms. No control

action is taken when a warning occurs; it is indicated to

alert the operator that the alarm condition needs

attention. To make sure that they are read, the operator

must manually clear all warnings. Dirty Filter indication

is an example of a warning.

Generally, a specific alarm condition generates an alarm that

falls into only one of these categories. Under different sets of

circumstances, however, the freezestat and most of the sensor

failure alarm conditions can generate alarms that fall into

multiple categories.

McQuay Catalog 860-9 21

Page 22

MicroTech III Unit Controls

Adjustable Alarm Limits

Four alarm indications have adjustable limits that are used to

trigger the alarm. The high return temperature alarm and the

high and low supply temperature alarms are adjusted at the

user interface. The dirty filter alarm(s) is adjusted at the

sensing device.

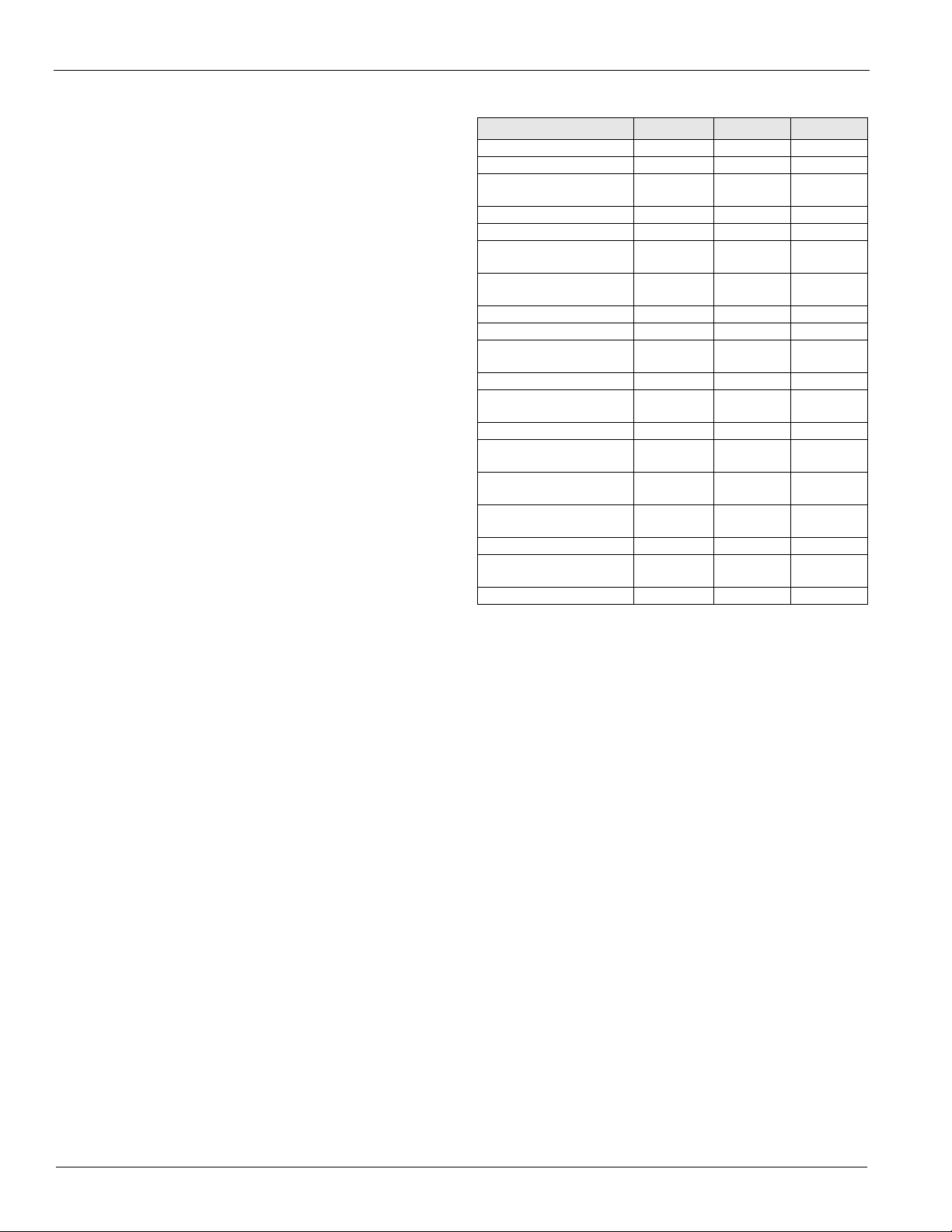

Table 1: MicroTech III Alarm Summary

Alarm Name Fault Problem Warning

Freeze X X

Smoke X

Temperature Sensor

Failure

Duct High Limit X

High Return Temperature X

High Discharge

Temperature

Low Discharge

Temperature

Fan Failure X

Fan Retry X

Discharge Air Capacity

Feedback

Economizer Stuck X X

Auxillary Control Board

Enabled

Low Airflow X

Circuit 1–8

High Pressure

Circuit 1–8

Low Pressure/Frost

Compressor 1–8 Motor

Protection

Compressor 1–8 Failure X

Airflow Switch

(False Airflow)

Dirty Filter X

XX

X

X

X

X

X

X

X

X

22 McQuay Catalog 860-9

Page 23

Application Considerations

Evaporator Coil

Motor

Control Panel

Airflow

24"

See Note

18"

or

24"

36"

42"

Rear Side

Front Side

Opposite

Access

Side

Access

Side

NOTE: If water and condenser drains are on the motor side, 24" is required.

This section contains basic application and installation

guidelines to consider as part of the detailed analysis of any

project.

General

Units are intended for use in normal heating, ventilating, and

air conditioning applications. Consult your local McQuay sales

representative for

• Applications involving operation at high entering condenser water temperatures; high altitudes; or noncataloged voltages.

• Applications requiring modified or special control

sequences.

• Job-specific unit selections that fall outside of the range

of the catalog tables, such as 100% outside air applications.

For proper operation, rig units following instructions in IM

1032. If fire dampers are required, install them in the ductwork

according to local codes. Space is not provided for these

dampers in the unit.

Explicitly follow factory check, test, and start procedures for

satisfactory start-up and operation (see IM 1032).

Many self-contained system applications take advantage of the

significant energy savings provided by the use of economizer

operation. When a water economizer system is used,

mechanical refrigeration typically is not required below an

entering condenser water temperature of 55°F. Standard

McQuay self-contained systems are designed to operate with

entering water temperatures down to 50°F when a water

economizer is used and 55°F with no water economizer. For

applications where a water economizer system cannot be used,

a modulating head pressure control system is available to

permit operation at entering condenser water temperatures

below 55°F.

Application Considerations

Unit Location

The floor must be structurally strong enough to support the

unit with minimum deflection (see “Unit Weights” starting on

page 66). Provide proper structural support to minimize sound

and vibration transmission. Consider a concrete floor. Extra

design consideration is required when installing on a wooden

structure. Install units level from front-to-back and over their

length.

Locate unit fresh air intakes away from building flue stacks,

exhaust ventilators, and areas containing automot i ve or other

exhaust to prevent the possible introduction of contaminated

air to the system. Consult code requirements for minimum

fresh air volumes.

Allow sufficient space around the unit for service and

maintenance clearance. Refer to Figure 19 for recommended

service/maintenance clearances and “Recommended

Clearances” on page 61. Locate equipment room access doors

in a manner that can assist in service access if needed (e.g.,

coil removal). Contact your local McQuay sales representative

if reduced service/maintenance clearances are required.

Where code considerations such as the NEC require extended

clearances, they take precedence over minimum service/

maintenance clearances.

Figure 19: Recommended Service and Maintainance

Clearances

McQuay Catalog 860-9 23

Page 24

Application Considerations

Acoustical Considerations

Good acoustical design is a critical part of any successful

installation and should start at the earliest stages in the design

process. Each of the four common sound paths must be

addressed. They are:

• Radiated sound through the casing of the unit

• Structure-borne vibration

• Airborne sound through the supply air duct

• Airborne sound through the return air duct

Basic guidelines for good acoustical performance include:

1 Always provide proper structural support under the unit.

2 Provide adequate mass in the floor structure, especially

when located over an occupied space where good

acoustics are essential.

3 Seal all supply and return air duct penetrations once the

duct is installed.

4 Don’t overlook the return air path. Always include some

duct work (acoustically-lined drop down elbow) at the

return inlet.

5 Minimize system static pressure losses to reduce fan

sound generation.

6 Select the appropriate unit/fan for the application. Select

fans as close as possible to their peak static efficiency . T o

assist you, peak static efficiency is identified by the first

system curve to the right of the shaded “Do not select”

region on each fan curve. See page 54 through page 60.

7 Design duct systems to minimize turbulence.

8 Account for low frequency duct breakout noise in system

design. Route the first 20' of rectangular duct over

nonsensitive areas and avoid large duct aspect ratios.

Consider round or oval duct to reduce breakout.

Equipment Room

Locate the equipment room away from sound sensitive areas.

Whenever possible, isolate the equipment room from these

areas by locating restrooms, utility rooms, stairwells, hallways,

elevators, etc. around its perimeter. This allows not only

isolation from radiated sound but provides the capability to

route ductwork over less sensitive areas.

Acoustically seal the equipment room with a high quality,

flexible material to prevent air and noise from escaping. Even

a small leak compromises the acoustic performance of the

installation. Design the equipment room door to seal tightly on

a perimeter gasket.

Equipment room wall construction should be concrete block or

offset, double stud. The decision depends on the critical nature

of the application. If offset, use double stud construction. Line

the cavity with glass fiber insulation and use a double layer of

wallboard on each side of the wall.

Ductwork

Fan noise travels through the ductwork to occupied spaces; it

likely is the most challenging to control. Careful duct design

and routing practice is required. The ASHRAE Applications

Handbook discusses sound attenuation relevant to selfcontained system applications. Advances in acoustical science

allow for designing sound levels in a given space if equipment

sound power data is available. Contact your local McQuay

sales representative for sound power data for your specific

application.

Return Duct

The return duct is often overlooked. Duct return air directly to